Abstract

Industries strive to prevent ecologically destructive actions in their supply chains. At the same time, the optimization of their resources is a major concern for industries to minimize carbon emissions, boost sustainable practices, and improve a country’s long-term economic development. Therefore, the objective of this study is to examine the impact of Green Supply Chain Management (GSCM) methods on operational performance with the mediation of technological innovation, in the context of Pakistani manufacturing firms. The partial least square-structural modeling (PLS-SEM) method is adopted in this paper. Data were gathered from 223 different manufacturing firms in Pakistan and then analyzed among these variables. The data show good validity and reliability, and structural model explains 61% of the variance in operational performance and 45.4% of the variance in technical innovation, demonstrating its predictive validity. The R-square criteria classify R-square entities of 0.67, 0.33, and 0.19 as considerable, moderate, and weak, respectively. It is demonstrated that all the f-square values are greater than 0.020 and 0.35, indicating a significant effect on the model’s validity. The findings of this study reveal that GSCM practices have a significantly positive effect on both technological innovation and operational performance. Technological innovation has a direct influence on operational performance and has a partial mediating effect on the relationship between GSCM practices and operational performance. Therefore, this research offers managers insight into the importance of technological innovation and GSCM practice adoption to achieve competitive advantages. It further provides the groundwork for managers, practitioners, and environmental management researchers to emphasize the value of GSCM practice in improving operational performance.

1. Introduction

The “green concept” is acquiring footing in the manufacturing industry these days. Most manufacturing firms attempt to boost their resource effectiveness while limiting adverse consequences on human wellbeing, efficiency, and the environment. The essential and focused activity of a manufacturing firm is supply chain management. Consequently, GSCM practices are being adopted by most manufacturing companies to reduce waste, pollution, natural resource usage, and emissions [1]. As a result of increased global environmental problems and global warming, GSCM approaches have become vital and the most successful sustainability practices for professionals, researchers, and industries [2,3]. GSCM procedures and ecological issues have become well-known subjects in the scholarly world. Because of financial and environmental problems brought about by unreliable or exploitative business activities during the time spent on obtaining unrefined components, manufacturing, coordinated operations, and item removal toward the end of the items’ useful lives, sustainability has turned into a problematic issue in the competitive world [4]. The components of GSCM’s environmental management system include product creation, procurement, purchasing, manufacturing, distribution, and logistics [5]. It can be seen that many manufacturers value customer expectations, and existing customers are well-informed and majorly concerned about the environment. They pressure manufacturers to avoid environmentally damaging operations and protect the environment. Clients are becoming very much aware of environmental issues and increasingly request environmentally friendly products [6]. The manufacturing sector of Pakistan is vital for its economy, as it contributes to a variety of social and economic goals and employs a vast number of workers. In 2019, the manufacturing sector added up to 13.3% of Pakistan’s total gross domestic product (GDP) [7]. Even though Pakistan’s manufacturing industry plays a crucial role in economic development, it also significantly affects the environment. Economic growth has environmental implications, including high temperatures, smog, noise, and air pollution. In a developing country such as Pakistan, industries are supposed to achieve sustainable and long-term economic growth without harming the environment [8,9]. In this situation, it is difficult for manufacturing organizations to reduce carbon emissions, enhance sustainable methods, and improve their long-term economic development. However, cost-effective and efficient green innovation initiatives could transform the manufacturing sector [10]. Due to a lack of research on GSCM and its influence on a firm’s performance, only a few industries in Pakistan are adopting green practices [11]. Therefore, the primary aim of this work is to give a better understanding of the link be-tween GSCM practices and operational performance in the context of Pakistan’s manufacturing industry, with the mediating influence of technological innovation. The successful execution of GSCM practices will lead to reduced waste, cost reductions, green marketing awareness, staff morale, and public response, all of which will enhance the company’s performance, including environmental, economic, and manufacturing operations [12]. Environmental protection, innovation, and collaboration are used to help communities transition to a green lifestyle [13]. The concepts of GSCM strategies will support the use of greener and digitalized supply chains, enabling more efficient and successful plan development and execution [14].

The economy of Pakistan is mainly dependent on the manufacturing sector, and within this, the textile sector is said to be the backbone of the country’s economy. Small- and medium-sized industries also contribute to Pakistan’s economy, and most of them provide vendor services to large enterprises. GSCM is a reasonably new idea in Pakistan, and its adoption is still in its initial phases. Pollution is a big problem in Pakistan, and societal pressure and environmental constraints drive businesses to use GSCM approaches. Due to a lack of research on GSCM and its influence on a firm’s progress, only a tiny fraction of Pakistan’s industry has adopted green practices [11].

The aim of this work is to highlight the relationship between GSCM practices and operational performance in the context of Pakistan’s manufacturing industry, with the mediating influence of technological innovation. Therefore, this study highlights the role of sustainable practices along with technological innovation to increase operational performance, resulting in greater productivity and profit. This study further ensures that sustainable practice saves the environment and helps boost the productivity of the firms and makes important theoretical and practical contributions. Firstly, current GSCM research is summarized while a new antecedent of GSCM rules is found. Secondly, the direct influence of GSCM adoption on technological innovation and operational performance, as well as technological innovation’s link with operational performance, is explored in this study. Thirdly, this study also fills the gap in the literature regarding the mediating effect of technological advancements on the link among GSCM practices and operational performance.

2. Literature Review

2.1. Green Supply Chain Management Practices

Academics and practitioners are introducing the method of GSCM as a feasible solution to improve the environment. GSCM was initially proposed in the early 1990s, but its popularity surged around 2000, as indicated by increased scientific publications [15,16,17]. Nowadays, GSCM has gained more popularity, as it has become a need for every organization to reduce environmentally harmful activities and improve the interaction between the customers and the suppliers of green products [3]. Hervani, Helms [18] defined GSCM as all-green procurement, green manufacturing, green distribution, and reverse logistics activities. When making decisions, GSCM considers all stages of material and logistical management and post-consumer waste disposal [19]. Srivastava [20] described GSCM as the collection of environmental thinking and supply-chain management, including the design of the product, sourcing, fetching materials, manufacturing processes, and the distribution of the final product to the end-user.

Concerns about the natural issues of the environment and society in the design, acquisition, manufacture, distribution, use, reuse, and disposal of the firm’s goods and services led to the adoption of a set of supply chain management rules, actions, and connections [21]. These GSCM rules, actions, and relations are feasible solutions for reducing the environmental effect of operations while boosting operational performance. The use of GSCM was first motivated by ecological degradation, limited raw material resources, and rising pollution levels [22], and organizations are now able to increase their performance by implementing it [23]. With the rising popularity of GSCM and the adoption of green supply chain practices by large corporations, it is now vital to assess the effect of implementation on small businesses. Smaller businesses must be evaluated and cooperatively involved in environmental preservation to be motivated and contribute to a more sustainable process [17]. The state-of-the-art studies on GSCM are systematically summarized in Table 1. Previous research has found several dimensions of GSCM practices, such as eco-design, internal environmental management, green purchasing, investment recovery, customer cooperation, reverse logistics, green manufacturing, green information systems, supplier collaboration, and waste management. However, to measure GSCM practices, following a comprehensive literature review, we have selected green manufacturing, eco-design, investment recovery, green information systems, and green purchasing.

2.2. Technological Innovation (TI)

Industries are increasingly relying on environmentally friendly technology and sustainable energy sources that will improve environmental sustainability and technological growth. These environmentally friendly technologies have considerably enhanced and repaired the environment in modern economies due to the 4.0 industrial revolution. Research on the factors that influence green growth has drawn much attention from academics and politicians from all over the world [24]. In a volatile and changing business climate, technological innovation is critical to a company’s agility. Firms, regardless of size, are constantly competing to produce innovative items at a cheaper cost [25,26]. Innovation has grown into a platform for enhancing productivity, the volume of sales, and competitiveness for businesses. These situations also motivate organizations to be inventive to improve the design, quality, and consistency of their products and services. As a result, to preserve their competitive edge, organizations must increase their innovation skills to produce and market new technologies successfully and support technical improvements across the board [27,28,29]. Adopting new technology into products, services, or processes is defined as technological innovation [30,31]. Product and process innovation are the two common types of innovation that have historically been measured [32,33]. Gunday, Ulusoy [34] and Kim, Kumar [35] created a new dimension termed management innovation to quantify innovation performance comprehensively. In other words, they proposed that product innovation, process innovation, and management innovation be used to assess innovation performance [33]. As a result, both product and process innovation have been employed as elements in this research to technological innovation as a whole [26,36,37].

Table 1.

Summary of published studies on Green Supply Chain Management.

Table 1.

Summary of published studies on Green Supply Chain Management.

| Focus of the Study | Method | Findings of the Study | Year | Reference |

|---|---|---|---|---|

| To develop a comprehensive GSCM practice and performance model that can be theorized and experimentally evaluated. | Structural Equation Modelling | According to the findings, adoption of GSCM techniques by manufacturers improves environmental and economic performance, which has a significant impact on operational performance. | 2012 | Green, Zelbst [38] |

| To develop three models for evaluating the mediation linkages between the external and internal practices of GSCM in terms of environmental, economic, and operational performance using coordination theory. | Factor Analysis and Hierarchical Multiple Regression Analysis | The empirical results correspond to the mediation effects, implying that manufacturers must coordinate internal and external components of GSCM implementation to reap the performance gains. | 2012 | Zhu, Sarkis [39] |

| To examine the research framework and find a link between Green Supply Cchain Management practices and technical innovation in manufacturing companies. | PLS-SEM | The study indicated a strong positive association between three GSCM practices (internal environmental management, eco-design, and investment recovery) and technological innovation, but it did not find a significant positive relationship between green purchasing and customer cooperation with technological innovation. | 2014 | Lee, Ooi [26] |

| Performance evaluation of Green Supply Chain Management | Fuzzy ANP, Fuzzy DEMATEL, and Fuzzy TOPSIS | According to the study, the most important factors for evaluating the firm’s green SCM activities are green design, green logistics, and green transformation. | 2016 | Uygun and Dede [40] |

| To investigate the factors affecting green supply chain operational performance of the Thai auto parts manufacturing firm. | Factor Analysis and Multiple Linear Regression Analysis | The study’s findings show that green procurement is the most important component for implementing green SCM processes, followed by green transportation and green manufacturing. | 2016 | Tippayawong, Niyomyat [41] |

| To determine the degree of correlation between the two indicators of management support and their organization’s learning and the idea of Green Supply Chain Management. | Factor Analysis | This study found a positive significant association between organizational learning mechanisms, organizational support, and GSCM practices using controlled variables, such as organization size, the perspective of the country, cost pressure by firms, and industry practices at various levels. | 2018 | Suryanto, Haseeb [42] |

| To see how GSCM techniques (such as internal practices, external practices, investment recovery, and eco-design) affect organizational performance in Pakistan. | Factor Analysis and Linear Regression Analysis | The findings show that using GSCM practices reduces environmental pollution and operational costs, but it does not improve organizational flexibility in Pakistani industries. | 2018 | Mumtaz, Ali [43] |

| To determine whether external forces (regulatory and customer pressures) have a moderating influence on the link between GSCM and operational performance. | Linear Regression Analysis | The findings reveal the partial mediating effect of operational performance between GSCM, environmental, and financial performance, as well as the moderating effect of external pressures on the link between GSCM and operational success. | 2021 | Hashmi and Akram [44] |

| To find the influence of Industry 4.0 on economic and environmental performance in emerging economies such as Pakistan through the use of Green Supply Chain Management (GSCM) approaches. | PLS-SEM | The findings show that GSCM methods mitigate the impact of Industry 4.0 on both economic and environmental consequences. | 2021 | Umar, Khan [45] |

2.3. Operational Performance (OP)

Manufacturing organizations must develop operational strategies that help implement their corporate competitive strategies because the operational function is so important in establishing and sustaining competitiveness. Manufacturing competitive priorities are the strategies that a firm may use to choose how to compete in the marketplace and which markets it wants to target [46]. To be competitive in the market, organizations must mainly focus on their internal operations. Product quality, process quality, effectiveness, productivity, and operational performance are often characterized as a set of variables that represent an organization’s internal operations. These internal operations, productivity, effectiveness, and efficiency are employed to measure operational performance [47]. Manufacturing operational performance, which is defined as cost, time, quality, and delivery dependability metrics associated with manufacturing operations, is used to analyze the performance of manufacturing processes [48]. Prior work labeled the unit cost of production, quality, speed of new product launch, inventory turnover, adaptability, and delivery reliability as operational performance [49,50,51]. Production cost, flexibility, and quality have been used to measure operational performance in this study, and they are the most commonly used operational performance measures in the literature [31,52,53,54].

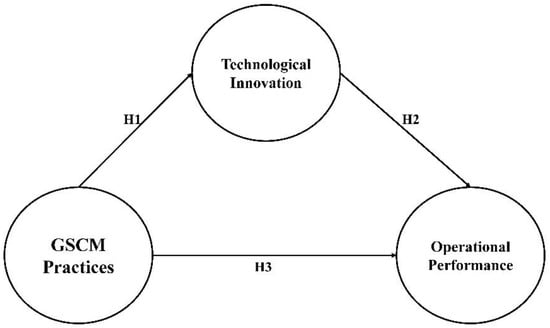

3. Research Framework and Hypothesis Development

3.1. Green Supply Chain Management Practices → Technological Advancement

GSCM is the interaction between customers and suppliers of green products. When making decisions, GSCM considers all stages of material and logistical management and post-consumer waste disposal after use [19,55]. Lee, Ooi [26] discovered that GSCM procedures had a considerable impact on technological innovation among manufacturing enterprises in Malaysia. Investment recovery, echo design, and inter-environmental management have a substantial and positive impact on technological innovation. Cooperation with the customer and green purchasing have a mild and minor negative impact on TI among manufacturing enterprises in Malaysia. Still, IEM is the key GSCM component highly associated with technological innovation. Green elements should be incorporated to increase environmental performance in manufacturing supply chain design and operational decision support [56] to reduce the overall carbon footprint [57] and recycle used/waste products and by-products [20,58]. According to Silva and Gomes [59], product and process innovation mediates the relationship between GSCM approaches and sustainable attributes. Song and Gao [60] illustrate that Green Supply Chain Management innovation produces results felt by consumers who are already sensitive to green products. It directly impacts product ecology and sales volume, which in turn affects manufacturer and store profitability. The key aim of green supply chain partners developing green innovations, according to Vachon and Klassen [61], is to meet consumer demand for green products. As per past work, there is no such study conducted in Pakistan that highlights the direct effect of GSCM on TI.

Hypothesis 1 (H1).

Green Supply Chain Management practices (GSCMP) have a significant impact on technological innovation (TI).

3.2. Technological Innovation → Operational Performance

Manufacturing enterprises achieve excellence in operational execution characteristics such as quality, cost, flexibility, and delivery by focusing their resources and efforts on improvements and innovations of products and processes, internally and externally [48]. Technology innovation and development can provide internal and external benefits [62]. According to Boer and During [63], technological innovation aims to increase flexibility, decrease delivery time, and lower operational expenses. Because of the new components and functionalities used, Gunday, Ulusoy [34] claim that technological advancements affect production methods, resulting in higher speed and quality, lower prices, and increased customer level of satisfaction. Ju, Park [64] observed that technological innovation boosts operational efficiency and links supply chain dynamic capacity and operational efficiency. Further, Kafetzopoulos and Psomas [65] discovered that inventiveness was linked to increased production and performance. Process innovation increases an organization’s manufacturing efficiency and productivity while improving quality and lowering unit costs [66].

Hypothesis 2 (H2).

Technological innovation has a positive impact on operational performance.

3.3. Green Supply Chain Management Practices → Operational Performance

GSCM practices have a significant effect on performance results. Manufacturing companies that use GSCM principles generally enhance their economic, environmental, and organizational performance, but organizational performance is improved through operational performance [38,67]. GSCM methods enhance functional attributes, such as feature, cost, and flexibility, without affecting lead time [68]. Customers’ participation in environmental management techniques, according to [69], can help boost customer willingness by lowering costs and improving product quality. The results of Feng, Yu [70] demonstrate that GSCM has a strong relationship with both operational and environmental performance, which tends to enhance financial success. In the case of Pakistani manufacturing enterprises, researchers looked at the effect of GSCM practices on organizational performance. Additionally, they recommended some independent variables that should be used in future research. Some of them are investment recovery and inter-environmental management to find the impact on organization performance, and they are taken in this study [71], and the constructs are provided in Table 2.

Hypothesis 3 (H3).

Green Supply Chain Management has a positive effect on operational performance.

3.4. The Mediating Role of Technological Innovation

GSCM techniques are technical enhancements to products and processes that aim to enhance resource effectiveness and lower the hazardous effects of products and processes on the environment [26,72,73]. To achieve these aims and highlight their importance, numerous studies have been done to find the association of GSCM practices with different constructs. Khan and Qianli [71] and Mumtaz, Ali [43] investigated the effect of GSCM practices on organizational performance in Pakistani manufacturing firms. Jermsittiparsert, Sutduean [74] discovered the mediating role of innovation performance on the relationship between GSCM skills and a firm’s environmental performance. Mughal [75] explored the strong moderating effect of traceability on the connection between eco-design and organizational performance and the association between internal environment management and organizational performance. Umar, Khan [45] further investigated the mediating role of GSCM practices on the relationship of Industry 4.0 to environmental and economic performance.

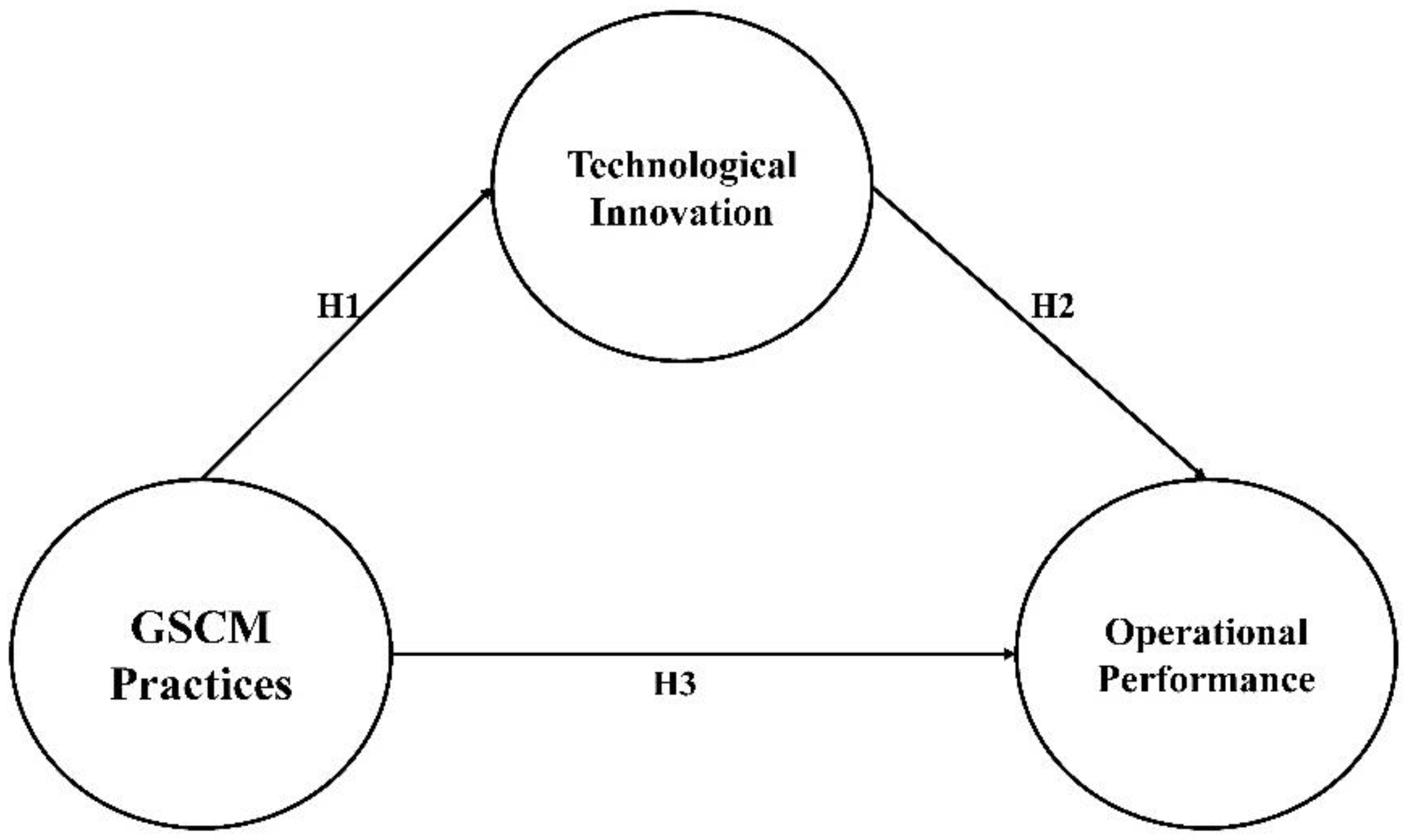

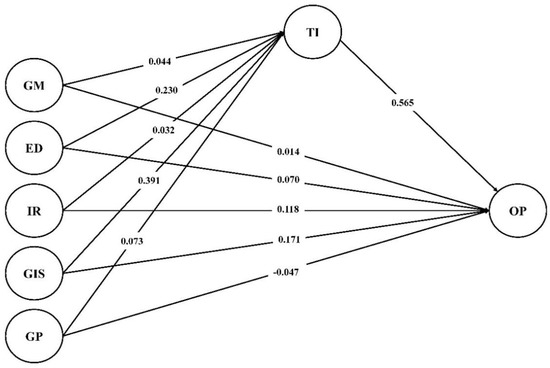

Prior studies focused mainly on the direct effect of GSCM practices on technological innovation [26] and operational performance [68,76]. However, this study provides the direct and indirect influence of GSCM practices on operational performance through technological innovation, as shown in Figure 1. Although the mediating role of technological innovation has been identified in different relationships [77], this research work explicitly proposes the mediating effect of technological innovation on the relationship between GSCM practices and operational performance. Therefore, the conceptualized hypothesis of this research is as follows:

Figure 1.

Theoretical framework.

Hypothesis 4 (H4).

Technological innovation facilitates the relationship between GSCM methods and operational performance.

Table 2.

Definitions of construct.

Table 2.

Definitions of construct.

| Constructs | Definitions |

|---|---|

| Green manufacturing | Green production focuses on planning, regulating, and reducing resources such as water, energy, and materials and reducing hazardous waste from the manufacturing process [71]. |

| Eco-design | Manufacturers must design goods that decrease materials and energy consumption; promote the recycling, reuse, and recovery of significant parts and materials; and reduce or prevent the use of poisonous and dangerous elements in manufacturing processes [78] |

| Investment recovery | Investment recovery is a strategy that encourages the sale of surplus materials, reduces energy consumption from equipment and machinery, and recycles discarded goods [71]. |

| Green information system | The green information system (GIS) refers to the collaborative use of information technology to construct focused systems that assist organizations in achieving ecological sustainability [79]. |

| Green purchasing | Green purchasing is concerned with the production and processing of ecologically friendly items and does not damage the environment and collaboration with suppliers [38]. |

| Technical innovation | The execution of a concept for a new product or a new service or the introduction of new elements in an organization’s manufacturing or service operation is what technical innovation refers to [80]. |

| Operational performance | The combination of efficient product creation, process improvements, quality conformance, and short lead times [81]. |

4. Methodology

4.1. Data Collection

This paper investigates the impacts of GSCM methods and technological innovation on operational attributes in Pakistani manufacturing firms. Because of the country’s pollution and climate change, GSCM rules have become a critical component of the manufacturing sector of Pakistan. The list of contact details was collected from the Karachi Chamber of Commerce (KCCI) to collect data from various manufacturing organizations. The provided list was filtered to only manufacturing companies that were small-, medium-, and large-scale. Small-scale companies appoint a maximum of 99 employees and medium-scale companies appoint a maximum of 250 employees. If the company appoints more than 250 employees, it is considered a large-scale company [82,83].

A survey-based questionnaire based upon extensive literature review and past studies was developed to obtain data from several leading manufacturing industries, such as the textile, steel, pharmaceutical, paper, chemical, and automobile sectors. The survey instrument was divided into two sections. The first section consisted of demographics, such as respondents’ qualification, work experience, designation, company size, and ISO certification. Therefore, the other section consisted of 43 questions (Appendix A) related to GSCM practices, technological innovation and operational performance. For a survey questionnaire for measuring green manufacturing, eight items were adopted from Rao and Bogale [84], three items of eco-design were selected from Habib, Bao [85], and four items of investment recovery were adopted from Zhu, Sarkis [78]. Seven indicators of green purchasing were taken from Yu, Zhang [86], and six items of green information systems were taken from Qu and Liu [87]. To measure the higher-order construct of GSCM practices, for measuring technological innovation, nine items were adopted from Shahid, Waseem [88], and six indicators of operational performance were taken from Hong, Liao [33]. Respondents were asked to agree or disagree with the given statements, using a five-point Likert scale of 1 to 5, where 1 = Strongly disagree, 2 = Disagree, 3 = Neutral, 4 = Agree, and 5 = Strongly agree.

Academic experts determined the face and content validity of the questionnaire. The pilot test was performed on a sample size of 40 to ensure that all the matters were going correctly. Survey responses were collected by meeting respondents personally or through email (recommended by some industries). Employees, including Assistant Managers, Senior Managers, Executives, and Engineers from the Quality, Operation, Production, Warehouse, and Inventory Control departments were among the respondents. The respondents’ work experience ranged from five to twenty years, as shown in Table 3. A variety of strategies were utilized to increase the response rate, including making phone calls, sending follow-up letters, and sending emails. A total of 246 responses (n) were received, of which 223 were valid for the study, yielding a response rate of 40.5%. This sample size is sufficient for further analysis, and a sample size of 100 samples and preferably 200 samples is enough for SEM [89].

Table 3.

Demographic of participants.

4.2. Data Analysis

The PLS-structural equation modeling method was used to test the hypotheses, as the PLS-SEM method is used to test and evaluate complex statistical models [90,91]. CB-SEM is another method that can also be used to examine the structural model quality [92]. It is based on the assumption that data distributions are normal but is hardly satisfying in social science research. On the other hand, PLS-SEM is non-parametric and works well with non-normal distributions and has minimal limits on the usage of ordinal and binary scales when appropriately coded [93]. However, PLS-SEM can handle complex models and provide better outcomes [94,95]. In recent years, the use of PLS-SEM has become more widespread in various domains, with non-normal data, small sample sizes, and the use of formative constructs being the most common reasons for its employment. PLS-analytical SEM’s toolkit has recently been expanded to support more complicated model construction and tackle data deficiencies such as heterogeneity [96]. PLS-SEM was found suitable for this study to evaluate the hypotheses. As discussed above, it has various advantages in analyzing higher-order constructs. The “Two-stage Approach” was used to examine the relationship between constructs as described by Sarstedt, Hair Jr [97]. The lower-order measurement model was constructed, and all the tests of reliability and validity were performed in the first stage. The indicators that were identified for the higher-order construct in the first stage were then put into a structural equation model to test the hypotheses in the second stage.

5. Results

Table 3 illustrates the sample profile of this study, including the type and size of the firm and the designation of the officials from the responding firms. The textile and apparel industry is Pakistan’s largest industrial sector, and this sample included the most responses from this industry, 52.9%. Moreover, it represents a solid mix of small, medium, and large enterprises, with a response rate of 91.9% from large corporations, 6.2% from medium-sized enterprises, and the rest from small businesses. Among them, 90% of the industries were determined to be ISO certified. Finally, in the designation area, assistant managers gave the highest number of responses, 33.6%, and 73.9% of respondents had experience from zero to five years.

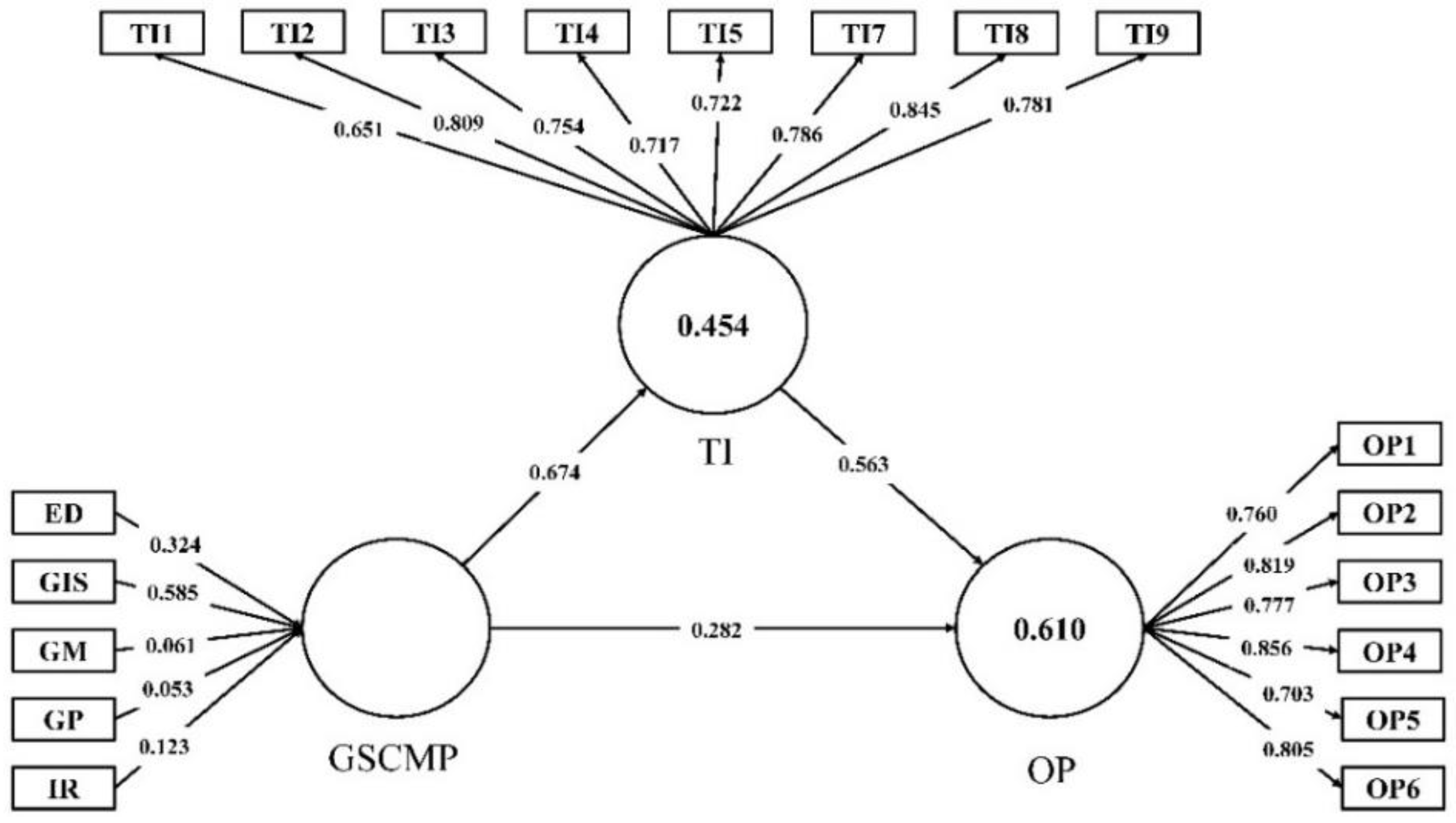

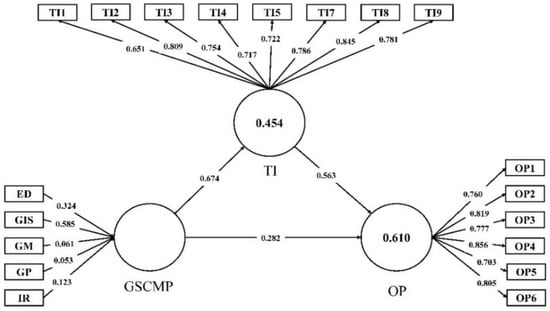

5.1. Measurement Model

The construct validity, convergent validity, and discriminant validity of the lower-order constructs (LOC) measurement model were examined. Figure 2 demonstrates the measurement model having LOC. Convergent validity was used to examine the correlation between constructs and latent variables. Individual item dependability may be verified using the standardized factor loading value. The standardized factor loading value explains the degree of association between each measurement item (indicator) and its concept. If the loading factor value is more than 0.7, the indicator is legitimate for assessing the construct. In empirical research, a loading factor value of >0.5 is still appropriate [98]. As a result, Green Manufacturing “GM1” showed low factor loading, thus dropping from the dataset. The composite reliability (CR) values of all the lower-order constructs were between 0.812 and 0.940, and all the values of Cronbach’s alpha were between 0.702 and 0.923, above the minimum criterion of 0.7 [96,99], shown in Table 4. This means that our construct’s measuring model is accurate and appropriate for the analysis. The average variance extracted (AVE) tests the convergent validity of different indicators in SEM model [100]. The AVE values were all in the range of 0.516 to 0.723, greater than the limit of 0.50, indicating that this model’s convergent validity is widely acknowledged [101].

Figure 2.

LOC measurement model.

Table 4.

Construct reliability and convergent validity.

Discriminant validity was examined using the Fornell-larger criterion, cross-loading, and Heterotrait–Monotrait ratio (HTMT). The square root of AVE as a diagonal element is more than the off-diagonal correlation in the rows and columns, showing that the Fornell–Larcker criteria were satisfied [100], as shown in Table 5. Consequently, the discriminant validity test findings revealed that the constructs were different. To qualify for the cross-loading evaluation, the outer loading of the measurement items on the associated construct must be more than the loadings of all other constructs. All measuring items had a higher loading on their intended construct, according to the findings of this study’s cross-loading matrix shown in Table 6. Finally, the correlation between lower-order constructs (sub-factors) was examined, and the values were found to be less than 0.9, suggesting that the HTMT was adequate, as shown in Table 7. The indicators “GP1” and “TI6” showed a high correlation, thus dropping from the dataset. As a consequence, the combined results of the Fornell–Larcker model, cross-loading framework, and HTMT revealed that the dataset had discriminant legitimacy. It was demonstrated that the variance inflation factors (VIFs) are less than 5, suggesting that our estimate model is not collinear. In PLS-SEM, VIF collinearity is sufficient to resolve the issue of common method variance (CMV). The comprehensive collinearity test of the constructs yielded a lower value than the suggested value of 3.3 in VIF [102].

Table 5.

Discriminant validity—Fornell–Larcker criterion.

Table 6.

Cross loadings.

Table 7.

HTMT (Heterotrait–Monotrait) ratio of correlations.

5.2. Validating Higher-Order Construct (HOC)

The study’s higher-order construct (HOC) was built on five LOCs: green manufacturing, green purchasing, eco-design, investment recovery, and green information systems. It should be noted that this study has a reflective/formative HOC, showing a relationship among HOCs and LOCs (reflective/formative). The outside weights, outer loadings, and VIF were crucial in establishing the HOC validity, as shown in Table 8. Furthermore, outer loadings were found to be more than 0.50 for each LOC [98]. Lastly, VIF values were determined to test the collinearity. All VIF values were found to be less than the suggested value of 5 [102].

Table 8.

Higher-order construct validity (HOC).

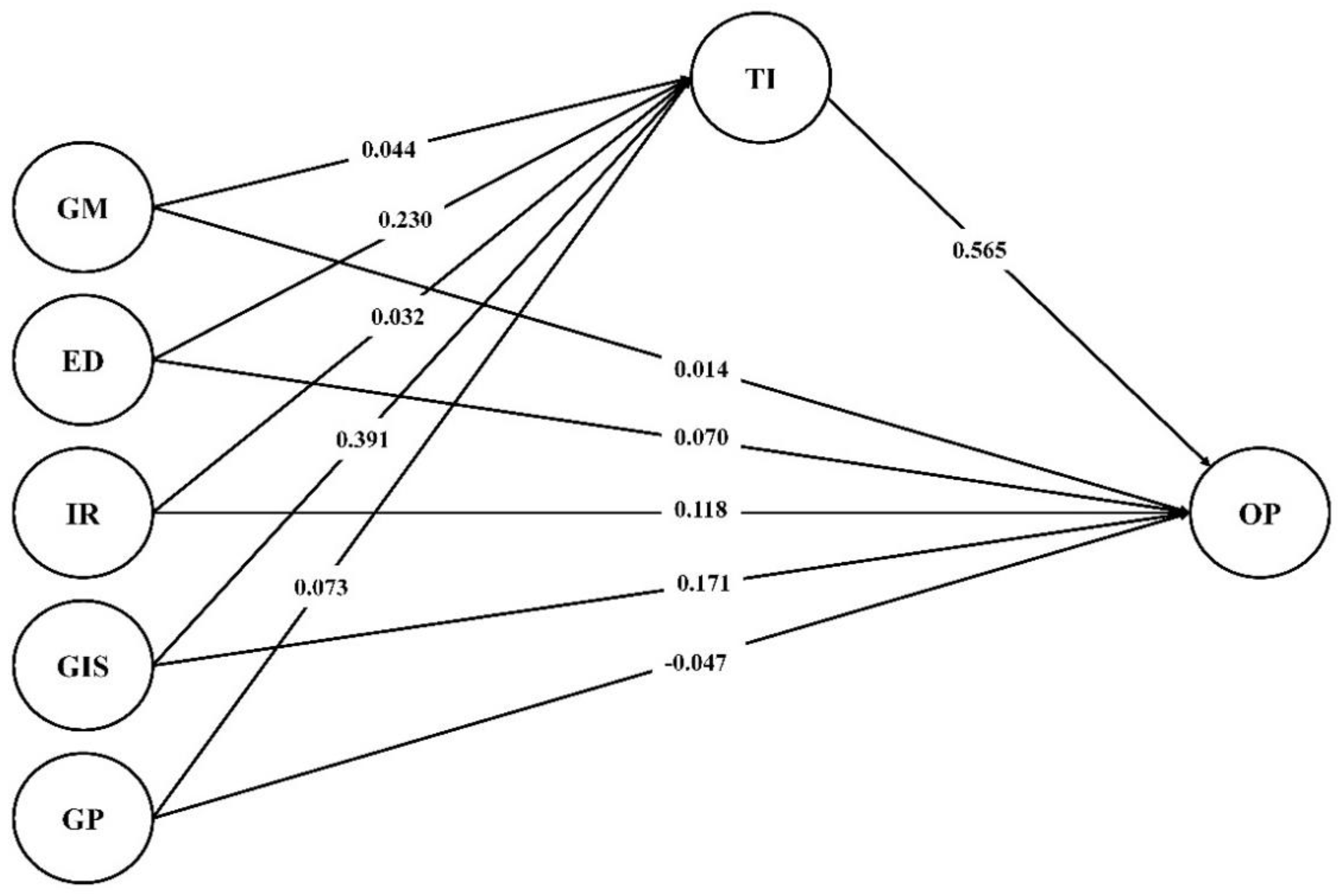

5.3. Structural Equation Model and Hypothesis Testing

The structured model (hypothetical model) is constructed as shown in Figure 3, to establish the relationships between constructs to achieve the research goals. The hypotheses were tested into two ways. First, there were 5000 bootstrapping samples to test the route coefficient significance of direct path analysis with set variables. After that, the mediation effects of technological innovation between GSCM practice and operational performance were investigated. The R-square value was utilized as the dependent variable to assess the structural model’s explanatory ability. The structural model explained 61% of the variance in operational performance and 45.4% of the variance in technical innovation, demonstrating its predictive validity. The R-square criteria classify R-square values of 0.67, 0.33, and 0.19 as considerable, moderate, and weak, respectively. R-square value changes can be used to see if the external latent variable significantly influences the endogenous latent variable. The f-square effect size may be used to quantify this and the projected effect. Exogenous latent variables with minor, moderate, and strong structural impacts have f-square sizes of 0.02, 0.15, and 0.35, respectively [98,103,104]. It has been demonstrated that all the f-square values are greater than 0.020 and 0.35, indicating a significant effect on the model’s validity. Furthermore, when Q-square values are greater than zero, the model has predictive significance [105]. Therefore, the R-square and Q-square values meet the dependent variables allowed range, as shown in Table 9.

Figure 3.

HOC measurement model.

Table 9.

R square and Q square.

The first hypothesis was about the significant influence of GSCM practices on technological innovation. The link between independent and dependent variables was tested by path coefficient and t-statistics. The positive and significant impact of GSCM practices was observed on technological innovation (t = 16.282, β = 0.674, p < 0.001). The second hypothesis was about the significant influence of technological innovation on operational performance. It was observed that the technological innovation has a significantly positive association with operational performance (t = 8.958, β = 0.564, p < 0.001). The third hypothesis was about the significant influence of GSCM practices on operational performance. This hypothesis was also supported, as there was also a significant and positive relationship was found between GSCM practices and operational performance (t = 4.489, β = 0.281, p < 0.001). The fourth hypothesis was about the mediating impact of technological innovation within GSCM practices and operational performance. The findings show that through the mediation of technical innovation (t = 8.144 β = 0.38, p < 0.001), GSCM practices have a considerable indirect effect on operational performance practices through technological innovation. This result indicates that technological innovation partially mediates the relationship between GSCM practices and operational performance. It means that technological innovation in the product and process of manufacturing firms will enhance the combined effect of GSCM practices (eco-design, green manufacturing, green purchasing, green information systems, and investment recovery) on operational performance (product quality, operational cost, and flexibility) in the organization. Hence, H1 (GSCMP → TI), H2 (TI → OP), H3 (GSCMP → OP), and H4 (GSCMP → TI → OP) are all supported, as shown in Table 10.

Table 10.

Bootstrapping results for structural model evaluation.

6. Discussion and Implication

The results of structural equation modeling show that GSCM practices have a significantly positive influence on technological innovation. This result is consistent with many studies [55,60,61,85,106]. Lee, Ooi [26] found that eco-design, internal environmental management, and investment recovery significantly correlate with technological innovation. Practicing green SCM will improve the innovational abilities of the manufacturing firms. Product and process innovation will be highly impacted due to effective GSCM practices (eco-design, green manufacturing, green purchasing, green information systems, and investment recovery).

The study further reveals a significant association between technological innovation and operational performance. It is observed that technological innovation has a significantly positive impact on operational performance. Previous research by Abdallah, Phan [31], Ju, Park [64], and Al-Sa’di, Abdallah [53] also found similar results that technological innovation will bring beneficial changes in the operations of an organization. Innovation in product and the process improves operational efficiency. To be competitive in the market, the organizations should improve their innovational abilities to produce good quality products at low prices, this will also help with long-term customer retention.

Moreover, the significant influence of GSCM practices on operational performance is also revealed from the study. GSCM practices have a significant and positive association with operational performance, according to the findings, which have been supported by earlier research, such as [15,38,67,70,106]; all of them revealed that GSCM practice in an organization improves productivity. Our research further revealed that practicing GSCM (eco-design, green manufacturing, green purchasing, green information systems, and investment recovery) will improve product quality and flexibility and reduce operational cost, which tends to improve the operational efficiency of the manufacturing firm.

The mediation result reveals the mediating impact of technological innovation within GSCM practices and operational performance. This result indicates that technological innovation partially mediates the relationship between GSCM practices and operational performance. It means that technological innovation in the product and process of manufacturing firms will enhance the combined effect of GSCM practices (eco-design, green manufacturing, green purchasing, green information system, and investment recovery) on operational performance (product quality, operational cost, and flexibility) in the organization. Previous studies, e.g., Shafique, Asghar [107], have found the mediating influence of green innovation on the association between GSCM and environmental performance. Seman, Govindan [108] found the mediating influence of green innovation on the connection between GSCM and environmental performance. However, no such study has researched how technological innovation mediates the effect of GSCM practices on operational performance.

6.1. Theoretical Implication

The study contributed to the literature of GSCM practices and technological innovation in several ways. Firstly, the research developed and analyzed the conceptual model between GSCM practices implementation, technological innovation, and operational performance. The mediating effect of technological innovation on the relationship between GSCM practices and operational performance has not been identified yet. Furthermore, very few studies are available in the literature that focus on technological innovation’s mediating effect. Past studies mainly focused on the influences of GSCM practices on environmental, economic, and organizational performance. Still, no theoretical framework provides a mediating link of technological innovation between the relationship of GSCM practices and operational performance. Therefore, the study has achieved this objective.

Secondly, the study considered five dimensions of GSCM practices (i.e., eco-design, green manufacturing, green purchasing, green information systems, and investment recovery). Green information systems and green manufacturing were included in this study to find the impact of GSCM practices on technological innovation and operational performance. Previous studies have not notably focused on the influence of green information systems and green manufacturing on technological innovation and operational performance.

6.2. Managerial Implication

This study has significant managerial implications for manufacturing firms of Pakistan and other developing countries. Firstly, organizations need to consider the importance of GSCM practices and be more proactive in implementing these practices. In particular, designing eco-friendly products, selecting methods of manufacturing the products, and purchasing environmentally friendly materials are major components of the green supply chain, which must be adopted by manufacturing organizations to improve sustainable performance.

Secondly, this study provides a practical implication to the firms to enhance their technological innovation through better understanding of the various practices of the green supply chain that may be applied in their firms. Moreover, the study also provides a self-diagnostic tool to the firms to identify and analyze the current status of improvement in the product and process of the firm and improve it by focusing more on GSCM practices.

Thirdly, those entrepreneurs and managers striving to achieve greater product quality, reduction in operational costs, and greater flexibility in the system should adopt GSCM practices to improve these operational performance parameters. Implementing a green supply chain will help managers and entrepreneurs build cost-effective and product- and process-oriented strategies to reduce the harmful effects of their products and processes in the environment.

Lastly, the study facilitates the implementation of GSCM practices in organizations and the improvement of technological innovation to increase operational performance and decrease negative impacts on the environment.

7. Conclusions

Sustainable environmental growth is a major concern nowadays. In a developing economy, industrial development aims to enhance the performance of the economy while addressing ecological sustainability. Implementing GSCM procedures in a corporation is a comparatively new concept in Pakistan. This research paper highlights the relationship between GSCM practices, technological innovation, and operational performance. This study collects data from different manufacturing industries situated in Pakistan. To perform hypothesis testing, SmartPLS3 software is used to employ PLS-SEM. The findings reveal that GSCM practices positively and considerably connect with both technological innovation and operational performance. A positive and significant effect is observed between technological innovation and operational performance. The partially mediating influence of technological innovation is also observed between GSCM practices and operational performance. According to the findings, operational performance can be improved by practicing GSCM, which leads to greater operational efficiency, better product quality, greater flexibility of the system, and a decrease in the extra utilization of resources, which further leads to a reduction in the production cost. Development in product and process will not negatively be affected by GSCM practices, but it will enhance the capabilities of innovation and enhance the impact of GSCM practices on an organization’s sustainable performance. Similarly, adopting the latest technology in product and process will also not divert the effects of GSCM practices in improving the operational performance, according to the results of this study. Organizations can grow their innovational abilities by practicing GSCM to obtain product novelty, the latest technological usage, the speed of new product development, upgrades to technology in the process, and greater system flexibility to manage large and slight variations in the product and the process. With technology, manufacturing firms can become more consistent in improving their productivity. For having sustainable environmental growth, there is a vital role for manufacturing firms in Pakistan. The organizations should focus on the effective utilization of energy, wastewater, and material consumption in manufacturing and designing their particular products.

Overall, this study makes a considerable contribution to the GSCM and TI literature and makes suggestions for managers and entrepreneurs in establishing an ecologically sustainable society and demonstrating their legitimacy. This research offers managers insight into the importance of technological innovation and GSCM practice adoption to achieve competitive advantages. Thus, it provides the groundwork for managers, practitioners, and environmental management researchers to emphasize the value of GSCM practice in improving operational sustainability.

Limitations and Future Research Direction

There are some limitations to this study. First, the study is limited to only a single country’s manufacturing sector. Second, the study’s generalizability is limited because the data were obtained from a single responder per firm (e.g., top or middle management). Third, most data were gathered from large firms, and only a small portion of SMEs’ data was considered. Future research may be conducted on SMEs that focuses on the relationships between different dimensions of GSCM (e.g., green transportation, internal environmental management, green packaging, and green distribution) and green innovational performance in Pakistani manufacturing companies.

Author Contributions

Manuscript writing and conceptual design, M.T.K.; data processing, methodology, and validation, M.D.I.; analysis and review, M.R.; Supervision, A.S.; contribution to manuscript text, A.A.; writing—review and editing, A.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Survey questionnaire (instrument).

Table A1.

Survey questionnaire (instrument).

| Questionnaire Items | SD | D | N | A | SA | |

|---|---|---|---|---|---|---|

| Green Manufacturing | ||||||

| GM1 | This organization’s product is recyclable and reusable. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GM2 | Manufacturing operations guarantee that hazardous compounds are used less frequently in the process. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GM3 | The product life cycle method is utilized to improve the product’s environmental performance, as well as its manufacturing efficiency. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GM4 | Efforts were made to limit the amount of material, water, and energy consumed in the production process. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GM5 | Compliance with all applicable requirements is ensured by a waste management program. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GM6 | In manufacturing operations, the use of energy obtained from renewable resources is optimized. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GM7 | Harmful waste is kept to a minimum during the production process. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GM8 | Pollution sources were identified and eliminated through the development of preventative initiatives. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| Eco-design | ||||||

| ED1 | Our company adheres to stringent product design guidelines in order to decrease material and energy usage. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| ED2 | Our company maintains a product design that allows for the reuse, recycling, and recovery of materials and parts. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| ED3 | Our company maintains product design in order to eliminate or limit the usage of hazardous goods and production processes. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| Investment Recovery | ||||||

| IR1 | During the previous year, surplus inventories/materials were recovered through investment (sale). | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| IR2 | During the previous year, scrap and used materials were sold. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| IR3 | During the previous year, surplus capital equipment was sold. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| IR4 | During the previous year, participation in environmental improvements was improved, and the recycled items were sold. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| Green Information System | ||||||

| GIS1 | Our organization has a formal structure in place to enhance the environment in its operations. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GIS2 | We have institutional departments in place that are in charge of environmental issues. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GIS3 | Green practices and steps in the system are generally available practices and processes in the system. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GIS4 | Within our company, we formally track and report on our environmental performance. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GIS5 | Within the firm, we measure, monitor, and communicate environmental data on a regular basis. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GIS6 | To track and monitor environmental risks, the company has a well-developed database. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| Green Purchasing | ||||||

| GP1 | Environmental criteria for bought products in design specifications is provided to vendors. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GP2 | Our organization collaborates with suppliers to achieve environmental goals. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GP3 | Internal environmental audit for suppliers’ management is performed. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GP4 | The ISO14001 certification of suppliers is performed. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GP5 | Environmentally friendly practice review of a second-tier supplier is performed. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GP6 | Environmental parameters are used to choose suppliers. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| GP7 | Products are eco-labeled. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| Technological Innovation | ||||||

| TI1 | We have the ability to create items with unique characteristics. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI2 | For new product development, we employ cutting-edge technologies. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI3 | The rate at which new products are developed is adequate and competitive. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI4 | There has already been a sufficient number of new items launched to the market. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI5 | We have a number of new goods that are first-to-market (early market entrants). | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI6 | In terms of technology, we are competitive. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI7 | In the process, we employ cutting-edge/new technology. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI8 | We are quick to integrate the most recent technology advancements. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| TI9 | Our company’s processes, procedures, and technology evolve at a quick pace. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| Operational Performance | ||||||

| OP1 | We create products that are high-performing and suit the expectations of customers. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| OP2 | Scrap, rework, and faults are all on the decline. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| OP3 | The number of complaints from consumers is steadily decreasing. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| OP4 | Productivity has been steadily rising. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| OP5 | Manufacturing unit costs are steadily falling. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

| OP6 | We respond quickly to changes in market demand. | ❑1 | ❑2 | ❑3 | ❑4 | ❑5 |

SD = Strongly Disagree; D = Disagree; N = Neutral; A = Agree; SA = Strongly Agree.

References

- Waidyasekara, K.; Sandamali, R. Impact of Green Concept on Business Objectives of an Organisation. In Proceedings of the World Construction Conference, Colombo, Sri Lank, 28–30 June 2012. [Google Scholar]

- Lin, Y.; Luo, J.; Ieromonachou, P.; Rong, K.; Huang, L. Strategic orientation of servitization in manufacturing firms and its impacts on firm performance. Ind. Manag. Data Syst. 2019, 119, 292–316. [Google Scholar] [CrossRef]

- Zahraee, M.S.; Mamizadeh, F.; Vafaei, S.A. Greening assessment of suppliers in automotive supply chain: An empirical survey of the automotive industry in Iran. Glob. J. Flex. Syst. Manag. 2018, 19, 225–238. [Google Scholar] [CrossRef]

- Fornasiero, R.; Zangiacomi, A.; Franchini, V.; Bastos, J.; Azevedo, A.; Vinelli, A. Implementation of customisation strategies in collaborative networks through an innovative Reference Framework. Prod. Plan. Control 2016, 27, 1158–1170. [Google Scholar] [CrossRef]

- Chan, T.Y.; Wong, C.W.; Lai, K.H.; Lun, V.Y.; Ng, C.T.; Ngai, E.W. Green service: Construct development and measurement validation. Prod. Oper. Manag. 2016, 25, 432–457. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z.; Muhamad Zainon, S.N.L. Green supply chain management practices and sustainability performance. Adv. Sci. Lett. 2015, 21, 1359–1362. [Google Scholar] [CrossRef]

- Ong, S.T.; Magsi, H.B.; Burgess, T.F. Organisational culture, environmental management control systems, environmental performance of Pakistani manufacturing industry. Int. J. Product. Perform. Manag. 2019, 68, 1293–1322. [Google Scholar] [CrossRef]

- Anwar, A.; Younis, M.; Ullah, I. Impact of Urbanization and Economic Growth on CO2 Emission: A Case of Far East Asian Countries. Int. J. Environ. Res. Public Health 2020, 17, 2531. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.S.A.; Solangi, Y.A. A sustainable solution for electricity crisis in Pakistan: Opportunities, barriers, and policy implications for 100% renewable energy. Environ. Sci. Pollut. Res. Int. 2019, 26, 29687–29703. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yang, Y. Analyzing the green innovation practices based on sustainability performance indicators: A Chinese manufacturing industry case. Environ. Sci. Pollut. Res. 2021, 28, 1181–1203. [Google Scholar] [CrossRef] [PubMed]

- Sarwar, A.; Zafar, A.; Hamza, M.; Qadir, A. The effect of green supply chain practices on firm sustainability performance: Evidence from Pakistan. Uncertain Supply Chain Manag. 2021, 9, 31–38. [Google Scholar] [CrossRef]

- Lorette, K. Why Businesses Should Go Green. Available online: http://smallbusiness.chron.com/businesses-should-green-766.html (accessed on 10 June 2018).

- Lin, H.-Y.; Tseng, M.-L. Assessing the competitive priorities within sustainable supply chain management under uncertainty. J. Clean. Prod. 2016, 112, 2133–2144. [Google Scholar] [CrossRef]

- Kurian, J. The role of digitalization in adopting green supply chain management practices: A critical review of literature. Econ. Environ. Cons. 2020, 26, 213–220. [Google Scholar]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Tseng, M.L.; Islam, M.S.; Karia, N.; Fauzi, F.A.; Afrin, S. A literature review on green supply chain management: Trends and future challenges. Resour. Conserv. Recycl. 2019, 141, 145–162. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking Int. J. 2005, 12, 330–350. [Google Scholar] [CrossRef]

- Fragouli, E.; Yankson, J.K. The role of strategic planning on the management of organizational change. Financ. Risk Manag. Rev. 2015, 1, 68–87. [Google Scholar] [CrossRef][Green Version]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Haake, H.; Seuring, S. Sustainable procurement of minor items–exploring limits to sustainability. Sustain. Dev. 2009, 17, 284–294. [Google Scholar] [CrossRef]

- Vanalle, R.M.; Ganga, G.M.D.; Godinho Filho, M.; Lucato, W.C. Green supply chain management: An investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- Zhu, Q.; Feng, Y.; Choi, S.-B. The role of customer relational governance in environmental and economic performance improvement through green supply chain management. J. Clean. Prod. 2017, 155, 46–53. [Google Scholar] [CrossRef]

- Wang, K.H.; Umar, M.; Akram, R.; Caglar, E. Is technological innovation making world “Greener”? An evidence from changing growth story of China. Technol. Forecast. Soc. Change 2021, 165, 120516. [Google Scholar] [CrossRef]

- Dodgson, M. Technological collaboration and innovation. In The Handbook of Industrial Innovation; Edward Elgar Publishing Ltd.: Cheltenham, UK, 1994; pp. 285–292. [Google Scholar]

- Lee, V.H.; Ooi, K.B.; Chong, A.Y.L.; Seow, C. Creating technological innovation via green supply chain management: An empirical analysis. Expert Syst. Appl. 2014, 41, 6983–6994. [Google Scholar] [CrossRef]

- Börjesson, S.; Elmquist, M.; Hooge, S. The challenges of innovation capability building: Learning from longitudinal studies of innovation efforts at Renault and Volvo Cars. J. Eng. Technol. Manag. 2014, 31, 120–140. [Google Scholar] [CrossRef]

- Wang, C.-H.; Lu, I.-Y.; Chen, C.-B. Evaluating firm technological innovation capability under uncertainty. Technovation 2008, 28, 349–363. [Google Scholar] [CrossRef]

- Aljanabi, A.R.A. The mediating role of absorptive capacity on the relationship between entrepreneurial orientation and technological innovation capabilities. Int. J. Entrep. Behav. Res. 2018, 24, 818–841. [Google Scholar] [CrossRef]

- Yonghong, Z.; Zigang, Z.; Kaijin, L. Impact of technological innovation on growth trajectory of enterprise’s technological capability: A theoretical analysis. Singap. Manag. Rev. 2005, 27, 81–102. [Google Scholar]

- Abdallah, B.A.; Phan, A.C.; Matsui, Y. Investigating the effects of managerial and technological innovations on operational performance and customer satisfaction of manufacturing companies. Int. J. Bus. Innov. Res. 2016, 10, 153–183. [Google Scholar] [CrossRef]

- Prajogo, I.D.; Sohal, A.S. The relationship between TQM practices, quality performance, and innovation performance: An empirical examination. Int. J. Qual. Reliab. Manag. 2003, 20, 901–918. [Google Scholar] [CrossRef]

- Hong, J.; Liao, Y.; Zhang, Y.; Yu, Z. The effect of supply chain quality management practices and capabilities on operational and innovation performance: Evidence from Chinese manufacturers. Int. J. Prod. Econ. 2019, 212, 227–235. [Google Scholar] [CrossRef]

- Gunday, G.; Ulusoy, G.; Kilic, K.; Alpkan, L. Effects of innovation types on firm performance. Int. J. Prod. Econ. 2011, 133, 662–676. [Google Scholar] [CrossRef]

- Kim, D.-Y.; Kumar, V.; Kumar, U. Relationship between quality management practices and innovation. J. Oper. Manag. 2012, 30, 295–315. [Google Scholar] [CrossRef]

- Liu, C.-C. An empirical study on the construction of a model for measuring organisational innovation in Taiwanese high-tech enterprises. Int. J. Innov. Manag. 2005, 9, 241–257. [Google Scholar] [CrossRef]

- Damanpour, F.; Gopalakrishnan, S. The dynamics of the adoption of product and process innovations in organizations. J. Manag. Stud. 2001, 38, 45–65. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Examining the effects of green supply chain management practices and their mediations on performance improvements. Int. J. Prod. Res. 2012, 50, 1377–1394. [Google Scholar] [CrossRef]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, 102, 502–511. [Google Scholar] [CrossRef]

- Tippayawong, K.Y.; Niyomyat, N.; Sopadang, A.; Ramingwong, S. Factors affecting green supply chain operational performance of the thai auto parts industry. Sustainability 2016, 8, 1161. [Google Scholar] [CrossRef]

- Suryanto, T.; Haseeb, M.; Hartani, N.H. The correlates of developing green supply chain management practices: Firms level analysis in Malaysia. Int. J. Supply Chain Manag. 2018, 7, 316. [Google Scholar]

- Mumtaz, U.; Ali, Y.; Petrillo, A. A linear regression approach to evaluate the green supply chain management impact on industrial organizational performance. Sci. Total Environ. 2018, 624, 162–169. [Google Scholar] [CrossRef] [PubMed]

- Hashmi, D.S.; Akram, S. Impact of green supply chain management on financial and environmental performance: Mediating role of operational performance and the moderating role of external pressures. LogForum 2021, 17, 359–371. [Google Scholar]

- Umar, M.; Khan, S.A.R.; Yusliza, M.Y.; Ali, S.; Yu, Z. Industry 4.0 and green supply chain practices: An empirical study. Int. J. Product. Perform. Manag. 2021, 71, 814–832. [Google Scholar] [CrossRef]

- Mady, M.T. The impact of plant size and type of industry on manufacturing competitive priorities: An empirical investigation. Compet. Rev. Int. Bus. J. 2008, 18, 351–366. [Google Scholar]

- Abdallah, B.A.; Obeidat, B.Y.; Aqqad, N.O. The impact of supply chain management practices on supply chain performance in Jordan: The moderating effect of competitive intensity. Int. Bus. Res. 2014, 7, 13. [Google Scholar] [CrossRef]

- Tan, K.-C.; Kannan, V.R.; Narasimhan, R. The impact of operations capability on firm performance. Int. J. Prod. Res. 2007, 45, 5135–5156. [Google Scholar] [CrossRef]

- Fine, H.C.; Hax, A.C. Manufacturing strategy: A methodology and an illustration. Interfaces 1985, 15, 28–46. [Google Scholar] [CrossRef]

- Ferdows, K.; de Meyer, A. Lasting improvements in manufacturing performance: In search of a new theory. J. Oper. Manag. 1990, 9, 168–184. [Google Scholar] [CrossRef]

- Squire, B.; Brown, S.; Readman, J.; Bessant, J. The impact of mass customisation on manufacturing trade-offs. Prod. Oper. Manag. 2006, 15, 10–21. [Google Scholar] [CrossRef]

- Ortega, H.C.; Garrido-Vega, P.; Machuca, J.A.D. Analysis of interaction fit between manufacturing strategy and technology management and its impact on performance. Int. J. Oper. Prod. Manag. 2012, 32, 958–981. [Google Scholar] [CrossRef]

- Di Al-Sa’, F.A.; Abdallah, A.B.; Dahiyat, S.E. The mediating role of product and process innovations on the relationship between knowledge management and operational performance in manufacturing companies in Jordan. Bus. Process Manag. J. 2017, 23, 349–376. [Google Scholar] [CrossRef]

- Abdallah, B.A.; Phan, A.C.; Matsui, Y. Investigating the relationship between strategic manufacturing goals and mass customization. In Proceedings of the 16th International Annual European Operations Management Association (EurOMA), Göteborg, Sweden, 14–17 June 2009. [Google Scholar]

- De Carvalho, L.S.; Stefanelli’, N.O.; Viana, L.C.; Vasconcelos, D.D.S.C.; Oliveira, B.G. Green supply chain management and innovation: A modern review. Manag. Environ. Qual. Int. J. 2020, 31, 470–482. [Google Scholar] [CrossRef]

- H’Mida, S.; Lakhal, S.Y. A model for assessing the greenness effort in a product supply chain. Int. J. Glob. Environ. Issues 2007, 7, 4–24. [Google Scholar] [CrossRef]

- Lee, K.-H. Integrating carbon footprint into supply chain management: The case of Hyundai Motor Company (HMC) in the automobile industry. J. Clean. Prod. 2011, 19, 1216–1223. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tan, K.; Chiu, A.S. Identifying the competitive determinants of firms’ green supply chain capabilities under uncertainty. Clean Technol. Environ. Policy 2016, 18, 1247–1262. [Google Scholar] [CrossRef]

- Silva, G.M.; Gomes, P.J.; Sarkis, J. The role of innovation in the implementation of green supply chain management practices. Bus. Strategy Environ. 2019, 28, 819–832. [Google Scholar] [CrossRef]

- Song, H.; Gao, X. Green supply chain game model and analysis under revenue-sharing contract. J. Clean. Prod. 2018, 170, 183–192. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Bowen, E.F.; Rostami, M.; Steel, P. Timing is everything: A meta-analysis of the relationships between organizational performance and innovation. J. Bus. Res. 2010, 63, 1179–1185. [Google Scholar] [CrossRef]

- Boer, H.; During, W.E. Innovation, what innovation? A comparison between product, process and organisational innovation. Int. J. Technol. Manag. 2001, 22, 83–107. [Google Scholar] [CrossRef]

- Ju, K.-J.; Park, B.; Kim, T. Causal relationship between supply chain dynamic capabilities, technological innovation, and operational performance. Manag. Prod. Eng. Rev. 2016, 7, 6–15. [Google Scholar] [CrossRef]

- Kafetzopoulos, D.; Psomas, E. The impact of innovation capability on the performance of manufacturing companies: The Greek case. J. Manuf. Technol. Manag. 2015, 26, 104–130. [Google Scholar] [CrossRef]

- Abdallah, A.; Phan, C. The relationship between just-in-time production and human resource management, and their impact on competitive performance. Yokohama Bus. Rev. 2007, 28, 27–57. [Google Scholar]

- Mallikarathna, D.H.; Silva, C.C. The impact of Green supply chain management practices on operational performance and customer satisfaction. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Bangkok, Thailand, 5–7 March 2019. [Google Scholar]

- Famiyeh, S.; Kwarteng, A.; Asante-Darko, D.; Dadzie, S.A. Green supply chain management initiatives and operational competitive performance. Benchmarking Int. J. 2018, 25, 607–631. [Google Scholar] [CrossRef]

- Yang, J.; Han, Q.; Zhou, J.; Yuan, C. The influence of environmental management practices and supply chain integration on technological innovation performance—Evidence from China’s manufacturing industry. Sustainability 2015, 7, 15342–15361. [Google Scholar] [CrossRef]

- Feng, M.; Yu, W.; Wang, X.; Wong, C.Y.; Xu, M.; Xiao, Z. Green supply chain management and financial performance: The mediating roles of operational and environmental performance. Bus. Strategy Environ. 2018, 27, 811–824. [Google Scholar] [CrossRef]

- Khan, R.S.A.; Qianli, D. Impact of green supply chain management practices on firms’ performance: An empirical study from the perspective of Pakistan. Environ. Sci. Pollut. Res. 2017, 24, 16829–16844. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.S.; Lu, C.S.; Haider, J.J.; Marlow, P.B. The effect of green supply chain management on green performance and firm competitiveness in the context of container shipping in Taiwan. Transp. Res. Part E Logist. Transp. Rev. 2013, 55, 55–73. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Latan, H.; Teixeira, A.A.; de Oliveira, J.H.C. Quality management, environmental management maturity, green supply chain practices and green performance of Brazilian companies with ISO 14001 certification: Direct and indirect effects. Transp. Res. Part E Logist. Transp. Rev. 2014, 67, 39–51. [Google Scholar] [CrossRef]

- Jermsittiparsert, K.; Sutduean, J.; Sutduean, C. The mediating role of innovation performance between the relationship of green supply chain management skills and environmental performance. Int. J. Supply Chain Manag. 2019, 8, 107–119. [Google Scholar]

- Mughal, M. Impact of green supply chain management practices on performance of manufacturing companies in Jordan: A moderating role of supply chain traceability. Arthatama 2019, 3, 67–82. [Google Scholar]

- Hasan, M. Sustainable supply chain management practices and operational performance. Am. J. Ind. Bus. Manag. 2013, 3, 42–48. [Google Scholar] [CrossRef]

- Bagheri, M.; Mitchelmore, S.; Bamiatzi, V.; Nikolopoulos, K. Internationalization orientation in SMEs: The mediating role of technological innovation. J. Int. Manag. 2019, 25, 121–139. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Gholami, R.; Molla, A.; Goswami, S.; Brewster, C. Green information systems use in social enterprise: The case of a community-led eco-localization website in the West Midlands region of the UK. Inf. Syst. Front. 2018, 20, 1345–1361. [Google Scholar] [CrossRef]

- Damanpour, F.; Evan, W.M. Organizational innovation and performance: The problem of “organizational lag”. Adm. Sci. Q. 1984, 29, 392–409. [Google Scholar] [CrossRef]

- Kotabe, M.; Martin, X.; Domoto, H. Gaining from vertical partnerships: Knowledge transfer, relationship duration, and supplier performance improvement in the US and Japanese automotive industries. Strateg. Manag. J. 2003, 24, 293–316. [Google Scholar] [CrossRef]

- Mustaghis-ur-Rahman, R.R.; Jalees, T. The effectiveness of support policies for SMEs in Pakistan: A study of Karachi based SMEs. Pak. Bus. Rev. 2015, 16, 829–916. [Google Scholar]

- Policy, S. SME Led Economic Growth—Creating Jobs and Reducing Poverty, Ministry of Industries, Production & Special Initiatives; Small and Medium Enterprise Development Authority Pakistan: Lahore, Pakistan, 2007.

- Rao, K.; Bogale, G.M. Developing tools to describe green manufacturing practices. Int. J. Manag. Soc. Sci. 2017, 5, 94–103. [Google Scholar]

- Habib, M.; Bao, Y.; Nabi, N.; Dulal, M.; Asha, A.A.; Islam, M. Impact of Strategic Orientations on the Implementation of Green Supply Chain Management Practices and Sustainable Firm Performance. Sustainability 2021, 13, 340. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, M.; Huo, B. The impact of supply chain quality integration on green supply chain management and environmental performance. Total Qual. Manag. Bus. Excell. 2019, 30, 1110–1125. [Google Scholar] [CrossRef]

- Qu, K.; Liu, Z. The Moderating Role of Green Information System over Supply Chain in Promoting Green Innovation and Production. 2020. Available online: https://ssrn.com/abstract=3516068 (accessed on 20 June 2018).

- Shahid, H.M.; Waseem, R.; Khan, H.; Waseem, F.; Hasheem, M.J.; Shi, Y. Process innovation as a moderator linking sustainable supply chain management with sustainable performance in the manufacturing sector of Pakistan. Sustainability 2020, 12, 2303. [Google Scholar] [CrossRef]

- Bagozzi, P.R.; Yi, Y. Specification, evaluation, and interpretation of structural equation models. J. Acad. Mark. Sci. 2012, 40, 8–34. [Google Scholar] [CrossRef]

- Munim, H.Z.; Schramm, H.-J. The impacts of port infrastructure and logistics performance on economic growth: The mediating role of seaborne trade. J. Shipp. Trade 2018, 3, 1. [Google Scholar] [CrossRef]

- Zeng, N.; Liu, Y.; Gong, P.; Hertogh, M.; König, M. Do right PLS and do PLS right: A critical review of the application of PLS-SEM in construction management research. Front. Eng. Manag. 2021, 8, 356–369. [Google Scholar] [CrossRef]

- Khan, R.A.S.; Yu, Z. Assessing the eco-environmental performance: An PLS-SEM approach with practice-based view. Int. J. Logist. Res. Appl. 2021, 24, 303–321. [Google Scholar] [CrossRef]

- Hair Jr, J.F.; Matthews, L.M.; Matthews, R.L.; Sarstedt, M. PLS-SEM or CB-SEM: Updated guidelines on which method to use. Int. J. Multivar. Data Anal. 2017, 1, 107–123. [Google Scholar] [CrossRef]

- Astrachan, B.C.; Patel, V.K.; Wanzenried, G. A comparative study of CB-SEM and PLS-SEM for theory development in family firm research. J. Fam. Bus. Strategy 2014, 5, 116–128. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Zhang, Y.; Kumar, A.; Zavadskas, E.; Streimikiene, D. Measuring the impact of renewable energy, public health expenditure, logistics, and environmental performance on sustainable economic growth. Sustain. Dev. 2020, 28, 833–843. [Google Scholar] [CrossRef]

- Hair Jr, J.F.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Sarstedt, M.; Hair Jr, J.F.; Cheah, J.H.; Becker, J.M.; Ringle, C.M. How to specify, estimate, and validate higher-order constructs in PLS-SEM. Australas. Mark. J. 2019, 27, 197–211. [Google Scholar] [CrossRef]

- Purwanto, A.; Sudargini, Y. Partial Least Squares Structural Squation Modeling (PLS-SEM) Analysis for Social and Management Research: A Literature Review. J. Ind. Eng. Manag. Res. 2021, 2, 114–123. [Google Scholar]

- Purwanto, A.; Asbari, M.; Santoso, T.I.; Paramarta, V.; Sunarsi, D. Social and Management Research Quantitative Analysis for Medium Sample: Comparing of Lisrel, Tetrad, GSCA, Amos, SmartPLS, WarpPLS, and SPSS. J. Ilm. Ilmu Adm. Publik J. Pemikir. Dan Penelit. Adm. Publik 2020, 9, 518–532. [Google Scholar]

- Fornell, C.; Larcker, D.F. Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics; Sage Publications: Los Angeles, CA, USA, 1981. [Google Scholar]

- Hult, G.T.M.; Hair Jr, J.F.; Proksch, D.; Sarstedt, M.; Pinkwart, A.; Ringle, C.M. Addressing endogeneity in international marketing applications of partial least squares structural equation modeling. J. Int. Mark. 2018, 26, 1–21. [Google Scholar] [CrossRef]

- Kock, N. Common method bias in PLS-SEM: A full collinearity assessment approach. Int. J. E Collab. 2015, 11, 1–10. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences; Lawrence Erlbaum Associates: Hillsdale, MI, USA, 1988; pp. 20–26. [Google Scholar]

- Geffen, A.C.; Rothenberg, S. Suppliers and environmental innovation: The automotive paint process. Int. J. Oper. Prod. Manag. 2000, 20, 166–186. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sinkovics, R.R. The use of partial least squares path modeling in international marketing. In New Challenges to International Marketing; Emerald Group Publishing Limited: Bingley, UK, 2009. [Google Scholar]

- Gharakhani, D.; Mavi, R.K.; Hamidi, N. Impact of supply chain management practices on innovation and organizational performance in Iranian Companies. Afr. J. Bus. Manag. 2012, 6, 5939–5949. [Google Scholar] [CrossRef]

- Shafique, M.; Asghar, M.; Rahman, H. The impact of green supply chain management practices on performance: Moderating role of institutional pressure with mediating effect of green innovation. Bus. Manag. Econ. Eng. 2017, 15, 91–108. [Google Scholar] [CrossRef]

- Seman, N.A.A.; Govindan, K.; Mardani, A.; Zakuan, N.; Samand, M.Z.M.; Hooker, R.E.; Ozkul, S. The mediating effect of green innovation on the relationship between green supply chain management and environmental performance. J. Clean. Prod. 2019, 229, 115–127. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).