Agricultural Biogas Production—Climate and Environmental Impacts

Abstract

:1. Introduction

2. Materials and Methods

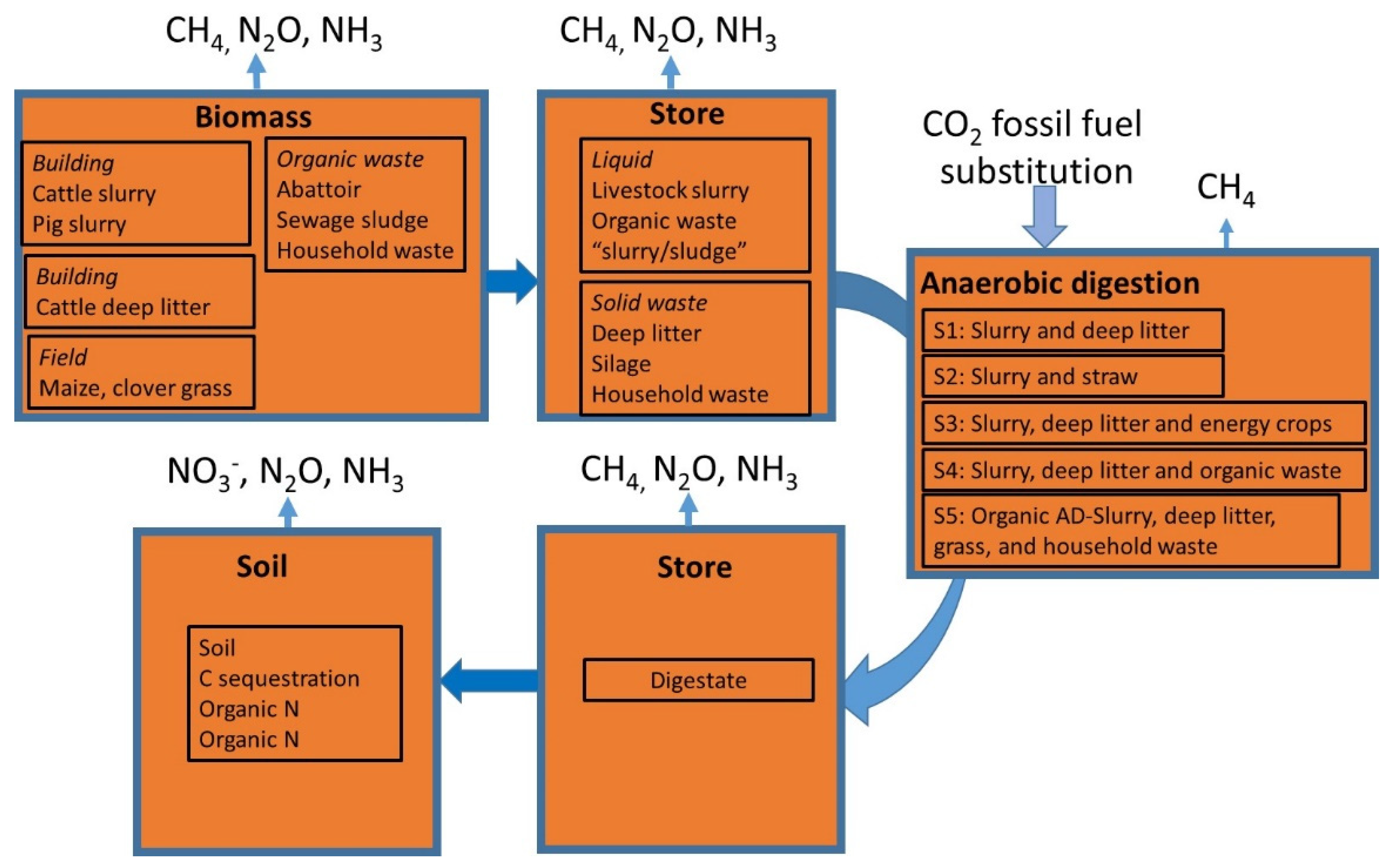

2.1. Slurry and Biowaste Management

2.2. Calculations

2.2.1. Biogas Production

2.2.2. Energy Production and Consumption

2.2.3. Methane Emission from Slurry and Digestate

2.2.4. Methane Emission from Solid Manure

2.2.5. Nitrous Oxide Emission

2.2.6. Ammonia Emission

2.2.7. Crop Production and Nitrate Leaching

2.2.8. Soil Carbon Storage

3. Results

3.1. Biogas Production

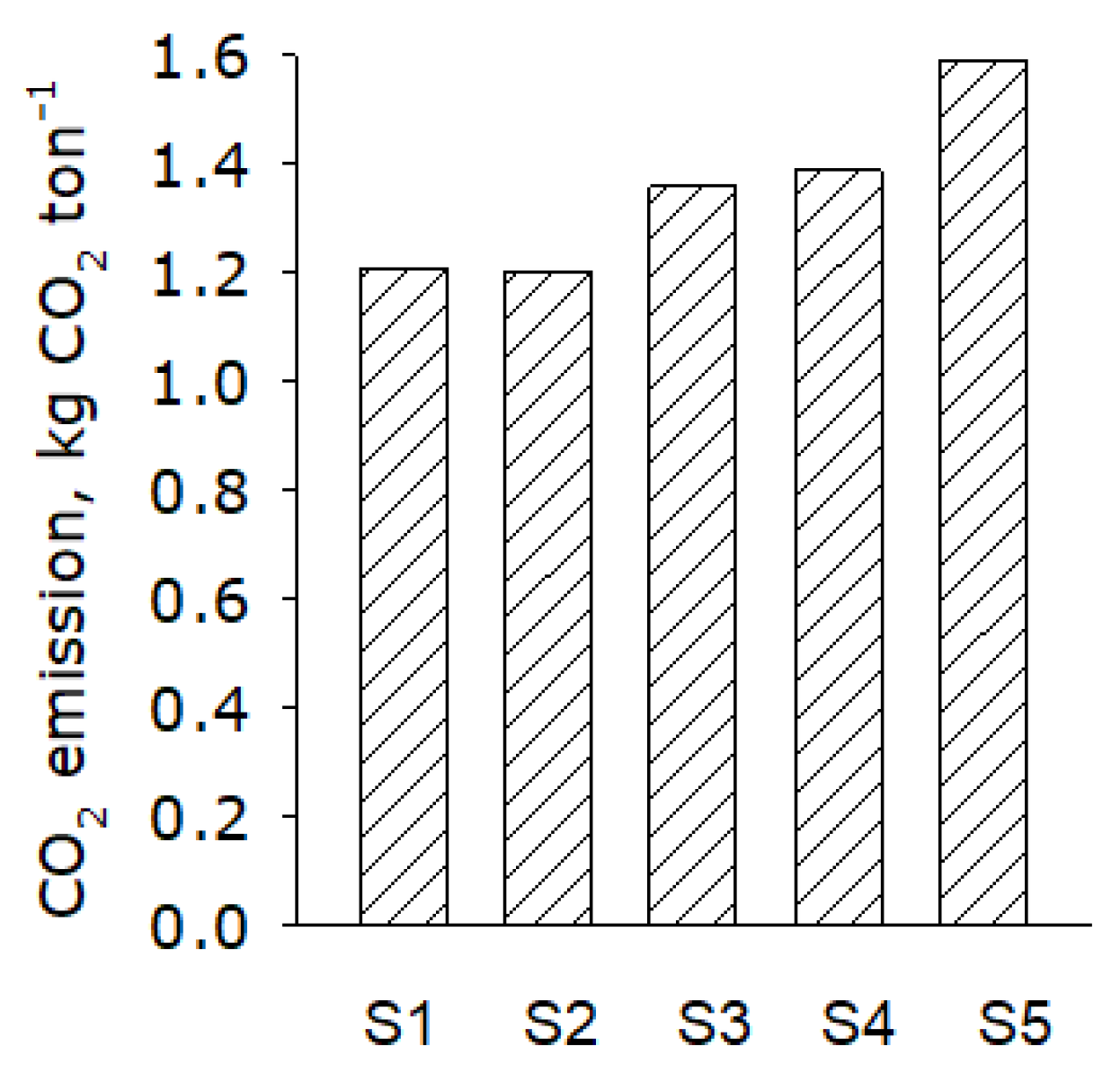

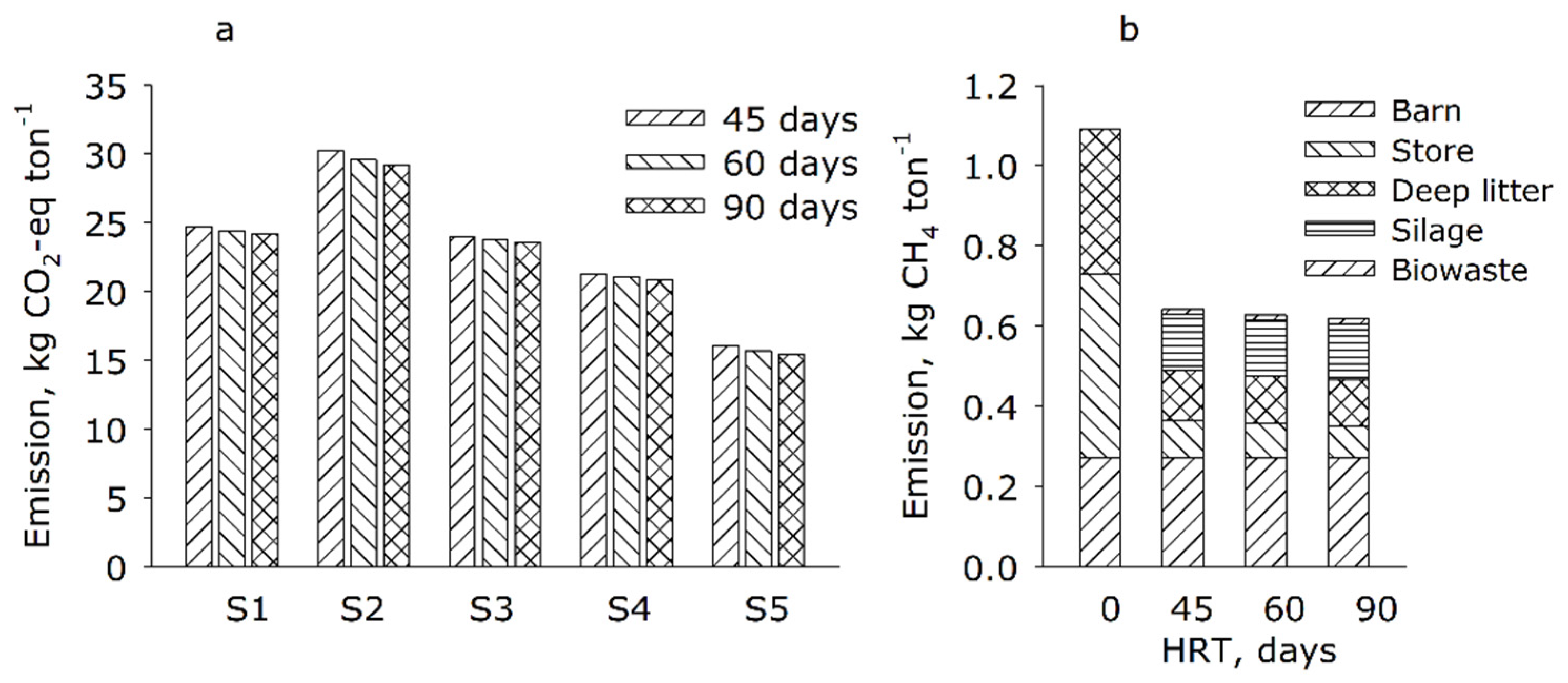

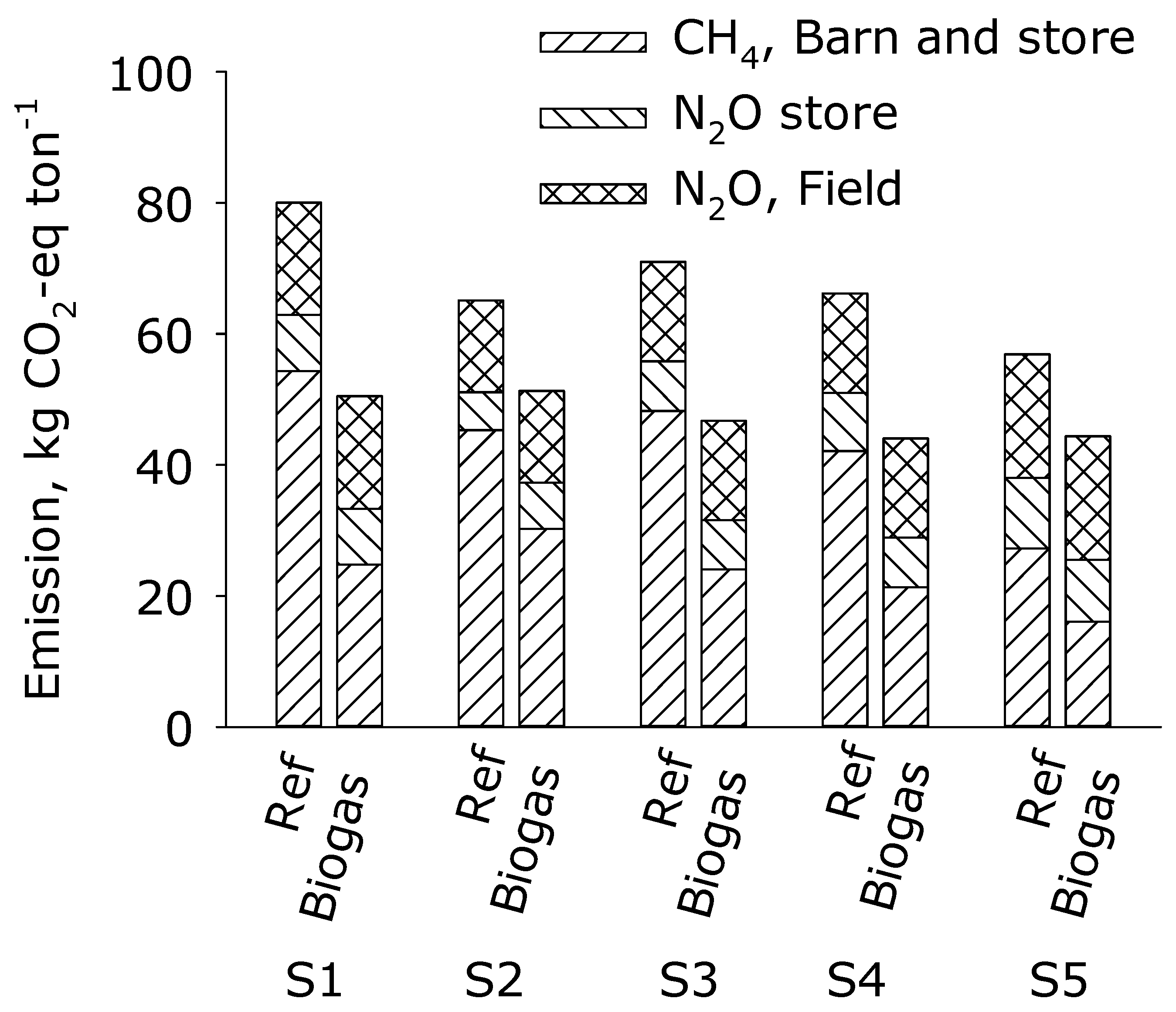

3.2. Methane Emissions

3.3. Ammonia Emission

3.4. Crop Production and Nitrate Leaching

3.5. Soil Carbon Storage

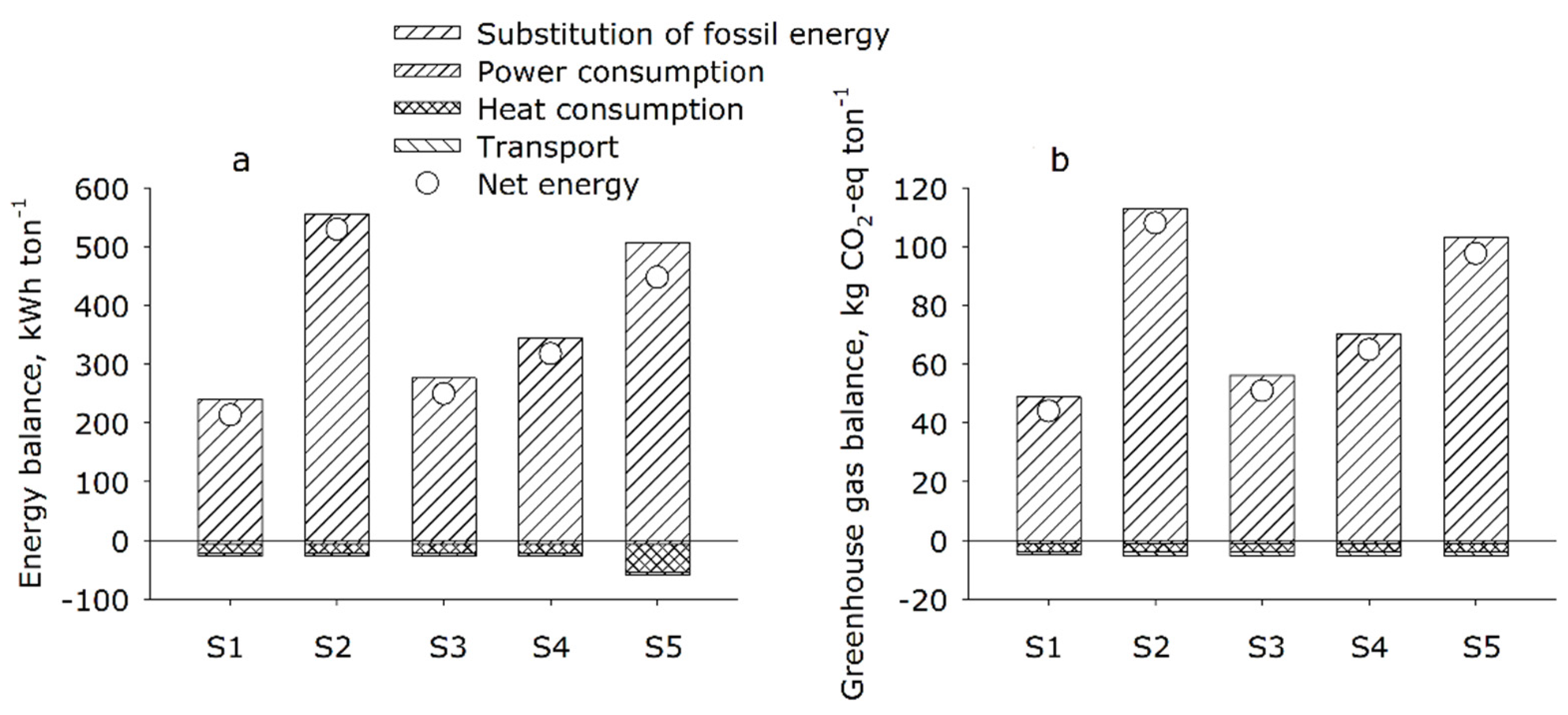

3.6. GHG Emissions

4. Discussion

4.1. Biomass Sources for Biogas

4.2. Biogas Plant Configuration

4.3. Nitrogen Losses

4.4. Uncertainties

- -

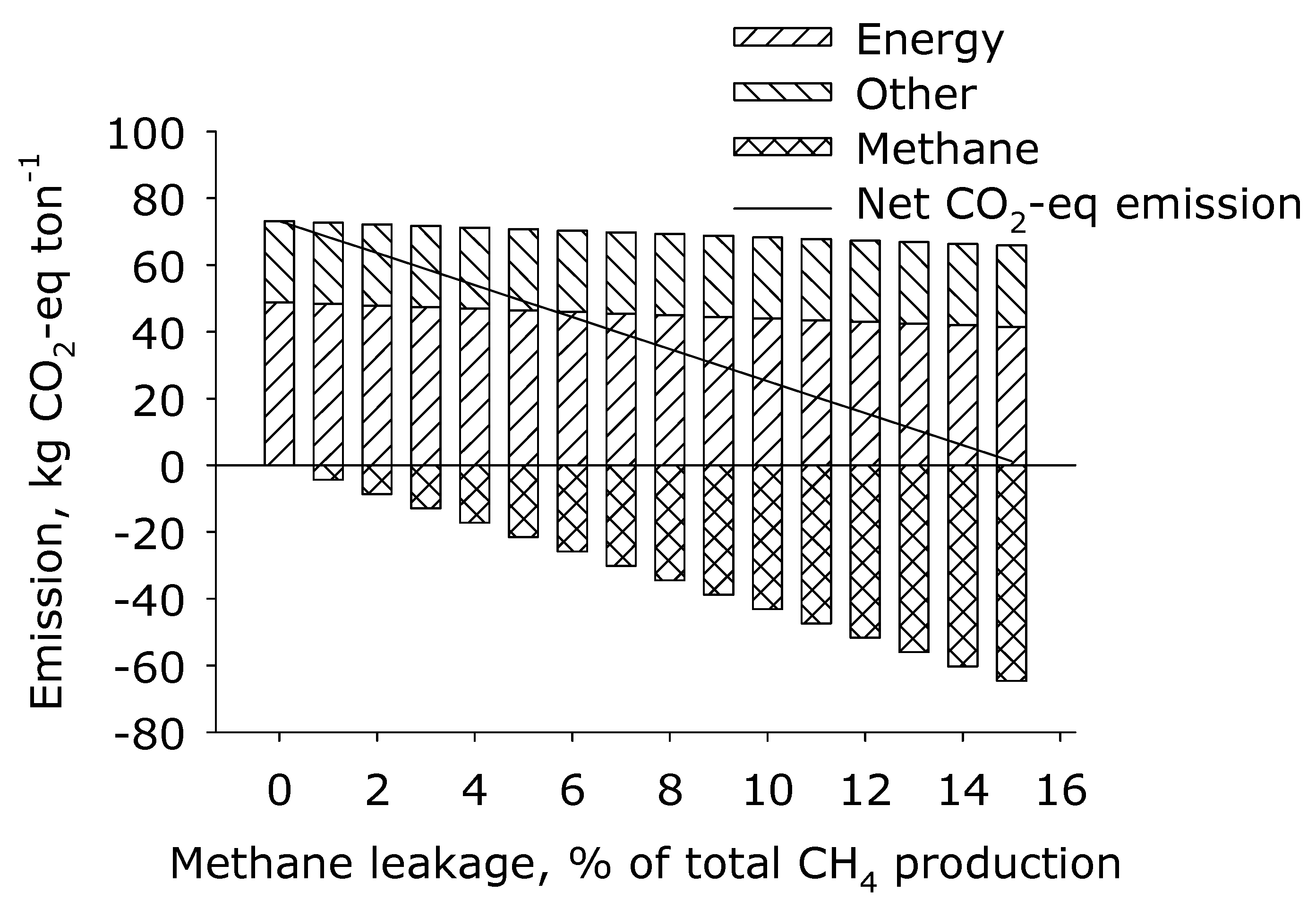

- CH4 leaks from the biogas installation should be minimized.

- -

- Digestate storage should be covered, and low-NH3-emission technology should be used for field application.

- -

- Heat exchangers should be employed to cool down the digestate to ambient temperature before storage to improve the energy balance and reduce GHG and NH3 emissions.

5. Conclusions

- (1)

- The scenarios investigated resulted in GHG mitigation ranging from 65 to 105 kg CO2-eq ton−1 biomass. Reductions per ton of biomass were greatest when straw or grass–clover was used for codigestion, whereas reductions per unit energy produced were highest with deep litter and deep litter plus maize silage.

- (2)

- The ammonia emission potential of digestate applied in the field was higher than that from untreated cattle and pig slurry because of digestates’ higher pH, resulting in an increase in ammonia emission of 0.14 to 0.3 kg NH3-N ton −1 biomass. The use of low-emissions application technology for a larger share of the digestate should limit these higher emissions.

- (3)

- All scenarios reduced nitrate leaching (0.04 to 0.45 kg NO3-N ton−1 biomass). However, introducing maize silage almost eliminated this reduction.

- (4)

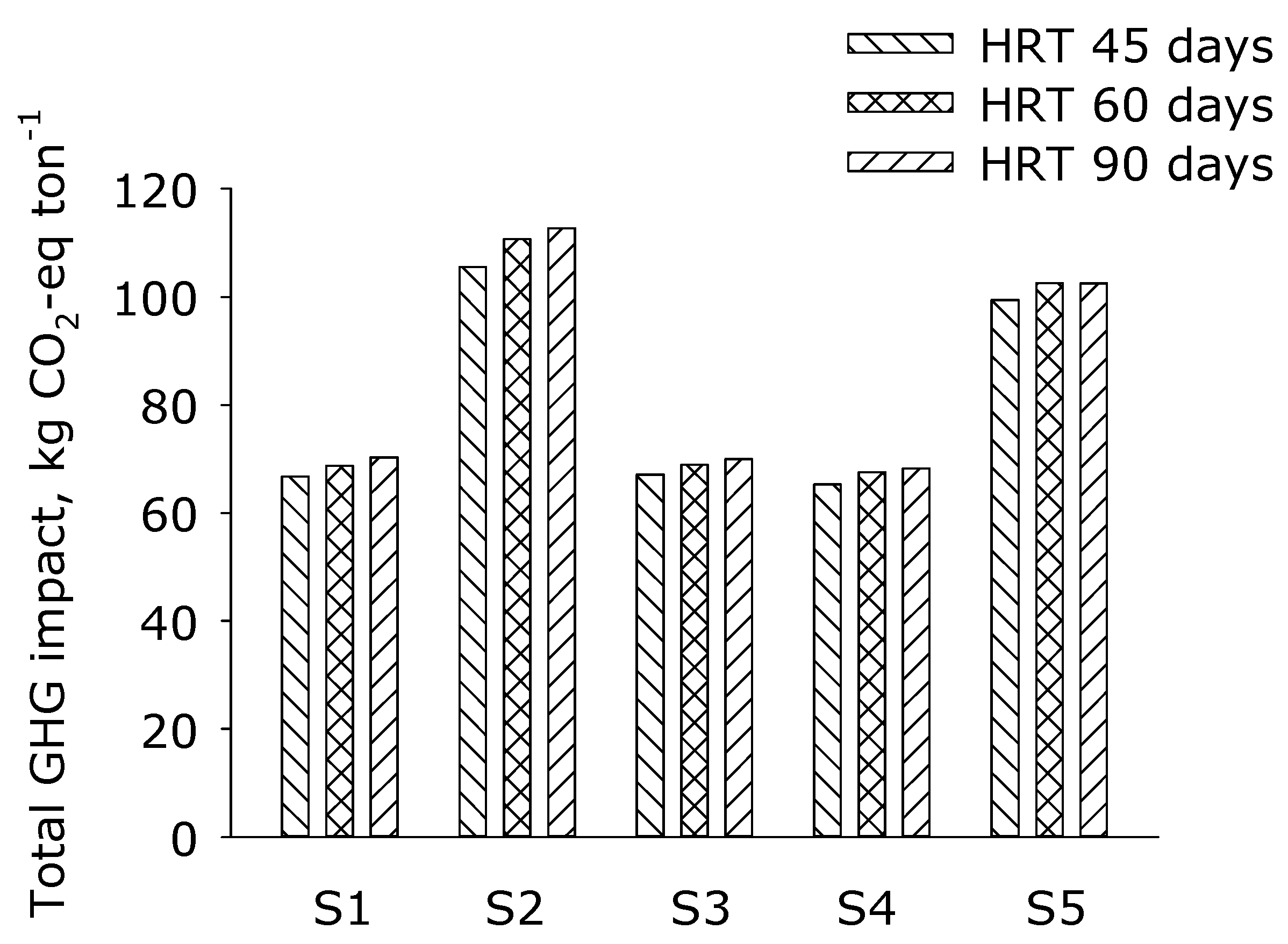

- Increasing the hydraulic retention times led to higher climate impact via increased energy production and lower amounts of volatile solids available for degradation and subsequent CH4 emission during digestate storage.

- (5)

- Methane leakages can have a significant effect on the total climate impact, with about 7% of the positive climate impact being lost for each percentage point of leakage in a manure-based biogas scenario.

- (6)

- The methodology used predicted significant reductions in CH4 emissions but assumed there was no reduction in direct emissions of N2O from digestates, which is not always true. Furthermore, iLUC, which was ignored which for bioenergy use, may have a negative impact on the GHG balance.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Owen, J.J.; Silver, W.L. Greenhouse gas emissions from dairy manure management: A review of field-based studies. Glob. Chang. Biol. 2014, 21, 550–565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olesen, J.E.; Møller, H.B.; Petersen, S.O.; Sørensen, P.; Nyord, T.; Sommer, S.G. Sustainable Biogas—Climate and Environmental Impacts of Biogas Production; DCA report nr. 181; Aarhus Universitet, DCA—Danish Centre for Food and Agriculture: Aarhus, Denmark, 2020; p. 85. Available online: https://dcapub.au.dk/djfpdf/DCArapport181.pdf (accessed on 1 January 2021).

- Venterea, R.T.; Halvorson, A.D.; Kitchen, N.; Liebig, M.A.; Cavigelli, M.A.; Del Grosso, S.J.; Motavalli, P.P.; Nelson, K.A.; Spokas, K.; Singh, B.P.; et al. Challenges and opportunities for mitigating nitrous oxide emissions from fertilized cropping systems. Front. Ecol. Environ. 2012, 10, 562–570. [Google Scholar] [CrossRef]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas In-ventories, Prepared by the National Greenhouse Gas Inventories Programme; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; IGES: Yokohama, Japan, 2006; Available online: www.ipcc-nggip.iges.or.jp/support/Primer_2006GLs.pdf (accessed on 1 January 2010).

- Yusuf, R.O.; Noor, Z.Z.; Abba, A.H.; Hassan, M.A.A.; Din, M.F.M. Methane emission by sectors: A comprehensive review of emission sources and mitigation methods. Renew. Sustain. Energy Rev. 2012, 16, 5059–5070. [Google Scholar] [CrossRef]

- Anonymous. Basisfremskrivning 2020—Danmarks Klima- og Energifremskrivning; Energistyrelsen: København, Denmark, 2020; Available online: https://ens.dk/sites/ens.dk/files/Basisfremskrivning/basisfremskrivning_2020-webtilg.pdf (accessed on 14 March 2021).

- EU Commission. 2030 Climate Target Plan. EU climate action and the European Green Deal. 2020. Available online: https://ec.europa.eu/clima/policies/eu-climate-action/2030_ctp (accessed on 14 March 2021).

- Eriksen, J.; Thomsen, I.K.; Hoffmann, C.C.; Hasler, B.; Jacobsen, B.H. Virkemidler Til Reduktion af Kvælstofbelastningen af Bandmiljøet; DCA rapport nr 174; Aarhus Universitet: Aarhus, Denmark, 2020; p. 452. [Google Scholar]

- Sommer, S.; Petersen, S.; Møller, H. Algorithms for calculating methane and nitrous oxide emissions from manure management. Nutr. Cycl. Agroecosyst. 2004, 69, 143–154. [Google Scholar] [CrossRef]

- Olesen, J.E.; Schelde, K.; Weiske, A.; Weisbjerg, M.; Asman, W.; Djurhuus, J. Modelling greenhouse gas emissions from European conventional and organic dairy farms. Agric. Ecosyst. Environ. 2006, 112, 207–220. [Google Scholar] [CrossRef]

- Sommer, S.G.; Olesen, J.E.; Petersen, S.O.; Weisbjerg, M.R.; Valli, L.; Rodhe, L.; Béline, F. Region-specific assessment of greenhouse gas mitigation with different manure management strategies in four agroecological zones. Glob. Chang. Biol. 2009, 15, 2825–2837. [Google Scholar] [CrossRef]

- Petersen, S.; Højberg, O.; Poulsen, M.; Schwab, C.; Eriksen, J. Methanogenic community changes, and emissions of methane and other gases, during storage of acidified and untreated pig slurry. J. Appl. Microbiol. 2014, 117, 160–172. [Google Scholar] [CrossRef] [Green Version]

- Baral, K.R.; Arthur, E.; Olesen, J.E.; Petersen, S.O. Predicting nitrous oxide emissions from manure properties and soil moisture: An incubation experiment. Soil Biol. Biochem. 2016, 97, 112–120. [Google Scholar] [CrossRef]

- Jacobsen, B.H.; Laugesen, F.M.; Dubgaard, A.; Bojesen, M. Biogas Production in Denmark—Assessments of Operation and Socioeconomics (Biogasproduktion i Danmark—Vurderinger af Drifts og Samfundsøkonomi); IFRO Report 220; University of Copenhagen: Copenhagen, Denmark, 2013. [Google Scholar]

- Møller, F.; Martinsen, L. Socioeconomic Evaluation of Selected Biogas Technologies; Scientific Report from DCE no. 62; University of Aarhus: Aarhus, Denmark, 2013. [Google Scholar]

- Mikkelsen, M.H.; Albrektsen, R.; Gyldenkærne, S. Consequences of Biogas Production for Greenhouse Gas Emissions in the Agricultural Sector (Biogasproduktions Konsekvenser for Drivhusgasudledning i Landbruget); Scientific Report from DCE—Danish Centre for Environment and Energy no. 197; Aarhus University: Aarhus, Denmark, 2016; p. 41. [Google Scholar]

- Chadwick, D.; Sommer, S.G.; Thorman, R.; Fangueiro, D.; Cardenas, L.; Amon, B.; Misselbrook, T. Manure management: Implications for greenhouse gas emissions. Anim. Feed Sci. Technol. 2011, 166–167, 514–531. [Google Scholar] [CrossRef]

- Nielsen, O.K.; Plejdrup, M.S.; Winther, M.; Nielsen, M.; Gyldenkærne, S.; Mikkelsen, M.H.; Albrektsen, R.; Thomsen, M.; Hjelgaard, K.; Fauser, P.; et al. Denmark’s National Inventory Report 2019. Emission Inventories 1990–2017—Submitted under the United Nations Framework Convention on Climate Change and the Kyoto Protocol; Scientific Report No. 318; Aarhus University, DCE—Danish Centre for Environment and Energy: Aarhus, Denmark, 2019; p. 886. [Google Scholar]

- Sommer, S.G.; Knudsen, L. Impact of Danish livestock and manure management regulations on nitrogen pollution, crop production and economy. Front. Sustain. 2021, 2, 658231. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Sun, M.; Xu, X.; Zhang, B.; Sun, Y. Evaluation of Biochemical Methane Potential and Kinetics on the Anaerobic Digestion of Vegetable Crop Residues. Energies 2018, 12, 26. [Google Scholar] [CrossRef] [Green Version]

- Møller, H.B.; Nielsen, A.; Murto, M.; Christensson, K. Manure and Energy Crops for Biogas Production; Nordic Council of Ministers TemaNord: Copenhagen, Denmark, 2008. [Google Scholar]

- Energinet.dk. 2019. Available online: https://energinet.dk/Om-nyheder/Nyheder/2020/01/16/Rekord-lav-CO2udledning-fradanskernes-elforbrug-i-2019 (accessed on 1 January 2021).

- Sørensen, P.; Børgesen, C.D. Nitrogen Leaching and Fertilising Effect from Digestate (Kvælstofudvaskning og GødningsVirkning ved Anvendelse af Afgasset Biomasse); DCA report no. 65; Aarhus University, DCA—Danish Centre for Food and Agriculture: Aarhus, Denmark, 2015; p. 46. Available online: https://pure.au.dk/portal/files/93094219/DCArapport065.pdf (accessed on 3 January 2022).

- Chojnacka, K.; Kowalski, Z.; Kulczycka, J.; Dmytryk, A.; Górecki, H.; Ligas, B.; Gramza, M. Carbon footprint of fertilizer technologies. J. Environ. Manag. 2018, 231, 962–967. [Google Scholar] [CrossRef] [PubMed]

- Elsgaard, L.; Olsen, A.B.; Petersen, S.O. Temperature response of methane production in liquid manures and co-digestates. Sci. Total Environ. 2016, 539, 78–84. [Google Scholar] [CrossRef]

- Petersen, S.O.; Olsen, A.B.; Elsgaard, L.; Triolo, J.M.; Sommer, S.G. Estimation of Methane Emissions from Slurry Pits below Pig and Cattle Confinements. PLoS ONE 2016, 11, e0160968. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maldaner, L.; Wagner-Riddle, C.; VanderZaag, A.C.; Gordon, R.; Duke, C. Methane emissions from storage of digestate at a dairy manure biogas facility. Agric. For. Meteorol. 2018, 258, 96–107. [Google Scholar] [CrossRef]

- Husted, S. Seasonal Variation in Methane Emission from Stored Slurry and Solid Manures. J. Environ. Qual. 1994, 23, 585–592. [Google Scholar] [CrossRef]

- Sharpe, R.; Harper, L.; Byers, F. Methane emissions from swine lagoons in Southeastern US. Agric. Ecosyst. Environ. 2002, 90, 17–24. [Google Scholar] [CrossRef]

- Clemens, J.; Trimborn, M.; Weiland, P.; Amon, B. Mitigation of greenhouse gas emissions by anaerobic digestion of cattle slurry. Agric. Ecosyst. Environ. 2006, 112, 171–177. [Google Scholar] [CrossRef]

- Sherlock, R.R.; Sommer, S.G.; Khan, R.Z.; Wood, C.W.; Guertal, E.A.; Freney, J.R.; Dawson, C.O.; Cameron, K.C. Ammonia, Methane, and Nitrous Oxide Emission from Pig Slurry Applied to a Pasture in New Zealand. J. Environ. Qual. 2002, 31, 1491–1501. [Google Scholar] [CrossRef] [Green Version]

- Pardo, G.; Moral, R.; Aguilera, E.; del Prado, A. Gaseous emissions from management of solid waste: A systematic review. Glob. Chang. Biol. 2014, 21, 1313–1327. [Google Scholar] [CrossRef] [Green Version]

- Chadwick, D. Emissions of ammonia, nitrous oxide and methane from cattle manure heaps: Effect of compaction and covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Hansen, M.N.; Henriksen, K.; Sommer, S.G. Observations of production and emission of greenhouse gases and ammonia during storage of solids separated from pig slurry: Effects of covering. Atmos. Environ. 2006, 40, 4172–4181. [Google Scholar] [CrossRef] [Green Version]

- Petersen, S.O.; Dorno, N.; Lindholst, S.; Feilberg, A.; Eriksen, J. Emissions of CH4, N2O, NH3 and odorants from pig slurry during winter and summer storage. Nutr. Cycl. Agroecosyst. 2013, 95, 103–113. [Google Scholar] [CrossRef]

- Thomsen, I.K.; Pedersen, A.R.; Nyord, T.; Petersen, S.O. Effects of slurry pre-treatment and application technique on short-term N2O emissions as determined by a new non-linear approach. Agric. Ecosyst. Environ. 2010, 136, 227–235. [Google Scholar] [CrossRef]

- Möller, K. Effects of anaerobic digestion on soil carbon and nitrogen turnover, N emissions, and soil biological activity. A review. Agron. Sustain. Dev. 2015, 35, 1021–1041. [Google Scholar] [CrossRef]

- Hansen, M.N.; Sommer, S.G.; Hutchings, N.J.; Sørensen, P. Emission Factors for Calculating Ammonia Evaporation from Storage and Application of Livestock Manure (Emissionsfaktorer til Beregning af Ammoniakfordampning ved Lagring og Udbringning af Husdyrgødning); DJF Husdyrbrug no. 84; Ministry of Agriculture: Aarhus, Denmark, 2008; p. 43. Available online: https://pure.au.dk/portal/files/2424282/djfhus84.pdf (accessed on 1 June 2019).

- Kupper, T.; Häni, C.; Neftel, A.; Kincaid, C.; Bühler, M.; Amon, B.; VanderZaag, A. Ammonia and greenhouse gas emissions from slurry storage—A review. Agric. Ecosyst. Environ. 2020, 300, 106963. [Google Scholar] [CrossRef]

- Søgaard, H.; Sommer, S.; Hutchings, N.; Huijsmans, J.; Bussink, D.; Nicholson, F. Ammonia volatilization from field-applied animal slurry—The ALFAM model. Atmos. Environ. 2002, 36, 3309–3319. [Google Scholar] [CrossRef]

- Sommer, S.G.; Webb, J.; Hutchings, N. New Emission Factors for Calculation of Ammonia Volatilization From European Livestock Manure Management Systems. Front. Sustain. Food Syst. 2019, 3, 101. [Google Scholar] [CrossRef] [Green Version]

- De Notaris, C.; Rasmussen, J.; Sørensen, P.; Olesen, J.E. Nitrogen leaching: A crop rotation perspective on the effect of N surplus, field management and use of catch crops. Agric. Ecosyst. Environ. 2018, 255, 1–18. [Google Scholar] [CrossRef]

- Pedersen, B.N.; Eriksen, J.; Christensen, B.T.; Sørensen, P. Fertilizer replacement value and leaching of nitrogen applied to spring barley in cattle deep litter: A 3-year lysimeter study. Soil Tillage Res. 2021, 209, 104954. [Google Scholar] [CrossRef]

- Børgesen, C.D.; Sørensen, P.; Blicher-Mathiesen, G.; Kristensen, K.; Pullens, J.W.M.; Zhao, J.; Olesen, J.E. NLES5: An Empirical Model for Predicting Nitrate Leaching from the Root Zone of Agricultural Land in Denmark; DCA report No. 163; Aarhus University, DCA—Danish Centre for Food and Agriculture: Aarhus, Denmark, 2019; p. 116. Available online: http://web.agrsci.dk/djfpublikation/index.asp?action=show&id=1313 (accessed on 1 June 2020).

- Blicher-Mathiesen, G.; Olesen, J.E.; Jung-Madsen, S. Update of Baseline 2021 (Opdatering af Baseline 2021); Technical report from DCE no. 162; Aarhus University, DCA—Danish Centre for Food and Agriculture: Aarhus, Denmark, 2020; p. 135. [Google Scholar]

- Thomsen, I.K.; Olesen, J.E.; Møller, H.; Sørensen, P.; Christensen, B.T. Carbon dynamics and retention in soil after anaerobic digestion of dairy cattle feed and faeces. Soil Biol. Biochem. 2013, 58, 82–87. [Google Scholar] [CrossRef]

- Christensen, B.T. Kulstoflagring ved nedmuldning af halm og efterafgrøder. In Jordbrug og klimaændringer—Samspil til Vandmiljøplaner; DJF rapport Markbrug nr. 109. s; Olesen, J.E., Petersen, S.O., Gyldenkærne, S., Mikkelsen, M.H., Jacobsen, B.H., Vesterdal, L., Jørgensen, A.M.K., Christensen, B.T., Abildtrup, J., Heidmann, T., et al., Eds.; Ministry of Agriculture: Copenhagen, Denmark, 2004; pp. 157–166. [Google Scholar]

- Taghizadeh-Toosi, A.; Olesen, J.E. Modelling soil organic carbon in Danish agricultural soils suggests low potential for future carbon sequestration. Agric. Syst. 2016, 145, 83–89. [Google Scholar] [CrossRef]

- Hu, T.; Sørensen, P.; Olesen, J.E. Soil carbon varies between different organic and conventional management schemes in arable agriculture. Eur. J. Agron. 2018, 94, 79–88. [Google Scholar] [CrossRef]

- Hijazi, O.; Munro, S.; Zerhusen, B.; Effenberger, M. Review of life cycle assessment for biogas production in Europe. Renew. Sustain. Energy Rev. 2016, 54, 1291–1300. [Google Scholar] [CrossRef]

- Petersen, S.O.; Sommer, S.G. Ammonia and nitrous oxide interactions: Roles of manure organic matter management. Anim. Feed Sci. Technol. 2011, 166–167, 503–513. [Google Scholar] [CrossRef]

- Poeschl, M.; Ward, S.; Owende, P. Environmental impacts of biogas deployment e Part II: Life cycle assessment of multiple production and utilization pathways. J. Clean. Prod. 2012, 24, 184–201. [Google Scholar] [CrossRef]

- Searchinger, T.D.; Wirsenius, S.; Beringer, T.; Dumas, P. Assessing the efficiency of changes in land use for mitigating climate change. Nature 2018, 564, 249–253. [Google Scholar] [CrossRef]

- European Commission. Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015 Amending Directive 98/70/EC Relating to the Quality of Petrol and Diesel Fuels and Amending Directive 2009/28/EC on the Promotion of the Use of Energy from Renewable Sources; Law, European Commission: Brussels, Belgium, 15 September 2015. [Google Scholar]

- Valin, H.; Peters, D.; van den Berg, M.; Frank, S.; Havlik, P.; Forsell, N.; Hamelinck, C.; Pirker, J.; Mosnier, A.; Balkovic, J.; et al. The Land Use Changes the Impact of Biofuels Consumed in the EU. Quantification of Area and Greenhouse Gas Impacts; European Commission Project: BIENL13120; Ecofys: Utrecht, The Netherlands, 2015; p. 242. [Google Scholar]

- Bohon, M.D.; Metzger, B.A.; Linak, W.P.; King, C.J.; Roberts, W.L. Glycerol combustion and emissions. Proc. Combust. Inst. 2010, 33, 2717–2724. [Google Scholar] [CrossRef]

- Nielsen, L.H.; Hjort-Gregersen, K.; Thygesen, P.; Christensen, J. Socioeconomic Analyses of Central Biogas Plants—with Technical and Financial Background Analyses (Samfundsøkonomiske Analyser af Biogasfællesanlæg—Med Tekniske og Selskabsøkonomiske Baggrundsanalyser); Report No. 136; Institute of Food and Resource Economics: Copenhagen, Denmark, 2002. [Google Scholar]

- Olesen, J.E.; Petersen, S.O.; Lund, P.; Jørgensen, U.; Kristensen, T.; Elsgaard, L.; Sørensen, P.; Lassen, J. Measures to Reduce Greenhouse Gasses in the Agricultural Sector (Virkemidler til Reduktion af Klimagasser i Landbruget); DCA Report No. 130; DCA—Danish Centre for Food and Agriculture: Aarhus, Denmark, 2018; p. 119. [Google Scholar]

- Li, X.; Petersen, S.O.; Sørensen, P.; Olesen, J.E. Effects of contrasting catch crops on nitrogen availability and nitrous oxide emissions in an organic cropping system. Agric. Ecosyst. Environ. 2015, 199, 382–393. [Google Scholar] [CrossRef]

- Fontaine, D.; Feng, L.; Labouriau, R.; Møller, H.B.; Eriksen, J.; Sørensen, P. Nitrogen and Sulfur Availability in Digestates from Anaerobic Co-digestion of Cover Crops, Straw and Cattle Manure. J. Soil Sci. Plant Nutr. 2019, 20, 621–636. [Google Scholar] [CrossRef]

- Bruun, S.; Jensen, L.S.; Vu, V.T.K.; Sommer, S.G. Small-scale household biogas digesters: An option for global warming mitigation or a potential climate bomb? Renew. Sustain. Energy Rev. 2014, 33, 736–741. [Google Scholar] [CrossRef]

- Baral, K.R.; Jégo, G.; Amon, B.; Bol, R.; Chantigny, M.H.; Olesen, J.E.; Petersen, S.O. Greenhouse gas emissions during storage of manure and digestates: Key role of methane for prediction and mitigation. Agric. Syst. 2018, 166, 26–35. [Google Scholar] [CrossRef]

- Dalby, F.R.; Hafner, S.D.; Petersen, S.O.; VanderZaag, A.C.; Habtewold, J.; Dunfield, K.; Chantigny, M.H.; Sommer, S.G. Understanding methane emission from stored animal manure: A review to guide model development. J. Environ. Qual. 2021. [Google Scholar] [CrossRef] [PubMed]

- Petersen, S.O.; Nissen, H.H.; Lund, I.; Ambus, P. Redistribution of slurry in soil as influenced by organic matter content and injection method. J. Environ. Qual. 2003, 32, 2399–2409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Scenario | Input | Input g DM kg−1 Biomass | Reactor g DM kg−1 Biomass | Reference Scenario |

|---|---|---|---|---|

| 1 | Slurry (80%) + deep litter (20%) | 112 | 95 | Animal slurry is stored in a slurry tank and then applied by injection or trailing hose. Deep litter is stored in covered stacks/manure piles for five months and applied before sowing spring cereals. |

| 2 | Slurry (80%) + straw (20%) | 220 | 95 | Straw is cut and incorporated. |

| 3 | Slurry (80%) + deep litter (8%) + energy crops (12%) | 94 | 51 | The land farmed with energy crops is used for cereal crops. |

| 4 | Slurry (70%) + deep litter (10%) + organic waste (20%) | 141 | 53 | The organic waste is stored as slurry and then spread directly on the field (slaughterhouse waste), incinerated (glycerine), or composted and then applied (biowaste). |

| 5 | Organic grass–clover (25%) + cattle slurry (50%) + deep litter (20%) + biowaste (5%) | 97 | 95 | At an organic farm without a biogas plant, the grass–clover is managed as green manure. |

| Category | Storage Period | lnA′ g CH4 kg−1 VS h−1 | Reference |

|---|---|---|---|

| Cattle slurry | Barn | 30.1 | [20] |

| Outside store | 29.2 ± 0.1 | [25,27,28] | |

| Pig slurry | Barn | 30.6 | [20] |

| Outside store | 30.3 ± 0.4 | [25,27,28] | |

| Digestate | Outside store | 27.9 ± 0.4 | [28,29] |

| Categories | Methane | Nitrous Oxide | |

|---|---|---|---|

| IPCC (housing and outside storage) | |||

| MCF (% of BMP) | kg CH4 kg−1 (VS) | N2O-N % of total N | |

| <1 month in housing | 3 | 0.005 | 1 |

| >1 month in housing | 17 | 0.027 | 1 |

| This study (outside storage) | |||

| kg CH4 kg−1 (C) | kg CH4 kg−1 (VS) | % of total-N | |

| Storage in covered heaps | 0.015 | 0.0075 | 0.5 |

| Composting | 0.03 | 0.015 | 2.2 |

| Untreated Slurry | Digested Slurry | ||||

|---|---|---|---|---|---|

| CH4/CO2 | Cattle | Pig | CH4/CO2 | Cattle | Pig |

| 12.5:87.5 | 0.99 | 0.79 | 5:95 | 0.98 | 0.99 |

| 25:75 | 1.00 | 1.00 | 10:90 | 1.00 | 1.00 |

| 50:50 | 1.01 | 1.17 | 20:80 | 1.01 | 1.00 |

| Source | Scenarios | ||||

|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | S5 | |

| NO3− (kg NO3−-N ton−1 (biomass)) | −0.19 | −0.13 | −0.04 | −0.18 | −0.45 |

| NH3 (kg NH3-N ton−1 (biomass)) | 0.19 | 0.18 | 0.21 | 0.14 | 0.30 |

| NOx (g NOx ton−1 (biomass)) | 2.49 | 2.48 | 2.30 | 3.97 | 2.13 |

| Source | Unit | S1 | S2 | S3 | S4 | S5 |

|---|---|---|---|---|---|---|

| Energy | kg CO2-eq ton−1 biomass or kg CO2-eq ton−1 DM | 50.44 (450.4) | 117.05 (532.1) | 57.84 (507.4) | 71.83 (509.4) | 105.30 (534.5) |

| Glycerol for heating | −13.80 (−97.9) | |||||

| Process energy | −4.08 (−36.4) | −4.08 (−18.5) | −4.08 (−35.8) | −4.08 (−28.9) | −4.08 (−20.9) | |

| Transport | −1.21 (−10.8) | −1.20 (−5.5) | −1.15 (−10.1) | −1.62 (−11.5) | −1.20 (−6.1) | |

| Fertilizer production, N | 1.61 (14.4) | 1.32 (6.0) | 1.43 (12.5) | 1.43 (10.1) | 1.77 (9.0) | |

| Methane leakage from biogas plant | −4.50 (−40.1) | −10.3 (−46.9) | −5.42 (−47.5) | −6.34 (−44.9) | −9.29 (−47.2) | |

| Methane from storage * | 29.91 (267.1) | 15.75 (71.6) | 24.50 (214.9) | 21.04 (149.2) | 11.54 (58.6) | |

| Nitrous oxide from storage * | 0.00 | −1.26 (−5.7) | 0.00 | 1.32 (9.3) | 1.32 (6.7) | |

| Nitrous oxide after application | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Nitrous oxide from nitrogen leaching | 0.40 (3.6) | 0.27 (1.3) | 0.04 (0.8) | 0.40 (2.8) | 1.01 (4.9) | |

| Nitrous oxide from ammonia emission | −0.69 (−6.2) | −0.66 (−3.0) | −0.76 (−6.6) | −0.51 (−3.6) | −1.11 (5.63) | |

| Nitrous oxide from maize cropping | 0.00 | 0.00 | −0.74 (−12.1) | 0.00 | 0.00 | |

| Soil C storage (digested biomass) | −3.14 (−28.0) | −6.16 (−28.0) | −2.12 (−18.6) | −2.11 (−15.0) | −2.64 (13.4) | |

| Total impact | 68.8 (613) | 110.7 (503) | 69.6 (604) | 67.6 (479) | 102.6 (520) | |

| Energy production | GJ gross energy ton−1 biomass | 0.90 | 2.07 | 1.02 | 1.27 | 1.86 |

| Total impact | kg CO2-eq GJ−1 gross energy | 76.47 | 53.61 | 68.19 | 53.29 | 55.21 |

| Nitrate leaching | kg NO3-N ton−1 biomass | 0.19 (1.7) | 0.13 (0.6) | 0.04 (0.4) | 0.18 (1.3) | 0.45 (2.3) |

| NH3 | kg NH3-N ton−1 biomass | −0.19 (−1.7) | −0.18 (−0.8) | −0.21 (−1.8) | −0.14 (1.0) | −0.30 (1.5) |

| NOx | g NOx ton−1 biomass | −2.49 (22.2) | −2.48 (11.3) | −2.30 (20.2) | −3.97 (28.1) | −2.13 (10.8) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Møller, H.B.; Sørensen, P.; Olesen, J.E.; Petersen, S.O.; Nyord, T.; Sommer, S.G. Agricultural Biogas Production—Climate and Environmental Impacts. Sustainability 2022, 14, 1849. https://doi.org/10.3390/su14031849

Møller HB, Sørensen P, Olesen JE, Petersen SO, Nyord T, Sommer SG. Agricultural Biogas Production—Climate and Environmental Impacts. Sustainability. 2022; 14(3):1849. https://doi.org/10.3390/su14031849

Chicago/Turabian StyleMøller, Henrik B., Peter Sørensen, Jørgen E. Olesen, Søren O. Petersen, Tavs Nyord, and Sven G. Sommer. 2022. "Agricultural Biogas Production—Climate and Environmental Impacts" Sustainability 14, no. 3: 1849. https://doi.org/10.3390/su14031849

APA StyleMøller, H. B., Sørensen, P., Olesen, J. E., Petersen, S. O., Nyord, T., & Sommer, S. G. (2022). Agricultural Biogas Production—Climate and Environmental Impacts. Sustainability, 14(3), 1849. https://doi.org/10.3390/su14031849