Sustainable Assignment of Egyptian Ornamental Stones for Interior and Exterior Building Finishes Using the AHP-TOPSIS Technique

Abstract

:1. Introduction

2. Ornamental Stones in Indoor and Outdoor Building Spaces

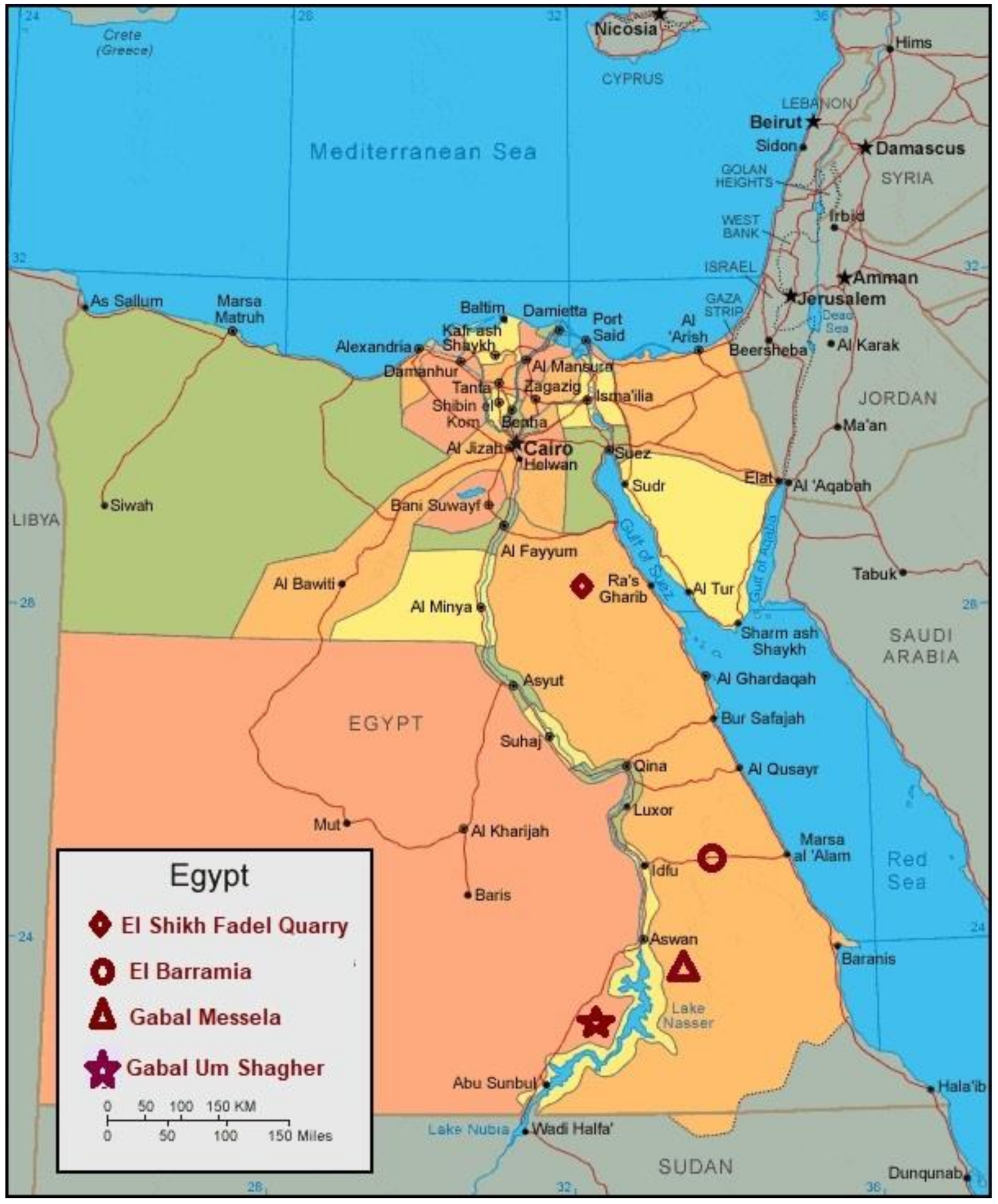

3. Location and Geological Settings

4. Mechanical and Physical Properties of the Specimens

5. AHP: An Approach for Estimating the Weight of the Samples

6. TOPSIS: Relevance

7. Methodology

7.1. Assigning Weight and Rate for Each Criterion

- (1)

- Growing a comparison matrix at every stage of the hierarchy beginning from the second stage and going down.

- (2)

- Computing the relative weights for every detail of the hierarchy.

- (3)

7.2. Ranking Alternatives Based on the TOPSIS Approach

- To normalize the decision matrix:

- 2.

- To calculate the weighted normalized decision matrix:

- 3.

- To determine the positive and negative ideal solutions:

- 4.

- To calculate the Euclidean distance from the ideal worst condition

- 5.

- To calculate the performance score and ranking:

8. Results and Discussion

8.1. Results

8.2. Discussion

9. Limitations and Implications of the Study

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vagnon, F.; Dino, G.A.; Umili, G.; Cardu, M.; Ferrero, A.M. New Developments for the Sustainable Exploitation of Ornamental Stone in Carrara Basin. Sustainability 2020, 12, 9374. [Google Scholar] [CrossRef]

- Hatefi, S.M.; Asadi, H.; Shams, G.; Tamošaitienė, J.; Turskis, Z. Model for the Sustainable Material Selection by Applying Integrated Dempster-Shafer Evidence Theory and Additive Ratio Assessment (ARAS) Method. Sustainability 2021, 13, 10438. [Google Scholar] [CrossRef]

- Naghoj, N.M.; Youssef, N.A.R.; Maaitah, O.N. Mechanical properties of natural building stone: Jordanian building limestone as an example. Jordan J. Earth Environ. Sci. 2010, 3, 37–48. [Google Scholar]

- Kourkoulis, S.; Ganniari-Papageorgiou, E. Experimental study of the size-and shape-effects of natural building stones. Constr. Build. Mater. 2010, 24, 803–810. [Google Scholar] [CrossRef]

- Eljufout, T.; Alhomaidat, F. Evaluation of natural building stones’ characterizations using ultrasonic testing technique. Arab. J. Sci. Eng. 2021, 46, 11415–11424. [Google Scholar] [CrossRef]

- Hasheminasab, H.; Zolfani, S.H.; Bitarafan, M.; Chatterjee, P.; Ezabadi, A.A. The Role of Façade Materials in Blast-Resistant Buildings: An Evaluation Based on Fuzzy Delphi and Fuzzy EDAS. Algorithms 2019, 12, 119. [Google Scholar] [CrossRef] [Green Version]

- Mousavi, S.; Silva, A.; de Brito, J.; Ekhlassi, A.; Hosseini, S.B. Degradation Assessment of Natural Stone Claddings over Their Service Life: Comparison between Tehran (Iran) and Lisbon (Portugal). Buildings 2021, 11, 438. [Google Scholar] [CrossRef]

- Sims, I. Quality and durability of stone for construction. Q. J. Eng. Geol. Hydrogeol. 1991, 24, 67–73. [Google Scholar] [CrossRef]

- Molina, E.; Cultrone, G.; Sebastián, E.; Alonso, F.J. Evaluation of stone durability using a combination of ultrasound, mechanical and accelerated aging tests. J. Geophys. Eng. 2013, 10, 035003. [Google Scholar] [CrossRef]

- Klemm, A.; Wiggins, D. Sustainability of Natural Stone as a Construction Material, in Sustainability of Construction Materials; Elsevier: Amsterdam, The Netherlands, 2016; pp. 283–308. [Google Scholar]

- Pereira, D.; Marker, B. The value of original natural stone in the context of architectural heritage. Geosciences 2016, 6, 13. [Google Scholar] [CrossRef] [Green Version]

- Autelitano, F.; Garilli, E.; Giuliani, F. Criteria for the selection and design of joints for street pavements in natural stone. Constr. Build. Mater. 2020, 259, 119722. [Google Scholar] [CrossRef]

- Petersen, A.K.; Solberg, B. Substitution between floor constructions in wood and natural stone: Comparison of energy consumption, greenhouse gas emissions, and costs over the life cycle. Can. J. For. Res. 2003, 33, 1061–1075. [Google Scholar] [CrossRef]

- Chakraborty, S.; Zavadskas, E.K.; Antucheviciene, J. Applications of WASPAS method as a multi-criteria decision-making tool. Econ. Comput. Econ. Cybern. Stud. Res. 2015, 49, 5–22. [Google Scholar]

- Kiker, G.A.; Todd, S.; Bridges, T.S.; Varghese, A.; Seager, T.P.; Linkov, I. Application of multicriteria decision analysis in environmental decision making. Integr. Environ. Assess. Manag. Int. J. 2005, 1, 95–108. [Google Scholar] [CrossRef]

- Huang, I.B.; Keisler, J.; Linkov, I. Multi-criteria decision analysis in environmental sciences: Ten years of applications and trends. Sci. Total Environ. 2011, 409, 3578–3594. [Google Scholar] [CrossRef] [PubMed]

- Zolfani, S.H.; Pourhossein, M.; Yazdani, M.; Zavadskasd, E.K. Evaluating construction projects of hotels based on environmental sustainability with MCDM framework. Alex. Eng. J. 2018, 57, 357–365. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Antucheviciene, J.; Vilutiene, T.; Adeli, H. Sustainable decision-making in civil engineering, construction and building technology. Sustainability 2018, 10, 14. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Aiwu, G.; Lukovac, V.; Vukic, M. A multicriteria model for the selection of the transport service provider: A single valued neutrosophic DEMATEL multicriteria model. Decis. Mak. Appl. Manag. Eng. 2018, 1, 121–130. [Google Scholar] [CrossRef]

- Kianpour, K.; Jusoh, A.; Mardani, A.; Streimikiene, D.; Cavallaro, F.; Nor, K.M.; Zavadskas, E.K. Factors influencing consumers’ intention to return the end of life electronic products through reverse supply chain management for reuse, repair and recycling. Sustainability 2017, 9, 1657. [Google Scholar] [CrossRef] [Green Version]

- Mardani, A.; Zavadskas, E.K.; Streimikiene, D.; Jusoh, A. Using fuzzy multiple criteria decision making approaches for evaluating energy saving technologies and solutions in five star hotels: A new hierarchical framework. Energy 2016, 117, 131–148. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Streimikiene, D. A novel integrated decision-making approach for the evaluation and selection of renewable energy technologies. Clean Technol. Environ. Policy 2018, 20, 403–420. [Google Scholar] [CrossRef]

- Kun, M.; Topaloğlu, Ş.; Malli, T. Evaluation of wheel loaders in open pit marble quarrying by using the AHP and TOPSIS approaches/Ocena pracy ładowarki na podwoziu kołowym w odkrywkowej kopalni marmuru w oparciu o metody AHP i topsis. Arch. Min. Sci. 2013, 58, 255–267. [Google Scholar] [CrossRef] [Green Version]

- Balali, A.; Valipour, A.; Zavadskas, E.K.; Turskis, Z. Multi-Criteria Ranking of Green Materials According to the Goals of Sustainable Development. Sustainability 2020, 12, 9482. [Google Scholar] [CrossRef]

- Roy, J.; Das, S.; Kar, S.; Pamučar, D. An extension of the CODAS approach using interval-valued intuitionistic fuzzy set for sustainable material selection in construction projects with incomplete weight information. Symmetry 2019, 11, 393. [Google Scholar] [CrossRef] [Green Version]

- Stojčić, M.; Zavadskas, E.K.; Pamučar, D.; Stević, Z.; Mardani, A. Application of MCDM methods in sustainability engineering: A literature review 2008–2018. Symmetry 2019, 11, 350. [Google Scholar] [CrossRef] [Green Version]

- Musingwini, C.; Minnitt, R. Ranking the efficiency of selected platinum mining methods using the analytic hierarchy process (AHP). In Proceedings of the Third International Platinum Conference ‘Platinum in Transformation’, Sun City, South Africa, 6–9 October 2008; The Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa. [Google Scholar]

- Sitorus, F.; Cilliers, J.J.; Brito-Parada, P.R. Multi-criteria decision making for the choice problem in mining and mineral processing: Applications and trends. Expert Syst. Appl. 2019, 121, 393–417. [Google Scholar] [CrossRef]

- Vakilipour, S.; Sadeghi-Niaraki, A.; Ghodousi, M.; Choi, S.M. Comparison between Multi-Criteria Decision-Making Methods and Evaluating the Quality of Life at Different Spatial Levels. Sustainability 2021, 13, 4067. [Google Scholar] [CrossRef]

- Escolar, S.; Villanueva, F.J.; Santofimia, M.J.; Villa, D.; del Toro, X.; López, J.C. A Multiple-Attribute Decision Making-based approach for smart city rankings design. Technol. Forecast. Soc. Chang. 2019, 142, 42–55. [Google Scholar] [CrossRef]

- Abd El-Ghafour, N.G.; Khalil, M.H.; Gharib, M.E.; Abd Latif, M.L. Mineralogical and radioactive properties of some Egyptian granitoid rocks and their suitability for ornamental stones. HBRC J. 2012, 8, 64–68. [Google Scholar] [CrossRef] [Green Version]

- Shohda, A.M.; Draz, W.M.; Ali, F.A.; Yassien, M.A. Quality Index to Determine the Optimum Utility of Some Egyptian Stones as Ornamental Stones. Int. J. Sci. Eng. Res. 2016, 7, 752–758. [Google Scholar]

- Fowler, T. Pan-African granite emplacement mechanisms in the Eastern Desert, Egypt. J. Afr. Earth Sci. 2001, 32, 61–86. [Google Scholar] [CrossRef]

- Vázquez, P.; Alonso, F.J.; Esbert, R.M.; Ordaz, J. Ornamental granites: Relationships between p-waves velocity, water capillary absorption and the crack network. Constr. Build. Mater. 2010, 24, 2536–2541. [Google Scholar] [CrossRef]

- Pereira, D.; Pereira, D.; Yenes, M.; Sánche, J.A.B.; Moreno, M.M.P. Characterization of serpentinites to define their appropriate use as dimension stone. Geol. Soc. Lond. Spec. Publ. 2007, 271, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Ismael, I.; Hassan, M. Characterization of some Egyptian serpentinites used as ornamental stones. Chin. J. Geochem. 2008, 27, 140–149. [Google Scholar] [CrossRef]

- Kandil, A.; Selim, T.H. Characteristics of Marble Industry in Egypt: Structure, Conduct, and Performance. Int. Bus. Econ. Res. J. 2006, 5, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Hubsch, H. What Style Should We Build? The German Debate on Architectural Style; Getty Publications: Santa Monica, CA, USA, 1996. [Google Scholar]

- Umathey, R.M.; Venugopal, S. Granite mining and environment issues in A.P. Indian Min. Eng. J. 1992, 2, 230–236. [Google Scholar]

- Chatterjee, T.K.; Chatterjee, R.; Singh, S. Classification of black decorative stones from Warangal District, Andhra Pradesh, India. Bull. Eng. Geol. Environ. 2005, 64, 167–173. [Google Scholar] [CrossRef]

- Zulcao, R.; Calmon, J.L.; Rebello, T.A.; Vieira, D.R. Life cycle assessment of the ornamental stone processing waste use in cement-based building materials. Constr. Build. Mater. 2020, 257, 119523. [Google Scholar] [CrossRef]

- Galetakis, M.; Soultana, A. A review on the utilisation of quarry and ornamental stone industry fine by-products in the construction sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- López, A.; Pozo-Antonio, J.S.; Ramil, A.; Rivas, T. Influence of the commercial finishes of ornamental granites on roughness, colour and reflectance. Constr. Build. Mater. 2018, 182, 530–540. [Google Scholar] [CrossRef]

- Rln, D. Enhancing the prospects of decorative granite industry in India. Indian Min. Eng. J. 1992, 2, 258–260. [Google Scholar]

- El Ramly, M.F. A new geological map for the basement rocks in the Eastern and Southwestern desert of Egypt: Scale 1: 1,000,000. Ann. Geol. Surv. Egypt 1972, 2, 1–18. [Google Scholar]

- Ali, M.A.; Abdellah, W.R.; El Aal, A.A.; Kim, J.G. The influence of the physical and mechanical properties on the abrasion rate of rocks along Idfo-Marsa Alam, eastern desert, Egypt. Geotech. Geol. Eng. 2020, 38, 1567–1577. [Google Scholar] [CrossRef]

- Mahrous, A.; Tantawi, M.M.; El-Sageer, H. Evaluation of the engineering properties of some Egyptian limestones as construction materials for highway pavements. Constr. Build. Mater. 2010, 24, 2598–2603. [Google Scholar] [CrossRef]

- Zayed, A.; Masoud, M.A.; Rashad, A.M.; El-Khayatt, A.M.; Sakr, K.; Kansouh, W.A.; Shahien, M.G. Influence of heavyweight aggregates on the physico-mechanical and radiation attenuation properties of serpentine-based concrete. Constr. Build. Mater. 2020, 260, 120473. [Google Scholar] [CrossRef]

- Bieniawski, Z.; Bernede, M. Suggested methods for determining the uniaxial compressive strength and deformability of rock materials: Part 1. Suggested method for determining deformability of rock materials in uniaxial compression. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1979, 16, 138–140. [Google Scholar] [CrossRef]

- Saaty, R.W. The analytic hierarchy process—What it is and how it is used. Math. Model. 1987, 9, 161–176. [Google Scholar] [CrossRef] [Green Version]

- Ataei, M.; Jamshidi, M.; Sereshki, F.; Jalali, S.M.E. Mining method selection by AHP approach. J. S. Afr. Inst. Min. Metall. 2008, 108, 741–749. [Google Scholar]

- Balt, K.D. A Methodology for Implementing the Analytical Hierarchy Process to Decision-Making in Mining; University of the Witwatersrand: Johannesburg, South Africa, 2015. [Google Scholar]

- Kluge, P.; Malan, D.F. The Application of the Analytical Hierarchical Process in Complex Mining Engineering Design Problems. J. S. Afr. Inst. Min. Metall. 2011, 111, 847–855. [Google Scholar]

- Reza, B.; Sadiq, R.; Hewage, K. Sustainability assessment of flooring systems in the city of Tehran: An AHP-based life cycle analysis. Constr. Build. Mater. 2011, 25, 2053–2066. [Google Scholar] [CrossRef]

- Guo, Q.; Yu, H.; Dan, Z.; Li, S. Mining Method Optimization of Gently Inclined and Soft Broken Complex Ore Body Based on AHP and TOPSIS: Taking Miao-Ling Gold Mine of China as an Example. Sustainability 2021, 13, 12503. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Yoon, K. Methods for Multiple Attribute Decision Making, in Multiple Attribute Decision Making; Springer: Berlin/Heidelberg, Germany, 1981; pp. 58–191. [Google Scholar]

- Yoon, K. A reconciliation among discrete compromise solutions. J. Oper. Res. Soc. 1987, 38, 277–286. [Google Scholar] [CrossRef]

- Khalili-Damghani, K.; Tavana, M.; Sadi-Nezhad, S. An integrated multi-objective framework for solving multi-period project selection problems. Appl. Math. Comput. 2012, 219, 3122–3138. [Google Scholar] [CrossRef]

- Zimonjić, S.; Đekić, M.; Kastratović, E. Application of Vikor Method in Ranking the Investment Projects. Int. J. Econ. Law 2018, 8, 125–134. [Google Scholar]

- Sharma, P.; Singhal, S. Implementation of fuzzy TOPSIS methodology in selection of procedural approach for facility layout planning. Int. J. Adv. Manuf. Technol. 2017, 88, 1485–1493. [Google Scholar] [CrossRef]

- Falqi, I.I.; Ahmed, M.; Mallick, J. Siliceous concrete materials management for sustainability using Fuzzy-TOPSIS Approach. Appl. Sci. 2019, 9, 3457. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.A.M.; Kim, J.-G. Selection mining methods via multiple criteria decision analysis using TOPSIS and modification of the UBC method. J. Sustain. Min. 2021, 20, 49–55. [Google Scholar] [CrossRef]

- Ye, F.; Li, Y. An extended TOPSIS model based on the possibility theory under fuzzy environment. Knowl.-Based Syst. 2014, 67, 263–269. [Google Scholar] [CrossRef]

- Baykasoğlu, A.; Gölcük, İ. Development of a novel multiple-attribute decision making model via fuzzy cognitive maps and hierarchical fuzzy TOPSIS. Inf. Sci. 2015, 301, 75–98. [Google Scholar] [CrossRef]

- Maldonado-Macías, A.; Alvarado, A.; García, J.L.; Balderrama, C.O. Intuitionistic fuzzy TOPSIS for ergonomic compatibility evaluation of advanced manufacturing technology. Int. J. Adv. Manuf. Technol. 2014, 70, 2283–2292. [Google Scholar] [CrossRef]

- Pérez-Domínguez, L.; Luviano-Cruz, D.; Valles-Rosales, D.; Hernández Hernández, J.I.; Rodríguez Borbón, M.I. Hesitant fuzzy linguistic term and TOPSIS to assess lean performance. Appl. Sci. 2019, 9, 873. [Google Scholar] [CrossRef] [Green Version]

- Cheng, J.; Zhang, Y.; Feng, Y.; Liu, Z.; Tan, J. Structural optimization of a high-speed Press considering multi-source uncertainties based on a new heterogeneous TOPSIS. Appl. Sci. 2018, 8, 126. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.-N.; Nguyen, V.T.; Duong, D.H.; Thai, H.T.N. A hybrid fuzzy analysis network process (FANP) and the technique for order of preference by similarity to ideal solution (TOPSIS) approaches for solid waste to energy plant location selection in Vietnam. Appl. Sci. 2018, 8, 1100. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Fang, M.; Liu, Z.; Wang, W. Comprehensive evaluation of power quality based on an improved TOPSIS method considering the correlation between indices. Appl. Sci. 2019, 9, 3603. [Google Scholar] [CrossRef] [Green Version]

- Esu, E.O.; Edet, A.E.; Teme, S.C.; Okereke, C.S. A study of some Nigerian carbonate rocks for the building construction industry. Eng. Geol. 1994, 37, 271–283. [Google Scholar] [CrossRef]

- Hartman, H.L.; Mutmansky, J.M. Introductory Mining Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

- Alpay, S.; Yavuz, M. Underground mining method selection by decision making tools. Tunn. Undergr. Space Technol. 2009, 24, 173–184. [Google Scholar] [CrossRef]

- Ataei, M. Multicriteria selection for an alumina-cement plant location in East Azerbaijan province of Iran. J. S. Afr. Inst. Min. Metall. 2005, 105, 507–514. [Google Scholar]

- Edet, A. Physical properties and indirect estimation of microfractures using Nigerian carbonate rocks as examples. Eng. Geol. 1992, 33, 71–80. [Google Scholar] [CrossRef]

- Gao, L.; Hailu, A. Identifying Preferred Management Options: An Integrated agent-based Recreational Fishing Simulation Model with an AHP-TOPSIS Evaluation Method. Ecol. Model. 2013, 249, 75–83. [Google Scholar] [CrossRef]

- Das, D. Selection of Materials in Engineering Design Using Ashby‘s Chart and AHP-TOPSIS; Jadavpur University Kolkata: West Bengal, India, 2012. [Google Scholar]

- Yurdakul, M.; Ic, Y.T. Development of a Performance Measurement Model for Manufacturing Companies Using the AHP and TOPSIS Approaches. Int. J. Prod. Res. 2005, 43, 4609–4641. [Google Scholar] [CrossRef]

- Bhutia, P.W.; Phipon, R. Application of AHP and TOPSIS Method for Supplier Selection Problem. IOSR J. Eng. 2012, 2, 43–50. [Google Scholar] [CrossRef]

- Lin, M.C.; Wang, C.C.; Chen, M.S.; Chang, C.A. Using AHP and TOPSIS Approaches in consumer-driven Product Design Process. Comput. Ind. 2008, 59, 17–31. [Google Scholar] [CrossRef]

- Soltanmohammadi, H.; Osanloo, M.; Aghajani, A. Developing a Fifty-attribute Framework for Mined Land Suitability Analysis Using AHP-TOPSIS Approach. In Proceedings of the Post-Mining Symposium, Nancy, France, 6–8 February 2008; pp. 1–12. [Google Scholar]

- Tavana, M.; Hatami-Marbini, A. A Group AHP-TOPSIS Framework for Human Spaceflight Mission Planning at NASA. Expert Syst. Appl. 2001, 38, 13588–13603. [Google Scholar] [CrossRef]

| Rock Type | Abbreviation | CS Kg/cm2 | SD Kg/cm2 | PLT Kg/cm2 | Water Absorption % | Density g/cm3 | Abrasion g/cm2 | Porosity, % |

|---|---|---|---|---|---|---|---|---|

| Black marble1 | B1 | 387.6 | 89.7 | 70.2 | 0.35 | 2.65 | 0.46 | 0.98 |

| Black marble2 | B2 | 445.7 | 86.4 | 45.6 | 0.39 | 2.78 | 0.51 | 0.3 |

| Black marble3 | B3 | 410.6 | 84.3 | 43.8 | 0.51 | 2.71 | 0.42 | 1.01 |

| White marble1 | W1 | 897.4 | 87.8 | 47.0 | 0.03 | 2.46 | 0.06 | 0.45 |

| White marble2 | W2 | 789.3 | 89.7 | 75.6 | 0.05 | 2.55 | 0.07 | 0.71 |

| Sunny marble | SM | 453.2 | 91.3 | 73.5 | 0.06 | 2.71 | 0.09 | 0.61 |

| Gray granite | GG | 546.8 | 95.4 | 68.9 | 0.03 | 2.67 | 0.31 | 0.42 |

| Red granite | RG | 645.9 | 94.6 | 43.9 | 0.04 | 2.87 | 0.33 | 0.32 |

| Pink granite | PG | 500.8 | 96.5 | 41.8 | 0.05 | 2.75 | 0.21 | 0.29 |

| Serpentine | S | 521.3 | 94.8 | 46.7 | 0.06 | 2.69 | 0.08 | 0.34 |

| Weights Properties | 0.176 | 0.116 | 0.176 | 0.057 | 0.063 | 0.049 | 0.041 | 0.319 |

| Properties | CS | SD | PLT | W. ab. | D. | Abr. | PO | Cost |

| Parameter | Rating | ||||

|---|---|---|---|---|---|

| 0.2 | 0.4 | 0.6 | 0.8 | 1 | |

| CS, Kg/cm2 | <250 | 250–500 | 500–750 | 750–1000 | >1000 |

| Very low | low | Medium | High | Very high | |

| SD, Kg/cm2 | <25 | 25–50 | 50–100 | 100–150 | >150 |

| Very low | low | Medium | High | Very high | |

| PLT Kg/cm2 | <50 | 50–60 | 60–75 | 75–100 | >100 |

| Very low | low | Medium | High | Very high | |

| Water absorption, % | >0.75 | 0.75–0.5 | 0.5–0.25 | 0.25–0.1 | <0.1 |

| Very high | high | Medium | low | Very low | |

| Density, g/cm3 | <2 | 2–2.3 | 2.3–2.6 | 2.6–2.9 | >3 |

| Very low | low | Medium | High | Very high | |

| Abrasion, % | >0.5 | 0.5–0.3 | 0.3–0.1 | 0.1–0.05 | <0.05 |

| Very high | High | Medium | low | Very low | |

| Porosity, % | >0.75 | 0.75–0.5 | 0.5–0.25 | 0.25–0.1 | <0.1 |

| Very high | high | Medium | low | Very low | |

| Cost, EGP | <500 | 500–750 | 750–1000 | 1000–2000 | >2000 |

| Very cheap | cheap | Moderate | Expansive | Extremely Expensive | |

| Weights/Rates | 0.176 | 0.116 | 0.176 | 0.057 | 0.063 | 0.049 | 0.041 | 0.319 |

|---|---|---|---|---|---|---|---|---|

| CS | SD | PLT | W. ab. | D. | Abr. | PO | Cost | |

| B1 | 0.4 | 0.6 | 0.6 | 0.2 | 0.8 | 0.4 | 0.2 | 0.2 |

| B2 | 0.4 | 0.6 | 0.2 | 0.2 | 0.8 | 0.2 | 0.6 | 0.2 |

| B3 | 0.4 | 0.6 | 0.2 | 0.2 | 0.8 | 0.4 | 0.2 | 0.2 |

| W1 | 0.8 | 0.6 | 0.2 | 1 | 0.6 | 0.8 | 0.4 | 0.4 |

| W2 | 0.8 | 0.6 | 0.6 | 1 | 0.6 | 0.8 | 0.4 | 0.4 |

| SM | 0.4 | 0.6 | 0.6 | 1 | 0.8 | 0.8 | 0.4 | 0.6 |

| GG | 0.6 | 0.6 | 0.6 | 1 | 0.8 | 0.6 | 0.6 | 0.8 |

| RG | 0.6 | 0.6 | 0.2 | 1 | 0.8 | 0.6 | 0.6 | 0.8 |

| PG | 0.6 | 0.6 | 0.2 | 1 | 0.8 | 0.6 | 0.6 | 1 |

| S | 0.6 | 0.6 | 0.2 | 1 | 0.8 | 0.8 | 0.6 | 1 |

| CS | SD | PLT | W. ab. | D. | Abr. | Po | Cost | |

|---|---|---|---|---|---|---|---|---|

| B1 | 0.2182 | 0.3162 | 0.4629 | 0.0750 | 0.3310 | 0.2000 | 0.1302 | 0.099 |

| B2 | 0.2182 | 0.3162 | 0.1543 | 0.0750 | 0.3310 | 0.1000 | 0.3906 | 0.099 |

| B3 | 0.2182 | 0.3162 | 0.1543 | 0.0750 | 0.3310 | 0.2000 | 0.1302 | 0.099 |

| W1 | 0.4364 | 0.3162 | 0.1543 | 0.3748 | 0.2483 | 0.4000 | 0.2604 | 0.198 |

| W2 | 0.4364 | 0.3162 | 0.4629 | 0.3748 | 0.2483 | 0.4000 | 0.2604 | 0.198 |

| SM | 0.2182 | 0.3162 | 0.4629 | 0.3748 | 0.3310 | 0.4000 | 0.2604 | 0.297 |

| GG | 0.3441 | 0.3536 | 0.5303 | 0.3769 | 0.3746 | 0.3078 | 0.4286 | 0.3961 |

| RG | 0.3273 | 0.3162 | 0.1543 | 0.3748 | 0.3310 | 0.3000 | 0.3906 | 0.398 |

| PG | 0.3273 | 0.3162 | 0.1543 | 0.3748 | 0.3310 | 0.3000 | 0.3906 | 0.4951 |

| S | 0.3273 | 0.3162 | 0.1543 | 0.3748 | 0.3310 | 0.4000 | 0.3906 | 0.4951 |

| CS | SD | PLT | W. ab. | D. | Abr. | Po | Cost | |

|---|---|---|---|---|---|---|---|---|

| B1 | 0.0384 | 0.0367 | 0.0815 | 0.0043 | 0.0209 | 0.0098 | 0.0053 | 0.0316 |

| B2 | 0.0384 | 0.0367 | 0.0272 | 0.0043 | 0.0209 | 0.0049 | 0.0160 | 0.0316 |

| B3 | 0.0384 | 0.0367 | 0.0272 | 0.0043 | 0.0209 | 0.0098 | 0.0053 | 0.0316 |

| W1 | 0.0768 | 0.0367 | 0.0272 | 0.0214 | 0.0156 | 0.0196 | 0.0107 | 0.0632 |

| W2 | 0.0768 | 0.0367 | 0.0815 | 0.0214 | 0.0156 | 0.0196 | 0.0107 | 0.0632 |

| SM | 0.0384 | 0.0367 | 0.0815 | 0.0214 | 0.0209 | 0.0196 | 0.0107 | 0.0948 |

| GG | 0.0606 | 0.0410 | 0.0933 | 0.0215 | 0.0236 | 0.0151 | 0.0176 | 0.1263 |

| RG | 0.0576 | 0.0367 | 0.0272 | 0.0214 | 0.0209 | 0.0147 | 0.0160 | 0.127 |

| PG | 0.0576 | 0.0367 | 0.0272 | 0.0214 | 0.0209 | 0.0147 | 0.0160 | 0.1579 |

| S | 0.0576 | 0.0367 | 0.0272 | 0.0214 | 0.0209 | 0.0196 | 0.0160 | 0.1579 |

| V+ | 0.0384 | 0.0367 | 0.0272 | 0.0043 | 0.0156 | 0.0049 | 0.0053 |

| V− | 0.0768 | 0.0410 | 0.0933 | 0.0215 | 0.0236 | 0.0196 | 0.0176 |

| Si+ | Si− | Pi | Rank | |

|---|---|---|---|---|

| 0.0548 | 0.1347 | 0.71 | 2 | B1 |

| 0.1495 | 0.1495 | 0.50 | 7 | B2 |

| 0.1496 | 0.1496 | 0.50 | 7 | B3 |

| 0.1161 | 0.1431 | 0.55 | 6 | W1 |

| 0.0962 | 0.0164 | 0.15 | 8 | W2 |

| 0.0754 | 0.1329 | 0.64 | 5 | SM |

| 0.0358 | 0.1275 | 0.78 | 1 | GG |

| 0.0759 | 0.1457 | 0.66 | 4 | RG |

| 0.0693 | 0.1441 | 0.68 | 3 | PG |

| 0.0691 | 0.1440 | 0.68 | 3 | S |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shohda, A.M.A.; Ali, M.A.M.; Ren, G.; Kim, J.-G.; Abdo, A.M.; Abdellah, W.R.; Hassan, A.M. Sustainable Assignment of Egyptian Ornamental Stones for Interior and Exterior Building Finishes Using the AHP-TOPSIS Technique. Sustainability 2022, 14, 2453. https://doi.org/10.3390/su14042453

Shohda AMA, Ali MAM, Ren G, Kim J-G, Abdo AM, Abdellah WR, Hassan AM. Sustainable Assignment of Egyptian Ornamental Stones for Interior and Exterior Building Finishes Using the AHP-TOPSIS Technique. Sustainability. 2022; 14(4):2453. https://doi.org/10.3390/su14042453

Chicago/Turabian StyleShohda, Ahmed M. A., Mahrous A. M. Ali, Gaofeng Ren, Jong-Gwan Kim, Ahmed M. Abdo, Wael R. Abdellah, and Abbas M. Hassan. 2022. "Sustainable Assignment of Egyptian Ornamental Stones for Interior and Exterior Building Finishes Using the AHP-TOPSIS Technique" Sustainability 14, no. 4: 2453. https://doi.org/10.3390/su14042453

APA StyleShohda, A. M. A., Ali, M. A. M., Ren, G., Kim, J.-G., Abdo, A. M., Abdellah, W. R., & Hassan, A. M. (2022). Sustainable Assignment of Egyptian Ornamental Stones for Interior and Exterior Building Finishes Using the AHP-TOPSIS Technique. Sustainability, 14(4), 2453. https://doi.org/10.3390/su14042453