Design, Development, and Characterization of Highly Efficient Colored Photovoltaic Module for Sustainable Buildings Applications

Abstract

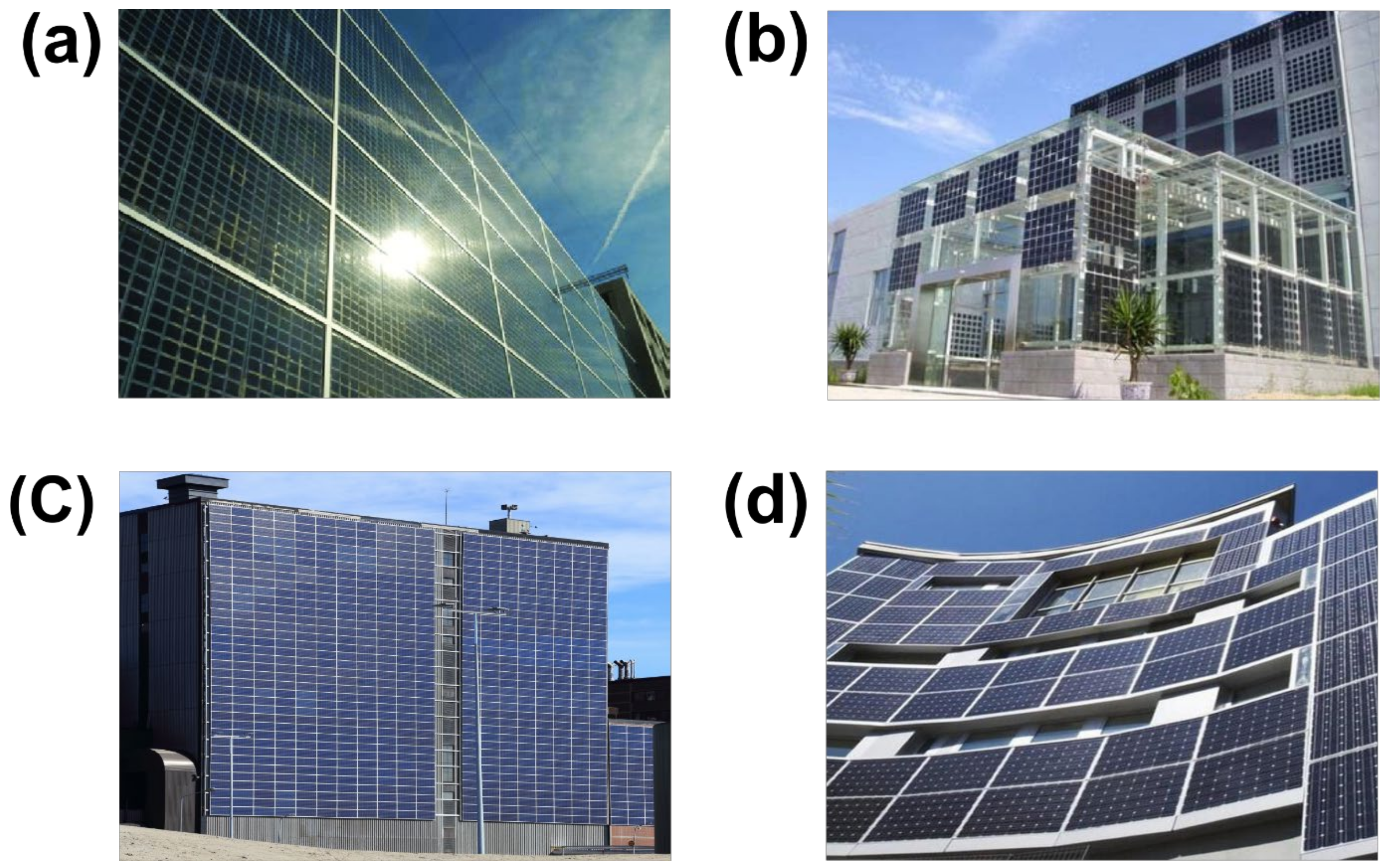

:1. Introduction

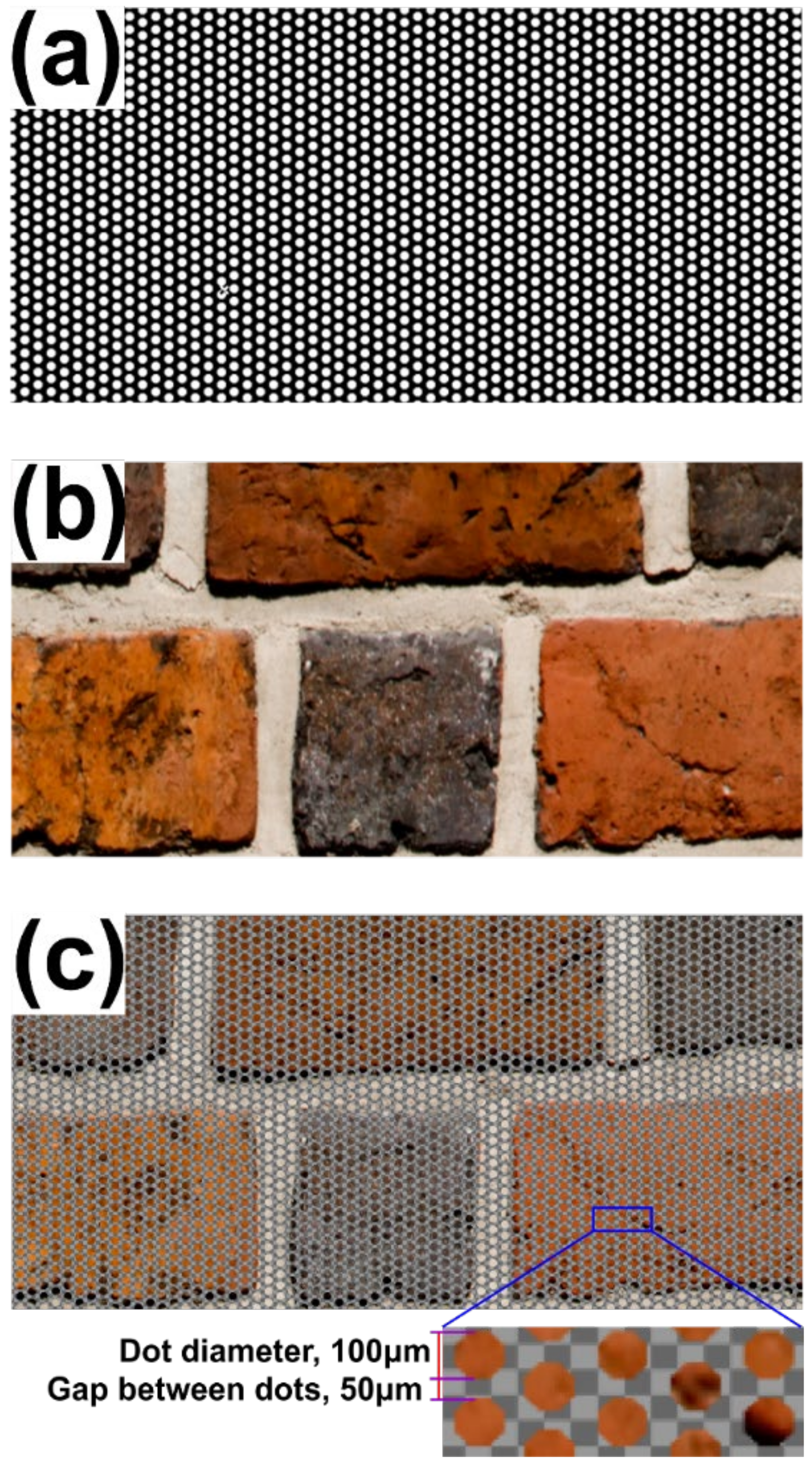

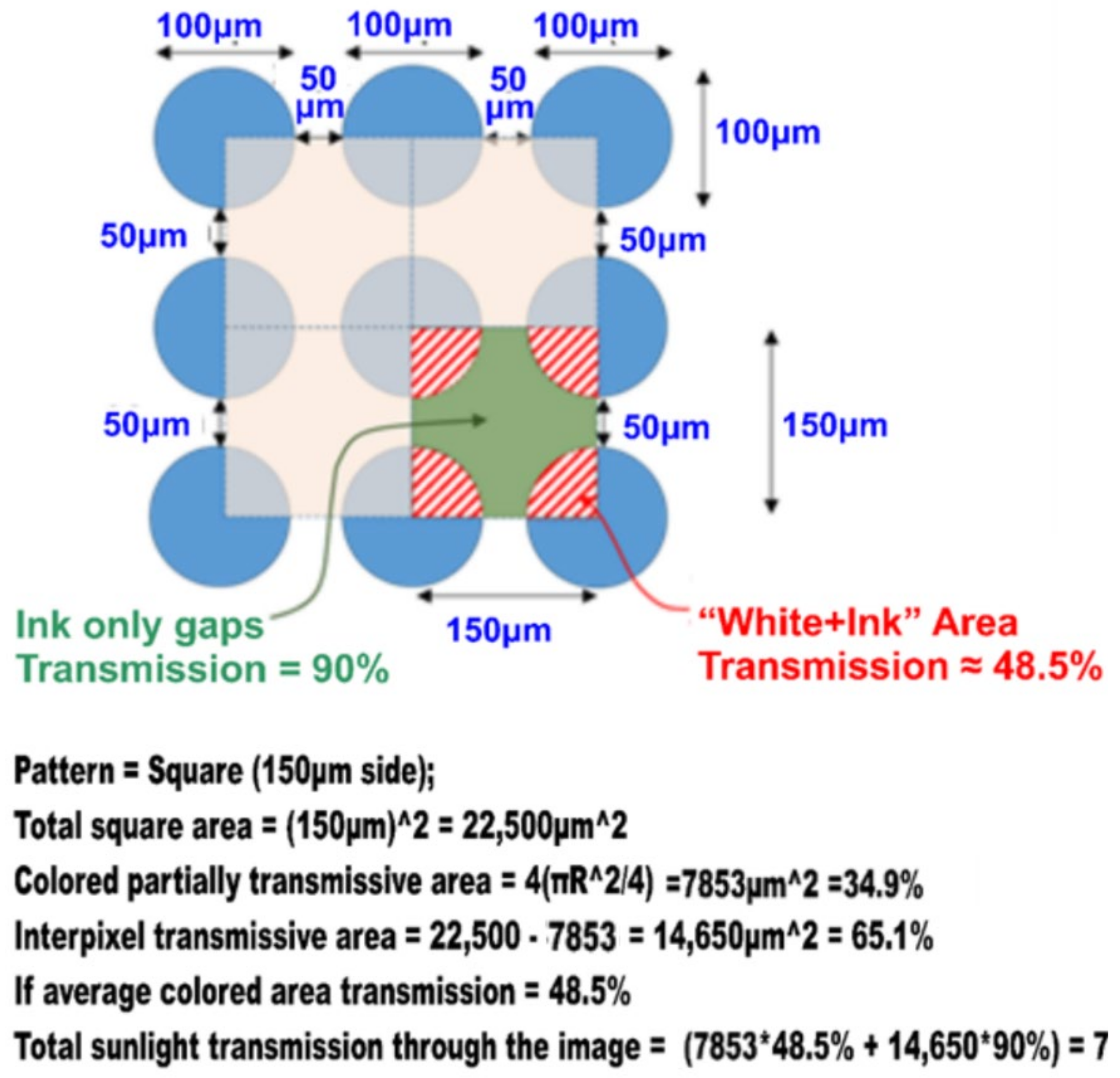

2. Experimental Procedure

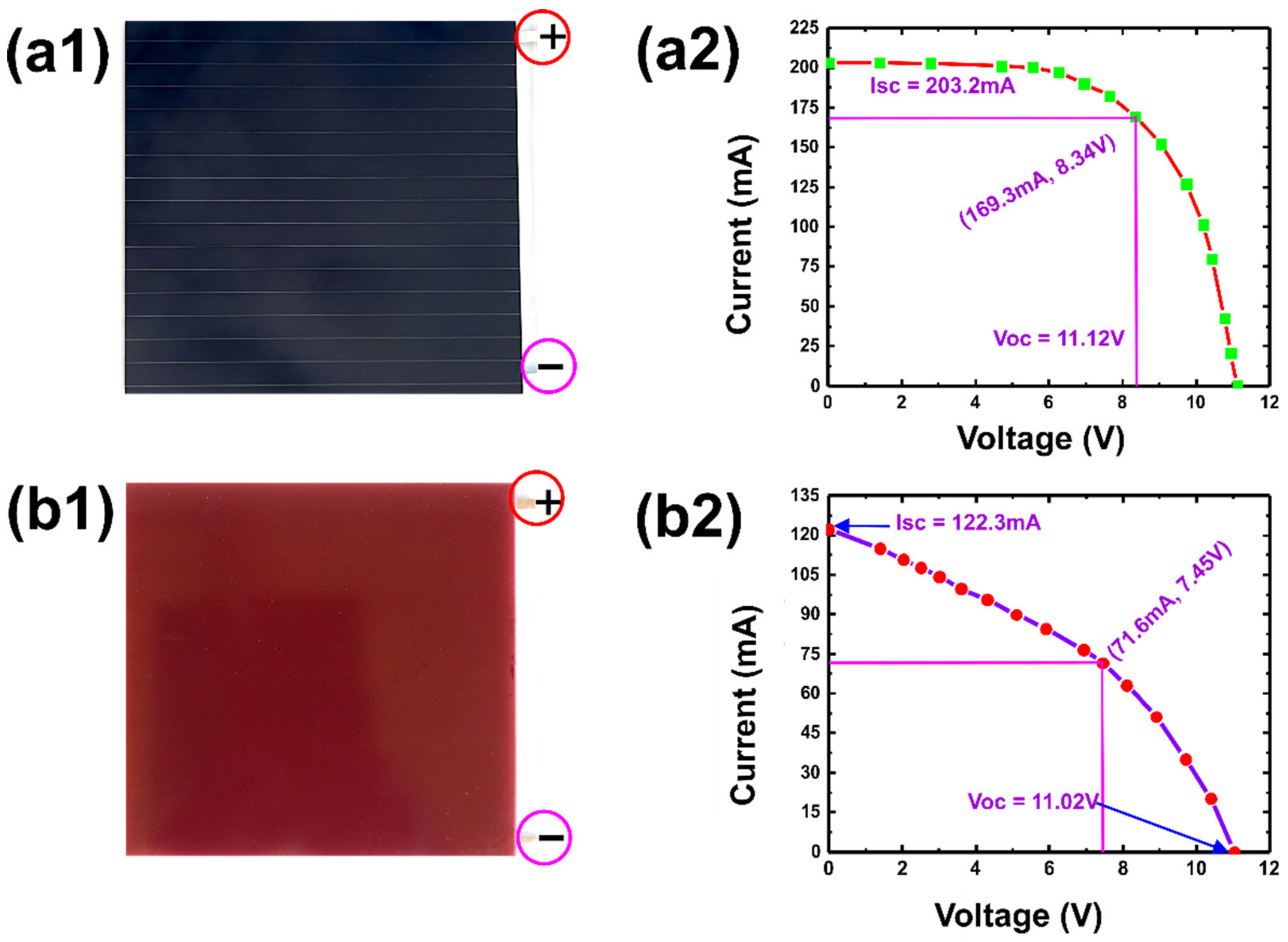

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nejat, P.; Jomehzadeh, F.; Taheri, M.M.; Gohari, M.; Abd Majid, M.Z. A global review of energy consumption, CO2 emissions and policy in the residential sector (with an overview of the top ten CO2 emitting countries). Renew. Sustain. Energy Rev. 2015, 43, 843–862. [Google Scholar] [CrossRef]

- Li, X.; Bowers, C.P.; Schnier, T. Classification of Energy Consumption in Buildings with Outlier Detection. IEEE Trans. Ind. Electron. 2010, 57, 3639–3644. [Google Scholar] [CrossRef]

- Attoye, D.E.; Aoul, K.A.T.; Hassan, A. A review on building integrated photovoltaic façade customization potentials. Sustainability 2017, 9, 2287. [Google Scholar] [CrossRef] [Green Version]

- Knera, D.; Heim, D. Application of a BIPV to cover net energy use of the adjacent office room. Manag. Environ. Qual. Int. J. 2016, 27, 649–662. [Google Scholar] [CrossRef]

- Evola, G.; Margani, G. Renovation of apartment blocks with BIPV: Energy and economic evaluation in temperate climate. Energy Build. 2016, 130, 794–810. [Google Scholar] [CrossRef]

- Jayathissa, P.; Luzzatto, M.; Schmidli, J.; Hofer, J.; Nagy, Z.; Schlueter, A. Optimising building net energy demand with dynamic BIPV shading. Appl. Energy 2017, 202, 726–735. [Google Scholar] [CrossRef]

- Wong, P.W.; Shimoda, Y.; Nonaka, M.; Inoue, M.; Mizuno, M. Semi-transparent PV: Thermal performance, power generation, daylight modelling and energy saving potential in a residential application. Renew. Energy 2008, 33, 1024–1036. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin facade in a cool-summer Mediterranean climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Bayoumi, M. Impacts of window opening grade on improving the energy efficiency of a façade in hot climates. Build. Environ. 2017, 119, 31–43. [Google Scholar] [CrossRef]

- Agathokleous, R.A.; Kalogirou, S.A. Double skin facades (DSF) and building integrated photovoltaics (BIPV): A review of configurations and heat transfer characteristics. Renew. Energy 2016, 89, 743–756. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, L.; Peng, J. Evaluation of potential benefits of solar photovoltaic shadings in Hong Kong. Energy 2017, 137, 1152–1158. [Google Scholar] [CrossRef]

- Eder, G.; Peharz, G.; Trattnig, R.; Bonomo, P.; Saretta, E.; Frontini, F.; Polo López, C.S.; Rose Wilson, H.; Eisenlohr, J.; Martin Chivelet, N.; et al. Coloured BIPV-Market, Research and Development; 2019; p. 60. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/IEA-PVPS_15_R07_Coloured_BIPV_report.pdf (accessed on 30 November 2021).

- Ballif, C.; Perret-Aebi, L.E.; Lufkin, S.; Rey, E. Integrated thinking for photovoltaics in buildings. Nat. Energy 2018, 3, 438–442. [Google Scholar] [CrossRef]

- Cohen, J.J.; Reichl, J.; Schmidthaler, M. Re-focussing research efforts on the public acceptance of energy infrastructure: A critical review. Energy 2014, 76, 4–9. [Google Scholar] [CrossRef]

- Mittag, M.; Kutter, C.; Ebert, M.; Wilson, H. Power Loss through Decorative Elements in the Front Glazing of BIPV Modules. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 2609–2613. [Google Scholar]

- Prieto, A.; Knaack, U.; Auer, T.; Klein, T. Solar façades—Main barriers for widespread façade integration of solar technologies. J. Facade Des. Eng. 2017, 5, 51–62. [Google Scholar]

- Munari Probst, M.C.; Roecker, C. Criteria for architectural integration of active solar systems IEA Task 41, Subtask A. Energy Procedia 2012, 30, 1195–1204. [Google Scholar]

- Tabakovic, M.; Fechner, H.; Van Sark, W.; Louwen, A.; Georghiou, G.; Makrides, G.; Loucaidou, E.; Ioannidou, M.; Weiss, I.; Arancon, S.; et al. Status and Outlook for Building Integrated Photovoltaics (BIPV) in Relation to Educational needs in the BIPV Sector. Energy Procedia 2012, 111, 993–999. [Google Scholar]

- Goh, K.C.; Goh, H.H.; Yap, A.B.K.; Masrom, M.A.N.; Mohamed, S. Barriers and Drivers of Malaysian BIPV Application: Perspective of Developers. Procedia Eng. 2017, 180, 1585–1595. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X.W. Building integrated photovoltaics (BIPV): Costs, benefits, risks, barriers and improvement strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Karakaya, E.; Sriwannawit, P. Barriers to the adoption of photovoltaic systems: The state of the art. Renew. Sustain. Energy Rev. 2015, 49, 60–66. [Google Scholar] [CrossRef] [Green Version]

- Yang, R.J. Overcoming technical barriers and risks in the application of building integrated photovoltaics (BIPV): Hardware and software strategies. Autom. Constr. 2015, 51, 92–102. [Google Scholar] [CrossRef]

- Azadian, F.; Radzi, M.A.M. A general approach toward building integrated photovoltaic systems and its implementation barriers: A review. Renew. Sustain. Energy Rev. 2013, 22, 527–538. [Google Scholar] [CrossRef]

- Taleb, H.M.; Pitts, A.C. The potential to exploit use of building-integrated photovoltaics in countries of the Gulf Cooperation Council. Renew. Energy 2009, 34, 1092–1099. [Google Scholar] [CrossRef]

- Scognamiglio, A.; Privato, C. Starting Points for A New Cultural Vision of Bipv. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference, Valencia, Spain, 1 September 2008; pp. 3222–3233. [Google Scholar]

- Lee, K.T.; Lee, J.Y.; Seo, S.; Guo, L.J. Colored ultrathin hybrid photovoltaics with high quantum efficiency. Light Sci. Appl. 2014, 3, e215. [Google Scholar] [CrossRef]

- Lien, S.-Y. Artist Photovoltaic Modules. Energies 2016, 9, 551. [Google Scholar] [CrossRef] [Green Version]

- Peharz, G.; Berger, K.; Kubicek, B.; Aichinger, M.; Grobbauer, M.; Gratzer, J.; Nemitz, W.; Großschädl, B.; Auer, C.; Prietl, C.; et al. Application of plasmonic coloring for making building integrated PV modules comprising of green solar cells. Renew. Energy 2017, 109, 542–550. [Google Scholar] [CrossRef]

- Halme, J.; Mäkinen, P. Theoretical efficiency limits of ideal coloured opaque photovoltaics. Energy Environ. Sci. 2019, 12, 1274–1285. [Google Scholar] [CrossRef]

- Calvo, M.E. Materials chemistry approaches to the control of the optical features of perovskite solar cells. J. Mater. Chem. A 2017, 5, 20561–20578. [Google Scholar] [CrossRef] [Green Version]

- Noh, J.H.; Im, S.H.; Heo, J.H.; Mandal, T.N.; Seok, S. Chemical Management for Colorful, Efficient, and Stable Inorganic–Organic Hybrid Nanostructured Solar Cells. Nano Lett. 2013, 13, 1764–1769. [Google Scholar] [CrossRef]

- Fakharuddin, A.; Jose, R.; Brown, T.M.; Fabregat-Santiago, F.; Bisquert, J. A perspective on the production of dye-sensitized solar modules. Energy Environ. Sci. 2014, 7, 3952–3981. [Google Scholar] [CrossRef]

- Ren, Y.; Sun, D.; Cao, Y.; Tsao, H.N.; Yuan, Y.; Zakeeruddin, S.M.; Wang, P.; Grätzel, M. A Stable Blue Photosensitizer for Color Palette of Dye-Sensitized Solar Cells Reaching 12.6% Efficiency. J. Am. Chem. Soc. 2018, 140, 2405–2408. [Google Scholar] [CrossRef]

- Hashmi, S.G.; Özkan, M.; Halme, J.; Zakeeruddin, S.M.; Paltakari, J.; Grätzel, M.; Lund, P.D. Dye-sensitized solar cells with inkjet-printed dyes. Energy Environ. Sci. 2016, 9, 2453–2462. [Google Scholar] [CrossRef] [Green Version]

- Ameri, T.; Dennler, G.; Waldauf, C.; Azimi, H.; Seemann, A.; Forberich, K.; Hauch, J.; Scharber, M.; Hingerl, K.; Brabec, C.J. Fabrication, Optical Modeling, and Color Characterization of Semitransparent Bulk-Heterojunction Organic Solar Cells in an Inverted Structure. Adv. Funct. Mater. 2010, 20, 1592–1598. [Google Scholar] [CrossRef]

- Klampaftis, E.; Ross, D.; Richards, B.S. Color, graphic design and high efficiency for photovoltaic modules. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 0025–0029. [Google Scholar]

- Selj, J.H.; Mongstad, T.T.; Søndenå, R.; Marstein, E.S. Reduction of optical losses in colored solar cells with multilayer antireflection coatings. Sol. Energy Mater. Sol. Cells 2011, 95, 2576–2582. [Google Scholar] [CrossRef]

- Li, M.; Zeng, L.; Chen, Y.; Zhuang, L.; Wang, X.; Shen, H. Realization of Colored Multicrystalline Silicon Solar Cells with SiO 2/SiN x:H Double Layer Antireflection Coatings. Int. J. Photoenergy 2013, 2013, 35247. [Google Scholar] [CrossRef] [Green Version]

- Tobias, I.; El Moussaoni, A.; Luque, A. Colored solar cells with minimal current mismatch. IEEE Trans. Electron Devices 1999, 46, 1858–1865. [Google Scholar] [CrossRef]

- Yoo, G.Y.; Jeong, J.; Lee, S.; Lee, Y.; Yoon, H.C.; Chu, V.B.; Park, G.S.; Hwang, Y.J.; Kim, W.; Min, B.K.; et al. Multiple-Color-Generating Cu(In,Ga)(S,Se)2 Thin-Film Solar Cells via Dichroic Film Incorporation for Power-Generating Window Applications. ACS Appl. Mater. Interfaces 2017, 9, 14817–14826. [Google Scholar] [CrossRef]

- BIPV Facade of the CSEM Research Center in Switzerland, City of Neuchâtel, Viteos and CSE. Available online: https://www.researchgate.net/figure/BIPV-facade-of-the-CSEM-Research-Center-in-Switzerland-City-of-Neuchatel-Viteos-and_fig6_290221424 (accessed on 31 March 2022).

- BIPV Solar Facades System [14] Figure 4. BIPV In-Roof Systems [15]. Available online: https://www.researchgate.net/figure/BIPV-solar-facades-system-14-Figure-4-BIPV-In-Roof-Systems-15_fig2_331313983 (accessed on 31 March 2022).

- File:Toppila Power Plant Oulu 20170604.jpg—Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:Toppila_Power_Plant_Oulu_20170604.jpg (accessed on 31 March 2022).

- Switch to Solar—The Hindu. Available online: https://www.thehindu.com/real-estate/the-importance-of-bipv/article23988347.ece (accessed on 21 March 2022).

- Bläsi, B.; Kroyer, T.; Höhn, O.; Wiese, M.; Ferrara, C.; Eitner, U.; Kuhn, T.E. Morpho Butterfly Inspired Coloured Bipv Modules. In Proceedings of the 33rd European PV Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 24 September 2017; pp. 25–29. [Google Scholar]

- Neder, V.; Luxembourg, S.L.; Polman, A. Efficient colored silicon solar modules using integrated resonant dielectric nanoscatterers. Appl. Phys. Lett. 2017, 111, 073902. [Google Scholar] [CrossRef]

- Lee, K.-T.; Lee, J.Y.; Xu, T.; Park, H.J.; Guo, L.J. Colored dual-functional photovoltaic cells. J. Opt. 2016, 18, 064003. [Google Scholar] [CrossRef]

- Hoffman, B. The impact of digital printing with ceramic inks on decorative and functional glass. Glass Int. 2013, 36, 38–40. [Google Scholar]

- Jolissaint, N.; Hanbali, R.; Hadorn, J.-C.; Schüler, A. Colored solar façades for buildings. Energy Procedia 2017, 122, 175–180. [Google Scholar] [CrossRef]

- File:Brick Wall Close-Up View.jpg—Wikimedia Commons. Available online: https://commons.wikimedia.org/wiki/File:Brick_wall_close-up_view.jpg (accessed on 19 March 2022).

- Electrical, 4U Characteristics of a Solar Cell and Parameters of a Solar Cell. Available online: https://www.electrical4u.com/characteristics-and-parameters-of-a-solar-cell/ (accessed on 20 March 2022).

- Jelle, B. Building Integrated Photovoltaics: A Concise Description of the Current State of the Art and Possible Research Pathways. Energies 2016, 9, 21. [Google Scholar] [CrossRef] [Green Version]

- Thornton, W.A. Spectral sensitivities of the normal human visual system, color-matching functions and their principles, and how and why the two sets should coincide. Color Res. Appl. 1999, 24, 139–156. [Google Scholar] [CrossRef]

- Soman, A.; Antony, A. Colored solar cells with spectrally selective photonic crystal reflectors for application in building integrated photovoltaics. Sol. Energy 2019, 181, 1–8. [Google Scholar] [CrossRef]

- Smith, T.; Guild, J. The C.I.E. colorimetric standards and their use. Trans. Opt. Soc. 1931, 33, 73–134. [Google Scholar] [CrossRef]

- Malacara, D. Color Vision and Colorimetry: Theory and Applications, 2nd ed.; SPIE: Bellingham, WA, USA, 2011; ISBN 9780819483980. [Google Scholar]

- Van Roosmalen, J.A.M.; Slooff, L.H.; Okel, L.A.G.; Minderhoud, T.; Sepers, T.; Versluis, A.; Frumau, F.; Rietbergen, M.; Polinder, L.; Heller, E.M.B.; et al. An architectural approach for improving aesthetics of PV. In Proceedings of the 33rd European PV Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 25–29 September 2017. [Google Scholar]

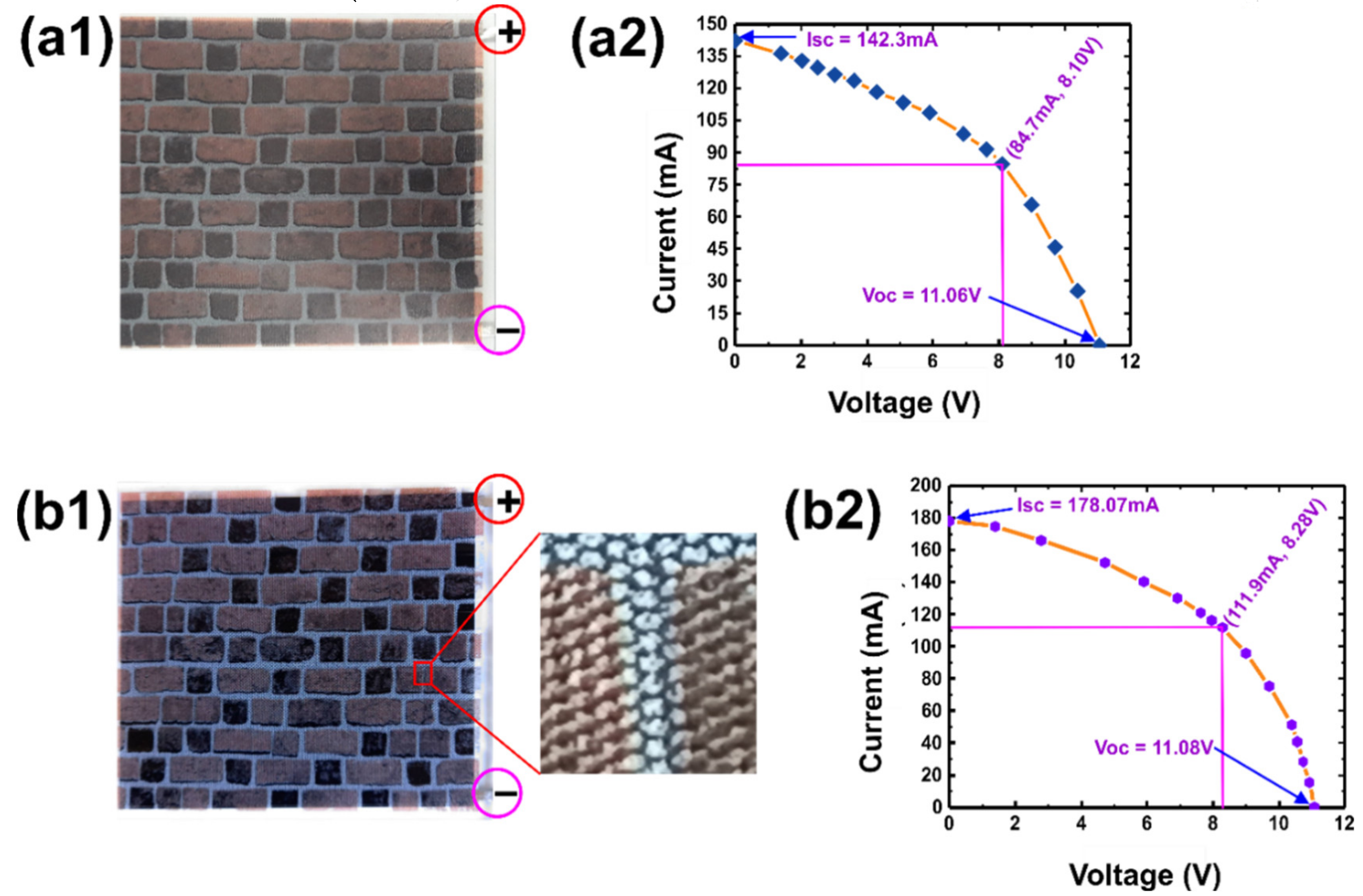

| Sample Name | Voc (V) | Isc (mA) | FF (%) | η (%) | Pmax (mW) |

|---|---|---|---|---|---|

| Reference (Black) PV Module | 11.12 | 203.2 | 62.4 | 14.5 | 1410 |

| Single-Colored PV (SCPV) Module | 11.02 | 122.3 | 39.5 | 5.49 | 533.42 |

| Multicolored (MCPV) PV Module | 11.06 | 142.5 | 43.5 | 7.07 | 686.07 |

| Micropatterned-based Multicolored (MPCPV) PV Module | 11.08 | 178.07 | 46.9 | 9.6 | 926.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basher, M.K.; Nur-E-Alam, M.; Rahman, M.M.; Hinckley, S.; Alameh, K. Design, Development, and Characterization of Highly Efficient Colored Photovoltaic Module for Sustainable Buildings Applications. Sustainability 2022, 14, 4278. https://doi.org/10.3390/su14074278

Basher MK, Nur-E-Alam M, Rahman MM, Hinckley S, Alameh K. Design, Development, and Characterization of Highly Efficient Colored Photovoltaic Module for Sustainable Buildings Applications. Sustainability. 2022; 14(7):4278. https://doi.org/10.3390/su14074278

Chicago/Turabian StyleBasher, Mohammad Khairul, Mohammad Nur-E-Alam, Md Momtazur Rahman, Steven Hinckley, and Kamal Alameh. 2022. "Design, Development, and Characterization of Highly Efficient Colored Photovoltaic Module for Sustainable Buildings Applications" Sustainability 14, no. 7: 4278. https://doi.org/10.3390/su14074278