3. Digital Transformation as an Enabler for Ecological Production Planning

The developed approach for including ecological factors in the planning of process chains includes forecasting energy and resource consumption. For this to be efficiently integrated into the planning of process chains, prediction must be automated. This forecast requires sufficient process knowledge, which can only be generated by collecting and analyzing process data. With an increasing degree of digitization in manufacturing, knowledge about manufacturing processes can be generated by using process models. Currently, different data sources are available for the creation of process models and allow automated data collection. For example, data can be read out directly from the machine control system (e.g., process parameters and the resulting power of the spindle and axis). External sensors can be used to include the resource consumption (e.g., amount of the consumed cooling lubricant) of the process or data can be generated by using process simulations (e.g., material removal simulations) to determine the amount of removed material. Today, the possibilities of automated data acquisition facilitate the use of process models and enable a reaction (e.g., post-control) of production in almost real-time. Recorded data from different sources (e.g., control data, sensor data, and simulation data) can be stored, synchronized, and aggregated in databases. Based on collected data, regression methods can be used to calculate the effects of input variables and process parameters on the output variables of the process, such as energy demand.

The structure of a process model can be illustrated using a milling process. The process model is intended to provide a prediction of the embodied energy demand depending on relevant input variables and process parameters. In milling processes, the properties of the machine tool (e.g., machine tool type, size, and power requirements) represent input variables. Furthermore, the process parameters feed rate and cutting speed can be identified as relevant process parameters. Output variables are the resulting energy and resource consumption (e.g., electrical energy or worn tools).

The process models are available for use within various levels of planning of production processes. Activities in process planning can be divided into categories that differ in their level of detail. The main categories are as follows [

25]:

Selection and sequencing of manufacturing operations;

Resource selection (raw material, machines, tools, and auxiliary devices);

Selection of suitable process parameters.

While there are numerous opportunities to include process models in the planning of processes and process chains in the age of Industry 4.0, the prevalence in practice varies. Studies show that the use of digital tools in process planning strongly depends on the characteristics of the respective company. For example, the size of a company has a major influence on the spread of digital tools in process planning.

Process models that predict embodied energy consequently allow sustainable planning of production process chains. Manually, this is a challenge because ecological sustainability cannot be observed directly (unlike quality criteria of workpieces). Thus, planning based on empirical values is difficult. By predicting energy and resource consumptions, a suitable process chain can be selected. As part of detailed planning, process parameters that lead to low consumption can be selected. The approach to sustainable planning of process chains, which uses process models, is described in more detail in the following chapter.

4. Approach for Resource-Efficient Process Planning

Various approaches exist for the ecological assessment and optimization of existing process chains or production systems. These show high savings potentials [

13,

17,

26]. A much greater contribution to achieving ecological goals can be reached if an ecological assessment of various alternative process chains is carried out from an early stage of planning of process chains [

3].

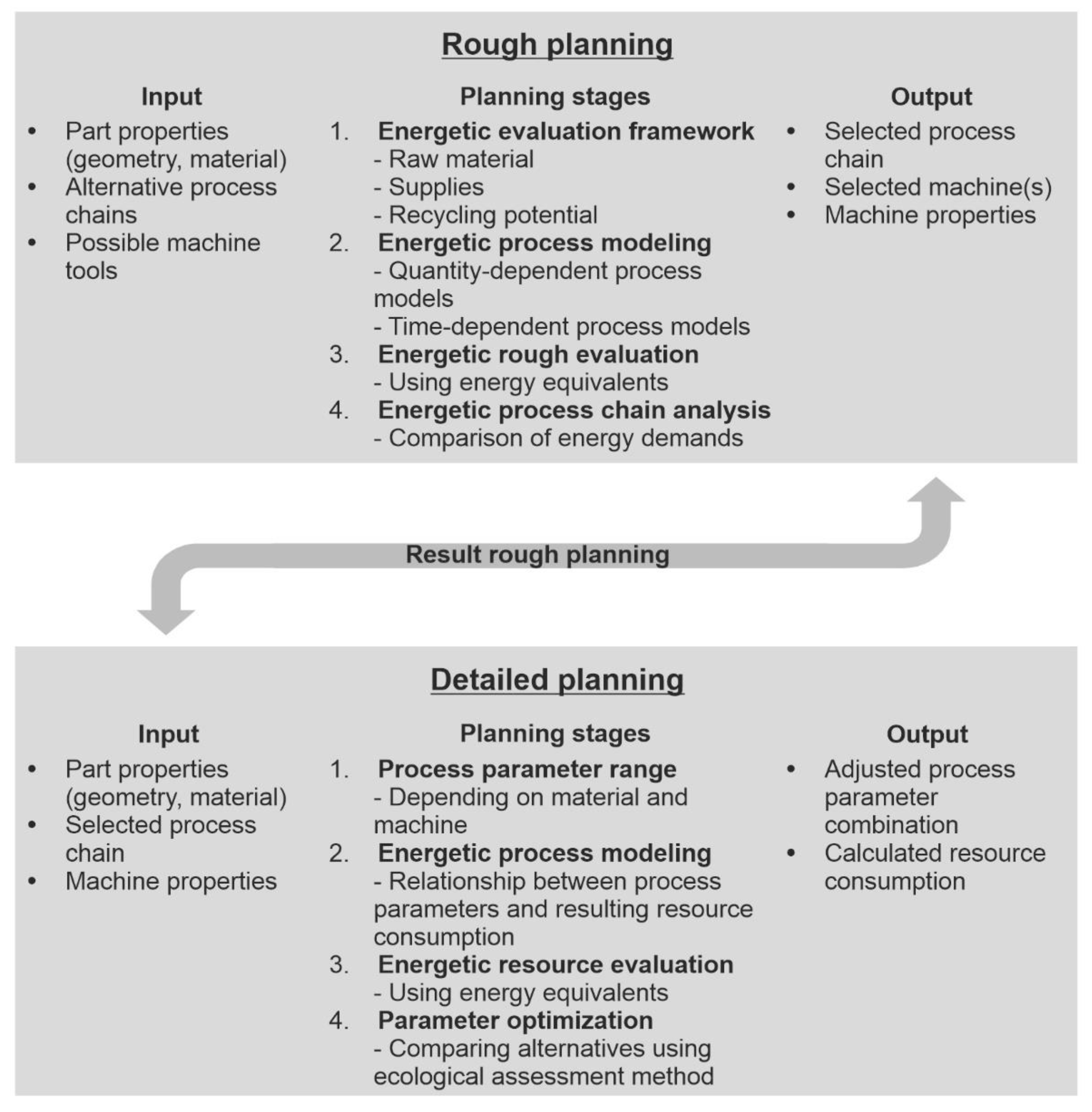

Thus, the issue of sustainability should not only be included in detailed planning of process chains but also in a rough assessment. This paper, therefore, presents a consistent approach to ecological planning of process chains, divided into two levels (see

Figure 1). At each level, process models are used as a digital representation of the processes. The first stage within sustainable planning consists of rough planning. The aim is to predict the energy requirements of alternative process chains in the design stage. After a successful rough assessment, sufficient knowledge about the later energy demand is already available before detailed process planning. This means that an initial preselection of process chains can be made under environmental assessment criteria as early as the process chain design stage. The result of the rough assessment is then passed onto detailed planning. Here, process steps and process parameters of the respective process chain are ecologically planned to ensure high energy and resource efficiency in production.

Input variables for rough planning include information on the product to be manufactured (e.g., geometry and material information) and the technically possible process chains. Another input variable is the possible machines. These result from the possible process chains and available machines of a company. In the course of rough planning, all resources that are used in the processes are first identified. For those resources, it is then checked which recycling share is achievable in practice. This share is, therefore, a fixed percentage and is not dependent on process planning. Process models are then created that are quantity or time dependent. The process is roughly mapped here, and resource consumption is predicted depending on the duration of the process or the quantity of resources used. For all alternatives, the calculated resource consumption is then converted into an energy equivalent and compared. Since process models represent a comparably rough view of a process chain, the uncertainties of the models are included. The process chain with the lowest calculated consumption is now selected. The selected process chain and information on the associated machines are passed on to the detailed planning.

In detailed planning, it is first determined which process parameters are to be adjusted and in which range they lie. This ensures stable process performance. Then, process models are created that show the relationships between process parameters and the resulting resource consumption. These are, therefore, no longer only time dependent or quantity dependent. An example of this is the relationship between process parameters and tool wear in milling: As cutting speed increases, so does tool wear. In addition to the effects on direct resource consumption, the effect of the process parameters on the recyclability of the used resources is also mapped. An example of this is the raw material titanium: Depending on the process parameters, the chemical composition of chips changes and, thus, also the recyclability of these chips. In the recycling process, this increases the consumption of energy and resources. All predicted resource consumption is converted into an energy equivalent. Subsequently, all alternatives of the detailed process planning (i.e., combinations of values of the process parameters) are evaluated and compared with the help of the process models. The process parameter combination with the lowest calculated energy consumption is selected.

Within the developed approach, it becomes clear that the topic of sustainability in planning of process chains must find its way into both rough and detailed planning to ensure efficient and sustainable planning. Under industrial conditions, the production planner cannot design various process chains and examine their energy and resource efficiency as part of detailed planning. Instead, a preliminary assessment of various process chains is already required as part of the rough assessment to ensure efficient planning.

A major influence on the ecological assessment of a production process is the chosen system boundaries. This is closely related to phases one and two of LCA analysis. They influence the extent to which a used resource affects the total energy input. This approach to resource-efficient detailed process planning distinguishes between four states of resources used in production processes:

Retention in the system—usable for the process;

Discharge from the system—usable;

Exit from the system—usable for the process after resetting to the initial state;

Disposal—no longer usable for the process.

The four states that resources can assume after they have been used in a process are illustrated in

Figure 2 using the example of a machine tool. Resources in the first state remain within the system boundaries of the process and can be reused immediately. An example for this is cooling lubricant, which is collected and returned to the process. Resources of the second state have a usable state and leave the system boundaries of the process and the ecological assessment. An example of this includes manufactured components of a process or auxiliary and operating materials that do not wear out. Resources of the third state can be used again for the process after use but only after a reprocessing process (transfer to the initial state). An example of this includes chips, which can be returned to the process after being remelted into solid material [

27]. Since reprocessing processes generally also lead to energy and resource consumption, these are included in the environmental assessment. As previously described, the choice of process parameters in detailed planning can influence the recyclability of resources and, thus, energy and resource consumption in the recycling process. Resources in the fourth state can no longer be used for the process and must be disposed of. An example of this includes indexable inserts, which are generally not reprocessed and are considered as a disposable product.

Since the disposal of goods and reprocessing cause resource and energy consumption, these are also included in the ecological assessment. It is important to note that resources cannot necessarily be assigned to only one state. For example, in the case of cooling lubricant, a large portion is returned to the process as described, but a portion is removed from the system boundaries of the process by adhesion to chips and is thereby subsequently disposed of.

In the first step of the ecological process assessment within the framework of detailed planning, the embodied energy of all used resources is calculated. Subsequently, this value is adjusted. For certain categories, energy values are “credited” due to the possibility of reuse:

Category 1 (E1): Resources that do not leave the system boundary of the process can be reused directly. Consequently, no energy is expended.

Category 3 (E3): Resources that can be reused in the process after reprocessing. The value for the resource itself is deducted. However, the required energy to prepare the resource (E3,rec) is added.

For ecological assessment in detailed planning, the following formula is obtained.

For the correct calculation, it should be noted that a resource can be assigned in parts to different categories. This can be illustrated by the example of cooling lubricant in machining processes: Normally, there is a cycle in which used cooling lubricant can be collected and returned to the process. However, a small part leaves the system boundaries, for example, due to adhesion to chips.

4.1. Sustainable Rough Planning of Process Chains

Conventional rough planning includes decisions about investments, production technologies, and process chains based on a defined production plan. By applying the developed method for sustainable rough assessment, the energy impact of alternative process chains can be determined despite an existing information deficit. The decisions to be made are taken under conditions of uncertainty, since at this planning stage only limited information is available on the respective process conditions and, thus, on the target variables of planning.

A preliminary requirement for carrying out a rough energy rating is knowledge of the workpiece and of alternative process chains for manufacturing the workpiece. The first planning phase begins by clarifying the energy rating framework. Here, an energetic assessment of the material has to be carried out. Depending on the production method or process chain, an energy assessment of the cooling lubricant must also be conducted and the recycling potential has to be considered. This is necessary when comparing alternative process chains. For example, a closed material loop can save a large amount of primary energy demand compared to process chains with no or lower energy demand. This saving potential can be offset in the form of an energy credit.

In a second step, the energetic process modeling is performed by creating energetic process models considering uncertainties. Two different methods are feasible for this, depending on the manufacturing process. On the one hand, the process models can be set up as a function of the material (e.g., kWh/kg). For this purpose, an empirical energetic database must be set up for each manufacturing process. In order to determine minimum and maximum energy requirements, 95% confidence intervals of the determined energy requirements shall be generated. On the other hand, process models can be set up as time-dependent (e.g., W). The expected minimum and maximum process conditions (e.g., process-related process parameters) are used to predict the process duration for each manufacturing process. In a third step, the material efficiency of various manufacturing processes is investigated. The ratio of input to output quantity can be determined from empirical study data. The material efficiency determined is then added to the weight of the workpiece blank. For example, with a material efficiency of 75% and a raw workpiece weight of 1 kg, a raw material using1 kg/0.75 = 1.33 kg is included in the energy assessment. This can have a significant influence on the resource efficiency of a process chain. Subsequently, the predicted total energy demand of the process chain is determined. By comparing respective energy requirements under uncertainties, the relevant process chain is selected, which is finally specified within detailed planning.

4.2. Sustainable Detailed Planning of Process Chains

The starting point of detailed planning is different than the starting point of rough planning. In contrast to rough planning, the product manufacturing steps and the manufacturing technologies are already determined. From this information base, the process parameters of the individual processes are to be determined. Based on this, the process parameters of the individual processes have to be determined. This applies to a wide variety of processes, such as machining or additive manufacturing as well as forming. For this purpose, the processes are considered in greater detail. The calculation is no longer based on average values for machines but on the properties of specific machines. Resource-efficient detailed process planning aims to minimize the resource requirements of the individual processes. This optimization also considers the condition of all resources after their use in the process; thus, the limits of the regarded system differ from those of rough planning.

Previously, the selection of system boundaries for the use case was described. Here, it is considered that used resources can have different states, which can influence the environmental sustainability of the process by different degrees. The described ecological assessment of production processes makes it possible to find an optimum from the point of view of resource efficiency. By process models, various scenarios can be analyzed and the most favorable one selected. Detailed planning considers that the shares of the different states can change depending on the process’s execution.

5. Use Case and Discussion

5.1. Use Case Description

A reference workpiece is defined for the application of the resource-efficient planning method for process chains. The properties of the workpiece to be manufactured are shown in

Table 1.

The dimensions of the reference workpiece are shown in

Figure 3.

Three different process chains for manufacturing the reference workpiece are illustrated in

Figure 4. The first process chain consists only of subtractive manufacturing. In the first step, material is removed from a blank made of solid material by a roughing process (milling). Here, it is assumed that the workpiece is made from a cuboid with a volume of 700 cm

3. It results in 28.5% of the material being removed in the milling process. The surface is then machined using a finishing process (also milling). In the second process chain, it is assumed that the blank in the first step is brought into the approximate shape of the final workpiece by forging. This is followed by a finishing operation. The last process chain uses an additive manufacturing process (laser powder bed fusion), which is followed by subtractive finishing.

The aim is to select and plan a process chain, which enables the most ecologically favorable production of the workpiece. The first step in rough planning is to evaluate which process chain is expected to consume the least amount of resources. Then, in detailed planning, suitable process parameters are selected for each process step of the chosen process chain. It should be noted that only ecological sustainability is used as a target parameter in resource-efficient planning.

5.2. Results of Rough Planning

For the presented reference case, models of the energetic assessment of the raw material, forging, and additive manufacturing (AM) were developed first, based on extensive literature research (see

Table 2).

Several studies have been conducted to determine the influence of different parameters on the resulting base load of a machine tool [

33]. The study by Behrendt et al. shows that a simple classification of machine tools only according to their size is not sufficient to reliably derive the corresponding base load. They conclude that the base load increases with the increasing size and complexity of a machine tool. Therefore, for better classification, the criteria of size should be enriched with further ones representing the complexity of a machine tool. The authors, therefore, suggest considering additional criteria such as the number of spindles or machine type. Based on the described research results of Berehndt et al., further possibilities of influence on the basic load of a machine tool were collected (see

Table 3). Subsequently, a significance analysis was performed to determine the influence of the parameters on the base load.

Multivariate linear regression models were formed for various combinations of the influencing parameters listed in

Table 3 and compared in terms of the achieved prediction performance. The resulting regression model with the criteria number of axes, type, and space requirement achieved the highest accuracy in calculating the expected base load in kilowatts (kW). The result is shown in Equation (2).

Corresponding data from 35 different machine tools were used to develop the regression model. The model has a correlation coefficient of r = 0.94. The coefficient of determination is R2 = 0.89, and the adjusted coefficient of determination is R2adj = 0.85. The process’s duration is determined by using the cutting volume and varying material removal rate, which can be calculated by assuming minimum and maximum process parameters.

The limit values of the process parameters are determined based on reference value tables, such as [

34]. As already described, a variety of process information is necessary, which forms the basis for rough energy rating. The process information and assumptions for the roughing and finishing of Ti-6Al-4V can be found in

Table 4 and

Table 5.

Based on the process information defined in

Table 4 for sustainable rough planning, the material removal rate in cubic centimeter per minute (cm

3/min) (Q

W) was first calculated according to Equation (3).

This results in varying metal removal rates between 60.16 and 350.14 cm3/min. Calculated with the corresponding chip volume of 159 cm3, the process duration varies between 0.45 and 2.64 min.

Based on the process information defined in

Table 5 for the finishing of Ti-6Al-4V, the first Q

W in cubic centimeter per minute (cm

3/min) is calculated according to Equation (3). This results in different material removal rates between 3.61 and 32.77 cm

3/min. With the corresponding chip volume of 41 cm

3, the process duration is calculated between 1.25 and 11.36 min. Due to the machine tool data defined in

Table 6, the expected base load is calculated to be 2.81 kW according to Equation (2).

Based on the described information, the first step of the developed approach of sustainable planning of process chains could be carried out for the presented process chains. The different expected energy demands for process chains 1–3 are shown graphically in

Figure 5. The results show that, under the given conditions, process chain 1 is the most energy efficient process chain, both on average and when considering the range of variation. However, the results show that, for an integrated energy rating, the supposed upstream processes of a process chain also need to be considered.

Thus, from a holistic point of view, it is not optimal to save the energy of pre-machining and choose less efficient pre-machining. Rather, the problem of energy and resource efficiency would be shifted to the supplier, for example. However, when viewed holistically, this step can sometimes result in worse energy and resource balance. By using the result of energy-related rough planning, efficient planning of the process chain can finally be carried out within the framework of detailed planning. Thus, an average of about 21% in energy could be achieved by choosing process chain 1 over a selection of process chain 2. The savings potential compared to process chain 3 is about 10%.

5.3. Results of Detailed Planning

Based on the results of the rough planning, only an assessment of the first process chain takes place. Here, values for two parameters of the milling processes have to be determined, with the aim of finding the most sustainable setting. The parameters are cutting speed and the pressure at which the cooling lubricant is supplied during titanium machining. With higher pressure, the process is supplied with correspondingly more coolant per time unit.

Various resource consumptions occur in the considered process chain: The machine consumes electrical energy. Furthermore, a proportion of the cooling lubricant used is consumed and thus represents a resource expense. Tool wear also leads to a consumption of resources. Finally, the material is also included in ecological assessment. In the case of chips, resource consumption arises from the recycling process.

The process parameters not only influence resource consumption by the process itself but can also influence the recyclability of the resources used (e.g., the chips). If recyclability is low, reprocessing can thus become more resource-intensive (e.g., due to the need to add primary material). When recycling chips, aviation quality (grade 5) is aimed for. Consequently, when processing chips, all quality criteria of the grade 5 classification must be met. According to standards for titanium alloy grade 5 ASTM B 256a Ti-6Al-4V, a maximum oxygen content of 2000 ppm, a maximum nitrogen content of 500 ppm, and a maximum carbon content of 800 ppm are permitted for high-quality applications [

35].

The data used to build the model of the milling process were generated as follows. Ti-6Al-4V workpieces were used, and all blanks were taken from one batch. A characterization of the initial chemical composition reveals oxygen content of 1650 ppm, nitrogen content of 150 ppm, and carbon content of 130 ppm. Milling tests were carried out on a Heller H5000 machine tool. For cooling, an internal cooling system with an 11% water- based emulsion was used. The used cutting tools were Walter Tiger-tec

® Silver inserts ADMT120408R-F56 WSM35S mounted on a Walter F4138.B27.063.Z05.34 Xtra-tec body. Cutting parameters are shown in

Table 7. The power consumption of the individual axes and process times was read out using DeltaLogic’s AGLink software. The power consumption of the peripheral devices was recorded using a performance measuring device. Tool wear was analyzed with a Keyence VHX600 video microscope. Following machining tests, the chemical composition of the chips was analyzed. Chips were cleaned with acetone in an ultrasonic bath. Finally, they were dried under air. The clean chips can be analyzed with melt samples. An analysis of oxygen, nitrogen, and carbon was then performed using a Leco T500 and a Leco CS200. All recorded data were transformed into regression models. This allows predictions to be made about individual resource consumption (electric energy, tool wear, coolant usage, and material recyclability). Subsequently, these resource consumptions are converted into energy equivalents. The reference values listed in the previous subsection are used for this purpose.

Figure 6 shows the planning result based on the created process model for the selection of cutting speed and pressure of the cooling lubricant supply for the roughing process. In this representation, the produced workpiece is not included in embodied energy because this value does not depend on process parameters. The horizontal axis shows the cutting speed, the vertical axis, and the resulting embodied energy. Individual graphs are drawn for different pressures.

If planning is carried out according to the previously described assessment method (inclusion of resource recycling in the determination of ecological sustainability), the optimal result does not aim for short process time alone. At a coolant supply pressure of 40 bar, embodied energy initially decreases as cutting speed increases since the process time is reduced and consequently fewer resources are used. However, as cutting speed continues to increase, the embodied energy rises sharply, as recyclability decreases due to impurities occurring (such as through the binding of oxygen and carbon). At a higher coolant supply pressure of 80 bar, the embodied energy is initially higher than at 40 bar because more coolant is supplied. As cutting speed increases, the lower recyclability of the chips (due to contamination in the milling process) initially causes the embodied energy to increase. This greatly increases the amount of material used in recycling the chips. However, as cutting speed increases (60 m/min), embodied energy decreases again. Here, again, there is high recyclability due to the low contamination of titanium chips, which results in low resource requirements.

Overall, two combinations are conceivable here:

Figure 7 shows the result of detailed planning for the finishing process according to the same scheme. Here, differentiation according to supply pressures is omitted, since only high pressures are considered for the process. Consequently, only the value of the cutting speed is adjusted. In this case, medium cutting speeds results in the most favorable planning result in each case, since the recyclability of the resulting chips is high, but the process time is short enough at the same time.

5.4. Discussion

This paper presents an approach to consider ecological factors at each planning phase. The special feature is that the level of detail of the ecological assessment is based on the level of detail of the planning phase. The application of the developed approach for the use case shows that a prediction of the ecologically most favorable process chain is possible even in planning phases with limited data (rough planning). The results for detailed planning show that a comprehensive consideration of the ecological impact of manufacturing processes can influence the planning result. In the case of the presented use case, a fast process with low usage of cooling lubricant is not ecologically optimal, although fewer resources are consumed in the process itself. The impact on the recyclability of chips makes the alternative process performance ecologically unfavorable. The application of the presented approach has limitations, mainly due to the necessary data acquisition for the creation of the process models. Access to necessary data via information technology interfaces (e.g., via machine controls) must be provided. If no such interfaces exist, the measured variables must at least be observable via external sensors. Overall, the implementation of the approach is limited by the degree of digitization of the company (or more precisely, of the production system).