Compressive Strength of Stabilised Granitic Residual Soil Using Mixture of Pineapple Fibre—Hydrated Lime

Abstract

:1. Introduction

2. Materials and Method

2.1. Materials

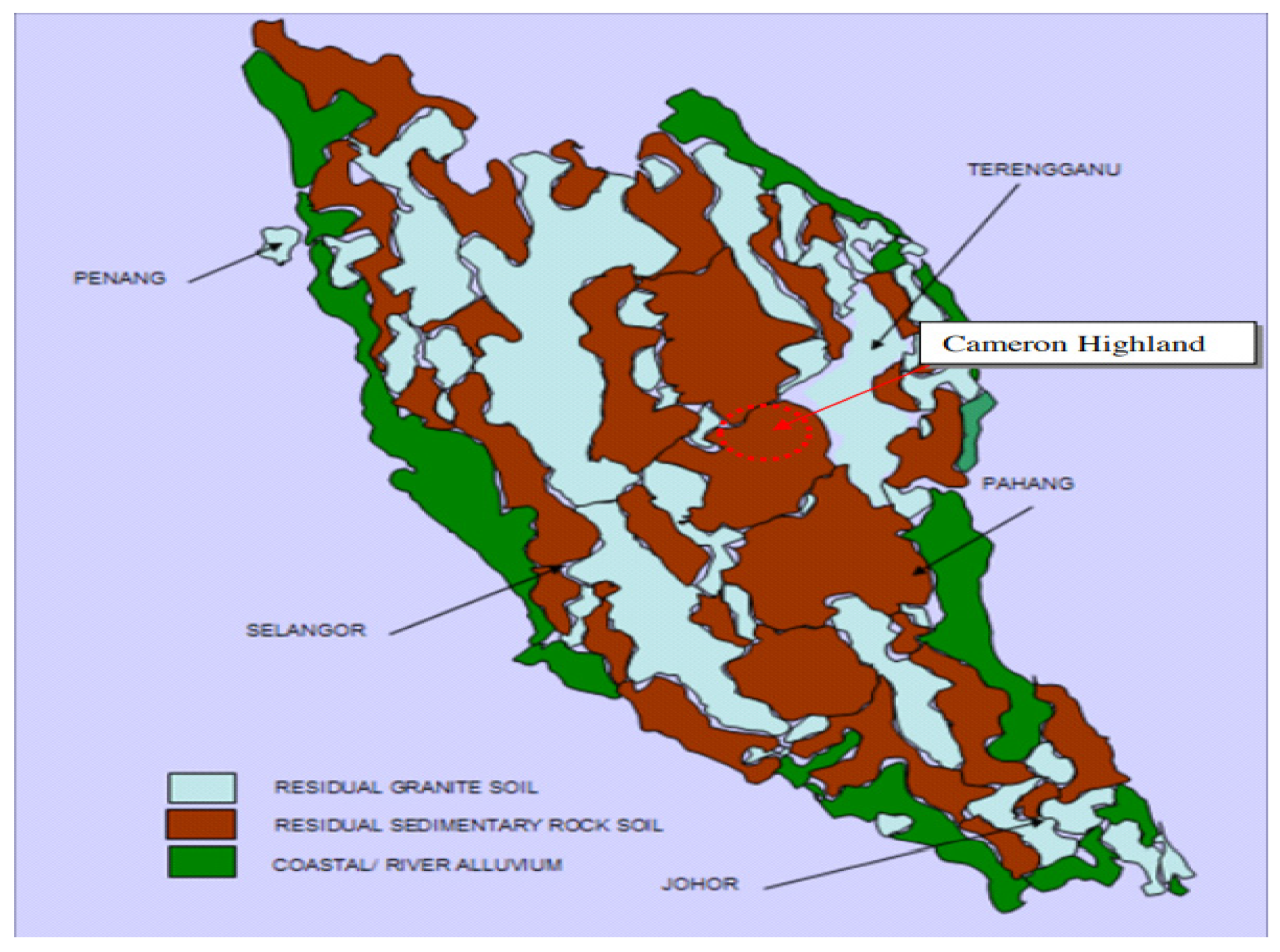

2.1.1. Granitic Residual Soil (GRS)

2.1.2. Pineapple (PA) Fibre

2.1.3. Hydrated Lime (HL)

2.2. Sample Preparation

2.3. Experimental Method

2.3.1. Particle Size Distribution

2.3.2. Moisture Content

2.3.3. Atterberg Limits

2.3.4. Compaction Test

2.3.5. Specific Gravity

2.3.6. Unconfined Compressive Strength (UCS)

3. Data Collection

3.1. Result and Discussion

3.1.1. Grain Size Distribution

3.1.2. Laboratory Determination of Water (Moisture) Content

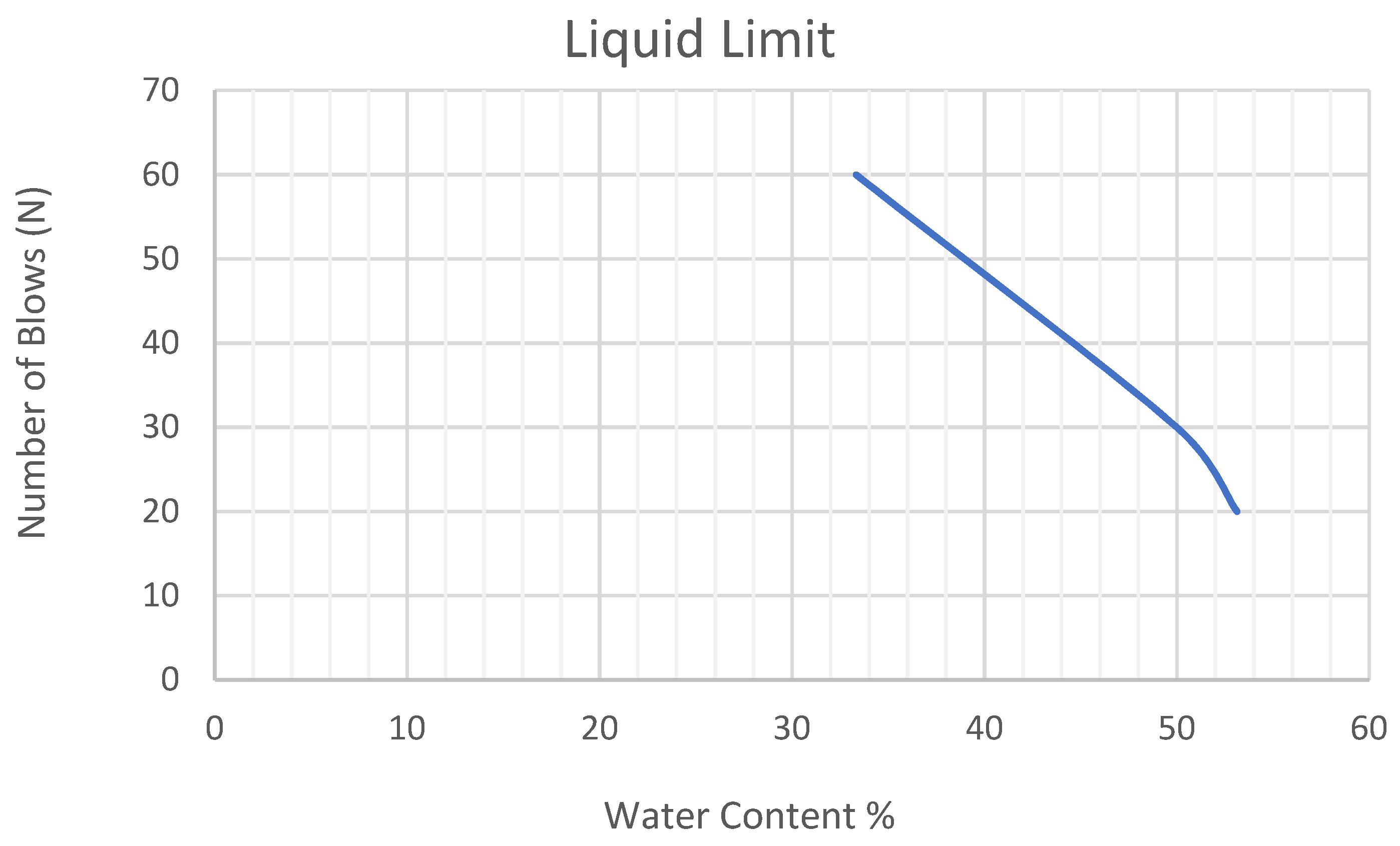

3.1.3. Atterberg’s Limit

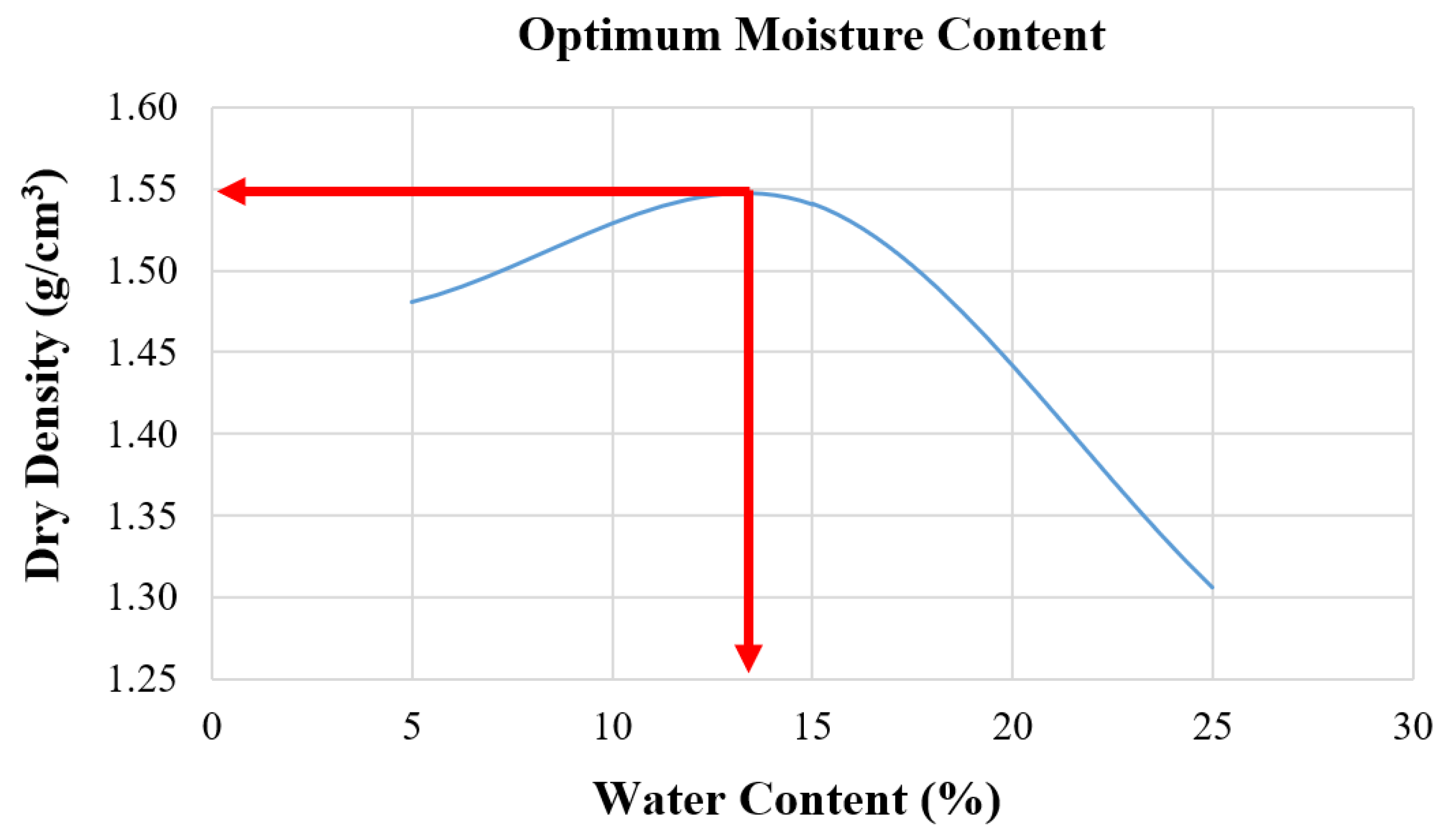

3.1.4. Compaction Test

3.1.5. Specific Gravity

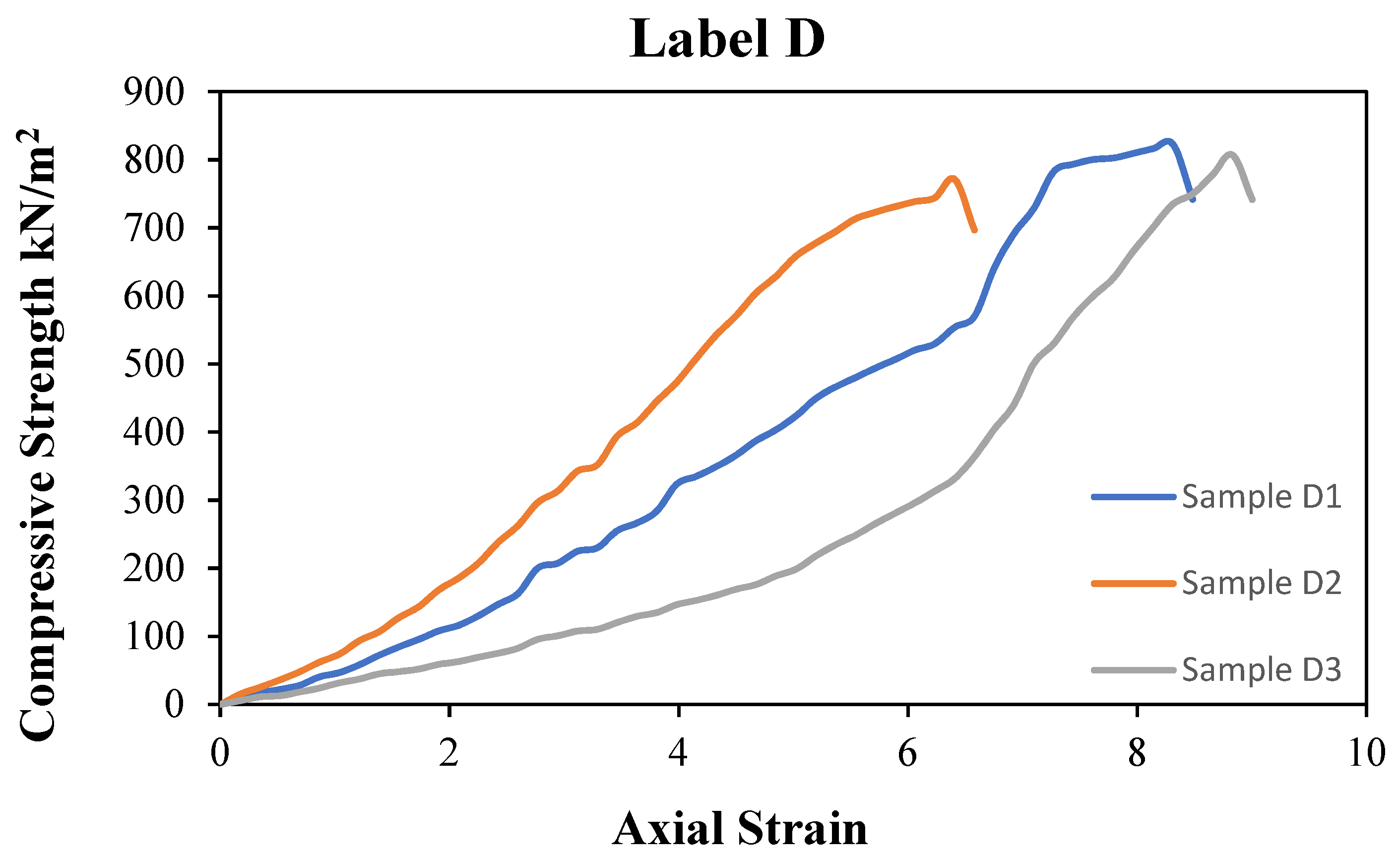

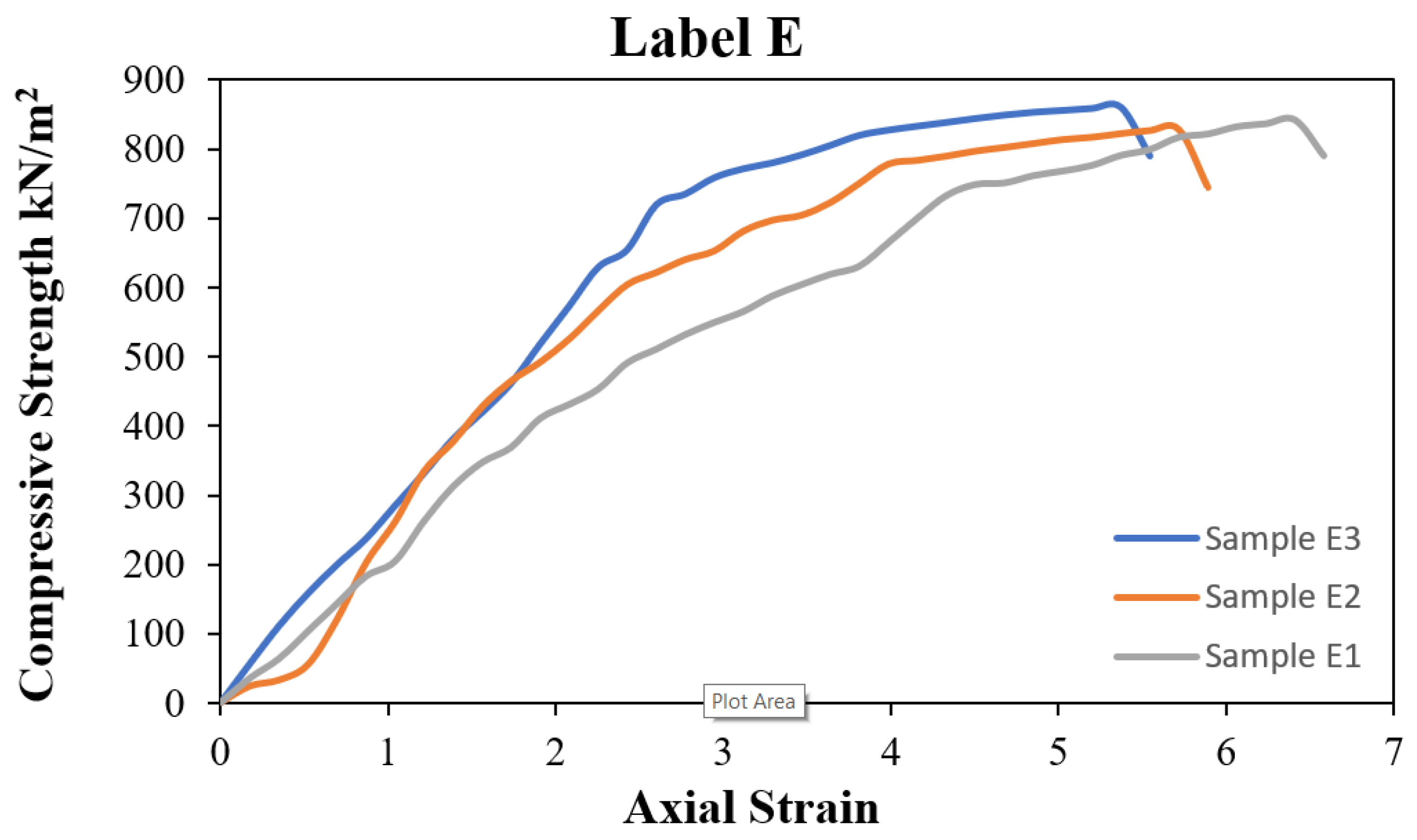

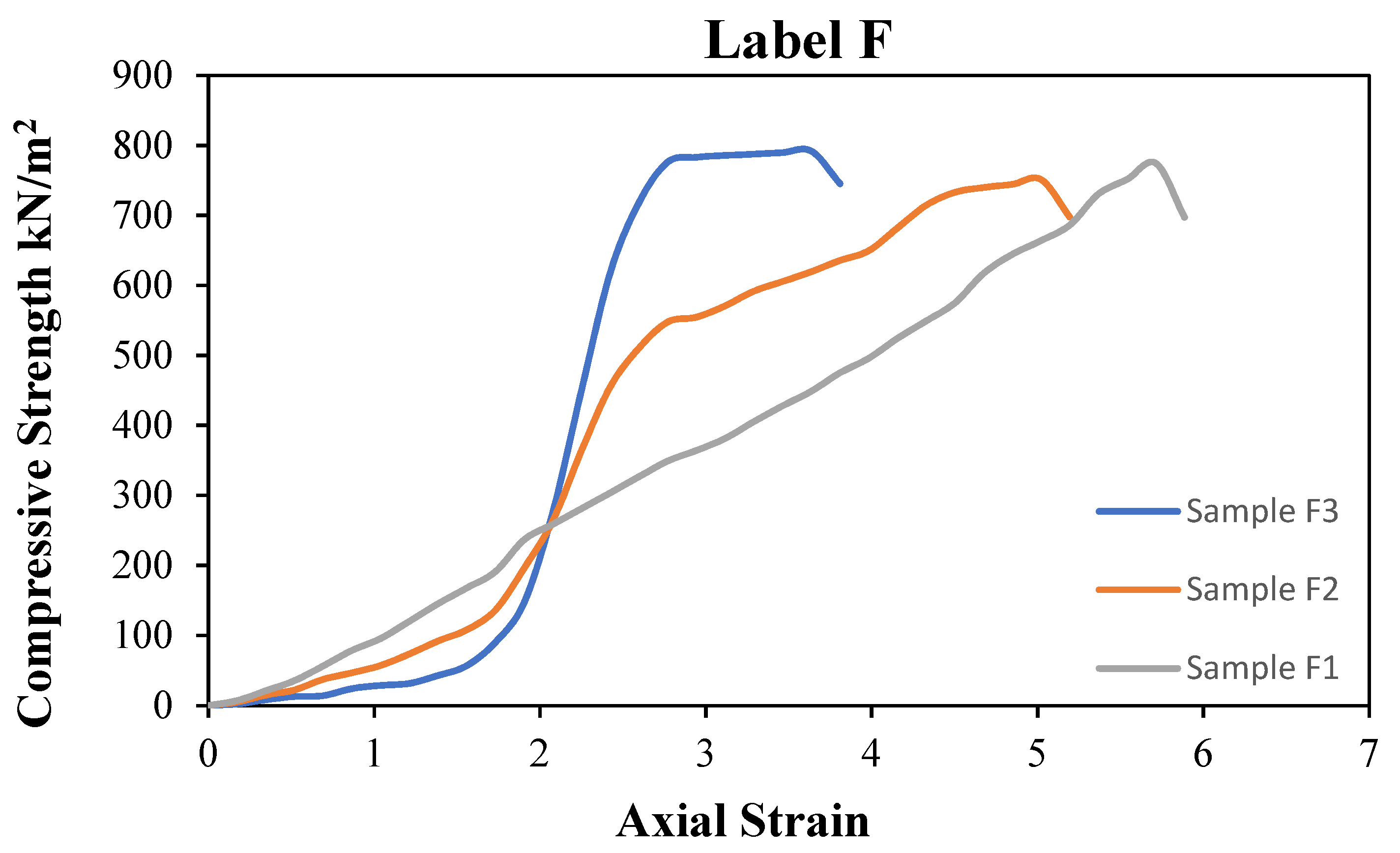

3.1.6. Unconfined Compressive Strength (UCS) Test

4. Conclusions

- The studied soil was classed as well-graded sand soil, based on the particle size distribution results and discussion.

- The moisture content of GRS was measured and the average moisture content for the test soil was 9.44%.

- The liquid and plastic limits of the Atterberg limits were determined for the tested soil. The liquid limit was 51.8%, while the plastic limit was 14.1%.

- The compaction test was conducted to evaluate the optimal moisture content and density for the tested soil, with the findings revealing a maximum dry density of 1.55 and a maximum optimum moisture content of 13.5%.

- The specific gravity of the tested soil was determined, and the result showed that the average specific gravity of the sample was 2.37.

- The compressive strength was greatly improved by combining soil with HL and PA. The resulting UCS showed that 0 curing days increased strength by 31% while 7 curing days increased strength by 26% before decreasing the strength by 8.4% to 9%.

- Natural fibre-based composites are eco-friendly and have the advantages of continuous supply, easy and safe handling and being biodegradable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saffari, P.; Nie, W.; Noor, M.J.; Zhang, X.; Liang, Q. Characterization the GEOTECHNICAL properties of a Malaysian Granitic RESIDUAL soil grade V. IOP Conf. Ser. Earth Environ. Sci. 2019, 289, 012006. [Google Scholar]

- Aishah Zarime, N. Leaching Behavior of Cadmium through Compacted Granitic Residual Soil Using Column Infiltration Test. EDP Sci. 2019, 101, 04002. [Google Scholar]

- Saffari, P.; Nie, W.; Noor, M.J.; Asadi, A.; Liu, J.; Zhang, X. Collapse behavior of unsaturated remolded granitic residual soil. Bull. Eng. Geol. Environ. 2020, 79, 3857–3868. [Google Scholar]

- Asmaa, G.S. Review on Granitic Residual Soils’ Geotechnical Properties. EJGE 2012, 11, 2645–2658. [Google Scholar]

- Amadi, A.A.; Okeiyi, A. Use of quick and hydrated lime in stabilization of lateritic soil: Comparative analysis of laboratory data. Int. J. Geo-Eng. 2017, 8, 119. [Google Scholar]

- Yusof, Z.M.; Mohamed, K.; Henry, O.M.; Yahya, N.A. Effects of hydrated lime-pond ash admixtures on the compaction characteristics of treated peat soils. Aust. J. Basic Appl. Sci. 2015, 9, 359–361. [Google Scholar]

- Mouillet, V.; Sejourne, D.; Delmotte, V.; Ritter, H.J.; Lesueur, D. Method of quantification of hydrated lime in asphalt mixtures. Constr. Build. Mater. 2014, 68, 348–354. [Google Scholar]

- Yusof, Z.M.; Harris, S.N.M.; Mohamed, K. Compressive strength improvement of stabilized peat Soil by pond ash-hydrated lime admixture. In Applied Mechanics and Materials Trans; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2015; Volume 747, pp. 242–245. [Google Scholar]

- Yusof, Z.M.; Mohamed, K. Strength of treated peat soil with pond ash-hydrated lime subjected to soaking time. Int.-Aided Civ. Infrastruct. Eng. 2015, 11, 319–329. [Google Scholar]

- Patel, A. Soil stabilization. In Geotechnical Investigations and Improvement of Ground Conditions; Woodhead Publishing: Sawston, UK, 2019; Volume 11, pp. 19–27. [Google Scholar]

- Taha, M.R.; Jamal, M.A.A. Performance of soil stabilized with carbon nanomaterials. Chem. Eng. Trans. 2018, 63, 124. [Google Scholar]

- Thomas, S.R.P.; Abhijith, R.; Joseph, A.; Unnikrishnan, V. Improvement in Shear Strength of Soil Reinforced with Pineapple Fibre. Int. Res. J. Eng. Technol. 2018, 5, 1827–1829. [Google Scholar]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.R.; Hoque, M.E. A review on pineapple leaves fibre and its composites. Int. J. Polym. Sci. 2015, 16, 1415. [Google Scholar]

- Yusof, Z.M. Strength characteristics of pond ash-hydrated lime admixture treated peat soil. IOP Conf. Ser. Mater. Sci. Eng. 2020, 932, 145. [Google Scholar]

- Jose, S.; Ammayappan, L.; Salim, R. An overview on production, properties, and value addition of pineapple leaf fibers (PALF). J. Nat. Fibers 2016, 13, 362–373. [Google Scholar]

- Parsons, R.L.; Milburn, J.P. Engineering behavior of stabilized soils. Transp. Res. Rec. J. Transp. Res. Board 2003, 1837, 20–29. [Google Scholar]

- Makusa, G.P. Soil Stabilization Methods and Materials in Engineering Practice; Luleå University of Technology: Luleå, Sweden, 2012. [Google Scholar]

- Mazlan, A.A.; Sultan, M.T.H.; Shah, A.U.M. The effect of different length of pineapple leaf fiber (PALF) of tensile properties of random oriented composites. Int. J. Recent Technol. Eng. 2019, 8, 15. [Google Scholar]

- Ko, Y.N.; Yusof, Z.M.; Surol, S.; Samsudin, N.S. Rice husk admixture’s effect on the compressive strength characteristics of Klang Valley’s clayey soil. AIP Conf. Proc. 2021, 2401, 20014. [Google Scholar]

- British Standard Method of Test—BS 1377 Methods of test for civil engineering purposes. In General Requirements and Sample Preparation; British Standard Institution: London, UK, 1990.

- Hadi, B.A.; Md Noor, M.J.; Ibrahim, A.; Ismail, B.N.; Ahmad, J.; Zakariah, Z. The effect of soaking on shear strength of a Malaysian granitic residual soil. IOP Conf. Ser. 2020, 476, 12049. [Google Scholar]

- Dang, L.; Hassan, H.A.; Fatahi, B.; Jones, R.; Khabbaz, H. Enhancing the engineering properties of expansive soil using bagasse ash and hydrated lime. Intern. J. GEOMATE 2016, 11, 2447–2454. [Google Scholar]

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar]

- Kassim, K.A.; Chern, K.K. Lime stabilized Malaysian cohesive soils. Malays. J. Civ. Eng. 2004, 16, 13–23. [Google Scholar]

- Ghobadi, M.H.; Abdilor, Y.; Babazadeh, R. Stabilization of clay soils using lime and effect of pH variations on shear strength parameters. Bull. Eng. Geol. Environ. 2014, 73, 611–619. [Google Scholar]

- Algaba, F. Tanzania Laboratory Testing Manual; Academia.edu.: San Francisco, CA, USA, 2020. [Google Scholar]

- Baalwy, H.A.; Yusof, Z.M.; Zain, N.H.M. Permeability of stabilised sandy soil using mixture of coir fibre-hydrated lime. AIP Conf. Proc. 2021, 2401, 20013. [Google Scholar]

- Yusof, Z.M.; Zain, N.H.M. Engineering properties of hydrated lime-pond ash treated peat soil. AIP Conf. Proc. 2021, 2401, 20012. [Google Scholar]

- Yusof, Z.M. Performance of Hydrated Lime-Pond Ash Treated Peat Soil. Ph.D. Thesis, MARA University of Technology, Shah Alam, Malaysia, 2018. [Google Scholar]

- Consoli, N.C.; Bittar Marin, E.J.; Quinonez Samaniego, R.A.; Heineck, K.S.; Johann, A.D.R. Use in sustainable binders in soil stabilization. J. Mater.Civ.Eng. 2019, 31, 6018023. [Google Scholar]

| Physical Properties | |

|---|---|

| Bulk density (kg/m3) | 400–600 |

| Specific gravity | 2.2–2.3 |

| Chemical Properties | |

| SiO2 | 1.8% |

| Al2O3 | 0.5% |

| CO2 | 2.5% |

| CaO | 72% |

| Type of Material | Standards Codes |

|---|---|

| HL | MS 850:1997 |

| PA fibre | - |

| GRS | BS 1377:1990 |

| Label | GRS % | HL % | PA % | Curing Days | |

|---|---|---|---|---|---|

| 0 | 7 | ||||

| No. of Samples | |||||

| A | 100 | - | - | 3 | - |

| B | 99.25 | - | 0.75 | 3 | - |

| C | 96.75 | 2.5 | 0.75 | - | 3 |

| D | 95.25 | 4.5 | 0.75 | - | 3 |

| E | 93 | 6.25 | 0.75 | - | 3 |

| F | 90.25 | 9 | 0.75 | - | 3 |

| Size Diameter (mm) | Percent Passing (%) |

|---|---|

| 3.35 | 87.33 |

| 2 | 69.81 |

| 1.18 | 51.89 |

| 0.6 | 34.27 |

| 0.425 | 28.14 |

| 0.3 | 23.39 |

| 0.212 | 19.93 |

| 0.15 | 17.86 |

| 0.063 | 8.36 |

| Label | Sample Content | Compressive Strength (kN/m2) (Average) | |

|---|---|---|---|

| Curing days | |||

| 0 | 7 | ||

| A | GRS only | 371 | - |

| B | GRS + 0.75% PA | 537 | - |

| C | GRS + 2.5HL + 0.75% PA | - | 591 |

| D | GRS + 4.5% HL + 0.75% PA | - | 800 |

| E | GRS + 6.25 HL + 0.75% PA | - | 843 |

| F | GRS + 9% HL + 0.75% PA | - | 772 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Md Yusof, Z.; Al-Adhami, A.M.Y.; Mohd Matore, M.E.E. Compressive Strength of Stabilised Granitic Residual Soil Using Mixture of Pineapple Fibre—Hydrated Lime. Sustainability 2022, 14, 3826. https://doi.org/10.3390/su14073826

Md Yusof Z, Al-Adhami AMY, Mohd Matore MEE. Compressive Strength of Stabilised Granitic Residual Soil Using Mixture of Pineapple Fibre—Hydrated Lime. Sustainability. 2022; 14(7):3826. https://doi.org/10.3390/su14073826

Chicago/Turabian StyleMd Yusof, Zeety, Abdullah Mahgoob Yahya Al-Adhami, and Mohd Effendi Ewan Mohd Matore. 2022. "Compressive Strength of Stabilised Granitic Residual Soil Using Mixture of Pineapple Fibre—Hydrated Lime" Sustainability 14, no. 7: 3826. https://doi.org/10.3390/su14073826

APA StyleMd Yusof, Z., Al-Adhami, A. M. Y., & Mohd Matore, M. E. E. (2022). Compressive Strength of Stabilised Granitic Residual Soil Using Mixture of Pineapple Fibre—Hydrated Lime. Sustainability, 14(7), 3826. https://doi.org/10.3390/su14073826