AAO Template-Assisted Fabrication of Ordered Ag Nanoparticles-Decorated Au Nanotubes Array for Surface-Enhanced Raman Scattering Detection

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Chemicals

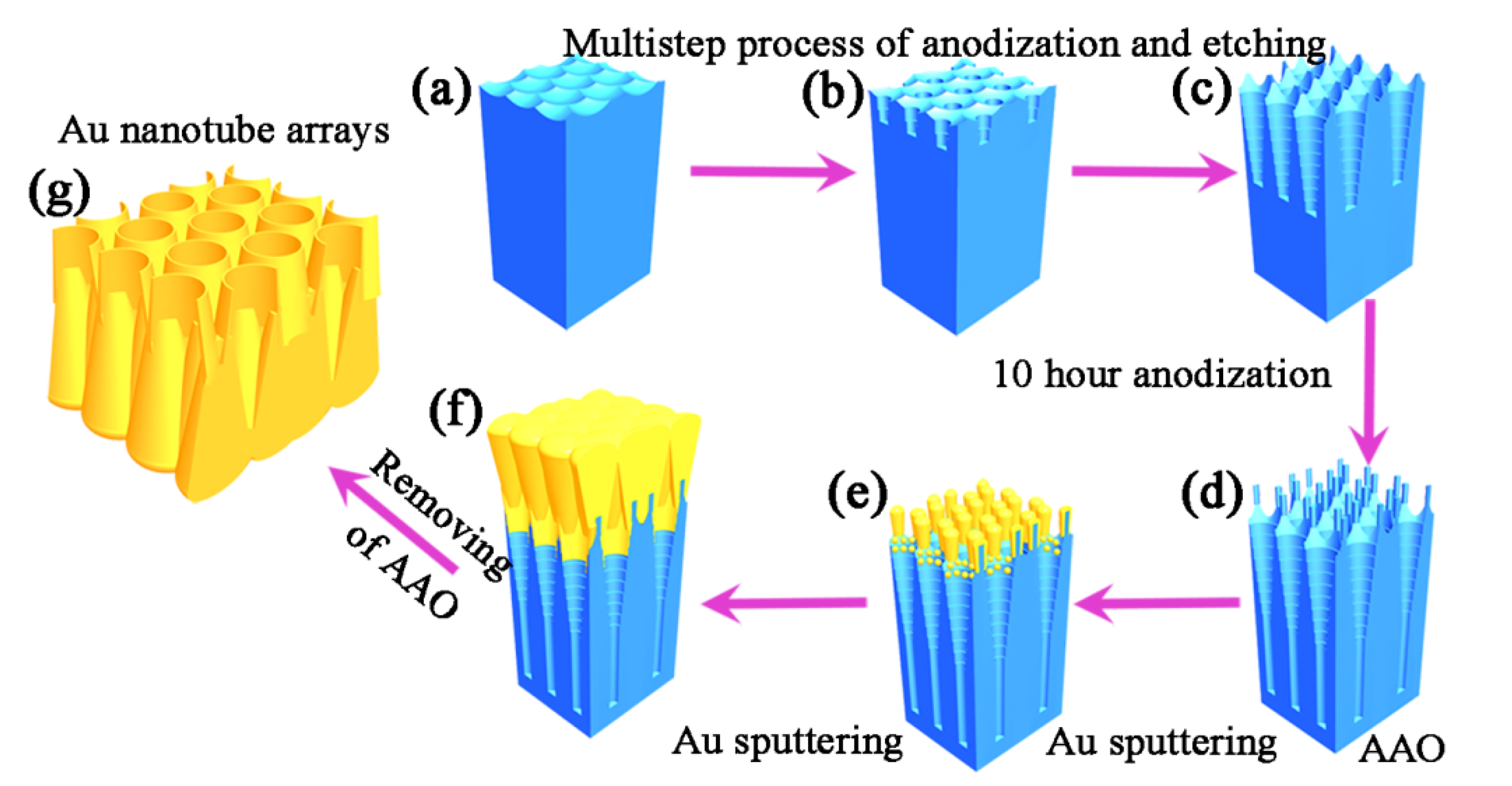

2.2. Fabrication of the Funnel-Shaped-Pore-AAO Templates

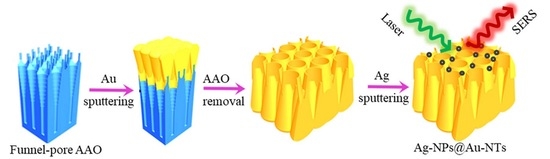

2.3. Preparation of Au-NT Arrays

2.4. Characterization

3. Results and Discussion

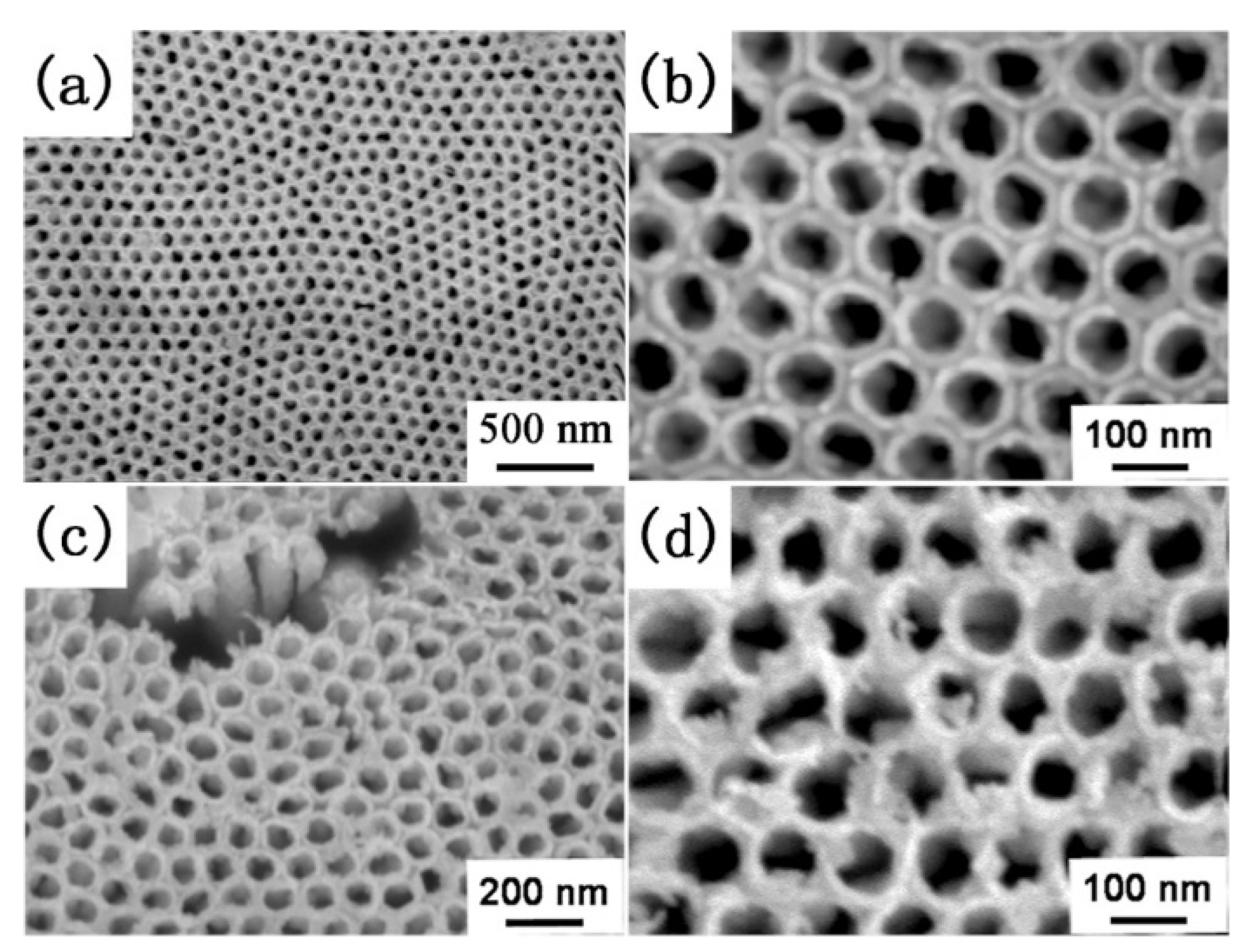

3.1. The Morphology of the Funnel-Shaped-Pore-AAO Templates and Achieved Ag-NPs@Au-NTs Array

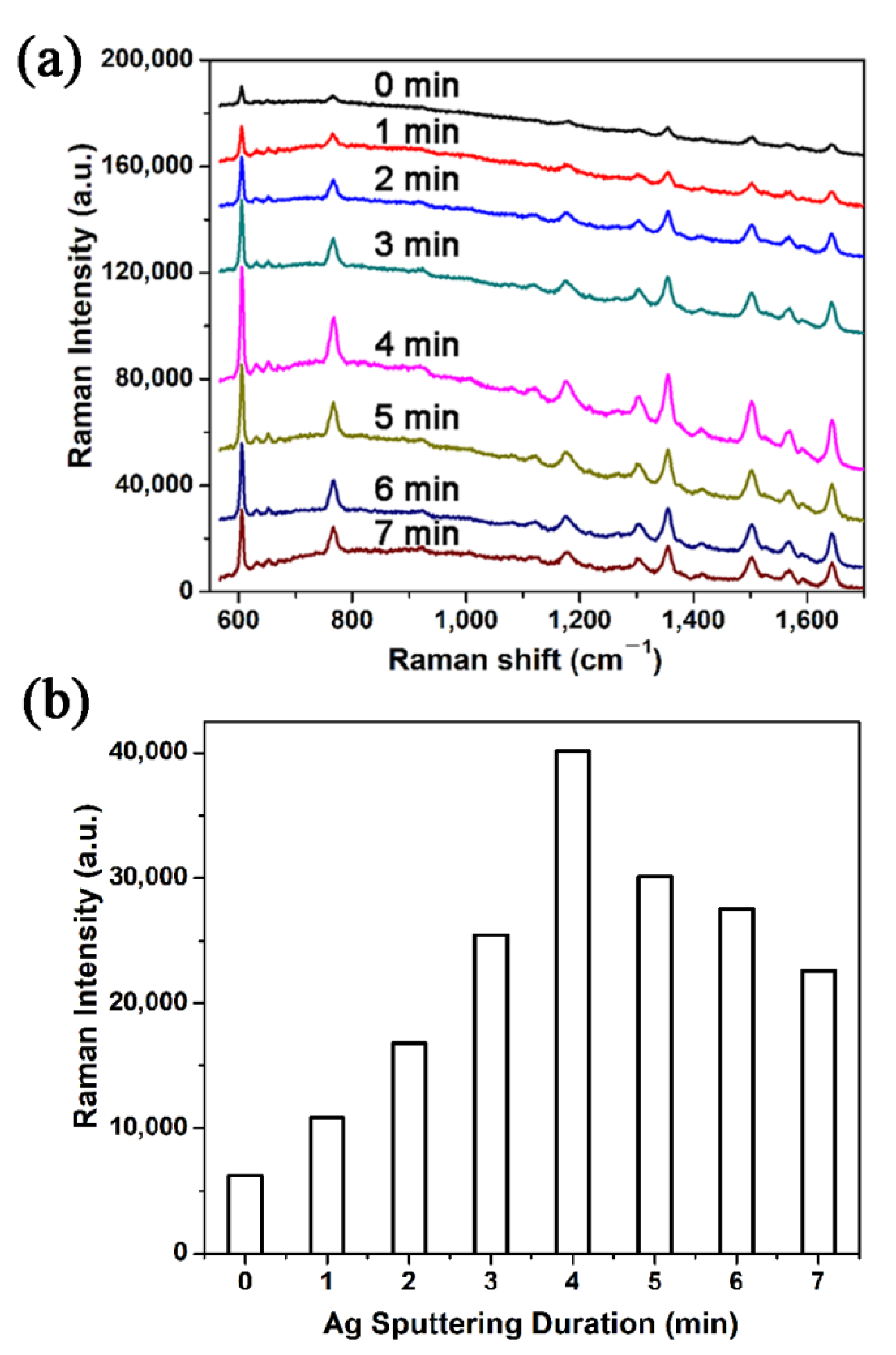

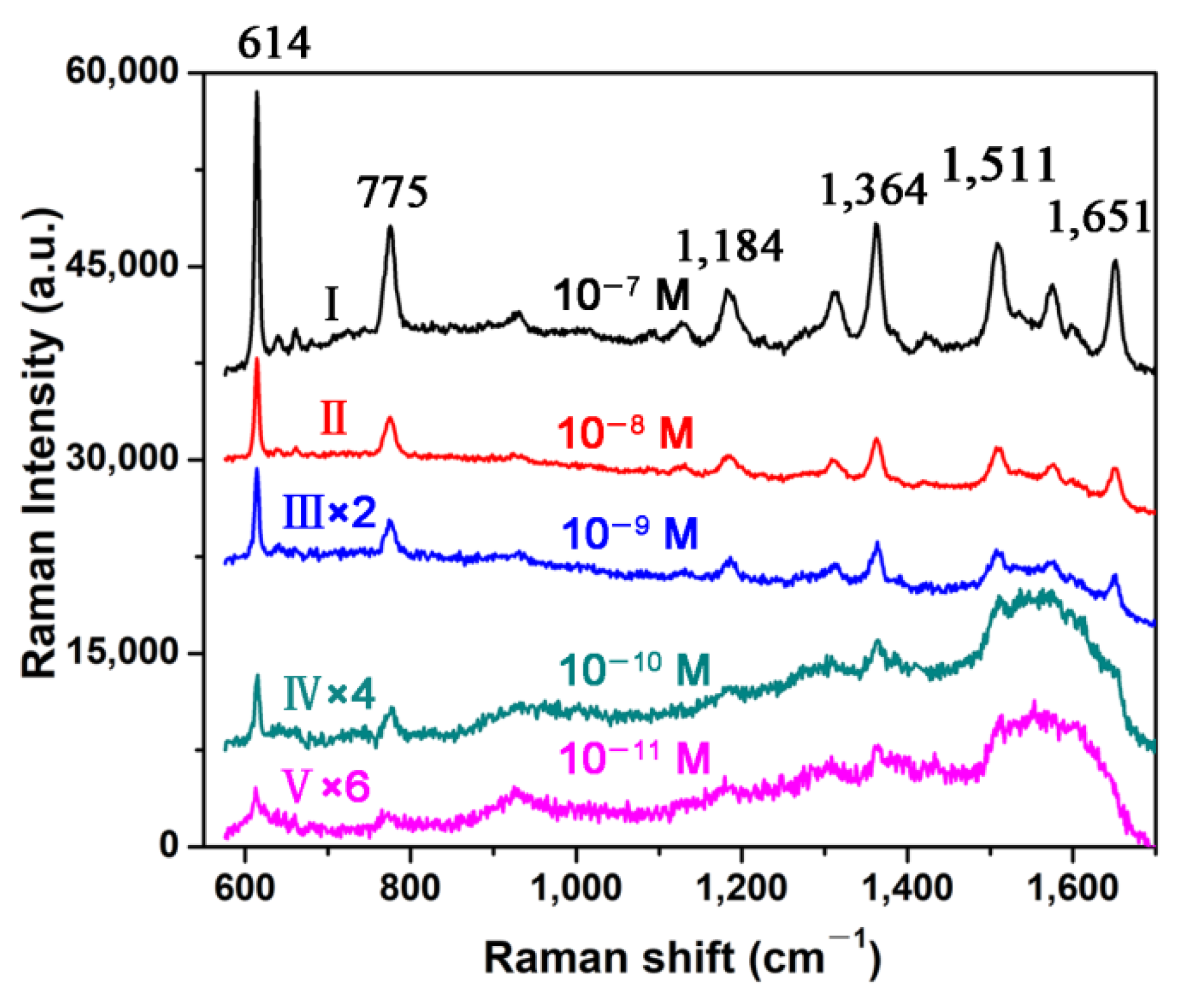

3.2. SERS Sensitivity of the Ag-NPs@Au-NTs Arrays

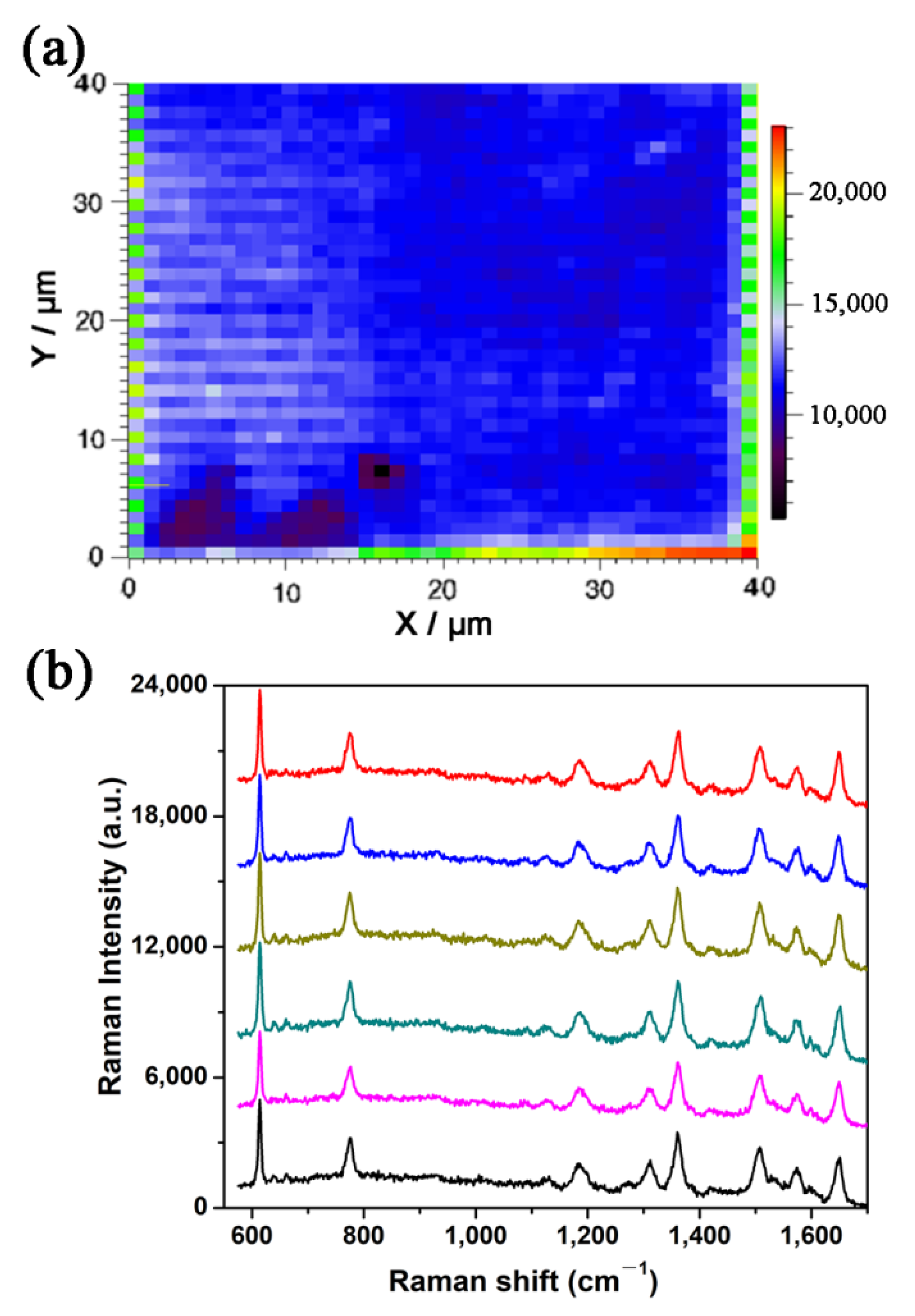

3.3. SERS Signal Homogeneity over the Ag-NPs@Au-NTs Arrays

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, L.; Lee, J.-H.; Rathnam, C.; Hou, Y.; Choi, J.-W.; Lee, K.-B. Dual-Enhanced Raman Scattering-Based Characterization of Stem Cell Differentiation Using Graphene-Plasmonic Hybrid Nanoarray. Nano Lett. 2019, 19, 8138–8148. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Chen, N.; Su, Y.; Wang, H.; He, Y. Silicon nanohybrid-based SERS chips armed with an internal standard for broad-range, sensitive and reproducible simultaneous quantification of lead(ii) and mercury(ii) in real systems. Nanoscale 2018, 10, 4010–4018. [Google Scholar] [CrossRef]

- Liao, P.-H.; Tseng, C.-Y.; Ke, Z.-Y.; Hsieh, C.-L.; Kong, K.V. Operando characterization of chemical reactions in single living cells using SERS. Chem. Commun. 2020, 56, 4852–4855. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Zhu, C.; Meng, G.; Wu, N. Review—Surface-Enhanced Raman Scattering Sensors for Food Safety and Environmental Monitoring. J. Electrochem. Soc. 2018, 165, B3098–B3118. [Google Scholar] [CrossRef]

- Tang, H.; Meng, G.; Li, Z.; Zhu, C.; Huang, Z.; Wang, Z.; Li, F. Hexagonally arranged arrays of urchin-like Ag hemispheres decorated with Ag nanoparticles for surface-enhanced Raman scattering substrates. Nano Res. 2015, 8, 2261–2270. [Google Scholar] [CrossRef]

- Li, M.; Cushing, S.K.; Wu, N. Plasmon-enhanced optical sensors: A review. Analyst 2015, 140, 386–406. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, Z.; Meng, G.; Hu, X.; Pan, Q.; Huo, D.; Zhou, H.; Ke, Y.; Wu, N. Plasmon-tunable Au@Ag core-shell spiky nanoparticles for surface-enhanced Raman scattering. Nano Res. 2019, 12, 449–455. [Google Scholar] [CrossRef]

- Li, J.; Deng, T.-S.; Liu, X.; Dolan, J.A.; Scherer, N.F.; Nealey, P.F. Hierarchical Assembly of Plasmonic Nanoparticle Heterodimer Arrays with Tunable Sub-5 nm Nanogaps. Nano Lett. 2019, 19, 4314–4320. [Google Scholar] [CrossRef]

- Yang, H.; Li, B.Q.; Jiang, X.; Shao, J. Hybrid nanostructure of SiO2@Si with Au-nanoparticles for surface enhanced Raman spectroscopy. Nanoscale 2019, 11, 13484–13493. [Google Scholar] [CrossRef]

- Tao, A.; Sinsermsuksakul, P.; Yang, P. Polyhedral Silver Nanocrystals with Distinct Scattering Signatures. Angew. Chem. Int. Ed. 2006, 45, 4597–4601. [Google Scholar] [CrossRef]

- Abu Hatab, N.A.; Oran, J.M.; Sepaniak, M.J. Surface-Enhanced Raman Spectroscopy Substrates Created via Electron Beam Lithography and Nanotransfer Printing. ACS Nano 2008, 2, 377–385. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Zhao, Q.; Meng, G.; Wang, X.; Hu, X.; Han, F.; Lei, Y. Silver nanoparticle-assembled micro-bowl arrays for sensitive SERS detection of pesticide residue. Nanotechnology 2020, 31, 205303. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Wu, L.; Lu, Z.; Li, Q.; Yin, W.; Ding, F.; Han, H. Gecko-Inspired Nanotentacle Surface-Enhanced Raman Spectroscopy Substrate for Sampling and Reliable Detection of Pesticide Residues in Fruits and Vegetables. Anal. Chem. 2017, 89, 2424–2431. [Google Scholar] [CrossRef] [PubMed]

- Fang, X.; Zheng, C.; Yin, Z.; Wang, Z.; Wang, J.; Liu, J.; Luo, D.; Liu, Y.J. Hierarchically Ordered Silicon Metastructures from Improved Self-Assembly-Based Nanosphere Lithography. ACS Appl. Mater. Interfaces 2020, 12, 12345–12352. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, X.; Chen, L.; Chen, S.; Wei, M.; Gao, M.; Zhao, Y.; Wang, C.; Qu, X.; Zhang, Y.; et al. Ordered Nanocap Array Composed of SiO2-Isolated Ag Islands as SERS Platform. Langmuir 2014, 30, 15285–15291. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Filipczak, P.; He, G.; Nowaczyk, G.; Witczak, L.; Raj, W.; Kozanecki, M.; Matyjaszewski, K.; Pietrasik, J. Synthesis and characterization of Ag NPs templated via polymerization induced self-assembly. Polymer 2017, 129, 144–150. [Google Scholar] [CrossRef]

- Zhu, C.; Meng, G.; Zheng, P.; Huang, Q.; Li, Z.; Hu, X.; Wang, X.; Huang, Z.; Li, F.; Wu, N. A Hierarchically Ordered Array of Silver-Nanorod Bundles for Surface-Enhanced Raman Scattering Detection of Phenolic Pollutants. Adv. Mater. 2016, 28, 4871–4876. [Google Scholar] [CrossRef]

- Anema, J.R.; Brolo, A.G.; Felten, A.; Bittencourt, C. Surface-enhanced Raman scattering from polystyrene on gold clusters. J. Raman Spectrosc. 2010, 41, 745–751. [Google Scholar] [CrossRef]

- Huang, Z.; Meng, G.; Chen, B.; Zhu, C.; Han, F.; Hu, X.; Wang, X.; Zhulin, H.; Guowen, M.; Bin, C.; et al. Surface-Enhanced Raman Scattering from Au-Nanorod Arrays with Sub-5-nm Gaps Stuck Out of an AAO Template. J. Nanosci. Nanotechnol. 2016, 16, 934–938. [Google Scholar] [CrossRef]

- Chen, B.; Meng, G.; Huang, Q.; Huang, Z.; Xu, Q.; Zhu, C.; Qian, Y.; Ding, Y. Green Synthesis of Large-Scale Highly Ordered Core@Shell Nanoporous Au@Ag Nanorod Arrays as Sensitive and Reproducible 3D SERS Substrates. ACS Appl. Mater. Interfaces 2014, 6, 15667–15675. [Google Scholar] [CrossRef]

- Huang, Z.; Meng, G.; Huang, Q.; Chen, B.; Zhu, C.; Zhang, Z. Large-area Ag nanorod array substrates for SERS: AAO template-assisted fabrication, functionalization, and application in detection PCBs. J. Raman Spectrosc. 2013, 44, 240–246. [Google Scholar] [CrossRef]

- Tang, H.; Meng, G.; Huang, Q.; Zhu, C.; Huang, Z.; Li, Z.; Zhang, Z.; Zhang, Y. Urchin-like Au-nanoparticles@Ag-nanohemisphere arrays as active SERS-substrates for recognition of PCBs. RSC Adv. 2014, 4, 19654–19657. [Google Scholar] [CrossRef]

- Zhou, Q.; Meng, G.; Huang, Q.; Zhu, C.; Tang, H.; Qian, Y.; Chen, B.; Chen, B. Ag-nanoparticles-decorated NiO-nanoflakes grafted Ni-nanorod arrays stuck out of porous AAO as effective SERS substrates. Phys. Chem. Chem. Phys. 2014, 16, 3686–3692. [Google Scholar] [CrossRef] [PubMed]

- Hendren, W.R.; Murphy, A.; Evans, P.; O’Connor, D.; Wurtz, G.A.; Zayats, A.V.; Atkinson, R.; Pollard, R.J. Fabrication and optical properties of gold nanotube arrays. J. Phys. Condens. Matter 2008, 20, 3931–3939. [Google Scholar] [CrossRef]

- Lee, W.; Scholz, R.; Nielsch, K.; Gösele, U. A Template-Based Electrochemical Method for the Synthesis of Multisegmented Metallic Nanotubes. Angew. Chem. Int. Ed. 2005, 44, 6050–6054. [Google Scholar] [CrossRef]

- Yu, Y.; Kant, K.; Shapter, J.G.; Addai-Mensah, J.; Losic, D. Gold nanotube membranes have catalytic properties. Microporous Mesoporous Mater. 2012, 153, 131–136. [Google Scholar] [CrossRef]

- Sun, K.; Huang, Q.; Meng, G.; Lu, Y. Highly Sensitive and Selective Surface-Enhanced Raman Spectroscopy Label-free Detection of 3,3′,4,4′-Tetrachlorobiphenyl Using DNA Aptamer-Modified Ag-Nanorod Arrays. ACS Appl. Mater. Interfaces 2016, 8, 5723–5728. [Google Scholar] [CrossRef]

- Sun, K.; Meng, G.; Huang, Q.; Zhao, X.; Zhu, C.; Huang, Z.; Qian, Y.; Wang, X.; Hu, X. Gap-tunable Ag-nanorod arrays on alumina nanotip arrays as effective SERS substrates. J. Mater. Chem. C 2013, 1, 5015–5022. [Google Scholar] [CrossRef]

- Yan, B.; Sun, K.; Chao, K.; Alharbi, N.S.; Li, J.; Huang, Q. Fabrication of a Novel Transparent SERS Substrate Comprised of Ag-nanoparticle Arrays and its Application in Rapid Detection of Ractopamine on Meat. Food Anal. Methods 2018, 11, 2329–2335. [Google Scholar] [CrossRef]

- Xu, W.; Zhu, X.; Chu, Z.; Wang, Z.; Xiao, Z.; Huang, Z. ScroBiculate sub-10 nm nanocavity arrays as effective sers substrate for the trace determination of 3,3′,4,4′—Polychlorinated biphenyls. Appl. Surf. Sci. 2017, 399, 711–715. [Google Scholar] [CrossRef]

- Hou, C.; Meng, G.; Huang, Z.; Chen, B.; Zhu, C.; Li, Z. Ordered arrays of vertically aligned Au-nanotubes grafted with flocky Au/Ag-nanospikes based on electrodeposition and subsequent redox reaction. Electrochem. Commun. 2015, 60, 104–108. [Google Scholar] [CrossRef]

- Erol, M.; Han, Y.; Stanley, S.K.; Stafford, C.; Du, H.; Sukhishvili, S. SERS Not to Be Taken for Granted in the Presence of Oxygen. J. Am. Chem. Soc. 2009, 131, 7480–7481. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Du, Z.; Sun, K.; He, X.; Chen, B. Controllable fabrication of Ag-nanoplate-decorated PAN-nanopillar arrays and their application in surface-enhanced Raman scattering. RSC Adv. 2017, 7, 53157–53163. [Google Scholar] [CrossRef] [Green Version]

- Zhou, N.; Meng, G.; Huang, Z.; Ke, Y.; Zhou, Q.; Hu, X. A flexible transparent Ag-NC@PE film as a cut-and-paste SERS substrate for rapid in situ detection of organic pollutants. Analyst 2016, 141, 5864–5869. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhu, C.; Hu, X.; Xu, Q.; Zhao, H.; Meng, G.; Lei, Y. Highly sensitive surface-enhanced Raman scattering detection of organic pesticides based on Ag-nanoplate decorated graphene-sheets. Appl. Surf. Sci. 2019, 486, 405–410. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, K.; Deng, Q.; Tang, H. AAO Template-Assisted Fabrication of Ordered Ag Nanoparticles-Decorated Au Nanotubes Array for Surface-Enhanced Raman Scattering Detection. Sustainability 2022, 14, 1305. https://doi.org/10.3390/su14031305

Sun K, Deng Q, Tang H. AAO Template-Assisted Fabrication of Ordered Ag Nanoparticles-Decorated Au Nanotubes Array for Surface-Enhanced Raman Scattering Detection. Sustainability. 2022; 14(3):1305. https://doi.org/10.3390/su14031305

Chicago/Turabian StyleSun, Kexi, Quan Deng, and Haibin Tang. 2022. "AAO Template-Assisted Fabrication of Ordered Ag Nanoparticles-Decorated Au Nanotubes Array for Surface-Enhanced Raman Scattering Detection" Sustainability 14, no. 3: 1305. https://doi.org/10.3390/su14031305

APA StyleSun, K., Deng, Q., & Tang, H. (2022). AAO Template-Assisted Fabrication of Ordered Ag Nanoparticles-Decorated Au Nanotubes Array for Surface-Enhanced Raman Scattering Detection. Sustainability, 14(3), 1305. https://doi.org/10.3390/su14031305