Abstract

The philosophy of total quality management is based on meeting quality requirements in all processes and meeting customer needs quickly and accurately through the contribution of all employees. This concept means that all the processes in an enterprise, all the technology used, and all the workforce employed represent the total quality of the enterprise, with the necessary controls and corrections made to ensure that the quality is sustainable. In this study, a detailed literature review and classification study regarding Industry 4.0, Industry 4.0 technologies, and quality has been carried out. The place and importance of quality in Industry 4.0 applications have been revealed by this classification study. In previous studies in the literature, the relationship between Industry 4.0 technologies and quality has not been examined. With this classification study, the importance of quality in Industry 4.0 has emerged, and an analysis has been conducted regarding which quality criteria are used and how often.

1. Introduction

Companies worldwide face significant challenges due to recent environmental, social, economic, and technological developments [1]. To meet these challenges, companies need to be agile and manage their entire value chain sensitively [2]. Various innovations can be made to realize agile management. In addition, companies need physical and virtual structures to enable collaboration and rapid adaptation throughout the entire lifecycle, from innovation to production and distribution [3]. Meeting these needs is essential for value chains to be effective. In addition, companies’ futures are changing with the development of digital environments, where value chains are more influenced by each other and processes are becoming smarter [4,5]. In order to keep up with this change, companies aim to reduce unnecessary costs, increase business performance and quality, and shorten cycle times.

With the advancement in technology, the systems and processes used to create value are also developing. In order to increase value production, development processes and technologies need to adapt to the new industrial revolution (Industry 4.0). Industry 4.0, known as the fourth industrial revolution, has emerged with the digitalization of the manufacturing industry [6]. Industry 4.0 is the digitization of all physical assets to create an infrastructure and the stakeholders that make up the e-value chain [7]. With Industry 4.0, which leads the digitalization era, production systems, processes, machines, and environments are all digitized [8,9,10].

In order to achieve digitalization, high technologies must be used. High technologies have an impact in every sector. However, the sustainability and continuity of these technologies are also important, and in this context, it is necessary to ensure the sustainability of Industry 4.0. Iyer [11] has researched developments in sustainable production processes worldwide. By perfoming a study in India, he examined how developing economies should transition to Industry 4.0. Environmental sustainability is becoming an essential competitive factor among manufacturing companies due to economic markets and international regulatory pressures. In recent years, the increase in awareness of environmental issues by consumers has resulted in companies offering products that are environmentally monitored and certified. Papetti et al. [12] states that by sharing data between components, a structure can be created that can effectively model complex supply chains and measure the environmental sustainability of items.

Industry 4.0 is a concept that has been studied frequently in recent years. There are many applications and classification studies compiled in the literature. Öztemel and Gürsev [13] carried out a classification study to provide an applied Industry 4.0 library to academics and to those who apply these technologies in the industry. In order to ensure the reliability of the review process, 619 studies related to Industry 4.0 were analyzed. In addition to classification, the researchers also presented a roadmap for those who want to achieve digitalization in production. Muhuri et al. [14] conducted bibliometric analyses on the latest developments in Industry 4.0 and examined how often Industry 4.0 was studied. Web of Science (WoS) and Scopus databases, which are widely used in bibliometric analysis, were preferred. As a result of the analysis, it was found that the most productive countries in Industry 4.0 are Germany and China, and the most frequently used keywords are: cyber–physical systems, Internet of Things, smart production, and simulation. Cobo et al. [15] examined the working areas of Industry 4.0. Cyber–physical methods, cloud computing techniques, innovative technologies, and supply chain comparisons were made. Researchers examined 333 studies on Industry 4.0 in the Web of Science with SciMAT software between 2013 and 2017, arguing that cyber–physical methods and cloud computing are the most preferred techniques. Culot et al. [16] analyzed the definitions of Industry 4.0 keywords in the literature. Classification was made by determining the elements for each definition. In the study of Mariani and Borghi [17], a bibliometric analysis of the potential development of Industry 4.0 in service sectors was carried out. Li et al. [18] examined the relationship between the existing literature on data, information, and knowledge dissemination in the manufacturing industry and Industry 4.0 technologies. This relationship was separated into groups and examined as *additive manufacturing, *cloud production, *information transfer, *information management, and *information sharing. Echchakoul and Barka [19] conducted a literature review on the effects of Industry 4.0 on the plastics industry. In the study, the Bibliometrix R tool and VOSviewer software were analyzed, and “Internet of Things” (IoT) was found to be the most used keyword. It was also discovered that Industry 4.0 could also be analyzed by dividing it into clusters.

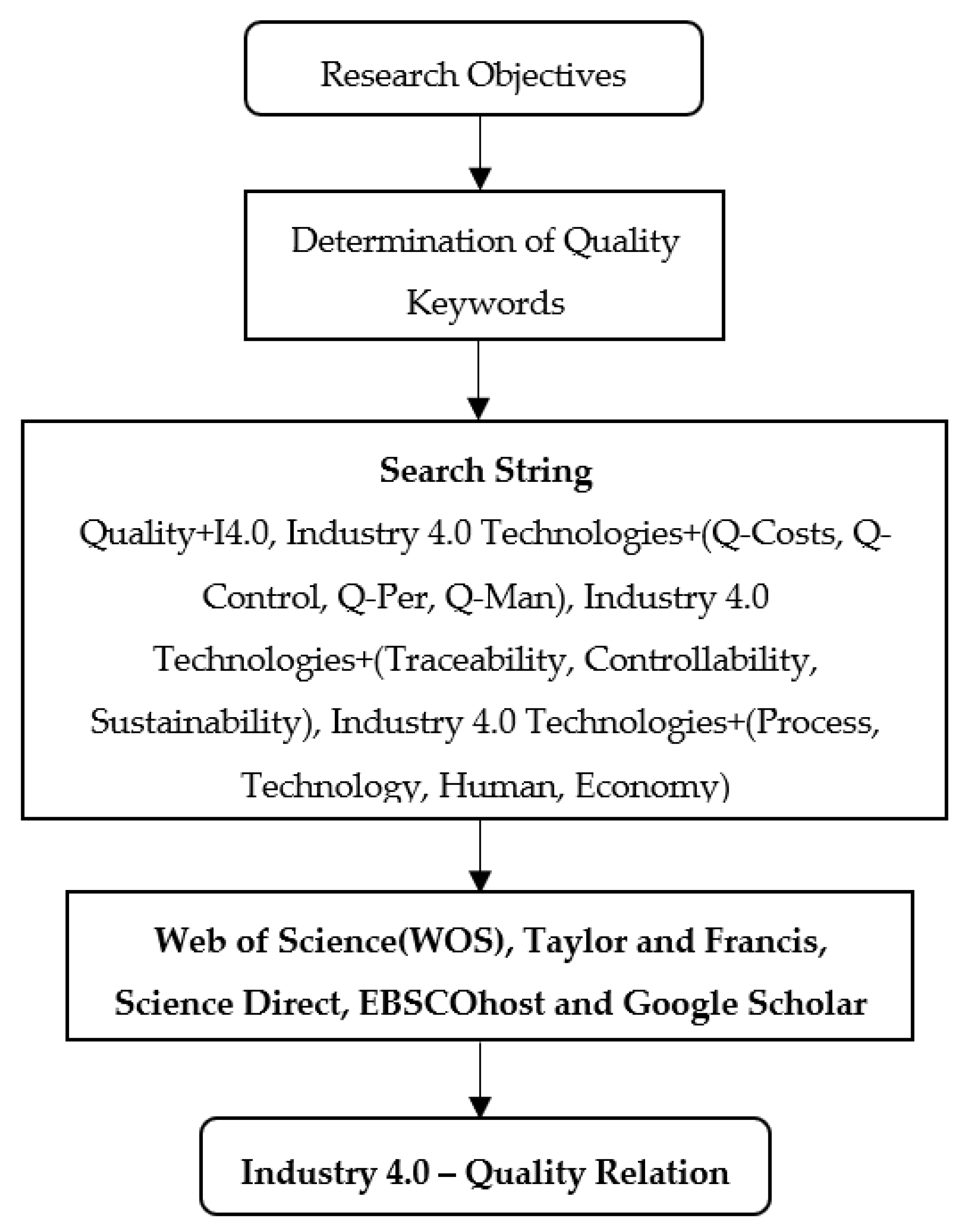

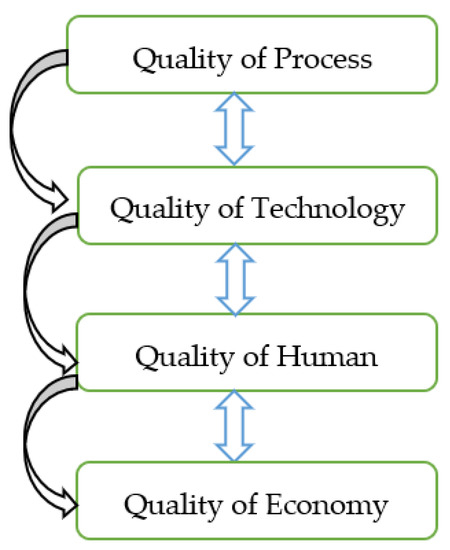

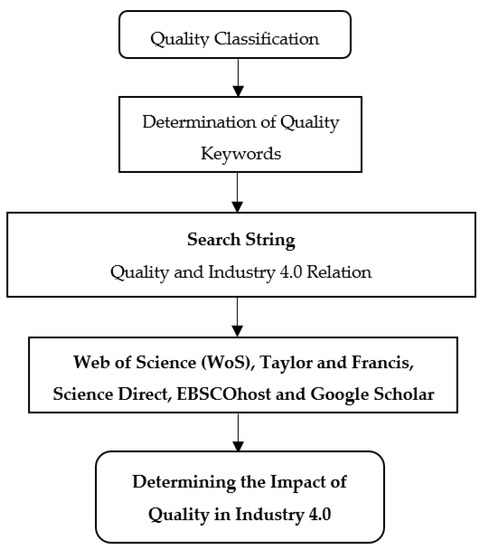

This study conducted a literature search on the definitions, application areas, advantages, and difficulties of Industry 4.0 and its technologies. In the first and second parts of the study, literature research on Industry 4.0 is included. In addition, how Industry 4.0 technologies are used on a sectoral basis is investigated. In the third part of the study, the content and scope of quality are explained. The traceability/controllability/sustainability of all the processes in the enterprise, the technology used, and the quality of the workforce employed are then examined within the scope of Industry 4.0 and the quality relationship. The flow of the study is shown in Figure 1.

Figure 1.

Flow-chart of the study.

In the fourth part of the study, quality and Industry 4.0 technologies (Internet of Things, cloud, artificial intelligence, big data, 3D printer, cyber-physical systems, augmented reality) are examined with the help of SciMAT and VOSviewer programs, and a classification study is carried out. The classification consists of four stages. In the first stage, 958 studies regarding quality and Industry 4.0 technologies were examined. In the second stage, quality was divided into four main titles (quality costs, quality control, quality performance, quality management), and the relationship of each subject with Industry 4.0 technologies was examined separately. The classification structure is shown in Table 1. In the second stage, a total of 226 articles were examined. In the third stage, 797 studies, in which each of the criteria of traceability, controllability, and sustainability in the quality assessment were used together with Industry 4.0 technologies, were examined. Finally, at the last stage of classification, how the relationship between process, technology, human, economy, and Industry 4.0 technologies determines quality in Industry 4.0 was examined. At this stage, 6954 articles were scanned.

Table 1.

Industry 4.0 studies.

In this study, a classification study was conducted by considering Industry 4.0 in terms of quality. There are many classification studies related to Industry 4.0 in the literature, but these studies are mostly classified in terms of technology and method. In addition, there are also classification studies carried out on a sectoral basis. However, there is no study in the literature that classifies quality, integrating it into Industry 4.0, and classifying the two together, as we have done in this study. In this sense, the study is original.

2. Literature Review

Industry 4.0, which also means digital transformation, is a concept that represents increasing capacity with technology, data exchange, and cyber systems. It plays a vital role in creating smart factory systems that aim to automate and remotely monitor all physical systems [62]. Many modern automation systems are the most important distinguishing elements of Industry 4.0 and include data exchange and production technology [63,64].

2.1. Smart Technologies in Industry 4.0

Industry 4.0 refers to the organization of production processes based on technologies and devices that communicate autonomously with each other throughout the value chain [65]. It creates production ecosystems driven by intelligent systems with autonomous features, such as self-configuration, self-monitoring, and self-development [66]. From the procurement process to the production process, applications are made with Industry 4.0 technologies in many smart factories, with more efficient work at maximum capacity being supported. Along with technological development, the way the factories work has also changed. With developing technologies, smart factories have begun to be used. The leading Industry 4.0 technologies are smart production, smart product, and smart supply [62,67]. In smart factories, processes at any stage of production can be renewed and improved using automation [68], work [69], and control [70]. Smart factories are used to provide an integrated data exchange between the physical world and the virtual world [71].

Bibby and Dehe [7] aimed to measure the application level of Industry 4.0 technologies in three dimensions in the evaluation model they developed. These dimensions were: *factory of the future, *people and culture, and *with strategy. Using Industry 4.0 applications, there could be seven technologies in future factories. These are: *Internet of Things and cyber–physical systems, *big data, *cloud computing, *blockchain, *autonomous systems and robots, *additive manufacturing (3D printers), and *augmented reality [62,72,73]. Simulation and some system integration tools also support the implementation of Industry 4.0 [74]. Connecting tangible assets to the internet makes it possible to access data remotely and to control objects. Synergetic systems such as the Internet of Things are needed to consolidate existing data on the internet [75]. With the increasing use of 4G-LTE (fourth generation long-term evolution) wireless internet access and wi-fi technologies, it has become essential to reach communication networks at any time [76]. With the spread of the internet, new paradigms have emerged, with one of the most prominent being the Internet of Things technology [77]. The term Internet of Things has become widespread and can be defined as an intelligent network structure in which objects communicate using techniques without manual data entry [76,78,79,80]. The Internet of Things means that addressable objects communicate with a specific protocol [81]. Smart devices used for the internet can identify themselves, establish networks, and transfer the collected information to public cloud services that can store and analyze it [82].

2.2. Big Data in Industry 4.0

Determining a data-based strategy is important for businesses to survive and gain a competitive advantage [83]. Big data technology ensures that many and various data are used effectively. Big data is a concept that defines and analyzes very different and large volumes of data that current database technologies fail to analyze [84]. The usage area for big data is quite wide; for example, it can be employed in national security [85], business and economic activities [86], entertainment, manufacturing [87], education [88], health [89], and transport and energy sectors [90]. Big data is a term used to describe datasets that are beyond the storage, management, and processing capacity of programs. Big data performs various operations, such as combining multiple unrelated datasets, processing large amounts of unstructured data, and collecting confidential information in a limited time [91].

2.3. Cloud Computing in Industry 4.0

The analysis of large volumes of data is essential, as is the storage and follow-up of the areas where it is used. For this reason, it is necessary to make use of technologies to carry out this follow-up. Information processing technology provides convenience in tracking when and by whom data is stored, along with instant intervention [92]. Cloud computing technologies are used in education to monitor individuals’ data/instant data and to control the education processes received [93]. Cloud computing also reduces information technology costs for individual users, small businesses, and office workers [94]. Cloud computing is a network model that usually includes certain services and offers them to the user with flexible configurability. Three essential services are offered in this network model: software, platform, and infrastructure services. A software service is a service that users benefit from by accessing applications from any platform connected to the internet without any installation [95]. A platform service offers its users the opportunity to develop, test, and distribute their software and applications online, and control and manage only the peripherals required to host this software [96]. An infrastructure service accesses the processor, storage, network resources, and other host components it needs, installing any operating system on them, and developing and running applications [97].

2.4. Blockchain in Industry 4.0

With developments in technology, it is no longer necessary to keep data in central systems. High-speed and secure communication can be established by duplicating the desired data set and sharing this data with a limited number of people [98]. In an environment with more than one user, the data added to the system must have a standard. Blockchain technology is supported to update, protect, and share data with the desired person/department in the digital world [99]. Blockchain can be defined as a shared, immutable ledger that facilitates the recording of transactions and tracking assets in a business network. An asset can be tangible (house, car, cash, land) or intangible (intellectual property, patents, copyrights, branding), and almost anything of value can be traced and traded on a blockchain network, reducing the risks and costs for everyone involved [100]. A blockchain consists of a data block that is produced based on the theory of cryptography [101,102]. The blocks are recorded in a distributed ledger according to the consensus rules agreed to by the network partners [103]. In addition, the system offers the opportunity for trading between individuals without the need for a trusted third party. All individuals can view the entire transaction history. The completeness of the transaction history also ensures the validity of each virtual transaction, and all virtual transactions can be traced from the moment they are created.

Blockchain also prevents the modification of existing records; thus, the need for management is reduced [104]. Blockchain technology can be used internally or in transactions with customers, suppliers, shareholders, or the government. It is used in e-commerce, international payments, lending, and microfinance [105]. Blockchain applications can be found in many areas; for example, in the supply chain process in production [106], in the follow-up of patients by creating a digital identity in health services [107] and inpatient intervention in emergencies [108], in the storage of student notes and the protection of personal data in education [109], and between suppliers and businesses. It is used to provide data communication [110], secure money transfers, and use bitcoin in finance [111].

2.5. Cyber-Physical Systems in Industry 4.0

Industry 4.0 applications often include cyber–physical systems, combining data exchange/processing in cyber–physical systems, information technologies, and electrical devices [75,112]. With the development of technologies, information technologies and the importance of cyber–physical systems are emerging. The development of cyber–physical systems, together with technology, has affected the development of machines and increased the role of machines in human life. Machines make people’s work easier in many industries; for example: in autonomous systems and robots in the defense industry [113], assisting people with disabilities in healthcare, surgical interventions [114] and assisting nurses in inpatient care [115], in quality control to increase productivity in production [116], in education (helping with laboratory work) [117], and in geodetic surveying and spatial decision support work in the mining industry [118].

2.6. 3D Printers in Industry 4.0

Three-dimensional (3D) printing, one of the most fundamental Industry 4.0 technologies, is a technology that was developed due to the interest of entrepreneurial individuals, rather than large-scale businesses. Three-dimensional printers enable the information stored on computers to be transformed from virtual to natural objects [119]. This technology, which enables 3D production, is also called additive manufacturing in the literature [120]. Additive manufacturing is a modern manufacturing technique in which the materials used with 3D data are added layer by layer, and the production of geometric parts is carried out swiftly [121]. It has application areas in many sectors; for example, Giannatsis and Dedoussis [122] investigated the benefits of additive manufacturing in preoperative planning studies for patient-specific implants in the healthcare industry and examining the human skeleton. In addition, 3D printers are frequently used to produce parts that are difficult to produce for vehicles such as aircraft and ships [123], and prototype products in R&D units [124].

2.7. Augmented Reality in Industry 4.0

Technology to increase image quality with graphics, sound systems, and animation is frequently used in augmented reality technology, which switches between the real and virtual world [125]. For example, augmented reality technology is used in astrology [126,127], in simulator training for trains [128,129], and in the analysis of planetary interactions with each other. Augmented reality has been suggested for use in the conversion of manuals [61] and in a newly developed CPR (cardiopulmonary resuscitation) training system in healthcare to measure the effectiveness of training [130], reduce costs [131], and control situations that employees may encounter in departments [10].

Studies on Industry 4.0 definitions, technologies, roadmaps for transition, applications in different sectors, and integration with different management styles are examined and summarized in Table 1.

3. Quality

Quality is the degree to which a service or product meets its characteristics or possible needs. Quality means customer satisfaction [132]. Increasing quality is possible with the participation of the employees involved in the process at all stages [133], including the participation of senior management employees and all team members. The efforts of employees to achieve this goal in line with a common goal increase the quality of the business in every field [134]. With the industrial revolutions and changes in management philosophies, quality is also diversifying. The development of quality has developed in parallel with the industrial revolutions. In Industry 4.0, the quality criteria determined to evaluate the quality of an enterprise are also considered in the revolutionary development of quality. Each quality revolution is evaluated using traceability, controllability, and sustainability quality criteria.

3.1. Quality Costs in Industry 4.0

The cost of quality arises from existing poor quality or measures taken to prevent potential poor quality [135]. Quality cost is one of the critical criteria that reflects the quality level of an enterprise [136,137]. Businesses should be able to predict their quality costs and plan accordingly. All quality costs should be kept to a minimum to maximize the impact of quality systems on earnings. Quality costs can be managed by measuring these costs effectively [138]. Industry 4.0 technologies can facilitate the measurement of costs more effectively; for example, it is possible to measure financial quality with the blockchain method by calculating costs for suppliers [139].

3.2. Quality Control in Industry 4.0

Quality control can be defined as mastering quality by taking precautions against situations that may reduce the quality efficiency of the process [140]. The primary purpose of quality control is to ensure continuity at the economic level by developing and implementing production plans that can meet customer expectations and the strategic goals of enterprises [141,142]. Quality control is an indispensable part of the processes in manufacturing companies. Proper quality control will reduce production costs and increase customer satisfaction [143]. In the case of unexpected changes during production, quality control ensures that the situation is detected and corrected immediately. Advanced technologies can be used for effective quality control, and many Industry 4.0 technologies can be used in the quality control of processes; for example, Alberts et al. [144] uses cloud technology to control products in the supply chain.

3.3. Quality Performance in Industry 4.0

Quality is one of the essential strategic tools in businesses [145], and businesses are aware that quality is the main factor in product and service development for sustainable success [146]. Therefore, improving quality performance is essential in product and service development. Some criteria are also taken into account in the measurement of quality performance, such as product performance, product/service quality, on-time delivery, product suitability, product standardization, total warranty cost, and suitability of product design [147]. These criteria used in measuring quality performance are also very effective in total quality management practices [148]. Performance measurement is also a measurement of the effectiveness of quality. With the smart technologies that entered our lives with Industry 4.0, quality performance is increasing. Smart factories, smart products, and the Industry 4.0 technologies that are used positively affect quality performance; for example, the quality of processes in departments can be measured using the Internet of Things [47].

3.4. Quality Management in Industry 4.0

Quality management is the act of controlling all the activities and tasks that must be performed to maintain the desired level of excellence [149]. The effect of quality management becomes even more critical when strategies are applied in businesses, especially when unexpected situations are encountered [150]. Quality management facilitates the control of all processes and data used in businesses [151,152]. In order to better manage quality, studies have been carried out using Industry 4.0 technologies; for example, IoT technology [153] has been used for planning capacity in manufacturing, and big data [154] has been used to manage the health records of healthcare workers.

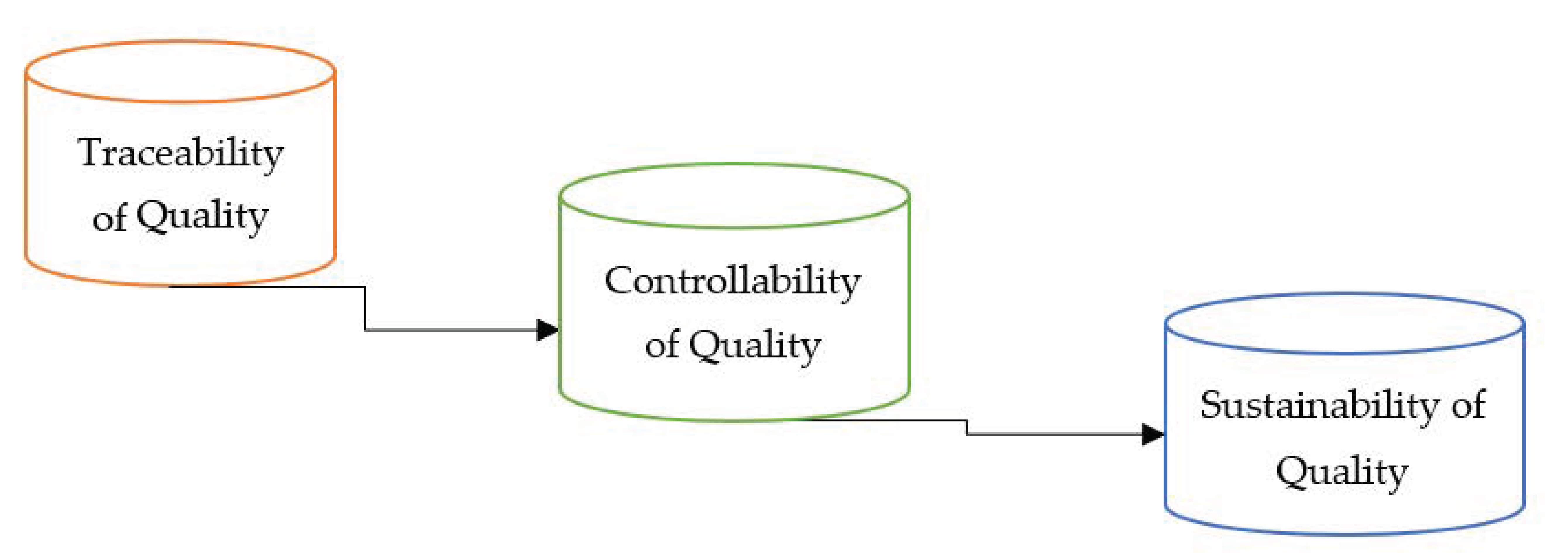

The development of quality has occurred in parallel with the industrial revolutions. The quality criteria determined to evaluate the quality of enterprises in Industry 4.0 were also considered in the revolutionary development of quality. Each quality revolution has been evaluated using traceability, controllability, and sustainability quality criteria. With the development in technology, it is becoming increasingly important to integrate these technologies into businesses and to reach a certain level of quality [155].

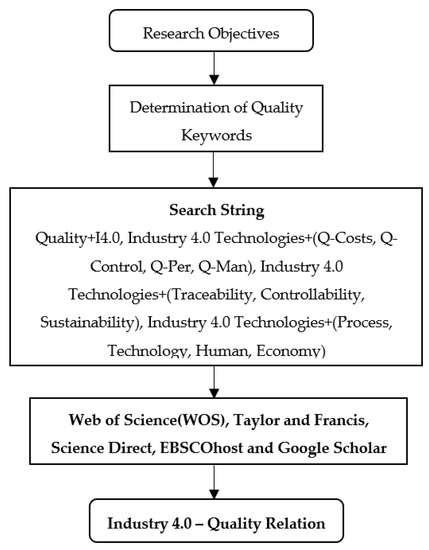

In this study, traceability, controllability, and sustainability criteria were used to evaluate the level of quality met. In Industry 4.0, for each business function, quality was evaluated according to each criterion. For example, while Industry 4.0 was being applied in production activities, an evaluation was made regarding the traceability of quality, the controllability of quality, and the sustainability of production. In Industry 4.0, Industry 4.0 technologies are used to ensure the traceability, controllability, and sustainability of quality. If the quality of the activities in an enterprise are mentioned, the quality must be traceable, controllable, and sustainable. Figure 2 shows the quality criteria.

Figure 2.

Quality criteria.

3.5. Quality Criteria

3.5.1. Traceability of Quality

With the traceability of the quality improvement process, businesses will be able to perceive any coordination problems [156]. These criteria monitor whether the process is carried out using the correct method/at the right time/the correct cost, considering the quality expected from the process. Assistance is received from Industry 4.0 technologies in monitoring, and with this follow-up, it is possible to intervene at the right time. For each business function, the quality of the processes can be monitored using Industry 4.0 technologies. Blockchain technology can be used to ensure the traceability of quality. With blockchain technology, accessibility between authorities and designated stakeholders is also determined, and confidentiality is ensured with information protocols. As blockchain technology records all data, both businesses and stakeholders ensure the traceability of products [102].

3.5.2. Controllability of Quality

With the quality traceability criteria in Industry 4.0, the tracking of processes has become more accessible. However, it has become essential to audit and control these processes, and make corrections if necessary [157]. The process should remain confidential, and only relevant persons should access this information. The decisions to be taken in line with this information, obtained as a result of the controls, should only be made by certain individuals [158]. It is not enough to simply follow the processes. With controllability, the efficiency of the monitored processes is controlled, and the possibility of intervention is provided. In addition, it is necessary to check whether the process should continue in the desired line and whether it progresses at the desired quality. Industry 4.0 technologies can be used for quality control, and it is essential to establish an information protocol in controllability, as with traceability. Quality controllability can be achieved with blockchain technology.

3.5.3. Sustainability of Quality

It is necessary to ensure the continuity of the quality improvement process. Quality improvement processes must be at a certain level and should meet expectations. The desired quality will be achieved by ensuring the continuity of assets in an enterprise [159]. The sustainability of the quality of processes in business functions is essential. Economic growth planning must be done correctly [160]. While achieving sustainability, it is necessary to ensure economic and environmental sustainability, the effective use of an environmental management system, and innovations [161,162]. Sivas et al. [163] examined the studies in which sustainable product development and quality management approaches were used together. They identified four areas that showed quality management’s support of sustainable product development (*supporting sustainability with the integration of management systems, *supporting the implementation of quality and environmental management systems, *sustainability, and *stakeholder management and customer orientation). Bastas and Liyanage [164] described the critical themes for the sustainability of product quality: leadership, customer focus, supply chain integration, relationship management, and evidence-based decision making. While operating business processes, this study focused on adaptation to the economy, adaptation to the environment, adaptation/orientation to technology, compliance/directing customer expectations, and not losing knowledge to provide environmental/social security. Industry 4.0 technologies were used while achieving these goals.

In the third stage of the classification, which is the second main subject of this study, the publications in which Industry 4.0 technologies and quality keywords are studied together were searched.

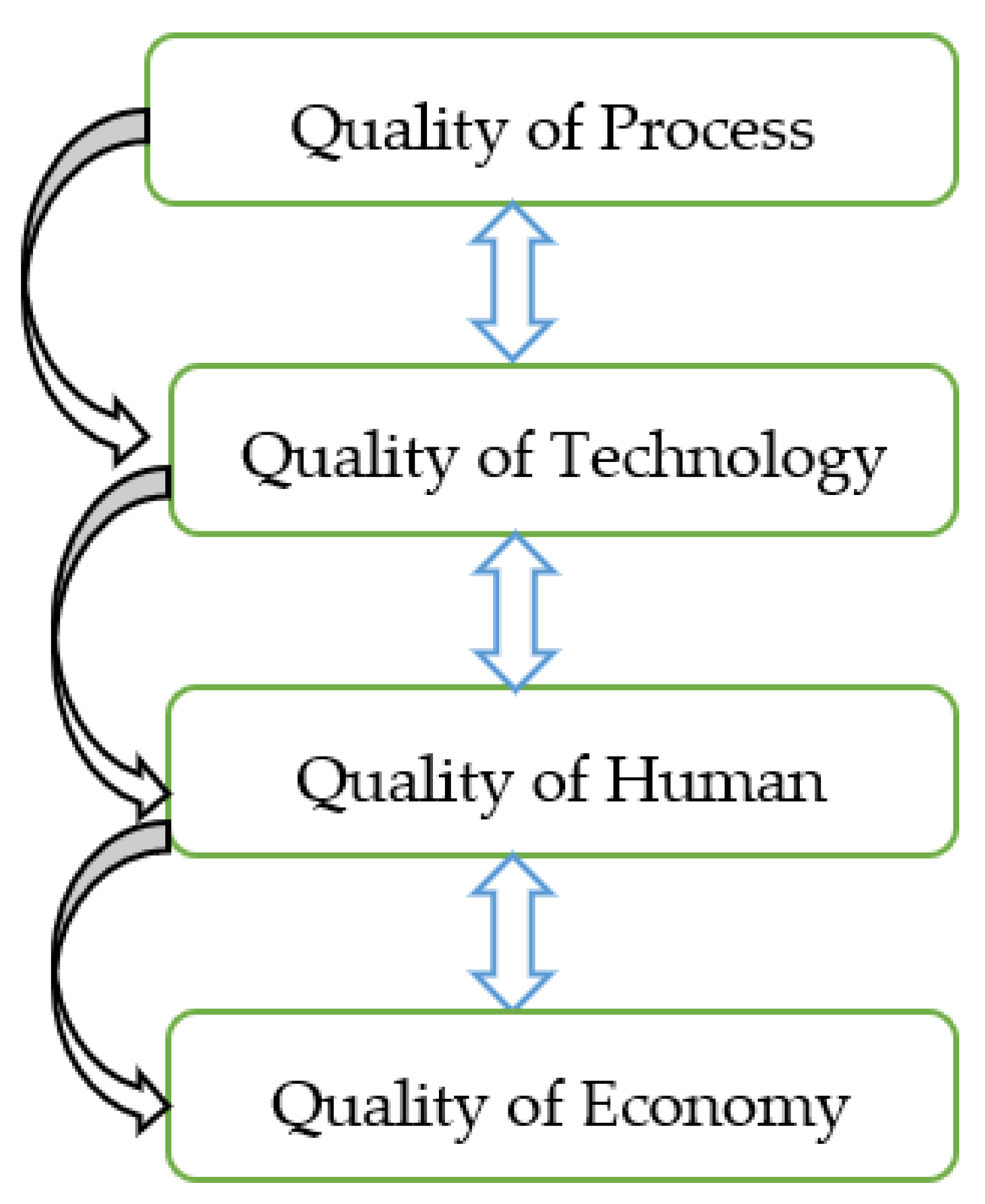

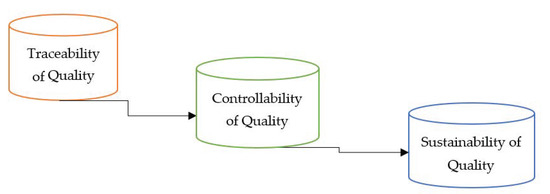

In order to discuss quality in an Industry 4.0 enterprise, it is necessary to look at the quality of the processes. Whether the operation of the processes is progressing in line with the determined quality requirements should be monitored. The quality of the existing technologies preferred also directly affects the quality of the enterprise; technology alone is not enough. The quality of the employees will increase the quality in every unit of the enterprise. As it is essential to increase the quality of an enterprise financially, it is also essential to increase the quality of the economy.

3.6. Quality Components

The quality components are process, technology, human, and economy, as shown in Figure 3.

Figure 3.

Quality components.

3.6.1. Quality of Process

A quality process can be measured if it is controlled, repeatable, reliable, and stable [165]. Increasing the quality of processes will positively affect the overall quality of the units. However, to comment on the increase or decrease in the quality of a process, the quality must be measurable. There are studies in the literature that include the measurement [166], structuring [167], design [168], quality evolution [169,170], and service quality [171] of the process. However, there is no study in the literature that measures the quality of the process with Industry 4.0 technologies.

3.6.2. Quality of Technology

With each industrial revolution, technology development has accelerated. The use of high technology directly affects product quality. With advanced technology, product quality can respond to demands better and more quickly, thus increasing the quality. In the literature, many studies involve the integration of Industry 4.0 technologies with the technologies used in the production and management activities in enterprises (e.g., Internet of Things technology [172] used in product development in R&D and the use of big data in the processing of suppliers). With information on purchasing [173], cloud computing technology has been used to keep personnel information records for human resources departments [174], and cloud computing technology has been used for remote access to production information in production [175]. However, no study has been found that measures the traceability, controllability, and sustainability of the technology used with Industry 4.0 technologies.

3.6.3. Quality of Human

To develop technologies to be used efficiently, it is necessary to employ individuals who can adapt to these technologies. Although technology and machinery are widely used in many sectors, qualified personnel are always necessary. In the literature, there are many studies that examine integrating the characteristics of the personnel involved in the enterprise processes and Industry 4.0 technologies. For example, cloud computing technology has been employed for keeping information regarding personnel employed in R&D [174], big data [176] has been used for product records in purchasing, cloud computing [177] has been utilized for accessing personnel information in human resources, and big data [178] has been applied for use with product records in production. The quality of Industry 4.0 technology processes can be improved by measuring the traceability, controllability, and sustainability of the employed personnel.

3.6.4. Quality of Economy

It is possible to measure how strong a firm can be using various cost analyses. Increasing the technology and workforce used in all corporate processes is vital to obtaining the appropriate quality while producing products or services. However, this increase has an economic cost for the business. For this reason, while the quality of the processes increases, “economy” is seen as a constraint. The quality of an economy can be measured using Industry 4.0 technologies for the traceability, controllability, and sustainability of the economy.

In Industry 4.0, criteria such as process, economy, technology, and people can be used to measure quality in business activities. For this reason, in the fourth stage of the classification study, Industry 4.0 technologies and the publications in which these quality keywords are studied together will be examined.

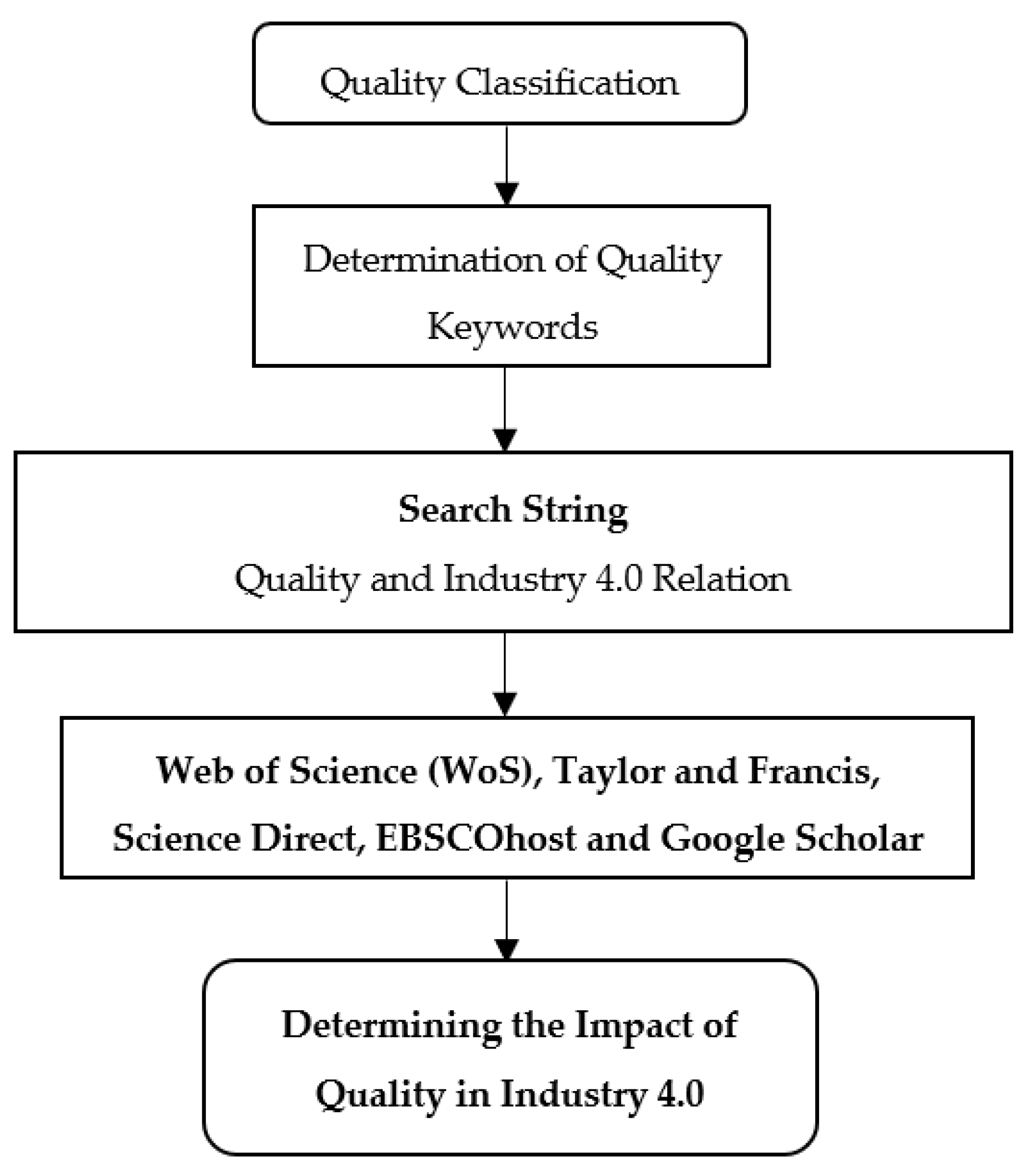

4. Classification

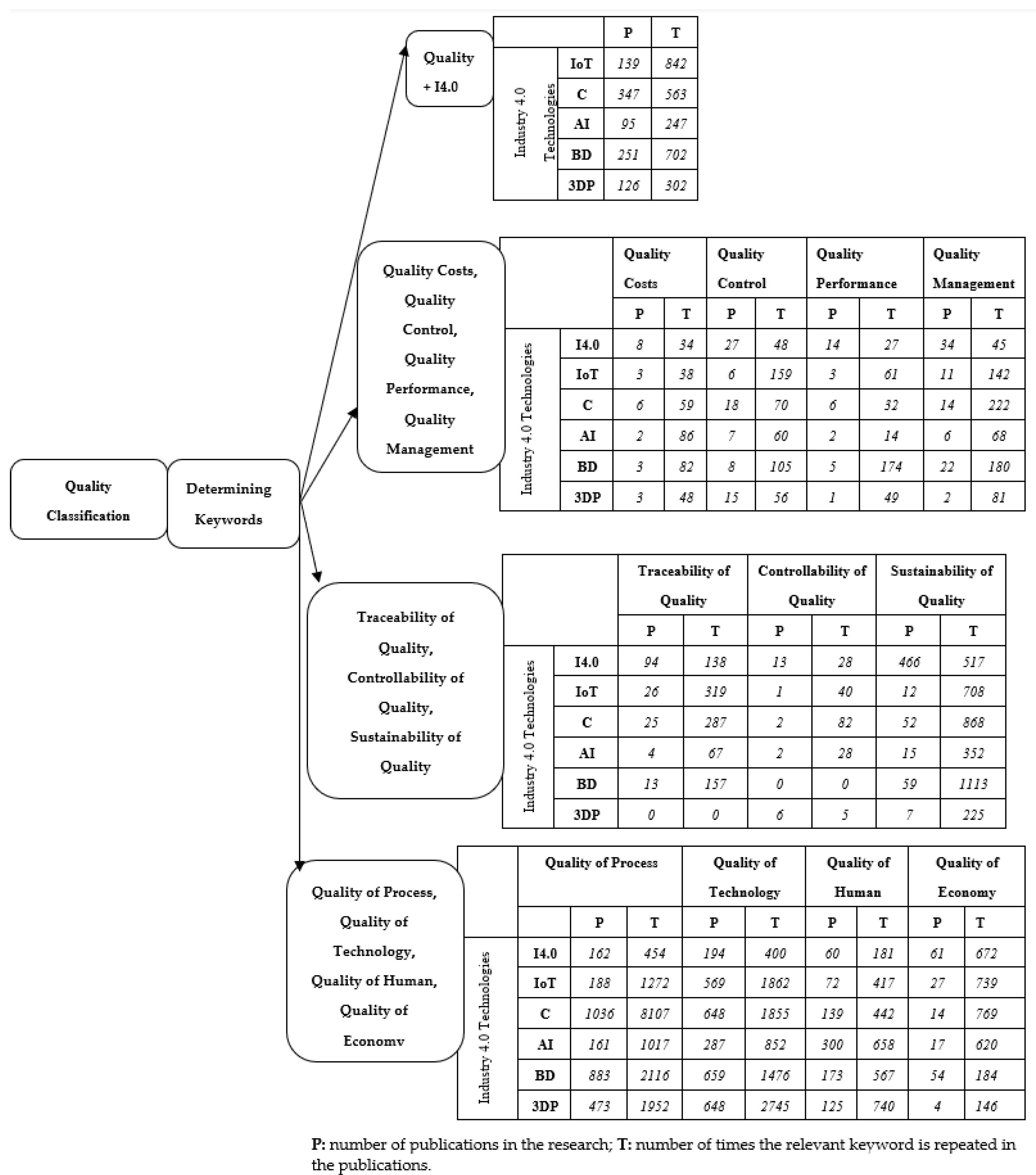

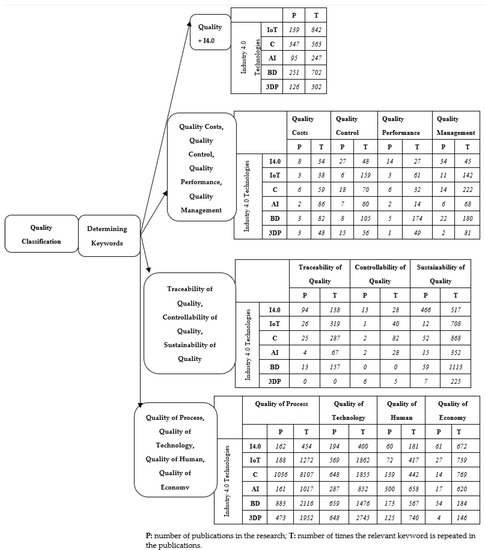

In the classification part of the study, the classification made with Industry 4.0 and quality studies was carried out in four stages. The keywords used in the classification are shown in Figure 4.

Figure 4.

Keywords.

In the first stage of classification, the Industry 4.0 technologies (Internet of Things (IoT), cloud computing (C), artificial intelligence (AI), big data (BD), and 3D printer (3D)) used in quality studies were examined. In the second stage of Industry 4.0 and quality research classification, the concept of quality was detailed under four main headings (quality costs, quality control, quality performance, and quality management).

In the third stage of classification, the studies in which Industry 4.0 technologies were used and the quality keywords (traceability, controllability, and sustainability) were examined. Finally, in the fourth stage of classification, studies in which process, economy, technology, and human criteria were used together with Industry 4.0 technologies were examined. The flow-chart of the classification is given in Figure 5.

Figure 5.

Flow-chart of classification.

In conducting the classification study, studies in engineering, management, and production from the last five years were examined in the databases of WoS, Taylor and Francis, Science Direct, EBSCOhost, and Google Scholar. In addition, the studies were examined using the VOSviever and SciMAT programs. The classification details are shown in Figure 6 (P represents the number of publications on the research, and T is the number of times the relevant keyword is repeated in the publications).

Figure 6.

Relationship between Industry 4.0 and quality.

In the classification, the Internet of Things (IoT), cloud computing technology (C), artificial intelligence (AI), big data (BD), and 3D printer (3DP) were the preferred Industry 4.0 (I4.0) technologies. The quality classification included quality cost, quality control, performance, and management. As seen in Figure 5, the most repeated subject in the classification for joint publications of quality and Industry 4.0 technologies, which was the first stage of classification, was the Internet of Things technology and quality joint studies, with 842 repetitions in 139 publications. On the other hand, it can be seen that cloud computing technology and quality were the most studied subjects with 347 publications. Therefore, the second stage of classification was for publications where Industry 4.0 and quality cost, quality control, quality performance, and quality management were used jointly.

5. Discussion

When examining the literature, many studies on Industry 4.0 can be found. The focus of these studies is on existing technologies and the sectors where these technologies can be applied. Although there are some publications related to Industry 4.0 manufacturing technology that indirectly address quality, there are only a few publications that focus solely on quality or that conduct a classification study to increase quality in general in Industry 4.0, such as [179,180]. In this sense, this study is original. In this study, the classification of quality is discussed in terms of Industry 4.0. The results can be discussed as follows:

- (1)

- Regarding quality costs, while the term Industry 4.0 had 34 repetitions in 8 publications, it was seen that cloud computing technology was studied in a maximum of 6 publications.

- (2)

- With regard to quality control, while the term Industry 4.0 was repeated 48 times in 27 publications, it was found that cloud computing technology works were carried out in a maximum of 18 publications.

- (3)

- Concerning quality performance, while the term Industry 4.0 was repeated 27 times in 14 publications, cloud computing technology was studied in a maximum of 6 publications.

- (4)

- With reference to quality management, while the term Industry 4.0 was repeated 45 times in 34 publications, it was seen that big data technology was studied in 22 publications at most. In this study’s third stage of classification, traceability/sustainability/controllability criteria and publications in which Industry 4.0 technologies were used jointly were examined.

- (5)

- As a result of the examination, with regard to traceability, the term Industry 4.0 was found to be repeated 183 times in 94 publications, with the most used technology being the Internet of Things in 26 publications.

- (6)

- As for controllability, while the term Industry 4.0 was repeated 28 times in 13 publications, the most used technology was 3D printing technology with 6 publications.

- (7)

- On the sustainability of quality, while the term Industry 4.0 was repeated 517 times in 466 publications, big data technology was the most studied technology with 59 publications. In the final stage of classification, the publications in which process, technology, people and economy, and Industry 4.0 technologies were used jointly were examined.

- (8)

- Regarding the quality of the process, while the term Industry 4.0 was repeated 454 times in 162 publications, the most studied technology was cloud computing technology with 1036 publications.

- (9)

- Concerning technology quality, the term Industry 4.0 was repeated 400 times in 194 publications, and big data technology was studied in 659 publications.

- (10)

- With regard to human component, the term Industry 4.0 was repeated 181 times in 60 publications, with artificial intelligence technology ranking first as the most studied technology with 300 publications.

In the last component, economy quality, the term Industry 4.0 was repeated 672 times in 61 publications, and the most studied technology was big data technology with 54 publications.

6. Conclusions

Process management has an important place in the philosophy of total quality management. Process management is a discipline that forms the basis of, and manages, processes to improve the performance of businesses. As Industry 4.0 applications are increasingly being used in the business world, it is impossible for quality management and process management to stay removed from digitalization. The concept of quality in Industry 4.0 aims to digitize all business processes in terms of quality to increase the use of Industry 4.0 technologies. The quality of the technology used in businesses and the quality of the workforce, especially the processes, are monitored in quality management, which are created using Industry 4.0 technologies to ensure the traceability/control/sustainability of the quality of all the processes that businesses need in order to continue their activities. This follow-up/increase is aimed at improving the economic quality.

First, keywords were determined for this classification study, which was the second main subject of the study. Studies in which Industry 4.0 technologies (Internet of Things (IoT), cloud computing technology (C), artificial intelligence (AI), big data (BD), and 3D printing (works using 3DP)) and the word “quality” were used together were examined. In the second stage, studies in which Industry 4.0 technologies were determined and quality costs, quality control, quality performance, and quality management worked together were investigated. In the third stage of this study, traceability/controllability/sustainability and Industry 4.0 technologies were examined together. In the last stage of the classification, the quality of the process, technology, people, and economy were examined together with Industry 4.0 technologies. It covers the classification of quality in Industry 4.0 and the literature review of the relationship between quality and Industry 4.0 technologies.

As can be observed from this classification study, there are publications in the literature where Industry 4.0 and quality issues have been studied together. However, as can be seen when examining quality in Industry 4.0, no study has used Industry 4.0 technologies to ensure quality monitoring/control/sustainability in the processes of all institutions, in all technologies used, and in all workforces employed. There are only a few studies in the literature that have explored the importance of quality in Industry 4.0. Therefore, this classification study reveals the need for studies that emphasize quality in Industry 4.0.

7. Future Research

In this research, a classification study was conducted by examining the relationship between Industry 4.0 and quality. In future studies, the scope of the study could be expanded by adding new criteria, such as real-time data and the circular economy. Again, as a result of the subtitles created for classification in this study, a new quality model could be created and integrated into Industry 4.0.

Author Contributions

Conceptualization, E.B. and T.K.P.; methodology, E.B. and T.K.P.; software, E.B. and T.K.P.; validation, E.B. and T.K.P.; formal analysis, E.B. and T.K.P.; investigation, E.B. and T.K.P.; resources, E.B. and T.K.P.; data curation, E.B. and T.K.P.; writing—original draft preparation, E.B. and T.K.P.; writing—review and editing, E.B. and T.K.P.; visualization, E.B. and T.K.P.; supervision, E.B. and T.K.P.; project administration, E.B. and T.K.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, G.; Hou, Y.; Wu, A. Fourth industrial revolution: Technological drivers, impacts and coping methods. Chin. Geogr. Sci. 2017, 27, 626–637. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing industry 4.0 readiness and maturity of manufacturing enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Gligor, D.M.; Holcomb, M.C. Antecedents and consequences of supply chain agility: Establishing the link to firm performance. J. Bus. Logist. 2012, 33, 295–308. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. A critical investigation of industry 4.0 in manufacturing: Theoretical operationalisation framework. Prod. Plan. Control. 2018, 29, 633–644. [Google Scholar] [CrossRef]

- Cottyn, J.; Landeghem, H.V.; Stockman, K.; Derammelaere, S. A method to align a manufacturing execution system with lean objectives. Int. J. Prod. Res. 2011, 49, 4397–4413. [Google Scholar] [CrossRef]

- Weking, J.; Stöcker, M.; Kowalkiewicz, M.; Böhm, M.; Krcmar, H. Archetypes for industry 4.0 business model innovations. In Proceedings of the Twenty-fourth Americans Conference on Information Systems, New Orleans, LA, USA, 16–18 August 2018. [Google Scholar]

- Bibby, L.; Dehe, B. Defining and assessing industry 4.0 maturity levels—Case of the defence sector. Prod. Plan. Control 2018, 29, 1030–1043. [Google Scholar] [CrossRef]

- Alcacer, V.; Cruz-Machado, V. Scanning the industry 4.0: A literature review on Technologies for manufacturing systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Ku, C.; Chien, C.; Ma, K. Digital transformation to empower smart production for industry 3.5 and an empirical study for textile dyeing. Comput. Ind. Eng. 2020, 142, 106297. [Google Scholar] [CrossRef]

- Longo, F.; Nicoletti, L.; Padovano, A. Smart operators in industry 4.0: A human-centered approach to enhance operators’ capabilities and competencies within the new smart factory context. Comput. Ind. Eng. 2017, 113, 144–159. [Google Scholar] [CrossRef]

- Iyer, A. Moving from industry 2.0 to industry 4.0: A case study from India on leapfrogging in smart manufacturing. Procedia Manuf. 2018, 21, 663–670. [Google Scholar] [CrossRef]

- Papetti, A.; Marconi, M.; Rossi, M.; Germani, M. Web-based platform for eco-sustainable supply chain management. Sustain. Prod. Consum. 2019, 17, 215–228. [Google Scholar] [CrossRef]

- Öztemel, E.; Gursev, S. Literature review of industry 4.0 and related Technologies. J. Intell. Manuf. 2018, 31, 127–182. [Google Scholar] [CrossRef]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A bibliometric analysis and detailed overview. Eng. Appl. Artif. Intell. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Cobo, M.J.; Jürgens, B.; Herrero-Solana, V.; Martinez, M.A.; Herrera-Viedma, E. Industry 4.0: A perspective based on bibliometric analysis. Procedia Comput. Sci. 2018, 139, 364–371. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the definition of industry 4.0: Analysis and open questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Mariani, M.; Borghi, M. Industry 4.0: A bibliometric review of its managerial intellectual structure and potantial evolution in the service industries. Technol. Forecast. Soc. Change 2019, 149, 119752. [Google Scholar] [CrossRef]

- Li, D.; Landström, A.; Fast-Berglund, A.; Almström, P. Human-centred dissemination of data, information and knowledge in industry 4.0. Procedia CIRP 2019, 84, 380–386. [Google Scholar] [CrossRef]

- Echchakoul, S.; Barka, N. Industry 4.0 and its impact in plastic industry: A literature review. J. Ind. Inf. Integr. 2020, 20, 100172. [Google Scholar]

- Wang, J.; Wan, D.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0. Procedia Manuf. 2019, 39, 1415–1420. [Google Scholar]

- Santos, C.; Mehrsai, A.; Barros, A.C.; Araujo, M.; Ares, E. Towards industry 4.0: An overview of European strategic roadmaps. Procedia Manuf. 2017, 13, 972–979. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Luque, A.; Peralta, M.E.; Heras, A.D.L.; Cordoba, A. State of the industry 4.0 in the Andalusian food sector. Procedia Manuf. 2017, 13, 1199–1205. [Google Scholar] [CrossRef]

- Rafael, L.D.; Jaione, G.E.; Christina, L.; Ibon, S.L. An industry 4.0 maturity model for machine tool companies. Technol. Forecast. Soc. Change 2020, 159, 120203. [Google Scholar] [CrossRef]

- Hamzeh, R.; Zhong, R.; Xu, X.W. A survey study on industry 4.0 for New Zealand manufacturing. Procedia Manuf. 2018, 26, 49–57. [Google Scholar] [CrossRef]

- Backhaus, S.K.H.B.; Nadarajah, D. Investigating the relationship between industry 4.0. and productivity: A conceptual framework for Malaysian manufacturing firms. Procedia Comput. Sci. 2019, 161, 696–706. [Google Scholar] [CrossRef]

- Faller, C.; Feldmüller, D. Industry 4.0 learning factory for regional SMEs. Procedia CIRP 2015, 32, 88–91. [Google Scholar] [CrossRef]

- Benesova, A.; Tupa, J. Requirements for education and qualification of people in industry 4.0. Procedia Manuf. 2017, 11, 2195–2202. [Google Scholar] [CrossRef]

- Sung, T.K. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Chang. 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Angelepoulou, A.; Mykoniatis, K.; Boyapati, N.R. Industry 4.0: The use of simulation for human reliability assessment. Procedia Manuf. 2020, 42, 296–301. [Google Scholar] [CrossRef]

- Miragliotta, G.; Sianesi, A.; Convertini, E.; Distante, R. Data driven management in industry 4.0: Method to measure data productivity. IFAC Pap. 2018, 51, 19–24. [Google Scholar] [CrossRef]

- Tupa, J.; Simota, J.; Steiner, F. Aspects of risk management implementation for industry 4.0. Procedia Manuf. 2017, 11, 1223–1230. [Google Scholar] [CrossRef]

- Motyl, B.; Baronio, G. How will change the future engineers’ skills in the industry 4.0 framework? A questionnaire survey. Procedia Manuf. 2017, 11, 1501–1509. [Google Scholar] [CrossRef]

- Centea, D.; Singh, I.; Wanyama, T.; Magolon, M.; Boer, J.; Elbestawi, M. Using the SEPT learning factory for the implementation of industry 4.0: Case of SMEs. Procedia Manuf. 2020, 45, 102–107. [Google Scholar] [CrossRef]

- Villa, A.; Taurino, T. SME innovation and development in the context of industry 4.0. Procedia Manuf. 2019, 39, 1415–1420. [Google Scholar] [CrossRef]

- Kolla, S.; Minufekr, M.; Plapper, P. Deriving essential components of lean and industry 4.0 assessment model for manufacturing SMEs. Procedia CIRP 2019, 81, 753–758. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Müller, J.M. Contributions of industry 4.0 to quality management—A SCOR perspective. IFAC Pap. Line 2019, 52, 1236–1241. [Google Scholar] [CrossRef]

- Zaimovic, T. Setting speed limit on industry 4.0—An Outlook of power mix and grid capacity challenge. Procedia Comput. Sci. 2019, 158, 107–115. [Google Scholar] [CrossRef]

- Hidayatno, A.; Destyanto, A.R.; Hulu, C.A. Industry 4.0 technology implementation impact industrial sustainable energy in Indonesia: A model conceptualization. Energy Proedia 2019, 156, 227–233. [Google Scholar] [CrossRef]

- Meyer, T.; Kuhn, M.; Hartmann, E. Blockchain technology enabling the physical internet: A synergetic application framework. Comput. Ind. Eng. 2019, 136, 5–17. [Google Scholar] [CrossRef]

- Bader, S.; Barth, T.; Krohn, P.; Ruchser, R.; Storch, L.; Wagner, L.; Findeisen, S.; Pokorni, B.; Braun, A.; Ohlhausen, P.; et al. Agile shopfloor organization design for industry 4.0 manufacturing. Procedia Manuf. 2019, 39, 756–764. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 technologies assessment: A sustainability perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Baboli, A.; Rother, E. The evolution of World class manufacturing toward industry 4.0: A case study in the automative industry. IFAC Pap. 2019, 52, 188–194. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Taurino, T.; Villa, A. A method for applying industry 4.0 in small enterprises. IFAC Pap. 2019, 52, 439–444. [Google Scholar] [CrossRef]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart factory performance and industry 4.0. Technol. Forecast. Soc. Change 2020, 150, 119790. [Google Scholar] [CrossRef]

- Karre, H.; Hammer, M.; Kleindienst, M.; Ramsauer, C. Transition towards an industry 4.0 state of the lean lab at Graz university of technology. Procedia Manuf. 2017, 9, 206–213. [Google Scholar] [CrossRef]

- Mehami, J.; Nawi, M.; Zhong, R.Y. Smart automated guided vehicles for manufacturing in the context of industry 4.0. Procedia Manuf. 2018, 26, 1077–1086. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Sanin, C.; Szczerbicki, E. Smart virtual product development (SVPD) to enhance product manufacturing in industry 4.0. Procedia Comput. Sci. 2019, 159, 2232–2239. [Google Scholar] [CrossRef]

- Pereira, T.; Barreto, L.; Amaral, A. Network and information security challenges within industry 4.0 paradigm. Procedia Manuf. 2017, 13, 1253–1260. [Google Scholar] [CrossRef]

- Ardito, L.; Petruzelli, A.M.; Panniello, U.; Garavelli, A.C. Mapping digital Technologies for supply chain management-marketing integration. Bus. Process Manag. J. 2019, 25, 323–346. [Google Scholar] [CrossRef]

- Silva, V.L.D.; Kovaleski, J.L.; Pagani, R.N. Technology transfer in the supply chain oriented to industry 4.0: A literature review. Technol. Anal. Strateg. Manag. 2019, 31, 546–562. [Google Scholar] [CrossRef]

- Zavadska, Z.; Zavadsky, J. Quality managers and their future technological expectations related to industry 4.0. Total Qual. Manag. Bus. Excell. 2020, 31, 717–741. [Google Scholar] [CrossRef]

- Javied, T.; Huprich, S.; Franke, J. Cloud based energy management system compatible with the industry 4.0 requirements. IFAC-Pap. 2019, 52, 171–175. [Google Scholar] [CrossRef]

- Shihundla, T.B.; Mpofu, K.; Adenurga, O.T. Integrating product-service systems into the manufacturing industry: Industry 4.0 perpectives. Procedia CIRP 2019, 83, 8–13. [Google Scholar] [CrossRef]

- Perez, S.A.M.; Olvera, R.; Garcia, C.C.; Soler, A.F.I.; Flores De La, M. Internet of things and industry 4.0 applied in the delivery system for the bicipuma bike-sharing sytem in UNAM-Mexico. Procedia Manuf. 2020, 42, 434–441. [Google Scholar] [CrossRef]

- Vespoli, S.; Grassi, A.; Guizzi, G.; Santillo, L.S. Evaluating the advantages of an novel decentralised scheduling approach in the industry 4.0 and cloud manufacturing era. IFAC-Pap. 2019, 52, 2170–2176. [Google Scholar] [CrossRef]

- Lototsky, V.; Sabitov, R.; Smirnova, G.; Sirazetdinov, B.; Elizarova, N.; Sabitov, S. Model of the automated warehouse management and forecasting system in the conditions of transition to industry 4.0. IFAC-Pap. 2019, 52, 78–82. [Google Scholar] [CrossRef]

- Osman, C.C.; Ghiran, A.M. When industry 4.0 meets process mining. Procedia Comput. Sci. 2019, 159, 2130–2136. [Google Scholar] [CrossRef]

- Gattulo, M.; Scurati, G.W.; Fiorentino, M.; Uva, A.E.; Ferrise, F.; Bordegoni, M. Towards augmented reality manuals for industry 4.0: A methodology. Robot. Comput. Integr. Manuf. 2019, 56, 276–286. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Özsoylu, A.F. Endüstri 4.0. Çukurova Üniv. İktisadi Ve İdari Bilimler Fakültesi Derg. 2017, 21, 41–64. [Google Scholar]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in management tudies: A systematic literature review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Fox, B.; Subic, A. An industry 4.0 approach to the 3D printing of composite materials. Engineering 2019, 5, 621–623. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital twins and cyber-physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Brettel, M.; Friederichsen, N.; Keller, M.; Rosenberg, M. How virtualization, decentralization and network building change the manufacturing landscape: An industry 4.0 perspective. Int. J. Sci. Eng. Technol 2014, 8, 37–44. [Google Scholar]

- Wang, Q.; Zhu, X.; Ni, Y.; Gu, L.; Zhu, H. Blockchain for the IoT and industrial IoT: A review. Internet Things 2020, 10, 100081. [Google Scholar] [CrossRef]

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The smart factory: Exploring adaptive and flexible manufacturing solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef]

- Wang, J.; Wan, D.; Zhang, D.; Li, D.; Zhang, C. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data-based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Gabaçlı, N.; Uzunöz, M.I.V. sanayi devrimi: Endüstri 4.0 ve otomotiv sektörü. In Proceedings of the 3rd International Congress on Political, Economic and Social Studies (ICPESS), Ankara, Turkey, 9–11 November 2017. [Google Scholar]

- Schwab, K. The Fourth Industrial Revolution; World Economic Forum: Geneva, Switzerland, 2016. [Google Scholar]

- Landriscina, F. Simulation and Learning a Model-Centered Approach; Springer: New York, NY, USA, 2013. [Google Scholar]

- Kopetz, H. Internet of things. In Real-Time Systems; Springer: New York, NY, USA, 2011; pp. 307–323. [Google Scholar]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of things: A vision, architectural elements and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Lee, G.M.; Crespi, N.; Choi, J.K.; Boussard, M. Internet of things. In Evolution of Telecommunication Services; Springer: Berlin/Heidelberg, Germany, 2013; pp. 257–282. [Google Scholar]

- Ulaş, S. Nesnelerin Interneti Ekosistemdeminde Makineler Arası Özerk Iletişim; Yüksek Lisans Tezi Gazi Üniversitesi: Ankara, Turkey, 2015. [Google Scholar]

- Bao, Y.F. Analysis of the learning evaluation of distance education based on the internet of things. World Trans. Eng. Technol. Educ. 2016, 14, 168–172. [Google Scholar]

- Aktaş, F.; Çeken, C.; Erdemli, Y.E. Nesnelerin interneti teknolojisinin biyomedikal alanındaki uygulamaları. Düzce Üniv. Bilim Ve Teknol. Derg. 2016, 4, 37–54. [Google Scholar]

- Yang, G.; Xie, L.; Mantsalo, M.; Zhou, X.; Pang, Z.; Xu, L.; Kao-Walter, S.; Chen, Q.; Zheng, L. Industrial informatics. IEEE Trans. 2014, 10, 2180–2191. [Google Scholar]

- Miorandi, D.; Sicari, S.; Pellegrini, F.D.; Chlamtac, I. Internet of things: Vision, applications and research challenges. J. Ad Hoc Netw. 2012, 10, 1497–1516. [Google Scholar] [CrossRef]

- Jagadish, H.V.; Gehrke, J.; Labrinidis, A.; Papakonstantinou, Y.; Patel, J.; Ramakrishnan, J.M.R.; Shahabi, C. Big data and its technical challenges. Commun. ACM 2014, 57, 86–94. [Google Scholar] [CrossRef]

- Gahi, Y.; Guennoun, M.; Mouftah, H.T. Big data analytics: Security and privacy challenges. In Proceedings of the IEEE Symposium on Computers and Communication, Messina, Italy, 27–30 June 2016; pp. 952–957. [Google Scholar]

- Chandra, S.; Ray, S.; Goswami, R.T. Big data security: Survey on frameworks and algorithms. In Proceedings of the IEEE 7th International Advance Computing Conference (IACC), Hyderabad, India, 5–7 January 2017; pp. 48–54. [Google Scholar]

- Diebold, W.F. Big data dynamic factor models for macroeconomic measurement and forecasting, advances in economics and econometrics. In Eight World Congress of the Econometric Society; Cambridge University Press: Cambridge, UK, 2000; pp. 115–122. [Google Scholar]

- Mauro, A.D.; Greco, M.; Grimaldi, M. A formal definition of big data based on its essential features. Libr. Rev. 2016, 65, 22–135. [Google Scholar] [CrossRef]

- Rubistein, I.S. Big data: The end of privacy or a new beginning? Int. Data Priv. 2013, 3, 74–86. [Google Scholar] [CrossRef]

- Tang, J.J.; Karim, K.E. Big data in business analytics: Implications for the audit profession. CPA J. 2017, 87, 34–39. [Google Scholar]

- Goes, P.B. Big data and IS research. MIS Q. 2014, 38, 3–8. [Google Scholar]

- Erl, T.; Wajid, K.; Paul, B. Big Data Fundamentals, Concepts, Drivers & Techniques; Arcitura Education Inc.: North Vancouver, BC, Canada, 2016. [Google Scholar]

- Goodburn, M.A.; Hill, S. The cloud transforms business. Financ. Exec. 2010, 26, 34–39. [Google Scholar]

- Fox, B. Cloud computing a game changer for EU economy. Kroes Saays. 2012. Available online: https://euobserver.com/news/117695 (accessed on 7 February 2022).

- Mladen, A.V. Cloud computing-issues, research and implementations. J. Comput. Inf. Technol. 2008, 6, 235–246. [Google Scholar]

- Shao, Y.; Di, L.; Gong, J.; Bai, Y.; Zhao, P. GIS in the cloud: Implementing a web coverage service on amazon cloud computing platform. In Electrical Engineering and Control, 98, Lectures Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2011; pp. 289–295. [Google Scholar]

- Pandey, S. Cloud computing technology & GIS applications. In Proceedings of the 8th Asian Symposium on Geographic Information Systems from Computer & Engineering View (ASGIS 2010), Chongqing, China, 22–24 April 2010. [Google Scholar]

- Lu, X. An approach to service and cloud computing techniques in GIS. Geosci. Remote Sens. (IITA-GRS) 2010, 1, 492–495. [Google Scholar]

- Kshetri, N. Blockcchain’s roles in strengthening cybersecurity and protecting privacy. Telecommun. Policy 2017, 41, 1027–1038. [Google Scholar] [CrossRef]

- Rao, A.R.; Clarke, D. Perspective on emerging directions in using IoT devices in blockchain applications. Internet Things 2019, 10, 100079. [Google Scholar] [CrossRef]

- Gupta, R.A.; Chow, M.Y. Networked control system: Overview and research trends. IEEE Trans. Ind. Electron. 2010, 57, 2527–2535. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-To-Peer Electronic Cash System; SSRN: Rochester, NY, USA, 2017. [Google Scholar]

- Agrawal, T.K.; Kumar, V.; Pal, R.; Wang, L.; Chen, Y. Blockchain-based framework for supply chain traceability: A case example of textile and clothing industry. Comput. Ind. Eng. 2021, 154, 107130. [Google Scholar] [CrossRef]

- Swan, M. Blockchain: Blueprint for a New Economy; O’reilly Media Inc.: North Sebastopol, CA, USA, 2015. [Google Scholar]

- Beck, R.; Czepluch, J.S.; Lollike, N.; Malone, S. Blockchain-the gateway to trust-free cryptographic transactions. Eur. Conf. Inf. Syst. 2016, 153. [Google Scholar]

- Risius, M.; Spohrer, K. A blockchain research framework. Bus. Inf. Syst. Eng. 2017, 59, 385–409. [Google Scholar] [CrossRef]

- Ducas, E.; Wilner, A. The security and financial implications of blockchain technologies: Regulating emerging technologies in Canada. Int. J. 2017, 72, 538–562. [Google Scholar] [CrossRef]

- Kuo, T.T.; Kim, H.E.; Ohno-Machado, L. Blockchain distributed ledger Technologies for biomedical and healthcare applications. J. Am. Med. Inform. Assoc. 2017, 24, 1211–1220. [Google Scholar] [CrossRef] [PubMed]

- Tandon, A.; Dhir, A.; Islam, A.K.M.N.; Mantymaki, M. Blockchain in healthcare: A systematic literature review, synthesizing framework and future research agenda. Comput. Ind. 2020, 122, 103290. [Google Scholar] [CrossRef]

- Chen, G.; Xu, B.; Lu, M.; Chen, N. Exploring blockchain technology and its potential applications for education. Smart Learn. Environ. 2018, 5, 1. [Google Scholar] [CrossRef]

- Thoben, K.; Wiesner, S.; Wuest, T. Industry 4.0 and smart manufacturing—A review of research issues and application examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Pisa, M.; Juden, M. Blockchain and economic development: Hype vs. reality. Cent. Glob. Dev. 2017, 107, 5–7. [Google Scholar]

- Baheti, R.; Gill, H. Cyber-physical systems. Impact Control Technol. 2011, 12, 161–166. [Google Scholar]

- Cross, T. Human obsolescence, science and technology. In The Economist: The World in 2018; The Economist Newspaper Limited: London, UK, 2018. [Google Scholar]

- Shaywitz, S. A new and complete science-based program for reading problems at any level. Overcoming Dyslexia 2005, 28, 575. [Google Scholar]

- Huang, S.; Tanioka, T.; Locsin, R.; Paker, M.; Marsoy, O. Functions of a caring robot in nursing. In Proceedings of the Seventh International Conference on Natural Language Processing and Knowledge Engineering, Tokushima, Japan, 27–29 November 2011. [Google Scholar]

- Verl, A. Robotics & Industrie 4.0. In IFR-International Federation of Robotics; 2017; Available online: https://scholar.archive.org/work/q26zts5rhjd5jhfbjzv6dhi62u/access/wayback/https://ifr.org/img/uploads/Presentation_Industry_i4.0_Rob_Alexander_VERL_29_9_16.pdf (accessed on 7 February 2022).

- Steele, M.J. Agent-Based Simulation of Unmanned Surface Vehicles: A Force in the Fleet; NPS: Monterrey, CA, USA, 2004. [Google Scholar]

- Thrun, S.; Burgards, W.; Fox, D. A probabilistic approach to cncurrent mapping and localization for mobile robots. Mach. Learn. Auton. Robot. 1998, 31, 1–25. [Google Scholar]

- Barnatt, C. 3D printing: The Next Industrial Revolution. In ABD: Create Space Independent Publishing Platform; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2013; p. 11120. [Google Scholar]

- Kneissl, W. 3D printing 2014-2025: Technologies, markets, players. In ABD: ID Tech Ex; IDTechEX: Boston, MA, USA, 2013; p. 4. [Google Scholar]

- Zhang, L.-C.; Han, M.; Huang, S. A improved interface between CAD and rapid prototyping systems. Int. J. Adv. Manuf. Technol 2003, 21, 15–19. [Google Scholar]

- Giannatsis, J.; Dedoussis, V. Additive fabrication technologies applied to medicine and health care: A review. Int. J. Adv. Manuf. Technol. 2009, 40, 116–127. [Google Scholar] [CrossRef]

- Olla, P. Opening Pandora’s 3D printed box. Technol. Soc. Mag. 2015, 34, 74–80. [Google Scholar] [CrossRef]

- Bergsma, J.; Zalm, M.; Pruyn, J. 3D-printing and the maritime construction sector. In Proceedings of the Conference Paper: Hiper, Cortona, Italy, 17–19 October 2016. [Google Scholar]

- Azuma, R.T. A survey of augmented reality. Teleoperatorsand Virtual Environ. 1997, 6, 355–385. [Google Scholar] [CrossRef]

- Chi, H.; Kang, S.; Wang, X. Research trends and opportunities of augmented reality applications in architecture, engineering and construction. Comput. Sci. Autom. Constr. 2013, 33, 116–122. [Google Scholar] [CrossRef]

- Sielhorst, T.; Obst, T.; Burgkart, R.; Riener, R.; Navab, N. An augmented reality delivery simülatör for medical training. Comput. Sci. 2004. [Google Scholar]

- Öztürk, V.; Arar, Ö.F.; Rende, F.Ş.; Öztemel, E.; Sezer, S. Validation of railway vehicle dynamic models in training simulators. Veh. Syst. Dyn. 2016, 55, 41–71. [Google Scholar] [CrossRef]

- Cole, C.; Spiryagin, M.; Wu, Q.; Sun, Y.Q. Modelling simulation and applications of longitudinal train dynamics. Veh. Syst. Dyn. 2017, 55, 1498–1571. [Google Scholar] [CrossRef]

- Balian, S.; McGovern, S.; Abella, B.S.; Blewer, A.L.; Leary, M. Feasibility of an augmented reality cardiopulmonary resuscitation training system for health care providers. Heliyon 2019, 5, e02205. [Google Scholar] [CrossRef]

- Ginters, E.; Gutierrez, J.M. Low cost augmented reality and RFID application for logistics items visualization. Procedia Comput. Sci. 2013, 26, 3–13. [Google Scholar] [CrossRef]

- Budianto, A. Customer loyalty: Quality of service. J. Manag. Rev. 2019, 3, 299–305. [Google Scholar] [CrossRef]

- Kauffman, R.; Dougles, Z. Quality Management Plus; The Continous Improvement of Education Press: Thousand Oaks, CA, USA, 1993. [Google Scholar]

- Othman, I.; Ghani, S.N.M.; Choon, S.W. The total quality management (TQM) journey of Malaysian building contractors. Ain Shams Eng. J. 2020, 11, 697–704. [Google Scholar] [CrossRef]

- Juran, J.; Godfrey, A.B. Quality Handbook; McGraw-Hill: New York, NY, USA, 1999. [Google Scholar]

- Battini, D.; Faccio, M.; Persona, A.; Sgarbosa, F. Design of an integrated quality assurance strategy in production systems. Int. J. Prod. Res. 2012, 50, 1682–1701. [Google Scholar] [CrossRef][Green Version]

- Castillo-Villar, K.K.; Smith, N.R.; Simonton, J.L. A model for supply chain design considering the cost of quality. Appl. Math. Model. 2012, 36, 5920–5935. [Google Scholar] [CrossRef]

- Moica, S.; Radulescu, E. Statistical controls have a significant influence on non-quality costs. Cases study in a company those manufacturing aluminum castings components. Procedia Technol. 2014, 12, 489–493. [Google Scholar] [CrossRef]

- Thakur, S.; Breslin, J.G. Scalable and secure product serialization for multi-party perishable good supply chains using blockchain. Internet Things 2020, 11, 100253. [Google Scholar] [CrossRef]

- Philips, B.P.; Gomez-Navarro, N.; Miller, E.A. Protein quality control in the endoplasmic reticulum. Curr. Opin. Cell Biol. 2020, 65, 96–102. [Google Scholar] [CrossRef]

- Scheimer, R.; Edwards, R.; Notes, A. Quality control and preprocessing of metagenomic datasets. Bioinformatics 2011, 27, 863–864. [Google Scholar]

- Zhang, Z.; Gui, D.; Sha, M.; Liu, J.; Wang, H. Raman chemical feature extraction for quality control of dairy products. J. Dairy Sci. 2019, 102, 68–76. [Google Scholar] [CrossRef]

- Szajna, A.; Stryjski, R.; Wozniak, W.; Chamier-Gliszczynski, N.; Krolikowski, T. The production quality control process, enhanced with augmented reality glasses and the new generation computing support system. Procedia Comput. Sci. 2020, 176, 3618–3625. [Google Scholar] [CrossRef]

- Albers, A.; Gladysz, B.; Pinner, T.; Butenko, V.; Stürmlinger, T. Procedure for defining the system of objectives in the initial phase of an industry 4.0 project focusing on intelligent quality control systems. Procedia CIRP 2016, 52, 262–267. [Google Scholar] [CrossRef]

- Saab, N.; Helms, R.; Zoet, M. Predictive quality performance control in BPM: Proposing a framework for predicting quality anomalies. Procedia Comput. Sci. 2018, 138, 714–723. [Google Scholar] [CrossRef]

- Boateng-Okrah, E.; Fening, F.A. TQM implementation: A case of a mining company in Ghana. Benchmarking Int. J. 2012, 19, 743–759. [Google Scholar] [CrossRef]

- Bolatan, G.I.; Gozlu, S.; Alpkan, L.; Zaim, S. The impact of technology transfer performance on total quality management and quality performance. Procedia-Soc. Behav. Sci. 2016, 235, 746–755. [Google Scholar] [CrossRef]

- Zehir, C.; Ertosun, Ö.G.; Zehir, S.; Müceldilli, B. Total quality management practices’ effects quality performance and innovative performance. Procedia Soc. Behav. Sci. 2012, 41, 273–280. [Google Scholar] [CrossRef]

- Bashan, A.; Kordova, S. Globalization, quality and systems thinking: Integrating global quality management and a systems view. Heliyon 2021, 7, e06161. [Google Scholar] [CrossRef] [PubMed]

- McAdam, R.; Miller, K.; McSorley, C. Towards a contingency theory perspective of quality management in enabling strategic alignment. Int. J. Prod. Econ. 2019, 207, 195–209. [Google Scholar] [CrossRef]

- Somasundaram, M.; Mohamed Junaid, K.A.M.; Mangadu, S. Artificial intelligence (AI) enabled intelligence quality management system(IQMS) for personalized learning path. Procedia Comput. Sci. 2020, 172, 438–442. [Google Scholar] [CrossRef]

- Badach, J.; Voordeckers, D.; Nyka, L.; Van Acker, M. A framework for air quality management zones—Useful GIS-based tool for urban planning: Case studies in Antwerp and Gdansk. Build. Environ. 2020, 174, 106743. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.I. The role of absorptive capacity and innovation strategy in the design of industry 4.0 business models—A comparison between SMEs and large enterprises. Eur. Manag. J. 2020, 39, 333–343. [Google Scholar] [CrossRef]

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern. Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- Feigenbaum, A. Total Quality Control; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Ramesh, B. Process knowledge management with traceability. IEEE Softw. 2002, 19, 50–52. [Google Scholar] [CrossRef]

- Lee, J.T.; Huang, S.; Dovek, M. PMR with Improved Writability and Process Controllability by Double Layer Patterning. U.S. Patent 8,027,125 B2, 2011. [Google Scholar]

- Barnett, S. Introduction to Mathematical Control Theory; Clarendon Press: Oxford, UK, 1975. [Google Scholar]

- Daoutidis, P.; Zachar, M.; Jogwar, S.S. Sustainability and process control: A survey and perspective. Chem. Eng. Mater. Sci. 2016, 44, 184–206. [Google Scholar] [CrossRef]

- Iwaniec, D.M.; Cook, E.M.; Davidson, M.J.; Berbes-Blazquez, M.; Georgescu, M.; Krayenhoff, E.S.; Middel, A.; Sampson, D.A.; Grimm, N.B. The co-production of sustainable future scenarios. Landsc. Urban Plan. 2020, 197, 103744. [Google Scholar] [CrossRef]

- Carpenter, S.R.; Booth, E.G.; Gillion, S. Plausible futures of a social-ecological system: Yahara watershed, Wisconsin, USA. Ecol. Soc. 2015, 20, 10. [Google Scholar] [CrossRef]

- Iwaniec, D.M.; Wiek, A. Advancing sustainability visioning practice in planning—The general plan update in Phoenix, Arizona. Plan. Pract. Res. 2014, 29, 543–568. [Google Scholar] [CrossRef]

- Siva, V.; Gremyr, I.; Bergquist, B.; Garvare, R.; Zobel, T. The support of quality management to sustainable development: A literature review. J. Clean. Prod. 2016, 138, 148–157. [Google Scholar] [CrossRef]

- Bastas, A.; Liyanage, K. Sustainable supply chain management: A systematic review. J. Clean. Prod. 2018, 181, 726–744. [Google Scholar] [CrossRef]

- Vörös, J.; Rappai, G. Process quality adjusted lot sizing and marketing interface in JIT environment. Appl. Math. Model. 2016, 40, 6708–6724. [Google Scholar] [CrossRef]

- Benesova, A.; Hirman, M.; Steiner, F.; Tupa, J. Determination of changes in process management within Industry 4.0. Procedia Manuf. 2019, 38, 1691–1696. [Google Scholar] [CrossRef]

- Kabugo, J.C.; Jamsa-Jounela, S.L.; Schiemann, R.; Binder, C. Industry 4.0. based process data analytics platform: A waste-to-energy plant case study. Int. J. Electr. Power Energy Syst. 2020, 115, 105508. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunites at the product, process, and system levels. Resour. Conversat. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Butnaru, G.L.; Miller, A.; Nita, V.; Stefanica, M. A new approach on the quality evaluation of tourist services. Econ. Res. Ekon. Istraz. 2018, 31, 1418–1436. [Google Scholar] [CrossRef]

- Butnaru, G.L.; Miller, A. Conceptual approaches on quality and theory of tourism services. Procedia Econ. Financ. 2012, 3, 375–380. [Google Scholar] [CrossRef][Green Version]

- Butnaru, G.L. Service quality and its competitive advantage. Case study of a hotel, Acta Universitatis Danubius. Economica 2017, 13, 70–87. [Google Scholar]

- Landherr, M.; Schneider, U.; Bauernhansl, T. The application center Industrie 4.0—Industry-driven manufacturing, research and development. Procedia CIRP 2016, 57, 26–31. [Google Scholar] [CrossRef]

- Yu, F.; Schweisfurth, T. Industry 4.0 technology implementation in SMEs—A survey in the Danish-German border region. Int. J. Innov. Stud. 2020, 4, 76–84. [Google Scholar] [CrossRef]

- Neumann, W.P.; Winkelhaus, S.; Groose, E.H.; Glock, C.H. Industry 4.0 and the human factor—A systems framework and analysis methodology for successful development. Int. J. Prod. Econ. 2021, 233, 107992. [Google Scholar] [CrossRef]

- Grassi, A.; Guizzi, G.; Santillo, L.C.; Vespoli, S. A semi-heterarchical production control architecture for industry 4.0—Based manufacturing systems. Manuf. Lett. 2020, 24, 43–46. [Google Scholar] [CrossRef]

- Lodgaard, E.; Dransfeld, S. Organizational aspects for successful integration of human-machine interaction in the industry 4.0 era. Procedia CIRP 2020, 88, 218–222. [Google Scholar] [CrossRef]

- Kadir, B.A.; Broberg, O. Human well-being and system performance in the transition to industry 4.0. Int. J. Ind. Ergon. 2020, 76, 102936. [Google Scholar] [CrossRef]

- Gallo, T.; Santolamazza, A. Industry 4.0 and human factor: How is technology changing the role of the maintenance operator? Procedia Comput. Sci. 2021, 180, 388–393. [Google Scholar] [CrossRef]

- Chiarini, A. Industry 4.0, quality management and TQM world. A systematic literature review and a proposed agenda for further research. TQM J. 2020, 32, 603–616. [Google Scholar] [CrossRef]

- Broday, E.E. The evolution of quality: From inspection to quality 4.0. Int. J. Qual. Serv. Sci. 2022. ahead of print. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).