Reinforced Concrete Wind Turbine Towers: Damage Mode and Model Testing

Abstract

:1. Introduction

2. Experimental Scheme

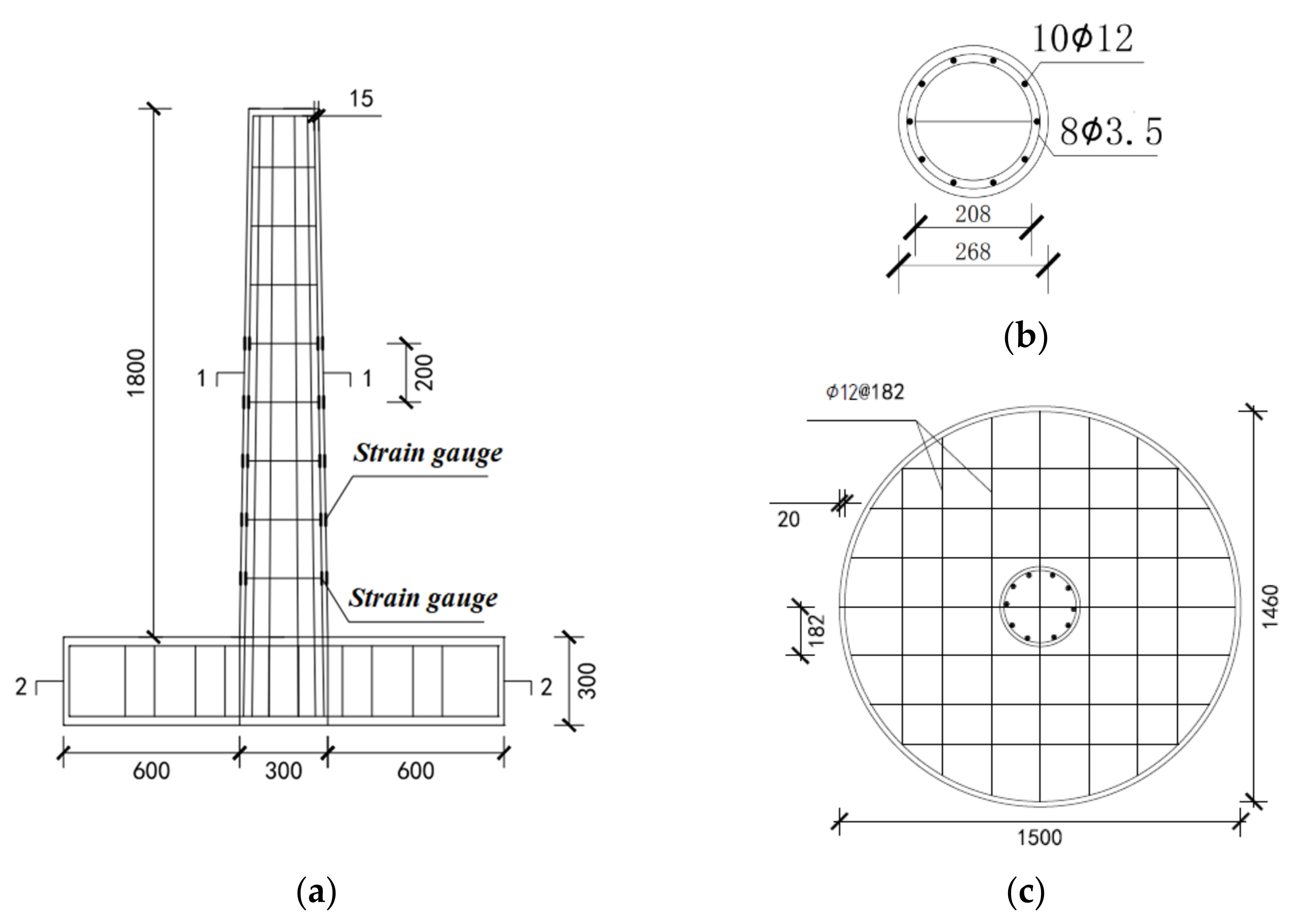

2.1. Model Design

2.2. Measuring Scheme

2.2.1. Strain Measurement of Longitudinal Reinforcement

2.2.2. Tower Strain and Displacement Measurement

2.3. Loading Scheme

3. Results and Analysis

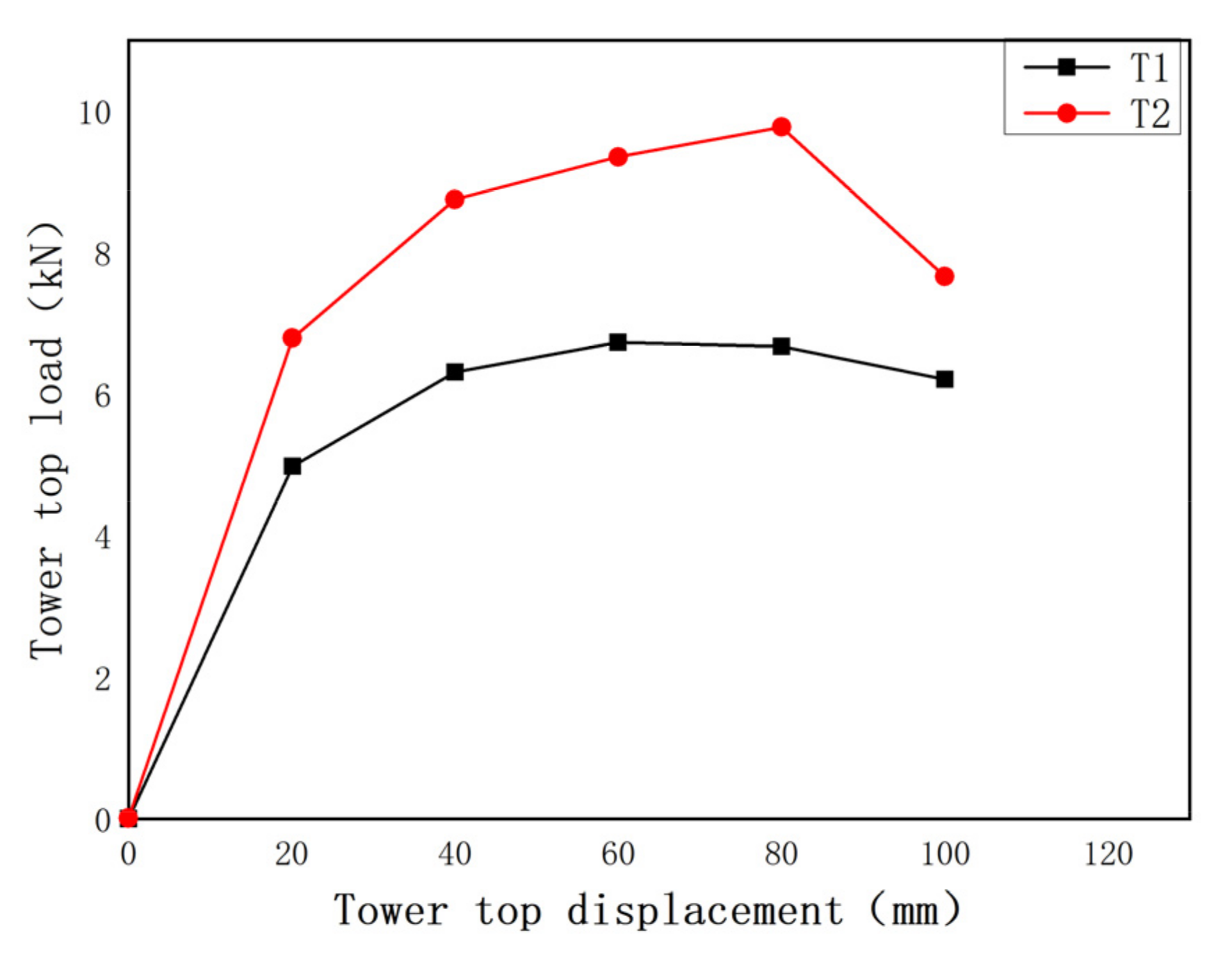

3.1. Tower Top Load-Displacement Curve

3.2. Tower Top Displacement-Strain Curve

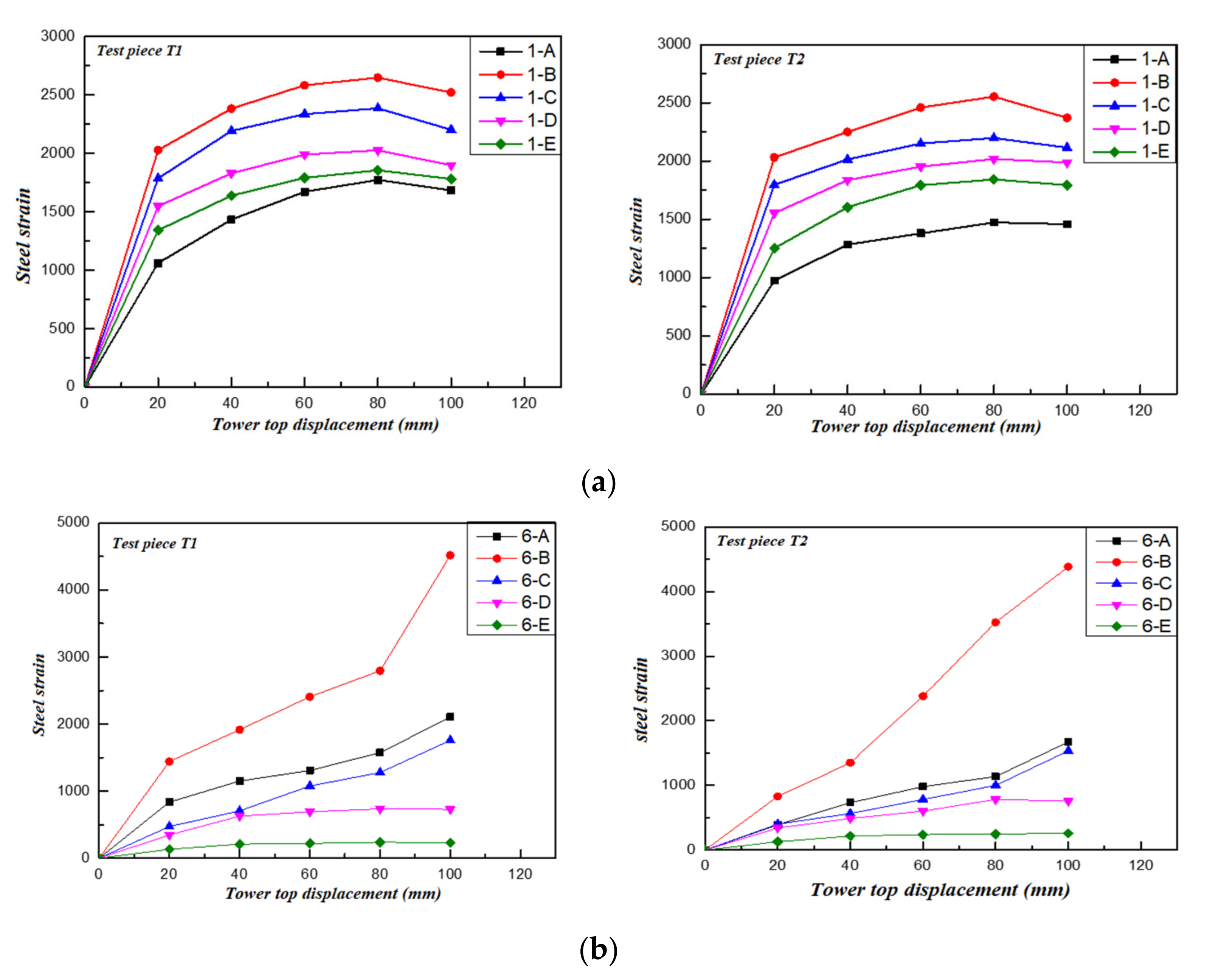

3.3. Reinforcement Strain Measurement

- The first stage is the elastic stage, where the friction between the longitudinal reinforcement and the concrete interface, as well as the stress on the longitudinal reinforcement, are both small.

- The second stage is the plastic stage, where the concrete tower is subjected to shear force due to the unilateral shear force generated by the overturning moment when the tower top bears the horizontal dynamic load. The reinforcement strain, especially the longitudinal reinforcement strain at the crack, increases significantly, indicating that the stress is primarily caused by bending.

- The third stage is the longitudinal reinforcement plastic failure and the increase in its cracks. The neutral axis travels upwards as the cracks on the concrete tower’s surface continue to expand, increasing the tension zone and narrowing the compression zone. The reinforcement strain increases abruptly and finally fails after reaching the yield point. This phenomenon is similar to the research findings of Xue et al. [30]. During our experiment, it was found that the longitudinal reinforcement strain on the top and in the middle of the test pieces is all in the elastic range and does not enter the plastic stage.

3.4. Tower Failure Mode and Damage Mode

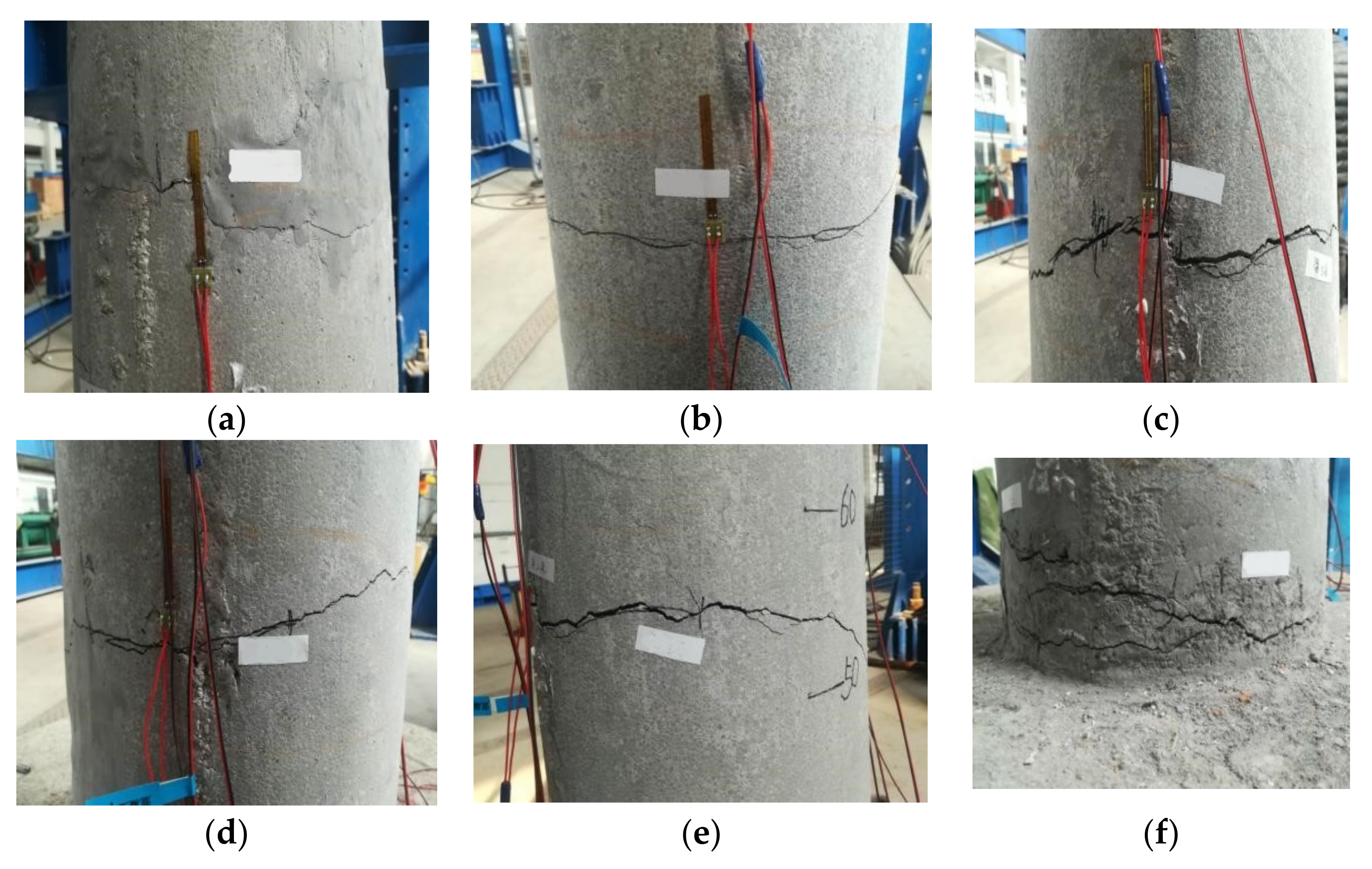

3.4.1. Crack Initiation and Failure Mode of Concrete Tower

3.4.2. Damage Mode

- Initial initiation stage: Friction between the aggregates or between the aggregate and cement occurs as the load is applied, considerably preventing the initiation and expansion of cracks. In other words, the test pieces do not crack because the stress within the tower node combinations is less than the concrete cracking stress.

- Stable growth stage: A few cracks occur as the load increases. New cracks appear as the aggregate and cement or aggregates gradually separate, and the test pieces undergo elastoplastic deformation. The cracks between the aggregates or between the aggregate and cement at the crack tip spread over as the external load increases, and the cracks on the tower’s surface widen. Still, massive aggregates inside the test pieces prevent the cracks from expanding, which is called the bridging effect. The tower’s longitudinal reinforcement is bent and severely deformed. Centrally symmetrical bending cracks emerge on both sides of the tower.

- High-speed growth stage: Many aggregates are completely cracked around the crack tip. Existing cracks widen, and new cracks form on the tower’s surface. The cracks are connected to form interlaced diagonal cracks as the bridging effect fails because the main diagonal tensile stress in the core area exceeds the concrete tensile strength. As a result, the reinforcement continues to deform and gradually yields.

- Instability failure stage: The bearing capacity of the test pieces does not increase as the load approaches its maximum value. Despite this, their deformation continues to worsen, as seen by the wider and longer cracks at the bottom of the test pieces. The internal reinforcement’s plastic strain increases, resulting in more cracks, and the concrete in the tower’s plastic hinge area is crushed and peeled off. The tower is displaced horizontally, the cracks extend to both sides, and the reinforcement enters the yielding stage. The load-displacement curve enters the descent stage as the load continues until it fails.

4. Conclusions

- The concrete strain in the compression zone of the reinforced concrete tower at various heights increases as the horizontal load on the loading device of the MTS electro-hydraulic servo loading system increases. The concrete becomes crushed and destroyed to the bottom of the tower when it reaches its peak. The structural failure of the tower is an extreme-point instability failure, which means it generally occurs all of a sudden. The weakest part of the structure becomes crushed first, causing the entire structure to deform sharply. Finally, the whole structure loses its load-bearing capacity.

- The bottom plastic hinge area of both test pieces reaches its maximum tensile strain, while the middle and top parts remain intact. The tower models deform similarly to a rigid body rotating around the bottom plastic hinge area until it collapses. The component’s ultimate bearing capacity is 8.894 kN. Plastic hinges are all generated at geometrical discontinuities. Once these plastic hinges expand over the entire cross-section, the wind turbine tower will become unstable. Therefore, attention should be paid to this position in the design.

- Internal reinforcement stress can be divided into three stages as external loads increase. In the first stage, the reinforcement and the concrete rub against each other and deform similarly, and the stress is small. In the second stage, due to the overturning moment under horizontal dynamic loads, the top of the tower produces unilateral shear, the concrete cracks, and the reinforcement strain increases significantly because of the bending stress. The reinforcement reaches its yield point under extreme load and fails in the third stage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vargas, S.A.; Esteves, G.R.T.; Maçaira, P.M.; Bastos, B.Q.; Oliveira, F.L.C.; Souza, R.C. Wind power generation: A review and a research agenda. J. Clean. Prod. 2019, 218, 850–870. [Google Scholar] [CrossRef]

- Zhang, T. Design and Research on Jumbo Size and High Tower Structure of Offshore Wind Turbine. Master’s Thesis, Dalian Maritime University, Dalian, China, 2020. [Google Scholar]

- Zhang, H.; David, J.; McCalley, J.; Jackman, J. Cost-production impact of increasing wind turbine tower height. In Proceedings of the 7th International Conference on Energy Sustainability and 11th Fuel Cell Science, Engineering and Technology Conference, Minneapolis, MN, USA, 24–26 August 2013. [Google Scholar]

- Lantz, E.; Roberts, O.; Nunemaker, J.; Edgar, D.; Dykes, K.; Scott, G. Increasing Wind Turbine Tower Heights: Opportunities and Challenges; National Renewable Energy Laboratory (NREL): Denver, CO, USA, 2019. [Google Scholar] [CrossRef] [Green Version]

- Li, D. Structure Analysis and Optimization of Reinforced Concrete Tower. Master’s Thesis, Chongqing University, Chongqing, China, 2018. [Google Scholar]

- Li, S.; Zhu, L.; Yao, X. Summary of research on reinforced concrete tower structure of horizontal axis wind turbine. In Proceedings of the China High-Rise Structure Academic Exchange Conference, Zhengzhou, China, 30 August–4 September 2014. [Google Scholar]

- Seidel, M. Experiences with two of the world’s largest wind turbine towers. In Proceedings of the 2003 European Wind Energy Conference and Exhibition, Madrid, Spain, 16–19 June 2003. [Google Scholar]

- Quilligan, A.; O’Connor, A.; Pakrashi, V. Fragility analysis of steel and concrete wind turbine towers. Eng. Struct. 2012, 36, 270–282. [Google Scholar] [CrossRef]

- Brughuis, F.J. Advanced tower solutions for large wind turbines and extreme tower heights. In Proceedings of the 2003 European Wind Energy Conference and Exhibition, Madrid, Spain, 16–19 June 2003. [Google Scholar]

- Singh, A.N. Concrete construction for wind energy towers. Indian Concr. J. 2007, 81, 43–49. [Google Scholar]

- Way, A.C.; van Zijl, G.P.A.G. A study on the design and material costs of tall wind turbine towers in South Africa. J. S. Afr. Inst. Civ. Eng. 2015, 57, 45–54. [Google Scholar] [CrossRef] [Green Version]

- Lyu, W.; Zhu, F.; Lu, B.; Shi, W.; Zhang, J.; He, X.; Qing, S. Experimental study on shear mechanism of perfobond connectors in wind turbines foundation. Eng. Mech. 2018, 35, 127–138. [Google Scholar] [CrossRef]

- Chen, D.; Zha, X.; Li, S.; Yu, M.; Xu, L. Experimental study on co-working of inner and outer steel part in concrete-filled steel tube tower frame with inner stiffening parts under tension. J. Build. Struct. 2017, 38, 485–492+501. [Google Scholar] [CrossRef]

- Li, B.; Yang, X.; Gao, C. Experimental research and comparative analysis on seismic performance of wind turbine frustum tower drum and latticed tower. J. Build. Struct. 2013, 34, 161–166. [Google Scholar] [CrossRef]

- Jin, T.; Wang, X.; Hu, M. Analysis on Causes of Cracking of Centrifugal Fan Impeller. Fluid. Mach. 1999, 27, 37–40. [Google Scholar]

- Zhang, D. Test and Analysis of Prestressed Concrete Wind Turbine Tower Model. Master’s Thesis, Shanghai Jiaotong University, Shanghai, China, 2015. [Google Scholar]

- Zhang, J.; Shi, F.; Xiang, J.; Zeng, Y.; Song, X. Contact analysis between steel and concrete in wind turbine foundation. Acta Energ. Sol. Sin. 2015, 36, 763–768. [Google Scholar]

- Wang, D.; Fan, G.; Zhang, H. Dynamic behaviors of reinforced concrete columns under multi-dimensional dynamic loadings. J. Vib. Shock. 2016, 35, 35–41. [Google Scholar] [CrossRef]

- Patil, A.; Jung, S.; Kwon, O.S. Structural performance of a parked wind turbine tower subjected to strong ground motions. Eng. Struct. 2016, 120, 92–102. [Google Scholar] [CrossRef]

- Liu, M.; Wang, G.; Zhang, D. Mechanical principle of reinforced concrete planar frame structures in fire. J. Build. Struct. 2020, 41, 94–101. [Google Scholar] [CrossRef]

- Tang, Z.; Huang, J. A Finite Element Modeling Method for a Fan Main Bearing. Constr. Des. Proj. 2019, 136–137. [Google Scholar] [CrossRef]

- Vries, E. Concrete-steel hybrid tower from ATS. Renew. Energy World 2009, 12, 109–111. [Google Scholar]

- Walia, D.; Schiinemann, P.; Kuhl, M.; Adam, F.; Hartmann, H.; Großmann, J.; Ritschel, U. Prestressed ultra high performance concrete members for a TLP substructure for floating wind turbines. In Proceedings of the 27th International Ocean and Polar Engineering Conference, San Francisco, CA, USA, 25–30 June 2017. [Google Scholar]

- Vernardos, S.M.; Gantes, C.J.; Badogiannis, E.G.; Lignos, X.A. Experimental and numerical investigation of steel-grout-steel sandwich shells for wind turbine towers. J. Constr. Steel. Res. 2021, 184, 106815. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, D. Seismic response of a prestressed concrete wind turbine tower. Int. J. Civ. Eng. 2016, 14, 561–571. [Google Scholar] [CrossRef]

- Lan, Y.; Li, Y.; Ren, W.; Huang, X.; Wang, Y. Research on Design Method of Steel-Concrete Hybrid Tower for Wind Turbines. Ship Eng. 2020, 42, 254–259+272. [Google Scholar] [CrossRef]

- Hu, D.; Deng, L.; Zeng, L. Study on the Aerodynamic Performance of Floating Offshore Wind Turbine Considering the Tower Shadow Effect. Processes 2021, 9, 1047. [Google Scholar] [CrossRef]

- Tang, X.; Liao, L.; Huang, B.; Li, C. Tensile Damage Study of Wind Turbine Tower Material Q345 Based on an Acoustic Emission Method. Materials 2021, 14, 2120. [Google Scholar] [CrossRef]

- De Lana, J.A.; Júnior, P.A.A.M.; Magalhães, C.A.; Magalhães, A.L.M.A.; de Andrade Junior, A.C.; de Barros Ribeiro, M.S. Behavior study of prestressed concrete wind-turbine tower in circular cross-section. Eng. Struct. 2021, 227, 111403. [Google Scholar] [CrossRef]

- Xue, W.; Yu, P.; Liu, S.; Hu, X. Study on the Details of Vertical Connecting Reinforcement in Double Composite Shear Wall. Constr. Technol. 2018, 47, 25–29. [Google Scholar]

- Jin, T. Experimental Study on the Whole Process of Nonlinear Stress of Reinforced Concrete Wind Power Tower. Master’s Thesis, Tongji University, Shanghai, China, 2009. [Google Scholar] [CrossRef]

| fc/(N/mm2) | fy/(N/mm2) | fu/(N/mm2) | Ec/(N/mm2) | Es/(N/mm2) | ρs/% | ρv/% |

|---|---|---|---|---|---|---|

| 32.56 | 335 | 400 | 30,000 | 200,000 | 2 | 1.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Liang, J.; Xu, W.; Liang, R.; Li, J.; Jiang, L. Reinforced Concrete Wind Turbine Towers: Damage Mode and Model Testing. Sustainability 2022, 14, 4410. https://doi.org/10.3390/su14084410

Xu X, Liang J, Xu W, Liang R, Li J, Jiang L. Reinforced Concrete Wind Turbine Towers: Damage Mode and Model Testing. Sustainability. 2022; 14(8):4410. https://doi.org/10.3390/su14084410

Chicago/Turabian StyleXu, Xinyong, Jinchang Liang, Wenjie Xu, Rui Liang, Jun Li, and Li Jiang. 2022. "Reinforced Concrete Wind Turbine Towers: Damage Mode and Model Testing" Sustainability 14, no. 8: 4410. https://doi.org/10.3390/su14084410

APA StyleXu, X., Liang, J., Xu, W., Liang, R., Li, J., & Jiang, L. (2022). Reinforced Concrete Wind Turbine Towers: Damage Mode and Model Testing. Sustainability, 14(8), 4410. https://doi.org/10.3390/su14084410