Exhaust Gas Recirculation on a Nano-Coated Combustion Chamber of a Diesel Engine Fueled with Waste Plastic Oil

Abstract

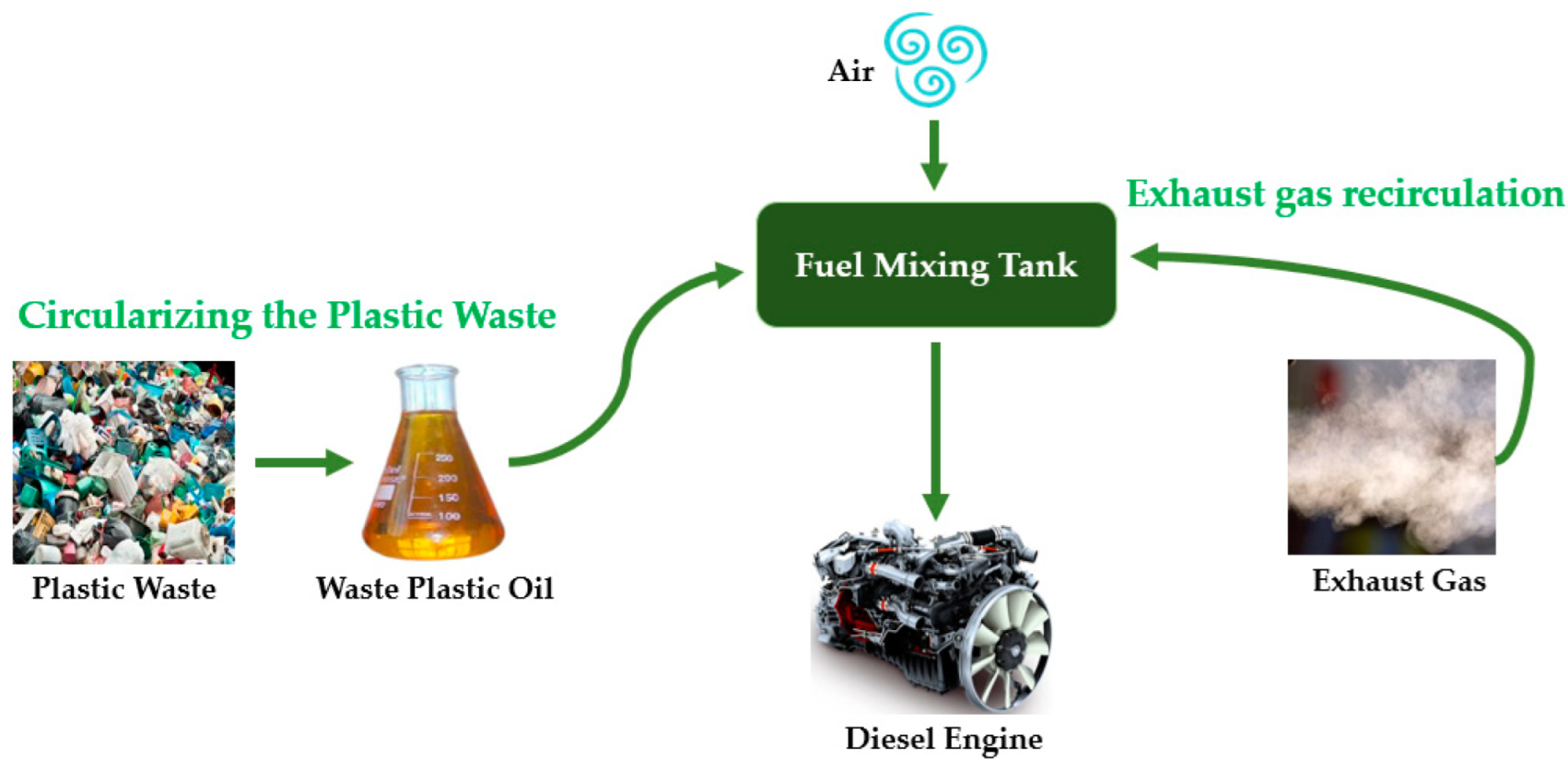

:1. Introduction

2. Materials and Methods

2.1. Waste Plastic Oil Preparation

2.2. Properties and Elemental Analysis

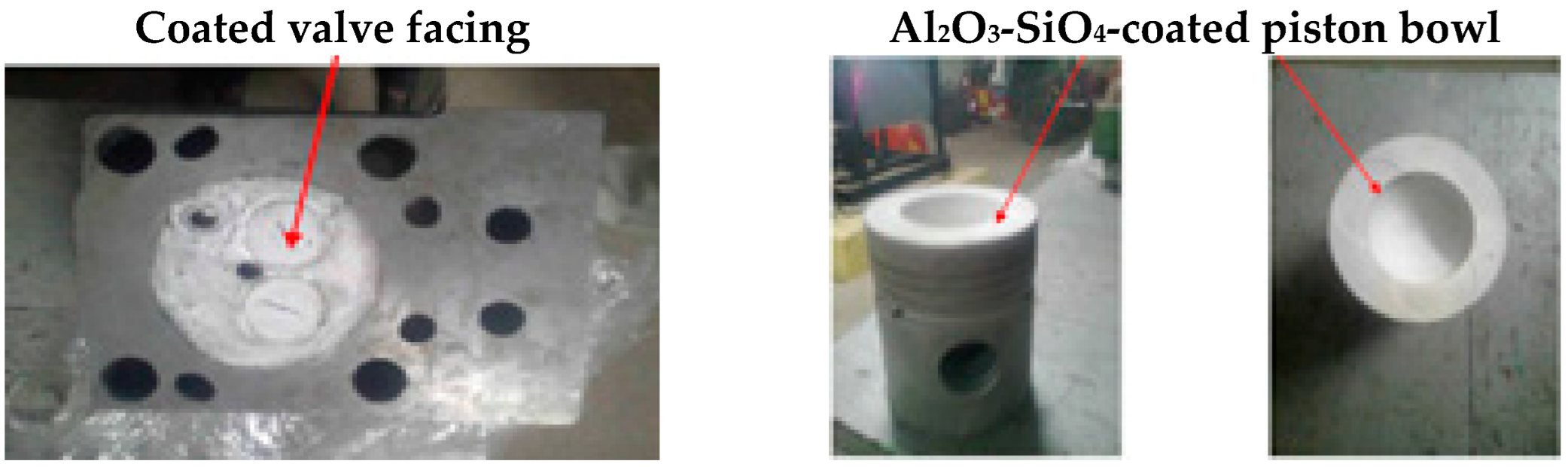

2.3. Nano-Coated Combustion Chamber of Diesel Engine

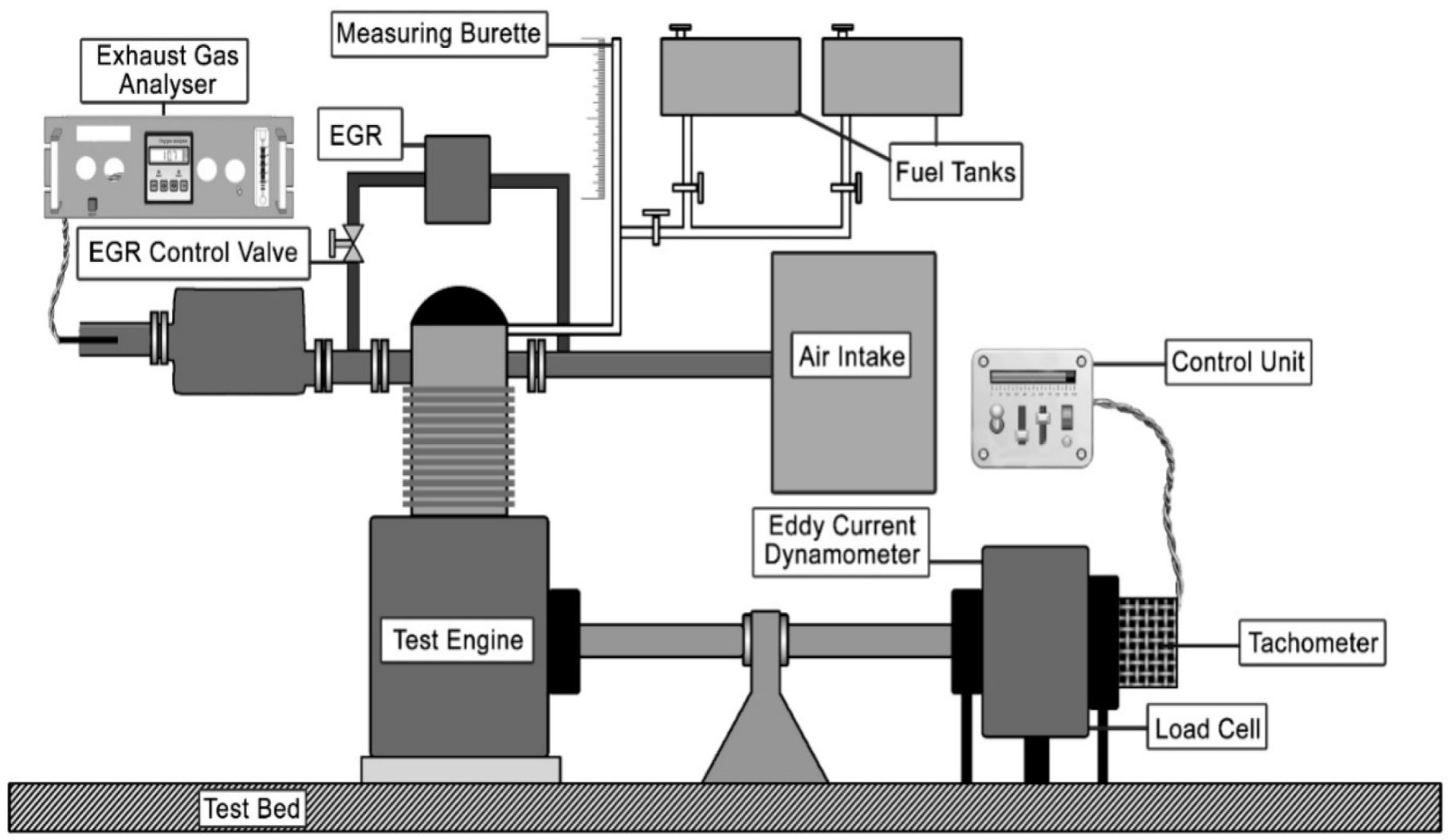

2.4. Experimental Testing

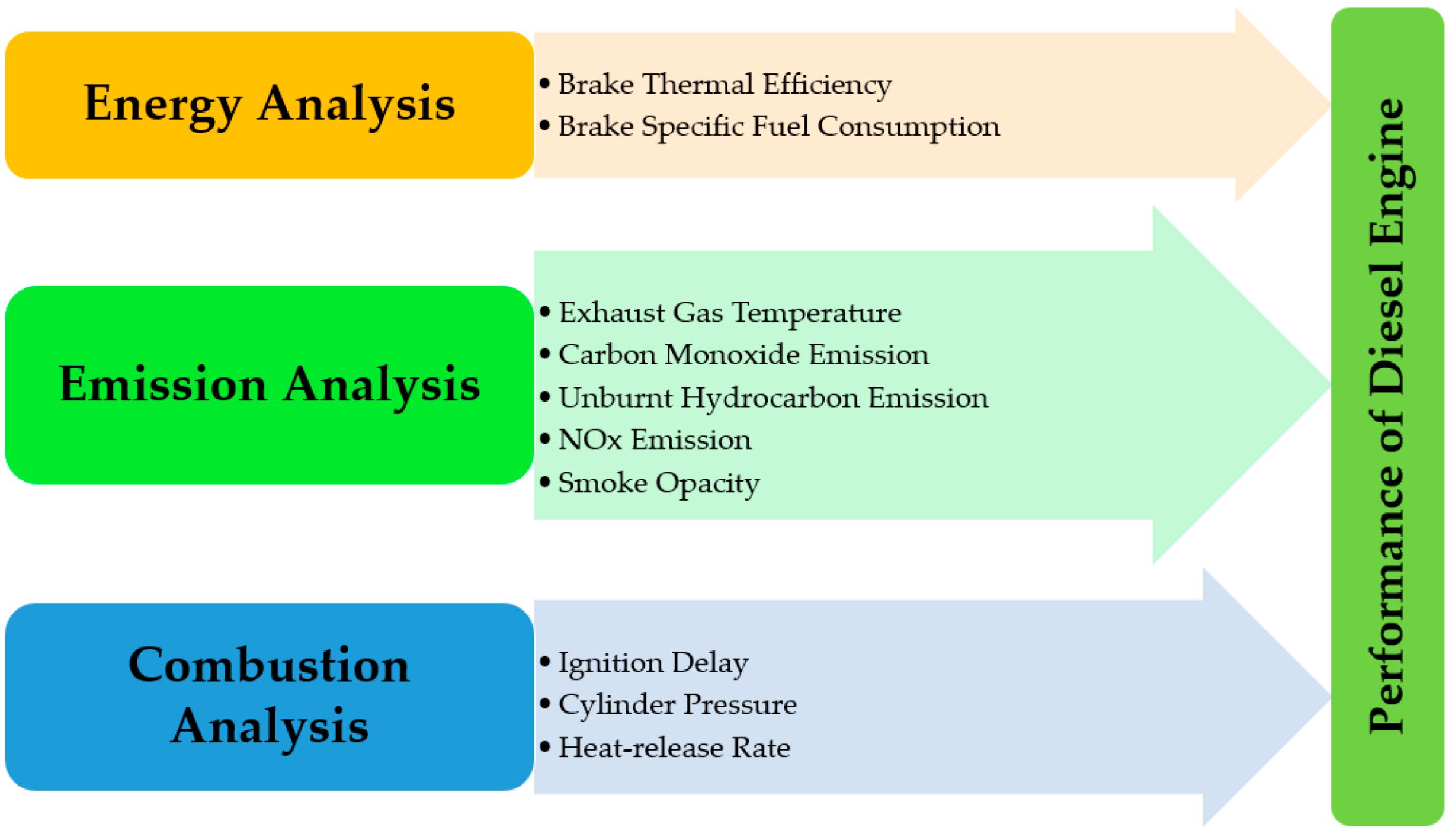

3. Results and Discussion

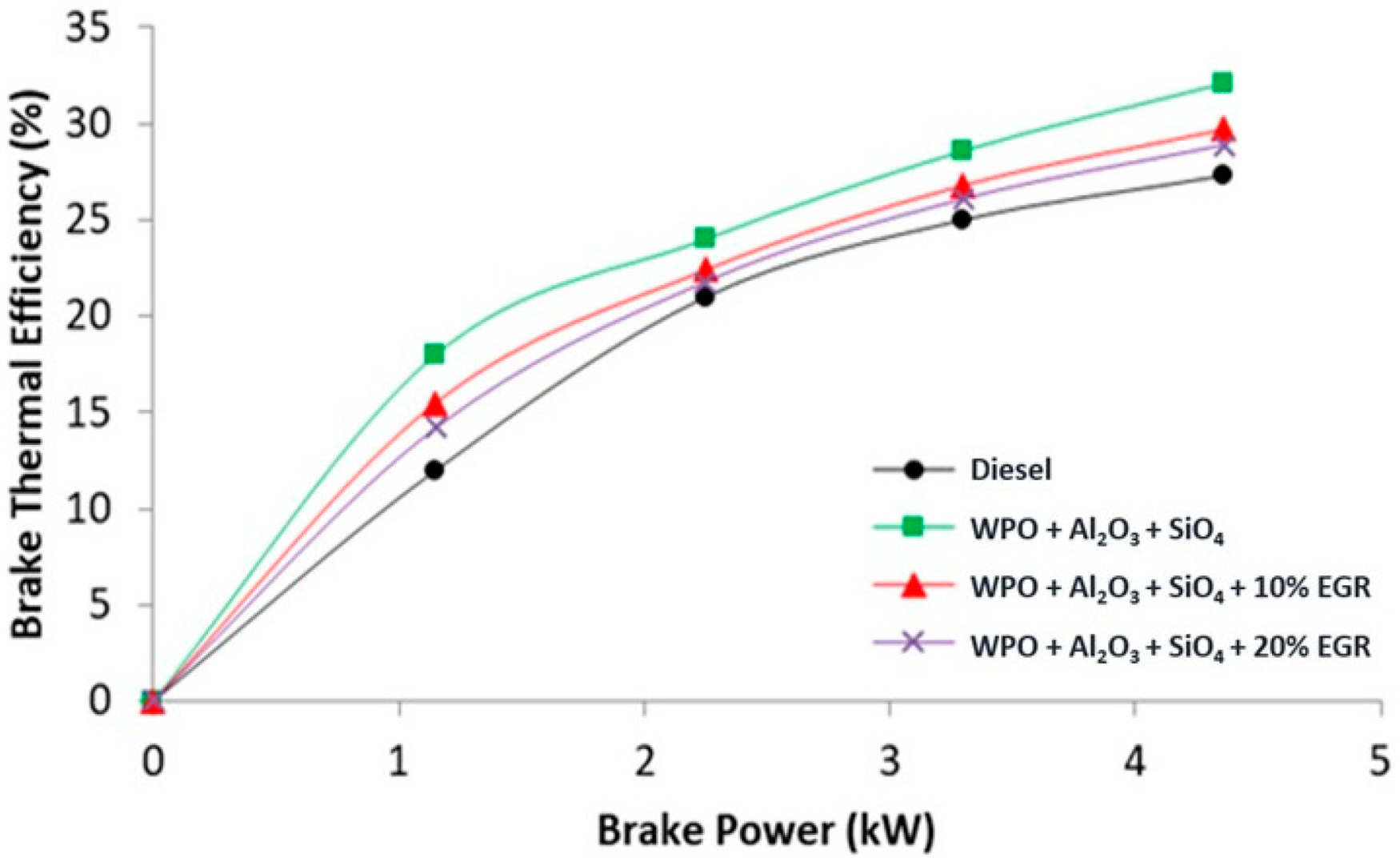

3.1. Brake Thermal Efficiency (BTE)

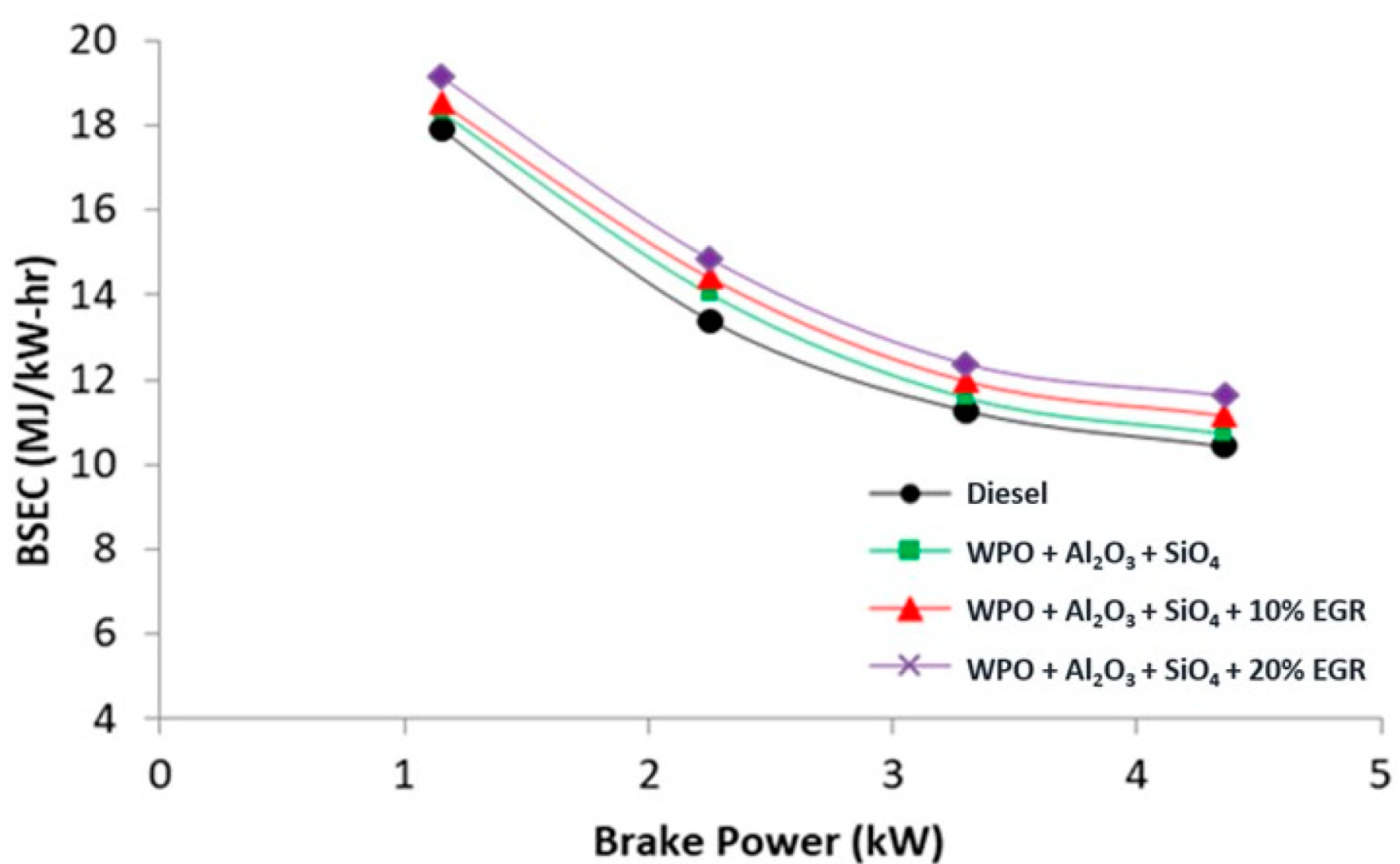

3.2. Brake-Specific Energy Consumption (BSEC)

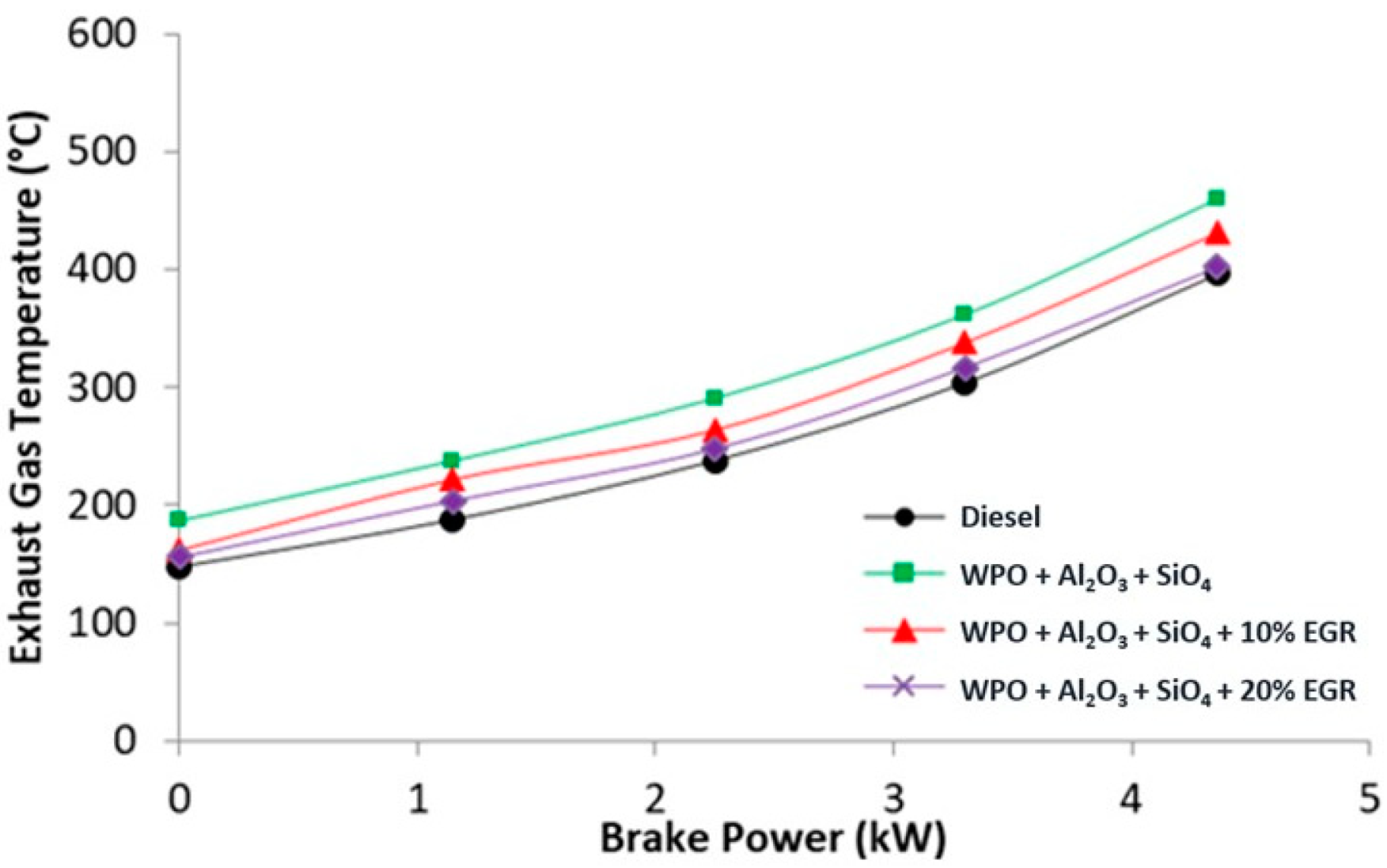

3.3. Exhaust Gas Temperature (EGT)

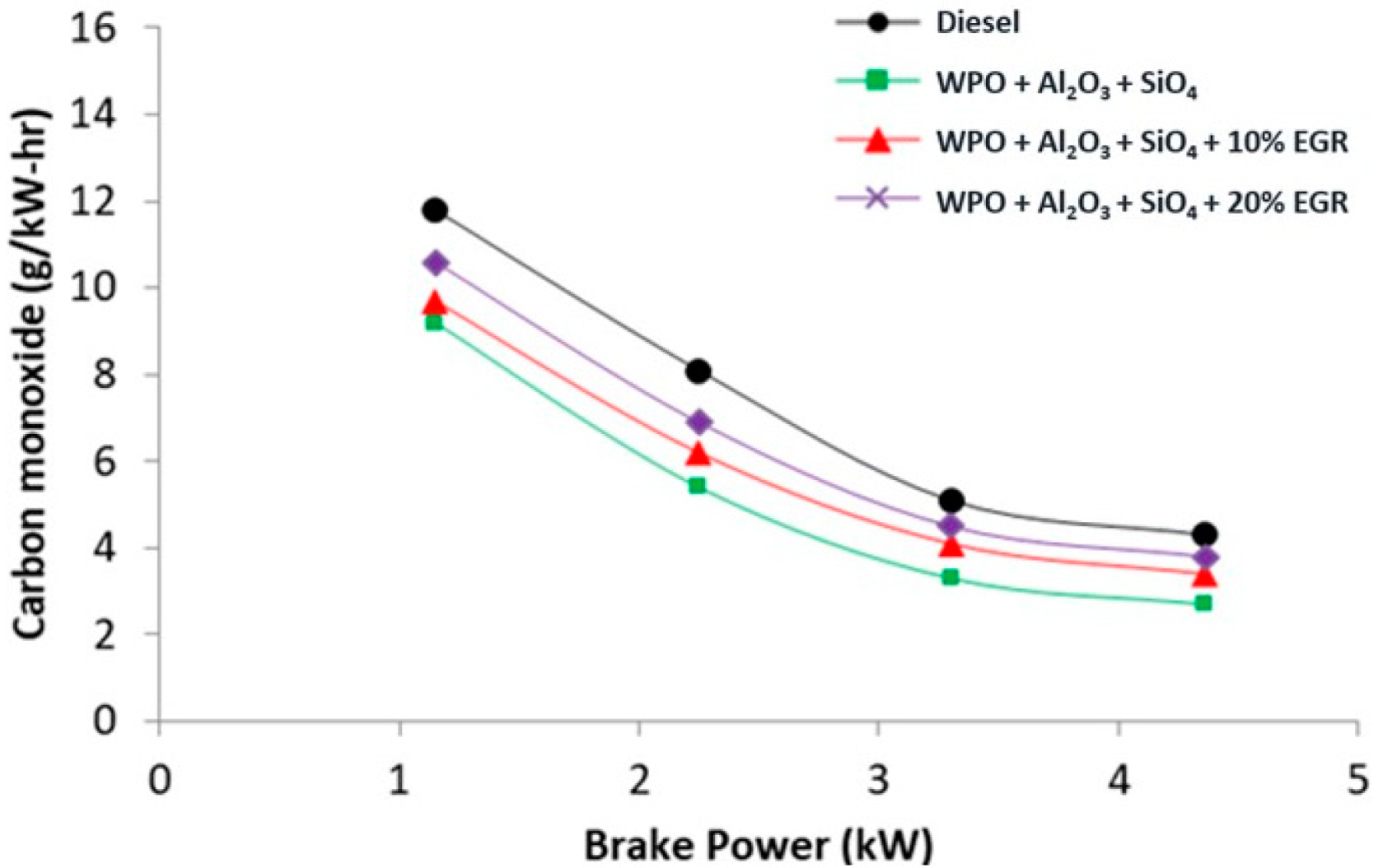

3.4. Carbon Monoxide (CO) Emissions

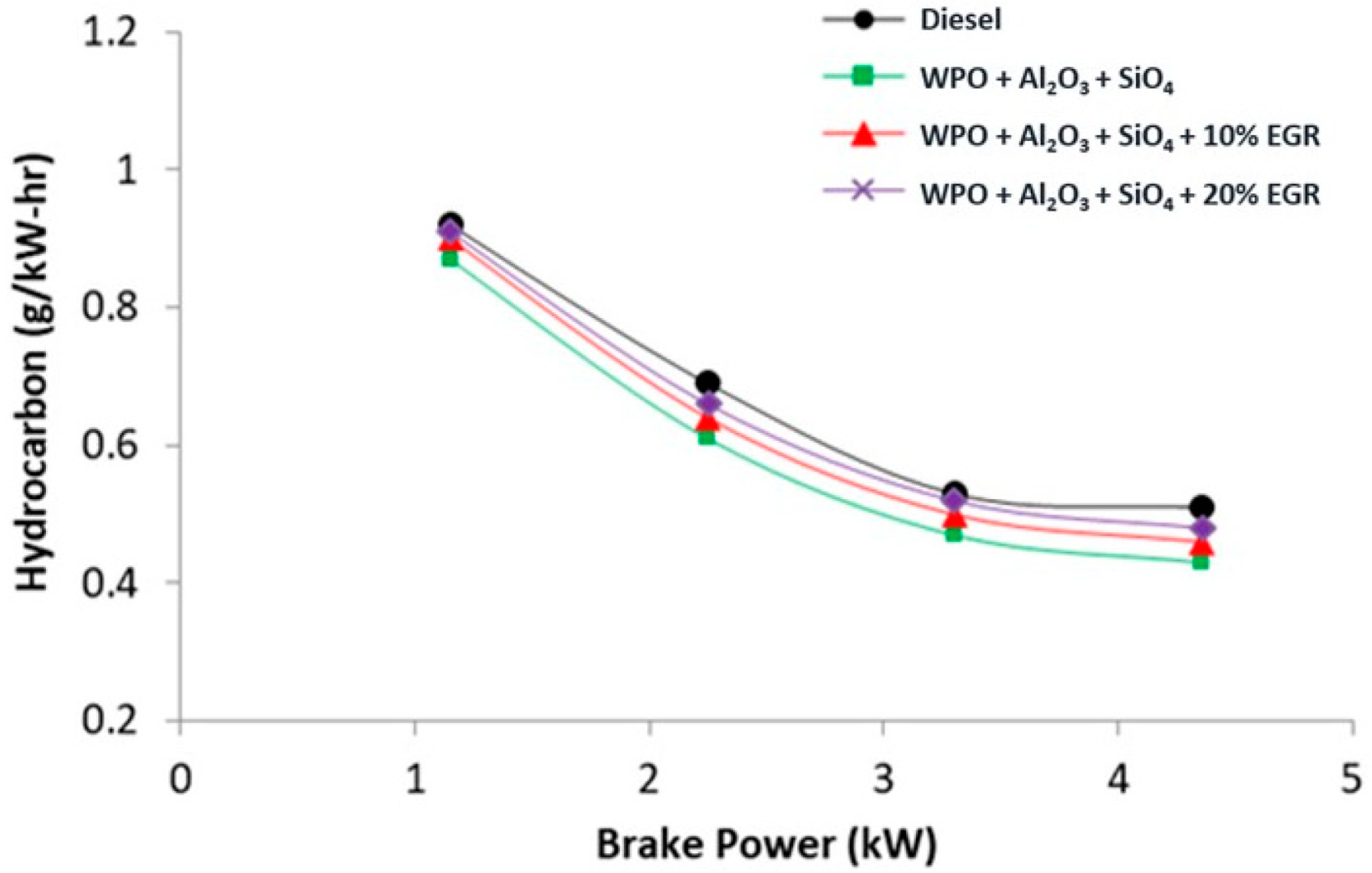

3.5. Unburnt Hydrocarbon (UHC) Emissions

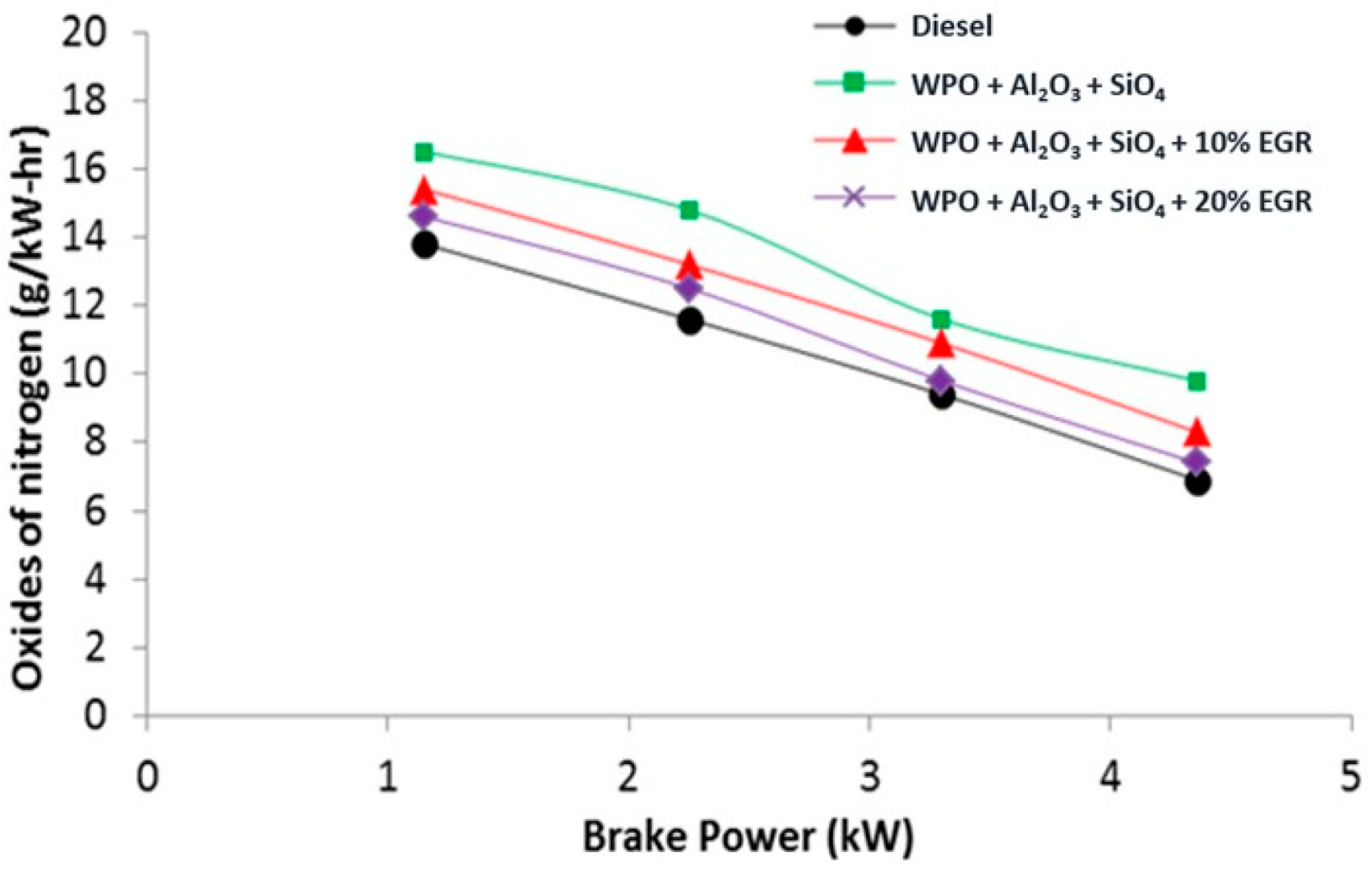

3.6. NOx Emissions

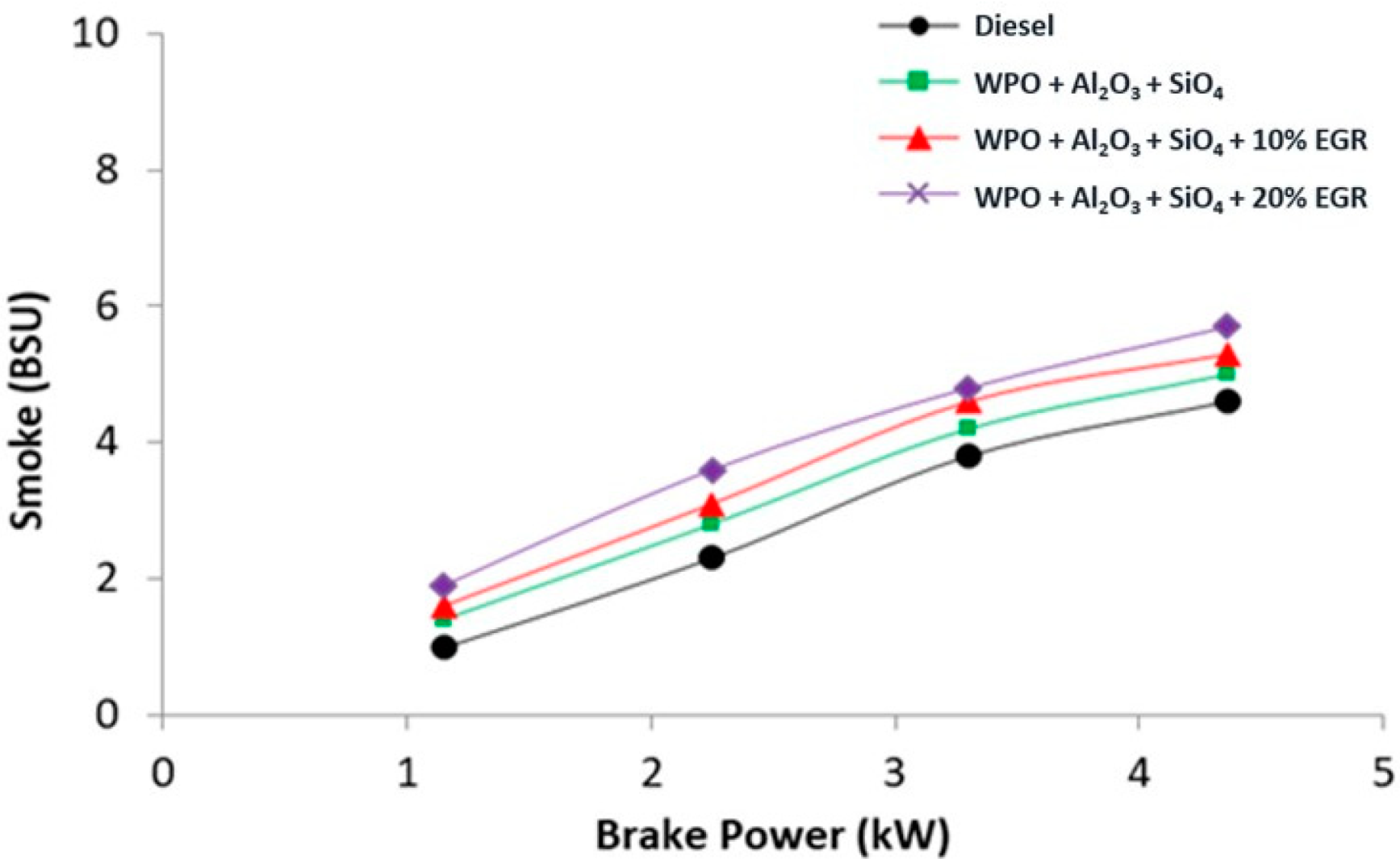

3.7. Smoke Opacity

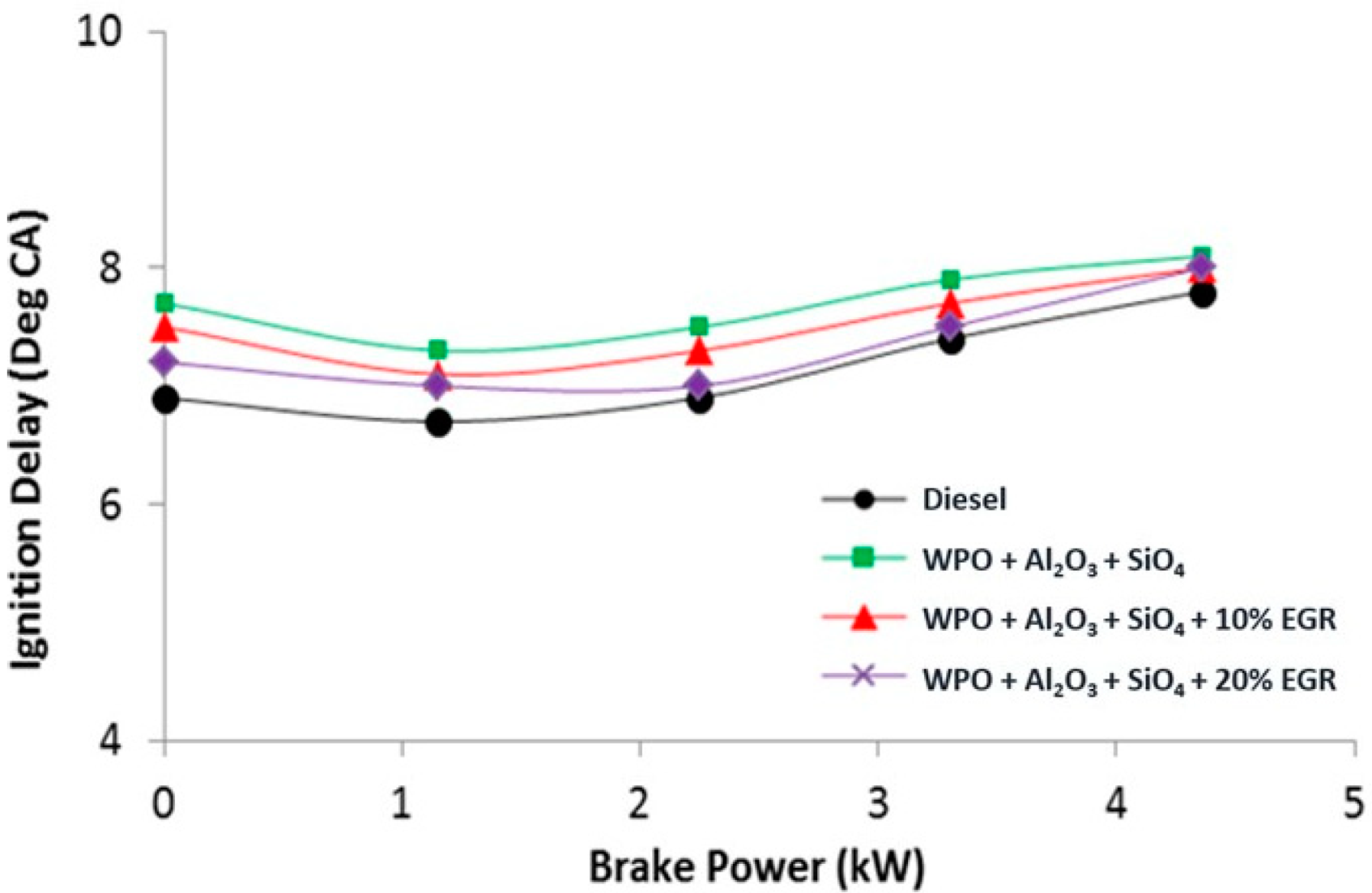

3.8. Ignition Delay

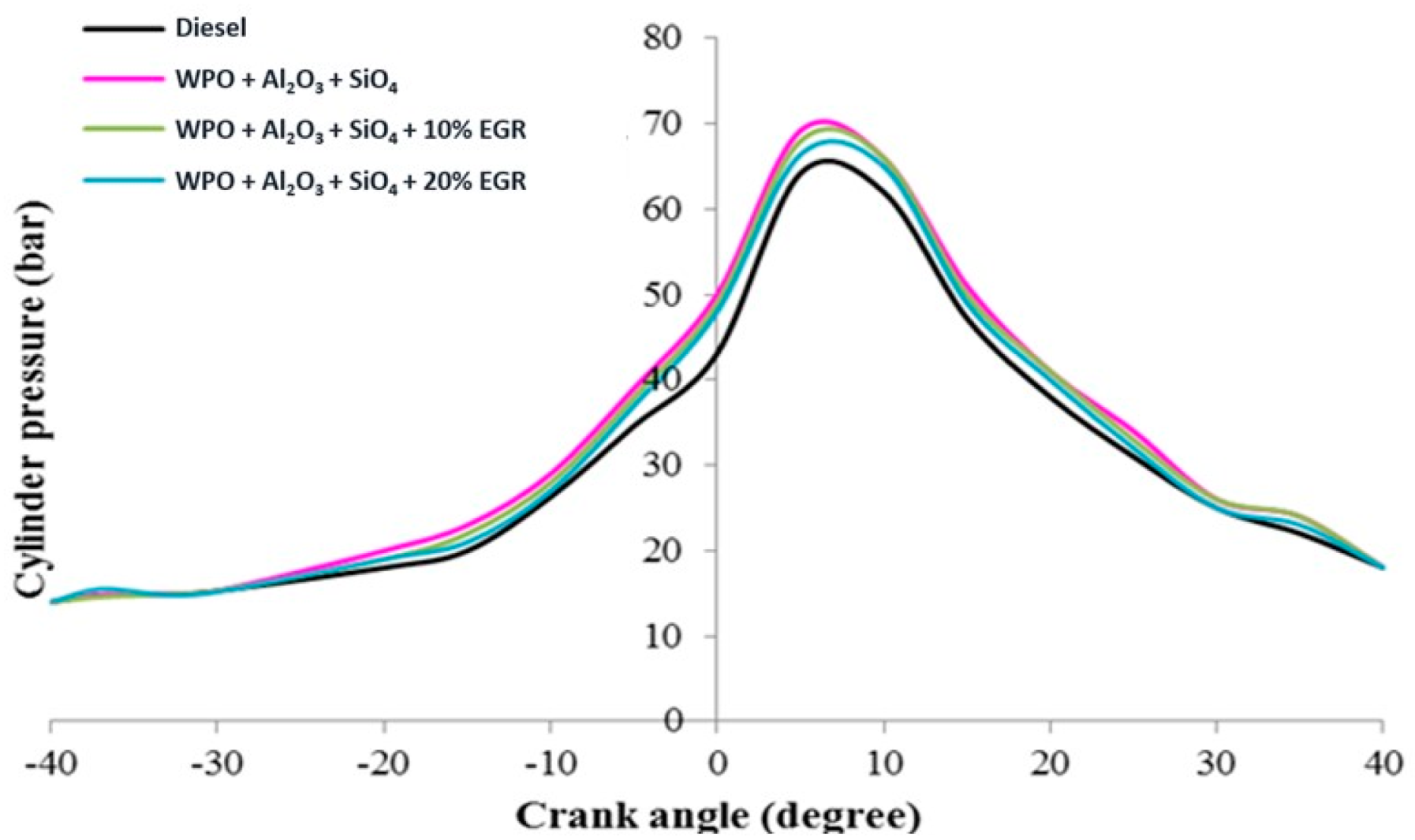

3.9. Cylinder Pressure

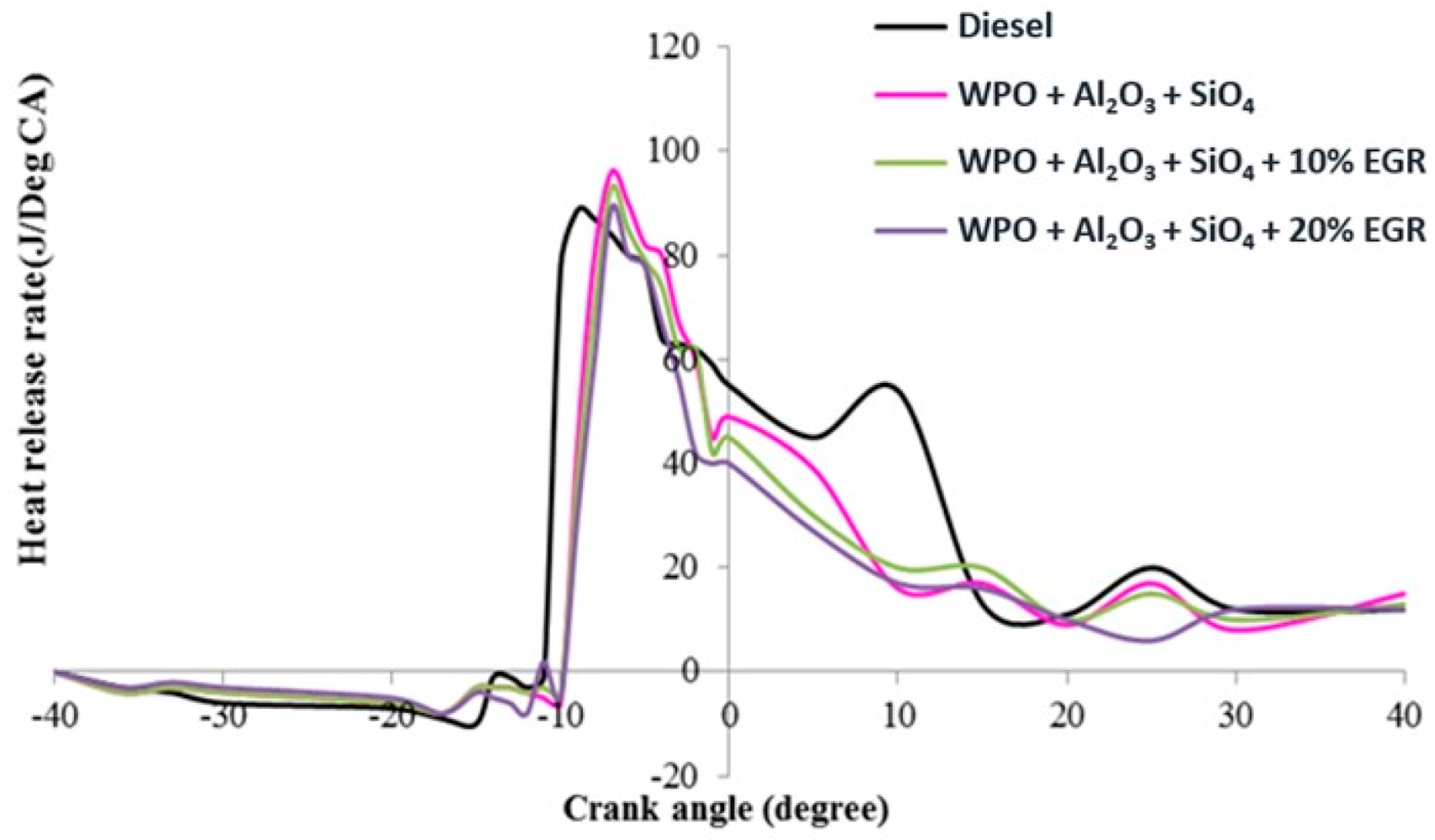

3.10. Heat-Release Rate

3.11. Comparison with WPO and Other Fuels in Available Literature

4. Conclusions

- The CI engine operated steadily on WPO and the combined approach of WPO and EGR even at maximum brake power loads;

- The use of WPO + Al2O3-SiO4 over the standard diesel fuel in CI engines reduced the CO and HC emissions by ~50% and ~22%, respectively; however, the NOx emissions increased by 13%. Additionally, the BTE was reduced by 12.86%, clearly suggesting that WPO alone cannot be used as fuel;

- The EGR mixture in the WPO resulted in variations in energy, combustion, and emission characteristics, suggesting that higher rates of EGR would result in high amounts of emissions compared to lower EGR or intermediate rates;

- The increases in NOX and CO emissions are mild when WPO + Al2O3-SiO4 + 10% EGR is used over the WPO + Al2O3-SiO4.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- British Petroleum (BP). Primary Energy. 2020. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy/primary-energy.html (accessed on 29 December 2021).

- Vieira, S. Pros and Cons of 10 Types of Energy. 2020. Available online: https://www.aje.com/arc/energy-types-pros-cons/ (accessed on 29 December 2021).

- UN; ESCAP. Energy Security and Sustainable Development in Asia and the Pacific; ESCAP Publications: Bangkok, Thailand, 2008; p. 216. ISBN 9211205441/9789211205442. [Google Scholar]

- Ritchie, H.; Roser, M. CO₂ and Greenhouse Gas Emissions. Our World Data. 2020. Available online: https://ourworldindata.org/co2-and-other-greenhouse-gas-emissions (accessed on 29 December 2021).

- Gielen, D.; Gorini, R.; Wagner, N.; Leme, R.; Gutierrez, L.; Prakash, G.; Renner, M. Global Energy Transformation: A Roadmap to 2050. International Renewable Energy Agency. 2019. Available online: https://www.irena.org/publications/2019/Apr/Global-energy-transformation-A-roadmap-to-2050-2019Edition (accessed on 29 December 2021).

- Elavarasan, R.M.; Shafiullah, G.M.; Padmanaban, S.; Kumar, N.M.; Annam, A.; Vetrichelvan, A.M.; Holm-Nielsen, J.B. A comprehensive review on renewable energy development, challenges, and policies of leading Indian states with an international perspective. IEEE Access 2020, 8, 74432–74457. [Google Scholar] [CrossRef]

- Koutsoyiannis, D. The unavoidable uncertainty of renewable energy and its management. In Proceedings of the EGU General Assembly Conference, Vienna, Austria, 17–22 April 2016; p. EPSC2016-18430. [Google Scholar]

- Jezard, A. Fossil Fuels Will Still Dominate Energy in 20 Years Despite Green Power Rising. World Economic Forum. 2017. Available online: https://www.weforum.org/agenda/2017/10/fossil-fuels-will-dominate-energy-in-2040/ (accessed on 29 December 2021).

- D’Adamo, I.; Gastaldi, M.; Morone, P.; Rosa, P.; Sassanelli, C.; Settembre-Blundo, D.; Shen, Y. Bioeconomy of sustainability: Drivers, opportunities and policy implications. Sustainability 2022, 14, 200. [Google Scholar] [CrossRef]

- Ikram, M.; Sroufe, R.; Awan, U.; Abid, N. Enabling Progress in Developing Economies: A Novel Hybrid Decision-Making Model for Green Technology Planning. Sustainability 2022, 14, 258. [Google Scholar] [CrossRef]

- D’Amico, G.; Szopik-Depczyńska, K.; Beltramo, R.; D’Adamo, I.; Ioppolo, G. Smart and Sustainable Bioeconomy Platform: A New Approach towards Sustainability. Sustainability 2022, 14, 466. [Google Scholar] [CrossRef]

- Ma’arof, N.A.N.B.; Hindryawati, N.; Khazaai, S.N.M.; Bhuyar, P.; Rahim, M.H.A.; Maniam, G.P. Biodiesel (Methyl Esters). Maejo Int. J. Energy Environ. Commun. 2021, 3, 30–43. [Google Scholar]

- Embong, N.H.; Hindryawati, N.; Bhuyar, P.; Govindan, N.; Rahim, M.H.A.; Maniam, G.P. Enhanced biodiesel production via esterification of palm fatty acid distillate (PFAD) using rice husk ash (NiSO4)/SiO2 catalyst. Appl. Nanosci. 2021, 1–9. [Google Scholar] [CrossRef]

- Khazaai, S.N.M.; Bhuyar, P.; Rahim, M.H.A.; Alwi, M.H.F.M.; Yiting, S.; Maniam, G.P. Rapid determination of diesel/biodiesel blend ratio using refractive index, density, and kinematic viscosity measurements. Biomass Convers. Biorefin. 2021, 1–7. [Google Scholar] [CrossRef]

- Zheng, Q.P.; Li, S.; Lang, X.J.; Zhang, K.P. Simulation and Experimental Study on Turbocharged Inter-Cooled Diesel Engine with Exhaust Gas Recirculation. Chin. Intern. Combust. Engine Eng. 2012, 33, 33–37. [Google Scholar]

- Anantha Raman, L.; Rajakumar, S.; Deepanraj, B.; Lokesh, P. Study on performance and emission characteristics of a single cylinder diesel engine using exhaust gas recirculation. Therm. Sci. 2017, 21, s435–s441. [Google Scholar] [CrossRef] [Green Version]

- Saravanan, P.; Kumar, N.M.; Ettappan, M.; Dhanagopal, R.; Vishnupriyan, J. Effect of exhaust gas recirculation o performance, emission and combustion characteristics of ethanol-fueled diesel engine. Case Stud. Therm. Eng. 2020, 20, 100643. [Google Scholar] [CrossRef]

- Yuan, X.; Kumar, N.M.; Brigljević, B.; Li, S.; Deng, S.; Byun, M.; Ok, Y.S. Sustainability-inspired upcycling of waste polyethylene terephthalate plastic into porous carbon for CO2 capture. Green Chem, 2022; Advance Article. [Google Scholar] [CrossRef]

- Taymaz, I.; Cakir, K.; Gur, M.; Mimaroglu, A. Experimental investigation of heat losses in a ceramic coated diesel engine. Surf. Coat. Technol. 2003, 169, 168–170. [Google Scholar] [CrossRef]

- Wu, X.J. The crack number density theory on air-plasma-sprayed thermal barrier coating. Surf. Coat. Technol. 2019, 358, 347–352. [Google Scholar] [CrossRef]

- Balu, P.; Saravanan, P.; Jayaseelan, V. Effect of ceramic coating on the performance, emission, and combustion characteristics of ethanol DI diesel engine. Mater. Today Proc. 2021, 39, 1259–1264. [Google Scholar] [CrossRef]

- Mani, M.; Nagarajan, G.; Sampath, S. An experimental investigation on a DI diesel engine using waste plastic oil with exhaust gas recirculation. Fuel 2010, 8, 1826–1832. [Google Scholar] [CrossRef]

- Paranthaman, S.; Dharmalingam, M.; Arockiaraj, G.A.; Venkatraman, V. An experimental investigation on a low heat rejection diesel engine using waste plastic oil with different injection timing. Therm. Sci. 2020, 24 Pt B, 453–461. [Google Scholar] [CrossRef]

- Saravanan, P.; Mala, D. Performance, Emission and Combustion Characteristics of Low Heat Rejection Diesel Engine Operated by Waste Plastic Oil and Diesel Fuel Blends. J. Balk. Tribol. Assoc. 2020, 26, 416–427. [Google Scholar]

- Saravanan, P.; Mala, D.; Jayaseelan, V.; Kumar, N.M. Experimental performance investigation of Partially Stabilized Zirconia coated low heat rejection diesel engine with waste plastic oil as a fuel. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–14. [Google Scholar] [CrossRef]

- Mani, M.; Subash, C.; Nagarajan, G. Performance, emission and combustion characteristics of a DI diesel engine using waste plastic oil. Appl. Therm. Eng. 2009, 29, 2738–2744. [Google Scholar] [CrossRef]

- Venkatesan, H.; Sivamani, S.; Bhutoria, K.; Vora, H.H. Experimental study on combustion and performance characteristics in a DI CI engine fuelled with blends of waste plastic oil. Alex. Eng. J. 2018, 57, 2257–2263. [Google Scholar] [CrossRef]

- Kaimal, V.K.; Vijayabalan, P. A detailed study of combustion characteristics of a DI diesel engine using waste plastic oil and its blends. Energy Convers. Manag. 2015, 105, 951–956. [Google Scholar] [CrossRef]

- Das, A.K.; Hansdah, D.; Mohapatra, A.K.; Panda, A.K. Energy, exergy and emission analysis on a DI single cylinder diesel engine using pyrolytic waste plastic oil diesel blend. J. Energy Inst. 2020, 93, 1624–1633. [Google Scholar] [CrossRef]

- Devaraj, J.; Robinson, Y.; Ganapathi, P. Experimental investigation of performance, emission and combustion characteristics of waste plastic pyrolysis oil blended with diethyl ether used as fuel for diesel engine. Energy 2015, 85, 304–309. [Google Scholar] [CrossRef]

- Srithar, K.; Arun Balasubramanian, K.; Vivar, M.; Skryabin, I. An experimental investigation on diesel and low heat rejection engines with dual biodiesel blends. Int. J. Green Energy 2013, 10, 1041–1055. [Google Scholar] [CrossRef]

- Ramalingam, S.; Rajendran, S.; Ganesan, P. Performance improvement and emission control in a direct injection diesel engine using nano catalyst coated pistons. Biofuels 2016, 7, 529–535. [Google Scholar] [CrossRef]

- Nandeeswaran, S.; Sriram, K. Experimental Investigation on Performance of Single Cylinder Diesel Engine with Mullite and Aluminium Titanate as Thermal Barrier Coating. Int. J. Eng. Res. Technol. 2021, 9, 64–67. [Google Scholar]

- Narad, A.M.; Joshi, M.P. Experimental analysis of CI engine using titanium oxide and aluminum oxide alloy coated piston fuelled with biofuel made up of agricultural waste. Results Mater. 2020, 8, 100140. [Google Scholar] [CrossRef]

- Musthafa, M.M.; Sivapirakasam, S.P.; Udayakumar, M. A comparative evaluation of Al2O3 coated low heat rejection diesel engine performance and emission characteristics using fuel as rice bran and pongamia methyl ester. J. Renew. Sustain. Energy 2010, 2, 053105. [Google Scholar] [CrossRef]

- Senthil, R.; Sivakumar, E.; Silambarasan, R.; Mohan, G. Performance and emission characteristics of a low heat rejection engine using Nerium biodiesel and its blends. Int. J. Ambient Energy 2017, 38, 186–192. [Google Scholar] [CrossRef]

| Analysis | Units | Fuel Types | ||

|---|---|---|---|---|

| WPO | Diesel | |||

| Thermophysical properties | Specific gravity | - | 0.835 | 0.840 |

| Calorific value | kJ/kg | 4.43 × 103 | 4.65 × 103 | |

| Kinematic viscosity | cSt at 40 °C | 2.52 | 2 | |

| Flash point | °C | 42 | 50 | |

| Fire point | °C | 45 | 56 | |

| Sulfur content | % | 0.034 | 0.046 | |

| Ash content | % | 0.00023 | 0.043 | |

| Elemental analysis | C | % | 74.36 | 86.03 |

| H | % | 14.31 | 13.36 | |

| O | % | 11.28 | 0 | |

| N | % | 0.395 | 0.251 | |

| S | % | 0 | 0.359 | |

| Property | Al2O3-SiO4 |

|---|---|

| Density (g·cm−3) | 3.6 |

| Modulus of Rupture (MPa) | 348 |

| Hardness–Knoop (GPa) | - |

| Specific Heat (J/kgK) | 437 |

| Young’s Modulus (GPa) | 23 |

| Thermal Conductivity (W/mK) | 2–5 |

| Poisson Ratio | 0.20 |

| Performance Category | Characteristics | [26] | [27] | [28] | [29] | [30] | This Study | ||

|---|---|---|---|---|---|---|---|---|---|

| WPO | WPO + Al2O3-SiO4 | WPO + Al2O3-SiO4 + 10% EGR | WPO + Al2O3-SiO4 + 20% EGR | ||||||

| Energy | BTE | 27.4% | 28.4% | 29.3% | 26.4% | 25.4% | 24% | 29.6%, | 31% |

| BSFC | - | 7.92 MJ/kW-h | 10.08 MJ/kW-h | 10.008 MJ/kW-h | 11.16 MJ/kW-h | 20 MJ/kW-h | 11.76 MJ/kW-h | 11.04 MJ/kW-h | |

| Combustion | Cylinder pressure | 71 bar | 75.33 bar | 76 bar | 75 bar | 77 bar | 52 bar | 70 bar | 75 bar |

| HRR | - | 64.31 J/°CA | 65.41 J/°CA | 66.81 J/°CA | 66.15 J/°CA | 108 J/°CA | 97 J/°CA | 99 J/°CA | |

| Emission | CO | 18.51 g/kW-h | - | 17.71 g/kW-h | 16.45 g/kW-h | 16.81 g/kW-h | 2.5 g/kW-h | 3.5 g/kW-h | 3.9 g/kW-h |

| NOx | 14.68 g/kW-h | - | 13.65 g/Kw-hr | 13.88 g/kW-h | 15.88 g/kW-h | 16 g/kW-h | 8.4 g/kW-h | 9.5 g/kW-h | |

| HC | - | - | - | - | - | 0.8 g/kW-h | 0.46 g/kW-h | 0.49 g/kW-h | |

| Performance Category | Characteristics | [31] | [32] | [33] | [34] | [35] | [36] | This Study | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| a | b | c | d | e | f | Diesel g | WPO + Al2O3-SiO4 | WPO + Al2O3-SiO4 + 10% EGR | WPO + Al2O3-SiO4 + 20% EGR | ||

| Energy | BTE | 34.45% | 34.93% | 33.23% | 32.33% | 30.33% | 28.82% | 27.3% | 24% | 29.6%, | 31% |

| BSFC | 14 MJ/kW-h | 21 MJ/kW-h | 17.5 MJ/kW-h | 14.6 MJ/kW-h | 10.56–10.84 MJ/kW-h | 18.5 MJ/kW-h | 16 MJ/kW-h | 20 MJ/kW-h | 11.76 MJ/kW-h | 11.04 MJ/kW-h | |

| Combustion | Cylinder pressure | 79.65 bar | 81.32 bar | 80.25 bar | 79.55 bar | 75.75 bar | 72 bar | 68 bar | 52 bar | 70 bar | 75 bar |

| Delay period | 16.5 °CA | 17 °CA | 18 °CA | 16 °CA | 20 °CA | 21 °CA | - | - | - | - | |

| EGT/HRR | 310–325 °C | 340–345 °C | 335–342 °C | 355–360 °C | 365–375 °C | 350–363 °C | 80 J/°CA | 108 J/°CA | 97 J/°CA | 99 J/°CA | |

| Emission | CO | 3.2 g/kW-h | 2.75 g/kW-h | 3.2 g/kW-h | 4.9 g/kW-h | 2.5–2.9 g/kW-h | 5.2 g/kW-h | 4.2 g/kW-h | 2.5 g/kW-h | 3.5 g/kW-h | 3.9 g/kW-h |

| NOx | 13 g/kW-h | 15 g/kW-h | 25.05 g/kW-h | 11.32 g/kW-h | 7.4–8.5 g/kW-h | 25.05 g/kW-h | 14 g/kW-h | 16 g/kW-h | 8.4 g/kW-h | 9.5 g/kW-h | |

| HC | 1.5 g/kW-h | 0.58 g/kW-h | 0.75 g/kW-h | 1.5 g/kW-h | 1.46–1.49 g/kW-h | 2.5 g/kW-h | 1 g/kW-h | 0.8 g/kW-h | 0.46 g/kW-h | 0.49 g/kW-h | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saravanan, P.; Ettappan, M.; Kumar, N.M.; Elangkeeran, N. Exhaust Gas Recirculation on a Nano-Coated Combustion Chamber of a Diesel Engine Fueled with Waste Plastic Oil. Sustainability 2022, 14, 1148. https://doi.org/10.3390/su14031148

Saravanan P, Ettappan M, Kumar NM, Elangkeeran N. Exhaust Gas Recirculation on a Nano-Coated Combustion Chamber of a Diesel Engine Fueled with Waste Plastic Oil. Sustainability. 2022; 14(3):1148. https://doi.org/10.3390/su14031148

Chicago/Turabian StyleSaravanan, P., M. Ettappan, Nallapaneni Manoj Kumar, and N. Elangkeeran. 2022. "Exhaust Gas Recirculation on a Nano-Coated Combustion Chamber of a Diesel Engine Fueled with Waste Plastic Oil" Sustainability 14, no. 3: 1148. https://doi.org/10.3390/su14031148

APA StyleSaravanan, P., Ettappan, M., Kumar, N. M., & Elangkeeran, N. (2022). Exhaust Gas Recirculation on a Nano-Coated Combustion Chamber of a Diesel Engine Fueled with Waste Plastic Oil. Sustainability, 14(3), 1148. https://doi.org/10.3390/su14031148