A Systematic Review of Sustainable Fresh Fruit and Vegetable Supply Chains

Abstract

:1. Introduction

2. Materials and Method

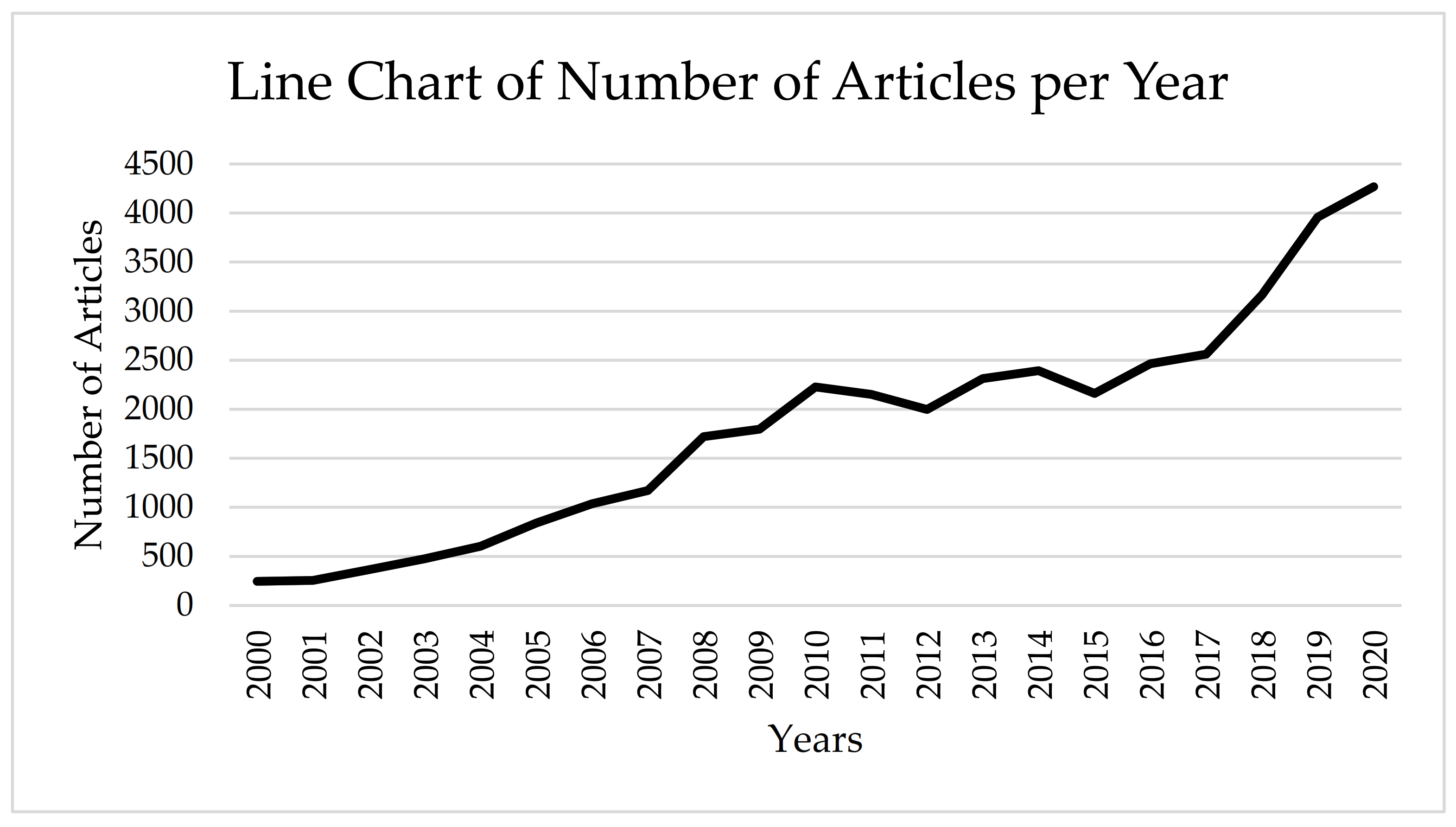

- Using Scopus to gain statistical information about SC and FFVSC literature;

- Scanning FFVSC literature by reading the abstracts, findings and concluding remarks, to separate and address only the appropriate papers;

- Reviewing all parts of remaining papers after elimination and examining their research purposes, tools and methods used;

- Plotting the data of published papers on graphs to create a visual overview;

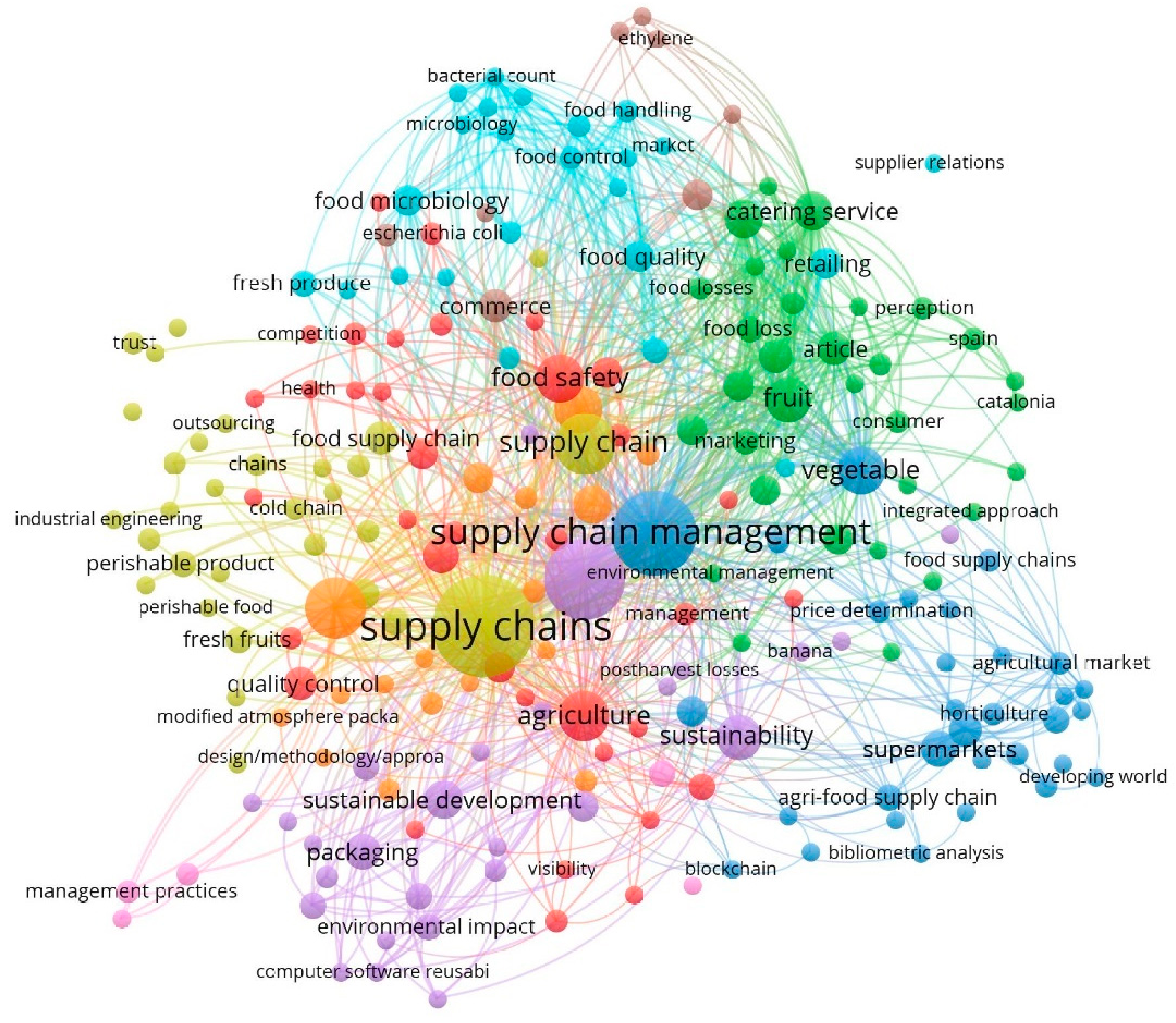

- Creating a thematic map of the research areas of the papers, which will help to form the categories, and also drawing a literature matrix; and

- Concluding remarks and future directions.

3. Literature Review

3.1. Value Chain Indicators of FFVSCs

3.2. Food-Related Problems/Postharvest Losses along the FFVSC

3.3. Role of Parties Involved in the FFV Value Chain

3.4. Review Papers

3.5. Technological Trends in FFVSCs

3.6. Packaging Issues of FFVSCs

3.7. Logistics Solutions of FFVSCs

3.8. Sustainable FFVSCs

4. Conclusions and Future Research

- The problem of establishing an effective value chain throughout the system while keeping KPIs in check has been widely studied. It is a common concern for both academics and practitioners, as underlined in Section 3.1. Because of the rapid changes at this time, the value chain and its performance should be evaluated or assessed in a very simple and understandable way. This will encourage involvement of almost all parties in the chain.

- Overcoming food-related problems along food SCs, especially postharvest losses, is also a significant topic according to information provided in Section 3.2, and still needs further research. At the moment, it appears that postharvest losses differ by country and crop. To the authors’ knowledge, there is no specific example which has a zero postharvest loss. We may employ a design thinking approach to find smart ways to handle this issue; different actors from different areas of expertise focusing on the same problem for their shared goal presents significant opportunities.

- Ensuring productivity for all parties in the value chain, reflecting the different parties involved in the system, is discussed in Section 3.3. The studies examined here consider different steps in the food SC, such as retail and wholesale. We need to conduct research considering small but impactful productivity gains across the chain.

- The review articles presented in Section 3.4 sought to cover the lack of resources relating to collective technical information.

- The difficulty in prioritizing technological innovations and solution approaches to existing SCs is described in Section 3.5. An innovative perspective is introduced to overcome the existing problems in the FFVSC. Sustainable innovation frameworks can be adopted for the FFVSC. It is a unique system because of the actors in the chain who have different expertise and backgrounds. It is also unique due to its issues of perishability and hard to manage inventories and has a major impact on our future in terms of nutrition and poverty.

- Inefficient postharvest processes that need to be improved in terms of packaging (Section 3.6) and shipment (Section 3.7) are also stressed. All these activities should be performed in a more environmentally conscious manner while maintaining or increasing their effectiveness. Processes along the food value chain can, thus, contribute to the world in terms of sustainability (Section 3.8).

4.1. Future Research

4.2. Limitations

References

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 17 | Wermund and Fearne | 2000 | Key challenges facing the cherry supply chain in the UK | Competition, cherries, market opportunity, supply chain | * Qualitative research | Cherry supply chain in the UK |

| 18 | Hewett | 2003 | Perceptions of supply chain management for perishable horticultural crops: An introduction | Fruits and vegetables, supply chain, management, logistics, quality, kiwifruit, apples, apricots, consumer satisfaction | Stone fruit industry from New Zealand | |

| 19 | Hingley | 2004 | Relationship development in the UK fresh produce supply chain | Relationships, supply chain, power and dependency, trust, fresh produce | Multiple leading UKfood retailers | |

| 20 | Maruyama and Hirogaki | 2007 | The evolution of fresh produce supply chains: From spot markets to contracts | Supply chain, fresh produce, vertical co-ordination | Japanese marketing chain | |

| 21 | Mergenthaler et al. | 2008 | Consumer demand for fruits and vegetables from modern supply chains in Vietnam | transformation, food systems, supermarkets, food safety, non-traditional imports, modern supply chain | * Two-stage budgeting framework | Vietnam’s two major cities, Hanoi and Ho Chi Minh City |

| 22 | Clements et al. | 2008 | Relationship connectors in NZ fresh produce supply chains | Fresh foods, supply chain management, supplier relations, New Zealand | * Case study approach | Two case studies of fresh produce supply chains in the South Island of New Zealand |

| 23 | Feng et al. | 2008 | VegRisk: A decision support system for risk management of vegetable supply chain | Decision support systems, risk management, supply chains, educational institutions, uncertainty, production, crisis management, agricultural engineering, protection, international trade | * Price risk management method * Coefficient of variation model | Xinfadi Agricultural Products Co., Ltd. |

| 24 | Zúñiga-Arias et al. | 2009 | Managing quality heterogeneity in the mango supply chain: evidence from Costa Rica | - | * Structured interviews * Laboratory analysis of mango quality | Mango supply chain from Costa Rica |

| 25 | Cadilhon et al. | 2009 | Market linkages: Characterizing business-to-business relationships in Vietnamese vegetable supply chains | B2B relationships, marketing, supply chain management, Viet Nam | * In-depth interviews | The tomato and butterhead lettuce supply chains in Ho Chi Minh City (HCMC) |

| 26 | Stringer et al. | 2009 | Producers, processors, and procurement decisions: The case of vegetable supply chains in China | Supply chains, vegetable markets, supermarkets, China | * Conjoint analysis | Vegetable processors from Laiyang County, Shandong province, China’s largest horticultural production and export region |

| 27 | King | 2010 | Comparing the structure, size, and performance of local and mainstream food supply chains (Book Chapter) | - | * Case study approach | Fifteen case studies in five metropolitan areas with the products of apples, blueberries, spring mix leafy greens, beef, and milk |

| 28 | Verdouw et al. | 2010 | Process modelling in demand-driven supply chains: A reference model for the fruit industry | Business process modelling, supply chain management, reference models, fruit industry | * Reference process models | In four European countries (The Netherlands, Spain, Poland, Greece) |

| 29 | Jiao and Shen | 2010 | Study on market equilibrium of sealed supply chain based on willingness to pay for food safety | - | * Classical Hotelling analytical framework | |

| 30 | Samuel et al. | 2012 | An insight into agri-food supply chains: A review | Agri-food supply chain, organised and unorganised retailing, value chain management, procurement and marketing strategies, international business, India, China, USA, UK, Australia, Southeast Asia | ||

| 31 | Fizzanty et al. | 2013 | Learning from failed supply chains: The application of complex adaptive systems and a modified SAFE framework in evaluating proposed system improvements | Supply chain management, fruit supply chains, developing country, complex adaptive systems, CAS, systems improvement, buyer–supplier relationships, agile systems | * Complex adaptive systems (CAS) perspective * Sustainability, acceptability, feasibility, efficiency (SAFE) framework * Cross-case analysis | Two case studies set in the mango industry of Indonesia |

| 32 | Cai et al. | 2013 | Fresh-product supply chain management with logistics outsourcing | Perishable product, supply chain management, multiple-party coordination, Third-party logistics, coordination contracts | NONE | |

| 33 | Kundu and Kar | 2013 | Identifying the physical distribution form and supply chain issues in marketing F&V products by organised supermarkets: A case on reliance distribution model | Fruits and vegetables, retailing, physical distribution model, supply chain, contract farming, supermarkets, distribution centers | * Traditional retail model * Reliance value chain business model | |

| 34 | Götz et al. | 2014 | Vertical price transmission in the international fresh fruit and vegetable supply chain: Israeli grapefruit exports to the EU after export liberalisation | International fresh fruit and vegetable supply chain, vertical price transmission, export liberalization, market power, Israel, citrus | * Cointegration approach * Engel–Granger representation theorem * Augmented Dickey–Fuller (ADF) Test | Israeli grapefruit growers. |

| 35 | Bahinipati | 2014 | The procurement perspectives of fruits and vegetables supply chain planning | Food industry, supply chain planning, information sharing, collaborative practices | The supermarket (SM) venture | |

| 36 | Obeth et al. | 2014 | Non-attractiveness of modern supply chains | Banana, modern supply chain, traditional supply chain, risk | * Open-ended interviews | Banana traders in Lampung Province, Sumatra Island and Banten, Java Island |

| 37 | Chen et al. | 2015 | Investigating the robustness of the agricultural supply chain based on colored Petri nets | Agricultural supply chain, simulation, colored Petri nets, robustness, optimization method | * Optimization method * colored Petri nets | |

| 38 | Aysoy et al. | 2015 | How does a shorter supply chain affect pricing of fresh food? Evidence from a natural experiment | Supply chain reform, fresh food prices, incomplete pass-through, quasi-experimental design | * Quasi-experimental methods | NONE |

| 39 | Karyani et al. | 2016 | Mango agricultural supply chain: Actors, business process, and financing scheme | Economic globalization, mango, supply chain financing, inclusive agribusiness, and value stream mapping. | * Value stream mapping * Descriptive analysis | Mango farmers in West Java |

| 40 | Gamboa et al. | 2016 | The complexity of food systems: Defining relevant attributes and indicators for the evaluation of food supply chains in Spain | Food systems, food supply chains, narratives, integrated assessment | * Integrated assessment * Content analysis * Lexicometric analysis | Three organic tomato supply chains in Spanish and Catalan contexts |

| 41 | Webb | 2017 | Towards an agri-food ‘culture’: Managing the impact on agricultural supply chains of changes in consumer culture (Book Chapter) | Agriculture, consumer culture, environment, food, public health, supply chains | * Critical theory | NONE |

| 42 | Negi and Anand | 2018 | Factors leading to supply chain inefficiency in agribusiness: Evidence from Asia’s largest wholesale market | Supply chain inefficiency, wholesale market, food supply chain, tomato supply chain, food losses and wastages | * Factor analysis | Tomato supply chain in India at Asia’s largest wholesale fruits and vegetable market (Mandi) in Azadpur, Delhi |

| 43 | Siddh et al. | 2018 | Structural model of perishable food supply chain quality (PFSCQ) to improve sustainable organizational performance | Supply chain, quality, perishable food supply chain quality (PFSCQ), perishable food supply chain quality (PFSCQ) practices, sustainable organizational performance | * PFSCQ practices | |

| 44 | Shashi et al. | 2018 | Evaluating partnerships in sustainability-oriented food supply chain: A five-stage performance measurement model | Sustainable and energy-efficient supply chain, food supply chain performance, partners’ performance, performance measurement, operations management, structural equation modeling | * Survey study * Structural equation modeling (SEM) * Kaiser–Meyer–Olkin (KMO) test * Exploratory factor analysis with the varimax rotation method | Indian food industry |

| 45 | Arshinder and Balaji | 2019 | Understanding the models of Indian fruit and vegetable supply chains-A case study approach | F&V supply chains, food supply chains, wholesale markets, price variability, India | * Case study approach | A typical Indian metropolitan city |

| 46 | Nakandala and Lau | 2019 | Innovative adoption of hybrid supply chain strategies in urban local fresh food supply chain | Efficiency, supply chain management, agility, supply chain strategy, trust, legality, local fresh food, collaboration and relationships, urban food systems | * Multiple case study method * Thematic analysis | Twelve urban local fresh food retailers in Sydney |

| 47 | Cao and Mohiuddin | 2019 | Sustainable emerging country agro-food supply chains: Fresh vegetable price formation mechanisms in rural China | Supply chain, fresh and raw vegetables, price conduction, granger causality test | * Elastic model of price conduction * Stationarity test * Co-Integration test * Granger causality analysis | Greenhouse cucumber supply chain in China |

| 48 | Negi and Anand | 2019 | Wholesalers’ perspectives on mango supply chain efficiency in India | Food supply chain, cold chain, food losses and wastages, fruit supply chain, smart mandi, supply chain efficiency, wholesale market | * Factor analysis | Wholesale stage of the mango supply chain in India, at Asia’s largest and the world’s second largest fruits and vegetable wholesale market (Mandi) in Azadpur, Delhi. |

| 49 | Pavez et al. | 2019 | Biosecurity institutions and the choice of contracts in international fruit supply chains | - | * Econometric analysis | Chilean apple exports |

| 50 | Nedumaran et al. | 2020 | Digital integration to enhance market efficiency and inclusion of smallholder farmers: A proposed model for fresh fruit and vegetable supply chain | Supply chain, fresh fruits and vegetables, primary processing centers, market information system, India | The main FFV-producing states in India | |

| 51 | Waqas et al. | 2020 | Underlying dimensions of supply chain risks amongst agropreneurs of fresh fruits and vegetables in Malaysia | Supply chain risks, agropreneurs, agri-fresh supply chain of fresh fruits and vegetables. | * Questionnaire survey * Snowballing and convenience sampling method | Malaysia |

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 52 | Digal | 2005 | Quality grading in the supply chain: The case of vegetables in Southern Philippines | Quality grading, price asymmetry, search cost, supply chain | * A model is employed which shows that grading provides information that lowers the search cost of buyers. | Vegetable industry in the Southern Philippines |

| 53 | Russell et al. | 2009 | Losses of vitamin C from fresh strawberries in a commercial supply chain | Cold chain, distribution, moisture, strawberries, supply chain, temperature, transportation, vitamin C | * HPLC method * Standard drying oven method * Statistical analysis (analysis of variance, multiple linear regression) | NONE |

| 54 | Cai et al. | 2010 | Optimization and coordination of fresh product supply chains with freshness-keeping effort | Supply chain management, perishable products, cold chains, freshness-keeping effort, pricing | NONE | |

| 55 | Jacxsens et al. | 2010 | Simulation modelling and risk assessment as tools to identify the impact of climate change on microbiological food safety-The case study of fresh produce supply chain | Climate change, food safety management system, fresh produce, microbiological food safety | * Risk assessment studies * Advanced simulation models * Mathematical models | Fresh-cut vegetables |

| 56 | Diez-Valcarce et al. | 2011 | construction and analytical application of internal amplification controls (IAC) for detection of food supply chain-relevant viruses by real-time PCR-based assays | Enteric virus, false negatives, food, internal amplification control, real-time PCR | * Real-Time PCR | NONE |

| 57 | Sivakumar and Wall | 2013 | Papaya fruit quality management during the postharvest supply chain | Carica papaya, fruit quality, health-promoting compounds, postharvest management practices, tropical fruit | * Postharvest management practices | Papaya fruit |

| 58 | Li and Qiao | 2013 | Preservation behavior decision of fruits and vegetables supply chain | Fruits and vegetables supply chain, iterative relationship preservation behavior, | Litchi supply chain | |

| 59 | Jraisat and Sawalha | 2013 | Quality control and supply chain management: A contextual perspective and a case study | Supply chain management, quality control, exports, fruit and vegetable industry, Jordan | * Case study approach | Fresh fruit and vegetable supply chain in Jordan |

| 60 | Macheka et al. | 2013 | Identifying causes of mechanical defects and critical control points in fruit supply chains: An overview of a banana supply chain | Postharvest losses, mechanical defects, banana, supply chain, critical control point | Banana fruit supply chain in Zimbabwe | |

| 61 | Bill et al. | 2014 | Avocado fruit quality management during the postharvest supply chain | Atmosphere modification, fruit softening, packaging, Persea americana, postharvest diseases | Avocado fruit | |

| 62 | Blanke | 2014 | Reducing ethylene levels along the food supply chain: A key to reducing food waste? | ethylene, ethylene absorber, ethylene inhibitor, ethylene scrubber, sensor technology, supply chain, waste, whole crop purchase (WCP) | Apple fruit | |

| 63 | Janssen et al. | 2014 | Ethylene detection in fruit supply chains | Electrochemical sensors, ethene, ethylene, gas analytics, gas chromatography, non-dispersive infrared | * Several measuring methods for the detection of ethylene | NONE |

| 64 | LeBlanc et al. | 2015 | A national produce supply chain database for food safety risk analysis | Relational database, food supply chain, logistics, food safety risk assessment, simulation, Escherichia coli O157:H7 | * Integrated simulation tool | Lettuce and leafy greens in Canada |

| 65 | Hou et al. | 2015 | Food safety standards and international supply chain organization: A case study of the Moroccan fruit and vegetable exports | Morocco, fruits and vegetables, food safety, supply chains, supermarket-channel, wholesaler-channel | * Principal components analysis | Moroccan fruit and vegetable supply chain (Souss Massa Region) |

| 66 | Hoaran et al. | 2016 | Fuzzy TOPSIS-based supply chain optimization of fresh agricultural products | Expert evaluation methods, fresh agricultural products, loss, supply chain network optimization, TOPSIS | * Fuzzy TOPSIS | NONE |

| 67 | Zoellner et al. | 2016 | Microbial dynamics of indicator microorganisms on fresh tomatoes in the supply chain from Mexico to the USA | Tomatoes, indicator microorganisms, postharvest, supply chain, safety | * Microbiological analyses * Statistical analyses (Analysis of variance, Tukey–Kramer honestly significant difference (HSD) test) | Roma tomatoes in the supply chain between Mexico and USA |

| 68 | Ramanathan et al. | 2017 | A study on sources of vegetable supply chain wastage with specific reference to retail outlets in Tamil Nadu | Food wastage, retail wastage, vegetable supply chains, transport wastage, vegetable wastage, vegetables, retail outlets, Tamil Nadu, India, vegetable retailers, travel distances, labour shortage, poor packing, handling damage | Vegetable retail stores in four locations of Tamilnadu such as Chennai, Dindugul, Coimbatore and suburban areas of Chennai, India | |

| 69 | Gardas et al. | 2017 | Modeling causal factors of post-harvesting losses in vegetable and fruit supply chain: An Indian perspective | Post-harvesting losses (PHL), vegetable and fruit supply chains, critical causal factors, interpretive structural modeling (ISM) methodology | * Interpretive structural modeling (ISM) approach * MICMAC analysis | In Maharashtra state, India |

| 70 | Jacxsens et al. | 2017 | Food safety management and risk assessment in the fresh produce supply chain | - | * Mathematical model * Fragmented microbiological analysis * Information of cultivation practices | Basil, strawberry and butterhead lettuce to which Belgian and Spanish consumers are exposed per year |

| 71 | Orjuela-Castro andAdarme-Jaimes | 2018 | Evaluating the supply chain design of fresh food on food security and logistics | Supply chain design, fresh food, food security, logistics | Three SCs of fresh fruits in Colombia | |

| 72 | Fabbri et al. | 2018 | Improving environmental performance of post-harvest supply chains of fruits and vegetables in Europe: Potential contribution from ultrasonic humidification | Humidification, life cycle assessment, food supply, food loss, food waste, ultrasonic | * Life cycle assessment | Strawberries, peaches, table grapes, and asparagus supply chains in Europe in terms of transportation distances and direction of the supply (with the general trend from the South of Europe to other European countries). between 2015 and 2016 |

| 73 | Mercier and Uysal | 2018 | Neural network models for predicting perishable food temperatures along the supply chain | Perishable food, cold chain, quality-driven distribution, temperature prediction, neural network, heat transfer | * Heat transfer model * Neural network | NONE |

| 74 | Zoellner et al. | 2018 | Postharvest supply chain with microbial travelers: A farm-to-retail microbial simulation and visualization framework | Fresh produce, microbial dynamics, postharvest, supply chain | * Postharvest supply chain with the microbial travelers (PSCMT) tool | Tomato supply chain from Mexico tothe United States |

| 75 | Hernández-Rubio et al. | 2018 | Determinants of food safety level in fruit and vegetable wholesalers’ supply chain: Evidence from Spain and France | Food safety, fruits and vegetables, wholesaler, importer, long supply chain | * Hypotheses of analysis | Spanish and French intermediaries working in key wholesale markets and in the southeast of Spain |

| 76 | Kelly et al. | 2019 | A novel approach to determine the impact level of each step along the supply chain on strawberry quality | Fragaria x ananassa, supply chain, waste, temperature, bioactive compounds, sugars | * Instrumental color and texture analysis * Ascorbic acid analysis * Statistical analysis (two-way analysis of variance) | Strawberry supply chain from Fancy Farms, USA |

| 77 | Diaz-Ruiz et al. | 2019 | Food waste prevention along the food supply chain: A multi-actor approach to identify effective solutions | Barcelona, food losses, Delphi, food waste prevention, food redistribution, reduction | * Delphi method * In-depth interviews | Barcelona metropolitan region |

| 78 | Caldeira et al. | 2019 | Quantification of food waste per product group along the food supply chain in the European Union: a mass flow analysis | Food waste, mass balance, food groups, by-products, systematic accounting, food value chain | * Mass flow analysis | Major EU food groups: sugar beets, oil crops, potatoes, vegetables, fruit, cereals, meat, fish, dairy, and eggs |

| 79 | Zhang et al. | 2019 | Novel model and kernel search heuristic for multi-period closed-loop food supply chain planning with returnable transport items | Closed-loop food supply chain, perishable food, returnable transport item, mixed integer linear programming, kernel search | * Mathematical problem | A food manufacturer in China |

| 80 | Xu et al. | 2020 | A real-time decision support framework to mitigate degradation in perishable supply chains | Perishable supply chains, real-time decision making, vehicle routing, inventory allocation, quality control, optimal environment factors | * Integer programming model * Quality index method | Fresh apple supply chain |

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 81 | Hingley | 2001 | Relationship management in the supply chain | Buyers, relationship marketing, retailing, supplier relations, supply-chain management | * Multiple depth interviews * Multi-case, multi-site | UK fresh produce market |

| 82 | Louw et al. | 2008 | Alternative marketing options for small-scale farmers in the wake of changing agri-food supply chains in South Africa | Agri-food supply chains, small-scale farmers, alternative marketing channels | South African agri-food chain | |

| 83 | Arumugam et al. | 2010 | Supply chain analysis of fresh fruits and vegetables (FFV): Prospects of contract farming | supply chain, contract farming, contract farmers, factor analysis | * Factor analysis * Descriptive and inferential statistics | Malaysia |

| 84 | Schipmann and Qaim | 2011 | Supply chain differentiation, contract agriculture, and farmers’ marketing preferences: The case of sweet pepper in Thailand | Choice experiment, contract design, farmers’ stated preferences, modern agricultural supply chains, Thailand | * Lancaster’s model * Random parameters logit (RPL) model | Sweet pepper in Thailand |

| 85 | Sayın et al. | 2011 | The role of wholesale markets in the supply chain for fresh fruit and vegetables in Turkey | supply chain management, distribution, domestic market, wholesale market, producer unions, European Union | * SWOT analysis | Supply chain for fresh fruit and vegetables in Turkey |

| 86 | Guarín | 2013 | The value of domestic supply chains: Producers, wholesalers, and urban consumers in Colombia | Colombia, smallholders, supermarkets, supply chains, wholesale markets | * Value chain approach * In-depth interviews * Semi-structured interviews | Perishables in Colombia, including fruits, vegetables, roots and tubers, and beef. |

| 87 | Schuster and Maertens | 2013 | Do private standards create exclusive supply chains? New evidence from the Peruvian asparagus export sector | Global supply chains, horticulture, Peru, private standards, small-scale farming | * Fixed effects * GMM estimators | Peruvian asparagus export sector |

| 88 | Wahyudin et al. | 2015 | An agri-food supply chain model for cultivating the capabilities of farmers in accessing capital using corporate social responsibility program | Agri-food supply chain, corporate social responsibility, multi-integer linear goal programming, small-scale vegetables farmers | * Multi-integer linear programming (MILP) | NONE |

| 89 | Jacob-John and Veerapa | 2016 | Perception of fairness within organic fresh produce supply chains: The case of small and medium fresh produce retailers | Fairness, ethics, retailers, supply chain, trust, B2B | * Multiple case study approach * Semi-structured interviews | Small and medium fresh produce retailers |

| 90 | Michelson et al. | 2018 | Connecting supermarkets and farms: The role of intermediaries in Walmart China’s fresh produce supply chains | Vertical integration, supply chains, small farmers, supermarkets, Walmart, agricultural development, China | * In-depth descriptive analysis | Walmart China |

| 91 | Devin andRichards | 2018 | Food waste, power, and corporate social responsibility in the Australian food supply chain | Corporate social responsibility (CSR), food supply chain, food waste, power, supermarkets | * Interviews * Document analysis | Australian fresh fruit and vegetable supply chain |

| 92 | Elder | 2019 | The impact of supermarket supply chain governance on smallholder farmer cooperatives: the case of Walmart in Nicaragua | Agricultural supply chains, cooperatives, Nicaragua, smallholder farmers, supermarkets, Walmart | * Interviews | Supermarkets and cooperatives in Nicaragua |

| 93 | Salvia | 2020 | The restructuring of Italian agriculture and its impact upon capital–labour relations: Labour contracting and exploitation in the fresh fruit and vegetable supply chain of the Lazio Region, Central Italy | Central Italy, agricultural labour, fresh fruit and vegetable production, labour contracting, value chains | * In-depth interviews | Lazio, Central Italy. |

| 94 | Gunarathna and Mahinda Bandara | 2020 | Post-Harvest Losses and the Role of Intermediaries in the Vegetable Supply Chain | intermediaries, post-harvest losses, vegetable supply chain | * In-depth personal interview | Vegetable supply chain in Sri Lanka |

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 95 | Rajurkar and Jain | 2011 | Food supply chain management: Review, classification and analysis of literature | Food supply chains, literature reviews, literature classification, literature analysis, global competition, codification, roadmaps, research, integrated supply chains, SCM, supply chain management | * Literature reviews* Literature classification* Literature analysis | _ |

| 96 | Kong et al. | 2013 | Auction logistics in perishable supply chain trading: A research agenda | Physical Internet, auction logistics, perishable supply chain trading, planning, scheduling and execution | * Literature reviews * Literature classification * Literature analysis | _ |

| 97 | Aung and Chang | 2014 | Traceability in a food supply chain: Safety and quality perspectives | Traceability, safety, quality, food supply chain, identification, food contamination | * Literature reviews * Literature classification * Literature analysis | _ |

| 98 | Sibomana et al. | 2016 | A review of postharvest handling and losses in the fresh tomato supply chain: a focus on Sub-Saharan Africa | Postharvest losses, tomatoes, packaging, temperature control, disinfection, transportation | * Literature reviews * Literature classification * Literature analysis | _ |

| 99 | Siddh et al. | 2017 | Agri-fresh food supply chain quality (AFSCQ): a literature review | Agri-fresh food, agri-fresh food supply chain quality, literature review, supply chain quality | * Literature reviews * Literature classification * Literature analysis | _ |

| 100 | Routroy and Behera | 2017 | Agriculture supply chain: A systematic review of literature and implications for future research | Agricultural products, agriculture, supply chain management | * Literature reviews * Literature classification * Literature analysis | _ |

| 101 | Raak et al. | 2017 | Processing- and product-related causes for food waste and implications for the food supply chain | By-products, expert interview, food losses, food processing, food waste, literature review, suboptimal food | * Literature reviews * Literature classification * Literature analysis | _ |

| 102 | Saitone and Sexton | 2017 | Agri-food supply chain: evolution and performance with conflicting consumer and societal demands | Food quality, modern agricultural markets, supply chain, vertical coordination | * Literature reviews * Literature classification * Literature analysis | _ |

| 103 | Gharehgozli et al. | 2017 | Trends in global E-food supply chain and implications for transport: literature review and research directions | E-business solutions, food supply chain management, new trends, research agenda, transport | * Literature reviews * Literature classification * Literature analysis | _ |

| 104 | Luo et al. | 2018 | Agri-food supply chain management: Bibliometric and content analyses | Agri-food supply chain, bibliometric analysis, citation analysis, co-citation analysis, content analysis | * Literature reviews * Literature classification * Literature analysis * Bibliometric analysis * Citation analysis | _ |

| 105 | Corrado and Sala | 2018 | Food waste accounting along global and European food supply chains: State of the art and outlook | Circular economy, estimation, food loss, food waste, Sustainable Development Goal 12, waste framework directive | * Literature reviews * Literature classification * Literature analysis | _ |

| 106 | Lezoche et al. | 2020 | Agri-food 4.0: A survey of the supply chains and technologies for thefuture agriculture | Agri-Food 4.0, Agriculture 4.0, artificial intelligence, big data, blockchain, Internet of Things, supply chains | * Literature reviews * Literature classification * Literature analysis | _ |

| 107 | Priyadarshi et al. | 2020 | Postharvest supply chain losses: a state-of-the-art literature review and bibliometric analysis | Agriculture supply chain losses, bibliometric analysis, postharvest supply chain losses, rural entrepreneurship, value addition, vertical integration | * Literature reviews * Literature classification * Literature analysis * Bibliometric analysis | _ |

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 108 | Duan et al. | 2007 | Accelerating internet adoption in China’s fresh produce supply chain: A vegnet approach | China, fresh produce supply chain, Internet adoption, Internet technologies, supply chain management | * Interviews * Case studies | China |

| 109 | Hu et al. | 2011 | AgriRiskIDSS: Development of an intelligent decision support system for price risk management of agricultural product supply chain | China, IDSS (intelligent decision support system), intelligent information process, price risk management, vertical search engine | * Intelligent decision support system * Genetic algorithm * Wavelet analysis coefficients * Neural network | NONE |

| 110 | Solanki and Brewster | 2014 | Enhancing visibility in EPCIS governing agri-food supply chains via linked pedigrees (Book Chapter) | - | Fresh fruit and vegetables supply chain in the agri-food sector. | |

| 111 | Liu et al. | 2015 | Enterprise-oriented IoT name service for agricultural product supply chain management | - | * IoT architecture | Five cities of China. |

| 112 | La Scalia et al. | 2017 | An innovative shelf-life model based on smart logistic unit for an efficient management of the perishable food supply chain | - | * Volatile organic compounds * microbiological analysis | Strawberries |

| 113 | Borrero | 2019 | Agri-food supply chain traceability for fruit and vegetable cooperatives using Blockchain technology | Agriculture supply chain, blockchain, cooperatives, food traceability, proof of concept, smart agriculture, smart contract, trust-building | * Blockchain * Smart contract | Spain |

| 114 | Pal and Kant | 2020 | Smart sensing, communication, and control in perishable food supply chain | Communication infrastructure, data analytics, food quality sensing, food supply chain, physical Internet, privacy, security | * Arrhenius equation * Michaelis–Menten kinetics equation * Kinetic modeling * Gompertz model | |

| 115 | Goisser et al. | 2020 | Food-scanners as a radical innovation in German fresh produce supply chains | Food-scanner, fruit and vegetable supply chain, qualitative research, quality measurement | * Semi-structured interviews * Qualitative content analysis | German fruit and vegetable supply chain |

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 119 | Accorsi et al. | 2014 | Economic and environmental assessment of reusable plastic containers: A food catering supply chain case study | Food supply chain (FSC), life cycle assessment (LCA), packaging, sensitivity analysis, sustainability | * Life cycle assessment (LCA) * Life cycle costing (LCC) | An Italian fresh food catering chain |

| 120 | Battini et al. | 2016 | Sustainable packaging development for fresh food supply chains | economic analysis, environmental analysis, fresh food distribution, fresh food packaging, sustainability | * Critical analysis | |

| 118 | Singh et al. | 2016 | Packaging’s role in sustainability: Reusable plastic containers in the agricultural-food supply chains | Agricultural-food supply chains, one-way and reusable packaging, sustainability | ||

| 121 | Giuggioli et al. | 2017 | Sustainable supply-chain: evolution of the quality characteristics of strawberries stored in green film packaging | Films, freshness quality, fruits, modified atmosphere, packaging, temperature | * Total soluble solids analysis * Nutraceutical analysis * Statistical analysis (two-way analysis of variance) * Principal components analysis | Portola strawberries in Italy |

| 122 | Bortolini et al. | 2018 | Bi-objective design of fresh food supply chain networks with reusable and disposable packaging containers | Bi-objective optimization, fresh food distribution network, packaging, supply chain design, sustainability | ||

| 123 | Zhao et al. | 2019 | Consolidated cold and modified atmosphere package system for fresh strawberry supply chains | Cold storage, expanded polystyrene box, package, phase change materials, polyethylene film | * Statistical analysis (analysis of variance (ANOVA) and Duncan’s multiple range test | Fresh strawberries |

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 124 | Busato and Berruto | 2006 | FruitGame: Simulation model to study the supply chain logistics for fresh produce | Fresh fruits, fresh vegetable, logistics, modeling, supply chain | * Object-oriented simulation | |

| 125 | Yan | 2009 | The research of supply chain logistics management on fruit E-commerce website | - | Fresh fruits in Sichuan Province | |

| 126 | Etemadnia et al. | 2015 | Optimal wholesale facilities location within the fruit and vegetables supply chain with bimodal transportation options: An LP-MIP heuristic approach | Operation research, optimal hub location bimodal transportation, supply chain | * Mixed integer linear programming (MILP) | An application is made to the U.S. fruit and vegetable industry |

| 127 | Chandrasekaran and Ranganathan | 2017 | Modelling and optimisation of Indian traditional agriculture supply chain to reduce post-harvest loss and CO2 emission | Carbon dioxide emission, post-harvest losses, respiration, supply chain planning, transportation | * Genetic algorithm * The closed transportation method | Indian traditional agriculture SC |

| 128 | Ghezavati et al. | 2017 | A Benders’ decomposition algorithm for optimizing distribution of perishable products considering postharvest biological behavior in agri-food supply chain: A case study of tomato | Agri-food supply chain, Benders’ decomposition, fair pricing, fresh products, mixed integer programming, postharvest maturity behavior | * Mixed integer programming model * Benders’ decomposition method | A case study of tomatoes in Iran |

| 129 | Mejjaouli and Babiceanu | 2018 | Cold supply chain logistics: System optimization for real-time rerouting transportation solutions | Cold supply chain, RFID monitoring system, system optimization, transportation rerouting | * RFID-WSN logistics model | Strawberries from California to Dallas |

| ID | Authors | Year | Title | Keywords | Method Used | Case Study/Test |

|---|---|---|---|---|---|---|

| 130 | Smith | 2008 | Developing sustainable food supply chains | Corporate social responsibility, food manufacture, food retail, food supply chains, sustainable agriculture | ||

| 131 | Styles et al. | 2012 | Environmental improvement of product supply chains: Proposed best practice techniques, quantitative indicators and benchmarks of excellence for retailers | Benchmarking, ecolabels, green procurement, lifecycle assessment, retail, supply chains, sustainability | * Performance benchmarking * Dissemination of better management practices | |

| 132 | Naik and Suresh | 2018 | Challenges of creating sustainable agri-retail supply chains | Agri-food supply chains, horticulture, organized retail, regulation, social impact, sustainability | ||

| 133 | Blanc et al. | 2019 | Use of bio-based plastics in the fruit supply chain: An integrated approach to assess environmental, economic, and social sustainability | Bio-based materials, green economy, life-cycle assessment, life-cycle costing, social impact | * Life cycle assessment (LCA) * Life cycle costing (LCC) * Externality assessment (ExA) | Raspberry supply chains in northwestern Italy |

| 134 | Corato and Cancellara | 2019 | Measures, technologies, and incentives for cleaning the minimally processed fruits and vegetables supply chain in the Italian food industry | Bio-based material, energy consumption and management, energy efficiency and saving, food processing, renewable source, waste recycling | * Analysis of the energy fluxes * Analysis of un-biodegradable materials | Italian MPFV companies (firms/cooperatives) |

| 135 | Slamet et al. | 2020 | Making food supply chain sustainable: Participating smallholder farmers in modern retail channels | ISM, enabler, interpretive structural modelling, modern retail, smallholder farmer, sustainable food supply chain | * Interpretive structural modelling | |

| 136 | Jabarzadeh et al. | 2020 | A multi-objective mixed-integer linear model for sustainable fruit closed-loop supply chain network | Closed-loop network, multi-objective optimization, reverse logistics, sustainable supply chains | * Multi-objective mixed-integerLinear programming model * LP-Metric and weighted Tchebycheff method | NONE |

References

- Liu, R.H. Potential synergy of phytochemicals in cancer prevention: Mechanism of action. J. Nutr. 2004, 134, 3479–3485. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- World Health Organization. Promoting Fruit and Vegetable Consumption around the World. Available online: https://www.who.int/dietphysicalactivity/fruit/en/ (accessed on 1 August 2020).

- Salunkhe, D.K.; Wu, M.T.; Rahman, A.R. Developments in technology of storage and handling of fresh fruits and vegetables. Crit. Rev. Food Sci. Nutr. 1974, 5, 15–54. [Google Scholar] [CrossRef]

- Council of Supply Chain Management Professional Supply Chain Management Definitions and Glossary. Available online: https://cscmp.org/CSCMP/Educate/SCM_Definitions_and_Glossary_of_Terms.aspx (accessed on 1 August 2020).

- Minnens, F.; Luijckx, N.L.; Verbeke, W. Food supply chain stakeholders’ perspectives on sharing information to detect and prevent food integrity issues. Foods 2019, 8, 225. [Google Scholar] [CrossRef] [Green Version]

- Elghannam, A.; Mesias, F.J.; Escribano, M.; Fouad, L.; Horrillo, A.; Escribano, A.J. Consumers’ perspectives on alternative short food supply chains based on social media: A focus group study in Spain. Foods 2020, 9, 22. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McKinsey & Company Agriculture Sector: Preparing for Disruption in the Food Value Chain. Available online: https://www.mckinsey.com/industries/agriculture/our-insights/agriculture-sector-preparing-for-disruption-in-the-food-value-chain (accessed on 8 December 2021).

- Deloitte the Future of Fresh Food Supply Chain. Available online: https://www2.deloitte.com/au/en/pages/consumer-business/articles/future-of-fresh-food.html (accessed on 8 December 2021).

- Food and Agriculture Organization (FAO). Building a Common Vision for Sustainable Food and Agriculture. Principles and Approaches; FAO: Rome, Italy, 2014. [Google Scholar]

- OECD. Global Value Chains in Agriculture and Food: A Synthesis of OECD Analysis; OECD: Paris, France, 2020. [Google Scholar]

- Neven, D. Developing Sustainable Food Value Chains: Guiding Principles; Food and Agriculture Organization (FAO): Rome, Italy, 2014; ISBN 9789251084816. [Google Scholar]

- Townsend, R.; Ronchi, L.; Brett, C.; Moses, G. Future of Food: Maximizing Finance for Development in Agricultural Value Chains; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- United Nations. The 17 GOALS|Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 1 August 2020).

- Food and Agriculture Organization (FAO). FRuit and Vegetables—Your Dietary Essentials. The International Year of Fruits and Vegetables; FAO: Rome, Italy, 2020. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual; Univeristeit Leiden: Leiden, The Netherlands, 2018. [Google Scholar]

- Wermund, U.; Fearne, A. Key Challenges Facing the Cherry Supply Chain in the UK. Acta Hortic. 2000, 536, 613–624. [Google Scholar] [CrossRef]

- Hewett, E.W. Perceptions of supply chain management for perishable horticultural crops: An introduction. Acta Hortic. 2003, 604, 37–46. [Google Scholar] [CrossRef]

- Hingley, M. Relationship Development in the UK Fresh Produce Supply Chain Relationship Development in the UK Fresh Produce Supply Chain. J. Mark. Channels 2004, 12, 27–50. [Google Scholar] [CrossRef]

- Maruyama, M.; Hirogaki, M. The evolution of fresh produce supply chains: From spot markets to contracts. Int. Rev. Retail. Distrib. Consum. Res. 2007, 17, 359–376. [Google Scholar] [CrossRef]

- Mergenthaler, M.; Qaim, M.; Weinberger, K. Consumer demand for fruits and vegetables from modern supply chains in vietnam. Acta Hortic. 2008, 794, 213–220. [Google Scholar] [CrossRef]

- Clements, M.D.; Lazo, R.M.; Martin, S.K. Relationship connectors in NZ fresh produce supply chains. Br. Food J. 2008, 110, 346–360. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, X.; Guo, X.; Fu, Z. VegRisk: A decision support system for risk management of vegetable supply chain. In Proceedings of the 2008 IEEE International Conference on Networking, Sensing and Control, ICNSC, Sanya, China, 6–8 April 2008; pp. 1547–1552. [Google Scholar]

- Zúñiga-Arias, G.; Ruben, R.; van Boekel, M. Managing quality heterogeneity in the mango supply chain: Evidence from Costa Rica. Trends Food Sci. Technol. 2009, 20, 168–179. [Google Scholar] [CrossRef]

- Cadilhon, J.J.; Fearne, A.P.; Tam, P.T.G.; Moustier, P.; Poole, N.D. Market linkages: Characterizing business-to-business relationships in vietnamese vegetable supply chains. Acta Hortic. 2009, 809, 135–146. [Google Scholar] [CrossRef]

- Stringer, R.; Sang, N.; Croppenstedt, A. Producers, Processors, and Procurement Decisions: The Case of Vegetable Supply Chains in China. World Dev. 2009, 37, 1773–1780. [Google Scholar] [CrossRef]

- Galli, F.; Bartolini, F.; Brunori, G.; Colombo, L.; Gava, O.; Grando, S.; Marescotti, A. Sustainability assessment of food supply chains: An application to local and global bread in Italy. Agric. Food Econ. 2015, 3, 21. [Google Scholar] [CrossRef] [Green Version]

- Verdouw, C.N.; Beulens, A.J.M.; Trienekens, J.H.; Wolfert, J. Process modelling in demand-driven supply chains: A reference model for the fruit industry. Comput. Electron. Agric. 2010, 73, 174–187. [Google Scholar] [CrossRef]

- Jiao, Z.; Shen, Y. Study on Market Equilibrium of Sealed Supply Chain Based on Willingness to Pay for Food Safety. In Proceedings of the International Conference of Logistics Engineering and Management (ICLEM) 2010, Chengdu, China, 8–10 October 2010; pp. 4683–4690. [Google Scholar]

- Samuel, M.V.; Shah, M.; Sahay, B.S. An insight into agri-food supply chains: A review. Int. J. Value Chain Manag. 2012, 6, 115. [Google Scholar] [CrossRef]

- Fizzanty, T.; Russell, I.; Collins, R. Learning from failed supply chains: The application of complex adaptive systems and a modified SAFE framework in evaluating proposed system improvements. Int. J. Agil. Syst. Manag. 2013, 6, 232. [Google Scholar] [CrossRef]

- Cai, X.; Chen, J.; Xiao, Y.; Xu, X.; Yu, G. Fresh-product supply chain management with logistics outsourcing. Omega 2013, 41, 752–765. [Google Scholar] [CrossRef]

- Kundu, S.; Kar, A. Identifying the physical distribution form and supply chain issues in marketing F&V products by organised supermarkets: A case on reliance distribution model. Int. J. Bus. Perform. Manag. 2013, 14, 396–403. [Google Scholar] [CrossRef]

- Götz, L.; Von Cramon-Taubadel, S.; Kachel, Y. Vertical price transmission in the international fresh fruit and vegetable supply chain: Israeli grapefruit exports to the EU after export liberalisation. Q. J. Int. Agric. 2014, 53, 99–120. [Google Scholar]

- Bahinipati, B.K. The procurement perspectives of fruits and vegetables supply chain planning. Int. J. Supply Chain Manag. 2014, 3, 111–131. [Google Scholar]

- Obeth, E.; Batt, P.J.; Butler, B. Non-attractiveness of modern supply chains. Acta Hortic. 2015, 1103, 225–231. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.C.; Li, J.; Wen, D. ping Investigating the robustness of the agricultural supply chain based on colored Petri nets. Simulation 2015, 91, 898–915. [Google Scholar] [CrossRef]

- Aysoy, C.; Kirli, D.H.; Tumen, S. How does a shorter supply chain affect pricing of fresh food? Evidence from a natural experiment. Food Policy 2015, 57, 104–113. [Google Scholar] [CrossRef]

- Karyani, T.; Utami, H.N.; Sadeli, A.H.; Rasmikayati, E.; Syamsiyah, N. Mango agricultural supply chain: Actors, business process, and financing scheme. Int. J. Appl. Bus. Econ. Res. 2016, 14, 7751–7764. [Google Scholar]

- Gamboa, G.; Kovacic, Z.; Di Masso, M.; Mingorría, S.; Gomiero, T.; Rivera-Ferré, M.; Giampietro, M. The Complexity of Food Systems: Defining Relevant Attributes and Indicators for the Evaluation of Food Supply Chains in Spain. Sustainability 2016, 8, 515. [Google Scholar] [CrossRef] [Green Version]

- Webb, T. Towards an agri-food ‘culture’: Managing the impact on agricultural supply chains of changes in consumer culture. In World Sustainable Development Outlook 2007; Routledge: London, UK, 2017; pp. 344–354. [Google Scholar] [CrossRef]

- Negi, S.; Anand, N. Factors leading to supply chain inefficiency in agribusiness: Evidence from Asia’s largest wholesale market. Int. J. Value Chain Manag. 2018, 9, 257. [Google Scholar] [CrossRef]

- Siddh, M.M.; Soni, G.; Jain, R.; Sharma, M.K. Structural model of perishable food supply chain quality (PFSCQ) to improve sustainable organizational performance. Benchmarking 2018, 25, 2272–2317. [Google Scholar] [CrossRef]

- Singh, R.; Centobelli, P.; Cerchione, R. Evaluating partnerships in sustainability-oriented food supply chain: A five-stage performance measurement model. Energies 2018, 11, 3473. [Google Scholar] [CrossRef] [Green Version]

- Arshinder, K.; Balaji, M. Understanding the models of Indian fruit and vegetable supply chains-A case study approach. Int. J. Agric. Resour. Gov. Ecol. 2019, 15, 307–322. [Google Scholar] [CrossRef]

- Nakandala, D.; Lau, H.C.W. Innovative adoption of hybrid supply chain strategies in urban local fresh food supply chain. Supply Chain Manag. 2019, 24, 241–255. [Google Scholar] [CrossRef]

- Cao, Y.; Mohiuddin, M. Sustainable Emerging Country Agro-Food Supply Chains: Fresh Vegetable Price Formation Mechanisms in Rural China. Sustainability 2019, 11, 2814. [Google Scholar] [CrossRef] [Green Version]

- Negi, S.; Anand, N. Wholesalers perspectives on mango supply chain efficiency in India. J. Agribus. Dev. Emerg. Econ. 2019, 9, 175–200. [Google Scholar] [CrossRef]

- Pavez, I.; Codron, J.-M.; Lubello, P.; Florêncio, M.C. Biosecurity institutions and the choice of contracts in international fruit supply chains. Agric. Syst. 2019, 176, 102668. [Google Scholar] [CrossRef]

- Nedumaran, S.; Selvaraj, A.; Nandi, R.; Suchiradipta, B.; Jyosthnaa, P.; Bose, D. Digital integration to enhance market efficiency and inclusion of smallholder farmers: A proposed model for fresh fruit and vegetable supply chain. Int. Food Agribus. Manag. Rev. 2020, 23, 319–338. [Google Scholar] [CrossRef]

- Waqas, U.; Rahman, A.A.; Ismail, N.W.; Basha, N.K. Underlying Dimensions of Supply Chain Risks Amongst Agropreneurs of Fresh Fruits and Vegetables in Malaysia. In Proceedings of the 2020 the 3rd International Conference on Computers in Management and Business, Tokyo, Japan, 31 January–2 February 2020; pp. 248–252. [Google Scholar]

- Digal, L.N. Quality grading in the supply chain: The case of vegetables in Southern Philippines. J. Int. Food Agribus. Mark. 2005, 17, 71–93. [Google Scholar] [CrossRef]

- Russell, L.F.; Leblanc, D.I.; McRae, K.B.; Ryan, D.A.J. Losses of vitamin C from fresh strawberries in a commercial supply chain. Int. J. Food Sci. Technol. 2009, 44, 820–828. [Google Scholar] [CrossRef]

- Cai, X.; Chen, J.; Xiao, Y.; Xu, X. Optimization and coordination of fresh product supply chains with freshness-keeping effort. Prod. Oper. Manag. 2010, 19, 261–278. [Google Scholar] [CrossRef]

- Jacxsens, L.; Luning, P.A.; van der Vorst, J.G.A.J.; Devlieghere, F.; Leemans, R.; Uyttendaele, M. Simulation modelling and risk assessment as tools to identify the impact of climate change on microbiological food safety—The case study of fresh produce supply chain. Food Res. Int. 2010, 43, 1925–1935. [Google Scholar] [CrossRef]

- Diez-Valcarce, M.; Kovač, K.; Cook, N.; Rodríguez-Lázaro, D.; Hernández, M. Construction and Analytical Application of Internal Amplification Controls (IAC) for Detection of Food Supply Chain-Relevant Viruses by Real-Time PCR-Based Assays. Food Anal. Methods 2011, 4, 437–445. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.T.; Qiao, Z. Preservation behavior decision of fruits and vegetables supply chain. In Proceedings of the 20th International Conference on Industrial Engineering and Engineering Management: Theory and Apply of Industrial Engineering; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1103–1108. [Google Scholar]

- Jraisat, L.E.; Sawalha, I.H. Quality control and supply chain management: A contextual perspective and a case study. Supply Chain Manag. 2013, 18, 194–207. [Google Scholar] [CrossRef]

- Macheka, L.; Ngadze, R.T.; Manditsera, F.A.; Mubaiwa, J.; Musundire, R. Identifying causes of mechanical defects and critical control points in fruit supply chains: An overview of a banana supply chain. Int. J. Postharvest Technol. Innov. 2013, 3, 109. [Google Scholar] [CrossRef]

- Sivakumar, D.; Wall, M.M. Papaya Fruit Quality Management during the Postharvest Supply Chain. Food Rev. Int. 2013, 29, 24–48. [Google Scholar] [CrossRef]

- Bill, M.; Sivakumar, D.; Thompson, A.K.; Korsten, L. Avocado Fruit Quality Management during the Postharvest Supply Chain. Food Rev. Int. 2014, 30, 169–202. [Google Scholar] [CrossRef] [Green Version]

- Blanke, M.M. Reducing ethylene levels along the food supply chain: A key to reducing food waste? J. Sci. Food Agric. 2014, 94, 2357–2361. [Google Scholar] [CrossRef]

- Janssen, S.; Schmitt, K.; Blanke, M.; Bauersfeld, M.L.; Wöllenstein, J.; Lang, W. Ethylene detection in fruit supply chains. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130311. [Google Scholar] [CrossRef]

- Leblanc, D.I.; Villeneuve, S.; Beni, L.H.; Otten, A.; Fazil, A.; McKellar, R.; Delaquis, P. A national produce supply chain database for food safety risk analysis. J. Food Eng. 2015, 147, 24–38. [Google Scholar] [CrossRef]

- Ait Hou, M.; Grazia, C.; Malorgio, G. Food safety standards and international supply chain organization: Acase study of the Moroccan fruit and vegetable exports. Food Control 2015, 55, 190–199. [Google Scholar] [CrossRef]

- Haoran, S.; Kejian, L.; Haihua, P.; Yang, Y. Fuzzy TOPSIS-based supply chain optimization of fresh agricultural products. Adv. Model. Anal. A 2016, 53, 186–203. [Google Scholar]

- Zoellner, C.; Venegas, F.; Churey, J.J.; Dávila-Aviña, J.; Grohn, Y.T.; García, S.; Heredia, N.; Worobo, R.W. Microbial dynamics of indicator microorganisms on fresh tomatoes in the supply chain from Mexico to the USA. Int. J. Food Microbiol. 2016, 238, 202–207. [Google Scholar] [CrossRef] [PubMed]

- Ramanathan, A.; Panneerselvam, G.; Parthasarathy, R. A study on sources of vegetable supply chain wastage with specific reference to retail outlets in Tamil Nadu. Int. J. Bus. Excell. 2017, 11, 141. [Google Scholar] [CrossRef]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Modeling causal factors of post-harvesting losses in vegetable and fruit supply chain: An Indian perspective. Renew. Sustain. Energy Rev. 2017, 80, 1355–1371. [Google Scholar] [CrossRef]

- Jacxsens, L.; Uyttendaele, M.; Luning, P.; Allende, A. Food safety management and risk assessment in the fresh produce supply chain. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Surakarta, Indonesia, 18–19 October 2016; Volume 193. [Google Scholar]

- Orjuela-Castro, J.; Adarme-Jaimes, W. Evaluating the Supply Chain Design of Fresh Food on Food Security and Logistics. In Applied Computer Sciences in Engineering; Figueroa-García, J.C., López-Santana, E.R., Rodriguez-Molano, J.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 257–269. [Google Scholar]

- Fabbri, S.; Olsen, S.I.; Owsianiak, M. Improving environmental performance of post-harvest supply chains of fruits and vegetables in Europe: Potential contribution from ultrasonic humidification. J. Clean. Prod. 2018, 182, 16–26. [Google Scholar] [CrossRef] [Green Version]

- Mercier, S.; Uysal, I. Neural network models for predicting perishable food temperatures along the supply chain. Biosyst. Eng. 2018, 171, 91–100. [Google Scholar] [CrossRef]

- Zoellner, C.; Al-mamun, M.A.; Grohn, Y.; Jackson, P.; Worobo, R. Postharvest Supply Chain with Microbial Travelers: A Farm-to- Retail Microbial Simulation and Visualization Framework. Appl. Environ. Microbiol. 2018, 84, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Hernández-Rubio, J.; Pérez-Mesa, J.C.; Piedra-Muñoz, L.; Galdeano-Gómez, E. Determinants of food safety level in fruit and vegetable wholesalers’ supply chain: Evidence from Spain and France. Int. J. Environ. Res. Public Health 2018, 15, 2246. [Google Scholar] [CrossRef] [Green Version]

- Kelly, K.; Madden, R.; Emond, J.P.; do Nascimento Nunes, M.C. A novel approach to determine the impact level of each step along the supply chain on strawberry quality. Postharvest Biol. Technol. 2019, 147, 78–88. [Google Scholar] [CrossRef]

- Diaz-Ruiz, R.; Costa-Font, M.; López-i-Gelats, F.; Gil, J.M. Food waste prevention along the food supply chain: A multi-actor approach to identify effective solutions. Resour. Conserv. Recycl. 2019, 149, 249–260. [Google Scholar] [CrossRef]

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef]

- Zhang, Y.; Chu, F.; Che, A.; Yu, Y.; Feng, X. Novel model and kernel search heuristic for multi-period closed-loop food supply chain planning with returnable transport items. Int. J. Prod. Res. 2019, 57, 7439–7456. [Google Scholar] [CrossRef]

- Xu, X.; Guo, W.G.; Rodgers, M.D. A real-time decision support framework to mitigate degradation in perishable supply chains. Comput. Ind. Eng. 2020, 150, 106905. [Google Scholar] [CrossRef]

- Hingley, M. Relationship Management in the Supply Chain. Int. J. Logist. Manag. 2001, 12, 57–71. [Google Scholar] [CrossRef]

- Louw, A.; Jordaan, D.; Ndanga, L.; Kirsten, J.F. Alternative marketing options for small-scale farmers in the wake of changing agri-food supply chains in South Africa. Agrekon 2008, 47, 287–308. [Google Scholar] [CrossRef]

- Arumugam, N.; Fatimah, M.A.; Chiew, E.F.C.; Zainalabidin, M. Supply chain analysis of fresh fruits and vegetables (FFV): Prospects of contract farming. Agric. Econ. 2010, 56, 435–442. [Google Scholar] [CrossRef] [Green Version]

- Schipmann, C.; Qaim, M. Supply chain differentiation, contract agriculture, and farmers’ marketing preferences: The case of sweet pepper in Thailand. Food Policy 2011, 36, 667–677. [Google Scholar] [CrossRef]

- Sayin, C.; Ozkan, B.; Ceylan, R.F. The role of wholesale markets in the supply chain for fresh fruit and vegetables in Turkey. Acta Hortic. 2011, 895, 263–268. [Google Scholar] [CrossRef]

- Guarín, A. The value of domestic supply chains: Producers, wholesalers, and urban consumers in Colombia. Dev. Policy Rev. 2013, 31, 511–530. [Google Scholar] [CrossRef]

- Schuster, M.; Maertens, M. Do private standards create exclusive supply chains? New evidence from the Peruvian asparagus export sector. Food Policy 2013, 43, 291–305. [Google Scholar] [CrossRef] [Green Version]

- Wahyudin, R.S.; Sutopo, W.; Hisjam, M.; Yuniaristanto, K. B: An agri-food supply chain model for cultivating the capabilities of farmers in accessing capital using corporate social responsibility program. Lect. Notes Eng. Comput. Sci. 2015, 2, 877–882. [Google Scholar]

- Jacob-John, J.; Veerapa, N. Perception of fairness within organic fresh produce supply chains: The case of small and medium fresh produce retailers. Acta Hortic. 2016, 233–240. [Google Scholar] [CrossRef]

- Michelson, H.; Boucher, S.; Cheng, X.; Huang, J.; Jia, X. Connecting supermarkets and farms: The role of intermediaries in Walmart China’s fresh produce supply chains. Renew. Agric. Food Syst. 2018, 33, 47–59. [Google Scholar] [CrossRef]

- Devin, B.; Richards, C. Food Waste, Power, and Corporate Social Responsibility in the Australian Food Supply Chain. J. Bus. Ethics 2018, 150, 199–210. [Google Scholar] [CrossRef]

- Elder, S.D. The impact of supermarket supply chain governance on smallholder farmer cooperatives: The case of Walmart in Nicaragua. Agric. Hum. Values 2019, 36, 213–224. [Google Scholar] [CrossRef]

- Salvia, L. The restructuring of Italian agriculture and its impact upon capital–labour relations: Labour contracting and exploitation in the fresh fruit and vegetable supply chain of the Lazio Region, Central Italy. J. Agrar. Chang. 2020, 20, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Gunarathna, R.T.; Bandara, Y.M. Post Harvest Losses and the Role of Intermediaries in the Vegetable Supply Chain. In Proceedings of the 2020 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 28–30 July 2020; pp. 378–383. [Google Scholar]

- Rajurkar, S.W.; Jain, R. Food supply chain management: Review, classification and analysis of literature. Int. J. Integr. Supply Manag. 2011, 6, 33–72. [Google Scholar] [CrossRef]

- Kong, X.T.R.; Huang, G.; Luo, H. Auction logistics in perishable supply chain trading: A research agenda. In Proceedings of the International Conference on Computers and Industrial Engineering, CIE, Hong Kong, China, 16–18 October 2013; Volume 1, pp. 305–319. [Google Scholar]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Sibomana, M.S.; Workneh, T.S.; Audain, K. A review of postharvest handling and losses in the fresh tomato supply chain: A focus on Sub-Saharan Africa. Food Secur. 2016, 8, 389–404. [Google Scholar] [CrossRef]

- Siddh, M.M.; Soni, G.; Jain, R.; Sharma, M.K.; Yadav, V. Agri-fresh food supply chain quality (AFSCQ): A literature review. Ind. Manag. Data Syst. 2017, 117, 2015–2044. [Google Scholar] [CrossRef] [Green Version]

- Routroy, S.; Behera, A. Agriculture supply chain: A systematic review of literature and implications for future research. J. Agribus. Dev. Emerg. Econ. 2017, 7, 275–302. [Google Scholar] [CrossRef]

- Raak, N.; Symmank, C.; Zahn, S.; Aschemann-Witzel, J.; Rohm, H. Processing- and product-related causes for food waste and implications for the food supply chain. Waste Manag. 2017, 61, 461–472. [Google Scholar] [CrossRef]

- Saitone, T.L.; Sexton, R.J. Agri-food supply chain: Evolution and performance with conflicting consumer and societal demands. Eur. Rev. Agric. Econ. 2017, 44, 634–657. [Google Scholar] [CrossRef]

- Gharehgozli, A.; Iakovou, E.; Chang, Y.; Swaney, R. Trends in global E-food supply chain and implications for transport: Literature review and research directions. Res. Transp. Bus. Manag. 2017, 25, 2–14. [Google Scholar] [CrossRef]

- Luo, J.; Ji, C.; Qiu, C.; Jia, F. Agri-food supply chain management: Bibliometric and content analyses. Sustainability 2018, 10, 1573. [Google Scholar] [CrossRef] [Green Version]

- Corrado, S.; Sala, S. Food waste accounting along global and European food supply chains: State of the art and outlook. Waste Manag. 2018, 79, 120–131. [Google Scholar] [CrossRef]

- Lezoche, M.; Panetto, H.; Kacprzyk, J.; Hernandez, J.E.; Alemany Díaz, M.M.E. Agri-food 4.0: A survey of the Supply Chains and Technologies for the Future Agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Routroy, S.; Garg, G.K. Postharvest supply chain losses: A state-of-the-art literature review and bibliometric analysis. J. Adv. Manag. Res. 2020, 18, 443–467. [Google Scholar] [CrossRef]

- Duan, Y.; Xu, X.; Liu, X.; Zografos, K.; Bemeleit, B. Accelerating internet adoption in China’s fresh produce supply chain: A vegnet approach. N. Z. J. Agric. Res. 2007, 50, 1299–1305. [Google Scholar] [CrossRef]

- Hu, J.; Chen, W.; Yuan, J.; Zhang, J. AgriRiskIDSS: Development of an intelligent decision support system for price risk management of agricultural product supply chain. J. Food Agric. Environ. 2011, 9, 299–303. [Google Scholar]

- Solanki, M.; Brewster, C. Enhancing visibility in EPCIS governing agri-food supply chains via linked pedigrees. Int. J. Semant. Web Inf. Syst. 2014, 10, 45–73. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Wang, J.; Qian, K.; Kong, N.; Wang, K.; Zheng, L.; Shi, Y.; Engels, D.W. Enterprise-oriented IoT name service for agricultural product supply chain management. Int. J. Distrib. Sens. Netw. 2015, 11, 308165. [Google Scholar] [CrossRef] [Green Version]

- La Scalia, G.; Nasca, A.; Corona, O.; Settanni, L.; Micale, R. An Innovative Shelf Life Model Based on Smart Logistic Unit for an Efficient Management of the Perishable Food Supply Chain. J. Food Process Eng. 2017, 40, e12311. [Google Scholar] [CrossRef]

- Borrero, J.D. Agri-food supply chain traceability for fruit and vegetable cooperatives using Blockchain technology. CIRIEC-Esp. Rev. Econ. Publica Soc. Coop. 2019, 95, 71–94. [Google Scholar] [CrossRef] [Green Version]

- Pal, A.; Kant, K. Smart sensing, communication, and control in perishable food supply chain. ACM Trans. Sens. Netw. 2020, 16, 1–41. [Google Scholar] [CrossRef]

- Goisser, S.; Mempel, H.; Bitsch, V. Food-Scanners as a Radical Innovation in German Fresh Produce Supply Chains. Int. J. Food Syst. Dyn. 2020, 11, 101–116. [Google Scholar]

- United States Department of Agriculture National Institute of Food and Agriculture Agriculture Technology. Available online: https://nifa.usda.gov/topic/agriculture-technology (accessed on 7 October 2020).

- Ahvenainen, R. Novel Food Packaging Techniques; Elsevier: Boca Raton, FL, USA, 2003; ISBN 1855737027. [Google Scholar]

- Singh, S.P.; Chonhenchob, V.; Singh, J. Life cycle inventory and analysis of re-usable plastic containers and display-ready corrugated containers used for packaging fresh fruits and vegetables. Packag. Technol. Sci. 2006, 19, 279–293. [Google Scholar] [CrossRef]

- Accorsi, R.; Cascini, A.; Cholette, S.; Manzini, R.; Mora, C. Economic and environmental assessment of reusable plastic containers: A food catering supply chain case study. Int. J. Prod. Econ. 2014, 152, 88–101. [Google Scholar] [CrossRef]

- Battini, D.; Calzavara, M.; Persona, A.; Sgarbossa, F. Sustainable Packaging Development for Fresh Food Supply Chains. Packag. Technol. Sci. 2016, 29, 25–43. [Google Scholar] [CrossRef]

- Giuggioli, N.R.; Girgenti, V.; Briano, R.; Peano, C. Sustainable supply-chain: Evolution of the quality characteristics of strawberries stored in green film packaging. CyTA-J. Food 2017, 15, 211–219. [Google Scholar] [CrossRef] [Green Version]

- Bortolini, M.; Galizia, F.G.; Mora, C.; Botti, L.; Rosano, M. Bi-objective design of fresh food supply chain networks with reusable and disposable packaging containers. J. Clean. Prod. 2018, 184, 375–388. [Google Scholar] [CrossRef]

- Zhao, X.; Xia, M.; Wei, X.; Xu, C.; Luo, Z.; Mao, L. Consolidated cold and modified atmosphere package system for fresh strawberry supply chains. LWT 2019, 109, 207–215. [Google Scholar] [CrossRef]

- Busato, P.; Berruto, R. FruitGame: Simulation Model to Study the Supply Chain Logistics for Fresh Produce. In Computers in Agriculture and Natural Resources, Proceedings of the 4th World Congress Conference, Orlando, FL, USA, 24–26 July 2006; ASABE: St. Joseph, MI, USA, 2006. [Google Scholar]

- Yan, L. The Research of Supply Chain Logistics Management on Fruit E-Commerce Website. Logistics 2009, 2139–2144. [Google Scholar] [CrossRef]

- Etemadnia, H.; Goetz, S.J.; Canning, P.; Tavallali, M.S. Optimal wholesale facilities location within the fruit and vegetables supply chain with bimodal transportation options: An LP-MIP heuristic approach. Eur. J. Oper. Res. 2015, 244, 648–661. [Google Scholar] [CrossRef]

- Chandrasekaran, M.; Ranganathan, R. Modelling and optimisation of Indian traditional agriculture supply chain to reduce post-harvest loss and CO2 emission. Ind. Manag. Data Syst. 2017, 117, 1817–1841. [Google Scholar] [CrossRef] [Green Version]

- Ghezavati, V.R.; Hooshyar, S.; Tavakkoli-Moghaddam, R. A Benders’ decomposition algorithm for optimizing distribution of perishable products considering postharvest biological behavior in agri-food supply chain: A case study of tomato. Cent. Eur. J. Oper. Res. 2017, 25, 29–54. [Google Scholar] [CrossRef]

- Mejjaouli, S.; Babiceanu, R.F. Cold supply chain logistics: System optimization for real-time rerouting transportation solutions. Comput. Ind. 2018, 95, 68–80. [Google Scholar] [CrossRef]

- Smith, B.G. Developing sustainable food supply chains. Philos. Trans. R. Soc. B Biol. Sci. 2008, 363, 849–861. [Google Scholar] [CrossRef] [Green Version]

- Styles, D.; Schoenberger, H.; Galvez-Martos, J.L. Environmental improvement of product supply chains: Proposed best practice techniques, quantitative indicators and benchmarks of excellence for retailers. J. Environ. Manag. 2012, 110, 135–150. [Google Scholar] [CrossRef]

- Naik, G.; Suresh, D.N. Challenges of creating sustainable agri-retail supply chains. IIMB Manag. Rev. 2018, 30, 270–282. [Google Scholar] [CrossRef]

- Blanc, S.; Massaglia, S.; Brun, F.; Peano, C.; Mosso, A.; Giuggioli, N.R. Use of bio-based plastics in the fruit supply chain: An integrated approach to assess environmental, economic, and social sustainability. Sustainability 2019, 11, 2475. [Google Scholar] [CrossRef] [Green Version]

- De Corato, U.; Cancellara, F.A. Measures, technologies, and incentives for cleaning the minimally processed fruits and vegetables supply chain in the Italian food industry. J. Clean. Prod. 2019, 237, 117735. [Google Scholar] [CrossRef]

- Slamet, A.S.; Hadiguna, R.A.; Mulyati, H. Making food supply chain sustainable: Participating smallholder farmers in modern retail channels. Int. J. Sustain. Agric. Manag. Inform. 2020, 6, 135–162. [Google Scholar]

- Jabarzadeh, Y.; Yamchi, H.R. A multi-objective mixed-integer linear model for sustainable fruit closed-loop supply chain network. Manag. Environ. Qual. Int. J. 2020, 31, 1351–1373. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO). What Is Sustainable Food Value Chain Development? Available online: https://www.fao.org/sustainable-food-value-chains/what-is-it/en/ (accessed on 1 December 2021).

- Commission on Sustainable Agriculture Intensification (CSAI). Paying for Nature and Society: Innovation in Financial Incentives for a Sustainable and Inclusive Transition in Agriculture. Available online: https://wle.cgiar.org/cosai/news/paying-nature-and-society-innovation-financial-incentives-sustainable-and-inclusive-transition (accessed on 1 December 2021).

- Handfield, R.B.; Nichols, E.L., Jr. Supply Chain Management: Transforming Supply Chains into Integrated “Value Systems.” In Supply Chain Redesign: Transforming Supply Chains into Integrated Value Systems; Financial Times Prentice Hall: Upper Saddle River, NJ, USA, 2002; pp. 1–34. [Google Scholar]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Macmillan Publishing: New York, NY, USA, 1985. [Google Scholar]

- Galanakis, C.M. The Food Systems in the Era of the Coronavirus (COVID-19) Pandemic Crisis. Foods 2020, 9, 523. [Google Scholar] [CrossRef]

- Giudice, F.; Caferra, R.; Morone, P. COVID-19, the Food System and the Circular Economy: Challenges and Opportunities. Sustainability 2020, 12, 7939. [Google Scholar] [CrossRef]

- Swanepoel, L.; Tioti, T.; Eria, T.; Tamuera, K.; Tiitii, U.; Larson, S.; Paul, N. Supporting women’s participation in developing a seaweed supply chain in Kiribati for health and nutrition. Foods 2020, 9, 382. [Google Scholar] [CrossRef] [Green Version]

- KPMG. Agri-Food Supply Chain Disruption. Available online: https://home.kpmg/in/en/blogs/home/posts/2021/11/agriculture-resilience-eco-system-e-marketplace-mantra.html (accessed on 8 December 2021).

- Dijital Tarım Pazarı. Available online: https://ditap.gov.tr/ditap-nedir.html (accessed on 17 November 2020).

| Categories of the Articles Considered | Number of Articles |

|---|---|

| Value Chain Indicators of FFVSCs | 35 |

| Food-Related Problems/Postharvest Losses along the FFVSC | 29 |

| Role of Parties Involved in the FFV Value Chain | 14 |

| Review Papers | 13 |

| Technological Trends in the FFVSC | 8 |

| Packaging Issues of the FFVSC | 6 |

| Logistics Solutions of the FFVSC | 6 |

| Sustainable FFVSCs | 7 |

| Total | 118 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tort, Ö.Ö.; Vayvay, Ö.; Çobanoğlu, E. A Systematic Review of Sustainable Fresh Fruit and Vegetable Supply Chains. Sustainability 2022, 14, 1573. https://doi.org/10.3390/su14031573

Tort ÖÖ, Vayvay Ö, Çobanoğlu E. A Systematic Review of Sustainable Fresh Fruit and Vegetable Supply Chains. Sustainability. 2022; 14(3):1573. https://doi.org/10.3390/su14031573

Chicago/Turabian StyleTort, Ömer Özgür, Özalp Vayvay, and Emine Çobanoğlu. 2022. "A Systematic Review of Sustainable Fresh Fruit and Vegetable Supply Chains" Sustainability 14, no. 3: 1573. https://doi.org/10.3390/su14031573