The Impact of Cement Kiln Dust and Cement on Cold Mix Asphalt Characteristics at Different Climate

Abstract

:1. Introduction

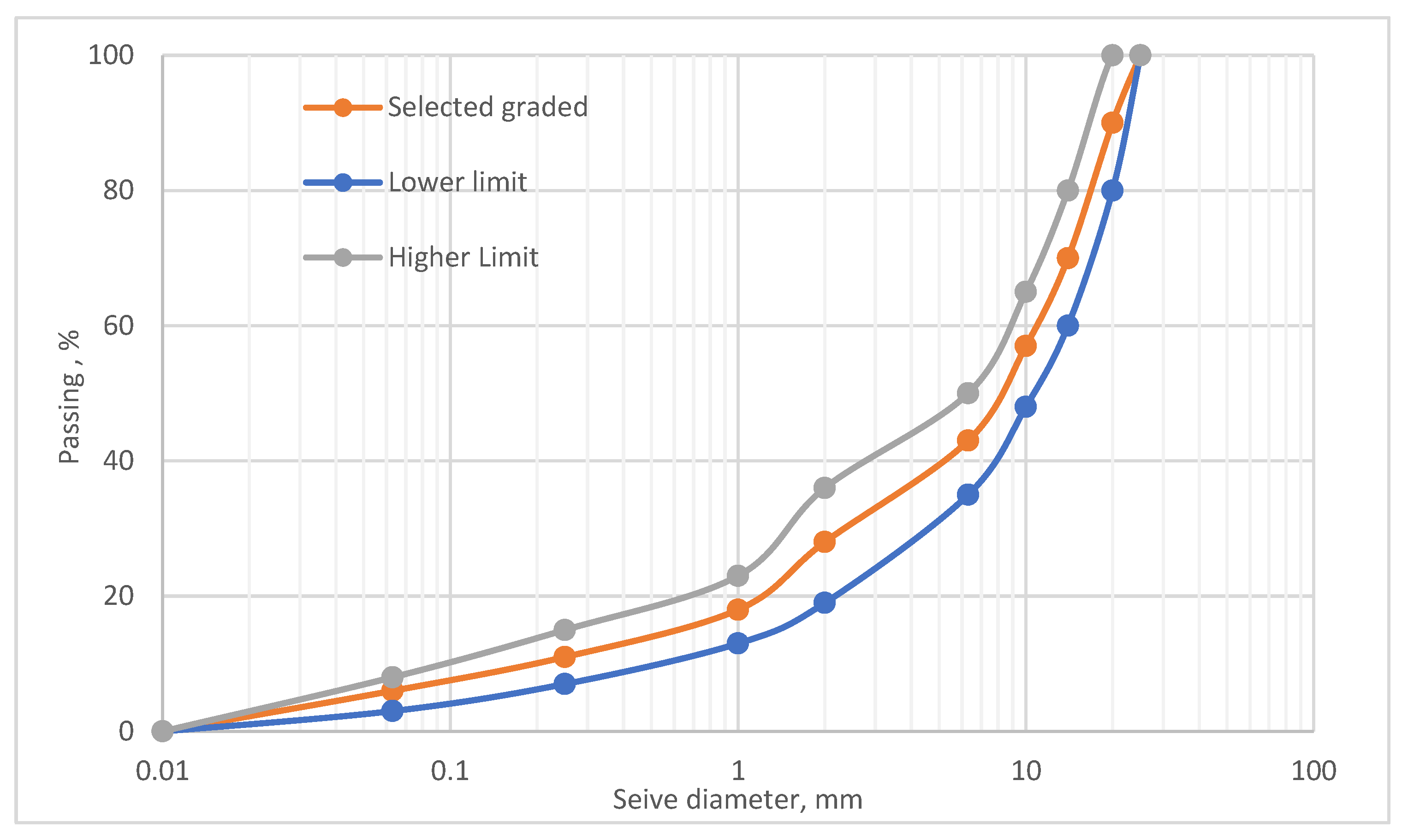

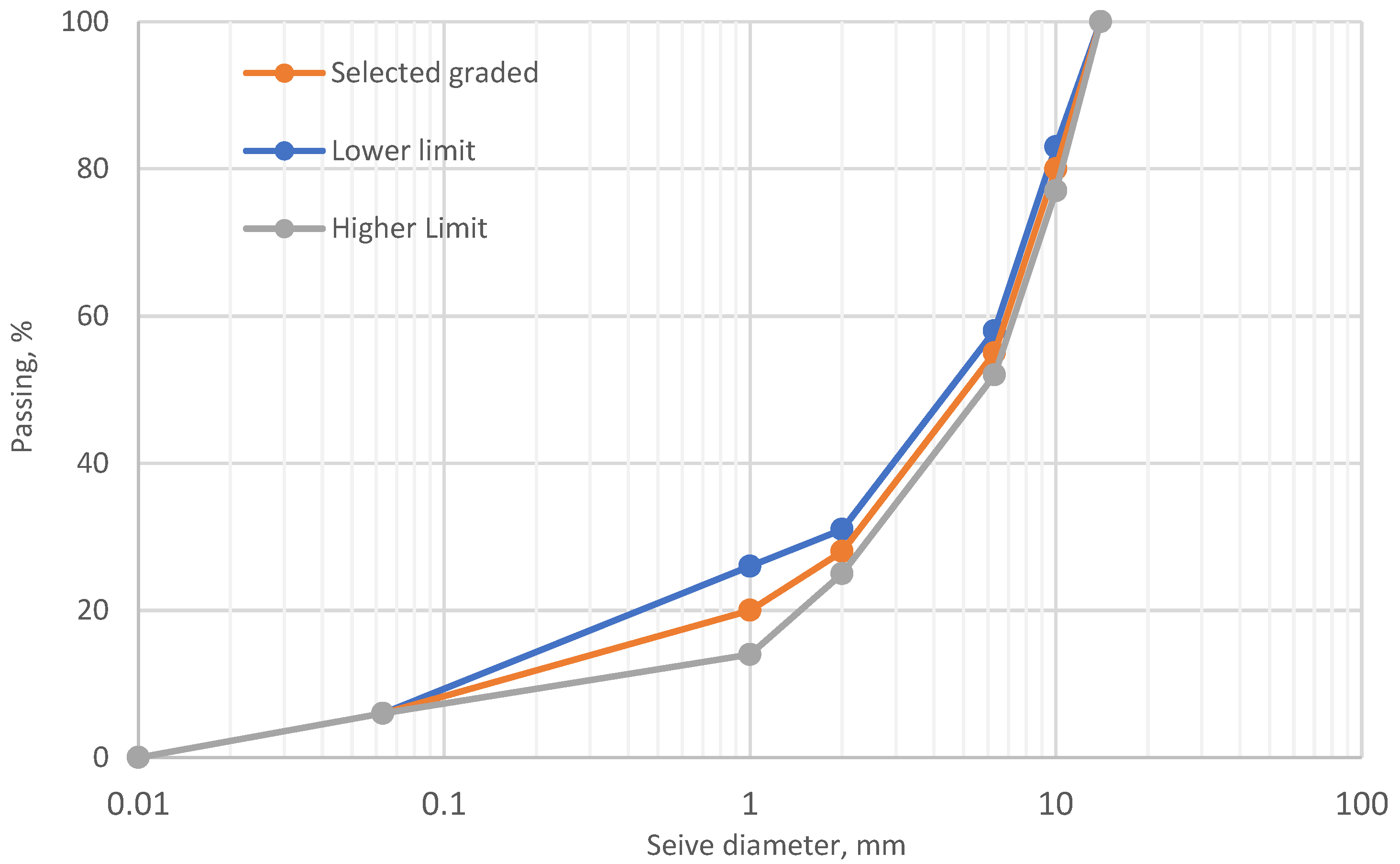

2. Material and Testing

2.1. Materials

2.2. Sample Preparation

2.3. Testing

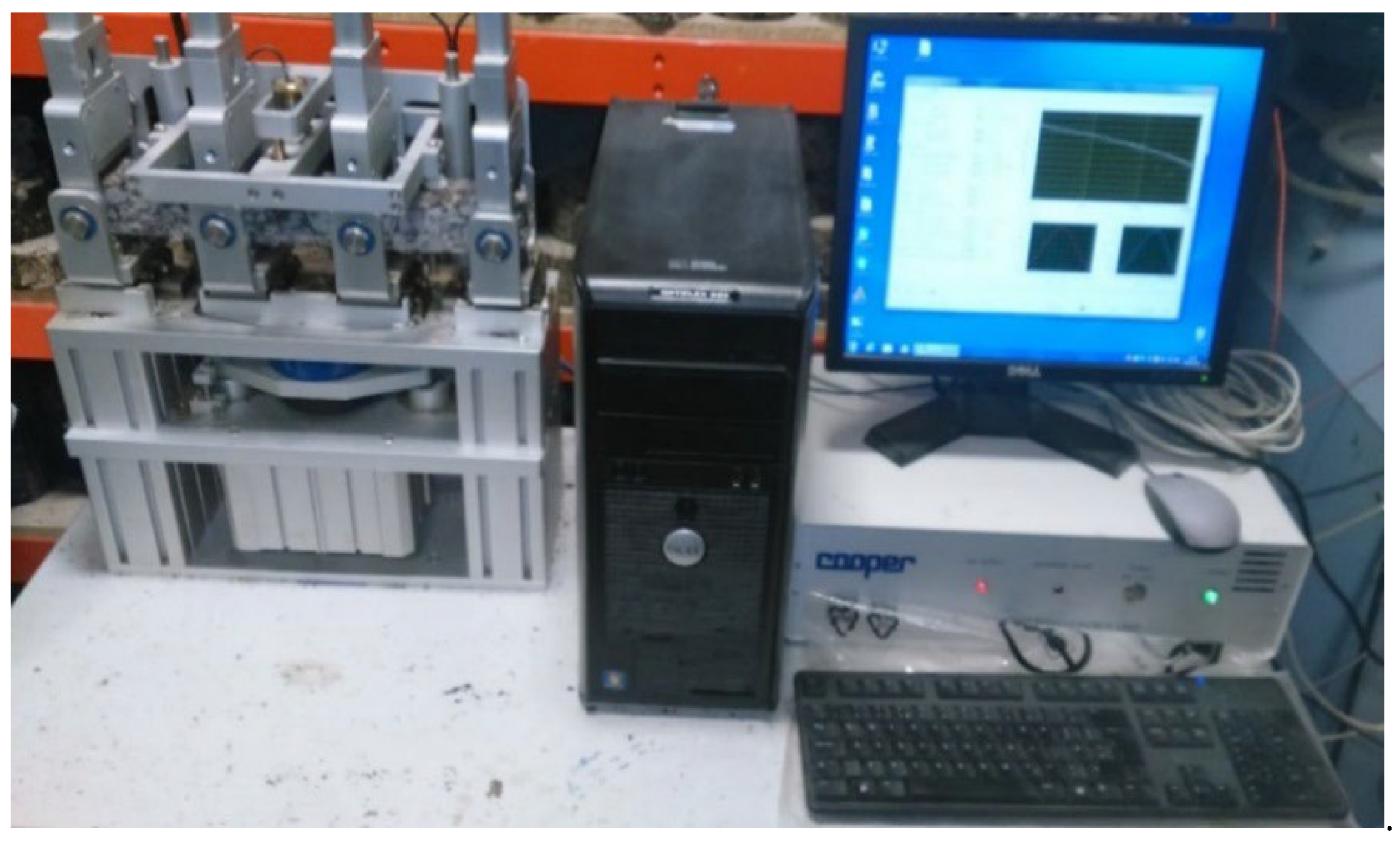

2.3.1. Indirect Tensile Stiffness Modulus (ITSM)

2.3.2. Fatigue Resistance

2.3.3. Resistance to Rutting

3. Results and Discussion

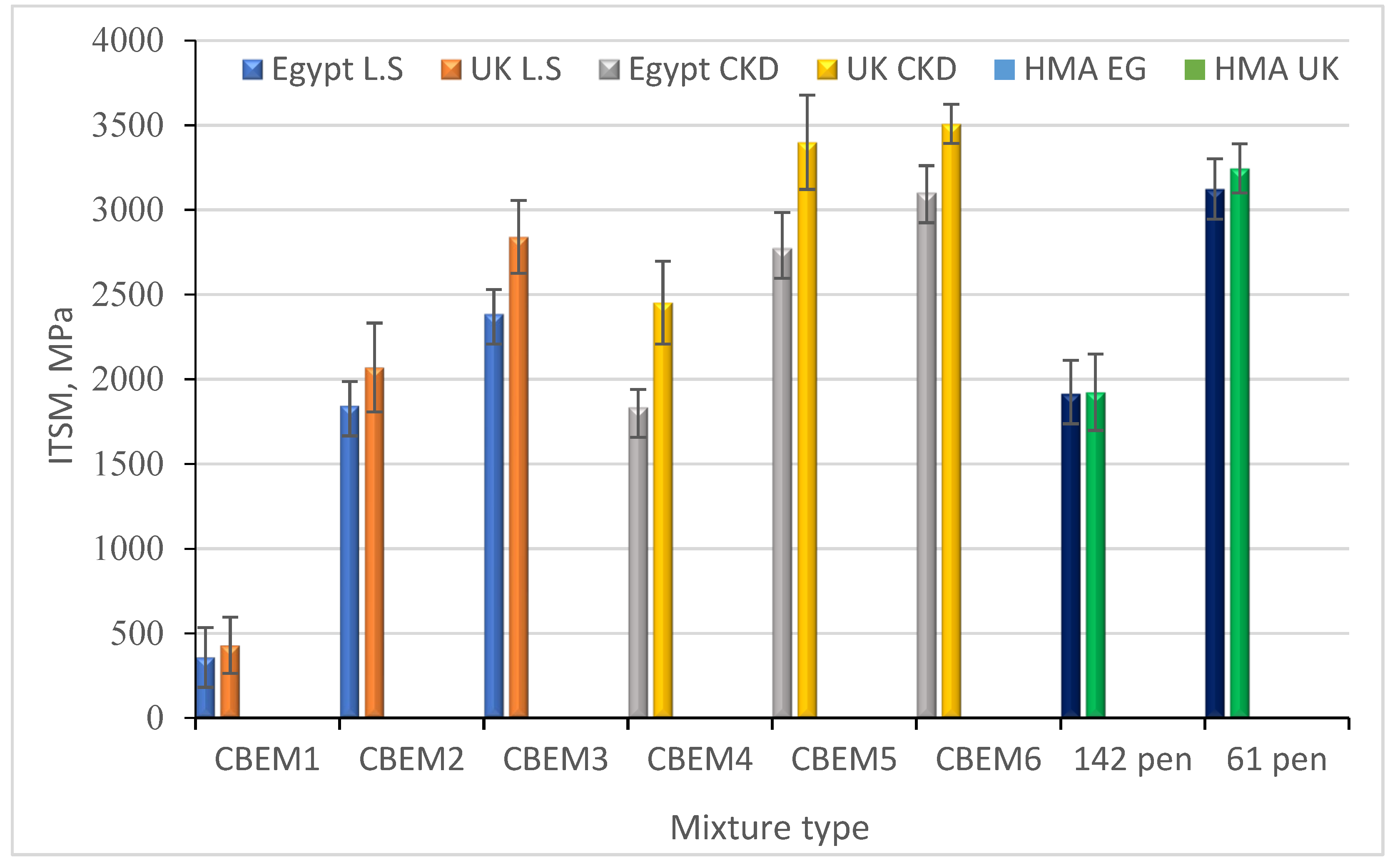

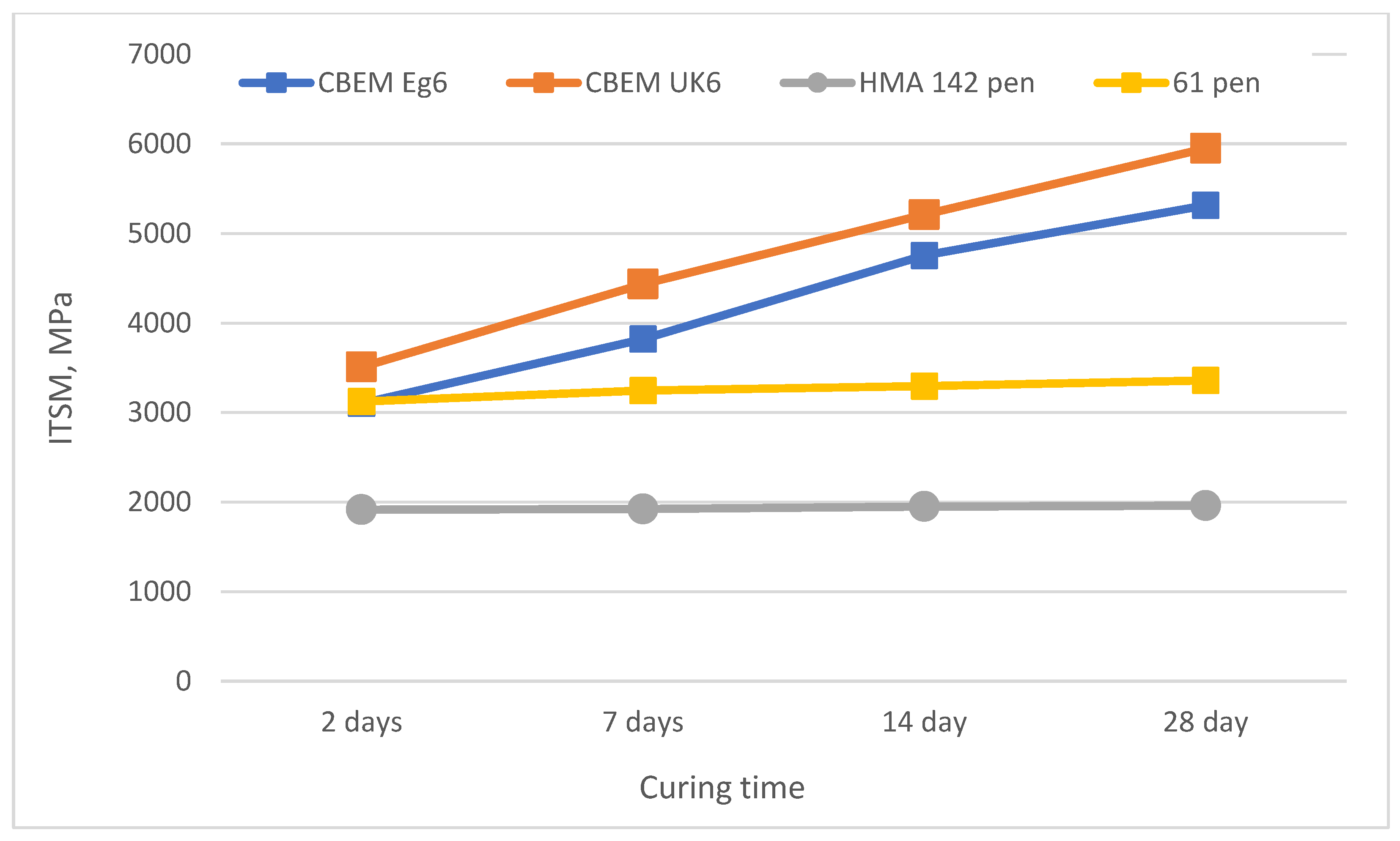

3.1. Indirect Tensile Stiffness Modulus

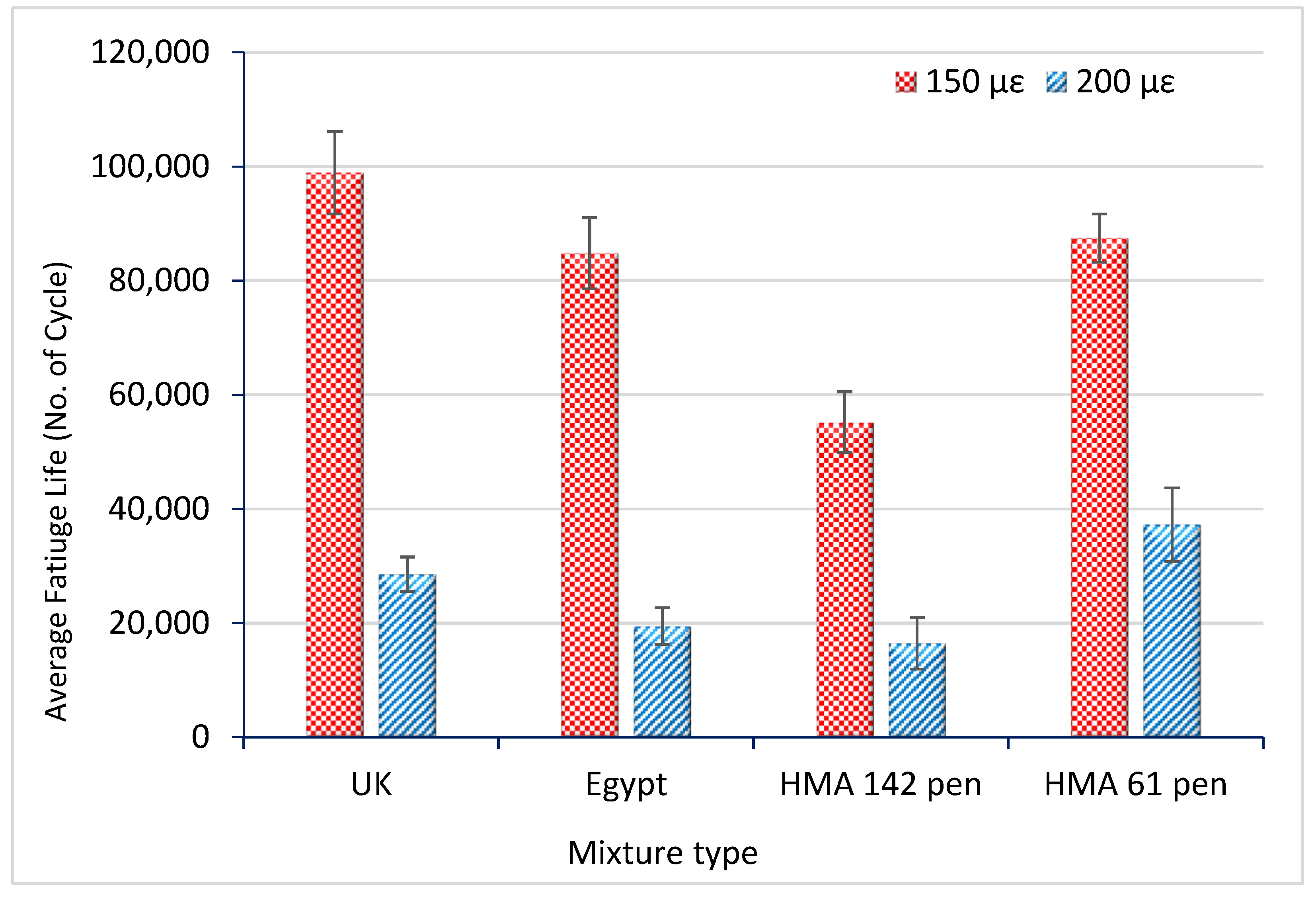

3.2. Fatigue Resistance

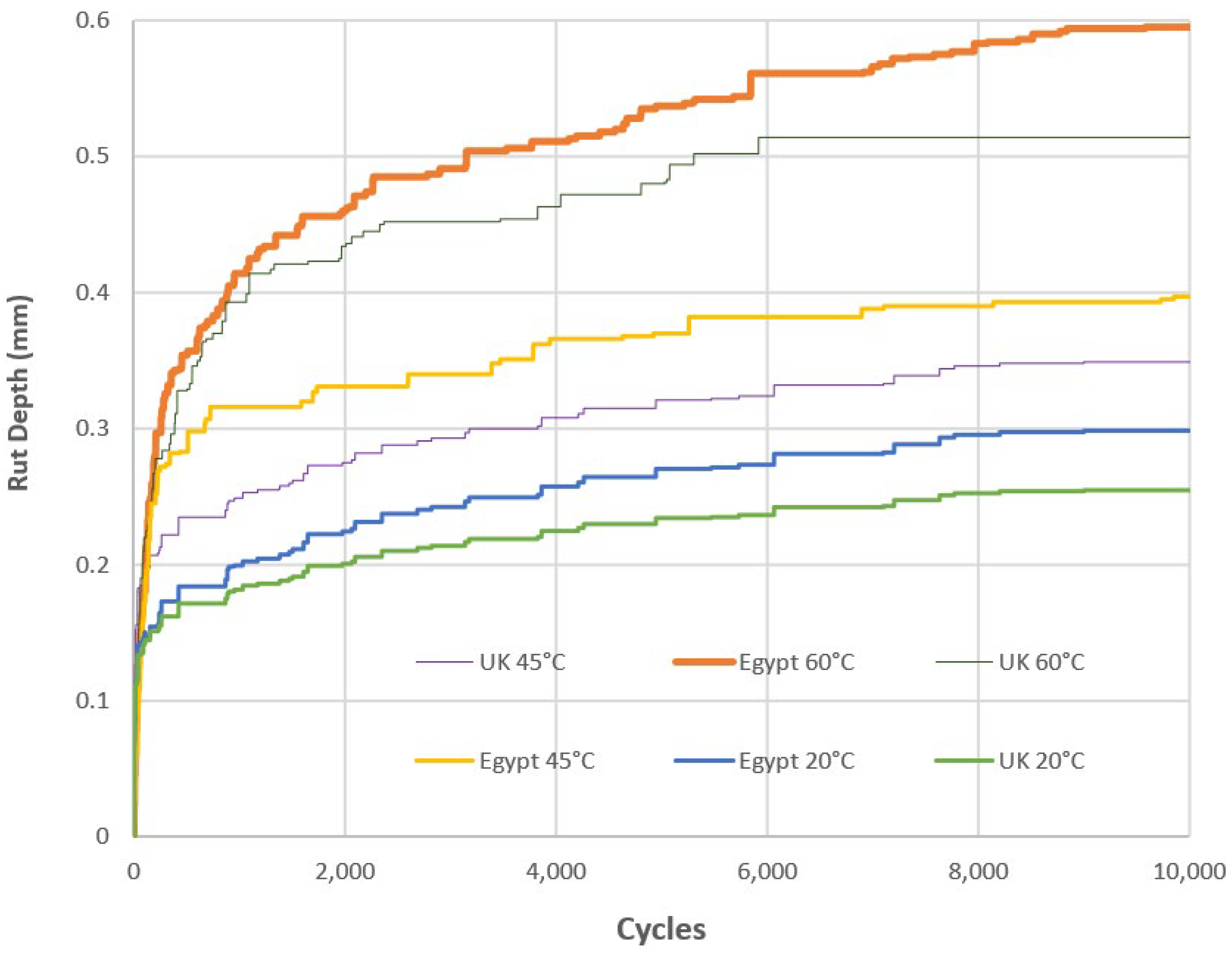

3.3. Resistance to Rutting

4. Conclusions

- (1)

- Ordinary Portland cement plays a significant role in improving the stiffness modulus of CBEMs, especially at high percentages (50% and 80% of total filler). This may be attributed to its providing a secondary cementitious binder, and the main role of cement in the hydration process. Increasing OPC from 20% to 80% improved the ITSM for both UK and Egypt gradations by around 8 and 9 times, respectively;

- (2)

- The best CKD percentage is 20%, which provides the highest ITSM when blended with 80% OPC. Reducing CKD from 80% to 20% improved the ITSM for both UK and Egypt gradations by 140% and 170%, respectively;

- (3)

- The results of rutting resistance also indicate that replacing LS with both OPC and CKD improved the performance at 20, 45 and 60 °C. It is noted that CBEM6 that have 80% OPC with 20% CKD achieved the highest rut resistance at 20 °C. Thus, the improved CBEM6 mix can be used as a structural layer in different climates, either in Egypt or in Britain;

- (4)

- The addition of OPC and CKD to CBEMs resulted in a substantial improvement in fatigue life for both British and Egyptian gradations at 150 and 200 microstrains;

- (5)

- This study showed that the British gradation (14C) gave improved results in all experimental tests compared to the Egyptian gradation (4C) commonly used in Egypt as a surface course. Accordingly, the British one may be a better gradation for Egyptian roads;

- (6)

- CBEMs with OPC and CKD as filler showed clearly improved mechanical properties, compared to CBEMs with OPC and limestone. Thus, this lab-scale trial should be expanded into the field.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Investigating the effect of corrective maintenance on the pavement life cycle and the optimal maintenance strategies. In Proceedings of the 19th COTA International Conference of Transportation Professionals: Transportation in China—Connecting the World, Nanjing, China, 6–8 July 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 811–822. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Investigating effective maintenance policies for urban networks of residential cities by using optimum and sensitivity analyses. Can. J. Civ. Eng. 2020, 47, 691–703. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Abdel-Wahed, T.A.; Othman, A.M. Modelling the raveling propagation in hot and dry climate by using the statistical analysis concepts. In Proceedings of the 19th COTA International Conference of Transportation Professionals: Transportation in China—Connecting the World, Nanjing, China, 6–8 July 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 868–879. [Google Scholar] [CrossRef]

- Bouteiller, É.l. Asphalt emulsions for sustainable pavements. In Proceedings of the First International Conference on Pavement Preservation, Newport Beach, CA, USA, 13–15 April 2010. [Google Scholar]

- Wang, Z.; Sha, A. Micro hardness of interface between cement asphalt emulsion mastics and aggregates. Mater. Struct. 2010, 43, 453–461. [Google Scholar] [CrossRef]

- Nageim, H.A.; Al-Busaltan, S.F.; Atherton, W.; Sharples, G. A comparative study for improving the mechanical properties of cold bituminous emulsion mixtures with cement and waste materials. Constr. Build. Mater. 2012, 36, 743. [Google Scholar] [CrossRef]

- Schmidt, R.J.; Santucci, L.E.; Coyne, L.D. Performance characteristics of cement-modified asphalt emulsion mixes. In Proceedings of the Association of Asphalt Paving Technologists Conference Proceeding (AAPT), Houston, TX, USA, 12–14 February 1973; pp. 300–319. Available online: https://trid.trb.org/view/35231 (accessed on 24 February 2022).

- Li, G.; Zhao, Y.; Pang, S.S.; Huang, W. Experimental Study of Cement-Asphalt Emulsion Composite. Cem. Concr. Res. 1998, 28, 635–641. [Google Scholar] [CrossRef]

- Brown, S.F.; Needham, D. A Study of cement modified bitumen emulsion mixtures. In Proceedings of the Association of Asphalt Paving Technologists Conference Proceeding (AAPT), Reno, NV, USA, 10–13 January 2000; Available online: https://trid.trb.org/view/675393 (accessed on 24 February 2022).

- Pouliot, N.; Marchand, J.; Pigeon, M. Hydration mechanisms, microstructure, and mechanical properties of mortars prepared with mixed binder cement slurry-asphalt emulsion. J. Mater. Civ. Eng. 2003, 15, 54–59. [Google Scholar] [CrossRef]

- Song, H.; Do, J.; Soh, Y. Feasibility study of asphalt-modified mortars using asphalt emulsion. Constr. Build. Mater. 2006, 20, 332–337. [Google Scholar] [CrossRef]

- Thanaya, I.N.A.; Zoorob, S.E.; Forth, J.P. A laboratory study on cold-mix, cold-lay emulsion mixtures. Proc. Inst. Civ. Eng.-Transp. Thomas Telford Ltd, February 2009, 162, 47–55. [Google Scholar] [CrossRef] [Green Version]

- Abdel-Wahed, T.; Al Nageim, H. Investigating the effects of cement and cement kiln dust as a filler on the mechanical properties of cold bituminous emulsion mixtures. Int. J. Civ. Eng. Technol. 2016, 7, 441–453. [Google Scholar]

- Shanbara, H.K.; Dulaimi, A.; Al-Mansoori, T.; Al-Busaltan, S.; Herez, M.; Sadique, M.; Abdel-Wahed, T. The future of eco-friendly cold mix asphalt. Renew. Sustain. Energy Rev. 2021, 149, 111318. [Google Scholar] [CrossRef]

- Abdel-Wahed, T.A.; Rashwan, N.K. Application of Cement Dust and OPC as Mineral Filler in the binder Hot Mix Asphalt. In Proceedings of the LJMU International Conference on; Asphalt, Pavement Engineering and Infrastructure, Liverpool, UK, 24–25 February 2016; Volume 15. [Google Scholar]

- Chelelgo, K.; C Abiero Gariy, Z.; Muse Shitote, S. Laboratory mix design of cold bitumen emulsion mixtures incorporating reclaimed asphalt and virgin aggregates. Buildings 2018, 8, 177. [Google Scholar] [CrossRef] [Green Version]

- Dulaimi, A.; Nageim, H.A.; Ruddock, F.; Seton, L. Laboratory Studies to Examine the Properties of a Novel Cold-Asphalt Concrete Binder Course Mixture Containing Binary Blended Cementitious Filler. J. Mater. Civ. Eng. 2017, 29, 04017139. [Google Scholar] [CrossRef]

- Dulaimi, A.; Nageim, H.A.; Ruddock, F.; Seton, L. Performance Analysis of a Cold Asphalt Concrete Binder Course Containing High-Calcium Fly Ash Utilizing Waste Material. J. Mater. Civ. Eng. 2017, 29, 04017048. [Google Scholar] [CrossRef]

- Al-Busaltan, S.; Nageim, H.A.; Atherton, W.; Sharples, G. Mechanical properties of an upgrading cold-mix asphalt using waste materials. J. Mater. Civ. Eng. 2012, 24, 1484–1491. [Google Scholar] [CrossRef]

- Bueno, B.d.S.; Silva WRd Lima DCd Minnete, E. Engineering properties of fiber reinforced cold asphalt mixes. J. Environ. Eng. 2003, 129, 952–955. [Google Scholar] [CrossRef]

- Al Nageim, H.; Dulaimi, A.; Ruddock, F.; Seton, L. Development of a new cementitious filler for use in fast-curing cold binder course in pavement application. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016; pp. 167–180. [Google Scholar]

- Dulaimi, A.; Al Nageim, H.; Ruddock, F.; Seton, L. Microanalysis of Alkali-Activated Binary Blended Cementitious Filler in a Novel Cold Binder Course Mixture. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016. [Google Scholar]

- Dulaimi, A.; Al Nageim, H.; Ruddock, F.; Seton, L. Assessment the Performance of Cold Bituminous Emulsion Mixtures with Cement and Supplementary Cementitious Material for Binder Course Mixture. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016. [Google Scholar]

- Dulaimi, A.; Shanbara, H.K.; Jafer, H.; Sadique, M. An evaluation of the performance of hot mix asphalt containing calcium carbide residue as a filler. Constr. Build. Mater. 2020, 261, 119918. [Google Scholar] [CrossRef]

- Lu, D.; Wang, Y.; Leng, Z.; Zhong, J. Influence of ternary blended cementitious fillers in a cold mix asphalt mixture. J. Clean. Prod. 2021, 318, 128421. [Google Scholar] [CrossRef]

- Mignini, C.; Cardone, F.; Graziani, A. Using fine aggregate matrix mortars to predict the curing behaviour of cement bitumen treated materials produced with different cements. Constr. Build. Mater. 2021, 268, 121201. [Google Scholar] [CrossRef]

- Ministry of Housing, Utilities and Urban Development, National Center for Housing and Building Research. The Egyptian Code for the Fundamentals of the Design and Requirements for the Implementation of Urban and Rural Road Works; Code No. 104/4—2020; ECP—2020; National Center for Housing and Building Research: Giza, Egypt, 2020.

- BS EN 13108; European Committee for Standardization. Part 1. Bituminous Mixtures Materials Specification-Asphalt Concrete. British Standards Institution: London, UK, 2013.

- Asphalt Institute. Asphalt Cold Mix Manual, Manual Series No. 14(MS-14), 3rd ed.; Asphalt Institute: Lexington, KY, USA, 1997. [Google Scholar]

- BS EN 12697; European Committee for Standardization. Part 26. Bituminous Mixtures-Test Methods for Hot Mix Asphalt- Stiffness. British Standards Institution: London, UK, 2012.

- Mohamed, A.S.; Xiao, F.; Hettiarachchi, C.; Abdel-Wahed, T. Bond Strength in Dry Condition of Reclaimed Asphalt Modified by Crumb Rubber Modified Binder. J. Adhes. 2022; in press. [Google Scholar] [CrossRef]

- Pramesti, F.P.; Molenaar, A.A.A.; Van de Ven, M.F.C. The Prediction of Fatigue Life based on Four Point Bending Test. Procedia Eng. 2013, 54, 851–862. [Google Scholar] [CrossRef] [Green Version]

- BS EN 12697; European Committee for Standardization. Part 24. Bituminous Mixtures-Test Methods for Hot Mix Asphalt- Resistance to Fatigue. British Standard Institution: London, UK, 2012.

- Moussa, G.S.; Abdel-Raheem, A.; Abdel-Wahed, T. Effect of Nanoclay Particles on the Performance of High-Density Polyethylene-Modified Asphalt Concrete Mixture. Polymers 2021, 13, 434. [Google Scholar] [CrossRef]

- Tavassoti, P.; Solaimanian, M.; Chen, X. Characterization of fatigue performance of cold mix recycled asphalt mixtures through uniaxial tension–compression testing. Constr. Build. Mater. 2022, 329, 127155. [Google Scholar] [CrossRef]

- BS EN 12697-22; European Committee for Standardization. Part 22. Bituminous Mixtures-Test Methods for Hot Mix Asphalt-Wheel Tracking Test Methods for Hot Mix Asphalt. British Standard Institution: London, UK, 2012.

- Mathew, T.; Krishna, R. Introduction to Transportation Engineering; National Programme on Technology Enhanced Learning: Delhi, India, 2009; Chapter 27; pp. 1–8. [Google Scholar]

| Properties | Value |

|---|---|

| Fine aggregate | |

| Absorption of Water | 1.55% |

| Bulk Density | 2.66 gm/cm3 |

| Apparent Density | 2.71 gm/cm3 |

| Coarse aggregate | |

| Absorption of Water | 0.61% |

| Bulk Density | 2.77 gm/cm3 |

| Apparent Density | 2.80 gm/cm3 |

| Mix Type | Filler | Mix Type | Filler |

|---|---|---|---|

| CBEM Eg1 | 20% OPC + 80% L.S | CBEM UK 1 | 20% OPC + 80% L.S |

| CBEM Eg2 | 50% OPC + 50% L.S | CBEM UK 2 | 50% OPC + 50% L.S |

| CBEM Eg3 | 80% OPC + 20% L.S | CBEM UK 3 | 80% OPC + 20% L.S |

| CBEM Eg4 | 20% OPC + 80% CKD | CBEM UK 4 | 20% OPC + 80% CKD |

| CBEM Eg5 | 50% OPC + 50% CKD | CBEM UK 5 | 50% OPC + 50% CKD |

| CBEM Eg6 | 80% OPC + 20% CKD | CBEM UK 6 | 80% OPC + 20% CKD |

| Bitumen Emulsion | Bituminous Binder | 100–150 | 50–70 | |

|---|---|---|---|---|

| Properties | Value | Properties | Value | Value |

| Appearance | Black to darkbrown liquid | Appearance | Black | Black |

| Relative density at 15 °C, g/mL | 1.06 | Softening point, °C | 43 | 48.5 |

| Boiling point, °C | 101 | Penetration, 25 °C | 143 | 61 |

| Residue by distillation, % | 50 | Kinematic viscosity at 135 °C | 169 | 321 |

| Density at 25 °C | 1.00 | 1.01 | ||

| According to the Asphalt Institute (1989) | Egyptian Samples | British Samples |

|---|---|---|

| The initial residual bitumen content (P) (%) | 6.16 | 6.16 |

| The initial emulsion content (IEC) = (P/0.5) (%) | 12.32 | 12.32 |

| Pre-wetting water content (%) | 3.00 | 3.0 |

| The optimum total liquid content at compaction (%) | 13.5 | 14.0 |

| The optimum residual bitumen content (%) | 6.3 | 6.5 |

| Item | Range |

|---|---|

| Test temperature (°C) | 20 ± 0 |

| Specimen diameter (mm) | 100 ± 3 |

| Compaction Marshall | 50 for each face |

| Rise time | 124 ± 4 ms |

| Transient peak horizontal deformation | 5 µm |

| Poisson’s ratio | 0.35 |

| Specimen thickness (mm) | 63 ± 3 |

| Loading time | 3–300 s |

| Specimen temp. conditioning | 4 h before testing |

| No. of conditioning plus | 10 |

| No. of test plus | 5 |

| Item | Range |

|---|---|

| Force transducer | ±5 Kn |

| Specimen dimensions (mm) | 400 × 50 × 50 |

| Frequency | 10 Hz |

| Specimen transducer range | ±1 mm |

| Test temperature (°C) | 20 ± 0.5 |

| Strain | 150, 200 × 106 m/m |

| Test frame dimensions (mm) | 440 × 190 × 570 |

| Test end value | 50% |

| Specimen temp. conditioning | 14 days before testing |

| Item | Range |

|---|---|

| Slab dimension (mm) | 400 × 305 × 50 |

| Trolley travel speed | 42 s/min ± 1 s/min |

| Trolley travel distance | 230 ± 10 mm |

| Ground pressure test round Rutting experimental time | 0.7 MPa ± 0.05 MPa 20–300 min |

| Test temperature (°C) | 20, 45, and 60 °C ± 0.1 |

| Specimen temp. conditioning: | |

| At oven (40 °C) | 14 day |

| At test temperature | 4 h before test beginning |

| Country | Microstrain | Formula | R2 | F | Sig. |

|---|---|---|---|---|---|

| Egypt | 150–200 | Y = 0.256 + 1.998 x | 0.782 | 9920 | 0.000 |

| British | 150–200 | Y = −0.702 + 4.665 x | 0.854 | 13,350 | 0.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdel-Wahed, T.; Dulaimi, A.; Shanbara, H.K.; Al Nageim, H. The Impact of Cement Kiln Dust and Cement on Cold Mix Asphalt Characteristics at Different Climate. Sustainability 2022, 14, 4173. https://doi.org/10.3390/su14074173

Abdel-Wahed T, Dulaimi A, Shanbara HK, Al Nageim H. The Impact of Cement Kiln Dust and Cement on Cold Mix Asphalt Characteristics at Different Climate. Sustainability. 2022; 14(7):4173. https://doi.org/10.3390/su14074173

Chicago/Turabian StyleAbdel-Wahed, Talaat, Anmar Dulaimi, Hayder Kamil Shanbara, and Hassan Al Nageim. 2022. "The Impact of Cement Kiln Dust and Cement on Cold Mix Asphalt Characteristics at Different Climate" Sustainability 14, no. 7: 4173. https://doi.org/10.3390/su14074173

APA StyleAbdel-Wahed, T., Dulaimi, A., Shanbara, H. K., & Al Nageim, H. (2022). The Impact of Cement Kiln Dust and Cement on Cold Mix Asphalt Characteristics at Different Climate. Sustainability, 14(7), 4173. https://doi.org/10.3390/su14074173