Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador

Abstract

:1. Introduction

2. Sun-Tracking System

- Based on drives

- A passive sun-tracking system uses the pressure difference of special liquids or gases created by the thermal differences of the shaded and illuminated sides of the tracking system to move solar panel systems towards the sun position. These do not need an additional power supply and are rarely used since their accuracy is relatively low.

- An active sun-tracking system uses electrical drivers and mechanical assemblies to operate, such as a microprocessor, an electric motor, gearboxes, and sensors.

- Based on the degree of freedom

- Fixed PV systems are the most common systems mounted directly on the roofs of buildings or houses, most of the time at the same slope as the roof and south-oriented, inclined at a certain angle, depending on the latitude and longitude.

- Single-axis tracking PV systems have only one degree of freedom, which serves as an axis rotation. These systems are divided into three different types: (1) horizontal single-axis tracking system (HSAT); (2) vertical single-axis tracking system (VSAT); and (3) tilted single-axis tracking system (TSAT).

- Dual-axis tracking PV systems have two degrees of freedom, which serve as axes of the simultaneous rotation left–right (azimuth angle) and up–down (zenith angle) directions. Two common types are the azimuth–altitude tracking system (AADAT) and tip-til tracking system (TTDAT).

- Based on strategies

- The open-loop control system uses a mathematical algorithm to determine the precise position of the sun; the use of this system implies not having any control to correct the errors that could occur during the tracking process.

- The closed-loop control system is based on a light intensity sensor feedback control system; through an algorithm loaded in a microprocessor, the position of the sun is evaluated from the data of the sensors to move the axes of the solar system towards its position.

3. System Realization and Experimentation

3.1. Research Location

3.2. Proposed System

3.2.1. Static PV System

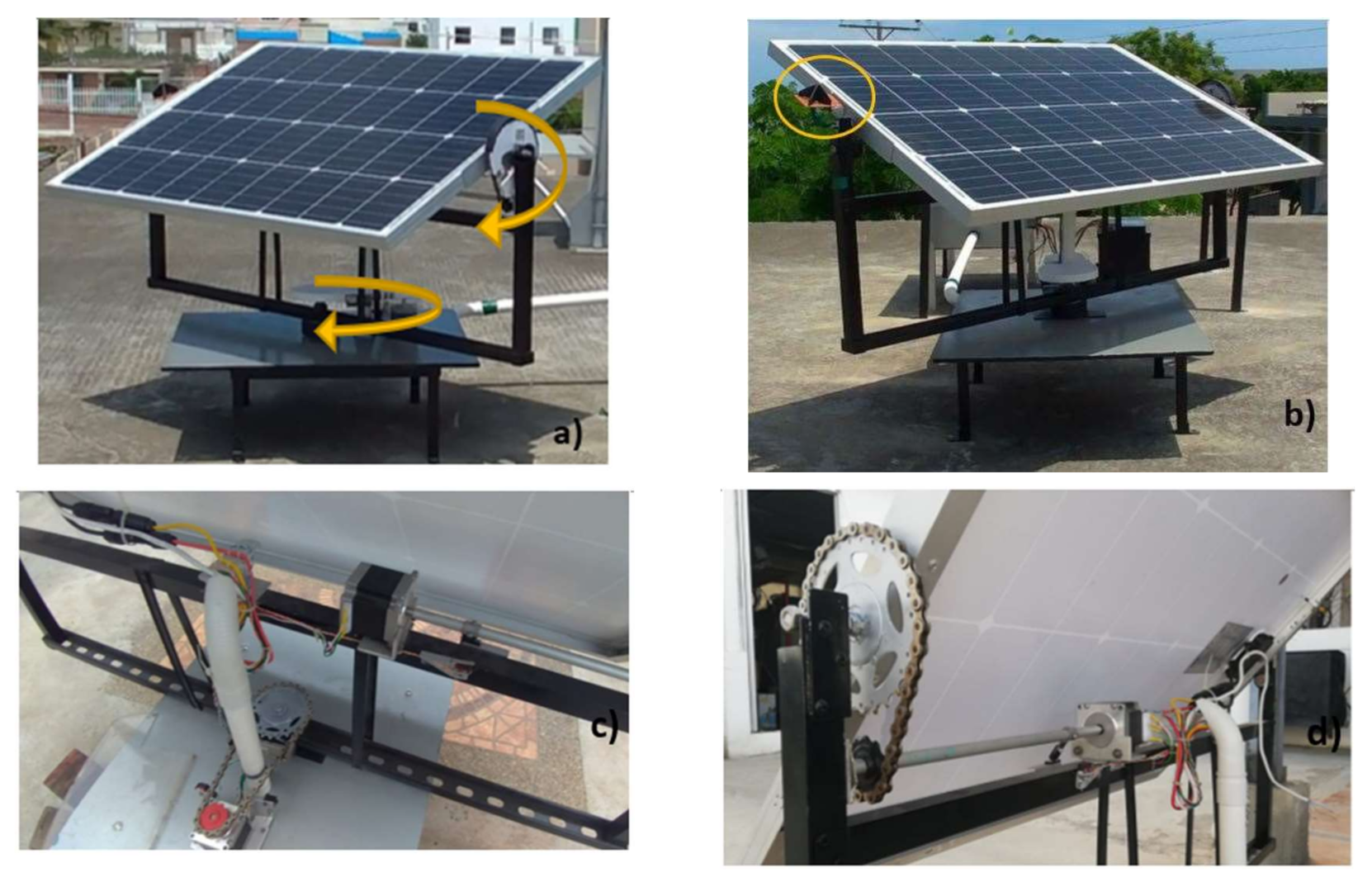

3.2.2. Dual-Axis Tracking PV System

3.2.3. Light Dependent Resistors Sensing System

3.2.4. Voltage, Current, and Temperature Sensing System

4. Results and Discussion

Systems Comparison Performance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Belyakov, N. Sustainable Power Generation: Current Status, Future Challenges, and Perspectives; Academic Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Jean, J.; Brown, P.R.; Jaffe, R.L.; Buonassisi, T.; Bulović, V. Pathways for solar photovoltaics. Energy Environ. Sci. 2015, 8, 1200–1219. [Google Scholar] [CrossRef]

- SPE. Solar Power Europe. Global Market Outlook for Solar Power 2017–2021. 2017. Available online: https://static1.squarespace.com/static/597512eb579fb3d3de0207aa/t/5980696c46c3c486918975af/1501587836470/Global+market+outlook+2017.pdf (accessed on 20 November 2017).

- BNEF. Bloomberg New Energy Finance. Investing Trillions in Electricity’s Sunny Future. 2017. Available online: https://about.bnef.com/blog/investing-trillions-electricitys-sunny-future/ (accessed on 18 November 2017).

- NREL. National Renewable Energy Laboratory—National Center for Photovoltaics. Research Cell Efficiency Records. 2021. Available online: https://energy.gov/eere/solar/photovoltaics-research-and-development (accessed on 5 July 2021).

- Vieira, R.G.; Guerra, F.K.O.M.V.; Vale, M.R.B.G.; Araújo, M.M. Comparative performance analysis between static solar panels and single-axis tracking system on a hot climate region near to the equator. Renew. Sustain. Energy Rev. 2016, 64, 672–681. [Google Scholar] [CrossRef]

- Malge, S.; Bhole, K.; Narkhede, R. Designing of dual-axis Solar tracking system with remote monitoring. In Proceedings of the 2015 International Conference on Industrial Instrumentation and Control (ICIC), Pune, India, 28–30 May 2015; pp. 1524–1527. [Google Scholar] [CrossRef]

- Rus-Casas, C.; Aguilar, J.D.; Rodrigo, P.; Almonacid, F.; Pérez-Higueras, P.J. Classification of methods for annual energy harvesting calculations of photovoltaic generators. Energy Convers. Manag. 2014, 78, 527–536. [Google Scholar] [CrossRef]

- Lee, C.Y.; Chou, P.C.; Chiang, C.M.; Lin, C.F. Sun Tracking Systems: A Review. Sensors 2009, 9, 3875–3890. [Google Scholar] [CrossRef]

- Racharla, S.; Rajan, K. Solar tracking system—A review. Int. J. Sustain. Eng. 2017, 10, 72–81. [Google Scholar] [CrossRef]

- Chowdhury, M.E.H.; Khandakar, A.; Hossain, B.; Abouhasera, R. A Low-Cost Closed-Loop Solar Tracking System Based on the Sun Position Algorithm. J. Sens. 2019, 2019, 3681031. [Google Scholar] [CrossRef] [Green Version]

- Ismail, M.A.; Ramanathan, K.A.; Idris, M.H.; Ananda-Rao, K.; Mazlan, M.; Fairuz, N. Improving the performance of solar panels by the used of dual axis solar tracking system with mirror reflection. J. Phys. Conf. Ser. 2020, 1432, 012060. [Google Scholar] [CrossRef]

- Sharma, P.; Malhotra, N. Solar Tracking System Using Microcontroller. no. Iconce. 2014, pp. 77–79. Available online: www.theijes.com (accessed on 20 September 2021).

- Fotopoulou, M.; Rakopoulos, D.; Blanas, O. Day Ahead Optimal Dispatch Schedule in a Smart Grid Containing Distributed Energy Resources and Electric Vehicles. Sensors 2021, 21, 7295. [Google Scholar] [CrossRef] [PubMed]

- Hohne, P.A.; Kusakana, K.; Numbi, B.P. Model validation and economic dispatch of a dual axis pv tracking system connected to energy storage with grid connection: A case of a healthcare institution in South Africa. J. Energy Storage 2020, 32, 101986. [Google Scholar] [CrossRef]

- Vaca-Jiménez, S.; Morales, C.; Ordóñez, F. Improvements of photovoltaic systems by using solar tracking in equatorial regions. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 November 2017; pp. 2352–2357. [Google Scholar] [CrossRef]

- Ordonez, F.; Morales, C.; Lopez-Villada, J.; Vaca, S. Assessment of the Energy Gain of Photovoltaic Systems by Using Solar Tracking in Equatorial Regions. J. Sol. Energy Eng. 2018, 140, 031003. [Google Scholar] [CrossRef]

- GAISMA. Sun Path Diagram—Manta, Ecuador. 2021. Available online: https://www.gaisma.com/en/location/manta.html (accessed on 5 October 2021).

- Seme, S.; Štumberger, B.; Hadžiselimović, M.; Sredenšek, K. Solar Photovoltaic Tracking Systems for Electricity Generation: A Review. Energies 2020, 13, 4224. [Google Scholar] [CrossRef]

- Nayak, S.R.; Pradhan, C.R. Solar Tracking Application. IOSR J. Eng. 2012, 2, 1278–1281. [Google Scholar] [CrossRef]

- CLIMATE-DATA.ORG. Clima Manta Ecuador. 2021. Available online: https://es.climate-data.org/america-del-sur/ecuador/provincia-de-manabi/manta-764127/ (accessed on 6 October 2021).

- CONELEC. Consejo Nacional de Electricidad. Atlas Solar del Ecuador. 2008. Available online: http://biblioteca.olade.org/opac-tmpl/Documentos/cg00041.pdf (accessed on 6 October 2021).

- Ponce-Jara, M.; Talavera, A.; Velásquez, C.; Peralta, D.T. Prediction of Solar Radiation Using Neural Networks Forecasting; Springer: Berlin/Heidelberg, Germany, 2021; pp. 181–194. [Google Scholar]

- PROSTAR. PMS120W Energía del sol Placas Solares 120w 12v Monocristalino. 2021. Available online: https://www.prostarsolar.net/es/producto-detalles/prostar-pms120w-energia-del-sol-placas-solares-120w-12v-monocristalino (accessed on 11 September 2021).

- NEMA. Stepper Motor Nema 23. 2021. Available online: https://components101.com/sites/default/files/component_datasheet/NEMA23 Stepper Motor.pdf (accessed on 8 October 2021).

- SOROTEC. Stepper Motor Driver TB6600. 2021. Available online: https://components101.com/sites/default/files/component_datasheet/TB6600-Datasheet.pdf (accessed on 8 October 2021).

- Mustafa, F.I.; Shakir, S.; Mustafa, F.F.; Naiyf, A.T. Simple design and implementation of solar tracking system two axis with four sensors for Baghdad city. In Proceedings of the 2018 9th International Renewable Energy Congress (IREC), Hammamet, Tunisia, 20–22 March 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Adeeb, J.; Farhan, A.; Al-Salaymeh, A. Temperature effect on performance of different solar cell technologies. J. Ecol. Eng. 2019, 20, 249–254. [Google Scholar] [CrossRef]

- Allegro. ACS712 Current Sensor. 2021. Available online: https://pdf1.alldatasheet.com/datasheet-pdf/view/168326/ALLEGRO/ACS712.html (accessed on 10 October 2021).

- TEXAS INSTRUMENTS. LM35 Precision Centigrade Temperature Sensors. 2021. Available online: https://pdf1.alldatasheet.com/datasheet-pdf/view/517588/TI1/LM35.html (accessed on 10 October 2021).

- Altronics. Voltage Sensor for Arduino FZ0430. 2021. Available online: https://altronics.cl/sensor-voltaje-fz0430 (accessed on 10 October 2021).

| Title | Type | Country | Findings |

|---|---|---|---|

| Comparative performance analysis between static solar panels and single-axis tracking system in a hot climate region near to the equator [6] | Experimental | Brazil | The efficiency of a single-axis tracking PV system proved to be, on average, 11% higher than a fixed PV system. In this study, the consumption of the solar tracker was not taken into consideration. |

| Improvements in photovoltaic systems using solar tracking in equatorial regions [17] | Simulation | Ecuador | Comparative simulations between the fixed PV system and the single-axis and dual-axis tracking PV system showed efficiency improvements of 27.3% and 31.2%, respectively. Given that the difference is only 4%, single-axis tracking PV systems are recommended. |

| Assessment of the energy gain of photovoltaic systems using solar tracking in equatorial regions [18] | Simulation | Ecuador | Comparative simulations between the fixed PV system and the single-axis and dual-axis tracking PV system showed efficiency improvements of 30% and 34.62%, respectively. |

| Maximum Power (Pmax) | 120 Wp |

| Maximum Power Current (Imp) | 6.67 A |

| Maximum Power Voltage (Vmp) | 18.0 V |

| Short-Circuit Current (Isc) | 7.20 A |

| Open-Circuit Voltage (Voc) | 22.5 V |

| Cell Operating Temperature | −40 °C to +85 °C |

| STC Efficiency | 18.46% |

| Dimensions | 670 × 970 × 30 mm |

| Image | Circuit Configuration | Characteristics |

|---|---|---|

|  | FZ0430 voltage sensor [29]

|

|  | ACS712ELC current sensor [30]

|

|  | LM35 temp. sensor [30]

|

| Dual-Axis Tracking PV System | Static PV System | ||||||

|---|---|---|---|---|---|---|---|

| Day | Global Radiation (W/m2) | Gain (%) | State of the Sky | Energy (Wh) | Temperature (°C) | Energy (Wh) | Temperature (°C) |

| 1 | 182.82 | 31.00 | cloudy | 259.26 | 25.61 | 197.91 | 24.24 |

| 2 | 199.45 | 26.58 | cloudy | 291.39 | 27.16 | 230.20 | 26.00 |

| 3 | 346.61 | 42.68 | partially cloudy | 473.46 | 28.62 | 331.83 | 27.29 |

| 4 | 223.75 | 38.96 | cloudy | 138.99 | 23.80 | 100.02 | 23.19 |

| 5 | 418.8 | 16.57 | sunny | 613.95 | 28.62 | 526.69 | 26.83 |

| 6 | 393.95 | 22.88 | partially cloudy | 476.70 | 23.83 | 387.93 | 26.61 |

| 7 | 318.1 | 8.74 | partially cloudy | 329.30 | 26.72 | 302.84 | 25.00 |

| 8 | 303.47 | 11.44 | partially cloudy | 302.85 | 29.15 | 271.77 | 25.31 |

| 9 | 412.49 | 23.61 | sunny | 720.99 | 28.50 | 583.28 | 26.94 |

| 10 | 302.01 | 19.04 | partially cloudy | 456.08 | 25.96 | 383.13 | 25.75 |

| 11 | 358.45 | 12.20 | partially cloudy | 508.,48 | 29.71 | 453.20 | 24.47 |

| 12 | 402.93 | 13.03 | sunny | 687.85 | 27.00 | 608.53 | 25.54 |

| 13 | 235.61 | 13.88 | cloudy | 371.70 | 24.98 | 326.37 | 23.6 |

| 14 | 300.41 | 16.20 | partially cloudy | 493.03 | 27.91 | 424.30 | 26.61 |

| 15 | 293.18 | 21.45 | partially cloudy | 414.59 | 27.78 | 341.38 | 26.48 |

| 16 | 405.69 | 14.70 | sunny | 703.30 | 29.25 | 613.18 | 27.95 |

| 17 | 287.96 | 13.98 | partially cloudy | 488.63 | 26.77 | 428.68 | 25.36 |

| 18 | 524.89 | 15.87 | sunny | 765.09 | 29.25 | 660.31 | 27.94 |

| 19 | 396.72 | 22.55 | partially cloudy | 512.40 | 27.98 | 418.12 | 26.68 |

| 20 | 494.42 | 11.11 | sunny | 511.35 | 29.68 | 460.24 | 28.43 |

| 21 | 391.38 | 15.46 | partially cloudy | 318.99 | 27.79 | 276.27 | 26.56 |

| Average | 342.52 | 19.62 | --- | 468.49 | 27.43 | 396.48 | 26.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ponce-Jara, M.A.; Velásquez-Figueroa, C.; Reyes-Mero, M.; Rus-Casas, C. Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador. Sustainability 2022, 14, 1696. https://doi.org/10.3390/su14031696

Ponce-Jara MA, Velásquez-Figueroa C, Reyes-Mero M, Rus-Casas C. Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador. Sustainability. 2022; 14(3):1696. https://doi.org/10.3390/su14031696

Chicago/Turabian StylePonce-Jara, Marcos A., Carlos Velásquez-Figueroa, María Reyes-Mero, and Catalina Rus-Casas. 2022. "Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador" Sustainability 14, no. 3: 1696. https://doi.org/10.3390/su14031696

APA StylePonce-Jara, M. A., Velásquez-Figueroa, C., Reyes-Mero, M., & Rus-Casas, C. (2022). Performance Comparison between Fixed and Dual-Axis Sun-Tracking Photovoltaic Panels with an IoT Monitoring System in the Coastal Region of Ecuador. Sustainability, 14(3), 1696. https://doi.org/10.3390/su14031696