Evaluation on Seismic Performance of Beam-Column Joints of Fabricated Steel Structure with Replaceable Energy-Dissipating Elements

Abstract

:1. Introduction

- (1)

- Investigate the failure mechanism and the strength, stiffness, ductility, hysteresis curve, and energy dissipation capacity under external loads for the joints with replaceable energy-dissipating elements, fully fabricated, beam-column hinged.

- (2)

- Investigate the stress distribution of the energy-dissipating elements for the joints with replaceable energy-dissipating elements, fully fabricated, beam-column hinged when part or all of the section of the energy dissipation element enters the yield state.

- (3)

- Investigate the influence of the linear stiffness ratio of the energy dissipation element to the steel beam on the strength, stiffness, ductility, hysteresis curve, and energy dissipation capacity for the joints with replaceable energy-dissipating elements, fully fabricated, beam-column hinged when the position of the energy dissipation element is constant.

- (4)

- Investigate the influence of the vertical position of the replaceable energy-dissipating element on the strength, stiffness, ductility, hysteresis curve, and energy dissipation capacity for the joints with replaceable energy-dissipating elements, fully fabricated, beam-column hinged when the vertical position of the replaceable energy dissipation element remains unchanged.

- (5)

- Investigate the seismic performance differences between the joints with replaceable energy-dissipating elements, fully fabricated and traditional all-welded steel frame beam-column joints, and find out reasonable design principles or methods.

2. Experimental Program

2.1. Test Specimens

2.2. Test Device and Loading System

3. Failure Mode

4. Comparison of Results

4.1. Strength

4.2. Stiffness

4.3. Ductility

4.4. Hysteresis Curve

4.5. Energy Dissipation

5. Numerical Verification

5.1. FEA Model

5.2. Stress

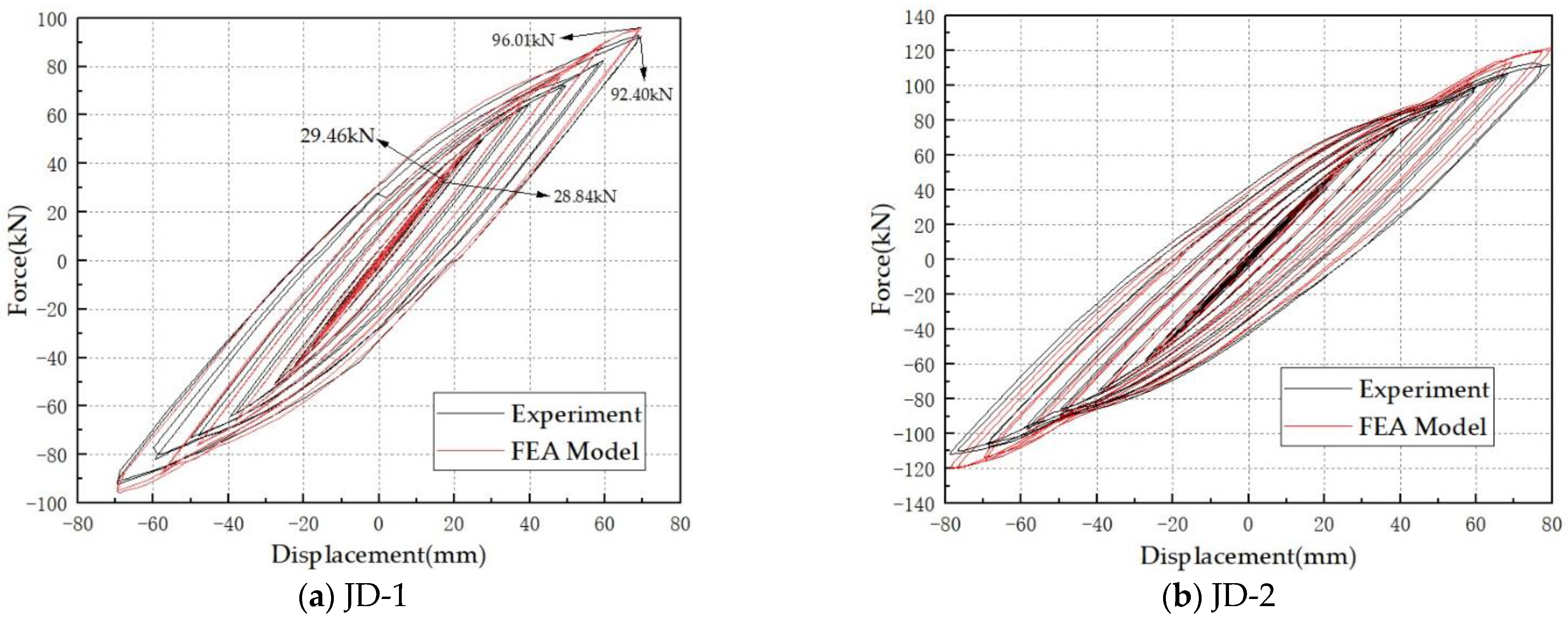

5.3. Hysteretic Behavior

5.4. Failure Mode

5.5. Energy Consumption Capacity

6. Conclusions

- (1)

- For the assembled and beam-column hinged joints with replaceable energy-dissipating elements, the seismic performance evaluation factors of the test and finite element numerical simulation such as the strength, stiffness, ductility, hysteresis curve energy dissipation coefficient, and equivalent damping coefficient are approximately consistent, which verifies that the test results are basically reliable.

- (2)

- For the assembled and beam-column hinged joints with replaceable energy-dissipating elements, as the failure process obtained by the test is consistent with the finite element numerical simulation in general, their destruction mode can realize the new seismic design concept of “energy consumption destruction first, and replacement after earthquake”. Subjected to the action of frequent earthquakes, the energy dissipating elements cooperate with the rest of the structure in elastic behavior and provide sufficient strength and stiffness; Subjected to the action of moderate earthquakes and rare earthquakes, the energy-dissipating elements enter the plastic stage, providing sufficient energy-dissipating capacity, while the remaining components and accessories still maintain elastic behavior.

- (3)

- For the assembled and beam-column hinged joints with replaceable energy-dissipating elements, when the horizontal length is constant, and the ratio of the linear stiffness of the energy dissipation element to the steel beam is approximately 0.7, their seismic performance is in a relatively good state. From the analysis of the 6 groups of tests, it can be concluded that the seismic performance of JD-2 and JD-4 is better than the other groups.

- (4)

- For the assembled and beam-column hinged joints with replaceable energy-dissipating elements, under the condition of constant vertical position and the material properties of energy dissipation elements and steel beams, when the ratio of horizontal length to span is 0.225, their seismic performances are superior. From the analysis of 6 groups of tests, it can be concluded that the seismic performance of JD-4 is better than that of JD-2.

- (5)

- For the assembled and beam-column hinged joints with replaceable energy-dissipating elements, compared with the traditional welded beam-column joints in the steel frame, when the ratio of linear stiffness of energy dissipation element to steel beam is about 0.7, and the ratio of horizontal length to span is about 0.225, they are considered to be a good alternative of it, because the seismic performance is basically close to or beyond that of traditional welded steel frame beam-column joints. From the 6 groups of test analysis, it can be concluded that the seismic performance of JD-4 is better than any other group, and it is closer to the beam-column joint of the traditional welded steel frame.

- (6)

- For the assembled and beam-column hinged joints with replaceable energy-dissipating elements, their welding works can be completed in the factory, and there is basically no welding on site, which is conducive to environmental protection; Their beam-column connection nodes are hinged, which is completely controllable in practical applications compared to rigid or semi-rigid connection nodes connected by bolts; after the earthquake damage, the damaged energy-consuming components can be removed to restore normal use, which is convenient and fast and is conducive to improving the resilience of the city.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ciutina, A.L.; Dubina, D. Seismic behaviour of steel beam-to-column joints with column web stiffening. Steel Compos. Struct. 2006, 6, 493–512. [Google Scholar] [CrossRef]

- Saravanan, M.; Jayachandran, S.A.; Marimuthu, V.; Prabha, P. Advanced analysis of cyclic behaviour of plane steel frames with semi-rigid connections. Steel Compos. Struct. 2009, 9, 381–395. [Google Scholar] [CrossRef]

- Hsu, H.L.; Tsao, J.W. Flexural–torsional performance of thin-walled steel hollow box columns subjected to a cyclic eccentric load. Thin-Walled Struct. 2007, 45, 149–158. [Google Scholar] [CrossRef]

- Miller, D.K. Lessons learned from the Northridge earthquake. Eng. Struct. 1998, 20, 249–260. [Google Scholar] [CrossRef]

- Popov, E.P.; Yang, T.-S.; Chang, A.-P. Design of steel MRF connections before and after 1994 Northridge earthquake. Eng. Struct. 1998, 20, 1030–1038. [Google Scholar] [CrossRef]

- Nakashima, M.; Inoue, K.; Tada, M. Classification of damage to steel buildings observed in the 1995 Hyogoken-Nanbu earthquake. Eng. Struct. 1998, 20, 271–281. [Google Scholar] [CrossRef]

- Swanson, J.A.; Leon, R.T. Bolted steel connections: Tests on t-stub components. J. Struct. Eng. 2000, 126, 50–56. [Google Scholar] [CrossRef]

- Popov, E.P.; Takhirov, S.M. Bolted large seismic steel beam-to-column connections Part 1: Experimental study. Eng. Struct. 2002, 24, 1523–1534. [Google Scholar] [CrossRef]

- Chen, C.-C.; Lin, C.-C.; Lin, C.-H. Ductile moment connections used in steel column-tree moment-resisting frames. J. Constr. Steel Res. 2006, 62, 793–801. [Google Scholar] [CrossRef]

- Wu, L.-Y.; Chung, L.-L.; Tsai, S.-F.; Shen, T.-J.; Huang, G.-L. Seismic behavior of bolted beam-to-column connections for concrete filled steel tube. J. Constr. Steel Res. 2005, 61, 1387–1410. [Google Scholar] [CrossRef]

- Zhang, A.-L.; Su, L.; Jiang, Z.-Q.; Kang, Y.-T.; Qiu, P. Cyclic loading tests of earthquake-resilient prefabricated steel cross joints with different FCP connections. Structures 2021, 32, 1–14. [Google Scholar] [CrossRef]

- Priestley, M.J.N. Overview of PRESSS research program. PCI J. 1991, 36, 50–57. [Google Scholar] [CrossRef]

- Priestley, M.J.N. The PRESSS program: Current status and proposed plans for phase Ⅲ. PCI J. 1996, 41, 22–40. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary results and conclusions from the PRESSS five-story precast concrete test building. PCI J. 1999, 44, 42–67. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Tao, J. Seismic response of precast prestressed concrete frames with partially debonded tendons. PCI J. 1993, 38, 58–69. [Google Scholar] [CrossRef]

- Hitaka, T.; Sakino, K. Cyclic tests on a hybrid coupled wall utilizing a rocking mechanism. Earthq. Eng. Struct. Dyn. 2008, 37, 1657–1676. [Google Scholar] [CrossRef]

- Stevens, D.; Wiebe, L. Large-scale testing of a replaceable connection for concentrically braced frames. In Proceedings of the 16th World Conference on Earthquake Engineering, Santiago, Chile, 9–13 January 2017. Paper No. 3354. [Google Scholar]

- Asghari, A.; Gandomi, A.H. Ductility reduction factor and collapse mechanism evaluation of a new steel knee braced frame. Struct. Infrastruct. Eng. 2016, 12, 17. [Google Scholar] [CrossRef]

- Asghari, A.; Saharkhizan, S. Seismic design and performance evaluation of steel frames with knee-element connections. J. Constr. Steel Res. 2017, 154, 113–123. [Google Scholar] [CrossRef]

- Hsu, H.-L.; Li, Z.-C. Seismic performance of steel frames with controlled buckling mechanisms in knee braces. J. Constr. Steel Res. 2015, 107, 50–60. [Google Scholar] [CrossRef]

- Latour, M.; D’Aniello, M.; Zimbru, M.; Rizzano, G.; Piluso, V.; Landolfo, R. Removable friction dampers for low-damage steel beam-to-column joints. Soil Dyn. Earthq. Eng. 2018, 115, 66–81. [Google Scholar] [CrossRef]

- Fathizadeh, S.; Dehghani, S.; Yang, T.; Vosoughi, A.; Farsangi, E.N.; Hajirasouliha, I. Seismic performance assessment of multi-story steel frames with curved dampers and semi-rigid connections. J. Constr. Steel Res. 2021, 182, 1–25. [Google Scholar] [CrossRef]

- Zeng, J.; Kim, Y.H. Stiffness Modification-Based Bayesian Finite Element Model Updating to Solve Coupling Effect of Structural Parameters: Formulations. Appl. Sci. 2021, 11, 10615. [Google Scholar] [CrossRef]

- GB50017; Standard for Design of Steel Structures. China Construction Industry Press: Beijing, China, 2017.

- Łacny, Ł.; Ścisło, L.; Guinchard, M. Application of Probabilistic Power Spectral Density Technique to Monitoring the Long-Term Vibrational Behaviour of CERN Seismic Network Stations. Vib. Phys. Syst. 2020, 31, 2020311. [Google Scholar]

- Cislo, L.; Guinchard, M. Source based measurements and monitoring of ground motion conditions during civil engineering works for high luminosity upgrade of the LHC. In Proceedings of the 26th International Congress on Sound and Vibration, ICSV, Montreal, 7–11 July 2019. [Google Scholar]

- GB50011; Code for Seismic Design of Building. China Construction Industry Press: Beijing, China, 2016.

- Azuma, K.; Kurobane, Y.; Makino, Y. Cyclic testing of beam-to-column connections with weld defects and assessment of safety of numerically modeled connections from brittle fracture. Eng. Struct. 2000, 22, 1596–1608. [Google Scholar] [CrossRef]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering, 2nd ed.; Pearson Education: Upper Saddle River, NJ, USA, 2001. [Google Scholar]

- Ricles, J.M.; Fisher, J.W.; Lu, L.W.; Kaufmann, E.J. Development of Improved Welded Moment Connections for Earthquake-Resistant Design. J. Constr. Steel Res. 2002, 58, 565–604. [Google Scholar] [CrossRef]

- Maleki, S.; Tabbakhha, M. Numerical study of Slotted-Web-Reduced-Flange moment connection. J. Constr. Steel Res. 2012, 69, 1–7. [Google Scholar] [CrossRef]

- ABAQUS, Inc. ABAQUS Analysis User’s Manual; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2012; Volume 6.12. [Google Scholar]

| Specimen | Length H/Lb/Ldg (mm) | Specific Part | Yield Strength (MPa) | Young’s Modulus E (105 MPa) | Linear Stiffness EI/L (106 N·m2/m) | Ratio of Linear Stiffness to Steel Beam |

|---|---|---|---|---|---|---|

| Steel Beam | 4530 | Flange | 397 | 2.04 | 1.59 | 1.00 |

| Web | 395 | |||||

| Steel column | 3225 | Flange | 396 | 2.05 | - | - |

| Web | 396 | |||||

| Energy dissipating components | 750 | JD-1 | 393 | 2.04 | 1.07 | 0.67 |

| 1000 | JD-2 | 395 | 2.03 | 1.15 | 0.72 | |

| 1125 | JD-3 | 391 | 2.05 | 0.82 | 0.51 | |

| 1125 | JD-4 | 394 | 2.03 | 1.12 | 0.71 | |

| 1125 | JD-5 | 392 | 2.04 | 1.33 | 0.83 | |

| 1250 | JD-6 | 392 | 2.04 | 1.19 | 0.75 |

| Joint Type | Elastic Ultimate Strength | Plastic Ultimate Strength | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Experiment | FEA | %EUS | Experiment | FEA | %PUS | |||||

| Dis (mm) | F (KN) | Dis (mm) | F (KN) | Dis (mm) | F (KN) | Dis (mm) | F (KN) | |||

| JD-1 | 14.50 | 28.84 | 14.22 | 29.46 | 2.15 | 68.84 | 92.40 | 69.68 | 96.01 | 3.91 |

| JD-2 | 14.50 | 32.52 | 14.50 | 33.22 | 2.15 | 79.00 | 112.06 | 79.83 | 121.12 | 8.08 |

| JD-3 | 14.50 | 30.45 | 14.50 | 31.57 | 3.68 | 59.05 | 84.47 | 59.04 | 88.12 | 4.32 |

| JD-4 | 14.50 | 33.37 | 14.50 | 34.64 | 3.81 | 79.00 | 121.79 | 79.08 | 130.54 | 7.18 |

| JD-5 | 14.50 | 34.73 | 14.50 | 37.31 | 7.43 | 79.70 | 133.14 | 79.79 | 139.01 | 4.41 |

| JD-6 | 14.50 | 34.42 | 14.50 | 34.95 | 1.54 | 79.00 | 129.21 | 79.08 | 135.35 | 4.75 |

| NSF | - | - | 39.29 | 53.39 | - | - | - | 98.22 | 108.08 | - |

| Joint Type | Elastic Stiffness (kN/m) | ||

|---|---|---|---|

| Experiment | FEA | %ES | |

| JD-1 | 2.00 | 2.04 | 2.00 |

| JD-2 | 2.21 | 2.26 | 2.26 |

| JD-3 | 2.08 | 2.15 | 3.37 |

| JD-4 | 2.27 | 2.31 | 1.76 |

| JD-5 | 2.36 | 2.43 | 2.97 |

| JD-6 | 2.35 | 2.44 | 3.83 |

| NSF | - | 1.36 | - |

| Joint Type | Ductility | ||

|---|---|---|---|

| Experiment | FEA | % Ductility | |

| JD-1 | 4.84 | 4.90 | 1.24 |

| JD-2 | 5.45 | 5.51 | 1.10 |

| JD-3 | 4.07 | 4.07 | 0 |

| JD-4 | 5.45 | 5.45 | 0 |

| JD-5 | 5.50 | 5.50 | 0 |

| JD-6 | 5.45 | 5.45 | 0 |

| NSF | - | 2.50 | - |

| Joint Type | Energy Dissipation Coefficient E | Equivalent Viscous Damping Coefficient ζeq | ||||

|---|---|---|---|---|---|---|

| Experiment | FEA | %E | Experiment | FEA | %ζeq | |

| JD-1 | 0.86 | 0.87 | 1.16 | 0.14 | 0.14 | 0 |

| JD-2 | 0.95 | 0.97 | 2.11 | 0.15 | 0.15 | 0 |

| JD-3 | 0.87 | 0.87 | 0 | 0.14 | 0.14 | 0 |

| JD-4 | 0.87 | 0.89 | 2.30 | 0.14 | 0.14 | 0 |

| JD-5 | 0.64 | 0.64 | 0 | 0.10 | 0.10 | 0 |

| JD-6 | 0.67 | 0.67 | 0 | 0.11 | 0.11 | 0 |

| NSF | - | 0.744 | - | - | 0.12 | - |

| Joint Type | Equivalent Damping Coefficient under Various Interlayer Displacement Ratios | ||||||

|---|---|---|---|---|---|---|---|

| 1.24% | 1.55% | 1.86% | 2.17% | 2.48% | 2.79% | 3.10% | |

| JD-1 | 0.063 | 0.093 | 0.103 | 0.138 | - | - | - |

| JD-2 | 0.055 | 0.085 | 0.096 | 0.117 | 0.154 | - | - |

| JD-3 | 0.078 | 0.106 | 0.138 | - | - | - | - |

| JD-4 | 0.020 | 0.053 | 0.071 | 0.089 | 0.141 | - | - |

| JD-5 | 0.044 | 0.0625 | 0.076 | 0.080 | 0.102 | - | - |

| JD-6 | 0.040 | 0.062 | 0.078 | 0.087 | 0.107 | - | - |

| NSF | - | - | - | 0.01 | 0.048 | 0.085 | 0.118 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Huang, B. Evaluation on Seismic Performance of Beam-Column Joints of Fabricated Steel Structure with Replaceable Energy-Dissipating Elements. Sustainability 2022, 14, 3350. https://doi.org/10.3390/su14063350

Li Y, Huang B. Evaluation on Seismic Performance of Beam-Column Joints of Fabricated Steel Structure with Replaceable Energy-Dissipating Elements. Sustainability. 2022; 14(6):3350. https://doi.org/10.3390/su14063350

Chicago/Turabian StyleLi, Yuanqi, and Binhui Huang. 2022. "Evaluation on Seismic Performance of Beam-Column Joints of Fabricated Steel Structure with Replaceable Energy-Dissipating Elements" Sustainability 14, no. 6: 3350. https://doi.org/10.3390/su14063350

APA StyleLi, Y., & Huang, B. (2022). Evaluation on Seismic Performance of Beam-Column Joints of Fabricated Steel Structure with Replaceable Energy-Dissipating Elements. Sustainability, 14(6), 3350. https://doi.org/10.3390/su14063350