Ergonomic Risk Assessment of Aluminum Form Workers’ Musculoskeletal Disorder at Construction Workstations Using Simulation

Abstract

1. Introduction

- To address the awkward postures of aluminum-type formwork tasks based on real site layout and their corresponding durations.

- To carry out an ergonomic simulation to estimate OWAS, RULA, and EER risk scores for the whole body to provide comprehensive feedback that will enable form-workers to avoid awkward postures.

- To propose and simulate simple ergonomic solutions to reduce MSD.

2. Related Work

Contribution of Ergonomics and DHM on Industrial Workstations

3. Materials and Methods

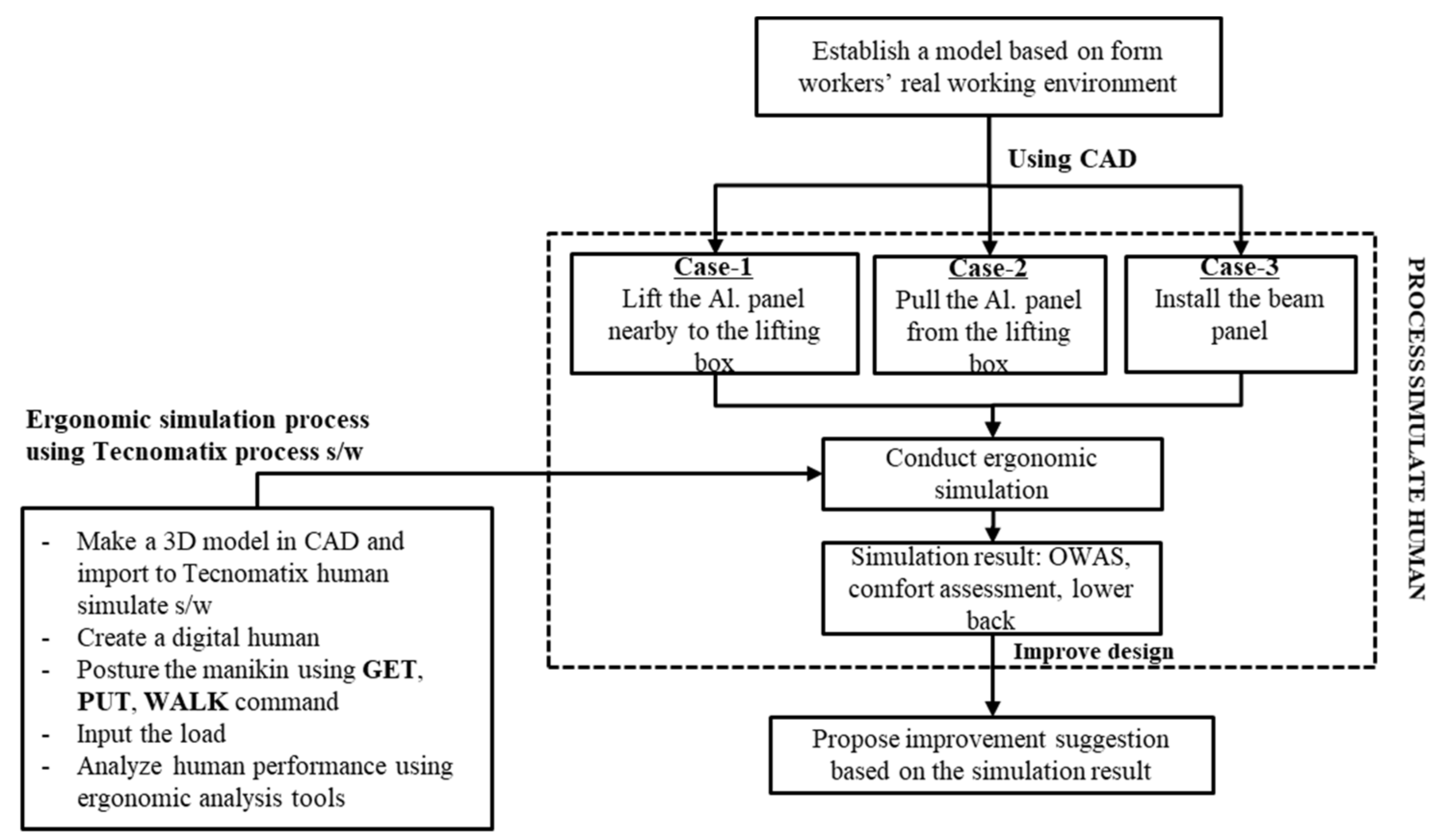

3.1. Software-JACK (Process Simulate Human)

3.2. OWAS, RULA, and Energy Expenditure Analysis (EEA)

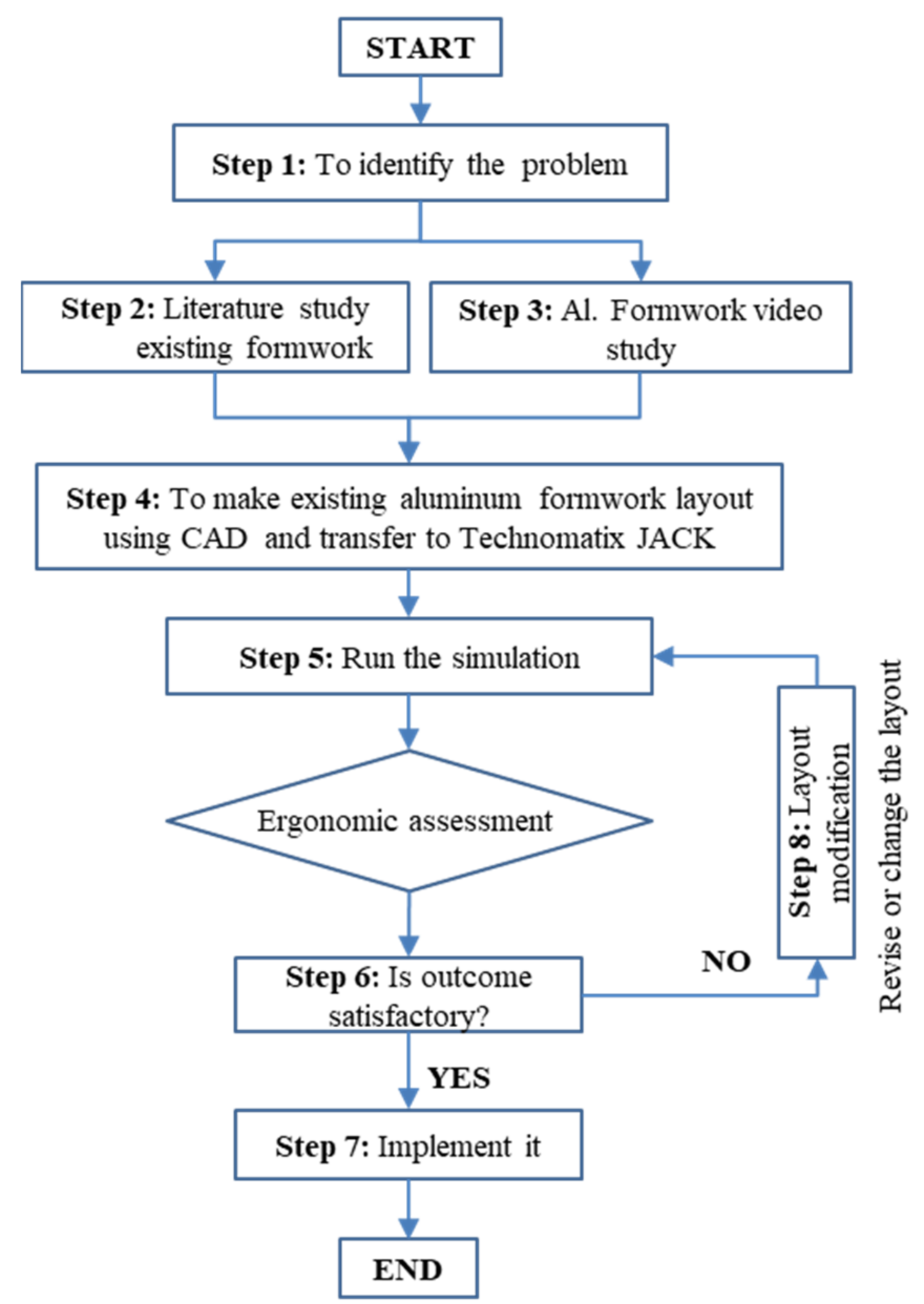

3.3. Flow Chart of the Research Methodology

3.4. Simulation Parameters

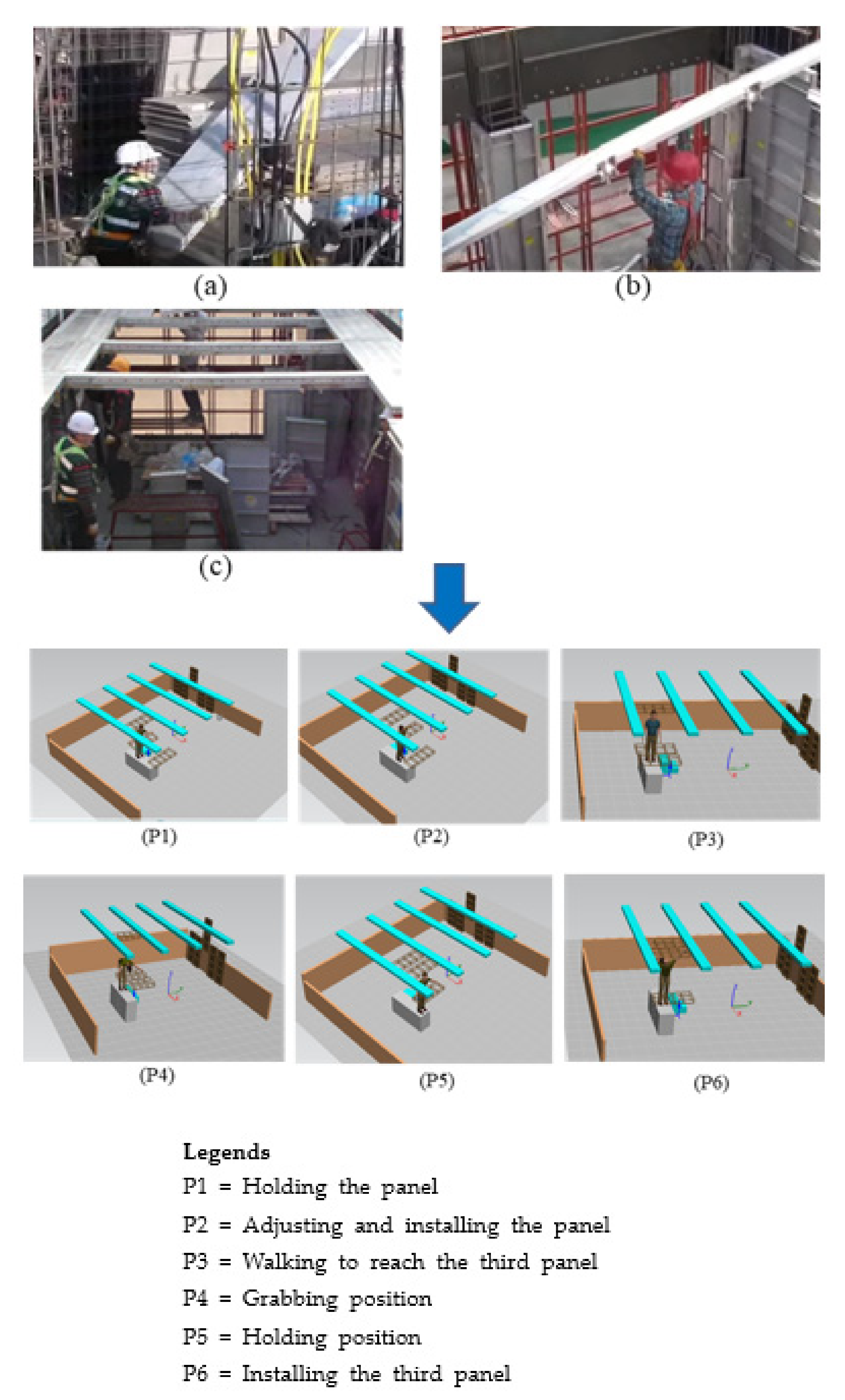

3.5. Test Cases

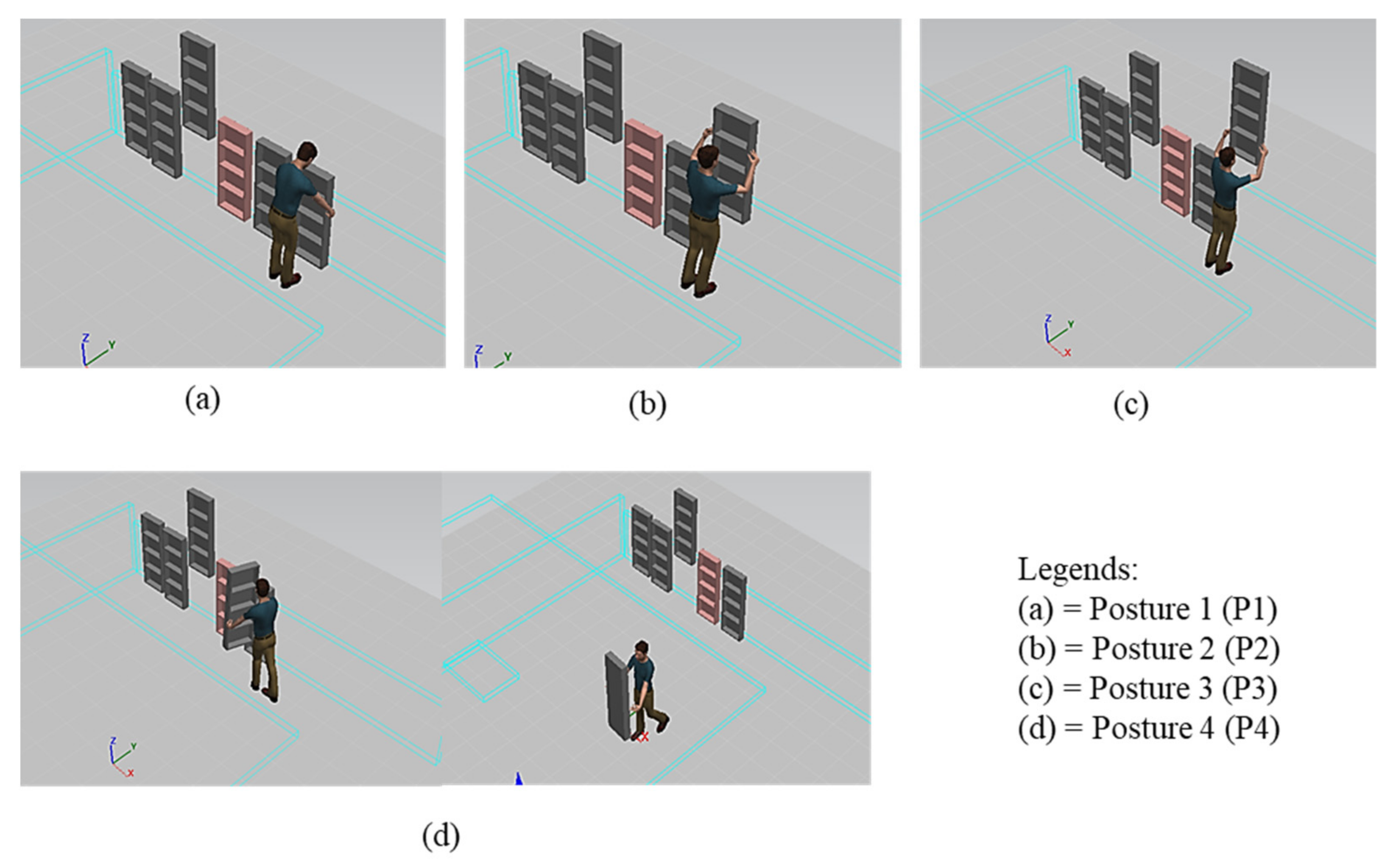

3.5.1. Test Case 1: Lift the Aluminum Panel (AP) near the Lifting Box

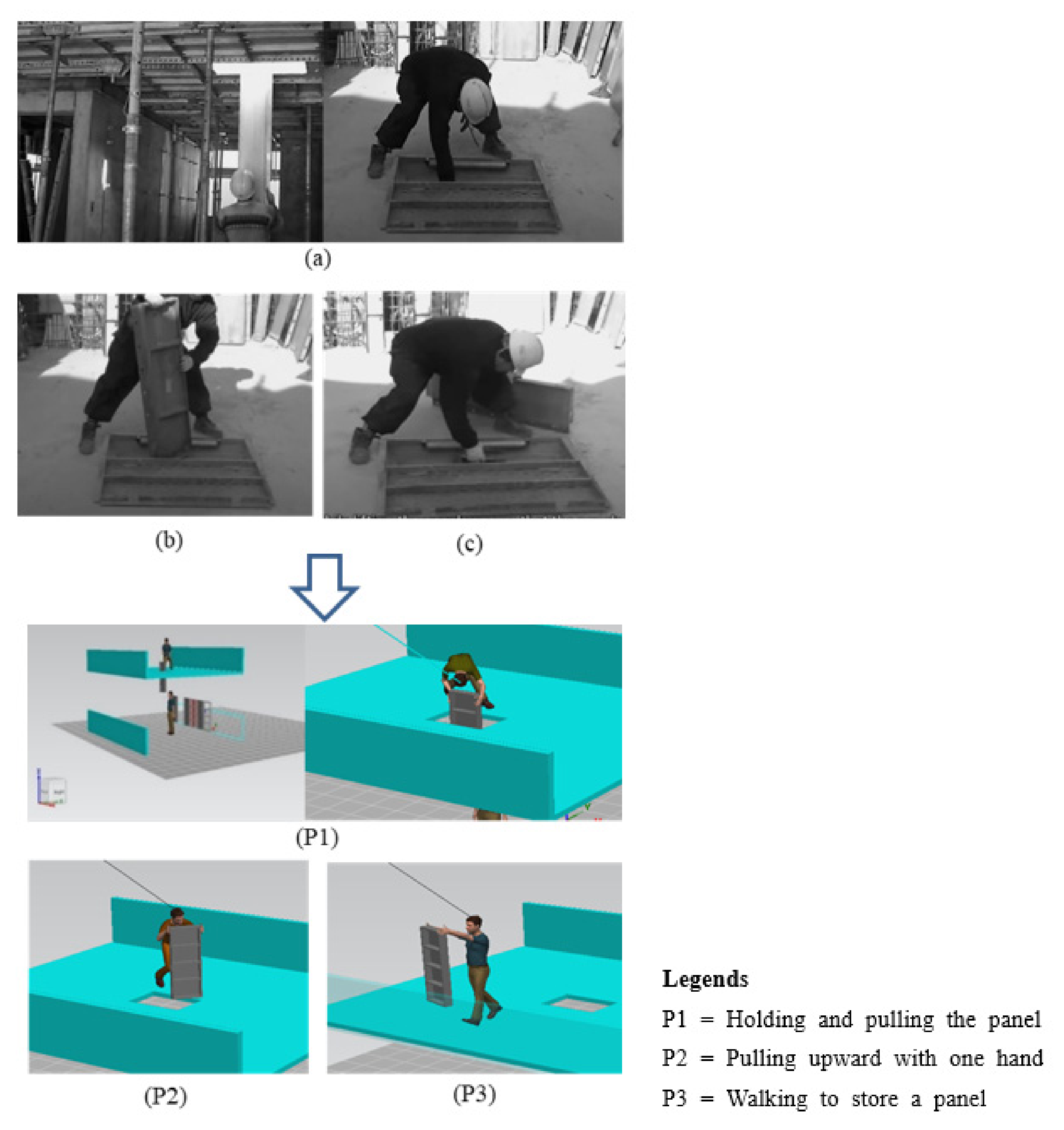

3.5.2. Test Case 2: Pull the Aluminum Panel (AP) from the Lifting Box

3.5.3. Test Case 3: Installing the Beam Panel

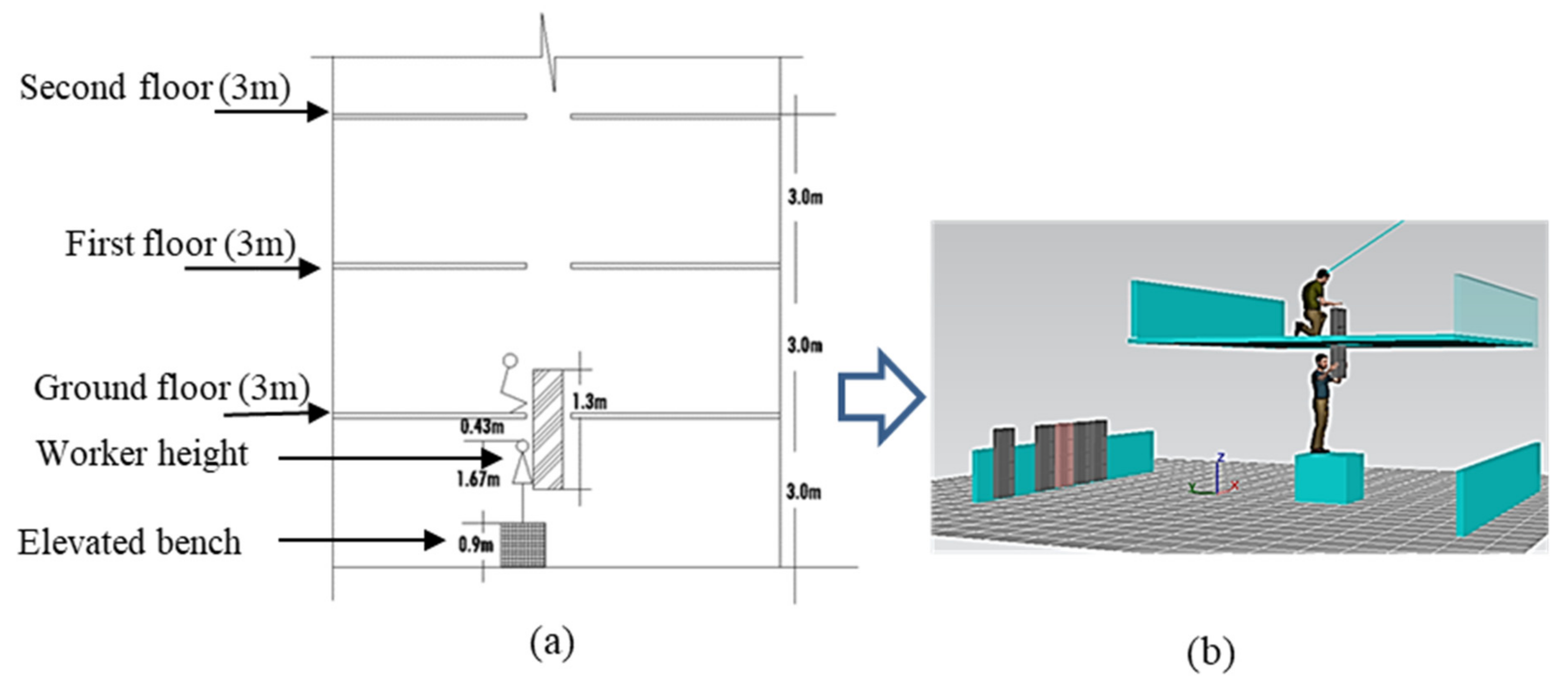

3.5.4. Test Case 4: Simple Layout Modification of Test Case 2

4. Results

4.1. Identified Awkward Postures Based on Simulation

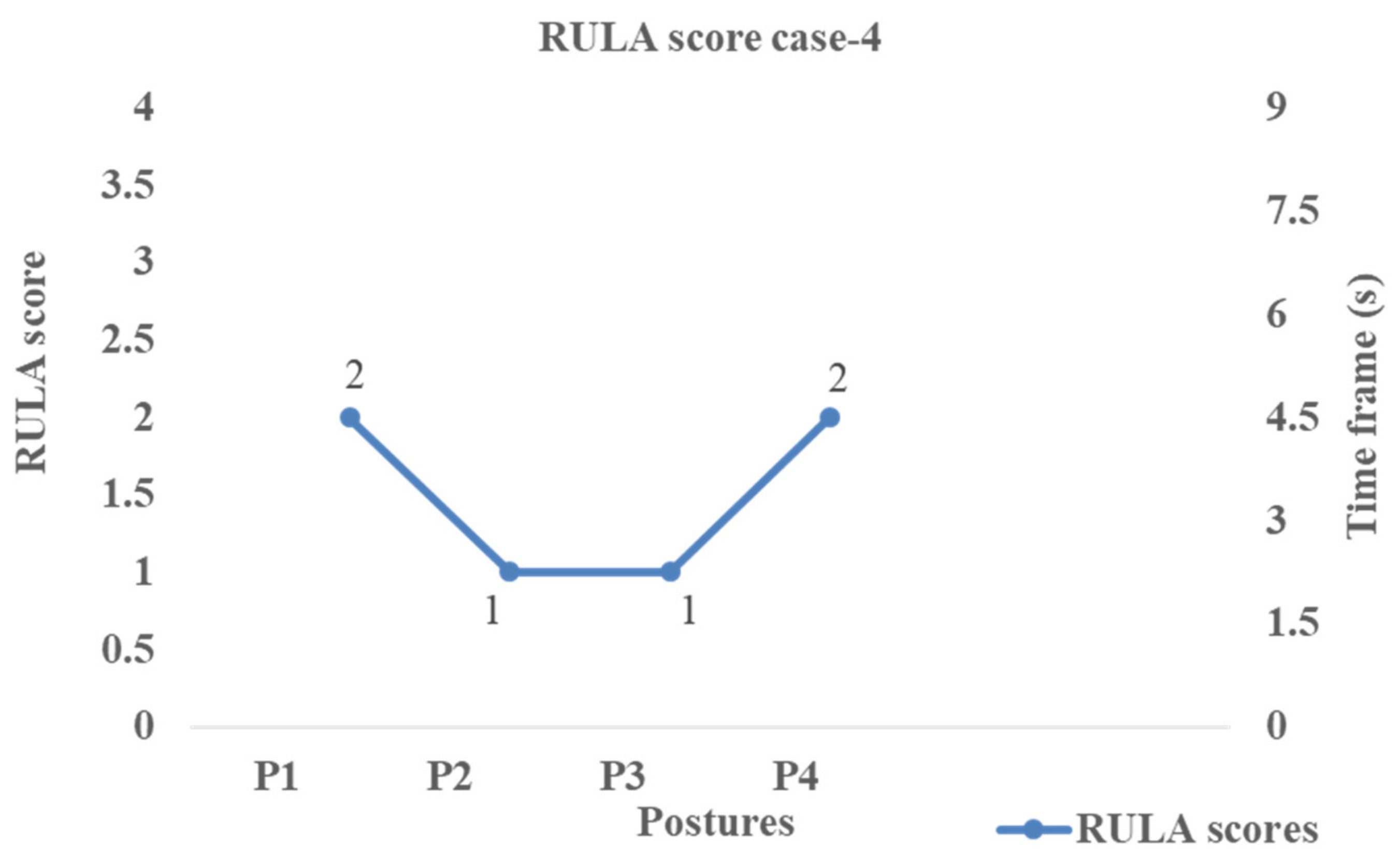

4.2. The RULA Grand Score

4.3. The OWAS Score

4.4. Estimation of the Energy Expenditure Rate (EER)

4.5. Simple Layout Modifications Test Model (Case-4) Results

5. Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chang, F.L.; Sun, Y.M.; Chuang, K.H.; Hsu, D.J. Work fatigue and physiological symptoms in different occupations of high elevation construction workers. Appl. Ergon. 2009, 40, 591–596. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.S. Current Status of Industrial Accident Occurrence in 2016. Available online: http://wwwkosha.or.kr/main.do? (accessed on 12 April 2017).

- Ministry of Employment and Labor-MOEL. Status of Occupational Chronic Disease. 2021. Available online: https://kosis.kr/statHtml/statHtml.do?orgId=118&tblId=DT_11806_N038&vw_cd=MT_ZTITLE&list_id=118_11806_cie647&seqNo=&lang_mode=ko&language=kor&obj_var_id=&itm_id=&conn_path=MT_ZTITLE (accessed on 28 April 2018).

- International Labor Organization [ILO]. Improving Safety and Health of Young Workers; International Labor Organization [ILO]: Geneva, Switzerland, 2018. [Google Scholar]

- Verbeek, J.; Mischke, C.; Robinson, R.; Ijaz, S.; Kuijer, P.; Kievit, A.; Ojajärvi, A.; Neuvonen, K. Occupational Exposure to Knee Loading and the Risk of Osteoarthritis of the Knee: A Systematic Review and a Dose-Response Meta-Analysis. Saf. Health Work 2017, 8, 130–142. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Galán, M.; Pérez-Alonso, J.; Callejón-Ferre, Á.-J.; López-Martínez, J. Musculoskeletal disorders: OWAS review. Ind. Health 2017, 55, 314–337. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Galán, M.; Callejón-Ferre, Á.-J.; Pérez-Alonso, J.; Díaz-Pérez, M.; Carrillo-Castrillo, J.-A. Musculoskeletal Risks: RULA Bibliometric Review. Int. J. Environ. Res. Public Health 2020, 17, 4354. [Google Scholar] [CrossRef] [PubMed]

- Awolusi, I.; Marks, E.; Hallowell, M. Wearable technology for personalized construction safety monitoring and trending: Review of applicable devices. Autom. Constr. 2018, 85, 96–106. [Google Scholar] [CrossRef]

- Skals, S.; Bláfoss, R.; de Zee, M.; Andersen, L.L.; Andersen, M.S. Effects of load mass and position on the dynamic loading of the knees shoulders and lumbar spine during lifting: A musculoskeletal modeling approach. Appl. Ergon. 2021, 96, 103491. [Google Scholar] [CrossRef]

- Bubb, H.; Engstler, F.; Fritzsche, F.; Mergl, C.; Sabbah, O.; Schaefer, P.; Zacher, I. The development of RAMSIS in the past and future as an example for the cooperation between industry and university. Int. J. Hum. Factors Model. Simul. 2006, 1, 140–157. [Google Scholar] [CrossRef]

- Grobelny, J.; Michalski, R.; Waldemar, K. Workload Assessment Predictability for Digital Human Models. In Handbook of Digital Human Modeling; Duffy, V., Ed.; CRC Press: Boca Raton, FL, USA, 2008; Volume 20081561, pp. 1–13. [Google Scholar]

- Sengupta, A.K.; Das, B. An AutoCAD-based three-dimensional anthropometric human model for workstation design. Int. J. Ind. Ergon. 1997, 19, 345–352. [Google Scholar] [CrossRef]

- Chaffin, D.B. On the validity of biomechanical models of the low back for weight lifting analysis. In ASME Proceedings; American Society of Mechanical Engineers: New York, NY, USA, 1975; Volume 75. [Google Scholar]

- Constantinescu, C.; Muresan, P.C.; Simon, G.M. JackEx: The new digital manufacturing resource for optimization of exoskeleton based factory environments. Procedia CIRP. 2016, 50, 508–511. [Google Scholar] [CrossRef]

- Bubb, H. Computer aided tools of ergonomics and system design. Hum. Factors Ergon. Manuf. 2002, 12, 249–265. [Google Scholar] [CrossRef]

- Polášek, P.; Bureš, M.; Šimon, M. Comparison of digital tools for ergonomics in Practice. Proced. Eng. 2015, 100, 1277–1285. [Google Scholar] [CrossRef]

- Manghisi, V.M.; Uva, A.E.; Fiorentino, M.; Bevilacqua, V.; Totta, G.F.; Monno, G. Real time RULA assessment using Kinect v2 sensor. Appl. Ergon. 2016, 65, 481–491. [Google Scholar] [CrossRef] [PubMed]

- Golabchi, A.; Guo, X.; Liu, M.; Han, S.; Lee, S.; Abourizk, S. An integrated ergonomics framework for evaluation and design of construction operations. Autom. Constr. 2018, 95, 72–85. [Google Scholar] [CrossRef]

- Schall, M.C.; Fethke, N.B.; Roemig, V. Digital Human Modeling in the Occupational Safety and Health Process: An Application in Manufacturing. IISE Trans. Occup. Ergon. Hum. Factors. 2018, 6, 64–75. [Google Scholar] [CrossRef]

- Raschke, U.; Cort, C. Siemens Jack. In DHM and Posturography; Academic Press: Cambridge, MA, USA, 2019; pp. 35–48. [Google Scholar]

- Peruzzini, M.; Pellicciari, M.; Gadaleta, M. A comparative study on computer-integrated set-ups to design human-centered manufacturing systems. Robot. Comput. Integr. Manuf. 2019, 55, 265–278. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, X.; Gao, J.; Chen, J.; Xv, X. Simulation and Ergonomic Evaluation of Welders’ Standing Posture Using Jack Software. Int. J. Environ. Res. Public Health 2019, 16, 4354. [Google Scholar] [CrossRef]

- Anton, D.; Bray, M.; Hess, J.A.; Weeks, D.L.; Kincl, L.D.; Vaughan, A. Prevalence of work-related musculoskeletal pain in masonry apprentices. Ergonomics 2020, 63, 1194–1202. [Google Scholar] [CrossRef]

- Atamney, L.; Corlett, E.N. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Hovanec, M. Digital factory as a prerequisite for successful application in the area of ergonomics and human factor. Theor. Issues Ergon. Sci. 2017, 18, 35–45. [Google Scholar] [CrossRef]

- Mifflin, M.D.; St Jeor, S.T.; Hill, L.A.; Scott, B.J.; Daugherty, S.A.; Koh, Y.O. A new predictive equation for resting energy expenditure in healthy individuals. Am. J. Clin. Nutr. 1990, 51, 241–247. [Google Scholar] [CrossRef]

- Palikhe, S.; Yirong, M.; Choi, B.Y.; Lee, D.-E. Analysis of musculoskeletal disorders and muscle stresses on construction workers’ awkward postures using simulation. Sustainability 2020, 12, 5693. [Google Scholar] [CrossRef]

- Rajendran, M.; Sajeev, A.; Shanmugavel, R.; Rajpradedeesh, T. Ergonomin Evaluation of workers during manual material handling. Mater. Today Proc. 2021, 46, 7770–7776. [Google Scholar] [CrossRef]

- Deros, B.M.; Daruis, D.D.I.; Basir, I.M. A study on Ergonomic awareness among workers performing manual material handling activities. Procedia-Soc. Behav. Sci. 2015, 195, 1666–1673. [Google Scholar] [CrossRef]

- Basahel, A.M. Investigation of work related musculoskeletal disorders in warehouse workers in Saudi Arabia. Procedia Manuf. 2015, 3, 4643–4649. [Google Scholar] [CrossRef][Green Version]

- Naweed, A.; Bowditch, L.; Trigg, J.; Unsworth, C. Injury by design: A thematic networks and system dynamics of work-related musculoskeletal disorders in tram drivers. Appl. Ergon. 2022, 100, 130644. [Google Scholar] [CrossRef] [PubMed]

- Cimino, A.; Longo, F.; Mirabelli, G. A Multi measure-based methodology for the ergonomic effective design of manufacturing system workstations. Int. J. Ind. Ergon. 2009, 39, 447–455. [Google Scholar] [CrossRef]

- Berlin, C.; Kajaks, T. Time-related ergonomics evaluation for DHMs: A literature review. Int. J. Hum. Factors Model. Simul. 2010, 1, 356–379. [Google Scholar] [CrossRef]

- Yang, Q.; Wu, D.L.; Zhu, H.M.; Bao, J.S.; Wei, Z.H. Assembly operation process planning by mapping a virtual assembly simulation to real operation. Comput. Ind. 2013, 64, 869–879. [Google Scholar] [CrossRef]

| Authors | Few Selected Applications of Ergonomics and DHM on Construction Industry | Outcomes |

|---|---|---|

| Chaffin, et al., 1997 | 3DSSPP and CAD software for biomechanical analysis | Forecasted the user’s dynamic strength, but it cannot be used as the sole determinant. |

| Groblelny, et al., 2008 | DHM studies on painters, polishers, technicians and warehouse deliverables | Construction injuries were identified, and ergonomic design for the given profession was predicted. |

| Constantinescu, et al., 2016, Bubb, 2002 | Jack + RAMSIS, optimization for exoskeletons based experiments | Collisions within the exoskeleton were detected, and the workstation was determined to be unsuitable. |

| Polasek et al., 2015 | DELMIA ergonomics software for whole body analysis | Analyzed whole body specific posture but correct manipulation of a posture is a challenging task. |

| Manghisi, et al., 2016 | K2 RULA, a semi- automatic s/w that uses Kinect sensor | Ergonomic posture was examined and compared to the Jack toolkit. |

| Raschke, et al., 2019 | Tecnomatix process simulate software, which is a part of Jack software. | Human postures simulated for ergonomics. |

| Zhang, et al., 2019 | DHM studies on welders’ postures and adjustment strategy using Jack s/w + 3D simulation | Workers’ fatigue and injury were prevented. |

| Anton, et al., 2020 | Ergonomic research on brick and masonry work | MSD pain was found in 78 percent of construction workers. |

| Tasks ID | Description | Dimension Length (m) × BREADTH (m) | Weight of Panel (kg) |

|---|---|---|---|

| Case-1 | Wall panel | 12 × 6 | 13.5 |

| Case-2 | Wall panel | 12 × 6 | 13.5 |

| Case-3 | Slab panel | 24.5 × 6 | 27.3 |

| Tasks ID | Selected Awkward Postures | Total Task Duration (s) |

|---|---|---|

| Case-1 | P1, P2, P3 and P4 | 15.5 |

| Case-2 | P1, P2, and P3 | 12 |

| Case-3 | P1, P2, P3, P4, P5 and P6 | 11.7 |

| Back | Description | Case 1 | Case 2 | ||||||

| Postures | Score | P1 | P2 | P3 | P4 | P1 | P2 | P3 | |

| Straight | 1 | 2 | 1 | 2 | 1 | 4 | 2 | 1 | |

| Bent | 2 | ||||||||

| Twisted | 3 | ||||||||

| Bent and twisted | 4 | ||||||||

| Arms | Both arms below the shoulder | 1 | 1 | 3 | 3 | 3 | 1 | 3 | 3 |

| One arm at or above shoulder level | 2 | ||||||||

| Both arms at or above shoulder level | 3 | ||||||||

| Leg | Seated | 1 | 2 | 2 | 7 | 7 | 2 | 7 | 7 |

| Standing | 2 | ||||||||

| Uni-podal, straight leg | 3 | ||||||||

| Knees bent | 4 | ||||||||

| Uni-podal support, bent | 5 | ||||||||

| Kneeling or squatting | 6 | ||||||||

| walking | 7 | ||||||||

| Sitting with legs and buttocks | 8 | ||||||||

| Additional postures in which legs give no support | 9 | ||||||||

| Crawling or climbing | 0 | ||||||||

| Weight | <10 kg | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| 10 kg–20 kg | 2 | ||||||||

| >20 kg | 3 | ||||||||

| Head | Free | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Bent forwards | 2 | ||||||||

| Bent to the side | 3 | ||||||||

| Dent backwards | 4 | ||||||||

| Twisted | 5 | ||||||||

| Total | OWAS score | 2122-1 | 1322-1 | 2372-1 | 1372-1 | 4122-1 | 2372-1 | 1372-1 | |

| Action category | 2 | 1 | 3 | 1 | 2 | 3 | 1 | ||

| Back | Description | Case-3 | ||||||

| Postures | Score | P1 | P2 | P3 | P4 | P5 | P6 | |

| Straight | 1 | 2 | 2 | 1 | 2 | 2 | 2 | |

| Bent | 2 | |||||||

| Twisted | 3 | |||||||

| Bent and twisted | 4 | |||||||

| Arms | Both arms below the shoulder | 1 | 1 | 3 | 1 | 1 | 1 | 3 |

| One arm at or above shoulder Level | 2 | |||||||

| Both arms at or above shoulder Level | 3 | |||||||

| Leg | Seated | 1 | 2 | 2 | 7 | 2 | 2 | 2 |

| Standing | 2 | |||||||

| Unipodal, straight leg | 3 | |||||||

| Knees bent | 4 | |||||||

| Unipodal support, bent | 5 | |||||||

| Kneeling or squatting | 6 | |||||||

| Walking | 7 | |||||||

| Sitting with legs and buttocks | 8 | |||||||

| Additional postures in which legs give no support | 9 | |||||||

| Crawling or climbing | 0 | |||||||

| Weight | <10 kg | 1 | 3 | 3 | 3 | 3 | 3 | 3 |

| 10–20 kg | 2 | |||||||

| >20 kg | 3 | |||||||

| Head | Free | 1 | 1 | 4 | 1 | 4 | 4 | 4 |

| Bent forwards | 2 | |||||||

| Bent to the side | 3 | |||||||

| Dent backwards | 4 | |||||||

| Twisted | 5 | |||||||

| Total | OWAS score | 2123-1 | 2323-4 | 1173-1 | 2123-4 | 2123-4 | 2323-4 | |

| OWAS Action category | 3 | 3 | 1 | 3 | 3 | 3 | ||

| Description | Details | Load (kg) | Cycle (min) | Frequency | Total Task Energy | Energy Expenditure Rate (kcal/min) |

|---|---|---|---|---|---|---|

| Case-1 | Lifts | 13.5 | <1 | 7 | 3 | 8.8 (above recommended value of 8.2 kcal/min) |

| Lifts | 13.5 | <1 | 6 | 2.4 | ||

| Holds | 13.5 | <1 | 4 | 0.2 | ||

| pushing | 13.5 | <1 | 4 | 2.5 | ||

| Case-2 | Push pull | 13.5 | <1 | 12 | 4.9 | 7.33 (above recommended value of 7 Kcal/min |

| Carries | 13.5 | <1 | 10 | 1.8 | ||

| Arm length at sides, both | 13.5 | <1 | 4 | 0.27 | ||

| Walks | 13.5 | <1 | 5 | 0.4 | ||

| Case-3 | Lateral arm work | 27.3 | <1 | 1 | 0.2 | 6 (above recommended value of 5.8 Kcal/min |

| Holds | 27.3 | <1 | 4 | 0.2 | ||

| Lateral arm work | 27.3 | <1 | 4 | 0.7 | ||

| Walks | 27.3 | <1 | 3 | 0.1 | ||

| Carries | 27.3 | <1 | 4 | 0.6 | ||

| Lateral arm work | 27.3 | <1 | 15 | 15 |

| Back | Description | Case 4 | ||||

| Postures | Score | P1 | P2 | P3 | P4 | |

| Straight | 1 | 2 | 1 | 1 | 1 | |

| Bent | 2 | |||||

| Twisted | 3 | |||||

| Bent and twisted | 4 | |||||

| Arms | Both arms below the shoulder | 1 | 1 | 3 | 3 | 3 |

| One arm at or above shoulder level | 2 | |||||

| Both arms at or above shoulder level | 3 | |||||

| Leg | Seated | 1 | 2 | 2 | 2 | 7 |

| Standing | 2 | |||||

| Uni-podal, straight leg | 3 | |||||

| Knees bent | 4 | |||||

| Uni-podal support, bent | 5 | |||||

| Kneeling or squatting | 6 | |||||

| walking | 7 | |||||

| Sitting with legs and buttocks | 8 | |||||

| Additional postures in which legs give no support | 9 | |||||

| Crawling or climbing | 0 | |||||

| Weight | <10 kg | 1 | 2 | 2 | 2 | 2 |

| 10 kg–20 kg | 2 | |||||

| >20 kg | 3 | |||||

| Head | Free | 1 | 1 | 1 | 1 | 1 |

| Bent forwards | 2 | |||||

| Bent to the side | 3 | |||||

| Dent backwards | 4 | |||||

| Twisted | 5 | |||||

| Total | OWAS score | 2122-1 | 1322-1 | 1322-1 | 1372-1 | |

| Action category | 2 | 1 | 1 | 1 | ||

| Description | Details | Load (kg) | Cycle (min) | Frequency | Total Task Energy | Energy Expenditure Rate (kcal/min) |

|---|---|---|---|---|---|---|

| Case-4 | Push pull | 13.5 | <1 | 10 | 3.5 | 6.5 (Below the recommended value of 7 kcal/min) |

| Carry | 13.5 | <1 | 10 | 1.8 | ||

| Arm length at sides, both | 13.5 | <1 | 4 | 0.27 | ||

| Walk | 13.5 | <1 | 5 | 0.4 |

| Analysis | CASE-1 | CASE-2 | CASE-3 | CASE-4 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Postures ( P1 to P6) | P1 | P2 | P3 | P4 | P1 | P2 | P3 | P1 | P2 | P3 | P4 | P5 | P6 | P1 | P2 | P3 | P4 |

| OWAS (Action category) | 2 | 1 | 3 | 1 | 2 | 1 | 3 | 2 | 2 | 1 | 3 | 3 | 4 | 2 | 1 | 1 | 1 |

| RULA | 2 | 1 | 1 | 2 | 2 | 3 | 4 | 3 | 3 | 7 | 7 | 5 | 4 | 2 | 1 | 1 | 2 |

| Metabolic energy expenditure (kcal/min) (recommended value) | 8.8 (above recommended value (8.2) | 7.33 (above recommended value) (7) | 6 (above Recommended value) (5.8) | 6.5 (below 7 recommended value) | |||||||||||||

| Time taken | <1 min | <1 min | <1 min | <1 min | |||||||||||||

| Remarks | Not safe for workers (HIGH) | Not safe for workers (MOSTLY HIGH) | Not safe for workers (HIGH) | Safe for workers (LOW) | |||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palikhe, S.; Lee, J.Y.; Kim, B.; Yirong, M.; Lee, D.-E. Ergonomic Risk Assessment of Aluminum Form Workers’ Musculoskeletal Disorder at Construction Workstations Using Simulation. Sustainability 2022, 14, 4356. https://doi.org/10.3390/su14074356

Palikhe S, Lee JY, Kim B, Yirong M, Lee D-E. Ergonomic Risk Assessment of Aluminum Form Workers’ Musculoskeletal Disorder at Construction Workstations Using Simulation. Sustainability. 2022; 14(7):4356. https://doi.org/10.3390/su14074356

Chicago/Turabian StylePalikhe, Shraddha, Jae Young Lee, Bubryur Kim, Mi Yirong, and Dong-Eun Lee. 2022. "Ergonomic Risk Assessment of Aluminum Form Workers’ Musculoskeletal Disorder at Construction Workstations Using Simulation" Sustainability 14, no. 7: 4356. https://doi.org/10.3390/su14074356

APA StylePalikhe, S., Lee, J. Y., Kim, B., Yirong, M., & Lee, D.-E. (2022). Ergonomic Risk Assessment of Aluminum Form Workers’ Musculoskeletal Disorder at Construction Workstations Using Simulation. Sustainability, 14(7), 4356. https://doi.org/10.3390/su14074356