A Life Cycle Assessment of Organic and Chemical Fertilizers for Coffee Production to Evaluate Sustainability toward the Energy–Environment–Economic Nexus in Indonesia

Abstract

:1. Introduction

1.1. Sustainability Issue in the Global Market Demand

1.2. Coffee Production in Indonesia and its Sustainability Issue

1.3. Sustainability Measurement

1.4. Research Objective

2. Materials and Methods

2.1. Research Location and Object Studied

2.2. Work Procedure

2.2.1. Goal and Scope Definition

2.2.2. Data Collection and Life Cycle Inventory Analysis (LCI)

2.2.3. Sustainability Analysis

Energy Requirement Analysis

Life Cycle Impact Assessment (LCIA)

Life Cycle Cost Analysis (LCC)

2.2.4. Sustainability Interpretation

3. Result

3.1. Energy Requirement Analysis

3.2. Environmental Impact Assessment and Its Contributing Factors

3.2.1. Environmental Impact

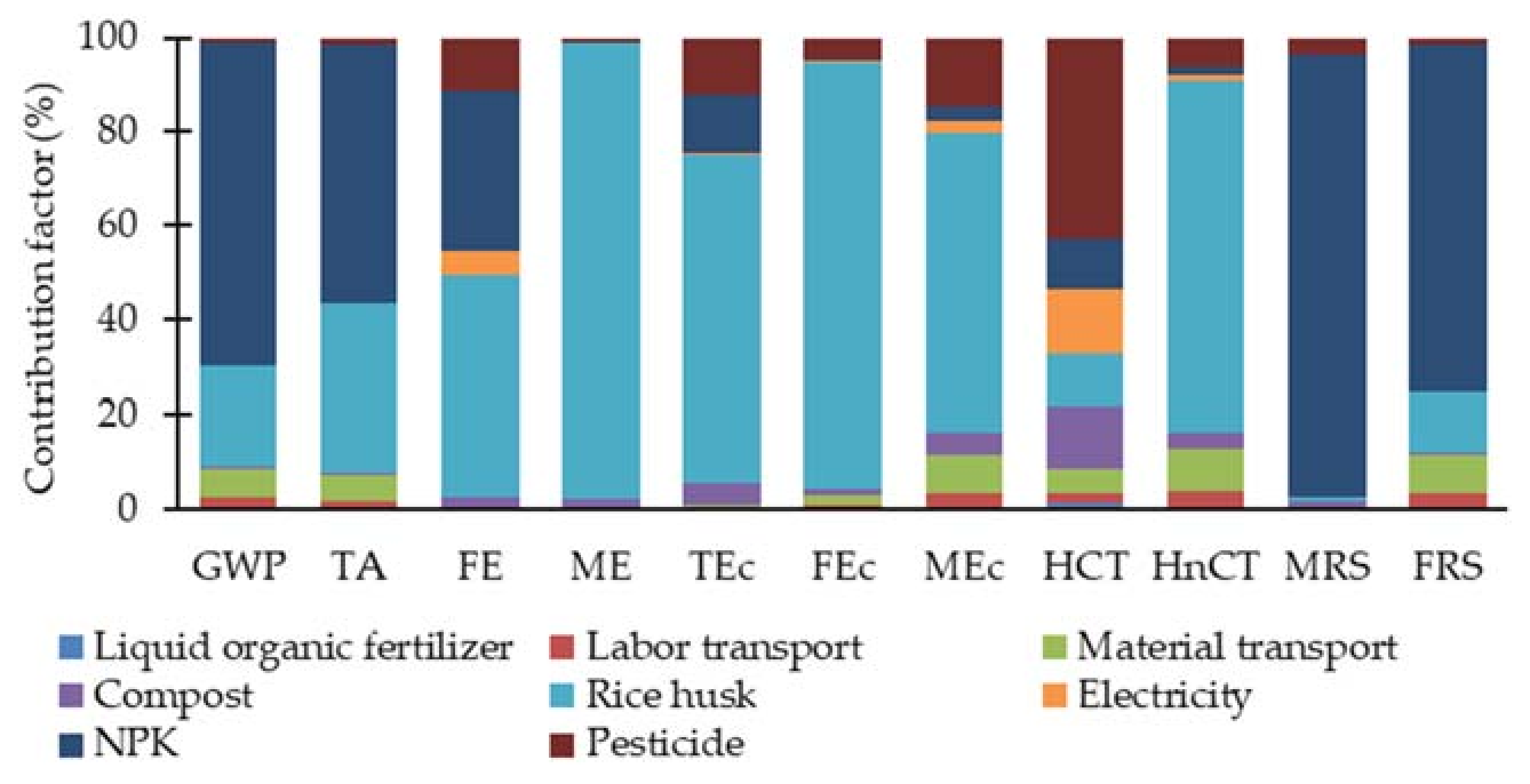

3.2.2. Contribution Factor of Environmental Impact

3.2.3. Sensitivity Analysis of Environmental Impact

3.3. Life Cycle Cost Analysis

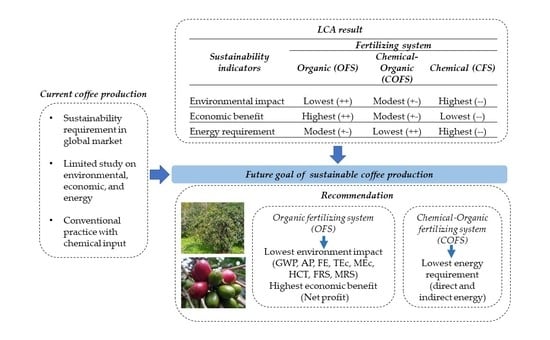

3.4. Sustainability Interpretation

4. Discussion

4.1. Energy, Environment, and Economic Hotspots and Its Strategies on Reducing the Negative Impact Factor

4.2. Future Challenges of the Green Coffee Plantation System

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| COFS | Chemical-Organic fertilizing system | kg | Kilogram |

| CFS | Chemical fertilizing system | LCA | Life cycle assessment |

| d | day | LCC | Life cycle costing |

| DCB | Dichlorobenzene | ME | Marine eutrophication |

| EF | Energy factor | MEc | Marine ecotoxicity |

| EI | Environmental impact | MRS | Mineral resource scarcity |

| FE | Freshwater eutrophication | n | Number of input system |

| FEc | Freshwater ecotoxicity | OFS | Organic fertilizing system |

| FRS | Fossil resource scarcity | TA | Terrestrial acidification |

| GWP | Global warming potential | TE | Terrestrial ecotoxicity |

| h | hour | TLCC | Total life cycle cost |

| HCT | Human carcinogenic toxicity | USD | United States Dollar |

| HnCT | Human non-carcinogenic toxicity | y | year |

| IDR | Indonesia Rupiah |

Appendix A

| Input Energy | Fertilizing System | ||

|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |

| Energy Requirement (MJ kg−1) | |||

| Direct energy | |||

| Gasoline | 0.34 | 0.29 | 0.6 |

| Electricity | 0.0031 | 0.0027 | 0.006 |

| Indirect energy | |||

| Poultry manure | 5.47 | 2.35 | 0.3 |

| Compost | 0.16 | 0.16 | 0.35 |

| Liquid organic fertilizer | 0.003 | 0.003 | 0.006 |

| Rice husk | 0.43 | 0.38 | 0.86 |

| Water | 1.1 | 0.97 | 2.2 |

| NPK | - | 1.64 | 4.97 |

| Pesticide | - | 0.044 | 0.455 |

| Human Labor | 0.39 | 0.36 | 0.57 |

| Total | 7.92 | 6.19 | 10.35 |

| Impact Category | Unit | Fertilizing System | ||

|---|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | ||

| Global warming potential (GWP) | kg CO2 eq kg−1 | 0.0678 | 0.182 | 0.496 |

| Terrestrial acidification (TA) | kg SO2 eq kg−1 | 0.0005 | 0.00096 | 0.00254 |

| Freshwater eutrophication (FE) | kg P eq kg−1 | 0.0000049 | 0.000008 | 0.000023 |

| Marine eutrophication (ME) | kg N eq kg−1 | 0.000059 | 0.000053 | 0.00012 |

| Terrestrial ecotoxicity (TEc) | kg 1,4-DCB kg−1 | 0.0564 | 0.0655 | 0.1819 |

| Freshwater ecotoxicity (FEc) | kg 1,4-DCB kg−1 | 0.0031 | 0.0028 | 0.00678 |

| Marine ecotoxicity (MEc) | kg 1,4-DCB kg−1 | 0.00096 | 0.00098 | 0.0026 |

| Human carcinogenic toxicity (HCT) | kg 1,4-DCB kg−1 | 0.000085 | 0.00015 | 0.00056 |

| Human non-carcinogenic toxicity (HnCT) | kg 1,4-DCB kg−1 | 0.0378 | 0.0345 | 0.0804 |

| Mineral resource scarcity (MRS) | kg Cu eq kg−1 | 0.000039 | 0.00149 | 0.0046 |

| Fossil resource scarcity (FRS) | kg oil eq kg−1 | 0.014 | 0.043 | 0.118 |

| Activities | Detail Activities | Working Days (d) | Working Hour per Day (h) | Total Labor (Person) | Subtotal (h y−1) | Total Working Hour (h) | Contribution Percentage (%) |

|---|---|---|---|---|---|---|---|

| Seeding | Preparation | 2 | 8 | 2 | 32 | 32 | 0.47 |

| Maintenance | 42 | 1 | 2 | 84 | 84 | 1.23 | |

| Nursery | Preparation | 5 | 8 | 2 | 80 | 80 | 1.18 |

| Maintenance | 240 | 1 | 1 | 240 | 240 | 3.53 | |

| Planting | Planting | 30 | 8 | 2 | 480 | 480 | 7.05 |

| Subtotal at 1st year | 916 | 916 | 13.46 | ||||

| Maintenance in pre-productive stage | Clearing | 6 | 8 | 2 | 96 | 192 | 2.82 |

| Pruning | 1 | 8 | 2 | 16 | 32 | 0.47 | |

| Fertilizing | 3 | 8 | 2 | 48 | 96 | 1.41 | |

| Subtotal 2nd–3rd year | 160 | 320 | 4.70 | ||||

| Maintenance in productive stage and harvesting | Clearing | 6 | 8 | 2 | 96 | 576 | 8.47 |

| Pruning | 1 | 8 | 2 | 16 | 96 | 1.41 | |

| Fertilizing | 3 | 8 | 2 | 48 | 288 | 4.23 | |

| Harvesting | 24 | 4 | 8 | 768 | 4608 | 67.72 | |

| Subtotal at the 4–9th year | 928 | 5568 | 81.83 | ||||

| Total working hour | 6804 | 100 | |||||

| Activities | Detail Activities | Working Days (d) | Working Hour per Day (h) | Total Labor (Person) | Sub Total (h y−1) | Total Hour (h) | Contribution Percentage (%) |

|---|---|---|---|---|---|---|---|

| Seeding | Preparation | 2 | 8 | 2 | 32 | 32 | 0.47 |

| Maintenance | 42 | 1 | 2 | 84 | 84 | 1.22 | |

| Nursery | Preparation | 5 | 8 | 2 | 80 | 80 | 1.16 |

| Maintenance | 240 | 1 | 1 | 240 | 240 | 3.49 | |

| Planting | Planting | 30 | 8 | 2 | 480 | 480 | 6.99 |

| Subtotal at the 1st year | 916 | 916 | 13.34 | ||||

| Maintenance in pre-productive stage | Clearing | 1 | 8 | 2 | 16 | 32 | 0.47 |

| Pruning | 1 | 8 | 2 | 16 | 32 | 0.47 | |

| Fertilizing | 4 | 8 | 2 | 64 | 128 | 1.86 | |

| Subtotal at the 2nd–3rd year | 96 | 192 | 2.8 | ||||

| Maintenance in productive stage and harvesting | Clearing | 1 | 8 | 2 | 16 | 96 | 1.4 |

| Pruning | 1 | 8 | 2 | 16 | 96 | 1.4 | |

| Fertilizing | 4 | 8 | 2 | 64 | 384 | 5.59 | |

| harvesting | 24 | 4 | 9 | 864 | 5184 | 75.48 | |

| Subtotal 4–9th | 960 | 5760 | 83.87 | ||||

| Total working hour | 6868 | 100 | |||||

| Activities | Detail Activities | Working Days (d) | Working Hour per Day (h) | Total Labor (Person) | Sub Total (h y−1) | Total Hour (h) | Contribution Percentage (%) |

|---|---|---|---|---|---|---|---|

| Seeding | Preparation | 2 | 8 | 2 | 32 | 32 | 0.84 |

| Maintenance | 42 | 1 | 2 | 84 | 84 | 2.21 | |

| Nursery | Preparation | 5 | 8 | 2 | 80 | 80 | 2.11 |

| Maintenance | 240 | 1 | 1 | 240 | 240 | 6.32 | |

| Planting | Planting | 30 | 8 | 2 | 480 | 480 | 12.64 |

| Subtotal at the 1st year | 916 | 916 | 24.13 | ||||

| Maintenance in pre-productive stage | Clearing | 1 | 8 | 2 | 16 | 32 | 0.84 |

| Pruning | 1 | 8 | 2 | 16 | 32 | 0.84 | |

| Fertilizing | 4 | 8 | 2 | 64 | 128 | 3.37 | |

| Subtotal at the 2nd–3rd year | 96 | 192 | 5.06 | ||||

| Maintenance in productive stage and harvesting | Clearing | 1 | 8 | 2 | 16 | 96 | 2.53 |

| Pruning | 1 | 8 | 2 | 16 | 96 | 2.53 | |

| Fertilizing | 2 | 8 | 2 | 32 | 192 | 5.06 | |

| Harvesting | 24 | 4 | 4 | 384 | 2304 | 60.7 | |

| Subtotal at the 4–9th year | 448 | 2688 | 70.81 | ||||

| Total working hour | 3796 | 100 | |||||

| Impact Category | Unit (×10−6) | Liquid Organic Fertilizer | Labor Transport | Material Transport | Compost | Rice Husk | Electricity |

|---|---|---|---|---|---|---|---|

| GWP | kg CO2 eq | 130.11 | 8328.0 | 14,280 | 1,290 | 43,071 | 299.92 |

| TA | kg SO2 eq | 0.89 | 31.99 | 65.87 | 7.08 | 387.10 | 1.04 |

| FE | kg P eq | 0.02 | - | - | 0.19 | 4.24 | 0.47 |

| ME | kg N eq | 0.14 | 0.04 | 0.07 | 1.08 | 58.02 | 0.03 |

| TEc | kg 1,4-DCB | 223.21 | 149.31 | 252.90 | 3598 | 51,293 | 369.36 |

| FEc | kg 1,4-DCB | 3.48 | 45.41 | 76.91 | 42.14 | 2880.05 | 20.68 |

| MEc | kg 1,4-DCB | 4.29 | 61.19 | 103.64 | 50.78 | 704.53 | 27.11 |

| HCT | kg 1,4-DCB | 2.02 | 6.31 | 10.68 | 21.98 | 19.40 | 23.88 |

| HnCT | kg 1,4-DCB | 60.83 | 2447 | 4145 | 1328 | 28,977 | 509.04 |

| MRS | kg Cu eq | 0.36 | - | - | 24.90 | 14.09 | 0.16 |

| FRS | kg oil eq | 9.17 | 2736.9 | 4635.8 | 125.7 | 6256.3 | 76.46 |

| Impact Category | Unit (×10−6) | NPK | Liquid Organic Fertilizer | Pesticide | Labor Transport | Material Transport | Compost | Rice Husk | Electricity |

|---|---|---|---|---|---|---|---|---|---|

| GWP | kg CO2 eq | 125,102 | 114.89 | 1694 | 4092 | 10,915 | 1146 | 38,260 | 264.05 |

| TA | kg SO2 eq | 528.26 | 0.78 | 12.74 | 15.72 | 50.35 | 6.29 | 343.85 | 0.92 |

| FE | kg P eq | 2.72 | 0.02 | 0.91 | - | - | 0.16 | 3.77 | 0.41 |

| ME | kg N eq | 0.13 | 0.12 | 0.51 | 0.02 | 0.06 | 0.96 | 51.53 | 0.03 |

| TEc | kg 1,4-DCB | 7999 | 197.10 | 7965 | 73.36 | 193.32 | 3196 | 45,563 | 325.18 |

| FEc | kg 1,4-DCB | 2.93 | 3.07 | 130.96 | 22.31 | 58.79 | 37.43 | 2558 | 18.20 |

| MEc | kg 1,4-DCB | 29.54 | 3.79 | 144.59 | 30.06 | 79.22 | 45.11 | 625.82 | 23.87 |

| HCT | kg 1,4-DCB | 16.19 | 1.78 | 65.07 | 3.10 | 8.17 | 19.52 | 17.23 | 21.02 |

| HnCT | kg 1,4-DCB | 506.23 | 53.71 | 2188 | 1202 | 3168 | 1179 | 25,740 | 448.16 |

| MRS | kg Cu eq | 1412 | 0.32 | 52.50 | - | - | 22.12 | 12.51 | 0.14 |

| FRS | kg oil eq | 31,746 | 8.10 | 578.41 | 1345 | 3544 | 111.66 | 5557 | 67.32 |

| Impact Category | Unit (×10−6) | NPK | Liquid Organic Fertilizer | Pesticide | Labor Transport | Material Transport | Compost | Rice Husk | Electricity |

|---|---|---|---|---|---|---|---|---|---|

| GWP | kg CO2 eq | 381,541 | 261.04 | 9627 | 9299 | 5368 | 2602 | 86,886 | 599.61 |

| TA | kg SO2 eq | 1611 | 1.78 | 72.37 | 35.72 | 24.76 | 14.29 | 780.87 | 2.09 |

| FE | kg P eq | 8.30 | 0.05 | 5.19 | - | - | 0.37 | 8.56 | 0.94 |

| ME | kg N eq | 0.39 | 0.28 | 2.88 | 0.05 | 0.03 | 2.17 | 117.03 | 0.06 |

| TEc | kg 1,4-DCB | 24,394 | 447.83 | 45,255 | 166.72 | 95.07 | 7257 | 103,472 | 738.43 |

| FEc | kg 1,4-DCB | 8.93 | 6.98 | 744.08 | 50.70 | 28.91 | 85.01 | 5810 | 41.34 |

| MEc | kg 1,4-DCB | 90.08 | 8.61 | 821.56 | 68.32 | 38.96 | 102.43 | 1421 | 54.20 |

| HCT | kg 1,4-DCB | 49.38 | 4.05 | 369.72 | 7.04 | 4.02 | 44.34 | 39.13 | 47.74 |

| HnCT | kg 1,4-DCB | 1544 | 122.04 | 12,430 | 2732 | 1558 | 2678 | 58,455 | 1018 |

| MRS | kg Cu eq | 4306 | 0.73 | 298.27 | - | - | 50.23 | 28.42 | 0.33 |

| FRS | kg oil eq | 96,821 | 18.40 | 3286 | 3056 | 1743 | 253.58 | 12,621 | 152.86 |

| Impact Category | Liquid Organic Fertilizer | Labor Transport | Material Transport | Compost | Rice Husk | Electricity |

|---|---|---|---|---|---|---|

| GWP | 0.19 | 12.6 | 21.19 | 1.91 | 63.90 | 0.44 |

| TA | 0.18 | 6.48 | 13.33 | 1.43 | 78.37 | 0.21 |

| FE | 0.48 | - | - | 3.77 | 86.19 | 9.56 |

| ME | 0.23 | 0.07 | 0.12 | 1.81 | 97.71 | 0.05 |

| TEc | 0.40 | 0.27 | 0.45 | 6.44 | 91.78 | 0.66 |

| FEc | 0.11 | 1.48 | 2.51 | 1.37 | 93.85 | 0.67 |

| MEc | 0.45 | 6.43 | 10.9 | 5.34 | 74.04 | 2.85 |

| HCT | 2.39 | 7.48 | 12.7 | 26.1 | 23.02 | 28.3 |

| HnCT | 0.16 | 6.53 | 11.1 | 3.54 | 77.34 | 1.36 |

| MRS | 0.92 | - | - | 63.0 | 35.65 | 0.42 |

| FRS | 0.07 | 19.7 | 33.5 | 0.91 | 45.20 | 0.55 |

| Impact Category | NPK | Liquid Organic Fertilizer | Pesticide | Labor Transport | Material Transport | Compost | Rice Husk | Electricity |

|---|---|---|---|---|---|---|---|---|

| GWP | 68.89 | 0.06 | 0.93 | 2.25 | 6.01 | 0.63 | 21.07 | 0.15 |

| TA | 55.09 | 0.08 | 1.33 | 1.64 | 5.25 | 0.66 | 35.86 | 0.10 |

| FE | 34.00 | 0.26 | 11.40 | - | - | 2.06 | 47.09 | 5.18 |

| ME | 0.24 | 0.23 | 0.95 | 0.04 | 0.10 | 1.79 | 96.60 | 0.05 |

| TEc | 12.21 | 0.30 | 12.16 | 0.11 | 0.30 | 4.88 | 69.55 | 0.50 |

| FEc | 0.10 | 0.11 | 4.62 | 0.79 | 2.08 | 1.32 | 90.34 | 0.64 |

| MEc | 3.01 | 0.39 | 14.72 | 3.06 | 8.07 | 4.59 | 63.73 | 2.43 |

| HCT | 10.65 | 1.17 | 42.79 | 2.04 | 5.37 | 12.84 | 11.33 | 13.82 |

| HnCT | 1.47 | 0.16 | 6.34 | 3.49 | 9.19 | 3.42 | 74.64 | 1.30 |

| MRS | 94.16 | 0.02 | 3.50 | - | - | 1.48 | 0.83 | 0.01 |

| FRS | 73.90 | 0.02 | 1.35 | 3.13 | 8.25 | 0.26 | 12.94 | 0.16 |

| Impact Category | NPK | Liquid Organic Fertilizer | Pesticide | Labor Transport | Material Transport | Compost | Rice Husk | Electricity |

|---|---|---|---|---|---|---|---|---|

| GWP | 76.89 | 0.053 | 1.94 | 1.87 | 1.08 | 0.52 | 17.51 | 0.12 |

| TA | 63.35 | - | 2.85 | 1.405 | 0.97 | 0.56 | 30.7 | 0.08 |

| FE | 35.45 | 0.2 | 22.15 | - | - | 1.59 | 36.56 | 4.02 |

| ME | 0.32 | 0.225 | 2.34 | 0.039 | 0.02 | 1.76 | 95.23 | 0.047 |

| TEc | 13.41 | 0.24 | 24.89 | 0.09 | 0.05 | 3.99 | 56.9 | 0.4 |

| FEc | 0.13 | 0.1 | 10.98 | 0.75 | 0.43 | 1.25 | 85.74 | 0.61 |

| MEc | 3.45 | 0.33 | 31.53 | 2.62 | 1.49 | 3.93 | 54.55 | 2.08 |

| HCT | 8.73 | 0.71 | 65.39 | 1.246 | 0.71 | 7.84 | 6.92 | 8.44 |

| HnCT | 1.91 | 0.15 | 15.43 | 3.39 | 1.93 | 3.32 | 72.58 | 1.26 |

| MRS | 91.93 | 0.015 | 6.37 | - | - | 1.07 | 0.607 | 0.007 |

| FRS | 82.08 | 0.016 | 2.78 | 2.59 | 1.47 | 0.21 | 10.7 | 0.13 |

| Impact Category | Unit | Potential Decrease or Increase | Percentage Decrease or Increase (%) | ||||

|---|---|---|---|---|---|---|---|

| OFS vs. CFS | OFS vs. CFS | COFS vs. CFS | OFS vs. COFS | OFS vs. COFS | COFS vs. CFS | ||

| GWP | kg CO2 eq | −0.114 | −0.428 | −0.314 | −62.6 | −86.3 | −63.4 |

| TA | kg SO2 eq | −0.00046 | −0.00204 | −0.00158 | −48.1 | −80.4 | −62.3 |

| FE | kg P eq | −3.1E-06 | −0.000018 | −0.000015 | −38.8 | −78.7 | −65.2 |

| ME | kg N eq | 0.000006 | −0.000064 | −0.00007 | 11.3 | −52 | −56.9 |

| TEc | kg 1,4-DCB | −0.009 | −0.126 | −0.116 | −13.9 | −69 | −64 |

| FEc | kg 1,4-DCB | 0.0003 | −0.0037 | −0.0039 | 9.3 | −54.3 | −58.2 |

| MEc | kg 1,4-DCB | −0.00002 | −0.00164 | −0.00162 | −2.4 | −63.2 | −62.3 |

| HCT | kg 1,4-DCB | −0.000067 | −0.00048 | −0.00041 | −44.4 | −85 | −73.1 |

| HnCT | kg 1,4-DCB | 0.0033 | −0.0427 | −0.046 | 9.5 | −53.1 | −57.1 |

| MRS | kg Cu eq | −0.0015 | −0.0046 | −0.0032 | −97.4 | −99.2 | −68 |

| FRS | kg oil eq | −0.029 | −0.104 | −0.075 | −67.6 | −88.2 | −63.5 |

| Item of Cost | Fertilizing System | ||

|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |

| Fixed cost | |||

| Equipment | 17.35 | 17.35 | 17.35 |

| Device maintenance | 249.85 | 249.85 | 249.85 |

| Variable cost | |||

| Human labor cost | 4577.79 | 4638.87 | 2517.92 |

| NPK | - | 990.64 | 1329 |

| Rent transportation | 1811.41 | 1894.69 | 1728.12 |

| Compost | 180.45 | 180.45 | 180.45 |

| Manure | 2025.44 | 1031.60 | 54.41 |

| Polybag | 19.09 | 19.09 | 19.09 |

| Rice Husk | 45.11 | 45.11 | 45.11 |

| Seed | 10.41 | 10.41 | 10.41 |

| Pesticide | - | 6.25 | 24.98 |

| Total cost | 8936.90 | 9084.31 | 6176.69 |

| Item of Cost | Cost per kg (USD) | Percentage (%) | ||||

|---|---|---|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |

| Fixed cost | ||||||

| Equipment | 0.0004 | 0.0003 | 0.0008 | 0.19 | 0.19 | 0.28 |

| Device maintenance | 0.006 | 0.005 | 0.011 | 2.8 | 2.75 | 4.05 |

| Variable cost | ||||||

| Labor | 0.104 | 0.093 | 0.114 | 51.22 | 51.06 | 40.76 |

| NPK | - | 0.02 | 0.06 | - | 10.9 | 21.52 |

| Transportation | 0.04 | 0.04 | 0.08 | 20.27 | 20.86 | 27.98 |

| Compost | 0.004 | 0.004 | 0.008 | 2.02 | 1.99 | 2.92 |

| Manure | 0.046 | 0.021 | 0.002 | 22.66 | 11.36 | 0.88 |

| Polybag | 0.0004 | 0.0004 | 0.001 | 0.21 | 0.21 | 0.31 |

| Rice Husk | 0.001 | 0.001 | 0.002 | 0.5 | 0.5 | 0.73 |

| Seed | 0.0002 | 0.0002 | 0.0005 | 0.12 | 0.11 | 0.17 |

| Pesticide | - | 0.0001 | 0.0011 | 0 | 0.07 | 0.4 |

| Total cost | 0.203 | 0.182 | 0.28 | 100 | 100 | 100 |

| Fertilizing Systems | Coffee Cherry Bean Production (kg) | Emission per Kilogram Coffee Cherry Bean (kg CO2 eq kg−1) | Emission Tax (USD t−1) | Total Emission (USD ha−1) |

|---|---|---|---|---|

| Organic (OFS) | 44,000 | 0.068 | 9.7 | 29.07 |

| Chemical-Organic (COFS) | 50,000 | 0.182 | 9.7 | 88.42 |

| Chemical (CFS) | 22,000 | 0.496 | 9.7 | 106.03 |

| Fertilizing Systems | Coffee Cherry Bean Production (kg ha−1) | Selling Price (USD kg−1) | Revenue (USD ha−1) | Net Profit (USD ha−1) |

|---|---|---|---|---|

| Organic (OFS) | 44,000 | 0.69 | 30,537 | 21,571 |

| Chemical-Organic (COFS) | 50,000 | 0.59 | 29,496 | 20,323 |

| Chemical (CFS) | 22,000 | 0.59 | 12,978 | 6695 |

| Item of Cost | Fertilizing System | ||

|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |

| Percentage (%) | |||

| Fixed cost | |||

| Equipment | 0.19 | 0.19 | 0.28 |

| Device maintenance | 2.8 | 2.75 | 4.05 |

| Variable cost | |||

| Human labor cost | 51.22 | 51.06 | 40.76 |

| Fertilizer (NPK) | - | 10.9 | 21.52 |

| Rent transportation | 20.27 | 20.86 | 27.98 |

| Compost | 2.02 | 1.99 | 2.92 |

| Manure | 22.66 | 11.36 | 0.88 |

| Polybag | 0.21 | 0.21 | 0.31 |

| Rice Husk | 0.5 | 0.5 | 0.73 |

| Seed | 0.12 | 0.11 | 0.17 |

| Pesticide | - | 0.07 | 0.4 |

| Total | 100 | 100 | 100 |

| Input Energy | Fertilizing System | ||

|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |

| Energy Requirement (×103 MJ ha−1) | |||

| Direct energy | |||

| Electricity | 0.13 | 0.13 | 0.13 |

| Gasoline | 15.14 | 14.32 | 13.22 |

| Direct energy | |||

| Poultry manure | 240.77 | 117.48 | 6.6 |

| Compost | 7.8 | 7.8 | 7.8 |

| Liquid organic fertilizer | 0.14 | 0.14 | 0.14 |

| Rice husk | 18.98 | 18.98 | 18.98 |

| Water | 48.42 | 48.42 | 48.42 |

| NPK | - | 81.91 | 109.92 |

| Pesticide | - | 2.22 | 10.01 |

| HUman labor | 12.93 | 13.1 | 7.11 |

| Total | 344.31 | 304.51 | 222.34 |

| Stage | Fertilizing System | ||

|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |

| Energy per Hectare (×103 MJ ha−1) | |||

| Seeding | 2.92 | 2.92 | 2.92 |

| Nursery | 76.95 | 77.03 | 77.11 |

| Planting | 5.68 | 5.68 | 5.68 |

| Maintenance 1 | 54.32 | 49.41 | 27.44 |

| Maintenance 2 | 185.92 | 149.76 | 94.97 |

| Harvesting | 18.53 | 19.71 | 14.22 |

| Total | 344.31 | 304.51 | 222.34 |

References

- Li, M.; Fu, Q.; Singh, V.P.; Liu, D.; Li, T.; Li, J. Sustainable management of land, water, and fertilizer for rice production considering footprint family assessment in a random environment. J. Clean. Prod. 2020, 258, 120785. [Google Scholar] [CrossRef]

- Al-Mansour, F.; Jejcic, V. A model calculation of the carbon footprint of agricultural products: The case of Slovenia. Energy 2017, 136, 7–15. [Google Scholar] [CrossRef]

- Amini, S.; Rohani, A.; Aghkhani, M.H.; Abbaspour-Fard, M.H.; Asgharipour, M.R. Sustainability assessment of rice production systems in Mazandaran Province, Iran with emergy analysis and fuzzy logic. Sustain. Energy Technol. Assess. 2020, 40, 100744. [Google Scholar] [CrossRef]

- Fiore, M.; Spada, A.; Contò, F.; Pellegrini, G. GHG and cattle farming: CO-assessing the emissions and economic performances in Italy. J. Clean. Prod. 2018, 172, 3704–3712. [Google Scholar] [CrossRef]

- Nowak, A.; Krukowski, A.; Różańska-Boczula, M. Assessment of sustainability in agriculture of the European Union countries. Agronomy 2019, 9, 890. [Google Scholar] [CrossRef] [Green Version]

- Troiano, S.; Novelli, V.; Geatti, P.; Marangon, F.; Ceccon, L. Assessment of the sustainability of wild rocket (Diplotaxis tenuifolia) production: Application of a multi-criteria method to different farming systems in the province of Udine. Ecol. Indic. 2019, 97, 301–310. [Google Scholar] [CrossRef]

- Vinyes, E.; Asin, L.; Alegre, S.; Muñoz, P.; Boschmonart, J.; Gasol, C.M. Life Cycle Assessment of apple and peach production, distribution and consumption in Mediterranean fruit sector. J. Clean. Prod. 2017, 149, 313–320. [Google Scholar] [CrossRef]

- Joyce, A.; Paquin, R.L. The triple layered business model canvas: A tool to design more sustainable business models. J. Clean. Prod. 2016, 135, 1474–1486. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, M.; Zhang, H.; Jiang, Z.; Liu, C.; Cai, W. A review on energy, environment and economic assessment in remanufacturing based on life cycle assessment method. J. Clean. Prod. 2020, 255, 120160. [Google Scholar] [CrossRef]

- United Nation. Sustainable Development Goals. 2015. Available online: https://sdgs.un.org/goals. (accessed on 16 March 2022).

- Olabi, A.G.; Obaideen, K.; Elsaid, K.; Wilberforce, T.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Assessment of the pre-combustion carbon capture contribution into sustainable development goals SDGs using novel indicators. Renew. Sustain. Energy Rev. 2021, 153, 111710. [Google Scholar] [CrossRef]

- International Coffee Organization (ICO). World Coffee Consumption. 2021. Available online: https://ico.org/prices/new-consumption-table.pdf (accessed on 1 June 2021).

- Widaningsih, R.; Susanti, A.A.; Musyafak, A.; Putra, R.K.; Suyati, Y. Coffee Outlook Indonesia. Agriculture Data Information Center. Indonesia Agricultural Ministre. 2020. Available online: https://epublikasi.pertanian.go.id/arsip-outlook/75-outlook-perkebunan/723-outlook-kopi-2020 (accessed on 25 December 2020).

- Noponen, M.R.A.; Edwards-Jones, G.; Haggar, J.P.; Soto, G.; Attarzadeh, N.; Healey, J.R. Greenhouse gas emissions in coffee grown with differing input levels under conventional and organic management. Agric. Ecosyst. Environ. 2012, 151, 6–15. [Google Scholar] [CrossRef] [Green Version]

- Biernat-Jarka, A.; Trębska, P. The Importance of Organic Farming in the Context of Sustainable Development of Rural Areas in Poland. Acta Sci. Pol. Oecon. 2018, 17, 39–47. [Google Scholar] [CrossRef]

- Hassard, H.; Couch, M.; Techa-Erawan, T.; McLellan, B. Product carbon footprint and energy analysis of alternative coffee products in Japan. J. Clean. Prod. 2014, 73, 310–321. [Google Scholar] [CrossRef] [Green Version]

- Acosta-Alba, I.; Boissy, J.; Chia, E.; Andrieu, N. Integrating diversity of smallholder coffee cropping systems in environmental analysis. Int. J. Life Cycle Assess. 2019, 25, 252–266. [Google Scholar] [CrossRef] [Green Version]

- Jiménez-Ortega, A.D.; Ibarra, A.A.; Galeana-Pizaña, J.M.; Núñez, J.M. Changes over Time Matter: A Cycle of Participatory Sustainability Assessment of Organic Coffee in Chiapas, Mexico. Sustainability 2022, 14, 2012. [Google Scholar] [CrossRef]

- Coltro, L.; Mourad, A.; Oliveira, P.; Baddini, J.; Kletecke, R. Environmental Profile of Brazilian Green Coffee. Int. J. Life Cycle Assess. 2006, 11, 16–21. [Google Scholar] [CrossRef]

- Byrareddy, V.; Kouadio, L.; Mushtaq, S.; Stone, R. Sustainable Production of Robusta Coffee under a Changing Climate: A 10-Year Monitoring of Fertilizer Management in Coffee Farms in Vietnam and Indonesia. Agronomy 2019, 9, 499. [Google Scholar] [CrossRef] [Green Version]

- Neilson, J.; Wright, J.; Aklimawati, L. Geographical indications and value capture in the Indonesia coffee sector. J. Rural Stud. 2018, 59, 35–48. [Google Scholar] [CrossRef]

- Halog, A.; Manik, Y. Life Cycle Sustainability Assessments. Encycl. Inorg. Bioinorg. Chem. 2016, 25–41. [Google Scholar] [CrossRef]

- Dabkienė, V.; Baležentis, T.; Štreimikienė, D. Calculation of the carbon footprint for family farms using the Farm Accountancy Data Network: A case from Lithuania. J. Clean. Prod. 2020, 262, 121509. [Google Scholar] [CrossRef]

- Mancini, M.S.; Galli, A.; Niccolucci, V.; Lin, D.; Bastianoni, S.; Wackernagel, M.; Marchettini, N. Ecological Footprint: Refining the carbon Footprint calculation. Ecol. Indic. 2016, 61, 390–403. [Google Scholar] [CrossRef]

- González-Cencerrado, A.; Ranz, J.P.; Jiménez, M.T.L.-F.; Gajardo, B.R. Assessing the environmental benefit of a new fertilizer based on activated biochar applied to cereal crops. Sci. Total Environ. 2020, 711, 134668. [Google Scholar] [CrossRef] [PubMed]

- Putra, A.S.; Noguchi, R.; Ahamed, T.; Nakagawa-Izumi, A.; Ohi, H. Development of integrated oil palm empty fruit bunches (EFB)-based dissolving pulp and furfural production: A consequential LCA approach. Int. J. Life Cycle Assess. 2021, 26, 175–188. [Google Scholar] [CrossRef]

- International Coffee Organization (ICO). New ICO Study: Assessing the Economic Sustainability of Coffee Growing. 2016. Available online: https://ico.org/show_news.asp?id=567 (accessed on 10 March 2022).

- Bosona, T.; Gebresenbet, G.; Dyjakon, A. Implementing life cycle cost analysis methodology for evaluating agricultural pruning-to-energy initiatives. Bioresour. Technol. Rep. 2019, 6, 54–62. [Google Scholar] [CrossRef]

- Swarr, T.E.; Hunkeler, D.; Klöpffer, W.; Pesonen, H.-L.; Ciroth, A.; Brent, A.; Pagan, R. Environmental life-cycle costing: A code of practice. Int. J. Life Cycle Assess. 2011, 16, 389–391. [Google Scholar] [CrossRef]

- Wang, H.; Oguz, E.; Jeong, B.; Zhou, P. Life cycle cost and environmental impact analysis of ship hull maintenance strategies for a short route hybrid ferry. Ocean Eng. 2018, 161, 20–28. [Google Scholar] [CrossRef] [Green Version]

- Kamali, F.P.; van der Linden, A.; Meuwissen, M.P.; Malafaia, G.C.; Lansink, A.G.O.; de Boer, I.J. Environmental and economic performance of beef farming systems with different feeding strategies in southern Brazil. Agric. Syst. 2016, 146, 70–79. [Google Scholar] [CrossRef]

- Kizilaslan, H. Input–output energy analysis of cherries production in Tokat Province of Turkey. Appl. Energy 2009, 86, 1354–1358. [Google Scholar] [CrossRef]

- West Bandung Regency Profile. Medium-Term Investment Program Plan of West Bandung Regency. 2015. Available online: https://sippa.ciptakarya.pu.go.id/sippa_online/ws_file/dokumen/rpi2jm/DOCCRPIJM_3a3c8d3e3b_BAB%20IIBAB%202.pdf (accessed on 17 March 2022).

- Guo, J.H.; Liu, X.J.; Zhang, Y.; Shen, J.L.; Han, W.X.; Zhang, W.F.; Christie, P.; Goulding, K.W.T.; Vitousek, P.M.; Zhang, F.S. Significant Acidification in Major Chinese Croplands. Science 2010, 327, 1008–1010. [Google Scholar] [CrossRef] [Green Version]

- ISO 14040; Environmental Management E Life Cycle Assessment-Principles and Framework. International Standard Organization: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/37456.html?browse=tc (accessed on 22 February 2022).

- Vinyes, E.; Gasol, C.M.; Asin, L.; Alegre, S.; Muñoz, P. Life Cycle Assessment of multiyear peach production. J. Clean. Prod. 2015, 104, 68–79. [Google Scholar] [CrossRef] [Green Version]

- IOR Energy Pty Ltd-University of California, Berkeley. List of Common Conversion Factor. Available online: https://w.astro.berkeley.edu/~wright/fuel_energy.html (accessed on 25 December 2021).

- Kaab, A.; Sharifi, M.; Mobli, H.; Nabavi-Pelesaraei, A.; Chau, K.-W. Use of optimization techniques for energy use efficiency and environmental life cycle assessment modification in sugarcane production. Energy 2019, 181, 1298–1320. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Safarzadeh, D.; Ahmadi, E.; Nabavi-Pelesaraei, A.; Hosseinzadeh-Bandbafha, E. Applying data envelopment analysis to evaluation of energy efficiency and decreasing of greenhouse gas emissions of fattening farms. Energy 2017, 120, 652–662. [Google Scholar] [CrossRef]

- Unakitan, G.; Hurma, H.; Yilmaz, F. An analysis of energy use efficiency of canola production in Turkey. Energy 2010, 35, 3623–3627. [Google Scholar] [CrossRef]

- Ozkan, B.; Akcaoz, H.; Fert, C. Energy input–output analysis in Turkish agriculture. Renew. Energy 2004, 29, 39–51. [Google Scholar] [CrossRef]

- Avval, S.H.M.; Rafiee, S.; Sharifi, M.; Hosseinpour, S.; Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Application of multi-objective genetic algorithms for optimization of energy, economics and environmental life cycle assessment in oilseed production. J. Clean. Prod. 2017, 140, 804–815. [Google Scholar] [CrossRef]

- Rafiee, S.; Avval, S.H.M.; Mohammadi, A. Modeling and sensitivity analysis of energy inputs for apple production in Iran. Energy 2010, 35, 3301–3306. [Google Scholar] [CrossRef]

- Antizar-Ladislao, B.; Irvine, G.; Lamont, E.R. Energy from Waste: Reuse of Compost Heat as a Source of Renewable Energy. Int. J. Chem. Eng. 2010, 2010, 627930. [Google Scholar] [CrossRef] [Green Version]

- Zea, P.; Chilpe, J.; Sánchez, D.; Chica, E.J. Energy efficiency of smallholder commercial vegetable farms in Cuenca (Ecuador). Trop. Subtrop. Agroecosyst. 2020, 23, 1–8. [Google Scholar]

- McLaughlin, N.B.; Hiba, A.; Wall, G.J.; King, D.J. Comparison of energy inputs for inorganic fertilizer and manure based corn production. Can. Agric. Eng. 2000, 42, 9–18. [Google Scholar]

- Neira, D.P.; Montiel, M.S.; Fernández, X.S. Energy Analysis of Organic Farming in Andalusia (Spain). J. Sustain. Agric. 2012, 37, 231–256. [Google Scholar] [CrossRef]

- Pimentel, D.; Burgess, M. An Environmental, Energetic and Economic Comparison of Organic and Conventional Farming Systems. Integr. Pest Manag. 2014, 3, 141–166. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- OECD. Taxing Energy Use. Using Taxes for Climate Action. 2019. Available online: https://www.oecd.org/tax/tax-policy/brochure-taxing-energy-use-2019.pdf (accessed on 20 December 2021).

- Indonesian Bank. Statistics Economic and Finance in Indonesia. Available online: https://www.bi.go.id/en/statistic/informasi-kurs/transaksi-bi/Default.aspx. (accessed on 16 December 2021).

- Basavalingaiah, K.; Paramesh, V.; Parajuli, R.; Girisha, H.; Shivaprasad, M.; Vidyashree, G.; Thoma, G.; Hanumanthappa, M.; Yogesh, G.; Misra, S.D.; et al. Energy flow and life cycle impact assessment of coffee-pepper production systems: An evaluation of conventional, integrated and organic farms in India. Environ. Impact Assess. Rev. 2021, 92, 106687. [Google Scholar] [CrossRef]

- Guo, M.; Murphy, R. LCA data quality: Sensitivity and uncertainty analysis. Sci. Total Environ. 2012, 435–436, 230–243. [Google Scholar] [CrossRef] [PubMed]

| Particulars | Unit | Fertilizing System | ||

|---|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | ||

| Geographical information | ||||

| Elevation | MSAL * | 1200–1300 | ||

| Slope | Degree | 0–45 | ||

| Land area | ha | 25 | 480 | 5 |

| Input and Output | Unit | Fertilizing System | |||||

|---|---|---|---|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |||||

| Quantity | |||||||

| Input | |||||||

| Seeding | Gasoline | L ha−1 | 2 | 2 | 2 | ||

| Electricity | kWh ha−1 | 0.03 | 0.03 | 0.03 | |||

| Poultry manure | kg ha−1 | 100 | 100 | 100 | |||

| Compost | kg ha−1 | 100 | 100 | 100 | |||

| Liquid organic fertilizer | L ha−1 | 8 | 8 | 8 | |||

| Rice husk | kg ha−1 | 100 | 100 | 100 | |||

| Water | L ha−1 | 420 | 420 | 420 | |||

| Seed | kg ha−1 | 2 | 2 | 2 | |||

| Human labor | h ha−1 | 116 | 116 | 116 | |||

| Nursery | Gasoline | L ha−1 | 5 | 5 | 5 | ||

| Electricity | kWh ha−1 | 11.25 | 11.25 | 11.25 | |||

| Poultry manure | kg ha−1 | 2400 | 2400 | 2400 | |||

| Compost | kg ha−1 | 1200 | 1200 | 1200 | |||

| Liquid organic fertilizer | L ha−1 | 96 | 96 | 96 | |||

| Rice husk | kg ha−1 | 1200 | 1200 | 1200 | |||

| Water | L ha−1 | 48,000 | 48,000 | 48,000 | |||

| NPK |  | kg ha−1 | - | 0.93 | 1.83 | ||

| kg ha−1 | - | 0.93 | 1.83 | ||||

| kg ha−1 | - | 0.93 | 1.83 | ||||

| Human labor | h ha−1 | 320 | 320 | 320 | |||

| Planting | Gasoline | L ha−1 | 42 | 42 | 42 | ||

| Poultry manure | kg ha−1 | 2500 | 2500 | 2500 | |||

| Human labor | h ha−1 | 480 | 480 | 480 | |||

| Maintenance 1 1 | Gasoline | L ha−1 | 26 | 20 | 12 | ||

| (Pre-productive) | Poultry manure | kg ha−1 | 40,000 | 24,000 | - | ||

| NPK |  | kg ha−1 | - | 180 | 266.43 | ||

| kg ha−1 | - | 180 | 266.43 | ||||

| kg ha−1 | - | 180 | 266.43 | ||||

| Pesticide | L ha−1 | - | 3 | 12 | |||

| Human labor | h ha−1 | 320 | 192 | 128 | |||

| Maintenance 2 2 | Gasoline | L ha−1 | 78 | 60 | 36 | ||

| (Productive) | Poultry manure | kg ha−1 | 137,400 | 60,000 | - | ||

| NPK |  | kg ha−1 | - | 750 | 981 | ||

| kg ha−1 | - | 750 | 981 | ||||

| kg ha−1 | - | 750 | 981 | ||||

| Pesticide | L ha−1 | - | 5 | 24 | |||

| Human labor | h ha−1 | 960 | 576 | 384 | |||

| Harvesting 3 | Gasoline | L ha−1 | 288 | 288 | 288 | ||

| Human labor | h ha−1 | 4400 | 5000 | 2200 | |||

| Output | Coffee cherry bean | kg ha−1 | 44,000 | 50,000 | 22,000 | ||

| Input System | Unit | Energy Conversion Factor (MJ Unit−1) | References | |

|---|---|---|---|---|

| Gasoline | L | 34.2 | [37] | |

| Electricity | kWh | 11.93 | [38] | |

| Human labor | h | 1.96 | [39,40] | |

| Pesticide | L | 278 | [40] | |

| NPK |  | kg | 64.4 | [41] |

| kg | 12.44 | [42,43] | ||

| kg | 11.15 | [42,43] | ||

| Compost | kg | 6 | [44] | |

| Poultry manure | kg | 1.32 | [45,46,47] | |

| Water | L | 1 | [43,45] | |

| Liquid organic fertilizer | L | 1.32 | [45,46,47] | |

| Rice husk | kg | 14.6 | [48] | |

| Stage of Plantation | Input System | Fertilizing System | |||

|---|---|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |||

| Energy Requirement (×103 MJ ha−1) | |||||

| Seeding | Gasoline | 0.068 | 0.068 | 0.068 | |

| Electricity | 0.0004 | 0.0004 | 0.0004 | ||

| Poultry manure | 0.132 | 0.132 | 0.132 | ||

| Compost | 0.6 | 0.6 | 0.6 | ||

| Liquid organic fertilizer | 0.011 | 0.011 | 0.011 | ||

| Rice husk | 1.46 | 1.46 | 1.46 | ||

| Water | 0.42 | 0.42 | 0.42 | ||

| Seed | - | - | - | ||

| Human labor | 0.23 | 0.23 | 0.23 | ||

| Nursery | Gasoline | 0.17 | 0.17 | 0.17 | |

| Electricity | 0.13 | 0.13 | 0.13 | ||

| Poultry manure | 3.17 | 3.17 | 3.17 | ||

| Compost | 7.2 | 7.2 | 7.2 | ||

| Liquid organic fertilizer | 0.13 | 0.13 | 0.13 | ||

| Rice husk | 17.52 | 17.52 | 17.52 | ||

| Water | 48 | 48 | 48 | ||

| NPK |  | - | 0.06 | 0.12 | |

| - | 0.012 | 0.023 | |||

| - | 0.01 | 0.02 | |||

| Human labor | 0.63 | 0.63 | 0.63 | ||

| Planting | Gasoline | 1.44 | 1.44 | 1.44 | |

| Poultry manure | 3.3 | 3.3 | 3.3 | ||

| Human labor | 0.94 | 0.94 | 0.94 | ||

| Maintenance 1 1 | Gasoline | 0.89 | 0.68 | 0.41 | |

| Poultry manure | 52.8 | 31.68 | - | ||

| NPK |  | - | 11.59 | 17.16 | |

| - | 2.24 | 3.31 | |||

| - | 2 | 2.97 | |||

| Pesticide | - | 0.83 | 3.34 | ||

| Human labor | 0.63 | 0.38 | 0.25 | ||

| Maintenance 2 2 | Gasoline | 2.67 | 2.05 | 1.23 | |

| Poultry manure | 181.37 | 79.2 | - | ||

| NPK |  | - | 48.3 | 63.18 | |

| - | 9.33 | 12.2 | |||

| - | 8.36 | 10.94 | |||

| Pesticide | - | 1.39 | 6.67 | ||

| Human labor | 1.88 | 1.13 | 0.75 | ||

| Harvesting 3 | Gasoline | 9.91 | 9.91 | 9.91 | |

| Human labor | 8.62 | 9.8 | 4.31 | ||

| Total | 344.31 | 304.51 | 222.34 | ||

| Research | Boundary | Scenario | Environmental Impact (kg CO2 eq kg−1) |

|---|---|---|---|

| Martin R.A. Noponen, et al. [14] | Coffee cultivation in Costa Rica and Nicaragua with average annual coffee production since the second year of production | Conventional | 0.26–0.67 |

| Organic | 0.12–0.52 | ||

| Basavalingaiah, K., et al. [52] | Coffee-pepper in India in general | Conventional | 1.24 |

| Integrated | 1.07 | ||

| Organic | 0.27 | ||

| This study | Coffee cultivation in Indonesia in all life cycle of coffee cultivation from seeding until replanting | Organic (OFS) | 0.068 |

| Chemical-Organic (COFS) | 0.182 | ||

| Chemical (CFS) | 0.496 |

| Indicators | Unit | Fertilizing System | ||

|---|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | ||

| Production Cost | USD ha−1 | 8936 | 9084 | 6176 |

| USD kg−1 | 0.2031 | 0.1816 | 0.2800 | |

| Emission cost | USD ha−1 | 29.07 | 88.42 | 106.02 |

| USD kg−1 | 0.0006 | 0.0017 | 0.0048 | |

| Revenue | USD ha−1 | 30,537 | 29,496 | 12,978 |

| USD kg−1 | 0.69 | 0.59 | 0.59 | |

| Net profit | USD ha−1 | 21,571 | 20,330 | 6720 |

| USD kg−1 | 0.49 | 0.41 | 0.30 | |

| Category | Indicators | Unit | Fertilizing System | ||

|---|---|---|---|---|---|

| Organic (OFS) | Chemical-Organic (COFS) | Chemical (CFS) | |||

| Environmental Impact | GWP | kg CO2 eq kg−1 | 0.068 | 0.182 | 0.496 |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| TA | kg SO2 eq kg−1 | 0.0005 | 0.001 | 0.0025 | |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| FE | kg P eq kg−1 | 0.000005 | 0.000008 | 0.000023 | |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| Mec | kg N eq kg−1 | 0.00006 | 0.00005 | 0.00012 | |

| Modest (+−) | Lowest (++) | Highest (−−) | |||

| TEc | kg 1,4-DCB kg−1 | 0.056 | 0.066 | 0.182 | |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| Fec | kg 1,4-DCB kg−1 | 0.0031 | 0.0028 | 0.0068 | |

| Modest (+−) | Lowest (++) | Highest (−−) | |||

| MEc | kg 1,4-DCB kg−1 | 0.00096 | 0.00098 | 0.0026 | |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| HCT | kg 1,4-DCB kg−1 | 0.00008 | 0.00015 | 0.00057 | |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| HnCT | kg 1,4-DCB kg−1 | 0.038 | 0.034 | 0.08 | |

| Modest (+−) | Lowest (++) | Highest (−−) | |||

| MRS | kg 1,4-DCB kg−1 | 0.00004 | 0.0015 | 0.0047 | |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| FRS | kg 1,4-DCB kg−1 | 0.0139 | 0.043 | 0.1178 | |

| Lowest (++) | Modest (+−) | Highest (−−) | |||

| Economic benefit | Net profit | USD kg−1 | 0.49 | 0.41 | 0.31 |

| Highest (++) | Modest (+−) | Lowest (−−) | |||

| Energy Requirement | Total energy | MJ kg−1 | 7.92 | 6.19 | 10.35 |

| Modest (+−) | Lowest (++) | Highest (−−) | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahmah, D.M.; Putra, A.S.; Ishizaki, R.; Noguchi, R.; Ahamed, T. A Life Cycle Assessment of Organic and Chemical Fertilizers for Coffee Production to Evaluate Sustainability toward the Energy–Environment–Economic Nexus in Indonesia. Sustainability 2022, 14, 3912. https://doi.org/10.3390/su14073912

Rahmah DM, Putra AS, Ishizaki R, Noguchi R, Ahamed T. A Life Cycle Assessment of Organic and Chemical Fertilizers for Coffee Production to Evaluate Sustainability toward the Energy–Environment–Economic Nexus in Indonesia. Sustainability. 2022; 14(7):3912. https://doi.org/10.3390/su14073912

Chicago/Turabian StyleRahmah, Devi Maulida, Agusta Samodra Putra, Riaru Ishizaki, Ryozo Noguchi, and Tofael Ahamed. 2022. "A Life Cycle Assessment of Organic and Chemical Fertilizers for Coffee Production to Evaluate Sustainability toward the Energy–Environment–Economic Nexus in Indonesia" Sustainability 14, no. 7: 3912. https://doi.org/10.3390/su14073912

APA StyleRahmah, D. M., Putra, A. S., Ishizaki, R., Noguchi, R., & Ahamed, T. (2022). A Life Cycle Assessment of Organic and Chemical Fertilizers for Coffee Production to Evaluate Sustainability toward the Energy–Environment–Economic Nexus in Indonesia. Sustainability, 14(7), 3912. https://doi.org/10.3390/su14073912