Evaluating the COVID-19 Impacts on Sustainable Procurement: Experiences from the Australian Built Environment Sector

Abstract

:1. Introduction

2. Literature Review

3. Methods

3.1. Data Collection

3.2. Data Analysis

4. Results

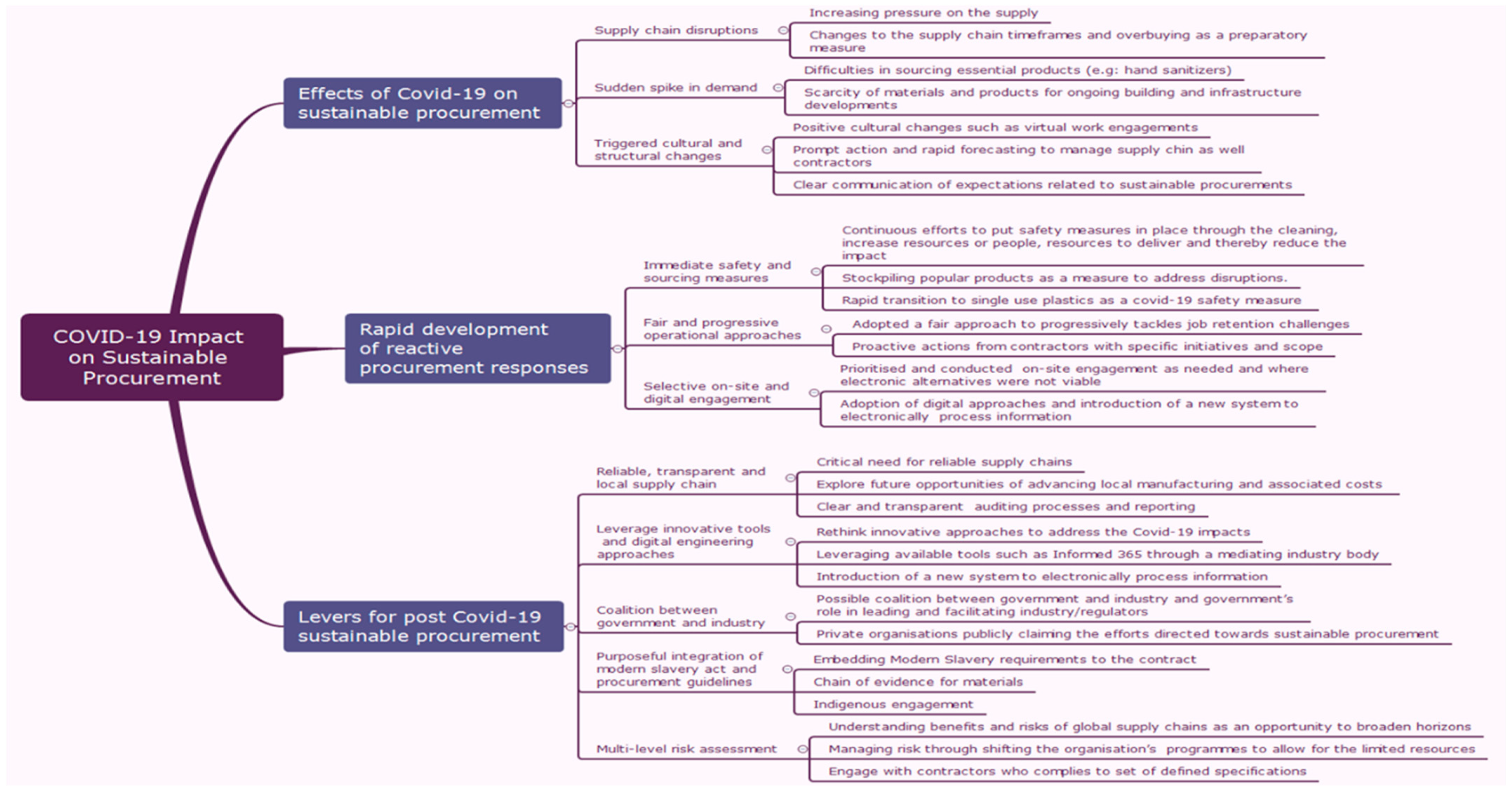

4.1. Findings of the First-Order Analysis

4.2. Findings of the Second-Order Analysis

- Supply chain disruptions;

- Sudden spikes in demand;

- Triggers for cultural and structural changes;

- Immediate safety and sourcing measures;

- Fair and progressive operational approaches;

- Selective on-site and digital engagement;

- Reliable, transparent and local supply chains;

- Leveraging innovative tools and DE approaches;

- Coalition between government and industry;

- Purposeful integration of Modern Slavery Act and procurement guidelines;

- Multi-level risk assessment.

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Walker, H.; Miemczyk, J.; Johnsen, T.; Spencer, R. Sustainable Procurement: Past, Present and Future; Elsevier: Amsterdam, The Netherlands, 2012; Volume 18, pp. 201–206. [Google Scholar]

- Walker, H.; Phillips, W. Sustainable procurement: Emerging issues. Int. J. Procure. Manag. 2009, 2, 41–61. [Google Scholar] [CrossRef]

- Haroon, S.; Wasif, M.; Khalid, R.; Khalidi, S. Supply Chain Practitioners’ Perception on Sustainability: An Empirical Study. Sustainability 2021, 13, 9872. [Google Scholar] [CrossRef]

- Feng, Y.; Papastamoulis, V.; Mohamed, S.A.; Le, T.; Caldera, S.; Zhang, P. Developing a Framework for Enabling Sustainable Procurement: Research Report# 2; Sustainable Built Environment National Research Centre: Bentley, WA, USA, 2021. [Google Scholar]

- Liu, J.; Ma, Y.; Appolloni, A.; Cheng, W. How external stakeholders drive the green public procurement practice? An organizational learning perspective. J. Public Procure. 2021, 21, 138–166. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Appolloni, A.; Liu, J. Does green public procurement encourage firm’s environmental certification practice? The mediation role of top management support. Corp. Soc. Responsib. Environ. Manag. 2021, 28, 1002–1017; [Google Scholar] [CrossRef]

- Cheng, W.; Appolloni, A.; D’Amato, A.; Zhu, Q. Green Public Procurement, Missing Concepts and Future Trends—A Critical Review. J. Clean. Prod. 2018, 176, 770–784. [Google Scholar] [CrossRef]

- Mace, M. Coronavirus and Globalization: What Next for Supply Chain Sustainability? Available online: https://www.edie.net/library/Coronavirus-and-globalisation--What-next-for-supply-chain-sustainability-/6973 (accessed on 8 May 2021).

- The Organisation for Economic Co-Operation and Development (OECD). Stocktaking Report on Immediate Public Procurement and Infrastructure Responses to COVID-19. Available online: https://www.oecd.org/coronavirus/policy-responses/stocktaking-report-on-immediate-public-procurement-and-infrastructure-responses-to-covid-19-248d0646/ (accessed on 13 July 2021).

- Karmaker, C.L.; Ahmed, T.; Ahmed, S.; Ali, S.M.; Moktadir, M.A.; Kabir, G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: Exploring drivers using an integrated model. Sustain. Prod. Consum. 2021, 26, 411–427. [Google Scholar] [CrossRef]

- Jan, O. COVID-19 Impacts on Supply Chains, Sustainability and Climate Change. Available online: https://www2.deloitte.com/global/en/blog/responsible-business-blog/2020/covid-19-impacts-on-supply-chains-sustainability-and-climate-change.html (accessed on 13 July 2021).

- Sherman, E. 94% of the Fortune 1000 Are Seeing Coronavirus Supply Chain Disruptions: Report. Available online: https://fortune.com/2020/02/21/fortune-1000-coronavirus-china-supply-chain-impact/ (accessed on 7 March 2021).

- Loosemore, M. How We Can Re-Build Our Economy after COVID-19 through Social Procurement and Construction. The Fifth Estate. Available online: https://thefifthestate.com.au/articles/how-we-can-re-build-our-economy-after-covid-19-through-social-procurement-and-construction/ (accessed on 11 April 2021).

- Australian Government. Water an Environment Sustainable Procurement Guide. Available online: https://www.awe.gov.au/environment/protection/waste/publications/sustainable-procurement-guide (accessed on 30 November 2021).

- Halkos, G.; Skouloudis, A. Corporate social responsibility and innovative capacity: Intersection in a macro-level perspective. J. Clean. Prod. 2018, 182, 291–300. [Google Scholar] [CrossRef] [Green Version]

- Christopher, M.; Peck, H. Building the resilient supply chain. Int. J. Logist. Manag. 2004, 15, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Sheffi, Y.; Rice, J.B.; Fleck, J.M.; Caniato, F. Supply chain response to global terrorism: A situation scan. In Proceedings of the EurOMA POMS Joint International Conference, Cernobbio, Italy, 17 June 2003; Center for Transportation and Logistics, MIT, Department of Management, Economics and Industrial Engineering, Politecnico di Milano: Cambridge, MA, USA, 2003; pp. 1–6. [Google Scholar]

- Li, W.-Y.; Choi, T.-M.; Chow, P.-S. Risk and benefits brought by formal sustainability programs on fashion enterprises under market disruption. Resour. Conserv. Recycl. 2015, 104, 348–353. [Google Scholar] [CrossRef]

- Ivanov, D. Revealing interfaces of supply chain resilience and sustainability: A simulation study. Int. J. Prod. Res. 2018, 56, 3507–3523. [Google Scholar] [CrossRef] [Green Version]

- LLC, D.D. COVID-19 Impact, A Proactive Response to a Shifting Planning, Design, and Construction Landscape. Available online: https://www2.deloitte.com/content/dam/Deloitte/us/Documents/finance/us-covid-19-impact-construction-landscape.pdf (accessed on 18 May 2021).

- Carmeli, A.; Dothan, A.; Boojihawon, D.K. Resilience of sustainability-oriented and financially-driven organizations. Bus. Strateg. Environ. 2020, 29, 154–169. [Google Scholar] [CrossRef]

- Yang, C.-C.; Hsu, W.-L. Evaluating the impact of security management practices on resilience capability in maritime firms—A relational perspective. Transp. Res. Part A Policy Pract. 2018, 110, 220–233. [Google Scholar] [CrossRef]

- Speier, C.; Whipple, J.M.; Closs, D.J.; Voss, M.D. Global supply chain design considerations: Mitigating product safety and security risks. J. Oper. Manag. 2011, 29, 721–736. [Google Scholar] [CrossRef]

- The Organisation for Economic Co-Operation and Development (OECD). Infrastructure and Public Procurement COVID-19 Responses Management of Ongoing Infrastructure Contracts. Available online: https://www.oecd.org/gov/public-procurement/IPP-Webinar-Management-ongoing-infrastructure-Summary.pdf (accessed on 29 November 2021).

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Developing a framework for enhancing survivability of sustainable supply chains during and post-COVID-19 pandemic. Int. J. Logist. Res. Appl. 2020, 1–21, ahead-of-print. [Google Scholar] [CrossRef]

- Klibi, W.; Martel, A.; Guitouni, A. The design of robust value-creating supply chain networks: A critical review. Eur. J. Oper. Res. 2010, 203, 283–293. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus. Strateg. Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Rajesh, R. Optimal trade-offs in decision-making for sustainability and resilience in manufacturing supply chains. J. Clean. Prod. 2021, 313, 127596. [Google Scholar] [CrossRef]

- Lindberg, N.; Nordin, F. From products to services and back again: Towards a new service procurement logic. Ind. Mark. Manag. 2008, 37, 292–300. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring supply chain resilience: Development of a conceptual framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Shishodia, A.; Sharma, R.; Rajesh, R.; Munim, Z.H. Supply chain resilience: A review, conceptual framework and future research. Int. J. Logist. Manag. 2021. ahead of print. [Google Scholar] [CrossRef]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Hingley, M.; Vilalta-Perdomo, E.L.; Ramsden, G.; Twigg, D. Sustainability of supply chains in the wake of the coronavirus (COVID-19/SARS-CoV-2) pandemic: Lessons and trends. Mod. Supply Chain. Res. Appl. 2020, 2, 117–122. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Jabbour, A.B.L.d.S.; Govindan, K.; Teixeira, A.A.; Freitas, W.R.d.S. Environmental management and operational performance in automotive companies in Brazil: The role of human resource management and lean manufacturing. J. Clean. Prod. 2013, 47, 129–140. [Google Scholar] [CrossRef]

- Alicke, K.; Azcue, X.; Barriball, E. Supply-Chain Recovery in Coronavirus Times—Plan for Now and the Future. Available online: https://www.mckinsey.com/business-functions/operations/our-insights/supply-chain-recovery-in-coronavirus-times-plan-for-now-and-the-future (accessed on 20 May 2021).

- Queensland Government Department of Communities, Housing and Digital Economy. Procuring during the COVID-19 Emergency. Available online: https://www.hpw.qld.gov.au/__data/assets/pdf_file/0018/11790/emergency-procurement-covid-19.pdf (accessed on 30 May 2021).

- World Service Civil. Sustainable Procurement: An Opportunity Presented by COVID-19. Available online: https://www.civilserviceworld.com/news/article/sustainable-procurement-an-opportunity-presented-by-covid19 (accessed on 30 May 2021).

- United Nations Conference on Trade and Development (UNCTAD). Sustainable Public Procurement can Help Us Build Back Better after COVID-19. Available online: https://unctad.org/news/sustainable-public-procurement-can-help-us-build-back-better-after-covid-19 (accessed on 30 May 2021).

- United Nations. Recover Netter Economic and Social Challenges and Opportunities. Available online: https://www.un.org/development/desa/en/wp-content/uploads/2020/07/RECOVER_BETTER_0722-1.pdf (accessed on 20 May 2021).

- Manta, O. Measures and possible support solutions of the sustainable European economy in the context of actual crises. Eur. J. Mark. Econ. 2020, 3, 93–107. [Google Scholar] [CrossRef]

- Acioli, C.; Scavarda, A.; Reis, A. Applying Industry 4.0 technologies in the COVID–19 sustainable chains. Int. J. Product. Perform. Manag. 2021, 70, 988–1016. [Google Scholar] [CrossRef]

- KPMG. COVID-19: Supply Chain Disruptions. Available online: https://home.kpmg/au/en/home.html (accessed on 30 June 2021).

- Stewart, D.W.; Shamdasani, P.N. Focus Groups: Theory and Practice; Applied Social Research Methods Series; Sage Publications, Inc.: Thousand Oaks, CA, USA, 1990. [Google Scholar]

- Nyumba, T.; Wilson, K.; Derrick, C.J.; Mukherjee, N. The use of focus group discussion methodology: Insights from two decades of application in conservation. Methods Ecol. Evol. 2018, 9, 20–32. [Google Scholar] [CrossRef] [Green Version]

- Gioia, C. Seeking qualitative rigor in inductive research: Notes on the Gioia methodology. Organ. Res. Methods 2013, 16, 15–31. [Google Scholar] [CrossRef]

- Glaser, B.G.; Strauss, A.L. The Discovery of Grounded Theory: Strategies for Qualitative Research; Transaction Publishers: Piscataway, NJ, USA, 2009. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods; Sage Publications: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- Klein, H.K.; Myers, M.D. A Set of Principles for Conducting and Evaluating Interpretive Field Studies in Information Systems. Manag. Inf. Syst. Q. 1999, 23, 67–93. [Google Scholar] [CrossRef]

- Caldera, H.T.S.; Desha, C.; Dawes, L. Exploring the characteristics of sustainable business practice in small and medium-sized enterprises: Experiences from the Australian manufacturing industry. J. Clean. Prod. 2017, 177, 338–349. [Google Scholar] [CrossRef]

| Procurement Stage | First-Level Concepts (Selected) | Supporting Quotes | Participant Code |

|---|---|---|---|

| Planning | Rethinking innovative approaches | One of the things these matters do is have a rethink about some of the innovation that we were asking to look at around more just in time. | P3 |

| Rapid interactions and tasks on prestart checks and cleaning | The first impact I notice there was really around having to work very quickly with supplies on their working practices, prestart checks, cleaning all of those sorts of things | P4 | |

| Positive cultural changes such as virtual work engagements | Perhaps the positives have been more on the cultural side. People are open to change in this time, and this is more generic. But one positive that’s comes out is this virtual working situation with been able to resource more, I guess, waste specialists. | P2 | |

| Continuous efforts to put safety measures in place through cleaning, increasing resources or people | You know, it was really very fortunate rather other than the supply chain change in how we operate like split shifts, for example, you know, we had to maintain distancing and hygiene. How is that are going to operate, increase the cleaning, increase resources or people, resources to deliver. And there wasn’t that much of an impact. | P1 | |

| Prioritized and conducted on-site engagement as needed and where electronic alternatives were not viable | It was really very fortunate rather other than the supply chain change in how we operate like split shifts, for example, you know, we had to maintain distancing and hygiene. How is that are going to operate, increase the cleaning, increase resources or people, resources to deliver. And there wasn’t that much of an impact. | P1 | |

| Positively nudged the organisations to adopt IT tools | Because it’s so hard to get a change made; so, COVID-19 has been very positive actually. Cause it’s just pushed that button, you know! It’s really sped up a lot of the IT stuff out of necessity. | P2 | |

| Sourcing | Received feedback from contractors about limited supply | Once COVID hit, we realised well, because we’ve got a lot of feedback from our contractors with limited supply, and obviously they do not stockpile, and a lot of the supply was coming from overseas and that all stopped. | P1 |

| Processes in this private organisation were insulated because of vertical integration | I guess we’re structurally we’re kind of insulated a bit because we about vertical integration. So, we start at the quarries in it, all the way through to the concrete. I think looking at where we’re at now that the stimulus is changed. It’s flipped it on its head. We’re doing bigger numbers than we’ve ever done | P5 | |

| Variety of impacts including affecting the timely delivery by contractors, maintenance activities, limited supply of products | So that’s what we found, you know, was the supply chain stock to the supply chain, which affected our contractors in being able to deliver, let alone, you know, and in the maintenance space, obviously, you know, running out of, out of products was, it was a big thing | P1 | |

| Potential price barrier for local manufacturing | Yes, I guess that isn’t when it goes on price, right. So you’re always driven onto the manufacturing ability locally and price, you know, can that happen? You know, do you pushful a local manufacturer? You know, we can perhaps prompt it as a developer, but we could definitely not, you know, entice our contractors or our suppliers to start local manufacturing. | P1 | |

| Managed risk through shifting the private organisation’s program to allow for limited resources | So, I guess how, in terms of risk, we manage the risk by shifting our program or extending our program to allow for the limited resources in certain areas. So, the industry would share, and I guess that would also maintain a certain level of cost for everyone. | P1 | |

| Rapid transition to single-use plastics in the government organisation as a COVID-19 safety measure | the main one, which was switching to a lot of disposable options at the safety. You know, it’s harder when you suggest any alternative, I suppose. | P2 | |

| Changes to the supply chain timeframes and overbuying as a preparatory measure | And I think that was a big one really, and then supply chain timeframes. I haven’t heard specific examples of this, but Defence has a tendency to be very risk adverse, and I would guess that there’s probably areas in Defence where you’ve probably done a bit of overbuying, because of this situation to sort of prepare for the worst. | P2 | |

| Contract management | Possible adoption of digital approaches and introduction of a new system to electronically process information | So, but anything else that wasn’t required was done electronically. we introduced a new system to embrace you know, more processes electronically, and more information. So outside of ‘Econex’. | P1 |

| Impacts on the timely delivery by contractors’ maintenance activities | So that’s what we found, you know, was the supply chain stock to the supply chain, which affected our contractors in being able to deliver, let alone, you know, and in the maintenance space, obviously, you know, running out of, out of products was, it was a big thing | P2 | |

| Some contractors are proactive from their end and approach the government organisations with specific initiatives and scope | We’ve got Veolia is our main waste management contractor and they’ve been very proactive, and they’ll come to us with, initiatives and scope it up and they’ll just say, they know we’ve got money sitting around and then now we want to do this. So, they’re proactive and they go, come to us. | P2 | |

| Prompt action and rapid forecasting to manage supply chains as well as contractors | We acted very fast internally in our project teams to identify, you know, straightaway as soon as something happens. It’s you know, you’re looking at the risks and you’re looking at the forecast of program with the contractors. | P1 | |

| Proactive actions were in place to manage the supply chain as well as contractors | I mentioned earlier and how we manage the supply chain as well as people, as well as contractors, as well as split shifts, et cetera, we staggered the program, which then allowed us time and allowed everything time. To manufacturer deliver, you know and arrive. | P1 | |

| Embedding Modern Slavery requirements to the contract | Embedded Modern Slavery requirements in the contract itself. How you do business. For instance, in [private organisation], we have a policy called ‘What [name of the private organisation] Expects from its Suppliers’, which is on our website and which we published to say, you know, Human Rights, Modern Slavery, you know, embedded Code of Conducts, you know, the Geneva Convention requirements like we really stepped through all of it right through. | P1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caldera, S.; Mohamed, S.; Feng, Y. Evaluating the COVID-19 Impacts on Sustainable Procurement: Experiences from the Australian Built Environment Sector. Sustainability 2022, 14, 4163. https://doi.org/10.3390/su14074163

Caldera S, Mohamed S, Feng Y. Evaluating the COVID-19 Impacts on Sustainable Procurement: Experiences from the Australian Built Environment Sector. Sustainability. 2022; 14(7):4163. https://doi.org/10.3390/su14074163

Chicago/Turabian StyleCaldera, Savindi, Sherif Mohamed, and Yingbin Feng. 2022. "Evaluating the COVID-19 Impacts on Sustainable Procurement: Experiences from the Australian Built Environment Sector" Sustainability 14, no. 7: 4163. https://doi.org/10.3390/su14074163

APA StyleCaldera, S., Mohamed, S., & Feng, Y. (2022). Evaluating the COVID-19 Impacts on Sustainable Procurement: Experiences from the Australian Built Environment Sector. Sustainability, 14(7), 4163. https://doi.org/10.3390/su14074163