Abstract

Argon oxygen decarburization (AOD) slag is the by-product of the stainless steel refining process, which has caused considerable environmental stress. In this work, the utilization of AOD slag as mineral fertilizer for alfalfa (Medicago sativa L.) and perennial ryegrass (Lolium perenne L.) planting were investigated by pot experiments. The morpho-physiological parameters of biomass, plant height, root morphology and the biochemical parameters of malondialdehyde (MDA) content, superoxide dismutase (SOD) activity, catalase (CAT) activity, peroxidase (POD) activity, and chlorophyll were measured. The accumulation of chromium in plants was also determined for an environmental safety perspective. It was found that low rates (≤0.5 wt.% for alfalfa and ≤2 wt.% for perennial ryegrass) of AOD slag fertilization are beneficial to the growth of these two plants. However, the soil enrichment with higher AOD slag amounts resulted in the reduction of biomass, plant height, and root growth. Compared with the alfalfa, the perennial ryegrass showed higher tolerance for AOD slag fertilization. The toxicity of the utilization of AOD slag as mineral fertilizer for perennial ryegrass planting is slight. Health risks induced by the consumption of the alfalfa grown on the soil with high AOD slag rates (≥8 wt.%) were detected.

1. Introduction

The continuous development of the iron and steel industry generates a vast amount of slag such as blast furnace (BF) slag, Linz-Donawitz (LD) slag, stainless steel slag (SSS), and other solid wastes [1,2,3]. China has become the main producer of stainless steel in the world. In 2018, the production of crude stainless steel was about 26.7 million tons in China [4]. With the output of the crude stainless steel, the generation of SSS exceeded 6 million tons. The SSS can be divided into electric arc furnace (EAF) slag and argon oxygen decarburization (AOD) slag depending on the manufacturing process [5]. The AOD slag, which is produced in the refining process, has caused considerable environmental stress. Currently, a small part of the AOD slag is utilized as cement [6,7], roadbed materials [8], CO2 capture [9], etc. Most of the AOD slag is stocked in open areas or landfills, resulting in the occupation of a lot of land resources. Finding an eco-friendly approach for AOD slag treatment and utilization is of great importance for the green development of the iron and steel industry.

The utilization of solid waste in agriculture has been investigated for a long time [10,11,12]. Recently, the use of slag as mineral fertilizer and soil amendment for plant growth has been reported. Chen et al. [13] reported that the low rate of molybdenum slag fertilization increased the height, leaf area, and biomass of the pakchoi seedling. Pietrini et al. [14] added ladle furnace (LF) slag to soil for Amaranthus paniculatus L. planting. They indicated that the addition of 5% LF slag did not impact the growth of Amaranthus paniculatus L. However, plants grown on the soil with high slag additions of 10% and 20% showed a marked reduction in growth, or even a very low survival rate. Ali et al. [15] used silicate iron slag for rice planting. The obtained results showed that the application of silicate iron slag increased rice grain yield. Silicate fertilization promoted rice plant growth, especially root biomass, root volume, and porosity.

The metallurgical slag produced in the ironmaking and steelmaking process contains micronutrients which are beneficial to plant growth. However, little information is present in the literature about the utilization of AOD slag as a mineral fertilizer and soil amendment. AOD slag with the main chemical compositions of CaO, SiO2, MgO, Al2O3, and FeO can provide micronutrients for plant growth [16]. Moreover, there are almost no heavy metals of Cd, As, Pb, Hg, Zn, or Cu in the AOD slag. One of the major limiting factors for the use of AOD slag as a mineral fertilizer is the heavy metal chromium. The chromium contained in AOD slag can be leached out under the leaching influence of rainwater. Although chromium has been suggested as being capable of promoting the growth of some plants at lower concentrations (<10 mg L−1), it is extremely toxic at higher concentrations. The high chromium concentration can inhibit photosynthesis, trigger lipid peroxidation, and lead to considerable damage or death of plants [17]. The unreasonable addition of AOD slag to soil as mineral fertilizer may result in a harmful effect on plant growth [18,19]. Alfalfa (Medicago sativa L.) and perennial ryegrass (Lolium perenne L.) are typical forage crops, which grow in various parts of the world [20,21]. Alfalfa belongs to leguminous forage, while perennial ryegrass is gramineous forage. Several studies have shown that alfalfa and perennial ryegrass can tolerate heavy metal without their growth being impacted [22,23,24]. Therefore, the application of AOD slag as mineral fertilizer for alfalfa and perennial ryegrass planting may be a good approach for its utilization.

This work aimed at finding a new approach for the management and valorization of AOD slag by investigating its fertilizer efficiency and toxicity for the growth of plants. In the present work, the potential application of AOD slag as mineral fertilizer for alfalfa and perennial ryegrass planting was explored. Pot experiments of alfalfa and perennial ryegrass were performed using soil with different addition rates of AOD slag. To investigate the effects of AOD slag addition on plant growth, the morpho-physiological and biochemical parameters (e.g., biomass, plant height, root morphology, malondialdehyde (MDA), superoxide dismutase (SOD) activity, catalase (CAT) activity, peroxidase (POD) activity, chlorophyll) of the sampled alfalfa and perennial ryegrass seedlings were measured. The accumulation of chromium in the plants was also determined for an environmental safety perspective.

2. Materials and Methods

2.1. AOD Slag

AOD slag was collected from a stainless steel-making industry in Qingshan, China. After sieving to a particle size smaller than 74 μm and drying at 105 °C for 6 h in an oven, the undersized AOD slag was used for physico-chemical analysis and soil fertilization.

The chemical composition of the sampled AOD slag was measured using X-ray fluorescence (XRF, Panalytical B.V., The Netherlands) and shown in Table 1. The AOD slag mainly consisted of CaO (62.076 wt.%), SiO2 (26.213 wt.%), and MgO (4.863 wt.%). The other oxides like Al2O3, Fe2O3, Cr2O3, TiO2, and MnO with lower content of 1.722 wt.%, 0.358 wt.%, 0.378 wt.%, 0.212 wt.%, and 0.171 wt.%, respectively, were the minor chemical composition of the AOD slag. AOD slag is an alkaline solid waste with a ternary basicity ((CaO + MgO)/SiO2) of 2.55.

Table 1.

Chemical composition of the AOD slag (wt.%).

Powder X-ray diffraction (XRD) measurement was conducted using the Brucker D8 Advance X-ray diffractometer (Brucker, Germany) with Cu-Kα radiation to determine the mineralogical composition of the AOD slag. The obtained result showed that the major mineralogical composition of the AOD slag was dicalcium silicate (Ca2SiO4), merwinite (Ca3Mg(SiO4)2), fluorite (CaF2), periclase (MgO), and augite (Ca(Mg0.85Al0.15)(SiO1.70Al0.30)O6). Due to the low content of Cr2O3, the Cr-bearing phase was not measured by XRD analysis. According to other studies, Cr is mainly exists in spinel phases of MgCr2O4 and FeCr2O4 in stainless steel slag [25,26]. Furthermore, Zhang et al. [27] and Samada et al. [28] reported that a certain amount of Cr can be dissolved into the glass phase, calcium silicate, and diopside phase.

2.2. Pot Experiment

The morpho-physiological and biochemical responses of alfalfa and perennial ryegrass to AOD slag fertilization were investigated by pot experiments. The soil used for alfalfa and perennial ryegrass planting was Klasmann peat 876#. The soil was air dried and sieved with a 2-mm sieve before adding AOD slag. The undersized soil was used for physico-chemical analysis and planting. Eight AOD slag addition rates of 0%, 0.25%, 0.5%, 1%, 2%, 4%, 8%, and 16%, in w/w, were used in this work. The soil and slag mixture was placed in 140 × 120 mm plastic pots with an addition amount of 0.15 kg pot−1.

The alfalfa and perennial ryegrass seeds used in this work were purchased from a seed company in Shandong, China, with germination rates of more than 90%. The pregermination of the alfalfa and perennial ryegrass seeds were conducted using 2% H2O2 at 25 °C for 24 h under dark conditions in an incubator before sowing. After pregermination, the obtained seeds were washed thoroughly with deionized water, and then thirty uniform seeds were sown in each plastic pot. For reliability, three replicate pot experiments were performed for each addition rate. The sowed alfalfa and perennial ryegrass seeds were incubated in a growth chamber having a day/night cycle of 16/8 h and day/night temperature of 25/20 °C. Pots were watered daily with a quantity of deionized water to maintain the water holding capacity of 60%. The alfalfa and perennial ryegrass seedlings were thinned to 10 per pot on the 7th day after emergence [29]. The alfalfa and perennial ryegrass seedlings were harvested at 30 days after sowing, and then the morpho-physiological and biochemical parameters were determined.

2.3. Characterization

2.3.1. Soil Properties

To investigate the effects of AOD slag addition on the physico-chemical properties of the peat soil, the pH, electrical conductivity (EC), total N (TN), total P (TP), and total K (TK) values of the original soil and the slag and soil mixtures were measured according to the methods described in the literature [30,31,32,33]. Soil pH and EC were measured by a soil-water solution using a pH meter (PHS-3C, Shanghai INESA Scientific Instrument Co., Ltd., Shanghai, China) and a conductivity meter (DDS-307, Shanghai Yueping Science Instrument Co., Ltd., Shanghai, China), respectively. The Kjeldahl method was employed to determine the TN value of the soil. The concentrated H2SO4-HClO4 digestion was combined with the molybdenum antimony colorimetric technique to measure the TP of the soil. The TK value of the soil was identified according to the standard of GB 9836-1988 [34].

2.3.2. Plant Analysis

The biomass, seedling height, root properties, malondialdehyde (MDA), superoxide dismutase (SOD) activity, catalase (CAT) activity, peroxidase (POD) activity, and chlorophyll of the harvested alfalfa and perennial ryegrass seedlings were measured using the fresh sample. The root morphology such as length, surface area, root tips and hairs were analyzed using a root analysis system (WinRHIZO pro 2009c, Regent Instruments, Quebec, QC, Canada). The MDA value was detected using the method described by Chen et al. [35]. The fresh sample was extracted using trichloroacetic acid and thiobarbituric acid. After heating at 95 °C for 30 min and centrifugation, the obtained supernatant was measured by UV-vis spectrophotometry (U-T3, Summit Instrument Manufacturing Co., Ltd., Shanghai, China) at the absorbance of 600 and 532 nm, respectively. The MDA content was calculated by subtracting the absorption at 600 nm from the absorption at 532 nm and calibrated by the extinction coefficient of 155 mM−1 cm−1. The SOD, CAT, and POD activities were determined according to the study of Chen et al. [13]. The SOD activity was detected by measuring its inhibition ability of the photochemical reduction of nitroblue tetrazolium at 550 nm. The CAT activity was identified by measuring the decomposition of H2O2 at 240 nm. The POD activity was determined by measuring the rate of guaiacol oxidation at 470 nm. The values of SOD, CAT, and POD activities all expressed in units per milligram protein (U mgprot−1). For chlorophyll measurements, the chlorophyll pigments were extracted using 80% acetone, and then detected at the absorbance of 663 and 645 nm, respectively. The chlorophyll concentration was calculated using the absorption at 663 and 645 nm.

The chromium accumulation in the plants was measured using the dry sample. The aboveground parts of the alfalfa and perennial ryegrass were harvested, and then rinsed with deionized water, and oven-dried at 60 °C to a constant weight. Then, 0.25 g dry sample was digested using HNO3 solution in a microwave digestion system (Master-18, Shanghai Sineo Microwave Chemistry Technology Co., Ltd., Shanghai, China). After digestion, the Cr in the obtained solution was measured using inductively coupled plasma mass spectrometry (ICP-MS, Agilent ICPMS7800, Agilent Technologies Inc., Santa Clara, CA, USA).

2.4. Statistical Analysis

The recorded data were statistically analyzed using SPSS version 25.0. One-way ANOVA followed by Duncan’s test were employed to examine the statistical significant difference among the mean of the application rates at a level of p < 0.05.

3. Results and Discussion

3.1. Effects of AOD Slag Addition on Soil Properties

To investigate the effects of AOD slag addition on the soil properties, the physicochemical properties of the original soil (addition rate of 0%) and the soil and slag mixtures were measured and shown in Table 2.

Table 2.

Physicochemical properties of the original soil and the soil-slag mixtures, expressed as dry basis.

3.1.1. pH

As observed, with increasing AOD slag addition rate from 0% to 16%, the pH of the soil increased from 6.13 to 9.87. AOD slag is a type of solid waste that contains a large amount of alkaline minerals. Among which, the amount of Ca2SiO4 is the highest. The dissolution of Ca2SiO4 generates OH− ions, resulting in the increase of pH [36]. A pH value higher than 8.0 was observed when the AOD slag addition rate was higher than 4%. The high pH of the soil may inhibit the growth of the alfalfa and perennial ryegrass.

3.1.2. Electrical Conductivity (EC)

The EC value is directly related to the total amount of dissolved solid of soil and AOD slag [37]. With increasing AOD slag addition rate, the EC value of soil increased from 0.50 mS cm−1 to 0.63 mS cm−1. This can be attributed to the soluble minerals containing in AOD slag. The dissolution of the minerals contained in AOD slag would release metallic and non-metallic ions such as Ca2+, H2SiO42−, Mg2+, Fe2+, etc. which enhances the EC of the soil. The release of the mineralogical micronutrients may benefit the growth of the alfalfa and perennial ryegrass.

3.1.3. Total N, P and K Content

The N, P, and K contents of soil play an important role in plant growth and quality development [38,39]. With increasing AOD slag addition, the TN, TP, and TK contents of soil continuously decreased from 7.06 g kg−1 to 2.60 g kg−1, 0.72 g kg−1 to 0.31 g kg−1, and 1.01 g kg−1 to 0.48 g kg−1, respectively. As shown in Table 1, AOD slag is an inorganic solid waste with a low content of P2O5 (0.006 wt.%) and almost no N and K. The addition of AOD slag to soil impoverished the TN, TP, and TK of the original soil, which may do harm to the growth of the alfalfa and perennial ryegrass.

3.2. Morpho-Physiological Properties of Plants

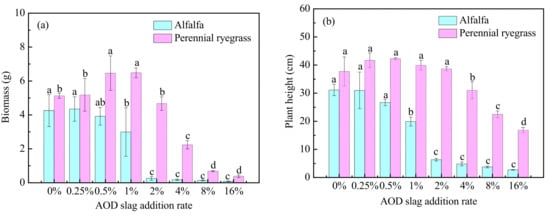

Figure 1 shows the effects of AOD slag fertilization on biomass and plant height of the alfalfa and perennial ryegrass seedlings after germination for 30 days. As shown in Figure 1, compared with the control, the low rates (≤0.5 wt.%) of addition of AOD slag almost did not impact the biomass and plant height of the alfalfa. The obvious decrease in biomass and plant height of the alfalfa was observed when the addition rate of AOD slag was higher than 0.5 wt.%. As for perennial ryegrass, the biomass and plant height increased, and then decreased with increasing AOD slag addition rate. The obvious decline in biomass and plant height could be observed at the addition rate higher than 2 wt.%. The obtained results indicated that perennial ryegrass shows higher tolerance for AOD slag fertilization than alfalfa. The growth of the alfalfa and perennial ryegrass seedlings after germination for 30 days can be clearly observed in Figure 2.

Figure 1.

Effects of AOD slag fertilization on biomass and plant height of the alfalfa and perennial ryegrass seedlings after germination for 30 days; (a) biomass, (b) plant height. The error bars indicate standard deviation and lower case letters show significance at p < 0.05 according to Duncan’s test.

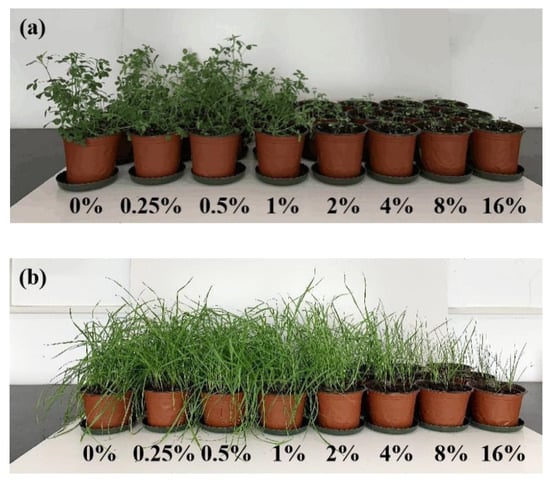

Figure 2.

Images of the alfalfa and perennial ryegrass seedlings after germination for 30 days; (a) alfalfa, (b) perennial ryegrass.

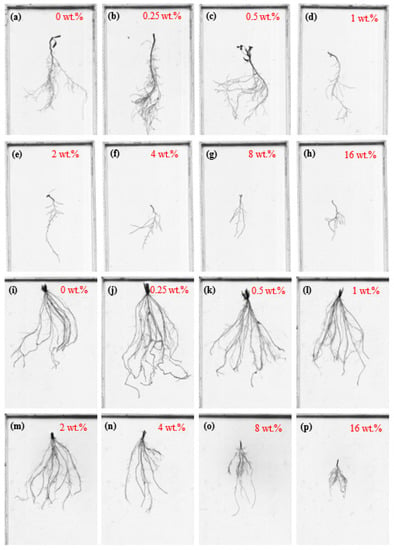

The root plays a key role in the transformation and circulation of elements and mineral/organic components for the growth of plant. To further investigate the effects of AOD slag fertilization on the growth of the alfalfa and perennial ryegrass seedlings, the root morphology and traits were analyzed and shown in Figure 3 and Table 3, respectively. As shown in Figure 3 and Table 3, the evolution of root length, surface area, and amount of tips and hairs showed the same trend as that of the plant biomass and height. The low rates of AOD slag fertilization promoted the growth of the root. However, the harmful effect of AOD slag fertilization on the growth of root could be obviously observed when the addition rate of AOD slag was high. As for alfalfa, the significant reduction in root growth was detected at the addition rate higher than 0.5%, while that of the perennial ryegrass was examined at the addition rate higher than 2%. Similar to the results of biomass and plant height, the root of perennial ryegrass showed higher tolerance for AOD slag fertilization than alfalfa.

Figure 3.

Root morphology of the alfalfa and perennial ryegrass seedlings after germination for 30 days; (a–h) alfalfa, (i–p) perennial ryegrass.

Table 3.

Root traits of the alfalfa and perennial ryegrass seedlings after germination for 30 days.

The irrigation of plants using water would result in the dissolution of the primary minerals of the AOD slag, releasing metallic and non-metallic ions (e.g., OH−, Ca2+, Mg2+, Fe2+, H2SiO42−, etc.) to soil. The slight addition of AOD slag to soil can improve the amount of micronutrients for plant growth. Moreover, the soil pH was not increased to a such high value. The low rate of AOD slag fertilization is beneficial to the growth of the alfalfa and perennial ryegrass. The main mineralogical composition of the AOD slag is Ca2SiO4. The high rate of AOD slag fertilization would significantly increase the Ca content and pH of the soil. As reported in the literature [40], the availability of P is often extremely low in the soil with high content of Ca due to the precipitation as calcium phosphate. In P-deficient plants, the reductions in biomass, plant height, and leaf area are commonly observed [41,42]. The high soil pH also has some negative effects on the root and plant growth. The water flux of the root, the elongation of the root cell, and the formation of the lateral roots and root hairs are inhibited when the soil pH is high [43,44]. Plants absorb soil N, P, and K and other micronutrients mainly through root tips and hairs [45]. The reduction in root growth by high soil pH inhibited the growth of the alfalfa and perennial ryegrass. Moreover, the availability of the essential elements such as Fe, Mn, and B is low in soil with high pH. Increasing the AOD slag addition rate also enhanced the chromium content in soil. The decreased availability of micronutrients and increased Cr content of soil may result in the reduction in plant growth [18,19]. Consequently, the high rate of AOD slag fertilization is detrimental to the growth of the alfalfa and perennial ryegrass.

Compared with the growth of alfalfa, the tolerance of perennial ryegrass for AOD slag fertilization was higher. As reported by Hannaway et al. [46], the perennial ryegrass tolerates both acidic and alkaline soils with pH ranges from 5.1 to 8.4. The optimal soil pH for the growth of the perennial ryegrass is 5.5 to 7.5. For the growth of alfalfa, a soil pH of 6.5 to 7.0 is necessary for achieving the optimum alfalfa yield [47]. The decrease in tissue K of the alfalfa was observed in the pH range of 7.0 to 7.3. Therefore, the difference of these two plants induced by the addition of AOD slag to soil may be mainly attributed to the increased soil pH.

3.3. Biochemical Properties of Plants

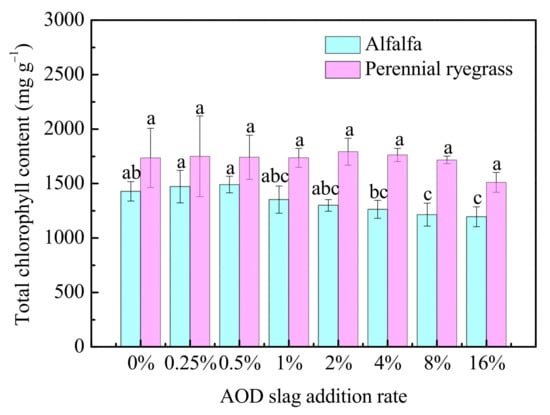

Figure 4 shows the effects of AOD slag fertilization on total chlorophyll content of the alfalfa and perennial ryegrass seedlings after germination for 30 days. As shown in Figure 4, the total chlorophyll contents of both the alfalfa and the perennial ryegrass seedlings increased, and then decreased with increasing AOD slag addition rate. The decline in the total chlorophyll content of the alfalfa was observed at the rate higher than 0.5 wt.%, while that of the perennial ryegrass was detected at the rate higher than 2 wt.%. Compared with the control, the total chlorophyll content of the alfalfa and the perennial ryegrass seedlings decreased by 16.4% and 13.0%, respectively, at the addition rate of 16 wt.%. The low addition rate of AOD slag can properly provide micronutrients Fe and Mg, which are beneficial to the biosynthesis of chlorophyll [43,48,49]. With the further increase of the addition rate, the growth of root was inhibited and the soil pH enhanced to a high value. The low amount of micronutrients adsorption by root and the high soil pH resulted in the reduction of the total chlorophyll content. A similar result was obtained by Zhang et al. [50]. They suggested that the chlorophyll concentration of leaf significantly decreased when the soil pH was higher than 7.0.

Figure 4.

Effects of AOD slag fertilization on total chlorophyll content of the alfalfa and perennial ryegrass seedlings after germination for 30 days. The error bars indicate standard deviation and lowercase letters show significance at p < 0.05 according to Duncan’s test.

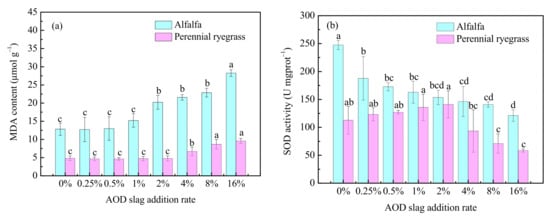

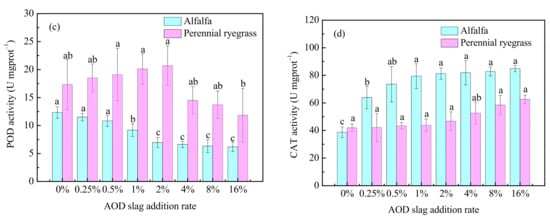

The heavy metal in plants generates reactive oxygen species (ROS), resulting in the damage of the membrane lipid and plant cell. The extent of ROS damage to membrane lipid can be estimated by the MDA content of the plant [51]. As shown in Figure 5a, compared with the control, the MDA content of the alfalfa almost did not change when the addition rate was lower than 0.5 wt.%. The continuous increase of MDA content of the alfalfa was observed when the addition rate was higher than 0.5 wt.%. As for perennial ryegrass, the obvious enhancement of the MDA content was detected when the addition rate was higher than 2 wt.%. The MDA content of the alfalfa and perennial ryegrass seedlings increased by 120.5% and 97.3%, respectively, at the addition rate of 16 wt.%. The obtained results indicated that the low rate of AOD slag addition to soil induced little oxidative stress to the alfalfa and perennial ryegrass seedlings. The phytotoxicity caused by the AOD slag fertilization could be observed when the addition rate was high. This may be attributed to the large leaching of Cr from the AOD slag.

Figure 5.

Effects of AOD slag fertilization on MDA content and antioxidant enzyme activities of the alfalfa and perennial ryegrass seedlings after germination for 30 days. (a) MDA content, (b) SOD activity, (c) POD activity, (d) CAT activity. The error bars indicate standard deviation and lower case letters show significance at p < 0.05 according to Duncan’s test.

To alleviate cellular damage by eliminating ROS, the plants evolve enzymatic defense mechanisms, including SOD, POD, and CAT [52]. Figure 5b–d shows the evolution of the antioxidant enzyme activities as a function of the AOD slag addition rate. As shown in Figure 5b,c, the SOD and POD activities of the alfalfa decreased with the increase of the AOD slag addition rate. While, the SOD and POD activities of the perennial ryegrass slightly increased, and then decreased with increasing AOD slag addition rate. This indicated that the AOD slag fertilization inhibited the antioxidant defense system of the alfalfa. While, for the perennial ryegrass, low rates (≤2 wt.%) of AOD slag fertilization promoted the antioxidative ability. High rates (4–16 wt.%) of AOD slag fertilization started to inhibit the antioxidant defense system. The decrease in SOD and POD activities may be mainly attributed to the increase of Cr content in plants [13]. Unlike the SOD and POD activities, the CAT activity continuously rose with increasing AOD slag addition rate (Figure 5d). The dissolution of AOD slag releases a large amount of Ca, which may be the main reason for the increase of the CAT activity.

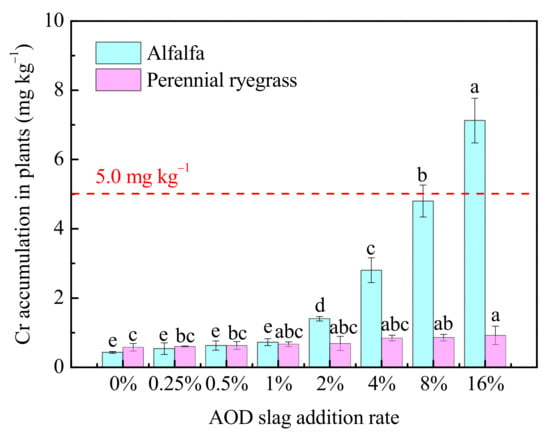

3.4. Chromium Accumulation and Toxicity Assessment

Figure 6 shows the evolution of the Cr content of the alfalfa and perennial ryegrass seedlings as a function of the AOD slag addition rate. As shown in Figure 6, with increasing AOD slag addition rate from 0 wt.% to 16 wt.%, the Cr content of the alfalfa rose from 0.43 mg kg−1 to 7.12 mg kg−1, while that of the perennial ryegrass increased from 0.57 mg kg−1 to 0.92 mg kg−1. Compared with the perennial ryegrass, the transfer of Cr from the mixed soil to the alfalfa seedling is easier. The largely uptake of Cr produced a large amount of ROS, resulting in the increase of the MDA content and the decrease of the antioxidant enzyme activities. The obtained results of chromium accumulation in plants shown in Figure 6 correspond to the results shown in Figure 5. Moreover, the large accumulation of Cr in plants is also detrimental to the biomass, plant height, and root growth, corresponding to the results shown in Figure 1, Figure 2 and Figure 3.

Figure 6.

Effects of AOD slag fertilization on chromium accumulation in the alfalfa and perennial ryegrass seedlings after germination for 30 days. The error bars indicate standard deviation and lower case letters show significance at p < 0.05 according to Duncan’s test.

Both alfalfa and perennial ryegrass are typical forage crops. The accumulation of Cr in alfalfa and perennial ryegrass may cause health risks for human beings through the food chain. According to the Chinese hygienical standard for feeds (GB 13078-2017) [53], the Cr content in feeds should not be higher than 5.0 mg kg−1, expressing as dry basis. The toxicity of the AOD slag fertilization to perennial ryegrass is slight. While, as for alfalfa, the consumption of the alfalfa grown on the soil with high AOD slag addition rates (≥8 wt.%) would induce health risk. Remarkably, in the present work, the germination time for alfalfa and perennial ryegrass seedlings was only 30 days, which is short. More Cr may accumulate in the plant over a long period of time. Although our previous study indicated that the leaching concentration of Cr from AOD slag was low and mainly presented as Cr(III) [54], the long-term risks of the utilization of AOD slag as a mineral fertilizer for alfalfa and perennial ryegrass planting should be further investigated.

4. Conclusions

The effects of the addition of AOD slag to soil on the growth of alfalfa and perennial ryegrass were investigated. For the environmental safety perspective, the toxicity of Cr accumulation in alfalfa and perennial ryegrass was also assessed. The obtained results indicated that adding AOD slag to soil increasesd pH and EC values, while it decreased OM, TN, TP, and TK contents of the original soil. Low rates (≤0.5 wt.% for alfalfa and ≤2 wt.% for perennial ryegrass) of AOD slag fertilization were beneficial to the biomass, plant height, and root growth of these two plants. On the contrary, soil enrichment with higher AOD slag amounts resulted in the reduction of plant growth. The harmful effects of AOD slag fertilization on the growth of alfalfa and perennial ryegrass can be mainly attributed to the increased soil pH and Cr content in the plants. Compared with the alfalfa, the perennial ryegrass showed higher tolerance for AOD slag fertilization. Increasing the AOD slag addition rate increased the Cr content of the alfalfa and perennial ryegrass. The transfer of Cr from the mixed soil to alfalfa is easier than perennial ryegrass. Under our experimental conditions, the toxicity of the utilization of AOD slag as a mineral fertilizer for perennial ryegrass planting was slight. However, health risks induced by the consumption of the alfalfa grown on the soil with high AOD slag addition rates (≥8 wt.%) were detected. Since more Cr may accumulate in plants over a long period of time, the long-term toxicity of the utilization of AOD slag as a mineral fertilizer should be further investigated.

Author Contributions

S.C.: Methodology, investigation, writing—original draft. B.L.: Methodology, investigation, visualization, writing—review and editing, funding acquisition. J.L.: Conceptualization, supervision, project administration, funding acquisition. Y.Z. (Yuzhu Zhang): Methodology. Y.Z. (Yanan Zeng): Investigation, resources. Y.W.: Investigation. T.L.: Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Natural Science Foundation of Hebei Province (No. E2020209195, No. E2021209043), Science and Technology Project of Hebei Education Department (No. BJ2021034), National Natural Science Foundation of China (No. 51574108), and Graduate Student Innovation Foundation of Hebei Province (No. CXZZBS2019140).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the data also forms part of an ongoing study.

Acknowledgments

The authors would like to thank North China University of Science and Technology for providing the materials and testing equipment for the experiments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gwon, H.S.; Khan, M.I.; Alam, M.A.; Das, S.; Kim, P.J. Environmental risk assessment of steel-making slags and the potential use of LD slag in mitigating methane emissions and the grain arsenic level in rice (Oryza sativa L.). J. Hazard. Mater. 2018, 353, 236–243. [Google Scholar] [CrossRef] [PubMed]

- Kim, G.; Sohn, I. Selective metal cation concentration during the solidification of stainless steel EAF dust and slag mixtures from high temperatures for increased Cr recovery. J. Hazard. Mater. 2018, 359, 174–185. [Google Scholar] [CrossRef] [PubMed]

- Ren, Q.; Zhang, Y.; Long, Y.; Zou, Z.; Pei, J. Crystallisation behaviour of blast furnace slag modified by adding fly ash. Ceram. Int. 2018, 44, 11628–11634. [Google Scholar] [CrossRef]

- Deng, L.; Wang, S.; Zhang, Z.; Li, Z.; Jia, R.; Yun, F.; Li, H.; Ma, Y.; Wang, W. The viscosity and conductivity of the molten glass and crystallization behavior of the glass ceramics derived from stainless steel slag. Mater. Chem. Phys. 2020, 251, 123159. [Google Scholar] [CrossRef]

- Park, B.; Moon, E.-J.; Choi, Y.C. Investigation of microstructure and mechanical performance of carbon-capture binder using AOD stainless steel slag. Constr. Build Mater. 2020, 242, 118174. [Google Scholar] [CrossRef]

- Mladenovič, A.; Mirtič, B.; Meden, A.; Zalar Serjun, V. Calcium aluminate rich secondary stainless steel slag as a supplementary cementitious material. Constr. Build Mater. 2016, 116, 216–225. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Agrela, F. Effect of stainless steel slag waste as a replacement for cement in mortars. Mechanical and statistical study. Constr. Build Mater. 2017, 142, 444–458. [Google Scholar] [CrossRef]

- Dong, Q.; Wang, G.; Chen, X.; Tan, J.; Gu, X. Recycling of steel slag aggregate in portland cement concrete: An overview. J. Cleaner Prod. 2021, 282, 124447. [Google Scholar] [CrossRef]

- Moon, E.-J.; Choi, Y.C. Development of carbon-capture binder using stainless steel argon oxygen decarburization slag activated by carbonation. J. Cleaner Prod. 2018, 180, 642–654. [Google Scholar] [CrossRef]

- Guerrini, I.A.; Croce, C.G.G.; Bueno, O.D.C.; Jacon, C.P.R.P.; Nogueira, T.a.R.; Fernandes, D.M.; Ganga, A.; Capra, G.F. Composted sewage sludge and steel mill slag as potential amendments for urban soils involved in afforestation programs. Urban For. Urban Green. 2017, 22, 93–104. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An Overview of Utilization of Steel Slag. Procedia. Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef] [Green Version]

- Ferreira Preston, H.A.; Henrique De Sousa Nunes, G.; Preston, W.; Barbosa De Souza, E.; De Lima Ramos Mariano, R.; Datnoff, L.E.; Araújo Do Nascimento, C.W. Slag-based silicon fertilizer improves the resistance to bacterial fruit blotch and fruit quality of melon grown under field conditions. Crop Prot. 2021, 147, 105460. [Google Scholar] [CrossRef]

- Chen, D.; Meng, Z.W.; Chen, Y.P. Toxicity assessment of molybdenum slag as a mineral fertilizer: A case study with pakchoi (Brassica chinensis L.). Chemosphere 2019, 217, 816–824. [Google Scholar] [CrossRef] [PubMed]

- Pietrini, F.; Iori, V.; Beone, T.; Mirabile, D.; Zacchini, M. Effects of a ladle furnace slag added to soil on morpho-physiological and biochemical parameters of Amaranthus paniculatus L. plants. J. Hazard. Mater. 2017, 329, 339–347. [Google Scholar] [CrossRef]

- Ali, M.A.; Oh, J.H.; Kim, P.J. Evaluation of silicate iron slag amendment on reducing methane emission from flood water rice farming. Agric. Ecosyst. Environ. 2008, 128, 21–26. [Google Scholar] [CrossRef]

- Baciocchi, R.; Costa, G.; Polettini, A.; Pomi, R. Effects of thin-film accelerated carbonation on steel slag leaching. J. Hazard. Mater. 2015, 286, 369–378. [Google Scholar] [CrossRef]

- Ao, M.; Chen, X.; Deng, T.; Sun, S.; Tang, Y.; Morel, J.L.; Qiu, R.; Wang, S. Chromium biogeochemical behaviour in soil-plant systems and remediation strategies: A critical review. J. Hazard. Mater. 2022, 424, 127233. [Google Scholar] [CrossRef]

- Mandiwana, K.L.; Panichev, N.; Kataeva, M.; Siebert, S. The solubility of Cr(III) and Cr(VI) compounds in soil and their availability to plants. J. Hazard. Mater. 2007, 147, 540–545. [Google Scholar] [CrossRef]

- Reijonen, I.; Hartikainen, H. Risk assessment of the utilization of basic oxygen furnace slag (BOFS) as soil liming material: Oxidation risk and the chemical bioavailability of chromium species. Environ. Technol. Innov. 2018, 11, 358–370. [Google Scholar] [CrossRef]

- Arienzo, M.; Adamo, P.; Cozzolino, V. The potential of Lolium perenne for revegetation of contaminated soil from a metallurgical site. Sci. Total Environ. 2004, 319, 13–25. [Google Scholar] [CrossRef]

- Wassie, M.; Zhang, W.; Zhang, Q.; Ji, K.; Cao, L.; Chen, L. Exogenous salicylic acid ameliorates heat stress-induced damages and improves growth and photosynthetic efficiency in alfalfa (Medicago sativa L.). Ecotoxicol. Environ. Saf. 2020, 191, 110206. [Google Scholar] [CrossRef] [PubMed]

- Hattab, S.; Hattab, S.; Boussetta, H.; Banni, M. Influence of nitrate fertilization on Cd uptake and oxidative stress parameters in alfalfa plants cultivated in presence of Cd. J. Soil Sci. Plant Nutr. 2014, 14, 89–99. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Almomin, S.; Al-Shatti, A.; Al-Aqeel, H.; Al-Salameen, F.; Shajan, A.B.; Nair, S.M. Enhancement of heavy metal tolerance and accumulation efficiency by expressing Arabidopsis ATP sulfurylase gene in alfalfa. Int. J. Phytoremediat. 2019, 21, 1112–1121. [Google Scholar] [CrossRef] [PubMed]

- Norini, M.P.; Thouin, H.; Miard, F.; Battaglia-Brunet, F.; Gautret, P.; Guegan, R.; Le Forestier, L.; Morabito, D.; Bourgerie, S.; Motelica-Heino, M. Mobility of Pb, Zn, Ba, As and Cd toward soil pore water and plants (willow and ryegrass) from a mine soil amended with biochar. J. Environ. Manag. 2019, 232, 117–130. [Google Scholar] [CrossRef]

- Kim, E.; Spooren, J.; Broos, K.; Horckmans, L.; Quaghebeur, M.; Vrancken, K.C. Selective recovery of Cr from stainless steel slag by alkaline roasting followed by water leaching. Hydrometallurgy 2015, 158, 139–148. [Google Scholar] [CrossRef]

- Adegoloye, G.; Beaucour, A.L.; Ortola, S.; Noumowe, A. Mineralogical composition of EAF slag and stabilised AOD slag aggregates and dimensional stability of slag aggregate concretes. Constr. Build Mater. 2016, 115, 171–178. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Y.L.; Qu, Z.M. Physicochemical property and chromium leaching behavior in different environments of glass ceramics prepared from AOD stainless steel slag. J. Alloys Compd. 2019, 805, 1106–1116. [Google Scholar] [CrossRef]

- Samada, Y.; Miki, T.; Hino, M. Prevention of chromium elution from stainless steel slag into seawater. ISIJ Int. 2011, 51, 728–732. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Li, Y.; Li, H.; Cheng, F. Evaluating heavy metal accumulation and potential risks in soil-plant systems applied with magnesium slag-based fertilizer. Chemosphere 2018, 197, 382–388. [Google Scholar] [CrossRef]

- Cen, R.; Feng, W.; Yang, F.; Wu, W.; Liao, H.; Qu, Z. Effect mechanism of biochar application on soil structure and organic matter in semi-arid areas. J. Environ. Manag. 2021, 286, 112198. [Google Scholar] [CrossRef]

- Wang, C.; Liu, J.; Shen, J.; Chen, D.; Li, Y.; Jiang, B.; Wu, J. Effects of biochar amendment on net greenhouse gas emissions and soil fertility in a double rice cropping system: A 4-year field experiment. Agric. Ecosyst. Environ. 2018, 262, 83–96. [Google Scholar] [CrossRef]

- Wang, F.; Wang, X.; Song, N. Biochar and vermicompost improve the soil properties and the yield and quality of cucumber (Cucumis sativus L.) grown in plastic shed soil continuously cropped for different years. Agric. Ecosyst. Environ. 2021, 315, 107425. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, T.; Guo, J.; Tan, Z.; Dong, W.; Wang, H. Changes in the understory diversity of secondary Pinus tabulaeformis forests are the result of stand density and soil properties. Glob. Ecol. Conserv. 2021, 28, e01628. [Google Scholar] [CrossRef]

- GB 9836-1988 Method for Determination of Total Potassium in Soils; Standardization Administration of the People’s Republic of China: Beijing, China, 1988.

- Chen, K.; Chen, L.; Fan, J.; Fu, J. Alleviation of heat damage to photosystem II by nitric oxide in tall fescue. Photosynth. Res. 2013, 116, 21–31. [Google Scholar] [CrossRef]

- De Windt, L.; Chaurand, P.; Rose, J. Kinetics of steel slag leaching: Batch tests and modeling. Waste Manag. 2011, 31, 225–235. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Li, J.; Wang, Z.; Zeng, Y.; Ren, Q. Long-term leaching characterization and geochemical modeling of chromium released from AOD slag. Environ. Sci. Pollut. Res. 2020, 27, 921–929. [Google Scholar] [CrossRef]

- Li, J.; Li, L.; Xia, S.; Zhang, R.; Zhang, R.; Chen, P.; Pan, J.; Liu, Y. K fertilizer alleviates N2O emissions by regulating the abundance of nitrifying and denitrifying microbial communities in the soil-plant system. J. Environ. Manag. 2021, 291, 112579. [Google Scholar] [CrossRef]

- Trap, J.; Blanchart, E.; Ratsiatosika, O.; Razafindrakoto, M.; Becquer, T.; Andriamananjara, A.; Morel, C. Effects of the earthworm Pontoscolex corethrurus on rice P nutrition and plant-available soil P in a tropical Ferralsol. Appl. Soil Ecol. 2021, 160, 103867. [Google Scholar] [CrossRef]

- Tunesi, S.; Poggi, V.; Gessa, C. Phosphate adsorption and precipitation in calcareous soils: The role of calcium ions in solution and carbonate minerals. Nutr. Cycl. Agroecosyst. 1999, 53, 219–227. [Google Scholar] [CrossRef]

- Fredeen, A.L.; Rao, I.M.; Terry, N. Influence of Phosphorus Nutrition on Growth and Carbon Partitioning in Glycine max. Plant Physiol. 1989, 89, 225–230. [Google Scholar] [CrossRef] [Green Version]

- Marschner, P. Marschner’s Mineral Nutrition of Higher Plants; Elsevier Ltd.: Waltham, MA, USA, 2012. [Google Scholar]

- Zhang, W.; Zwiazek, J.J. Responses of Reclamation Plants to High Root Zone pH: Effects of Phosphorus and Calcium Availability. J. Environ. Qual. 2016, 45, 1652–1662. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Xu, F.; Zwiazek, J.J. Responses of jack pine (Pinus banksiana) seedlings to root zone pH and calcium. Environ. Exp. Bot. 2015, 111, 32–41. [Google Scholar] [CrossRef]

- Gahoonia, T.S.; Care, D.; Nielsen, N.E. Root hairs and phosphorous acquisition of wheat and barely cultivars. Plant Soil 1997, 191, 181–188. [Google Scholar] [CrossRef]

- Hannaway, D.; Fransen, S.; Cropper, J. Perennial ryegrass (Lolium perenne L.). In A Pacifific Northwest Extension Publication; Oregon State University: Corvallis, OR, USA, 1999; Volume PNW 503. [Google Scholar]

- Peters, J.B.; Kelling, K.A.; Speth, P.E.; Offer, S.M. Alfalfa Yield and Nutrient Uptake as Affected by pH and Applied K. Commun. Soil Sci. Plant Anal. 2005, 36, 583–596. [Google Scholar] [CrossRef]

- Dalcorso, G.; Manara, A.; Piasentin, S.; Furini, A. Nutrient metal elements in plants. Metallomics 2014, 6, 1770–1788. [Google Scholar] [CrossRef] [PubMed]

- Mallick, S.; Sinam, G.; Kumar Mishra, R.; Sinha, S. Interactive effects of Cr and Fe treatments on plants growth, nutrition and oxidative status in Zea mays L. Ecotoxicol. Environ. Saf. 2010, 73, 987–995. [Google Scholar] [CrossRef]

- Zhang, W.; Calvo-Polanco, M.; Chen, Z.C.; Zwiazek, J.J. Growth and physiological responses of trembling aspen (Populus tremuloides), white spruce (Picea glauca) and tamarack (Larix laricina) seedlings to root zone pH. Plant Soil 2013, 373, 775–786. [Google Scholar] [CrossRef]

- Sytar, O.; Kumar, A.; Latowski, D.; Kuczynska, P.; Strzałka, K.; Prasad, M.N.V. Heavy metal-induced oxidative damage, defense reactions, and detoxification mechanisms in plants. Acta Physiol. Plant. 2012, 35, 985–999. [Google Scholar] [CrossRef]

- Bhaduri, A.M.; Fulekar, M.H. Antioxidant enzyme responses of plants to heavy metal stress. Rev. Environ. Sci. Bio/Technol. 2011, 11, 55–69. [Google Scholar] [CrossRef]

- GB 13078-2017 Hygienical Standard for Feeds; Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- Liu, B.; Li, J.; Zeng, Y.; Wang, Z. Toxicity assessment and geochemical model of chromium leaching from AOD slag. Chemosphere 2016, 144, 2052–2057. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).