Improving Sustainable Project Success Strategies Focused on Cost and Schedule for Electrical Construction Project Management

Abstract

:1. Introduction

1.1. Background and Research Objectives

1.2. Research Methodology

- (1)

- Review the existing studies on PCP and PE, and the concept of PCP-PE task strings.

- (2)

- Collect data of 50 recently completed projects from 25 electric companies in the United States.

- (3)

- Evaluate the importance of cost and schedule success for 239 continuous task strings by 29 electrical experts.

- (4)

- Introduce methods for applying the unweighted/weighted value to quantify the performance of task strings implementation.

- (5)

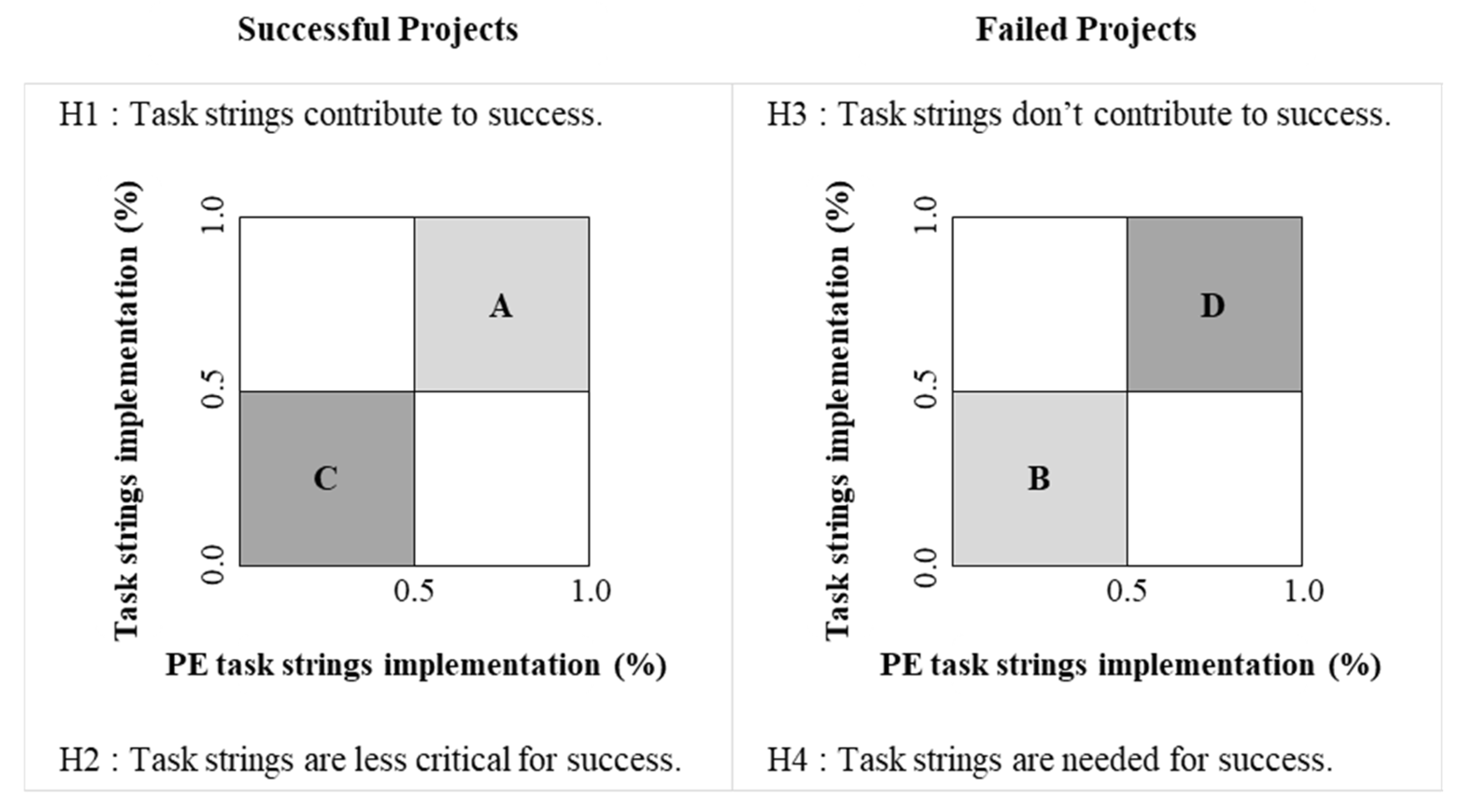

- Develop hypotheses regarding the mean of successful and failed projects to statistically analyze the effect of task strings.

- (6)

- Calculate continuous PCP-PE task strings implementation score for each PE group in terms of cost and schedule.

- (7)

- Compare and analyze successful and failed projects on unweighted and weighted values by performing an independent sample t-test.

2. Preliminary Study

2.1. Existing Studies of PCP and PE

2.1.1. PCP

2.1.2. PE

2.2. Concept of Task String

3. Continuous PCP-PE Task Strings Performance Analysis Plan for Project Success

3.1. Data Collection

3.2. Measurement Method of Implementing Continuous PCP-PE Task Strings

3.2.1. Implementation of Unweighted Task Strings

3.2.2. Weighted Task Strings Implementation

3.3. Hypothesis Setting

4. Performance Analysis of the Effect of Work Strings on Cost and Schedule

4.1. Analysis of Cost Success and Failure

4.1.1. Effect of Unweighted Task Strings

4.1.2. Effect of Weighted Task Strings

4.2. Analysis of Schedule Success and Failure

4.2.1. Effect of Unweighted Task Strings

4.2.2. Effect of Weighted Task Strings

5. Validation of Continuous PCP-PE Task Strings

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, D.Y.; Menches, C.L.; O’Connor, J.T. Stringing construction planning and execution tasks together for effective project management. J. Manag. Eng. 2015, 31, 04014042. [Google Scholar] [CrossRef]

- Meeks, S.E. Enhanced Work Packaging: Design through Workface Execution; Implementation Resource Rep. 272-2; Construction Industry Institute: Austin, TX, USA, 2011. [Google Scholar]

- Francis, A.; Thomas, A. Exploring the relationship between lean construction and environmental sustainability: A review of existing literature to decipher broader dimensions. J. Clean. Prod. 2020, 252, 119913. [Google Scholar] [CrossRef]

- Koskela, L.; Ballard, G.; Howell, G.; Tommelein, I. The Foundations of Lean Construction. Design and Construction: Building in Value; Routledge: London, UK, 2002; pp. 211–226. [Google Scholar]

- Bae, J.W.; Kim, Y.W. Sustainable value on construction projects and lean construction. J. Green Build. 2008, 3, 155–167. [Google Scholar] [CrossRef]

- Bidarianzadeh, G.R.; Fortune, C.J. Lean thinking and the delivery of sustainable construction projects. In Proceedings of the 18th Association of Researchers for Construction Management Conference, Northumbria, UK, 2–4 September 2002; Volume 2, pp. 2–4. [Google Scholar]

- Degani, C.M.; Cardoso, F.F. Environmental performance and lean construction concepts: Can we talk about a clean construction? In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland, 3–5 July 2002; pp. 1–13. [Google Scholar]

- Horman, M.J.; Riley, D.R.; Pulaski, M.H.; Leyenberger, C. Lean and Green: Integrating Sustainability and Lean Construction. In Proceedings of the CIB World Building Congress, International Council for Research and Innovation in Building and Construction, Toronto, ON, Canada, 1–7 May 2004; pp. 2–7. [Google Scholar]

- Khodeir, L.M.; Othman, R. Examining the interaction between lean and sustainability principles in the management process of AEC industry. Ain Shams Eng. J. 2018, 9, 1627–1634. [Google Scholar] [CrossRef]

- Nahmens, I. From lean to green construction: A natural extension. In Proceedings of the Construction Research Congress, Seattle, WA, USA, 5–7 April 2009; pp. 1058–1067. [Google Scholar]

- Ballard, G.; Howell, G. Lean project management. Build. Res. Inf. 2003, 31, 119–133. [Google Scholar] [CrossRef]

- Eriksson, P.E. Improving construction supply chain collaboration and performance: A lean construction pilot project. Supply Chain. Manag. Int. J. 2010, 15, 394–403. [Google Scholar] [CrossRef]

- Green, S.D. The missing arguments of lean construction. Constr. Manag. Econ. 1999, 17, 133–137. [Google Scholar] [CrossRef]

- Jorgensen, B.; Emmitt, S. Lost in transition: The transfer of lean manufacturing to construction. Eng. Constr. Archit. Manag. 2008, 15, 383–398. [Google Scholar] [CrossRef] [Green Version]

- Mao, X.; Zhang, X. Construction process reengineering by integrating lean principles and computer simulation techniques. J. Constr. Eng. Manag. 2008, 134, 371–381. [Google Scholar] [CrossRef]

- Kim, D.Y. Construction Planning and Execution Strategies for Enhancing Project Success on Electrical Construction Subcontracts. Ph.D. Thesis, The University of Texas, Austin, TX, USA, 2011. [Google Scholar]

- Guo, S.J. Identification and resolution of work space conflicts in building construction. J. Constr. Eng. Manag. 2002, 128, 287–295. [Google Scholar] [CrossRef]

- Horman, M.J.; Orosz, M.P.; Riley, R.D. Sequence planning for electrical construction. J. Constr. Eng. Manag. 2006, 132, 363–372. [Google Scholar] [CrossRef]

- Hanna, A.S.; Russell, J.S.; Nordheim, E.V.; Bruggink, M.J. Impact of change orders on labor efficiency for electrical construction. J. Constr. Eng. Manag. 1999, 125, 224–232. [Google Scholar] [CrossRef]

- Hanna, A.S.; Camlic, R.; Peterson, P.A.; Lee, M. Cumulative effect of project changes for electrical and mechanical construction. J. Constr. Eng. Manag. 2004, 130, 762–771. [Google Scholar] [CrossRef]

- Noyce, D.A.; Hanna, A.S. Planned schedule compression concept file for electrical contractors. J. Constr. Eng. Manag. 1997, 123, 189–197. [Google Scholar] [CrossRef]

- Rowings, J.E.; Federle, M.O.; Rusk, J. Design/build methods for electrical contracting industry. J. Constr. Eng. Manag. 2000, 126, 15–21. [Google Scholar] [CrossRef]

- Hanna, A.S.; Peterson, P.; Lee, M. Benchmarking productivity indicators for electrical/mechanical projects. J. Constr. Eng. Manag. 2002, 128, 331–337. [Google Scholar] [CrossRef]

- Abudayyeh, O.; Federicks, T.; Palmquist, M.; Torres, H.N. Analysis of occupational injuries and fatalities in electrical contracting industry. J. Constr. Eng. Manag. 2003, 129, 152–158. [Google Scholar] [CrossRef]

- Hanna, A.S.; Menches, C.L.; Sullivan, K.T.; Sargent, J.R. Factors affecting absenteeism in electrical construction. J. Constr. Eng. Manag. 2005, 131, 1212–1218. [Google Scholar] [CrossRef]

- Menches, C.L.; Hanna, A.S. Conceptual planning process for electrical construction. J. Constr. Eng. Manag. 2006, 132, 1306–1313. [Google Scholar] [CrossRef]

- Riley, D.R.; Varadan, P.; James, J.S.; Thomas, H.R. Benefitcost metrics for design coordination of mechanical, electrical, and plumbing systems in multistory buildings. J. Constr. Eng. Manag. 2005, 131, 877–889. [Google Scholar] [CrossRef]

- Korman, T.M.; Tatum, C.B. Prototype tool for mechanical, electrical, and plumbing coordination. J. Comput. Civ. Eng. 2006, 20, 38–48. [Google Scholar] [CrossRef]

- Khanzode, A.; Fischer, M.; Reed, D. Benefits and lessons learned of implementing building virtual design and construction (VDC) technologies for coordination of mechanical, electrical, and plumbing (MEP) systems on a large healthcare project. ITcon 2008, 13, 324–342. [Google Scholar]

- Hanna, A.; Boodai, F.; El Asmar, M. State of practice of building information modeling in mechanical and electrical construction industries. J. Constr. Eng. Manag. 2013, 139, 04013009. [Google Scholar] [CrossRef]

- Rojas, E. Identifying, recruiting, and retaining quality field supervisors and project managers in the electrical construction industry. J. Manag. Eng. 2013, 29, 424–434. [Google Scholar] [CrossRef]

- Said, H. Prefabrication best practices and improvement opportunities for electrical construction. J. Constr. Eng. Manag. 2015, 141, 04015045. [Google Scholar] [CrossRef]

- Aubry, M.; Hobbs, B.; Thuillier, D. A new framework for understanding organisational project management through the PMO. Int. J. Proj. Manag. 2007, 25, 328–336. [Google Scholar] [CrossRef]

- Cooke-Davies, T. Project management maturity models. In The Wiley Guide to Managing Projects; Morris, P.G.W., Pinto, J.K., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Iqbal, S. Organizational maturity: Managing programs better. In Program Management: A Life Cycle Approach; Levin, G., Ed.; CRC Press/Auerbach: Boca Raton, FL, USA, 2013. [Google Scholar]

- Yazici, H.J. The role of project management maturity and organizational culture in perceived performance. Proj. Manag. J. 2009, 40, 14–33. [Google Scholar] [CrossRef]

- Pasian, B.L. Extending the concept and modularization of project management maturity with adaptable, human and customer factors. Int. J. Manag. Proj. Bus. 2014, 7, 186–214. [Google Scholar] [CrossRef]

- Cleland, D.I.; Ireland, L.R. Project Management—Strategic Design and Implementation, 4th ed.; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Grant, K.P.; Pennypacker, J.S. Project management maturity: An assessment of project management capabilities among and between selected industries. IEEE Trans. Eng. Manag. 2006, 53, 59–68. [Google Scholar] [CrossRef]

- Kerzner, H. Using the Project Management Maturity Model, 2nd ed.; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Torres, L. A Contingency View on the Effect of Project Management Maturity on Perceived Performance. Ph.D. Thesis, Skema Business School, Raleigh, NC, USA, 2014. [Google Scholar]

- Lim, J.; Kim, S.; Kim, J.J. Dynamic simulation model for estimating in-situ production quantity of PC members. Int. J. Civ. Eng. 2020, 18, 935–950. [Google Scholar] [CrossRef]

- Kerzner, H. Planning. In Project Management: A Systems Approach to Planning, Scheduling, and Controlling; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; pp. 345–360. [Google Scholar]

- Oglesby, C.H.; Parker, H.W.; Howell, G. Productivity Improvement in Construction, 1st ed.; McGraw-Hill Higher Education: New York, NY, USA, 1989; pp. 85–89. [Google Scholar]

- Laufer, A.; Shpira, A.; Cohenca-Zall, D.; Howell, G.A. Prebid and Preconstruction Planning Process. J. Constr. Eng. Econ. 1993, 119, 426–444. [Google Scholar] [CrossRef]

- Laufer, A.; Tucker, R.L. Is construction project planning really doing its job? A critical examination of focus, role and process. Constr. Manag. Econ. 1987, 5, 243–266. [Google Scholar] [CrossRef]

- Gidado, K. Enhancing the prime contractor’s pre-construction planning. J. Constr. Res. 2004, 5, 87–106. [Google Scholar] [CrossRef]

- Menches, C.L. Effect of Pre-Construction Planning on Project Performance. Master’s Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2006. [Google Scholar]

- Nasr, Z.J.B. Electrical Project Management Mode. Master’s Thesis, The University of Texas at Austin, Austin, TX, USA, 2009. [Google Scholar]

- Görög, M. A broader approach to organisational project management maturity assessment. Int. J. Proj. Manag. 2016, 34, 1658–1669. [Google Scholar] [CrossRef]

- Andersen, E.S.; Jessen, S.A. Project maturity in organisations. Int. J. Proj. Manag. 2003, 21, 457–461. [Google Scholar] [CrossRef]

- Ibbs, C.W.; Kwak, Y.H. Assessing project management maturity. Proj. Manag. J. 2000, 31, 32–43. [Google Scholar] [CrossRef]

- Mullaly, M. If maturity is the answer, then exactly what was the question? Int. J. Manag. Proj. Bus. 2014, 7, 169–185. [Google Scholar] [CrossRef]

- Brooks, N.; Clark, R. Using maturity models to improve project management practice. In Proceedings of the POM 20th Annual Conference of the Production and Operations Management Society, Orlando, FL, USA, 1–5 May 2009. [Google Scholar]

- Lee, L.S.; Anderson, R.M. An Exploratory Investigation of the Antecedents of the IT Project Management Capability. E-Serv. J. 2006, 5, 27–42. [Google Scholar] [CrossRef]

- Thiry, M. Program Management; Gower, Farnham, Surrey; Routledge: London, UK, 2010. [Google Scholar]

- Wheatley, M. Maturity matters. PM Netw. 2007, 21, 49–53. [Google Scholar]

- Hillson, D. Assessing organizational project management capability. J. Facil. Manag. 2003, 2, 298–311. [Google Scholar] [CrossRef]

- Thomas, J.; Mullaly, M. Understanding the value of project management: First steps on an international investigation in search of value. Proj. Manag. J. 2007, 38, 74–89. [Google Scholar] [CrossRef]

| PCP Group No. | PCP Group | PCP No. | PCP Task |

|---|---|---|---|

| 1 | Team Selection & Turnover | 2 | Hold turnover meeting between project manager and estimator |

| 3 | Hold separate turnover meeting between field supervisor and project manager | ||

| 2 | Scope & Contract Review | 7 | Review plans, schedule, and specifications (Field supervisor) |

| 9 | Conduct site visit | ||

| 10 | Compare estimated materials and work activities to planned performance | ||

| 11 | Identify value engineering and prefabrication opportunities and how to simplify the tasks | ||

| 12 | Prepare construction takeoff | ||

| 3 | Budget Preparation | 27 | Develop, review, or expand cost code schemes |

| 4 | Layout & Sequencing Plan | 30 | Develop layout drawings and installation sequence |

| 31 | Develop including panel, field instructions, pull, or conduit schedules | ||

| 5 | Tracking & Control | 38 | Customize the control system and computerized tracking, i.e., schedule/database, and so on, for the current project |

| PE Group No. | PE Group | PE No. | PE Task |

|---|---|---|---|

| 1 | Team Selection & Turnover | 1 | Setup office trailer and in a convenient location in a timely manner |

| 2 | Setup and lay down storage trailer area | ||

| 7 | Make sure the foreman has everything he or she needs to get started | ||

| 2 | Document Management | 8 | Make use of a project file |

| 9 | Use a documentation control system | ||

| 10 | Use an RFI processing and tracking system | ||

| 11 | Use a change order processing and tracking system | ||

| 12 | Keep all schedule documents including delays | ||

| 3 | Material Management | 17 | Review of material and supplier bid documents |

| 19 | Establish delivery dates | ||

| 22 | Ensure good material handling on site | ||

| 23 | Communicate all material information to the field | ||

| 25 | Lock in the necessary prices | ||

| 27 | Make sure the invoice matches the material costs | ||

| 4 | Tool Management | 28 | Review contract drawing, specifications, and bid |

| 29 | Schedule deliveries and pickups | ||

| 5 | Subcontractors Management | 31 | Determine the scope of work for the subcontractors |

| 32 | Establish subcontracts | ||

| 33 | Determine the subcontractors’ schedule | ||

| 34 | Request submittals and shop drawings | ||

| 35 | Inform the site about the subcontractors | ||

| 37 | Ensure the subcontractors are capable of doing the job | ||

| 6 | Safety Management | 39 | Identify safety issues with the existing work |

| 40 | Plan for additional needs for safety equipment | ||

| 42 | Perform work walks to ensure the safety rules | ||

| 7 | Communication | 43 | Receive support from the company Chief Executive Officer or Vice President |

| 44 | Communicate with the foreman | ||

| 45 | Communicate with the subcontractors and vendors | ||

| 46 | Communicate with the owner and general contractor | ||

| 8 | Scope & Change Control | 54 | Track change orders |

| 9 | Scheduling | 57 | Identify milestone dates and review the schedule |

| 58 | Identify work that impacts electrical activity | ||

| 60 | Review the schedule with the site | ||

| 61 | Update the work schedule regularly | ||

| 10 | Cost Control & Billing | 63 | Use cost codes, i.e., cost breakdown |

| 64 | Track labor costs | ||

| 65 | Track subcontractor and material costs | ||

| 66 | Include issued change orders | ||

| 68 | Compare the project costs to the budget | ||

| 11 | Quality Management | 72 | Check the quality that the site needs |

| 73 | Check the installation quality through on-site visits | ||

| 74 | Perform test results/commissioning | ||

| 12 | Labor Management | 77 | Maintain the correct staff power and crew mix level |

| 78 | Ensure labor hours are turned in | ||

| 13 | Project Closeout | 79 | Ensure that all punch list items are signed off on |

| 82 | Ensure that all purchase/change orders are closed | ||

| 84 | Turn all project closeout documents over to the general contractor |

| Task Strings No. | PCP No. | PCP Task | PE Group |

|---|---|---|---|

| 1 | 3 | Hold separate turnover meeting between field supervisor and project manager | Mobilization |

| 2 | 7 | Review specifications, plans, and schedule (Field supervisor) | |

| 3 | 9 | Conduct site visits | |

| 4 | 11 | Identify prefabrication opportunities, value engineering and how to simplify the work | |

| 5 | 3 | Hold separate turnover meeting between field supervisor and project manager | |

| 236 | 3 | Hold separate turnover meeting between field supervisor and project manager | Project Closeout |

| 237 | 38 | Customize the computerized control and tracking system (database/schedule, etc.) for the current project | |

| 238 | 3 | Hold separate turnover meeting between field supervisor and project manager | |

| 239 | 38 | Customize the computerized control and tracking system (database/schedule, etc.) for the current project |

| Group No. | PCP Task-To-PE Group | Success Projects | Failure Projects | Mean Difference | t Statistic | Sig. (Two-Tailed) | Eta Square | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| N | M | SD | N | M | SD | ||||||

| 1 | Mobilization | 30 | 0.73 | 0.04 | 20 | 0.45 | 0.06 | 0.28 | 4.23 | 0.000 | 0.272 |

| 2 | Document Management | 30 | 0.63 | 0.26 | 20 | 0.42 | 0.27 | 0.21 | 2.81 | 0.007 | 0.141 |

| 3 | Material Management | 30 | 0.62 | 0.24 | 20 | 0.36 | 0.24 | 0.26 | 3.73 | 0.001 | 0.225 |

| 4 | Tool Management | 30 | 0.67 | 0.28 | 20 | 0.41 | 0.33 | 0.26 | 2.92 | 0.005 | 0.151 |

| 5 | Subcontractor Management | 30 | 0.59 | 0.29 | 20 | 0.49 | 0.34 | 0.10 | – | – | – |

| 6 | Safety Management | 30 | 0.57 | 0.37 | 20 | 0.39 | 0.36 | 0.18 | – | – | – |

| 7 | Communication | 30 | 0.58 | 0.32 | 20 | 0.35 | 0.34 | 0.23 | 2.45 | 0.018 | 0.111 |

| 8 | Scope Change & Control | 30 | 0.46 | 0.37 | 20 | 0.38 | 0.39 | 0.08 | – | – | – |

| 9 | Scheduling | 30 | 0.57 | 0.36 | 20 | 0.24 | 0.28 | 0.33 | 3.44 | 0.001 | 0.198 |

| 10 | Cost Control & Billing | 30 | 0.57 | 0.23 | 20 | 0.31 | 0.26 | 0.26 | 3.78 | 0.000 | 0.229 |

| 11 | Quality Management | 30 | 0.63 | 0.29 | 20 | 0.45 | 0.33 | 0.18 | 2.05 | 0.046 | 0.081 |

| 12 | Labor Management | 30 | 0.59 | 0.32 | 20 | 0.17 | 0.27 | 0.42 | 4.88 | 0.000 | 0.332 |

| 13 | Project Closeout | 30 | 0.68 | 0.27 | 20 | 0.49 | 0.30 | 0.19 | 2.39 | 0.021 | 0.106 |

| Group No. | PCP Task-To-PE Group | Success Projects | Failure Projects | Mean Difference | t Statistic | Sig. (Two-Tailed) | Eta Square | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| N | M | SD | N | M | SD | ||||||

| 1 | Mobilization | 30 | 3.77 | 1.10 | 20 | 2.33 | 1.32 | 1.43 | 4.18 | 0.000 | 0.266 |

| 2 | Document Management | 30 | 3.54 | 1.45 | 20 | 2.34 | 1.49 | 1.20 | 2.84 | 0.007 | 0.144 |

| 3 | Material Management | 30 | 3.53 | 1.39 | 20 | 2.04 | 1.38 | 1.49 | 3.74 | 0.000 | 0.226 |

| 4 | Tool Management | 30 | 3.88 | 1.68 | 20 | 2.40 | 1.92 | 1.48 | 2.89 | 0.006 | 0.148 |

| 5 | Subcontractor Management | 30 | 3.34 | 1.65 | 20 | 2.76 | 1.94 | 0.58 | – | – | – |

| 6 | Safety Management | 30 | 3.27 | 2.12 | 20 | 2.24 | 2.06 | 1.03 | – | – | – |

| 7 | Communication | 30 | 2.98 | 1.68 | 20 | 1.70 | 1.77 | 1.28 | 2.58 | 0.013 | 0.122 |

| 8 | Scope Change & Control | 30 | 2.68 | 2.19 | 20 | 2.27 | 2.35 | 0.41 | – | – | – |

| 9 | Scheduling | 30 | 3.43 | 2.15 | 20 | 1.41 | 1.68 | 2.02 | 3.54 | 0.001 | 0.207 |

| 10 | Cost Control & Billing | 30 | 3.24 | 1.33 | 20 | 1.73 | 1.47 | 1.51 | 3.78 | 0.000 | 0.229 |

| 11 | Quality Management | 30 | 3.17 | 1.49 | 20 | 2.23 | 1.66 | 0.94 | 2.10 | 0.041 | 0.084 |

| 12 | Labor Management | 30 | 3.46 | 1.85 | 20 | 0.98 | 1.59 | 2.48 | 4.92 | 0.000 | 0.335 |

| 13 | Project Closeout | 30 | 3.49 | 1.48 | 20 | 2.44 | 1.56 | 1.05 | 2.40 | 0.020 | 0.107 |

| Group No. | PCP Task-To-PE Group | Success Projects | Failure Projects | Mean Difference | t Statistic | Sig. (Two-Tailed) | Eta Square | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| N | M | SD | N | M | SD | ||||||

| 1 | Mobilization | 42 | 0.63 | 0.27 | 8 | 0.54 | 0.23 | 0.09 | – | – | – |

| 2 | Document Management | 42 | 0.56 | 0.29 | 8 | 0.50 | 0.24 | 0.06 | – | – | – |

| 3 | Material Management | 42 | 0.54 | 0.27 | 8 | 0.39 | 0.22 | 0.15 | – | – | – |

| 4 | Tool Management | 42 | 0.60 | 0.32 | 8 | 0.36 | 0.28 | 0.24 | 1.96 | 0.055 | 0.074 |

| 5 | Subcontractor Management | 42 | 0.59 | 0.29 | 8 | 0.34 | 0.34 | 0.25 | 2.16 | 0.036 | 0.089 |

| 6 | Safety Management | 42 | 0.54 | 0.37 | 8 | 0.29 | 0.35 | 0.26 | 1.81 | 0.076 | 0.064 |

| 7 | Communication | 42 | 0.48 | 0.35 | 8 | 0.56 | 0.35 | -0.09 | – | – | – |

| 8 | Scope Change & Control | 42 | 0.46 | 0.37 | 8 | 0.25 | 0.39 | 0.21 | – | – | – |

| 9 | Scheduling | 42 | 0.47 | 0.38 | 8 | 0.29 | 0.27 | 0.18 | – | – | – |

| 10 | Cost Control & Billing | 42 | 0.48 | 0.27 | 8 | 0.36 | 0.26 | 0.12 | – | – | – |

| 11 | Quality Management | 42 | 0.58 | 0.32 | 8 | 0.44 | 0.30 | 0.14 | – | – | – |

| 12 | Labor Management | 42 | 0.45 | 0.37 | 8 | 0.28 | 0.32 | 0.18 | – | – | – |

| 13 | Project Closeout | 42 | 0.62 | 0.29 | 8 | 0.53 | 0.35 | 0.09 | – | – | – |

| Group No. | PCP Task-To-PE Group | Success Projects | Failure Projects | Mean Difference | t Statistic | Sig. (Two-Tailed) | Eta Square | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| N | M | SD | N | M | SD | ||||||

| 1 | Mobilization | 42 | 3.64 | 1.56 | 8 | 3.13 | 1.35 | 0.51 | – | – | – |

| 2 | Document Management | 42 | 3.36 | 1.75 | 8 | 3.02 | 1.48 | 0.34 | – | – | – |

| 3 | Material Management | 42 | 3.32 | 1.67 | 8 | 2.37 | 1.34 | 0.95 | – | – | – |

| 4 | Tool Management | 42 | 3.83 | 2.06 | 8 | 2.30 | 1.79 | 1.53 | 1.97 | 0.055 | 0.075 |

| 5 | Subcontractor Management | 42 | 3.70 | 1.85 | 8 | 2.10 | 2.15 | 1.60 | 2.19 | 0.034 | 0.091 |

| 6 | Safety Management | 42 | 2.99 | 2.03 | 8 | 1.57 | 1.98 | 1.42 | 1.82 | 0.075 | 0.065 |

| 7 | Communication | 42 | 2.43 | 1.83 | 8 | 2.94 | 1.83 | -0.51 | – | – | – |

| 8 | Scope Change & Control | 42 | 2.63 | 2.11 | 8 | 1.44 | 2.21 | 1.19 | – | – | – |

| 9 | Scheduling | 42 | 2.98 | 2.41 | 8 | 1.85 | 1.68 | 1.13 | – | – | – |

| 10 | Cost Control & Billing | 42 | 2.53 | 1.48 | 8 | 1.88 | 1.31 | 0.65 | – | – | – |

| 11 | Quality Management | 42 | 3.02 | 1.67 | 8 | 2.34 | 1.57 | 0.68 | – | – | – |

| 12 | Labor Management | 42 | 2.72 | 2.24 | 8 | 1.69 | 1.94 | 1.03 | – | – | – |

| 13 | Project Closeout | 42 | 3.30 | 1.65 | 8 | 2.90 | 1.96 | 0.40 | – | – | – |

| Project Performance | Ranking of Task Strings | Original Task Strings No. | Validated Task Strings No. | Validated Task Strings (%) |

|---|---|---|---|---|

| Cost Success | Basic | 186 | 116 | 62.4 |

| Better | 48 | 41 | 85.4 | |

| Best | 5 | 3 | 60.9 | |

| Schedule Success | Basic | 233 | 133 | 57.1 |

| Better | 5 | 5 | 100.0 | |

| Best | 1 | 1 | 100.0 |

| Project Performance | Task Strings No. | PCP No. | PCP Tasks | PE No. | PE Tasks |

|---|---|---|---|---|---|

| Cost Success | 5 | 3 | Hold separate turnover meeting between project manager and field supervisor | 2 | Setup storage trailer and lay down area |

| 56 | 11 | Identify value engineering and prefabrication opportunities and how to simplify the work | 17 | Review bid documents for materials and vendors and any vendor responsibilities | |

| 171 | 11 | Identify value engineering and prefabrication opportunities and how to simplify the work | 58 | Identify work that impacts electrical activity | |

| Schedule Success | 126 | 7 | Review plans, specifications, and schedule (Field supervisor) | 33 | Determine the subcontractors’ schedule |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Lim, J.; Lim, H.-C.; Kim, D.Y. Improving Sustainable Project Success Strategies Focused on Cost and Schedule for Electrical Construction Project Management. Sustainability 2022, 14, 2653. https://doi.org/10.3390/su14052653

Kim J, Lim J, Lim H-C, Kim DY. Improving Sustainable Project Success Strategies Focused on Cost and Schedule for Electrical Construction Project Management. Sustainability. 2022; 14(5):2653. https://doi.org/10.3390/su14052653

Chicago/Turabian StyleKim, Janghwan, Jeeyoung Lim, Hyoung-Chul Lim, and Dae Young Kim. 2022. "Improving Sustainable Project Success Strategies Focused on Cost and Schedule for Electrical Construction Project Management" Sustainability 14, no. 5: 2653. https://doi.org/10.3390/su14052653