Prediction of China’s Industrial Solid Waste Generation Based on the PCA-NARBP Model

Abstract

:1. Introduction

- (1)

- In order to predict the ISWG of China in the next 10 years, a new PCA-NARBP combination model is proposed. The model can provide high precision prediction in combination with the actual national conditions and limited amount of data. Compared with BP and nonlinear autoregressive back propagation (NARBP) models, the accuracy and superiority of the combined model are highlighted.

- (2)

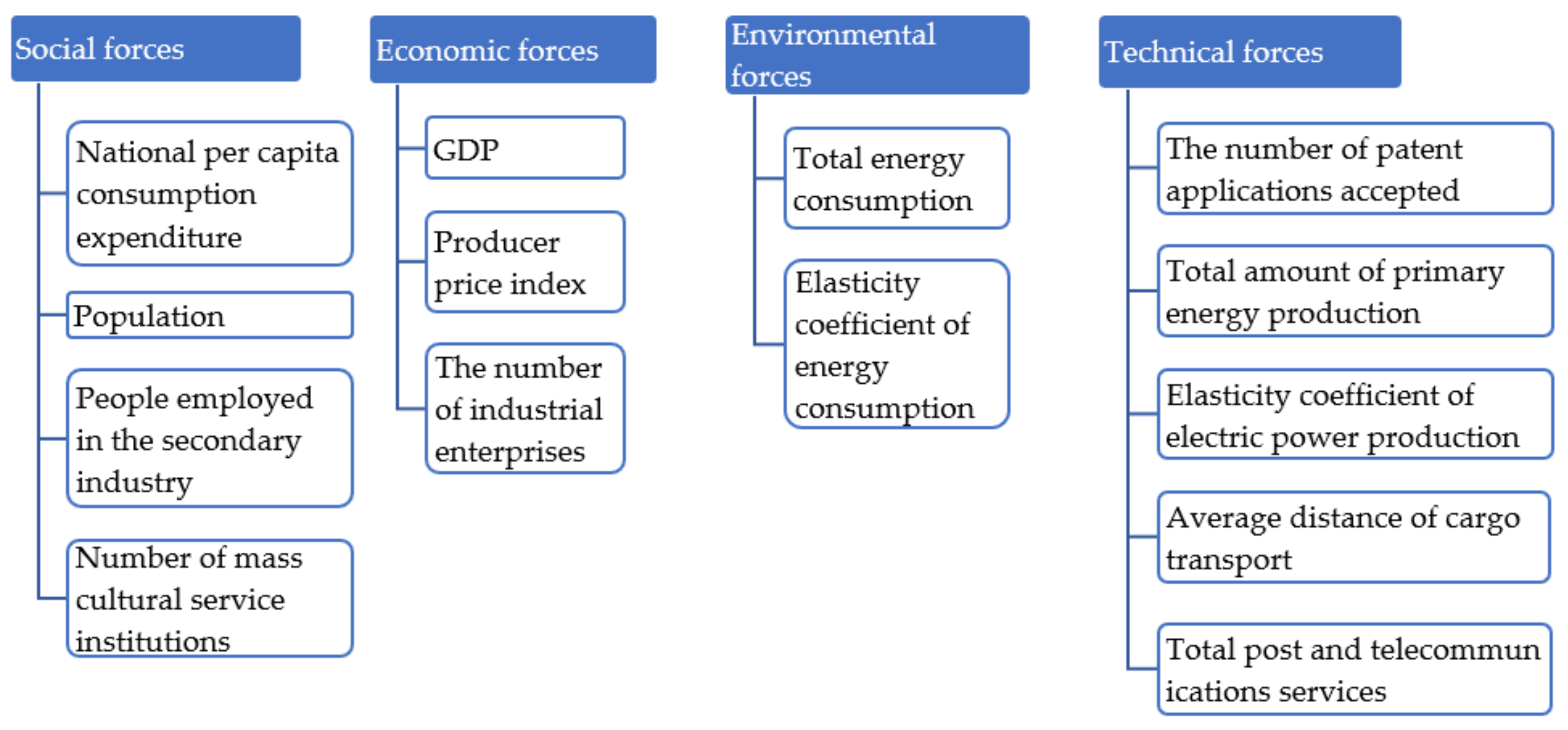

- Combined with China’s actual national conditions, the influencing factors of society, economy, environment and technology are added to the model. A new combination model is established in combination with NARBP model, which is of practical significance and convenient for the formulation of follow up plans. This paper is one of the few papers that combine the actual national conditions and establish a combination model to predict ISWG and realize the resource management of ISW.

2. Method

2.1. Data Collection

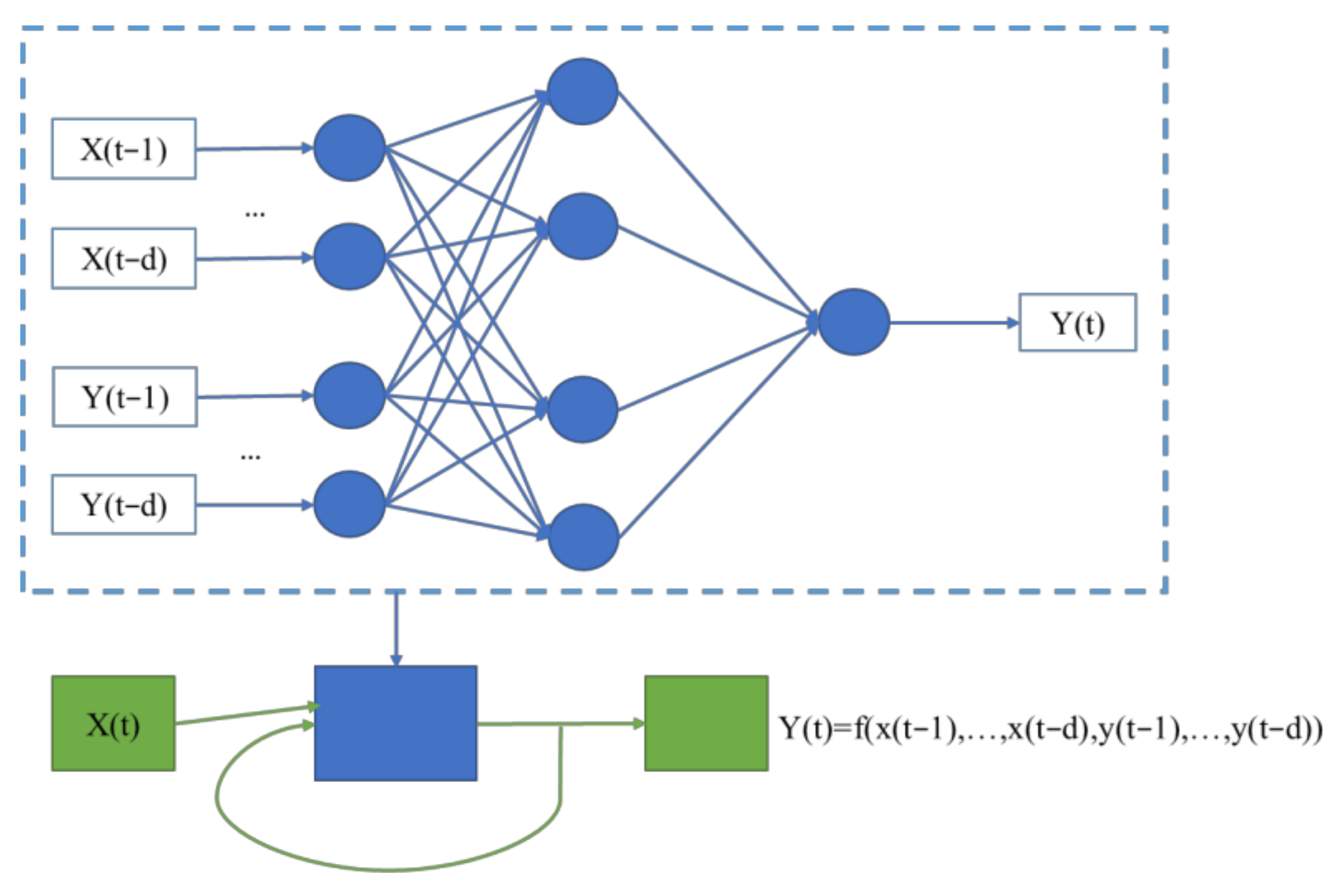

2.2. PCA-NARBP Combinatorial Model

3. Results

3.1. Correlation Discussion

| Forces | ISWG | Forces | ISWG |

|---|---|---|---|

| NPCCE | 0.988 | TEC | 0.975 |

| Pop | 0.851 | ECEC | −0.099 |

| IPop | 0.869 | TPEP | 0.969 |

| NCSI | 0.578 | ECEPP | 0.001 |

| GDP | 0.989 | ADT | 0.779 |

| PPI | −0.428 | TPTS | 0.759 |

| NIE | −0.040 | NPAA | 0.962 |

3.2. Principal Component Analysis

3.3. Error Test

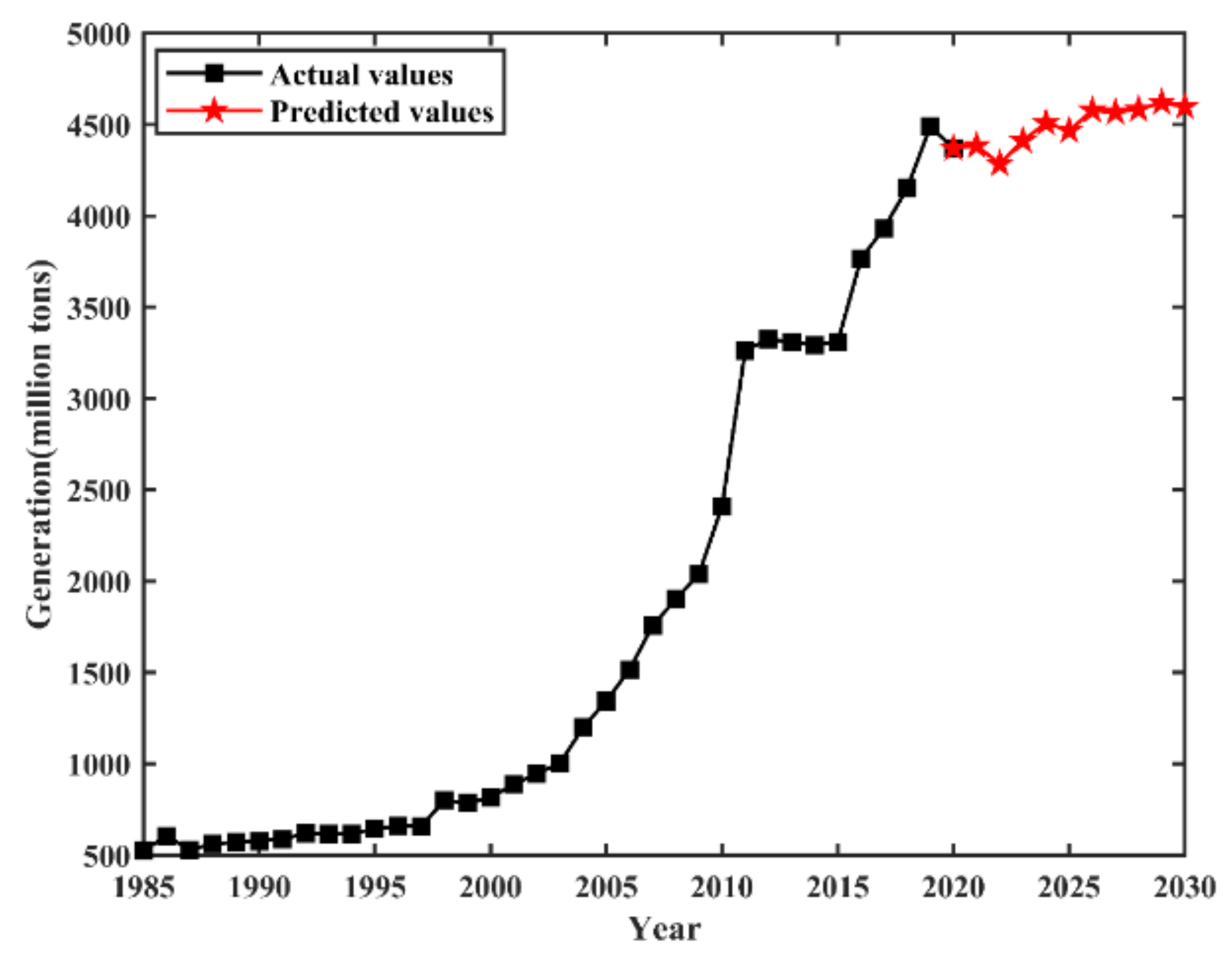

3.4. Forecast the ISWG in China in the Next Ten Years

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sorg, T.J. Industrial solid waste management. J. Water Pollut. Control Fed. 1972, 44, 1107–1108. [Google Scholar]

- Nai, C.; Tang, M.; Liu, Y.; Xu, Y.; Dong, L.; Liu, J.; Huang, Q. Potentially contamination and health risk to shallow groundwater caused by closed industrial solid waste landfills: Site reclamation evaluation strategies. J. Clean. Prod. 2021, 286, 125402. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, H.; Du, L.; Lu, W.; Qi, K. Exploring the industrial solid wastes management system: Empirical analysis of forecasting and safeguard mechanisms. J. Environ. Manag. 2021, 279, 111627. [Google Scholar] [CrossRef]

- Lima, D.Q.; Oliveira, L.C.A.; Bastos, A.R.R.; Carvalho, G.S.; Marques, J.G.S.M.; Carvalho, J.G.; de Souza, G.A. Leather Industry Solid Waste as Nitrogen Source for Growth of Common Bean Plants. Appl. Environ. Soil Sci. 2010, 2010, 703842. [Google Scholar] [CrossRef]

- Pablos, J.M.; Sichieri, E.P.; Izeli, R.L. Reuse of the industrial solid waste, consisting for foundry sands, in the confection of massive bricks and decorative pieces. J. Archit. Urban. 2009, 0, 112–125. [Google Scholar]

- Martinez-Avila, O.; Munoz-Torrero, P.; Sanchez, A.; Font, X.; Barrena, R. Valorization of agro-industrial wastes by producing 2-phenylethanol via solid-state fermentation: Influence of substrate selection on the process. Waste Manag. 2021, 121, 403–411. [Google Scholar] [CrossRef]

- Krishnan, S.; Zulkapli, N.S.; Kamyab, H.; Taib, S.M.; Din, M.F.B.M.; Majid, Z.A.; Chaiprapat, S.; Kenzo, I.; Ichikawa, Y.; Nasrullah, M.; et al. Current technologies for recovery of metals from industrial wastes: An overview. Environ. Technol. Innov. 2021, 22, 101525. [Google Scholar] [CrossRef]

- Krishna, R.S.; Mishra, J.; Meher, S.; Das, S.K.; Mustakim, S.M.; Singh, S.K. Industrial solid waste management through sustainable green technology: Case study insights from steel and mining industry in Keonjhar, India. Mater. Today Proc. 2020, 33, 5243–5249. [Google Scholar] [CrossRef]

- Mavroulidou, M.; Shah, S. Alkali-activated slag concrete with paper industry waste. Waste Manag. Res. 2021, 39, 466–472. [Google Scholar] [CrossRef]

- Khan, M.M.H.; Havukainen, J.; Horttanainen, M. Impact of utilizing solid recovered fuel on the global warming potential of cement production and waste management system: A life cycle assessment approach. Waste Manag. Res. 2021, 39, 561–572. [Google Scholar] [CrossRef]

- Viczek, S.A.; Aldrian, A.; Pomberger, R.; Sarc, R. Origins of major and minor ash constituents of solid recovered fuel for co-processing in the cement industry. Waste Manag. 2021, 126, 423–432. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Hu, X.; Luo, X.; Zhou, Y.; Wang, D.; Farah, S. Identifying the most significant input parameters for predicting district heating load using an association rule algorithm. J. Clean. Prod. 2020, 275, 122984. [Google Scholar] [CrossRef]

- Ayeleru, O.O.; Fajimi, L.I.; Oboirien, B.O.; Olubambi, P.A. Forecasting municipal solid waste quantity using artificial neural network and supported vector machine techniques: A case study of Johannesburg, South Africa. J. Clean. Prod. 2021, 289, 125671. [Google Scholar] [CrossRef]

- Christensen, T.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Bjorklund, A.; Arena, U.; Barlaz, M.A.; Starostina, V.; Boldrin, A.; Astrup, T.F.; et al. Application of LCA modelling in integrated waste management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef]

- Guo, H.N.; Wu, S.B.; Tian, Y.J.; Zhang, J.; Liu, H.T. Application of machine learning methods for the prediction of organic solid waste treatment and recycling processes: A review. Bioresour. Technol. 2021, 319, 124114. [Google Scholar] [CrossRef]

- Karamouz, M.; Zahraie, B.; Kerachian, R.; Mahjouri, N.; Moridi, A. Development of a master plan for industrial solid waste management. Int. J. Environ. Sci. Technol. 2006, 3, 229–242. [Google Scholar] [CrossRef] [Green Version]

- Nouri, D.; Sabour, M.R.; GhanbarzadehLak, M. Industrial solid waste management through the application of multi-criteria decision-making analysis: A case study of Shamsabad industrial complexes. J. Mater. Cycles Waste Manag. 2016, 20, 43–58. [Google Scholar] [CrossRef]

- Mesa Fernandez, J.M.; Palacios, H.M.; Alvarez Cabal, J.V.; Martinez Huerta, G.M. Methodology for industrial solid waste management: Implementation to sludge management in Asturias (Spain). Waste Manag. Res. 2014, 32, 1103–1112. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.; Song, Y.; Zhang, T.; Wang, J. Manifest system for management of non-hazardous industrial solid wastes: Results from a Tianjin industrial park. J. Clean. Prod. 2016, 133, 252–261. [Google Scholar] [CrossRef]

- Abdallah, M.; Abu Talib, M.; Feroz, S.; Nasir, Q.; Abdalla, H.; Mahfood, B. Artificial intelligence applications in solid waste management: A systematic research review. Waste Manag. 2020, 109, 231–246. [Google Scholar] [CrossRef]

- Fernandez Nascimento, V.; Loureiro, A.I.S.; Andrade, P.R.; Guasselli, L.A.; Ometto, J.P.B. A worldwide meta-analysis review of restriction criteria for landfill siting using geographic information systems. Waste Manag. Res. 2021, 39, 409–426. [Google Scholar] [CrossRef] [PubMed]

- Angelis-Dimakis, A.; Arampatzis, G.; Pieri, T.; Solomou, K.; Dedousis, P.; Apostolopoulos, G. SWAN platform: A web-based tool to support the development of industrial solid waste reuse business models. Waste Manag. Res. 2021, 39, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Ranieri, J.; Vincenzi, A.; Chebira, A.; Atienza, D.; Vetterli, M. Near-Optimal Thermal Monitoring Framework for Many-Core Systems-on-Chip. IEEE Trans. Comput. 2015, 64, 3197–3209. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Q.; Choi, G. Efficiency assessment of industrial solid waste generation and treatment processes with carry-over in China. Sci. Total Environ. 2020, 726, 138274. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Guo, D.; Dong, L.; Xu, Y.; Liu, J. Pollution Status and Environmental Sound Management (ESM) Trends on Typical General Industrial Solid Waste. Procedia Environ. Sci. 2016, 31, 615–620. [Google Scholar] [CrossRef] [Green Version]

- Buenrostro, O.; Bocco, G.; Vence, J. Forecasting generation of urban solid waste in developing countries—A case study in Mexico. J. Air Waste Manag. Assoc. 2001, 51, 86–93. [Google Scholar] [CrossRef] [Green Version]

- Falamaki, A.; Shahin, S. Determination of Shear Strength Parameters of Municipal Solid Waste from Its Physical Properties. IJST T. Civ. Eng. 2018, 43, 193–201. [Google Scholar] [CrossRef]

- Giantomassi, A.; Ippoliti, G.; Longhi, S.; Bertini, I.; Pizzuti, S. On-line steam production prediction for a municipal solid waste incinerator by fully tuned minimal RBF neural networks. J. Process Control 2011, 21, 164–172. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Nema, A.K. Forecasting of solid waste composition using fuzzy regression approach: A case of Delhi. Int. J. Environ. Waste Manag. 2008, 2, 65–74. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, Q.P.; Ma, X.Y.; He, J.H. Prediction of Urban Waste Disposal Based on ARIMA Model. Appl. Mech. Mater. 2015, 768, 707–713. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Al-Nasser, A.; Al-Dhafeeri, A.T. Multi-variable regression analysis for the solid waste generation in the State of Kuwait. Process Saf. Environ. 2018, 119, 172–180. [Google Scholar] [CrossRef]

- Eleyan, D.; Al-Khatib, I.A.; Garfield, J. System dynamics model for hospital waste characterization and generation in developing countries. Waste Manag. Res. 2013, 31, 986–995. [Google Scholar] [CrossRef] [PubMed]

- Bingöl, D.; Inal, M.; Çetintaş, S. Evaluation of Copper Biosorption onto Date Palm (Phoenix dactylifera L.) Seeds with MLR and ANFIS Models. Ind. Eng. Chem. Res. 2013, 52, 4429–4435. [Google Scholar] [CrossRef]

- Intharathirat, R.; Abdul Salam, P.; Kumar, S.; Untong, A. Forecasting of municipal solid waste quantity in a developing country using multivariate grey models. Waste Manag. 2015, 39, 3–14. [Google Scholar] [CrossRef]

- Karaca, F.; Özkaya, B. NN-LEAP: A neural network-based model for controlling leachate flow-rate in a municipal solid waste landfill site. Environ. Model. Softw. 2006, 21, 1190–1197. [Google Scholar] [CrossRef]

- Shu, H.Y.; Lu, H.C.; Fan, H.J.; Chang, M.C.; Chen, J.C. Prediction for energy content of Taiwan municipal solid waste using multilayer perceptron neural networks. J. Air Waste Manag. Assoc. 2006, 56, 852–858. [Google Scholar] [CrossRef]

- Noori, R.; Karbassi, A.; Salman Sabahi, M. Evaluation of PCA and Gamma test techniques on ANN operation for weekly solid waste prediction. J. Environ. Manage. 2010, 91, 767–771. [Google Scholar] [CrossRef]

- Abbasi, M.; Abduli, M.A.; Omidvar, B.; Baghvand, A. Forecasting Municipal Solid waste Generation by Hybrid Support Vector Machine and Partial Least Square Model. Int. J. Environ. Res. 2013, 7, 27–38. [Google Scholar]

- Liang, G.; Panahi, F.; Ahmed, A.N.; Ehteram, M.; Band, S.S.; Elshafie, A. Predicting municipal solid waste using a coupled artificial neural network with archimedes optimisation algorithm and socioeconomic components. J. Clean. Prod. 2021, 315, 128039. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Hou, A.; Havel, J. Artificial neural networks based on principal component analysis input selection for quantification in overlapped capillary electrophoresis peaks. Chemometr. Intell. Lab. 2006, 82, 165–175. [Google Scholar] [CrossRef]

- Zhang, Y.X. Artificial neural networks based on principal component analysis input selection for clinical pattern recognition analysis. Talanta 2007, 73, 68–75. [Google Scholar] [CrossRef]

- Noori, R.; Abdoli, M.A.; Ghasrodashti, A.A.; Jalili Ghazizade, M. Prediction of municipal solid waste generation with combination of support vector machine and principal component analysis: A case study of Mashhad. Environ. Prog. Sustain. Energy 2009, 28, 249–258. [Google Scholar] [CrossRef]

- Hatik, C.; Gatina, J.C. Waste production classification and analysis: A PCA-induced methodology. In Proceedings of the 4th International Conference on Energy and Environment Research ICEER 2017, Porto, Portugal, 17–20 July 2017. [Google Scholar]

- Sunayana; Kumar, S.; Kumar, R. Forecasting of municipal solid waste generation using non-linear autoregressive (NAR) neural models. Waste Manag. 2021, 121, 206–214. [Google Scholar] [CrossRef]

- Wang, F.; Yu, L.; Wu, A. Forecasting the electronic waste quantity with a decomposition-ensemble approach. Waste Manag. 2021, 120, 828–838. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhou, M.; Li, J.; Wei, L.; Dong, Y.; Hou, H.; Chen, C.; Wang, Z. Analysis of driving factors on China’s industrial solid waste generation: Insights from critical supply chains. Sci. Total Environ. 2021, 775, 145185. [Google Scholar] [CrossRef] [PubMed]

- Tsai, F.M.; Bui, T.-D.; Tseng, M.-L.; Wu, K.-J. A causal municipal solid waste management model for sustainable cities in Vietnam under uncertainty: A comparison. Resour. Conserv. Recycl. 2020, 154, 104599. [Google Scholar] [CrossRef]

- Nguyen, X.C.; Nguyen, T.T.H.; La, D.D.; Kumar, G.; Rene, E.R.; Nguyen, D.D.; Chang, S.W.; Chung, W.J.; Nguyen, X.H.; Nguyen, V.K. Development of machine learning-based models to forecast solid waste generation in residential areas: A case study from Vietnam. Resour. Conserv. Recycl. 2021, 167, 105381. [Google Scholar] [CrossRef]

- Li, J.S.; Fan, H.M. Analysis and Prediction of Waste Discharge in Liaoning Industrial Areas. Adv. Mater. Res. 2012, 599, 560–565. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Mcclelland, J.L. Parallel Distributed Processing: Explorations in the Microstructure of Cognition; MIT Press: Cambridge, MA, USA, 1986; pp. 45–76. [Google Scholar]

- Sadeghi, B.H.M. A BP-neural network predictor model for plastic injection molding process. J. Mater. Process. Technol. 2000, 103, 411–416. [Google Scholar] [CrossRef]

- Hoque, M.M.; Rahman, M.T.U. Landfill area estimation based on solid waste collection prediction using ANN model and final waste disposal options. J. Clean. Prod. 2020, 256, 120387. [Google Scholar] [CrossRef]

- Xu, A.; Chang, H.; Xu, Y.; Li, R.; Li, X.; Zhao, Y. Applying artificial neural networks (ANNs) to solve solid waste-related issues: A critical review. Waste Manag. 2021, 124, 385–402. [Google Scholar] [CrossRef] [PubMed]

- Azadi, S.; Karimi-Jashni, A. Verifying the performance of artificial neural network and multiple linear regression in predicting the mean seasonal municipal solid waste generation rate: A case study of Fars province, Iran. Waste Manag. 2016, 48, 14–23. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Luo, J.; Wang, S.; Yang, S. Feature selection in machine learning: A new perspective. Neurocomputing 2018, 300, 70–79. [Google Scholar] [CrossRef]

- Kang, L.; Du, H.L.; Zhang, H.; Ma, W.L. Systematic Research on the Application of Steel Slag Resources under the Background of Big Data. Complexity 2018, 2018, 6703908. [Google Scholar] [CrossRef] [Green Version]

| Components | Initial Eigenvalue | Variance % | Cumulative Contribution Rate % |

|---|---|---|---|

| 1 | 8.615 | 78.320 | 78.320 |

| 2 | 1.260 | 11.451 | 89.771 |

| 3 | 0.625 | 5.680 | 95.450 |

| 4 | 0.253 | 2.296 | 97.746 |

| 5 | 0.160 | 1.453 | 99.199 |

| 6 | 0.049 | 0.443 | 99.642 |

| 7 | 0.030 | 0.275 | 99.917 |

| 8 | 0.005 | 0.048 | 99.965 |

| 9 | 0.003 | 0.028 | 99.993 |

| 10 | 0.001 | 0.005 | 99.998 |

| 11 | 0 | 0.002 | 100 |

| BP | NARBP | PCA-NARBP | ||||

|---|---|---|---|---|---|---|

| MAPE (%) | R2 | MAPE (%) | R2 | MAPE (%) | R2 | |

| 1 | 6.8116 | 0.9734 | 5.7042 | 0.9917 | 6.0663 | 0.9897 |

| 2 | 15.2841 | 0.9628 | 11.7965 | 0.9074 | 5.3662 | 0.9813 |

| 3 | 6.9571 | 0.9717 | 4.6802 | 0.9951 | 36.8035 | 0.9357 |

| 4 | 3.9722 | 0.9925 | 3.7646 | 0.9950 | 26.1795 | 0.9643 |

| 5 | 7.6976 | 0.9866 | 3.7899 | 0.9930 | 1.2489 | 0.9993 |

| 6 | 4.2080 | 0.9896 | 2.9622 | 0.9952 | 7.2723 | 0.9708 |

| 7 | 3.1744 | 0.9722 | 4.5277 | 0.9948 | 9.2783 | 0.9840 |

| 8 | 26.1407 | 0.9562 | 3.5017 | 0.9930 | 8.9505 | 0.9200 |

| 9 | 5.0257 | 0.9847 | 3.2902 | 0.9960 | 11.5263 | 0.9835 |

| 10 | 3.0019 | 0.9845 | 21.4254 | 0.9264 | 19.3492 | 0.9752 |

| Results | 3.0019 | 0.9845 | 2.9622 | 0.9952 | 1.2489 | 0.9993 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.-M.; Sun, H.-H.; Guo, R.; Wang, D.; Yu, H.; Do Rosario Alves, D.; Hong, W.-M. Prediction of China’s Industrial Solid Waste Generation Based on the PCA-NARBP Model. Sustainability 2022, 14, 4294. https://doi.org/10.3390/su14074294

Liu H-M, Sun H-H, Guo R, Wang D, Yu H, Do Rosario Alves D, Hong W-M. Prediction of China’s Industrial Solid Waste Generation Based on the PCA-NARBP Model. Sustainability. 2022; 14(7):4294. https://doi.org/10.3390/su14074294

Chicago/Turabian StyleLiu, Hong-Mei, Hong-Hao Sun, Rong Guo, Dong Wang, Hao Yu, Diana Do Rosario Alves, and Wei-Min Hong. 2022. "Prediction of China’s Industrial Solid Waste Generation Based on the PCA-NARBP Model" Sustainability 14, no. 7: 4294. https://doi.org/10.3390/su14074294

APA StyleLiu, H.-M., Sun, H.-H., Guo, R., Wang, D., Yu, H., Do Rosario Alves, D., & Hong, W.-M. (2022). Prediction of China’s Industrial Solid Waste Generation Based on the PCA-NARBP Model. Sustainability, 14(7), 4294. https://doi.org/10.3390/su14074294