Influence of the Geosynthetic Type and Compaction Conditions on the Pullout Behaviour of Geosynthetics Embedded in Recycled Construction and Demolition Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

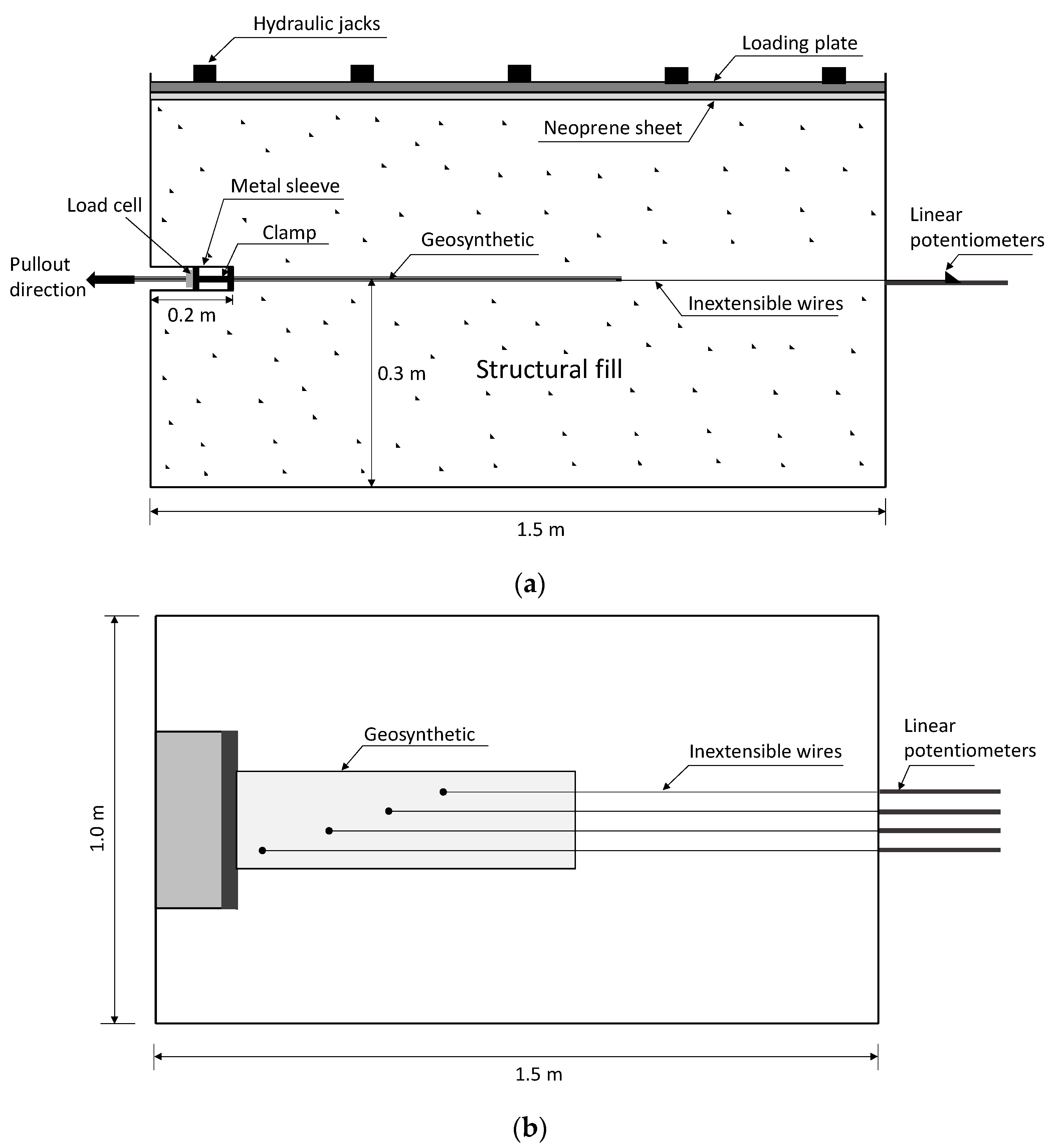

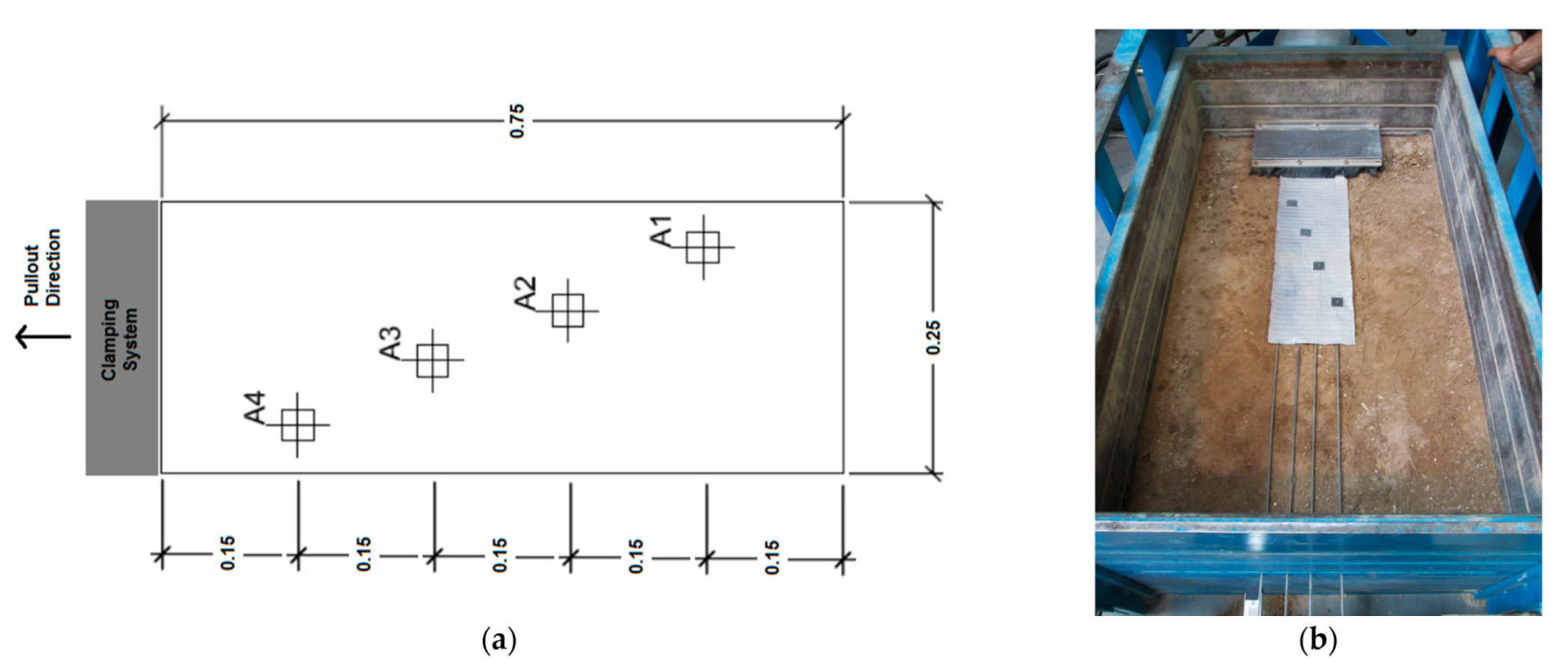

2.2. Pullout Tests

2.3. Pullout Interaction Coefficient

3. Results and Discussion

3.1. Physical and Mechanical Characterization of the Recycled C&D Material

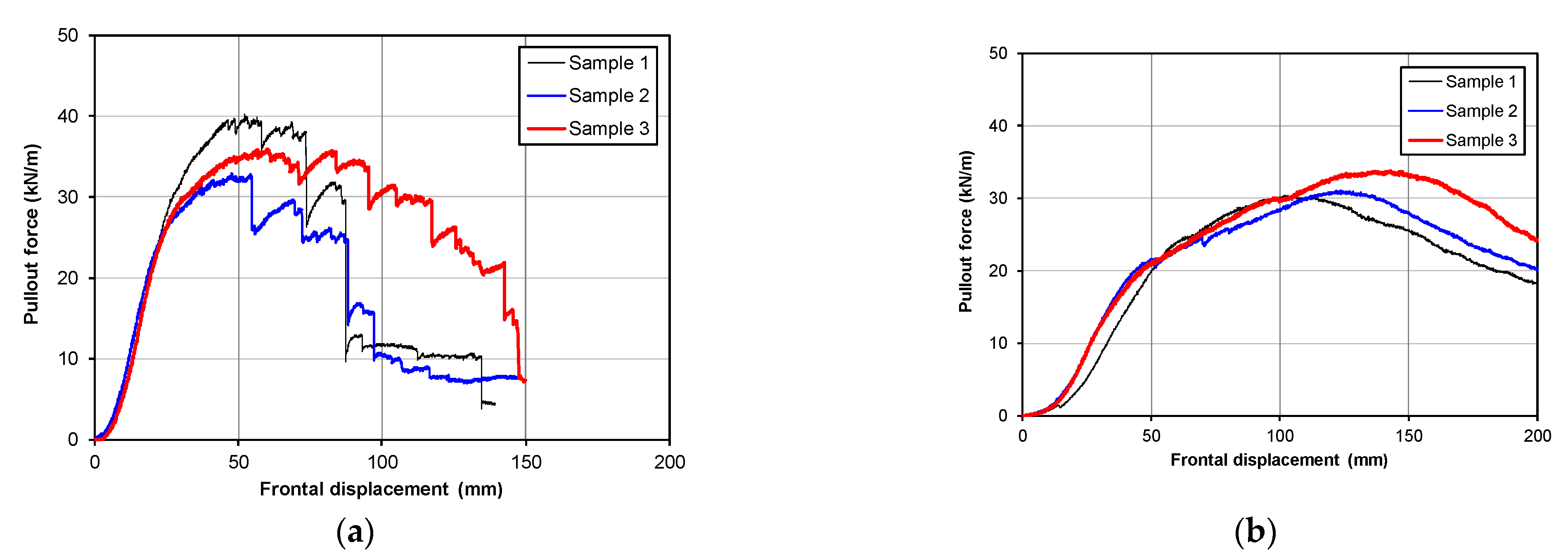

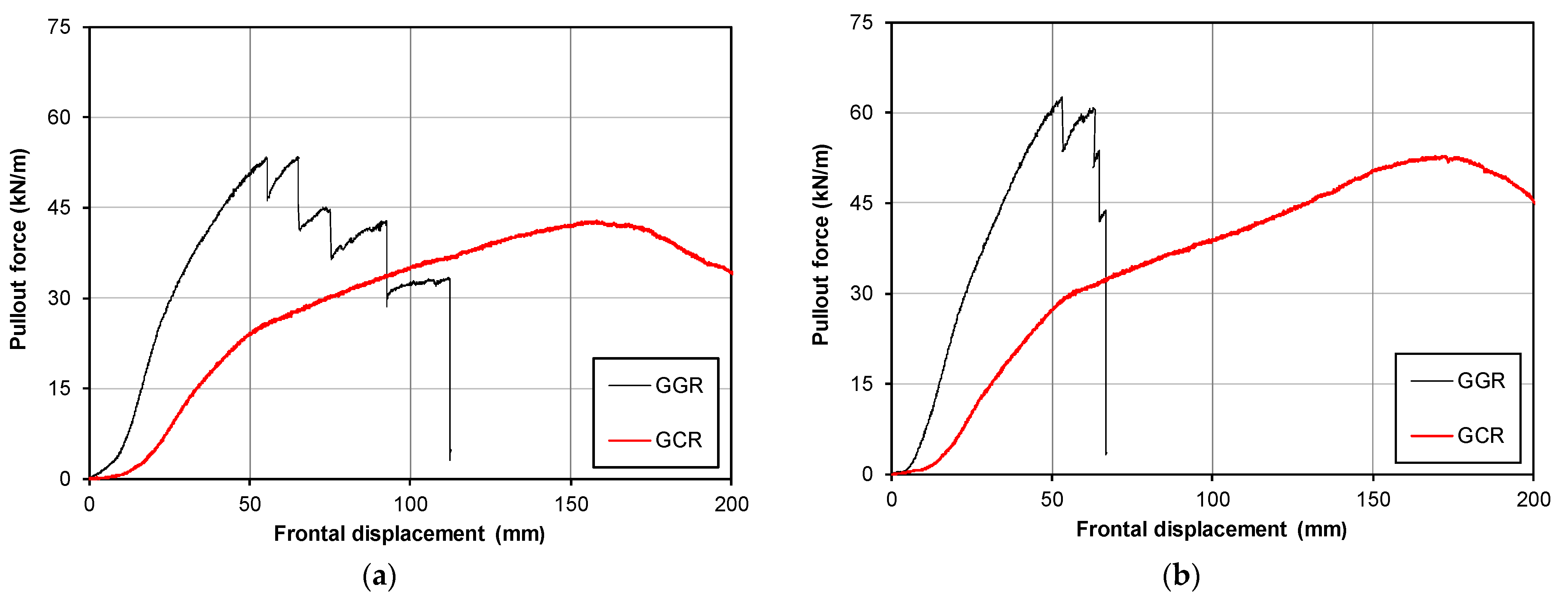

3.2. Influence of the Geosynthetic Type on the Pullout Behaviour

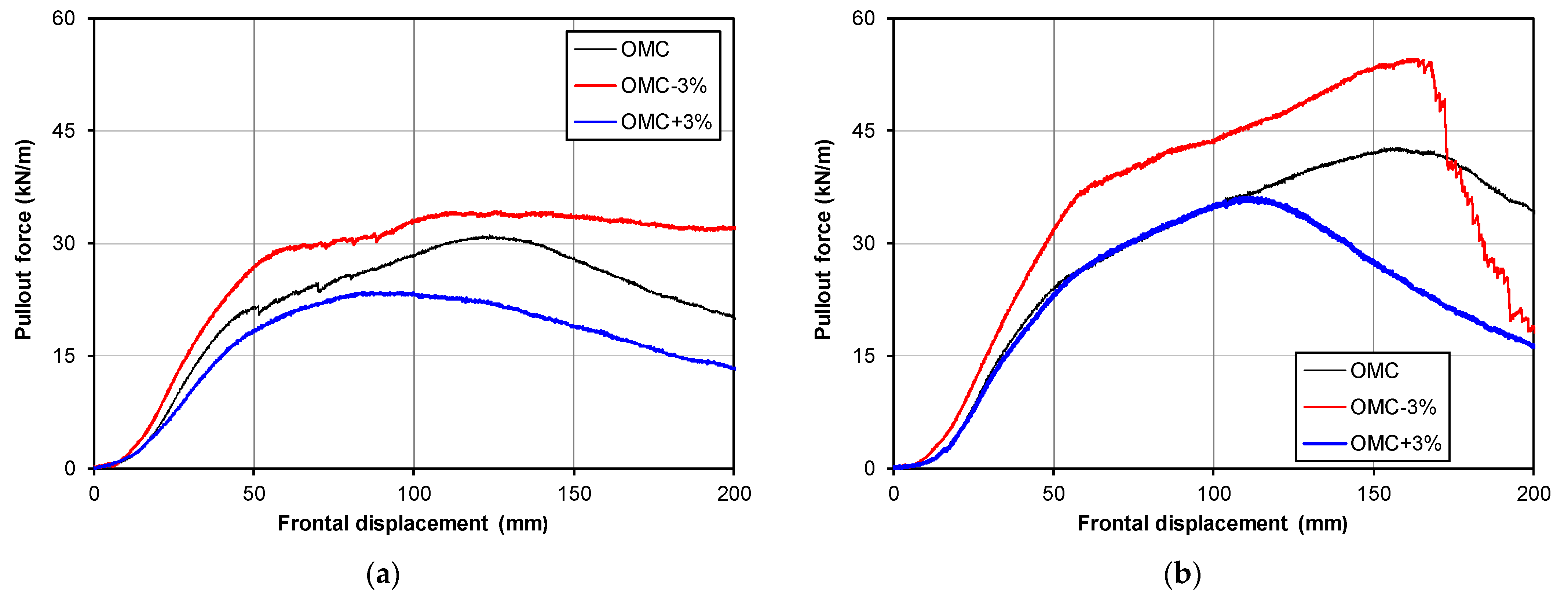

3.3. Influence of Moisture Content of the Recycled C&D Material

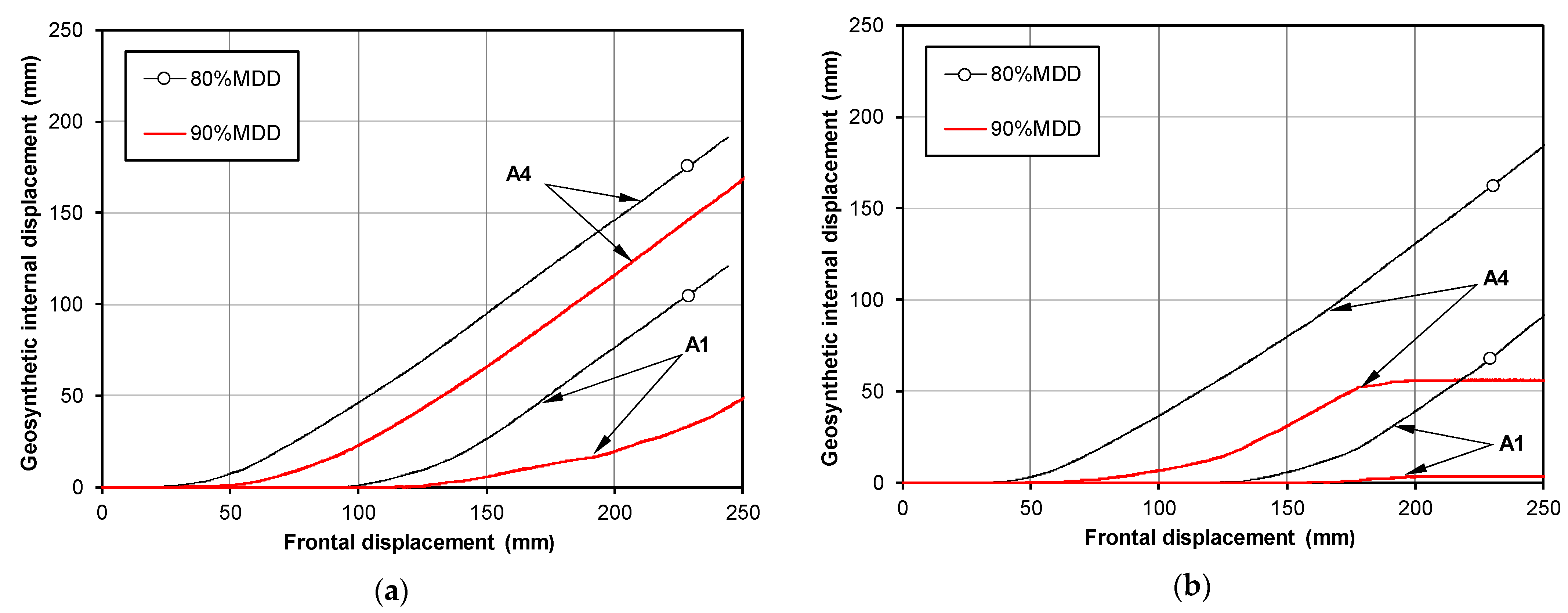

3.4. Influence of Compaction Degree of the Recycled C&D Material

3.5. Summary of Results and Pullout Interaction Coefficients

4. Conclusions

- In spite of the high fine content of the recycled C&D material, its particle size distribution fulfils the requirements of NCMA for segmental retaining walls and those of FHWA for reinforced soil slopes. However, this recycled material does not meet the gradation limits for backfill materials of mechanically stabilized earth walls.

- Increasing the moisture content of the recycled C&D material from OMC−3% to OMC+3% led to a decrease in the internal shear strength. As expected, the increase in the compaction dry density (from 80% to 90% of the maximum dry density) induced an increase in the backfill shear strength.

- Although the two geosynthetics have similar tensile strengths, the pullout resistance of the geogrid was higher than that of the geotextile and was achieved at lower frontal displacements, as a result of the different characteristics of the geogrid, namely its apertures and the consequent passive thrust on the transversal bars and its higher tensile stiffness.

- The compaction of the recycled material above the OMC had a very significant influence on the behaviour of the geogrid throughout the pullout test. When increasing the material moisture content from the OMC to OMC+3%, the geogrid pullout resistance decreased from 31% to 41% depending on the vertical confining stress. The influence of the increase in the moisture content on the geotextile pullout behaviour was less pronounced; even so, increases in the pullout resistance between 17% and 24% were observed.

- The reduction in the compaction moisture content from the OMC to OMC−3% induced a slight decrease in the geogrid pullout resistance (ranging from 5% to 7%). Conversely, the pullout capacity of the geotextile increased 7% and 22% (for σv = 10 kPa and σv = 25 kPa, respectively) when the recycled C&D material was compacted at OMC−3%.

- The expected trend concerning the effect of the degree of compaction on the geogrid pullout resistance was not observed. While for the confining pressure of 25 kPa the increase of the compaction degree induced a slight increase in the geogrid pullout resistance (around 3% on average), unexpectedly a decrease of around 10% was recorded for the geogrid pullout resistance at the lower confining pressure (10 kPa).

- The influence of the compaction degree of the recycled C&D material on the geotextile pullout resistance was the one anticipated: a higher compaction degree resulted in an increase in the geotextile pullout resistance. Regardless of the value of the confining pressure, the geotextile pullout resistance increased around 20%.

- The values of the pullout interaction coefficient, fb, tended to decrease with increasing vertical confining pressure and were within the usual range of this parameter for soil–geosynthetic interfaces.

- The variation of the compaction moisture content of the recycled C&D material around the OMC induced a decrease in the value of fb (higher values obtained for OMC) in the geogrid interface. This tendency was also observed, in general, for the geotextile.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wahlström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; Eionet Report—ETC/WMGE 2020/1; European Topic Centre Waste and Materials in a Green Economy: Boeretang, Belgium, 2020. [Google Scholar]

- European Commission. Competitiveness of the Construction Industry. A Report Drawn up by the Working Group for Sustainable Construction with Participants from the European Commission, Member States and Industry; European Commission: Brussels, Belgium, 2001. [Google Scholar]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D waste & Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Poon, C.S. Reducing construction waste. Waste Manag. 2007, 27, 1715–1716. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Santana Rangel, C.; Amario, M.; Pepe, M.; Martinelli, E.; Toledo Filho, R.D. Durability of Structural Recycled Aggregate Concrete Subjected to Freeze-Thaw Cycles. Sustainability 2020, 12, 6475. [Google Scholar] [CrossRef]

- Xiao, J.; Zou, S.; Ding, T.; Duan, Z.; Liu, Q. Fiber-reinforced mortar with 100% recycled fine aggregates: A cleaner perspective on 3D printing. J. Clean. Prod. 2021, 319. [Google Scholar] [CrossRef]

- Henzinger, C.; Heyer, D. Soil improvement using recycled aggregates from demolition waste. Proc. Inst. Civ. Eng.—Ground Improv. 2018, 171, 74–81. [Google Scholar] [CrossRef]

- Cristelo, N.; Fernández-Jiménez, A.; Vieira, C.; Miranda, T.; Palomo, Á. Stabilisation of construction and demolition waste with a high fines content using alkali activated fly ash. Constr. Build. Mater. 2018, 170, 26–39. [Google Scholar] [CrossRef]

- Kianimehr, M.; Shourijeh, P.T.; Binesh, S.M.; Mohammadinia, A.; Arulrajah, A. Utilization of recycled concrete aggregates for light-stabilization of clay soils. Constr. Build. Mater. 2019, 227, 116792. [Google Scholar] [CrossRef]

- Frías, M.; Martínez-Ramírez, S.; de la Villa, R.V.; Fernández-Carrasco, L.; García, R. Reactivity in cement pastes bearing fine fraction concrete and glass from construction and demolition waste: Microstructural analysis of viability. Cem. Concr. Res. 2021, 148. [Google Scholar] [CrossRef]

- Morón, A.; Ferrández, D.; Saiz, P.; Morón, C. Experimental study with cement mortars made with recycled concrete aggregate and reinforced with aramid fibers. Appl. Sci. 2021, 11, 7791. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build. Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- Jiménez, J.R.; Ayuso, J.; Galvín, A.P.; López, M.; Agrela, F. Use of mixed recycled aggregates with a low embodied energy from non-selected CDW in unpaved rural roads. Constr. Build. Mater. 2012, 34, 34–43. [Google Scholar] [CrossRef]

- Arulrajah, A.; Disfani, M.M.; Horpibulsuk, S.; Suksiripattanapong, C.; Prongmanee, N. Physical properties and shear strength responses of recycled construction and demolition materials in unbound pavement base/subbase applications. Constr. Build. Mater. 2014, 58, 245–257. [Google Scholar] [CrossRef]

- Teijón-López-Zuazo, E.; Vega-Zamanillo, Á.; Calzada-Pérez, M.Á.; Robles-Miguel, Á. Use of Recycled Aggregates Made from Construction and Demolition Waste in Sustainable Road Base Layers. Sustainability 2020, 12, 6663. [Google Scholar] [CrossRef]

- Rahman, M.A.; Imteaz, M.; Arulrajah, A.; Disfani, M.M. Suitability of recycled construction and demolition aggregates as alternative pipe backfilling materials. J. Clean. Prod. 2014, 66, 75–84. [Google Scholar] [CrossRef]

- Vieira, C.S.; Cristelo, N.; Lopes, M.L. Geotechnical and geoenvironmental characterization of recycled Construction and Demolition Wastes for use as backfilling of trenches. In The International Conference Wastes: Solutions, Treatments and Opportunities, 4th ed.; CRC Press Taylor & Francis Group: Porto, Portugal, 2017; pp. 175–181. [Google Scholar]

- Santos, E.C.G.; Palmeira, E.M.; Bathurst, R.J. Behaviour of a geogrid reinforced wall built with recycled construction and demolition waste backfill on a collapsible foundation. Geotext. Geomembr. 2013, 39, 9–19. [Google Scholar] [CrossRef]

- Arulrajah, A.; Rahman, M.; Piratheepan, J.; Bo, M.; Imteaz, M. Interface Shear Strength Testing of Geogrid-Reinforced Construction and Demolition Materials. ASTM Adv. Civ. Eng. Mater. 2013, 2, 189–200. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M. Interface shear properties of geosynthetics and construction and demolition waste from large-scale direct shear tests. Geosynth. Int. 2016, 23, 62–70. [Google Scholar] [CrossRef]

- Srivastava, A.; Jaiswal, S.; Chauhan, V.B. Potential Use of Construction and Demolition Recycled Wastes in Geosynthetic-Reinforced Structures. In Lecture Notes in Civil Engineering; Springer: Singapore, 2022; pp. 199–206. [Google Scholar]

- Vieira, C.S.; Lopes, M.L.; Caldeira, L.M. Sand-geotextile interface characterisation through monotonic and cyclic direct shear tests. Geosynth. Int. 2013, 20, 26–38. [Google Scholar] [CrossRef]

- Alfaro, M.C.; Miura, N.; Bergado, D.T. Soil-geogrid reinforcement interaction by pullout and direct shear tests. Geotech. Test. J. 1995, 18, 157–167. [Google Scholar]

- Lopes, M.L.; Ladeira, M. Role of specimen geometry, soil height and sleeve length on the pull-out behaviour of geogrids. Geosynth. Int. 1996, 3, 701–719. [Google Scholar] [CrossRef]

- Lopes, M.L.; Ladeira, M. Influence of the confinement, soil density and displacement rate on soil-geogrid interaction. Geotext. Geomembr. 1996, 14, 543–554. [Google Scholar] [CrossRef]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Pullout Behavior of Different Geosynthetics-Influence of Soil Density and Moisture Content. Front. Built Environ. 2020, 6. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L.; Ferreira, P.G. HDPE geogrid-residual soil interaction under monotonic and cyclic pullout loading. Geosynth. Int. 2020, 27, 79–96. [Google Scholar] [CrossRef]

- Moraci, N.; Cardile, G. Influence of cyclic tensile loading on pullout resistance of geogrids embedded in a compacted granular soil. Geotext. Geomembr. 2009, 26, 475–487. [Google Scholar] [CrossRef]

- Soleimanbeigi, A.; Tanyu, B.F.; Aydilek, A.H.; Florio, P.; Abbaspour, A.; Dayioglu, A.Y.; Likos, W.J. Evaluation of recycled concrete aggregate backfill for geosynthetic-reinforced MSE walls. Geosynth. Int. 2019, 26, 396–412. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M.; Lopes, M.L. Recycled Construction and Demolition Wastes as filling material for geosynthetic reinforced structures. Interface properties. J. Clean. Prod. 2016, 124, 299–311. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.; Ferreira, F.B.; Lopes, M.L. Pullout Behaviour of Geogrids Embedded in a Recycled Construction and Demolition Material. Effects of Specimen Size and Displacement Rate. Sustainability 2020, 12, 3825. [Google Scholar] [CrossRef]

- Vieira, C.S.; Ferreira, F.B.; Pereira, P.M.; Lopes, M.L. Pullout behaviour of geosynthetics in a recycled construction and demolition material—Effects of cyclic loading. Transp. Geotech. 2020, 23, 100346. [Google Scholar] [CrossRef]

- Gao, Y.; Hang, L.; He, J.; Zhang, F.; Van Paassen, L. Pullout behavior of geosynthetic reinforcement in biocemented soils. Geotext. Geomembr. 2021, 49, 646–656. [Google Scholar] [CrossRef]

- Pierozan, R.C.; Araujo, G.L.S.; Palmeira, E.M.; Romanel, C.; Zornberg, J.G. Interface pullout resistance of polymeric strips embedded in marginal tropical soils. Geotext. Geomembr. 2022, 50, 20–39. [Google Scholar] [CrossRef]

- Karnamprabhakara, B.K.; Balunaini, U. Modified axial pullout resistance factors of geogrids embedded in pond ash. Geotext. Geomembr. 2021, 49, 1245–1255. [Google Scholar] [CrossRef]

- Chang, J.C.; Hannon, J.B.; Forsyth, R.A. Pullout resistance and interaction of earthwork reinforcement and soil. Transp. Res. Rec. 1977, 640, 1–7. [Google Scholar]

- Palmeira, E.M.; Milligan, G.W.E. Scale and other factores affecting the results of pull out tests of grid buried in sand. Géotechnique 1989, 39, 511–524. [Google Scholar] [CrossRef]

- Ochiai, H.; Hayashi, S.; Otani, J.; Hirai, T. Evaluation of pull-out resistance of geogrid reinforced soils. Proc. Int. Symp. Earth Reinf. Pract. 1992, 146, 141–146. [Google Scholar]

- Fannin, R.J.; Raju, D.M. Large-scale pull out test results on geosynthetics. In Proceedings of Geosynthetics 93 Conference, Vancouver, BC, Canada, 30 March–1 April 1993; pp. 633–643. [Google Scholar]

- Moraci, N.; Recalcati, P. Factors affecting the pullout behaviour of extruded geogrids embedded in a compacted granular soil. Geotext. Geomembr. 2006, 24, 220–242. [Google Scholar] [CrossRef]

- Ezzein, F.M.; Bathurst, R.J. A new approach to evaluate soil-geosynthetic interaction using a novel pullout test apparatus and transparent granular soil. Geotext. Geomembr. 2014, 42, 246–255. [Google Scholar] [CrossRef]

- Moraci, N.; Cardile, G.; Domenio, G.; Mandaglio, M.C.; Calvarano, L.S.; Carbone, L. Soil Geosynthetic Interaction: Design Parameters from Experimental and Theoretical Analysis. Transp. Infrastruct. Geotechnol. 2014, 1, 165–227. [Google Scholar] [CrossRef] [Green Version]

- EN 13738. Geotextiles and Geotextile-Related Products—Determination of Pullout Resistance in Soil; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- NCMA. Design Manual for Segmental Retaining Walls, 3rd ed.; National Concrete Masonry Association: Herndon, VA, USA, 2010; 206p. [Google Scholar]

- FHWA. Design and Construction of Mechanically Stabilized Earth Walls and Reinforced Soil Slopes; Berg, R.R., Christopher, B.R., Samtani, N.C., Eds.; FHWA-NHI-10-024: Washington, DC, USA, 2010. [Google Scholar]

- Ferreira, F.B.; Vieira, C.S.; Lopes, M.L. Direct shear behaviour of residual soil–geosynthetic interfaces—influence of soil moisture content, soil density and geosynthetic type. Geosynth. Int. 2015, 22, 257–272. [Google Scholar] [CrossRef]

- EN ISO 12957-1. Geosynthetics—Determination of the Friction Characteristics—Part 1: Direct Shear Test; CEN—TC 189; CEN: Brussels, Belgium, 2018. [Google Scholar]

- Khoury, C.N.; Miller, G.A.; Hatami, K. Unsaturated soil–geotextile interface behavior. Geotext. Geomembr. 2011, 29, 17–28. [Google Scholar] [CrossRef]

- Esmaili, D.; Hatami, K.; Miller, G.A. Influence of matric suction on geotextile reinforcement-marginal soil interface strength. Geotext. Geomembr. 2014, 42, 139–153. [Google Scholar] [CrossRef]

- Abu-Farsakh, M.; Coronel, J.; Tao, M. Effect of soil moisture content and dry density on cohesive soil–geosynthetic interactions using large direct shear tests. J. Mater. Civ. Eng. 2007, 19, 540–549. [Google Scholar] [CrossRef]

- Mohiuddin, A. Analysis of Laboratory and Field Pull-Out Tests of Geosynthetics in Clayey Soils. Master’s Thesis, Faculty of the Louisiana State University and Agricultural and Mechanical College, Baton Rouge, LA, USA, 2003. [Google Scholar]

- Goodhue, M.J.; Edil, T.B.; Benson, C.H. Interaction of foundry sands with geosynthetics. J. Geotech. Geoenviron. Eng. 2001, 127, 353–362. [Google Scholar] [CrossRef]

- Hsieh, C.; Chen, G.H.; Wu, J.-H. The shear behavior obtained from the direct shear and pullout tests for different poor grades soil-geosynthetic systems. J. GeoEng. 2011, 6, 15–26. [Google Scholar]

| Reference | Dimensions Pullout Box—L × W × H (mm) | Geosynthetic Type | Filling Material | Assessed Parameters |

|---|---|---|---|---|

| Alfaro et al. [25] | 1600 × 600 × 500 | Geogrid | Dense granular soil | New test apparatus Soil dilatancy |

| Lopes and Ladeira [26,27] | 1530 × 1000 × 800 | Geogrid | Granular soil | Specimen geometry Soil height Sleeve length Confinement pressure Soil density Displacement rate |

| Ferreira et al. [28] | 1530 × 1000 × 800 | Geogrid Geocomposite Geotextile | Granite residual soil | Soil density Soil moisture content Geosynthetic type |

| Ferreira et al. [29] | 1530 × 1000 × 800 | Geogrid | Granite residual soil | Cyclic pullout loading Cyclic load frequency Cyclic load amplitude Number of cycles Soil density |

| Moraci and Cardile [30] | 1700 × 600 × 680 | Geogrid | Granular soil | Cyclic pullout loading Cyclic load amplitude Cyclic load frequency Vertical confining stress Geogrid properties |

| Soleimanbeigi et al. [31] | 1270 × 760 × 510 | Geogrid Geotextile | Recycled concrete aggregate | Vertical confining stress Geosynthetic type |

| Vieira et al. [32,33] | 1530 × 1000 × 800 | Geogrid Geocomposite (high-strength geotextile) | Fine-grain recycled C&D material | Geosynthetic type Geogrid specimen size Displacement rate Vertical confining pressure |

| Vieira et al. [34] | 1530 × 1000 × 800 | Geogrid Geocomposite (high-strength geotextile) | Fine-grain recycled C&D material | Cyclic pullout loading Pre-cyclic pullout load level Cyclic load frequency Cyclic load amplitude Geosynthetic type |

| GGR | GCR | |

|---|---|---|

| Raw material | PET | PP & PET |

| Aperture dimensions (mm) | 30 × 73 | - |

| Mass per unit area (g/m2) | 380 | 340 |

| Mean value of the tensile strength (kN/m) | 80 | 75 |

| Elongation at maximum load (%) | ≤8 | 10 |

| Secant stiffness at 2% strain (kN/m) | 1920 | 650 |

| Test Number | Geosynthetic Material | Moisture Content (%) | % Maximum Dry Density | Confining Pressure (kPa) | Number of Specimens |

|---|---|---|---|---|---|

| T1 | 10 | 3 | |||

| T2 | GGR | 9 * | 80 | 25 | 3 |

| T3 | 50 | 3 | |||

| T4 | GGR | 6 | 80 | 10 | 3 |

| T5 | 25 | 3 | |||

| T6 | 10 | 3 | |||

| T7 | GGR | 12 | 80 | 25 | 3 |

| T8 | 50 | 3 | |||

| T9 | GGR | 9 * | 90 | 10 | 3 |

| T10 | 25 | 3 | |||

| T11 | 10 | 3 | |||

| T12 | GCR | 9 * | 80 | 25 | 3 |

| T13 | 50 | 3 | |||

| T14 | GCR | 6 | 80 | 10 | 3 |

| T15 | 25 | 3 | |||

| T16 | 10 | 3 | |||

| T17 | GCR | 12 | 80 | 25 | 3 |

| T18 | 50 | 3 | |||

| T19 | GCR | 9 * | 90 | 10 | 3 |

| T20 | 25 | 3 |

| Properties | Values |

|---|---|

| D10 [mm] | 0.01 |

| D30 [mm] | 0.27 |

| D50 [mm] | 0.61 |

| D60 [mm] | 0.97 |

| Cu | 97 |

| Cc | 7.5 |

| Fines fraction (No. 200 sieve) [%] | 16.9 |

| Minimum void ratio, emin | 0.434 |

| Maximum void ratio, emax | 0.877 |

| Particle density, Gs | 2.58 |

| Maximum dry unit weight, γd,max [kN/m3] | 20.1 |

| Optimum moisture content, OMC [%] | 9.0 |

| 80% MDD | 90% MDD | |||

|---|---|---|---|---|

| Parameter | OMC−3% | OMC | OMC+3% | OMC |

| Cohesion, c [kPa] | 21.1 | 16.3 | 12.4 | 18.0 |

| Peak friction angle, φ [°] | 40.5 | 37.6 | 37.5 | 40.3 |

| GGR | GCR | |||

|---|---|---|---|---|

| Confining Pressure (kPa) | PR (kN/m) | dPR (mm) | PR (kN/m) | dPR (mm) |

| 10 | 36.4 | 53.4 | 31.8 | 123.9 |

| 25 | 53.0 | 60.6 | 43.4 | 154.7 |

| 50 | 61.4 | 58.7 | 50.7 | 171.0 |

| GGR | OMC−3% | OMC | OMC+3% | |||

|---|---|---|---|---|---|---|

| C. Pressure (kPa) | PR (kN/m) | dPR (mm) | PR(kN/m) | dPR (mm) | PR (kN/m) | dPR (mm) |

| 10 | 33.8 | 57.7 | 36.4 | 53.4 | 23.6 | 68.5 |

| 25 | 50.4 | 59.5 | 53.0 | 60.6 | 31.0 | 67 |

| 50 | - | - | 61.4 | 58.7 | 42.3 | 61.6 |

| GCR | OMC−3% | OMC | OMC+3% | |||

|---|---|---|---|---|---|---|

| C. Pressure (kPa) | PR (kN/m) | dPR (mm) | PR (kN/m) | dPR (mm) | PR (kN/m) | dPR (mm) |

| 10 | 34.1 | 121.5 | 31.8 | 123.9 | 24.3 | 77.8 |

| 25 | 54.5 | 168.3 | 43.4 | 154.7 | 36.8 | 118.9 |

| 50 | - | - | 50.7 | 171.0 | 42.3 | 130.9 |

| Test Number | C. Pressure (kPa) | PR (kN/m) | dPR (mm) | τp (kPa) | τds (kPa) | fb | fb (Average) |

|---|---|---|---|---|---|---|---|

| 40.2 | 52.2 | 28.8 | 1.20 | ||||

| T1 | 10 | 32.9 | 47.8 | 23.4 | 24.0 | 0.98 | 1.09 |

| 35.9 | 60.3 | 26.0 | 1.08 | ||||

| 53.4 | 65.0 | 39.0 | 1.10 | ||||

| T2 | 25 | 54.8 | 64.9 | 40.0 | 35.6 | 1.13 | 1.08 |

| 50.8 | 51.8 | 36.4 | 1.02 | ||||

| 64.4 | 60.8 | 46.7 | 0.85 | ||||

| T3 | 50 | 57.1 | 62.0 | 41.5 | 54.8 | 0.76 | 0.81 |

| 62.6 | 53.2 | 44.9 | 0.82 | ||||

| 34.2 | 51.1 | 24.5 | 0.83 | ||||

| T4 | 10 | 35.4 | 64.5 | 25.8 | 29.6 | 0.87 | 0.82 |

| 32.0 | 57.3 | 23.1 | 0.78 | ||||

| 49.3 | 52.1 | 35.3 | 0.83 | ||||

| T5 | 25 | 49.9 | 62.1 | 36.3 | 42.5 | 0.85 | 0.86 |

| 52.1 | 64.1 | 38.0 | 0.89 | ||||

| 24.4 | 68.1 | 17.9 | 0.89 | ||||

| T6 | 10 | 24.4 | 64.3 | 17.8 | 20.1 | 0.89 | 0.86 |

| 21.9 | 73.1 | 16.2 | 0.80 | ||||

| 33.3 | 79.7 | 24.8 | 0.79 | ||||

| T7 | 25 | 27.7 | 56.9 | 20.0 | 31.6 | 0.63 | 0.72 |

| 32.1 | 64.4 | 23.4 | 0.74 | ||||

| 44.6 | 60.6 | 32.3 | 0.64 | ||||

| T8 | 50 | 41.1 | 65.5 | 30.0 | 50.8 | 0.59 | 0.61 |

| 41.2 | 58.5 | 29.8 | 0.59 | ||||

| 34.7 | 62.6 | 25.3 | 0.95 | ||||

| T9 | 10 | 31.6 | 72.0 | 23.3 | 26.5 | 0.88 | 0.88 |

| 30.3 | 45.7 | 21.5 | 0.81 | ||||

| 56.0 | 84.0 | 42.0 | 1.07 | ||||

| T10 | 25 | 50.5 | 62.3 | 36.7 | 39.2 | 0.94 | 1.04 |

| 56.9 | 91.1 | 43.2 | 1.10 |

| Test Number | C. Pressure (kPa) | PR (kN/m) | dPR (mm) | τp (kPa) | τds (kPa) | fb | fb (Average) |

|---|---|---|---|---|---|---|---|

| 30.4 | 105.0 | 23.6 | 0.98 | ||||

| T11 | 10 | 31.1 | 123.7 | 24.8 | 24.0 | 1.03 | 1.06 |

| 33.8 | 143.0 | 27.8 | 1.16 | ||||

| 48.4 | 148.2 | 40.2 | 1.13 | ||||

| T12 | 25 | 42.8 | 158.0 | 36.1 | 35.6 | 1.02 | 1.05 |

| 43.1 | 142.6 | 35.4 | 1.00 | ||||

| 52.4 | 169.5 | 45.1 | 0.82 | ||||

| T13 | 50 | 52.8 | 172.5 | 45.7 | 54.8 | 0.83 | 0.80 |

| 46.9 | 171.0 | 40.5 | 0.74 | ||||

| 32.2 | 102.5 | 24.8 | 0.84 | ||||

| T14 | 10 | 35.9 | 135.0 | 29.2 | 29.6 | 0.98 | 0.92 |

| 34.3 | 127.0 | 27.5 | 0.93 | ||||

| 53.7 | 175.0 | 46.7 | 1.10 | ||||

| T15 | 25 | 54.6 | 163.4 | 46.5 | 42.5 | 1.10 | 1.10 |

| 55.0 | 166.5 | 47.2 | 1.11 | ||||

| 28.8 | 89.1 | 21.8 | 1.09 | ||||

| T16 | 10 | 20.6 | 60.3 | 15.0 | 20.1 | 0.75 | 0.90 |

| 23.5 | 84.1 | 17.7 | 0.88 | ||||

| 39.1 | 124.2 | 31.3 | 0.99 | ||||

| T17 | 25 | 36.1 | 110.7 | 28.2 | 31.6 | 0.89 | 0.92 |

| 35.2 | 121.9 | 28.0 | 0.89 | ||||

| 46.9 | 128.8 | 37.7 | 0.74 | ||||

| T18 | 50 | 36.8 | 120.8 | 29.2 | 50.8 | 0.58 | 0.67 |

| 43.2 | 143.1 | 35.6 | 0.70 | ||||

| 39.4 | 177.3 | 34.4 | 1.30 | ||||

| T19 | 10 | 40.5 | 155.6 | 34.1 | 26.5 | 1.29 | 1.25 |

| 37.8 | 139.4 | 31.0 | 1.17 | ||||

| 50.5 | 177.3 | 44.1 | 1.12 | ||||

| T20 | 25 | 47.1 | 153.2 | 39.5 | 39.2 | 1.01 | 1.12 |

| 55.1 | 171.7 | 47.6 | 1.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vieira, C.S.; Pereira, P.M. Influence of the Geosynthetic Type and Compaction Conditions on the Pullout Behaviour of Geosynthetics Embedded in Recycled Construction and Demolition Materials. Sustainability 2022, 14, 1207. https://doi.org/10.3390/su14031207

Vieira CS, Pereira PM. Influence of the Geosynthetic Type and Compaction Conditions on the Pullout Behaviour of Geosynthetics Embedded in Recycled Construction and Demolition Materials. Sustainability. 2022; 14(3):1207. https://doi.org/10.3390/su14031207

Chicago/Turabian StyleVieira, Castorina S., and Paulo M. Pereira. 2022. "Influence of the Geosynthetic Type and Compaction Conditions on the Pullout Behaviour of Geosynthetics Embedded in Recycled Construction and Demolition Materials" Sustainability 14, no. 3: 1207. https://doi.org/10.3390/su14031207

APA StyleVieira, C. S., & Pereira, P. M. (2022). Influence of the Geosynthetic Type and Compaction Conditions on the Pullout Behaviour of Geosynthetics Embedded in Recycled Construction and Demolition Materials. Sustainability, 14(3), 1207. https://doi.org/10.3390/su14031207