Industrial CO2 Capture by Algae: A Review and Recent Advances

Abstract

:1. Introduction

2. The Impact of Greenhouse Gases on the Environmental Situation in the World

3. Capture and Sequestration of Carbon Dioxide by Microalgae

4. Micro and Macro Algae—Rationale for the Use of Algae to Capture Carbon Dioxide

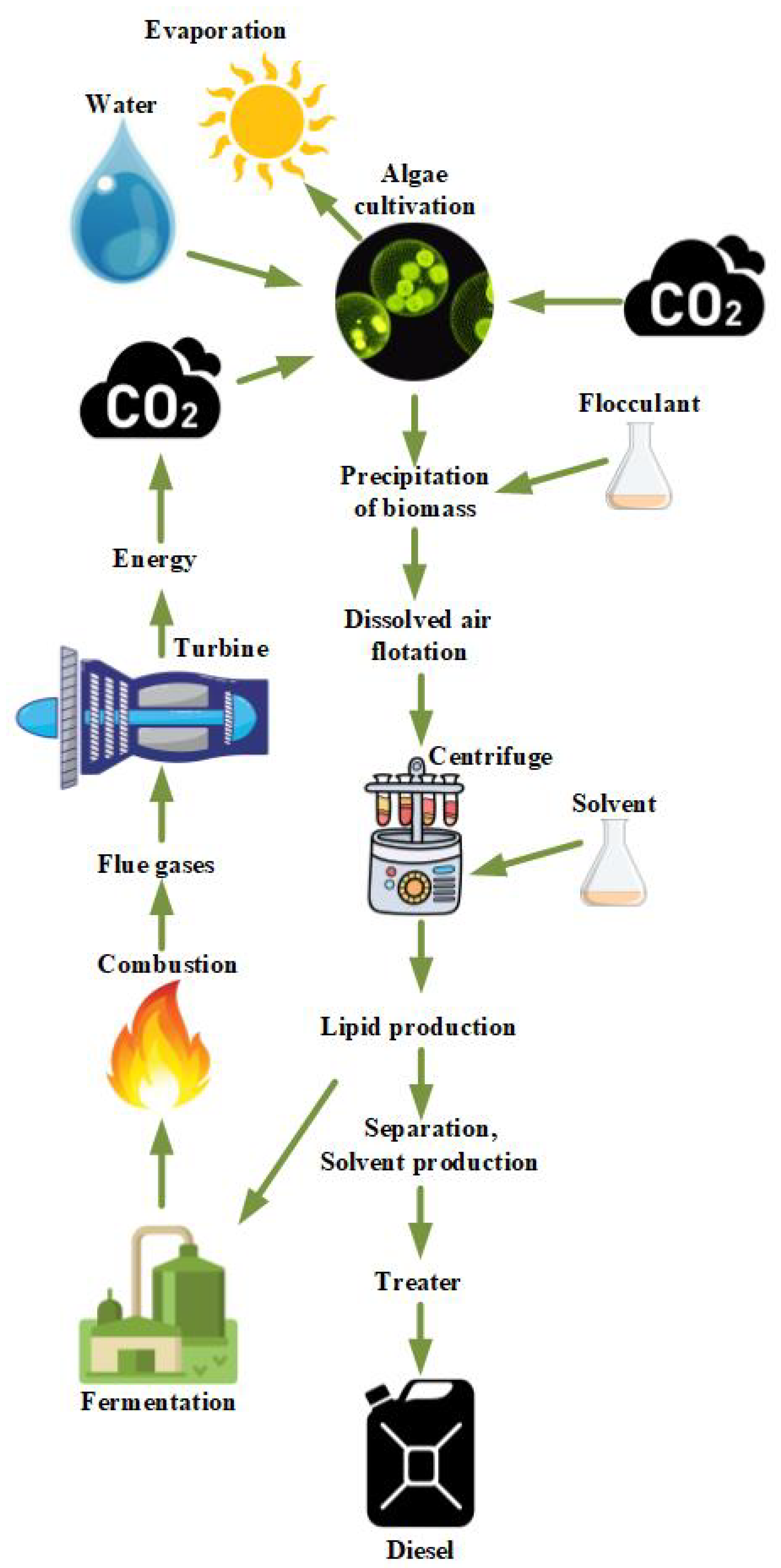

5. Algae Cultivation Methods

6. Using Micro and Macroalgae as an Energy Resource

7. Algae Gasification

8. Algae Pyrolysis

9. Drying and Flocculation of Biofuels

10. Illumination for Algae Growth

11. Description of Flue Gas Disposal Experiments

12. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Miyamoto, M.; Takeuchi, K. Climate agreement and technology diffusion: Impact of the Kyoto Protocol on international patent applications for renewable energy technologies. Energy Policy 2019, 129, 1331–1338. [Google Scholar] [CrossRef] [Green Version]

- Kuriyama, A.; Abe, N. Ex-post assessment of the Kyoto Protocol–quantification of CO2 mitigation impact in both Annex B and non-Annex B countries. Appl. Energy 2018, 220, 286–295. [Google Scholar] [CrossRef]

- Aichele, R.; Felbermayr, G. Kyoto and the carbon footprint of nations. J. Environ. Econ. Manag. 2012, 63, 336–354. [Google Scholar] [CrossRef] [Green Version]

- Maamoun, N. The Kyoto protocol: Empirical evidence of a hidden success. J. Environ. Econ. Manag. 2019, 95, 227–256. [Google Scholar] [CrossRef]

- Bauer, A.; Menrad, K. Standing up for the Paris Agreement: Do global climate targets influence individuals’ greenhouse gas emissions? Environ. Sci. Policy 2019, 99, 72–79. [Google Scholar] [CrossRef]

- Morais, R.R.; Pascoal, A.M.; Pereira-Júnior, M.A.; Batista, K.A.; Rodriguez, A.G.; Fernandes, K.F. Bioethanol production from Solanum lycocarpum starch: A sustainable non-food energy source for biofuels. Renew. Energy 2019, 140, 361–366. [Google Scholar] [CrossRef]

- Xu, C.; Wang, H.; Li, X.; Zhou, W.; Wang, C.; Wang, S. Explosion characteristics of a pyrolysis biofuel derived from rice husk. J. Hazard. Mater. 2019, 369, 324–333. [Google Scholar] [CrossRef]

- Chowdhury, H.; Loganathan, B. Third-generation biofuels from microalgae: A review. Curr. Opin. Green Sustain. Chem. 2019, 20, 39–44. [Google Scholar] [CrossRef]

- Hasan, M.M.; Chongbo, W. Estimating energy-related CO2 emission growth in Bangladesh: The LMDI decomposition method approach. Energy Strategy Rev. 2020, 32, 100565. [Google Scholar] [CrossRef]

- Xu, G.; Li, Y.; Hou, W.; Wang, S.; Kong, F. Effects of substrate type on enhancing pollutant removal performance and reducing greenhouse gas emission in vertical subsurface flow constructed wetland. J. Environ. Manag. 2021, 280, 111674. [Google Scholar] [CrossRef]

- Khayyam, U.; Nazar, U. Energy production and CO2 emissions: The case of coal fired power plants under China Pakistan economic corridor. J. Clean. Prod. 2021, 281, 124974. [Google Scholar]

- Ma, S.; Xiong, J.; Cui, R.; Sun, X.; Han, L.; Xu, Y.; Kan, Z.; Gong, X.; Huang, G. Effects of intermittent aeration on greenhouse gas emissions and bacterial community succession during large-scale membrane-covered aerobic composting. J. Clean. Prod. 2020, 266, 121551. [Google Scholar] [CrossRef]

- Zheng, J.; Fan, J.; Zhang, F.; Guo, J.; Yan, S.; Zhuang, Q.; Cui, N.; Guo, L. Interactive effects of mulching practice and nitrogen rate on grain yield, water productivity, fertilizer use efficiency and greenhouse gas emissions of rainfed summer maize in northwest China. Agric. Water Manag. 2021, 248, 106778. [Google Scholar] [CrossRef]

- Paiva, S.L.; Savi, M.A.; Viola, F.M.; Leiroz, A.J. Global warming description using Daisyworld model with greenhouse gases. Biosystems 2014, 125, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Pan, S.Y.; Chiang, P.C.; Pan, W.; Kim, H. Advances in state-of-art valorization technologies for captured CO2 toward sustainable carbon cycle. Crit. Rev. Environ. Sci. Technol. 2018, 48, 471–534. [Google Scholar] [CrossRef]

- Rahman, F.A.; Aziz, M.M.A.; Saidur, R.; Bakar, W.A.W.A.; Hainin, M.; Putrajaya, R.; Hassan, N.A. Pollution to solution: Capture and sequestration of carbon dioxide (CO2) and its utilization as a renewable energy source for a sustainable future. Renew. Sustain. Energy Rev. 2017, 71, 112–126. [Google Scholar] [CrossRef]

- Thiyagarajan, S.; Varuvel, E.G.; Martin, L.J.; Beddhannan, N. Mitigation of carbon footprints through a blend of biofuels and oxygenates, combined with post-combustion capture system in a single cylinder CI engine. Renew. Energy 2019, 130, 1067–1081. [Google Scholar] [CrossRef]

- Aziz, M.B.A.; Kassim, K.A.; Bakar, W.A.W.A.; Marto, A. Fossil Free Fuels: Trends in Renewable Energy; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Alami, A.H.; Alasad, S.; Ali, M.; Alshamsi, M. Investigating algae for CO2 capture and accumulation and simultaneous production of biomass for biodiesel production. Sci. Total Environ. 2021, 759, 143529. [Google Scholar] [CrossRef]

- Bhola, V.; Swalaha, F.; Kumar, R.R.; Singh, M.; Bux, F. Overview of the potential of microalgae for CO2 sequestration. Int. J. Environ. Sci. Technol. 2014, 11, 2103–2118. [Google Scholar] [CrossRef] [Green Version]

- Caetano, N.; Melo, A.; Gorgich, M.; Branco-Vieira, M.; Martins, A.; Mata, T. Influence of cultivation conditions on the bioenergy potential and bio-compounds of Chlorella vulgaris. Energy Rep. 2020, 6, 378–384. [Google Scholar] [CrossRef]

- Deprá, M.C.; Dias, R.R.; Severo, I.A.; de Menezes, C.R.; Zepka, L.Q.; Jacob-Lopes, E. Carbon dioxide capture and use in photobioreactors: The role of the carbon dioxide loads in the carbon footprint. Bioresour. Technol. 2020, 314, 123745. [Google Scholar] [CrossRef] [PubMed]

- De Morais, M.G.; Costa, J.A.V. Biofixation of carbon dioxide by Spirulina sp. and Scenedesmus obliquus cultivated in a three-stage serial tubular photobioreactor. J. Biotechnol. 2007, 129, 439–445. [Google Scholar] [CrossRef] [PubMed]

- Ghorbani, A.; Rahimpour, H.R.; Ghasemi, Y.; Zoughi, S.; Rahimpour, M.R. A review of carbon capture and sequestration in Iran: Microalgal biofixation potential in Iran. Renew. Sustain. Energy Rev. 2014, 35, 73–100. [Google Scholar] [CrossRef]

- Hulatt, C.J.; Thomas, D.N. Productivity, carbon dioxide uptake and net energy return of microalgal bubble column photobioreactors. Bioresour. Technol. 2011, 102, 5775–5787. [Google Scholar] [CrossRef]

- Tarhan, S.Z.; Koçer, A.T.; Özçimen, D.; Gökalp, İ. Cultivation of green microalgae by recovering aqueous nutrients in hydrothermal carbonization process water of biomass wastes. J. Water Process. Eng. 2020, 40, 101783. [Google Scholar] [CrossRef]

- Aliyu, A.; Lee, J.; Harvey, A. Microalgae for biofuels via thermochemical conversion processes: A review of cultivation, harvesting and drying processes, and the associated opportunities for integrated production. Bioresour. Technol. Rep. 2021, 14, 100676. [Google Scholar] [CrossRef]

- You, X.; Zhang, Z.; Guo, L.; Liao, Q.; Wang, Y.; Zhao, Y.; Jin, C.; Gao, M.; She, Z.; Wang, G. Integrating acidogenic fermentation and microalgae cultivation of bacterial-algal coupling system for mariculture wastewater treatment. Bioresour. Technol. 2021, 320, 124335. [Google Scholar] [CrossRef]

- Lim, Y.A.; Chong, M.N.; Foo, S.C.; Ilankoon, I. Analysis of direct and indirect quantification methods of CO2 fixation via microalgae cultivation in photobioreactors: A critical review. Renew. Sustain. Energy Rev. 2021, 137, 110579. [Google Scholar] [CrossRef]

- Aron, N.S.M.; Khoo, K.S.; Chew, K.W.; Veeramuthu, A.; Chang, J.S.; Show, P.L. Microalgae cultivation in wastewater and potential processing strategies using solvent and membrane separation technologies. J. Water Process Eng. 2021, 39, 101701. [Google Scholar] [CrossRef]

- Yew, G.Y.; Khoo, K.S.; Chia, W.Y.; Ho, Y.C.; Law, C.L.; Leong, H.Y.; Show, P.L. A novel lipids recovery strategy for biofuels generation on microalgae Chlorella cultivation with waste molasses. J. Water Process Eng. 2020, 38, 101665. [Google Scholar] [CrossRef]

- Mathimani, T.; Uma, L.; Prabaharan, D. Formulation of low-cost seawater medium for high cell density and high lipid content of Chlorella vulgaris BDUG 91771 using central composite design in biodiesel perspective. J. Clean. Prod. 2018, 198, 575–586. [Google Scholar] [CrossRef]

- Kumar, B.R.; Mathimani, T.; Sudhakar, M.; Rajendran, K.; Nizami, A.S.; Brindhadevi, K.; Pugazhendhi, A. A state of the art review on the cultivation of algae for energy and other valuable products: Application, challenges, and opportunities. Renew. Sustain. Energy Rev. 2021, 138, 110649. [Google Scholar] [CrossRef]

- Liu, S.; Yang, Y.; Yu, L.; Li, X. Thermodynamic and environmental analysis of solar-driven supercritical water gasification of algae for ammonia synthesis and power production. Energy Convers. Manag. 2021, 243, 114409. [Google Scholar] [CrossRef]

- Parvez, A.M.; Wu, T.; Hong, Y.; Chen, W.; Lester, E.H.; Mareta, S.; Afzal, M. Gasification reactivity and synergistic effect of conventional and microwave pyrolysis derived algae chars in CO2 atmosphere. J. Energy Inst. 2019, 92, 730–740. [Google Scholar] [CrossRef]

- Yan, J.; Jiang, S.; Song, T.; Shen, L. Chemical looping catalytic steam gasification (CLCSG) of algae over La1−xBaxFeO3 perovskites for syngas production. Biomass Bioenergy 2021, 151, 106154. [Google Scholar] [CrossRef]

- Zhao, M.; Raheem, A.; Memon, Z.M.; Vuppaladadiyam, A.K.; Ji, G. Iso-conversional kinetics of low-lipid micro-algae gasification by air. J. Clean. Prod. 2019, 207, 618–629. [Google Scholar] [CrossRef]

- Nurcahyani, P.R.; Hashimoto, S.; Matsumura, Y. Supercritical water gasification of microalgae with and without oil extraction. J. Supercrit. Fluids 2020, 165, 104936. [Google Scholar] [CrossRef]

- Farobie, O.; Matsumura, Y.; Syaftika, N.; Amrullah, A.; Hartulistiyoso, E.; Bayu, A.; Moheimani, N.R.; Karnjanakom, S.; Saefurahman, G. Recent advancement on hydrogen production from macroalgae via supercritical water gasification. Bioresour. Technol. Rep. 2021, 16, 100844. [Google Scholar] [CrossRef]

- Gallego-Cartagena, E.; Castillo-Ramírez, M.; Martínez-Burgos, W. Effect of stressful conditions on the carotenogenic activity of a Colombian strain of Dunaliella salina. Saudi J. Biol. Sci. 2019, 26, 1325–1330. [Google Scholar] [CrossRef]

- Radmann, E.M.; Reinehr, C.O.; Costa, J.A.V. Optimization of the repeated batch cultivation of microalga Spirulina platensis in open raceway ponds. Aquaculture 2007, 265, 118–126. [Google Scholar] [CrossRef]

- Sirikulrat, K.; Pekkoh, J.; Pumas, C. Illumination System for growth and Net Energy Ratio Enhancement of Arthrospira (Spirulina) platensis Outdoor Cultivation in Deep Raceway Pond. Bioresour. Technol. Rep. 2021, 14, 100661. [Google Scholar] [CrossRef]

- Mathimani, T.; Bhumathi, D.; Ahamed, T.S.; Dineshbabu, G.; Deviram, G.; Uma, L.; Prabaharan, D. Semicontinuous outdoor cultivation and efficient harvesting of marine Chlorella vulgaris BDUG 91771 with minimum solid co-precipitation and high floc recovery for biodiesel. Energy Convers. Manag. 2017, 149, 13–25. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M.; Krzemieniewski, M.; Dudek, M.; Grala, A. Microalgae–cultivation methods. Pol. J. Nat. Sci. 2012, 27, 151–164. [Google Scholar]

- Bhuyar, P.; Sundararaju, S.; Rahim, M.H.A.; Ramaraj, R.; Maniam, G.P.; Govindan, N. Microalgae cultivation using palm oil mill effluent as growth medium for lipid production with the effect of CO2 supply and light intensity. Biomass Convers. Biorefin. 2021, 11, 1555–1563. [Google Scholar] [CrossRef]

- Bhuyar, P.; Sundararaju, S.; Rahim, M.H.A.; Maniam, G.P.; Govindan, N. Enhanced productivity of lipid extraction by urea stress conditions on marine microalgae Coelastrum sp. for improved biodiesel production. Bioresour. Technol. Rep. 2021, 15, 100696. [Google Scholar] [CrossRef]

- Pankratz, S.; Kumar, M.; Oyedun, A.O.; Gemechu, E.; Kumar, A. Environmental performances of diluents and hydrogen production pathways from microalgae in cold climates: Open raceway ponds and photobioreactors coupled with thermochemical conversion. Algal Res. 2020, 47, 101815. [Google Scholar] [CrossRef]

- Noguchi, R.; Ahamed, T.; Rani, D.S.; Sakurai, K.; Nasution, M.A.; Wibawa, D.S.; Demura, M.; Watanabe, M.M. Artificial neural networks model for estimating growth of polyculture microalgae in an open raceway pond. Biosyst. Eng. 2019, 177, 122–129. [Google Scholar]

- De-Luca, R.; Trabuio, M.; Barolo, M.; Bezzo, F. Microalgae growth optimization in open ponds with uncertain weather data. Comput. Chem. Eng. 2018, 117, 410–419. [Google Scholar] [CrossRef]

- He, Q.; Yang, H.; Hu, C. Culture modes and financial evaluation of two oleaginous microalgae for biodiesel production in desert area with open raceway pond. Bioresour. Technol. 2016, 218, 571–579. [Google Scholar] [CrossRef]

- Langholtz, M.H.; Coleman, A.M.; Eaton, L.M.; Wigmosta, M.S.; Hellwinckel, C.M.; Brandt, C.C. Potential land competition between open-pond microalgae production and terrestrial dedicated feedstock supply systems in the US. Renew. Energy 2016, 93, 201–214. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Martin, G.J.; Kentish, S.E. Enhanced CO2 bio-utilization with a liquid–liquid membrane contactor in a bench-scale microalgae raceway pond. J. CO2 Util. 2019, 34, 207–214. [Google Scholar] [CrossRef] [Green Version]

- Usha, M.; Chandra, T.S.; Sarada, R.; Chauhan, V. Removal of nutrients and organic pollution load from pulp and paper mill effluent by microalgae in outdoor open pond. Bioresour. Technol. 2016, 214, 856–860. [Google Scholar] [CrossRef] [PubMed]

- Inostroza, C.; Solimeno, A.; García, J.; Fernández-Sevilla, J.M.; Acién, F.G. Improvement of real-scale raceway bioreactors for microalgae production using Computational Fluid Dynamics (CFD). Algal Res. 2021, 54, 102207. [Google Scholar] [CrossRef]

- Banerjee, S.; Ramaswamy, S. Comparison of productivity and economic analysis of microalgae cultivation in open raceways and flat panel photobioreactor. Bioresour. Technol. Rep. 2019, 8, 100328. [Google Scholar] [CrossRef]

- Xu, B.; Li, P.; Waller, P. Study of the flow mixing in a novel ARID raceway for algae production. Renew. Energy 2014, 62, 249–257. [Google Scholar] [CrossRef]

- Daneshvar, E.; Ok, Y.S.; Tavakoli, S.; Sarkar, B.; Shaheen, S.M.; Hong, H.; Luo, Y.; Rinklebe, J.; Song, H.; Bhatnagar, A. Insights into upstream processing of microalgae: A review. Bioresour. Technol. 2021, 329, 124870. [Google Scholar] [CrossRef]

- Lehr, F.; Posten, C. Closed photo-bioreactors as tools for biofuel production. Curr. Opin. Biotechnol. 2009, 20, 280–285. [Google Scholar] [CrossRef]

- Paladino, O.; Neviani, M. Scale-up of photo-bioreactors for microalgae cultivation by π-theorem. Biochem. Eng. J. 2020, 153, 107398. [Google Scholar] [CrossRef]

- Fard, G.H.; Mehrnia, M.R. Investigation of mercury removal by Micro-Algae dynamic membrane bioreactor from simulated dental waste water. J. Environ. Chem. Eng. 2017, 5, 366–372. [Google Scholar] [CrossRef]

- Sastre, R.R.; Csögör, Z.; Perner-Nochta, I.; Fleck-Schneider, P.; Posten, C. Scale-down of microalgae cultivations in tubular photo-bioreactors—A conceptual approach. J. Biotechnol. 2007, 132, 127–133. [Google Scholar] [CrossRef]

- Neviani, M.; Bagnerini, P.; Paladino, O. Gas bubble dynamics in airlift photo-bioreactors for microalgae cultivation by level set methods. Fuel 2021, 292, 120402. [Google Scholar] [CrossRef]

- Christopher, F.C.; Kumar, P.S.; Vo, D.V.N.; Joshiba, G.J. A review on critical assessment of advanced bioreactor options for sustainable hydrogen production. Int. J. Hydrogen Energy 2020, 46, 7113–7136. [Google Scholar] [CrossRef]

- Sun, L.; Tian, Y.; Zhang, J.; Cui, H.; Zuo, W.; Li, J. A novel symbiotic system combining algae and sludge membrane bioreactor technology for wastewater treatment and membrane fouling mitigation: Performance and mechanism. Chem. Eng. J. 2018, 344, 246–253. [Google Scholar] [CrossRef]

- Ma, L.; Wang, F.; Yu, Y.; Liu, J.; Wu, Y. Cu removal and response mechanisms of periphytic biofilms in a tubular bioreactor. Bioresour. Technol. 2018, 248, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Paul, T.; Baskaran, D.; Pakshirajan, K.; Pugazhenthi, G. Continuous bioreactor with cell recycle using tubular ceramic membrane for simultaneous wastewater treatment and bio-oil production by oleaginous Rhodococcus opacus. Chem. Eng. J. 2019, 367, 76–85. [Google Scholar] [CrossRef]

- Cheng, J.; Xu, J.; Ye, Q.; Lai, X.; Zhang, X.; Zhou, J. Strengthening mass transfer of carbon dioxide microbubbles dissolver in a horizontal tubular photo-bioreactor for improving microalgae growth. Bioresour. Technol. 2019, 277, 11–17. [Google Scholar] [CrossRef]

- Hosseini, N.S.; Shang, H.; Ross, G.M.; Scott, J.A. Comparative analysis of top-lit bubble column and gas-lift bioreactors for microalgae-sourced biodiesel production. Energy Convers. Manag. 2016, 130, 230–239. [Google Scholar] [CrossRef]

- Laamanen, C.A.; Scott, J.A. Microalgae biofuel bioreactors for mitigation of industrial CO2 emissions. In Bioreactors; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–16. [Google Scholar]

- Serna-García, R.; Borrás, L.; Bouzas, A.; Seco, A. Insights into the biological process performance and microbial diversity during thermophilic microalgae co-digestion in an anaerobic membrane bioreactor (AnMBR). Algal Res. 2020, 50, 101981. [Google Scholar] [CrossRef]

- Savage, E.; Nagle, N.; Laurens, L.M.; Knoshaug, E.P. Nitrogen derived from Combined Algal Processing supports algae cultivation for biofuels. Algal Res. 2020, 50, 101987. [Google Scholar] [CrossRef]

- Banerjee, S.; Banerjee, S.; Ghosh, A.K.; Das, D. Maneuvering the genetic and metabolic pathway for improving biofuel production in algae: Present status and future prospective. Renew. Sustain. Energy Rev. 2020, 133, 110155. [Google Scholar] [CrossRef]

- Khan, S.; Fu, P. Biotechnological perspectives on algae: A viable option for next generation biofuels. Curr. Opin. Biotechnol. 2020, 62, 146–152. [Google Scholar] [CrossRef] [PubMed]

- Adeniyi, O.M.; Azimov, U.; Burluka, A. Algae biofuel: Current status and future applications. Renew. Sustain. Energy Rev. 2018, 90, 316–335. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Periyasamy, M.; Prathima, A. Combustion analysis of a CI engine with Caulerpa racemosa algae biofuel with nano additives. Mater. Today Proc. 2020, 33, 3324–3329. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Periyasamy, M.; Prathima, A.; Sabariswaran, K. Performance analysis of diesel engine fueled with S. marginatum Macro algae biofuel-diesel blends. Mater. Today Proc. 2020, 33, 3464–3469. [Google Scholar] [CrossRef]

- Plouviez, M.; Shilton, A.; Packer, M.A.; Guieysse, B. Nitrous oxide emissions from microalgae: Potential pathways and significance. J. Appl. Phycol. 2019, 31, 1–8. [Google Scholar] [CrossRef]

- Mathimani, T.; Baldinelli, A.; Rajendran, K.; Prabakar, D.; Matheswaran, M.; van Leeuwen, R.P.; Pugazhendhi, A. Review on cultivation and thermochemical conversion of microalgae to fuels and chemicals: Process evaluation and knowledge gaps. J. Clean. Prod. 2019, 208, 1053–1064. [Google Scholar] [CrossRef]

- Saengsawang, B.; Bhuyar, P.; Manmai, N.; Ponnusamy, V.K.; Ramaraj, R.; Unpaprom, Y. The optimization of oil extraction from macroalgae, Rhizoclonium sp. by chemical methods for efficient conversion into biodiesel. Fuel 2020, 274, 117841. [Google Scholar] [CrossRef]

- Khammee, P.; Ramaraj, R.; Whangchai, N.; Bhuyar, P.; Unpaprom, Y. The immobilization of yeast for fermentation of macroalgae Rhizoclonium sp. for efficient conversion into bioethanol. Biomass Convers. Biorefin. 2021, 11, 827–835. [Google Scholar] [CrossRef]

- Onwudili, J.A.; Lea-Langton, A.R.; Ross, A.B.; Williams, P.T. Catalytic hydrothermal gasification of algae for hydrogen production: Composition of reaction products and potential for nutrient recycling. Bioresour. Technol. 2013, 127, 72–80. [Google Scholar] [CrossRef]

- Parvez, A.M.; Afzal, M.T.; Hebb, T.G.V.; Schmid, M. Utilization of CO2 in thermochemical conversion of biomass for enhanced product properties: A review. J. CO2 Util. 2020, 40, 101217. [Google Scholar] [CrossRef]

- Li, Y.; Hong, C.; Li, Z.; Xing, Y.; Chang, X.; Zheng, Z.; Zhao, X. Study on the nitrogen migration mechanism during penicillin fermentation residue fast pyrolysis based on the substance transformation and canonical variational theory. Sci. Total Environ. 2020, 737, 139739. [Google Scholar] [CrossRef] [PubMed]

- Liu, P.; Rao, D.; Zou, L.; Teng, Y.; Yu, H. Capacity and potential mechanisms of Cd (II) adsorption from aqueous solution by blue algae-derived biochars. Sci. Total Environ. 2021, 767, 145447. [Google Scholar] [CrossRef] [PubMed]

- Ji, R.; Wu, Y.; Bian, Y.; Song, Y.; Sun, Q.; Jiang, X.; Zhang, L.; Han, J.; Cheng, H. Nitrogen-doped porous biochar derived from marine algae for efficient solid-phase microextraction of chlorobenzenes from aqueous solution. J. Hazard. Mater. 2021, 407, 124785. [Google Scholar] [CrossRef] [PubMed]

- Chi, N.T.L.; Anto, S.; Ahamed, T.S.; Kumar, S.S.; Shanmugam, S.; Samuel, M.S.; Mathimani, T.; Brindhadevi, K.; Pugazhendhi, A. A review on biochar production techniques and biochar based catalyst for biofuel production from algae. Fuel 2021, 287, 119411. [Google Scholar] [CrossRef]

- Ranguin, R.; Delannoy, M.; Yacou, C.; Jean-Marius, C.; Feidt, C.; Rychen, G.; Gaspard, S. Biochar and activated carbons preparation from invasive algae Sargassum spp. for Chlordecone availability reduction in contaminated soils. J. Environ. Chem. Eng. 2021, 9, 105280. [Google Scholar] [CrossRef]

- Hung, C.M.; Huang, C.; Hsieh, S.L.; Tsai, M.L.; Chen, C.W.; Dong, C.D. Biochar derived from red algae for efficient remediation of 4-nonylphenol from marine sediments. Chemosphere 2020, 254, 126916. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Shen, F.; Wang, Z. Temporal release behavior of potassium during pyrolysis and gasification of sawdust particles. Renew. Energy 2020, 156, 98–106. [Google Scholar] [CrossRef]

- Bakthavatsalam, A. A comparative study on growth and degradation behavior of C. pyrenoidosa on synthetic phenol and phenolic wastewater of a coal gasification plant. J. Environ. Chem. Eng. 2019, 7, 103079. [Google Scholar]

- Wijayanta, A.T.; Aziz, M. Ammonia production from algae via integrated hydrothermal gasification, chemical looping, N2 production, and NH3 synthesis. Energy 2019, 174, 331–338. [Google Scholar] [CrossRef]

- Su, H.; Hantoko, D.; Yan, M.; Cai, Y.; Kanchanatip, E.; Liu, J.; Zhou, X.; Zhang, S. Evaluation of catalytic subcritical water gasification of food waste for hydrogen production: Effect of process conditions and different types of catalyst loading. Int. J. Hydrogen Energy 2019, 44, 21451–21463. [Google Scholar] [CrossRef]

- Raheem, A.; Ji, G.; Memon, A.; Sivasangar, S.; Wang, W.; Zhao, M.; Taufiq-Yap, Y.H. Catalytic gasification of algal biomass for hydrogen-rich gas production: Parametric optimization via central composite design. Energy Convers. Manag. 2018, 158, 235–245. [Google Scholar] [CrossRef]

- Guan, Q.; Savage, P.E.; Wei, C. Gasification of alga Nannochloropsis sp. in supercritical water. J. Supercrit. Fluids 2012, 61, 139–145. [Google Scholar] [CrossRef]

- Sun, J.; Feng, H.; Xu, J.; Jin, H.; Guo, L. Investigation of the conversion mechanism for hydrogen production by coal gasification in supercritical water. Int. J. Hydrogen Energy 2021, 46, 10205–10215. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, C.; Huang, J.; Li, L.; Jin, H. Enhancement of depolymerization slag gasification in supercritical water and its gasification performance in fluidized bed reactor. Renew. Energy 2021, 168, 829–837. [Google Scholar] [CrossRef]

- Gong, M.; Li, Z.; Wang, M.; Feng, A.; Wang, L.; Yuan, S. Effects of Lewis acid on catalyzing gasification of sewage sludge and model compounds in supercritical water. Int. J. Hydrogen Energy 2021, 46, 9008–9018. [Google Scholar] [CrossRef]

- Liu, S.; Guo, L.; Jin, H.; Li, L.; Li, G.; Yu, L. Hydrogen production by supercritical water gasification of coal: A reaction kinetic model including nitrogen and sulfur elements. Int. J. Hydrogen Energy 2020, 45, 31732–31744. [Google Scholar] [CrossRef]

- Shan, Y.Q.; Yin, L.X.; Djandja, O.S.; Wang, Z.C.; Duan, P.G. Supercritical water gasification of waste water produced from hydrothermal liquefaction of microalgae over Ru catalyst for production of H2 rich gas fuel. Fuel 2021, 292, 120288. [Google Scholar] [CrossRef]

- Bogdan, V.I.; Koklin, A.E.; Bogdan, T.V.; Mishanin, I.I.; Kalenchuk, A.N.; Laptinskaya, T.V.; Kustov, L.M. Hydrogen generation by gasification of phenol and alcohols in supercritical water. Int. J. Hydrogen Energy 2020, 45, 30178–30187. [Google Scholar] [CrossRef]

- Guan, Q.; Wei, C.; Ning, P.; Gu, J. Catalytic gasification of algae Nannochloropsis sp. in sub/supercritical water. Procedia Environ. Sci. 2013, 18, 844–848. [Google Scholar] [CrossRef] [Green Version]

- Butterman, H.C.; Castaldi, M.J. Influence of CO2 injection on biomass gasification. Ind. Eng. Chem. Res. 2007, 46, 8875–8886. [Google Scholar] [CrossRef]

- Valizadeh, S.; Lam, S.S.; Ko, C.H.; Lee, S.H.; Farooq, A.; Yu, Y.J.; Jeon, J.K.; Jung, S.C.; Rhee, G.H.; Park, Y.K. Biohydrogen production from catalytic conversion of food waste via steam and air gasification using eggshell-and homo-type Ni/Al2O3 catalysts. Bioresour. Technol. 2021, 320, 124313. [Google Scholar] [CrossRef] [PubMed]

- Prestipino, M.; Chiodo, V.; Maisano, S.; Zafarana, G.; Urbani, F.; Galvagno, A. Hydrogen rich syngas production by air-steam gasification of citrus peel residues from citrus juice manufacturing: Experimental and simulation activities. Int. J. Hydrogen Energy 2017, 42, 26816–26827. [Google Scholar] [CrossRef]

- Jeong, Y.S.; Kim, J.W.; Seo, M.W.; Mun, T.Y.; Kim, J.S. Characteristics of two-stage air gasification of polystyrene with active carbon as a tar removal agent. Energy 2021, 219, 119681. [Google Scholar] [CrossRef]

- Hwang, I.S.; Sohn, J.; Do Lee, U.; Hwang, J. CFD-DEM simulation of air-blown gasification of biomass in a bubbling fluidized bed gasifier: Effects of equivalence ratio and fluidization number. Energy 2021, 219, 119533. [Google Scholar] [CrossRef]

- Said, M.S.M.; Ghani, W.A.W.A.K.; Tan, H.B.; Ng, D.K. Prediction and optimisation of syngas production from air gasification of Napier grass via stoichiometric equilibrium model. Energy Convers. Manag. X 2020, 10, 100057. [Google Scholar] [CrossRef]

- Inayat, M.; Sulaiman, S.A.; Inayat, A.; Shaik, N.B.; Gilal, A.R.; Shahbaz, M. Modeling and parametric optimization of air catalytic co-gasification of wood-oil palm fronds blend for clean syngas (H2+CO) production. Int. J. Hydrogen Energy 2020, 46, 30559–30580. [Google Scholar] [CrossRef]

- Chew, K.W.; Chia, S.R.; Chia, W.Y.; Cheah, W.Y.; Munawaroh, H.S.H.; Ong, W.J. Abatement of hazardous materials and biomass waste via pyrolysis and co-pyrolysis for environmental sustainability and circular economy. Environ. Pollut. 2021, 278, 116836. [Google Scholar] [CrossRef]

- Phakedi, D.; Ude, A.U.; Oladijo, P. Co-pyrolysis of polymer waste and carbon-based matter as an alternative for waste management in the developing world. J. Anal. Appl. Pyrolysis 2021, 155, 105077. [Google Scholar] [CrossRef]

- He, J.; Strezov, V.; Zhou, X.; Kumar, R.; Weldekidan, H.; Kan, T. Effects of co-pyrolysis of heavy metal contaminated biomass with magnesium carbonate on heavy metal deportment and pyrolytic product properties. Fuel 2021, 294, 120545. [Google Scholar] [CrossRef]

- Qi, J.; Fan, C.; Li, S. Characteristics of lignite char derived from oxy-pyrolysis. Fuel 2021, 291, 120261. [Google Scholar] [CrossRef]

- Sun, C.; Li, W.; Chen, X.; Li, C.; Tan, H.; Zhang, Y. Synergistic interactions for saving energy and promoting the co-pyrolysis of Polylactic acid and wood flour. Renew. Energy 2021, 171, 254–265. [Google Scholar] [CrossRef]

- Ellison, C.R.; Boldor, D. Mild upgrading of biomass pyrolysis vapors via ex-situ catalytic pyrolysis over an iron-montmorillonite catalyst. Fuel 2021, 291, 120226. [Google Scholar] [CrossRef]

- Joardder, M.U.; Halder, P.; Rahim, A.; Paul, N. Solar assisted fast pyrolysis: A novel approach of renewable energy production. J. Eng. 2014, 2014, 252848. [Google Scholar] [CrossRef] [Green Version]

- Belotti, G.; de Caprariis, B.; De Filippis, P.; Scarsella, M.; Verdone, N. Effect of Chlorella vulgaris growing conditions on bio-oil production via fast pyrolysis. Biomass Bioenergy 2014, 61, 187–195. [Google Scholar] [CrossRef]

- Grierson, S.; Strezov, V.; Ellem, G.; Mcgregor, R.; Herbertson, J. Thermal characterisation of microalgae under slow pyrolysis conditions. J. Anal. Appl. Pyrolysis 2009, 85, 118–123. [Google Scholar] [CrossRef]

- Harman-Ware, A.E.; Morgan, T.; Wilson, M.; Crocker, M.; Zhang, J.; Liu, K.; Stork, J.; Debolt, S. Microalgae as a renewable fuel source: Fast pyrolysis of Scenedesmus sp. Renew. Energy 2013, 60, 625–632. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Vinu, R. Biomass waste conversion into value-added products via microwave-assisted Co-Pyrolysis platform. Renew. Energy 2021, 170, 400–409. [Google Scholar] [CrossRef]

- Wen, Y.; Xie, Y.; Jiang, C.; Li, W.; Hou, Y. Products distribution and interaction mechanism during co-pyrolysis of rice husk and oily sludge by experiments and reaction force field simulation. Bioresour. Technol. 2021, 329, 124822. [Google Scholar] [CrossRef]

- Li, Q.; Ye, H.; Wang, Z.; Zhou, H.; Wei, J. Characteristics and evolution of products under moderate and high temperature coal pyrolysis in drop tube furnace. J. Energy Inst. 2021, 96, 121–127. [Google Scholar] [CrossRef]

- Adánez-Rubio, I.; Fonts, I.; de Blas, P.; Viteri, F.; Gea, G.; Alzueta, M. Exploratory study of Polycyclic Aromatic Hydrocarbons occurrence and distribution in manure pyrolysis products. J. Anal. Appl. Pyrolysis 2021, 155, 105078. [Google Scholar] [CrossRef]

- Kim, Y.M.; Han, T.U.; Lee, B.; Watanabe, A.; Teramae, N.; Kim, J.H.; Park, Y.K.; Park, H.; Kim, S. Analytical pyrolysis reaction characteristics of Porphyra tenera. Algal Res. 2018, 32, 60–69. [Google Scholar] [CrossRef]

- Niu, Q.; Wang, J.; Cao, C.; Cheng, Z.; Zhu, Y.; Wen, W.; Wang, J.; Pan, Y.; Yan, B.; Chen, G.; et al. Comparative study of Different Algae Pyrolysis using Photoionization Mass Spectrometry and Gas Chromatography/Mass Spectrometry. J. Anal. Appl. Pyrolysis 2021, 155, 105068. [Google Scholar] [CrossRef]

- Piloni, R.V.; Daga, I.C.; Urcelay, C.; Moyano, E.L. Experimental investigation on fast pyrolysis of freshwater algae. Prospects for alternative bio-fuel production. Algal Res. 2021, 54, 102206. [Google Scholar] [CrossRef]

- Yu, D.; Hu, S.; Wang, L.; Chen, Q.; Dong, N. Comparative study on pyrolysis characteristics and kinetics of oleaginous yeast and algae. Int. J. Hydrogen Energy 2020, 45, 10979–10990. [Google Scholar] [CrossRef]

- Debiagi, P.E.A.; Trinchera, M.; Frassoldati, A.; Faravelli, T.; Vinu, R.; Ranzi, E. Algae characterization and multistep pyrolysis mechanism. J. Anal. Appl. Pyrolysis 2017, 128, 423–436. [Google Scholar] [CrossRef]

- Casoni, A.I.; Zunino, J.; Piccolo, M.C.; Volpe, M.A. Valorization of Rhizoclonium sp. algae via pyrolysis and catalytic pyrolysis. Bioresour. Technol. 2016, 216, 302–307. [Google Scholar] [CrossRef]

- Aziz, M.; Oda, T.; Kashiwagi, T. Enhanced high energy efficient steam drying of algae. Appl. Energy 2013, 109, 163–170. [Google Scholar] [CrossRef]

- Hussain, J.; Liu, Y.; Lopes, W.A.; Druzian, J.I.; Souza, C.O.; Carvalho, G.C.; Nascimento, I.A.; Liao, W. Effects of different biomass drying and lipid extraction methods on algal lipid yield, fatty acid profile, and biodiesel quality. Appl. Biochem. Biotechnol. 2015, 175, 3048–3057. [Google Scholar] [CrossRef]

- Chamola, R.; Khan, M.F.; Raj, A.; Verma, M.; Jain, S. Response surface methodology based optimization of in situ transesterification of dry algae with methanol, H2SO4 and NaOH. Fuel 2019, 239, 511–520. [Google Scholar] [CrossRef]

- Chang, K.L.; Lin, Y.C.; Shangdiar, S.; Chen, S.C.; Hsiao, Y.H. Hydrogen production from dry spirulina algae with downstream feeding in microwave plasma reactor assisted under atmospheric pressure. J. Energy Inst. 2020, 93, 1597–1601. [Google Scholar] [CrossRef]

- Liu, K. Effects of sample size, dry ashing temperature and duration on determination of ash content in algae and other biomass. Algal Res. 2019, 40, 101486. [Google Scholar] [CrossRef]

- Pongsiriyakul, K.; Kiatkittipong, W.; Adhikari, S.; Lim, J.W.; Lam, S.S.; Kiatkittipong, K.; Dankeaw, A.; Reubroycharoen, P.; Laosiripojana, N.; Faungnawakij, K.; et al. Effective Cu/Re promoted Ni-supported γ-Al2O3 catalyst for upgrading algae bio-crude oil produced by hydrothermal liquefaction. Fuel Process. Technol. 2021, 216, 106670. [Google Scholar] [CrossRef]

- Li, M.H.; Robinson, E.H.; Tucker, C.S.; Manning, B.B.; Khoo, L. Effects of dried algae Schizochytrium sp., a rich source of docosahexaenoic acid, on growth, fatty acid composition, and sensory quality of channel catfish Ictalurus punctatus. Aquaculture 2009, 292, 232–236. [Google Scholar] [CrossRef]

- Kuda, T.; Eda, M.; Kataoka, M.; Nemoto, M.; Kawahara, M.; Oshio, S.; Takahashi, H.; Kimura, B. Anti-glycation properties of the aqueous extract solutions of dried algae products and effect of lactic acid fermentation on the properties. Food Chem. 2016, 192, 1109–1115. [Google Scholar] [CrossRef] [PubMed]

- Aziz, M.; Oda, T.; Mitani, T.; Kurokawa, T.; Kawasaki, N.; Kashiwagi, T. Enhanced energy utilization system of algae: Integrated drying, gasification and combined cycle. Energy Procedia 2015, 75, 906–911. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.L.; Chang, J.S.; Lee, D.J. Dewatering and drying methods for microalgae. Dry. Technol. 2015, 33, 443–454. [Google Scholar] [CrossRef]

- Béchet, Q.; Shilton, A.; Guieysse, B. Modeling the effects of light and temperature on algae growth: State of the art and critical assessment for productivity prediction during outdoor cultivation. Biotechnol. Adv. 2013, 31, 1648–1663. [Google Scholar] [CrossRef]

- Muñoz-Fernández, J.; Del Rosal, Y.; Álvarez-Gómez, F.; Hernández-Mariné, M.; Guzmán-Sepúlveda, R.; Korbee, N.; Figueroa, F. Selection of LED lighting systems for the reduction of the biodeterioration of speleothems induced by photosynthetic biofilms in the Nerja Cave (Malaga, Spain). J. Photochem. Photobiol. B Biol. 2021, 217, 112155. [Google Scholar] [CrossRef]

- Chew, K.W.; Khoo, K.S.; Foo, H.T.; Chia, S.R.; Walvekar, R.; Lim, S.S. Algae utilization and its role in the developments of green cities. Chemosphere 2020, 268, 129322. [Google Scholar] [CrossRef]

- Harmon, V.L.; Wolfrum, E.; Knoshaug, E.P.; Davis, R.; Laurens, L.M.; Pienkos, P.T.; McGowen, J. Reliability metrics and their management implications for open pond algae cultivation. Algal Res. 2021, 55, 102249. [Google Scholar] [CrossRef]

- Aravind, S.; Barik, D.; Ragupathi, P.; Vignesh, G. Investigation on algae oil extraction from algae Spirogyra by Soxhlet extraction method. Mater. Today Proc. 2021, 43, 308–313. [Google Scholar] [CrossRef]

- Cao, Y.; Shao, P.; Chen, Y.; Zhou, X.; Yang, L.; Shi, H.; Yu, K.; Luo, X.; Luo, X. A critical review of the recovery of rare earth elements from wastewater by algae for resources recycling technologies. Resour. Conserv. Recycl. 2021, 169, 105519. [Google Scholar] [CrossRef]

- Leong, Y.K.; Chew, K.W.; Chen, W.H.; Chang, J.S.; Show, P.L. Reuniting the Biogeochemistry of Algae for a Low-Carbon Circular Bioeconomy. Trends Plant Sci. 2021, 26, 729–740. [Google Scholar] [CrossRef] [PubMed]

- Baskaran, V.; Saravanane, R. Experimental investigation on Spirulina algae based thermal still for effective bio-desalination. Environ. Nanotechnol. Monit. Manag. 2021, 15, 100434. [Google Scholar]

- Nwoba, E.G.; Parlevliet, D.A.; Laird, D.W.; Alameh, K.; Moheimani, N.R. Light management technologies for increasing algal photobioreactor efficiency. Algal Res. 2019, 39, 101433. [Google Scholar] [CrossRef]

- Jacob, A.; Ashok, B.; Alagumalai, A.; Chyuan, O.H.; Le, P.T.K. Critical review on third generation micro algae biodiesel production and its feasibility as future bioenergy for IC engine applications. Energy Convers. Manag. 2020, 228, 113655. [Google Scholar] [CrossRef]

- You, X.; Xu, N.; Yang, X.; Sun, W. Pollutants affect algae-bacteria interactions: A critical review. Environ. Pollut. 2021, 276, 116723. [Google Scholar] [CrossRef]

- Laurens, L.M. A new algae technical standards focus group: Summarizing and guiding the algae state of the art. Algal Res. 2021, 53, 102141. [Google Scholar] [CrossRef]

- Wray, J.L. Calcareous Algae; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Wahidin, S.; Idris, A.; Shaleh, S.R.M. The influence of light intensity and photoperiod on the growth and lipid content of microalgae Nannochloropsis sp. Bioresour. Technol. 2013, 129, 7–11. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Q.; Yu, H.; Feng, X. Tech-economic and environmental analysis of energy-efficient shale gas and flue gas coupling system for chemicals manufacture and carbon capture storage and utilization. Energy 2021, 217, 119348. [Google Scholar] [CrossRef]

- Cutshaw, A.; Daiek, C.; Zheng, Y.; Frost, H.; Marks, A.; Clements, D.; Uludag-Demirer, S.; Verhanovitz, N.; Pavlik, D.; Clary, W.; et al. A long-term pilot-scale algal cultivation on power plant flue gas–Cultivation stability and biomass accumulation. Algal Res. 2020, 52, 102115. [Google Scholar] [CrossRef]

- Singh, V.; Tiwari, A.; Das, M. Phyco-remediation of industrial waste-water and flue gases with algal-diesel engenderment from micro-algae: A review. Fuel 2016, 173, 90–97. [Google Scholar] [CrossRef]

- Chou, H.H.; Su, H.Y.; Chow, T.J.; Lee, T.M.; Cheng, W.H.; Chang, J.S.; Chen, H.J. Engineering cyanobacteria with enhanced growth in simulated flue gases for high-yield bioethanol production. Biochem. Eng. J. 2021, 165, 107823. [Google Scholar] [CrossRef]

- Cheng, J.; Zhu, Y.; Zhang, Z.; Yang, W. Modification and improvement of microalgae strains for strengthening CO2 fixation from coal-fired flue gas in power plants. Bioresour. Technol. 2019, 291, 121850. [Google Scholar] [CrossRef]

- Chu, F.; Cheng, J.; Hou, W.; Yang, W.; Zhang, P.; Park, J.Y.; Kim, H.; Xu, L. Fecitrate converted from Fe2O3 particles in coal-fired flue gas promoted microalgal biomass and lipid productivities. Sci. Total Environ. 2021, 760, 143405. [Google Scholar] [CrossRef]

- Chen, H.W.; Yang, T.S.; Chen, M.J.; Chang, Y.C.; Lin, C.Y.; Eugene, I.; Wang, C.; Ho, C.L.; Huang, K.M.; Yu, C.C.; et al. Application of power plant flue gas in a photobioreactor to grow Spirulina algae, and a bioactivity analysis of the algal water-soluble polysaccharides. Bioresour. Technol. 2012, 120, 256–263. [Google Scholar] [CrossRef]

- Singh, H.M.; Kothari, R.; Gupta, R.; Tyagi, V. Bio-fixation of flue gas from thermal power plants with algal biomass: Overview and research perspectives. J. Environ. Manag. 2019, 245, 519–539. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, W.; Wang, J.; Chen, Y.; Shen, S.; Liu, T. Utilization of simulated flue gas for cultivation of Scenedesmus dimorphus. Bioresour. Technol. 2013, 128, 359–364. [Google Scholar] [CrossRef]

- Kumar, P.K.; Krishna, S.V.; Verma, K.; Pooja, K.; Bhagawan, D.; Himabindu, V. Phycoremediation of sewage wastewater and industrial flue gases for biomass generation from microalgae. S. Afr. J. Chem. Eng. 2018, 25, 133–146. [Google Scholar] [CrossRef]

- Chiu, S.Y.; Kao, C.Y.; Huang, T.T.; Lin, C.J.; Ong, S.C.; Chen, C.D.; Chang, J.S.; Lin, C.S. Microalgal biomass production and on-site bioremediation of carbon dioxide, nitrogen oxide and sulfur dioxide from flue gas using Chlorella sp. cultures. Bioresour. Technol. 2011, 102, 9135–9142. [Google Scholar] [CrossRef]

- Doucha, J.; Straka, F.; Lívanskỳ, K. Utilization of flue gas for cultivation of microalgae Chlorella sp.) in an outdoor open thin-layer photobioreactor. J. Appl. Phycol. 2005, 17, 403–412. [Google Scholar] [CrossRef]

- Guruvaiah, M.; Lee, K. Effect of flue gas on microalgae population and study the heavy metals accumulation in biomass from power plant system. Int. J. Appl. Sci. Biotechnol. 2014, 2, 114–120. [Google Scholar] [CrossRef] [Green Version]

- Jacob-Lopes, E.; Franco, T.T. From oil refinery to microalgal biorefinery. J. CO2 Util. 2013, 2, 1–7. [Google Scholar] [CrossRef]

- de Morais, M.G.; Costa, J.A.V. Isolation and selection of microalgae from coal fired thermoelectric power plant for biofixation of carbon dioxide. Energy Convers. Manag. 2007, 48, 2169–2173. [Google Scholar] [CrossRef]

| % | NOX | SO2 | SO3 | CO | SPM | CO2 | CH4 | N2O |

|---|---|---|---|---|---|---|---|---|

| Domesticated | 6.6 | 7.0 | 8.6 | 0.9 | 1.8 | 25 | 7.3 | 4.2 |

| Industry | 9.3 | 22.2 | 32.1 | 0.4 | 2.8 | 16.6 | 4.1 | 2.6 |

| Transport | 48.4 | 28.7 | 30.6 | 96.8 | 86.8 | 23.4 | 79.7 | 47.9 |

| agriculture | 3.9 | 5.4 | 3.2 | 0.2 | 4.7 | 2.6 | 1.4 | 40.4 |

| Oil refineries | NA | NA | NA | NA | NA | 3.2 | 0.7 | 0.4 |

| Power plants | 31.8 | 36.7 | 25.5 | 1.7 | 3.9 | 29.1 | 6.7 | 4.4 |

| No. | Brief Description of Threats | Reference |

|---|---|---|

| 1 | Continuous increase in the temperature of planet Earth | [10] |

| 2 | Melting glaciers (Himalayan glaciers have melted by 21% in the last 40 years) | [3] |

| 3 | Radiation exposure | [11] |

| 4 | Changes in the composition of the atmosphere | [11] |

| 5 | Sea level rise | [12] |

| 6 | Violation of the agricultural system | [12] |

| 7 | Increased flood risk | [13] |

| Type of Algae | Biomass Productivity, mg/Ld | CO Content, mg/Ld | Temperature, °C | The Capture CO, mg/Ld |

|---|---|---|---|---|

| Nannochloris sp. | 350 | 15 | 25 | 658 |

| Nannochloropsis sp. | 300 | 15 | 25 | 564 |

| Chlorella sp. | 950 | 50 | 35 | 1790 |

| Chlorella sp. | 700 | 20 | 40 | 1316 |

| Chlorella sp. | 386 | 50 | 25 | 725 |

| Chlorella sp. | 1000 | 15 | 25 | 1880 |

| Chlorella sp. | 500 | 50 | 25 | 940 |

| Chlorogleopsis sp. | 40 | 5 | 50 | 20.45 |

| Hot spring algae | 266.7 | 15 | 50 | 501.3 |

| Chlorocuccum littorale | 44 | 50 | 22 | 82 |

| Proximate Analysis (wt.%) | Ultimate Analysis (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Moisture | Volatile | Fixed Carbon | Ash | C | H | O | N | S | ||

| Nannochloropsis | - | - | - | - | 43.3 | 6.0 | 25.1 | 6.4 | 0.5 | [34] |

| Chlorella | - | 72.9 | 18.4 | 8.7 | 51.9 | 7.1 | 30.5 | 9.6 | 0.9 | [35] |

| Chlorella | - | 12.36 | 72.3 | 15.1 | 85.7 | 2.1 | 7.5 | 4.3 | 0.4 | [35] |

| Algae | 7.53 | 75.59 | 10.91 | 5.97 | 42.3 | 10.84 | 23.84 | 9.26 | 0.27 | [36] |

| Chlorella | 6.18 | 85.85 | 2.66 | 5.31 | 38.98 | 6.46 | 48.25 | 0.51 | 0.16 | [37] |

| Spirulina | 4.47 | 84.54 | 5.85 | 5.14 | 36.29 | 6.15 | 45.35 | 0.68 | 0.15 | [37] |

| Chlorella original | - | - | - | 4.89 | 47.93 | 7.31 | 31.13 | 9.27 | - | [38] |

| Chlorella after extraction | - | - | - | 4.37 | 47.35 | 7.08 | 31.00 | 9.69 | - | [38] |

| Chorda filum | 13.1 | 52.2 | 24.9 | 11.61 | 39.1 | 4.7 | 37.2 | 1.4 | 1.6 | [39] |

| Fucus serratus | 11.4 | 45.5 | 24.2 | 23.4 | 33.5 | 4.8 | 34.4 | 2.4 | 1.3 | [39] |

| Gracilaria gracilis | 5.9 | 53.1 | 10.9 | 36.0 | 31.5 | 5.9 | 17.5 | 2.9 | 2.0 | [39] |

| Enteromorpha clathrata | 10.1 | 57.9 | 10.7 | 21.2 | 32.7 | 4.9 | 24.7 | 4.4 | 2.0 | [39] |

| Sample | NaOH (M) | Ni/ Al2O3 | H2 (mol%) | CO (mol%) | CO2 (mol%) | Methane (mol%) | C2 –C4 (mol%) | C (MJ/m) |

|---|---|---|---|---|---|---|---|---|

| Spirulina | – | – | 21.1 | 4.26 | 36.2 | 21.2 | 16.9 | 27.9 |

| Spirulina | 1.67 | – | 60.5 | – | – | 21.9 | 14.6 | 31.3 |

| Spirulina | 1.67 | Yes | 59.0 | – | – | 26.5 | 14.5 | 34.0 |

| Spirulina | – | Yes | 23.5 | 0.97 | 37.9 | 21.6 | 16.1 | 26.3 |

| Saccharina | – | – | 24.8 | 4.23 | 50.2 | 12.0 | 8.74 | 17.3 |

| Saccharina | 1.67 | – | 68.8 | – | – | 23.3 | 7.94 | 25.2 |

| Saccharina | 1.67 | Yes | 61.8 | – | – | 28.7 | 9.53 | 27.6 |

| Saccharina | – | Yes | 26.0 | 1.85 | 51.2 | 14.8 | 6.23 | 13.7 |

| Chlorella | – | – | 18.3 | 5.28 | 45.0 | 17.1 | 14.3 | 22.8 |

| Chlorella | 1.67 | – | 57.3 | – | – | 25.9 | 16.8 | 33.3 |

| Chlorella | 1.67 | Yes | 52.6 | – | – | 27.6 | 19.7 | 35.6 |

| Chlorella | – | Yes | 24.5 | 0.45 | 34.6 | 22.7 | 17.7 | 28.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iglina, T.; Iglin, P.; Pashchenko, D. Industrial CO2 Capture by Algae: A Review and Recent Advances. Sustainability 2022, 14, 3801. https://doi.org/10.3390/su14073801

Iglina T, Iglin P, Pashchenko D. Industrial CO2 Capture by Algae: A Review and Recent Advances. Sustainability. 2022; 14(7):3801. https://doi.org/10.3390/su14073801

Chicago/Turabian StyleIglina, Tatyana, Pavel Iglin, and Dmitry Pashchenko. 2022. "Industrial CO2 Capture by Algae: A Review and Recent Advances" Sustainability 14, no. 7: 3801. https://doi.org/10.3390/su14073801

APA StyleIglina, T., Iglin, P., & Pashchenko, D. (2022). Industrial CO2 Capture by Algae: A Review and Recent Advances. Sustainability, 14(7), 3801. https://doi.org/10.3390/su14073801