Feasibility of Bio-Coal Production from Hydrothermal Carbonization (HTC) Technology Using Food Waste in Malaysia

Abstract

1. Introduction

2. Methodology

2.1. Porter’s Five Forces Analysis Model

2.2. Data Sources, Sampling Method and Survey Design

2.3. Statistical Analysis

2.4. Case Study of Existing Waste Treatment Methods

3. Results

3.1. Porter’s Five Forces Analysis

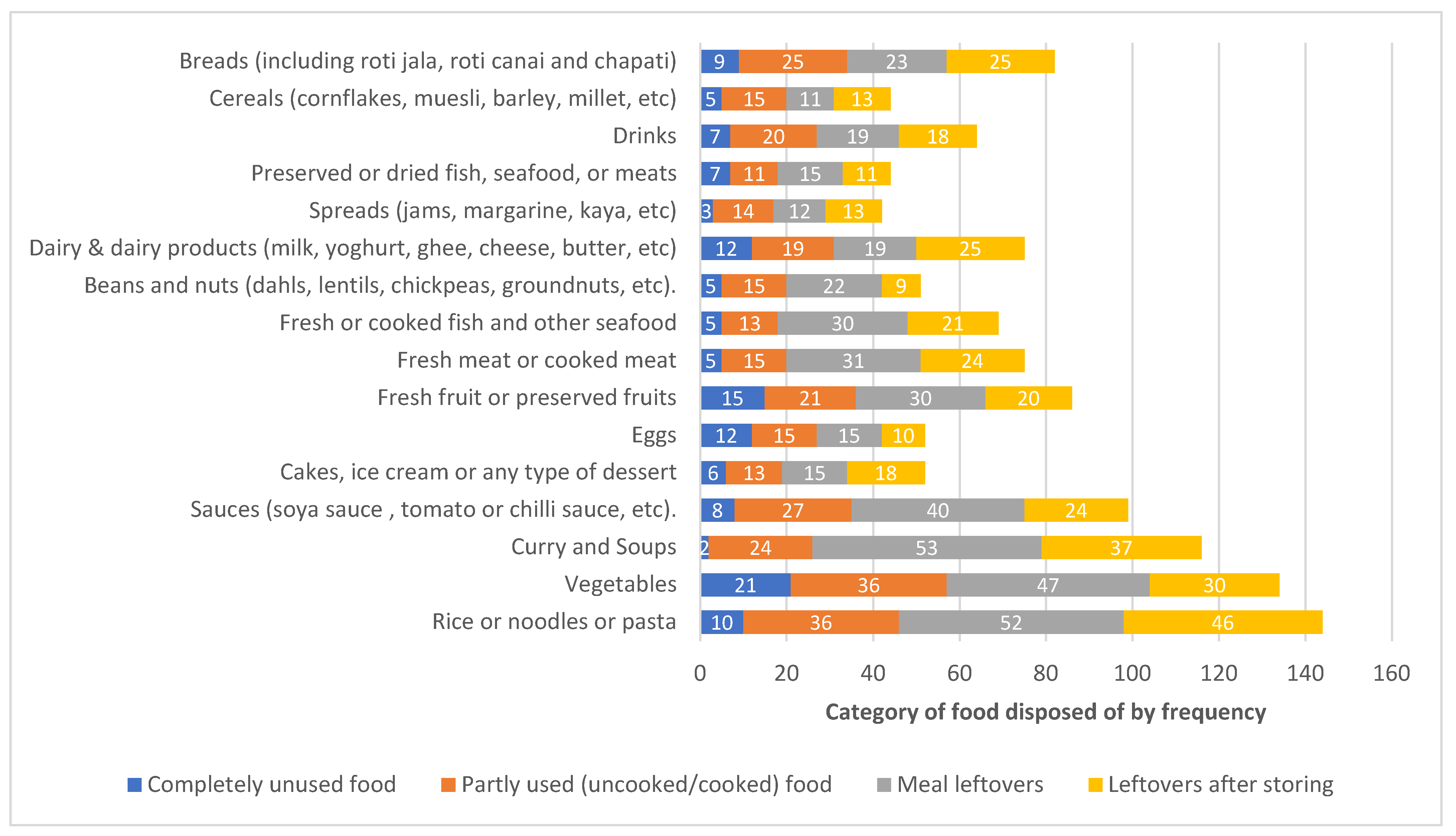

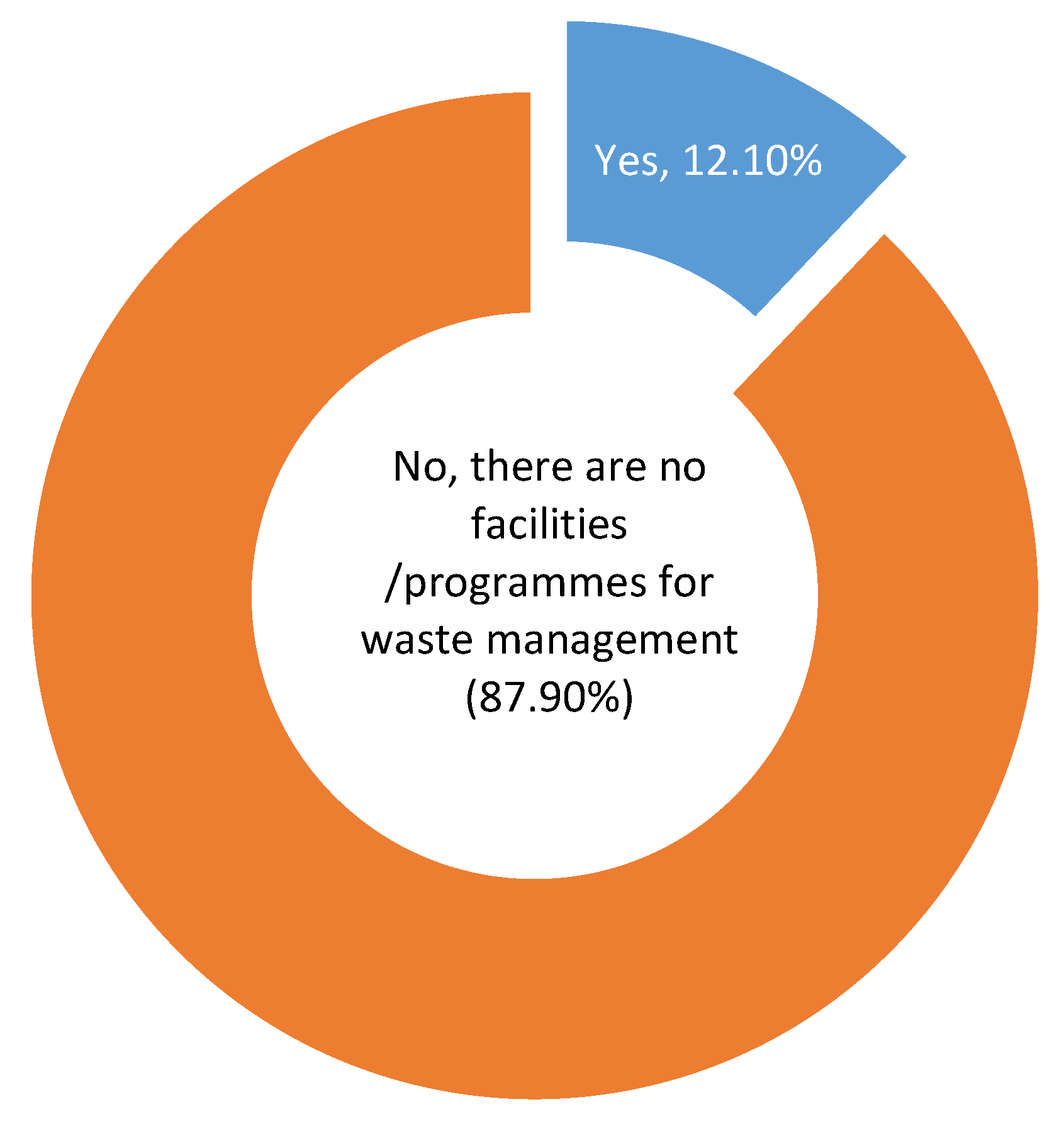

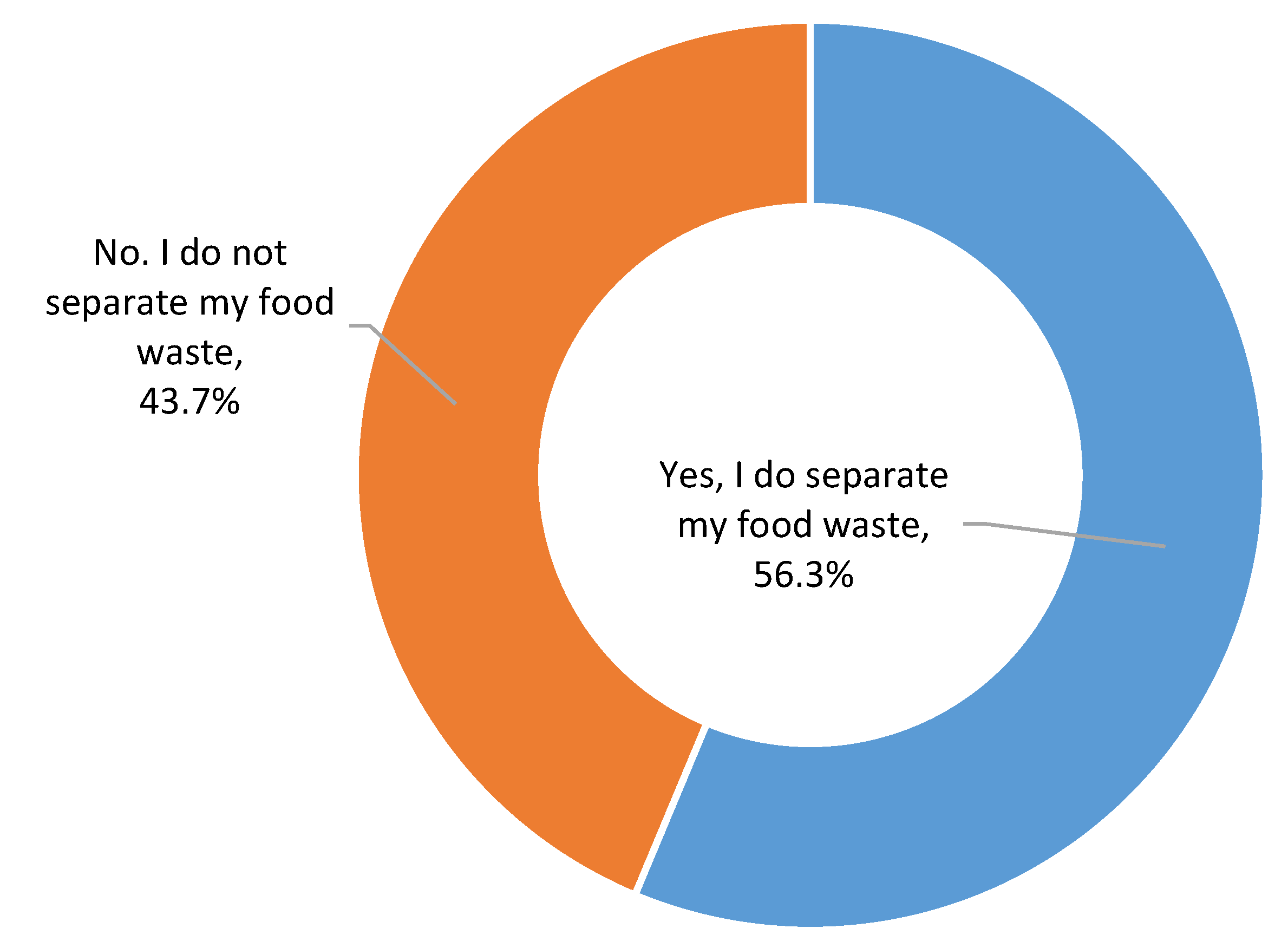

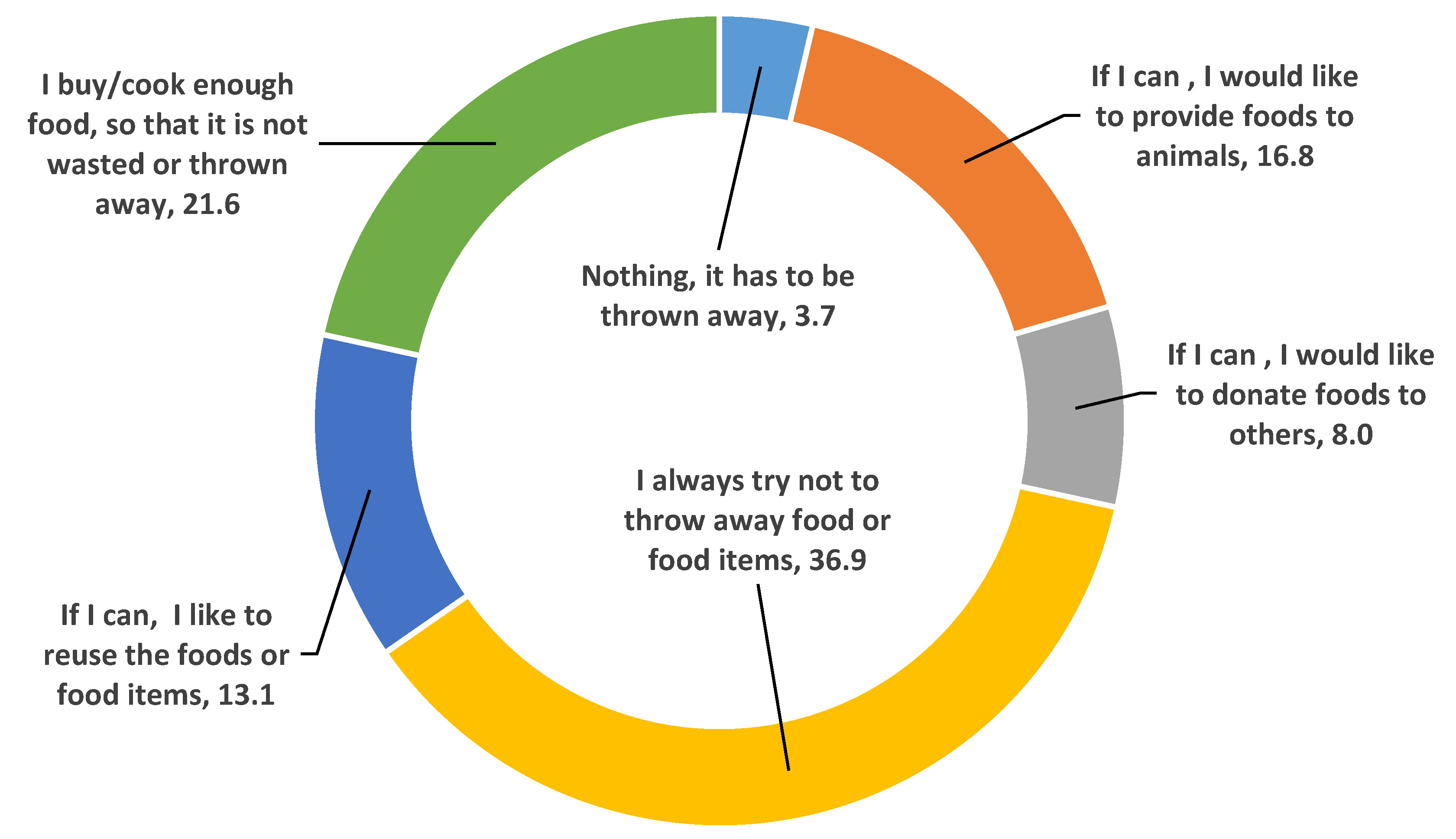

3.2. Survey Results of Household Attitudes and Behaviours towards Food Waste

3.3. Survey of Industrial Bio-Coal Consumers

3.4. Interview with Key Industry Players

3.5. Summary and Limitations

- The industry is still very nascent in terms of using bio-waste based on household waste as an energy resource;

- There are no competitors, thus giving the bio-coal project a first-mover advantage in the market. The closest competitor is currently being planned but is not yet operationalised. The Ministry of Housing and Local Government is planning six waste-to-energy plants for the year 2022, which utilise the same raw material for energy generation;

- One of the key factors facilitating the growth of the industry is the household food waste quantity and components. The survey on household waste has provided adequate information to support the availability of a sufficient quantity of food waste in the country to sustain the flow of raw material for the bio-coal project. However, the consistency in the supply of food waste feedstock is of utmost importance to keep the bio-coal production steady and the HTC plant profitable. Any fluctuation in the supply of food waste would greatly reduce the plant’s efficiency, hence leading to technical and economic issues. As such, the uptake of the HTC technology is encouraged by the fact that the system can integrate food waste with other sources of wet waste from industry (pulp and paper mill waste), agriculture (palm oil residue) or live-stock farming (animal manure). This can greatly reduce HTC’s susceptibility to fluctuating waste resources;

- The key consumer for coal in the country is the energy sector. Surveys and three separate interview sessions with key role players in the sector have provided valuable inputs on key industry priorities for energy generation. Overall, the findings suggest that consumers prioritise the costs and performance of bio-coal, with positive prospects if both are proven to be within an acceptable range;

- HTC has the potential to reduce the amount of food waste that ends up in landfill sites. HTC not only provides the best waste-to-energy technology in dealing with high-moisture-content food waste bound for landfills but also produces useful end-products (i.e., solid (bio-coal) and liquid (process water) phases). These can be used to generate a cleaner energy source (either through sole usage or by blending with fossil fuels), thereby drastically reducing greenhouse gas emissions, which would otherwise be hazardous to the environment if unmanaged. In addition, the liquid phase, i.e., HTC slurries, could be processed to produce bio-fertilizer for agricultural purposes. Besides, it also could be used as a source of biogas in an anaerobic digestion plant [41], thereby closing the loop and providing a circular renewable energy economy.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wong, K.K.S.; Sharifuddin, J.; Nik Masdek, N.R.; Wong, W.L.; Lai, K.S. Determinants of household’s intention of practicing sustainable food waste management in Malaysia. IOP Conf. Ser. Earth Environ. Sci. 2021, 756, 1–7. [Google Scholar] [CrossRef]

- Ghafar, S.W.A. Food Waste in Malaysia: Trends, Current Practices and Key Challenges. FFTC Agric. Policy Artic. 2017, 1–12. [Google Scholar]

- Ministry of Housing and Local Government (MHLG). The Study of National Waste Minimization in Malaysia; Japan International Cooperation Agency (JICA): Tokyo, Japan, 2006; Volume 1. [Google Scholar]

- Parry, M.; Osvaldo, C.; Jean, P.; Clair, H. Climate Change 2007—Impacts, Adaptation and Vulnerability: Working Group II Contribution to the Fourth Assessment Report of the IPCC; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- National Solid Waste Management Department. Laman Web Rasmi Jabatan Pengurusan Sisa Pepejal Negara. 2010. Available online: https://jpspn.kpkt.gov.my/index.php (accessed on 8 February 2022).

- Moh, Y.C.; Abd Manaf, L. Overview of household solid waste recycling policy status and challenges in Malaysia. Resour. Conserv. Recycl. 2014, 82, 50–61. [Google Scholar] [CrossRef]

- Samsudin, M.D.M.; Don, M.M. Municipal solid waste management in Malaysia: Current Practices, Challenges and Prospect. J. Teknol. 2013, 62, 95–101. [Google Scholar] [CrossRef][Green Version]

- Bhakta Sharma, H.; Panigrahi, S.; Dubey, B.K. Food waste hydrothermal carbonization: Study on the Effects of Reaction Severities, Pelletization and Framework Development Using Approaches of the Circular Economy. Bioresour. Technol. 2021, 333, 125187. [Google Scholar] [CrossRef]

- Heidari, M.; Norouzi, O.; MacDermid-Watts, K.; Acharya, B.; Zhang, Y.; Dutta, A. Product evaluation of hydrothermal carbonization of biomass: Semi-Continuous vs. Batch Feeding. Biomass Convers. Biorefinery 2020, 12, 15–25. [Google Scholar] [CrossRef]

- Akarsu, K.; Duman, G.; Yilmazer, A.; Keskin, T.; Azbar, N.; Yanik, J. Sustainable valorization of food wastes into solid fuel by hydrothermal carbonization. Bioresour. Technol. 2019, 292, 121959. [Google Scholar] [CrossRef]

- Urbanowska, A.; Kabsch-Korbutowicz, M.; Wnukowski, M.; Seruga, P.; Baranowski, M.; Pawlak-Kruczek, H.; Serafin-Tkaczuk, M.; Krochmalny, K.; Niedzwiecki, L. Treatment of liquid by-products of hydrothermal carbonization (HTC) of agricultural digestate using membrane separation. Energies 2020, 13, 262. [Google Scholar] [CrossRef]

- Etikan, I.; Musa, S.A.; Alkassim, R.S. Comparison of Convenience Sampling and Purposive Sampling. Am. J. Theor. Appl. Stat. 2016, 5, 1. [Google Scholar] [CrossRef]

- Naderifar, M.; Goli, H.; Ghaljaie, F. Snowball Sampling: A Purposeful Method of Sampling in Qualitative Research. Strides Dev. Med. Educ. 2017, 14, e67670. [Google Scholar] [CrossRef]

- Chakrabartty, S.N. Scoring and Analysis of Likert Scale: Few Approaches. J. Knowl. Manag. Inf. Technol. 2019, 1, 31–44. [Google Scholar]

- Yunna, W.; Yisheng, Y. The competition situation analysis of shale gas industry in China: Applying Porter’s Five Forces and Scenario Model. Renew. Sustain. Energy Rev. 2014, 40, 798–805. [Google Scholar] [CrossRef]

- Nation, C. Drive Business Strategy & Competitiveness with Porter’s Five Forces Disruptiv Nation. 2019. Available online: https://disruptivnation.com/2019/11/17/porters-five-forces/ (accessed on 10 October 2021).

- Bashir, M.J.K.; Ng, C.A.; Sethupathi, S.; Lim, J.W. Assessment of the Environmental, Technical and Economic Issues Associated with Energy Recovery from Municipal Solid Waste in Malaysia. IOP Conf. Ser. Earth Environ. Sci. 2019, 268, 012044. [Google Scholar] [CrossRef]

- Azman, N.H. KPKT: Six WTE Plants Planned Towards 2025. 2020. The Malaysian Reserve. Available online: https://themalaysianreserve.com/2020/06/22/kpkt-six-wte-plants-planned-towards-2025/ (accessed on 10 October 2021).

- Maragatham, K.; Strachan, N. Long-Term Decarbonisation Energy Pathways for Malaysia Using a Hybrid Demand-Supply Model. In Meeting the Energy Demand of Emerging Economies Implication for Energy and Environment Markets; IAEE: Cleveland, OH, USA, 2017; Volume 44, pp. 1–2. Available online: https://www.iaee.org/en/publications/proceedingsabstractpdf.aspx?id=14360 (accessed on 11 October 2021).

- Denchak, M. Paris Climate Agreement: Everything You Need to Know. National Resource Defend Council. 2021. Available online: https://www.nrdc.org/stories/paris-climate-agreement-everything-you-need-know (accessed on 10 October 2021).

- RE Generation. Sustainable Energy Development Authority. 2021. Available online: http://www.seda.gov.my/statistics-monitoring/re-generation/ (accessed on 10 October 2021).

- Malaysia Kini. Power Market—TNB Must Move Towards Liberalization. 2008. Available online: https://www.malaysiakini.com/letters/91889 (accessed on 11 October 2021).

- Bakhtyar, B.; Kacemi, T.; Nawaz, A. International Journal of Energy Economics and Policy A Review on Carbon Emissions in Malaysian Cement Industry. Int. J. Energy Econ. Policy 2017, 7, 282–286. [Google Scholar]

- Malaysia Competition Commission (MyCC). Market Review of Building Materials in the Construction Industry Under Competition Act 2010. 2017. Available online: http://mbam.org.my/wp-content/uploads/2017/11/Market-Review-of-Building-Materials-in-the-Construction-Industry-Draft-Final-091117-v2compressed.pdf (accessed on 11 October 2021).

- Mohamad Fozi, F.A.; Abd Hapiz, S. Legal Updates on the Solar Energy Industry in Malaysia. 2020. Azmilaw. Available online: https://www.azmilaw.com/insights/legal-updates-on-the-solar-energy-industry-in-malaysia/ (accessed on 11 October 2021).

- Ghazali, F.; Ansari, A.H.; Mustafa, M.; Zahari, W.M.Z.W. Renewable energy development and climate change mitigation in Malaysia: A Legal Study. J. Sustain. Sci. Manag. 2019, 14, 110–116. [Google Scholar]

- Energy Commission. Peninsular Malaysia Electricity Supply Industry Outlook 2019. 2019. Available online: https://www.st.gov.my/en/contents/files/download/106/Peninsular_Malaysia_Electricity_Supply_Industry_Outlook_2019_compressed.pdf (accessed on 11 October 2021).

- Ghazali, F.; Ansari, A.H. The Renewable Energy Act 2011: A Study on Renewable Energy Development in Malaysia. Int. J. Law Gov. Commun. 2018, 3, 143–151. [Google Scholar]

- Took Gee, L. Implementation of Green Technology Policy in Malaysia; Ministry of Energy, Green Technology & Water Malaysia: Putrajaya, Malaysia, 2015. [Google Scholar]

- Ahmad, A.; Sulaiman, N.F.A. Save The Food for A Better Future: A Discussion on Food Wastage in Malaysia. Int. J. Law Gov. Commun. 2018, 3, 12–21. [Google Scholar]

- Jereme, I.A.; Chamhuri, S.; Begum, R.A.; Abdul, B. Food wastes and food security: The Case of Malaysia. Int. J. Adv. Appl. Sci. 2017, 4, 6–13. [Google Scholar] [CrossRef]

- Lim, W.J.; Chin, N.L.; Yusof, A.Y.; Yahya, A.; Tee, T.P. Food waste handling in Malaysia and comparison with other Asian countries. Int. Food Res. J. 2016, 23, S1–S6. [Google Scholar]

- Department of Statistics Malaysia Official Portal. 2021. Available online: https://www.dosm.gov.my/v1/index.php?r=column/csearch&search_keyword=sexratio (accessed on 12 October 2021).

- Worldometer. Malaysia Coal Reserves and Consumption Statistics. 2021. Available online: https://www.worldometers.info/coal/malaysia-coal/ (accessed on 13 October 2021).

- Smith, A.M.; Whittaker, C.; Shield, I.F.; Ross, A.B. The potential for production of high quality bio-coal from early harvested Miscanthus by hydrothermal carbonisation. Fuel 2018, 220, 546–557. [Google Scholar] [CrossRef]

- Saha, N.; Volpe, M.; Fiori, L.; Volpe, R.; Messineo, A.; Reza, M.T. Cationic Dye Adsorption on Hydrochars of Winery and Citrus Juice Industries Residues: Performance, Mechanism, and Thermodynamics. Energies 2020, 13, 4686. [Google Scholar] [CrossRef]

- Rooney, K. Southeast Asia Energy Demand is Booming—How Will It Cope? 2019. World Economic Forum. Available online: https://www.weforum.org/agenda/2019/12/asean-southeast-asia-energy-emissions-renewables/ (accessed on 13 October 2021).

- Pontoni, L.; d’Antonio, G.; Esposito, G.; Fabbricino, M.; Frunzo, L.; Pirozzi, F. Thermal pretreatment of olive mill wastewater for efficient methane production: Control of Aromatic Substances Degradation by Monitoring Cyclohexane Carboxylic Acid. Environ. Technol. 2015, 36, 1785–1794. [Google Scholar] [CrossRef][Green Version]

- Pham, T.P.T.; Kaushik, R.; Parshetti, G.K.; Mahmood, R.; Balasubramanian, R. Food waste-to-energy conversion technologies: Current Status and Future Directions. Waste Manag. 2015, 38, 399–408. [Google Scholar] [CrossRef]

- Gao, L.; Volpe, M.; Lucian, M.; Fiori, L.; Goldfarb, J.L. Does hydrothermal carbonization as a biomass pretreatment reduce fuel segregation of coal-biomass blends during oxidation? Energy Convers. Manag. 2019, 181, 93–104. [Google Scholar] [CrossRef]

- Lucian, M.; Merzari, F.; Gubert, M.; Messineo, A.; Volpe, M. Industrial-Scale Hydrothermal Carbonization of Agro-Industrial Digested Sludge: Filterability Enhancement and Phosphorus Recovery. Sustainability 2021, 13, 9343. [Google Scholar] [CrossRef]

- Cacciattolo, K. Analysis of the Effectiveness of the Secondary Analysis of Existing Data in Quantitative Techniques. Res. Gate 2015, 2015, 1–7. [Google Scholar] [CrossRef]

- Demetriou, C.; Ozer, B.U.; Essau, C.A. Self-Report Questionnaires. Encycl. Clin. Psychol. 2015, 2015, 1–6. [Google Scholar] [CrossRef]

| Treatment Method | Percentage of Waste Disposed (%) | ||

|---|---|---|---|

| 2002 | 2006 | 2020 | |

| Recycling | 5.0 | 5.5 | 22.0 |

| Composting | 0.0 | 1.0 | 8.0 |

| Incineration | 0.0 | 0.0 | 16.8 |

| Inert landfill | 0.0 | 3.2 | 9.1 |

| Sanitary landfill | 5.0 | 30.9 | 44.1 |

| Other disposal sites | 90.0 | 59.4 | 0.0 |

| Objective | Vision |

|---|---|

| To facilitate the growth of the renewable energy industry | To achieve a 20% renewable energy capacity mix by 2025 |

| To ensure reasonable renewable energy generation costs | |

| To increase renewable energy in the national power generation mix | |

| To conserve the environment | |

| To enhance the awareness and importance of renewable energy |

| Parameter | Attribute | Frequency | Mass Percentage (%) | |

|---|---|---|---|---|

| 1. | Gender | Male | 95 | 44.2 |

| Female | 117 | 54.4 | ||

| Prefer not to say | 3 | 1.4 | ||

| 2. | Ethnicity | Malay | 94 | 44.1 |

| Chinese | 71 | 33.3 | ||

| Indian | 36 | 16.9 | ||

| Others | 12 | 5.6 | ||

| 3. | Age group | Less than 20 | 30 | 14.0 |

| 21–30 | 51 | 23.7 | ||

| 31–40 | 61 | 28.4 | ||

| 41–50 | 38 | 17.7 | ||

| 51–60 | 26 | 12.1 | ||

| More than 61 | 9 | 4.2 | ||

| 4. | Highest level of education | Secondary | 28 | 13.1 |

| Diploma | 23 | 10.7 | ||

| Bachelors | 87 | 40.7 | ||

| Masters and above | 76 | 35.5 | ||

| 5. | Monthly household income | 2500 and below | 31 | 14.6 |

| 2501–5000 | 43 | 20.3 | ||

| 5001–10,000 | 66 | 31.1 | ||

| 10,001–15,000 | 33 | 15.6 | ||

| 15,001 and above | 39 | 18.4 | ||

| 6. | Residential area type | Urban | 119 | 55.6 |

| Suburban | 82 | 38.3 | ||

| Rural | 13 | 6.1 |

| Food Category | Ranking | Percentage (%) |

|---|---|---|

| Rice or noodles or pasta | 1 | 13.0 |

| Vegetables | 2 | 12.2 |

| Curry and soups | 3 | 10.1 |

| Sauces (soya sauce, tomato or chilli sauce, etc.) | 4 | 7.9 |

| Breads (including roti jala, roti canai and chapati) | 5 | 6.6 |

| Fresh fruit or preserved fruits | 6 | 6.5 |

| Fresh meat or cooked meat | 7 | 6.0 |

| Dairy and dairy products (milk, yoghurt, ghee, cheese, butter, etc.) | 8 | 5.3 |

| Fresh or cooked fish and other seafood | 9 | 5.1 |

| Drinks | 10 | 4.3 |

| Spreads (jams, margarine, kaya, etc.) | 11 | 2.3 |

| Eggs | 12 | 3.9 |

| Cakes, ice cream or any type of dessert | 13 | 3.4 |

| Cereals (cornflakes, muesli, barley, millet, etc.) | 14 | 2.9 |

| Beans and nuts (dahls, lentils, chickpeas, groundnuts etc.) | 14 | 2.9 |

| Spreads (jams, margarine, kaya, etc.) | 15 | 2.3 |

| Preserved or dried fish, seafood, or meats | 16 | 2.2 |

| Parameter | Attribute | Freq | % |

|---|---|---|---|

| Name of organization | Cenergi SEA—Renewable Energy | 2 | 28.6 |

| Tex Cycle—Scheduled Waste Management & Renewable Energy | 1 | 14.3 | |

| Mukah Power Generation—Coal-Fired Power Plant | 1 | 14.3 | |

| Havys Oil Mill | 1 | 14.3 | |

| TNB | 2 | 28.6 | |

| Position/post in organization | Executive | 2 | 28.6 |

| Technical Engineer | 1 | 14.3 | |

| Station Manager | 1 | 14.3 | |

| Project Researcher | 1 | 14.3 | |

| Head of Section | 2 | 28.6 | |

| Number of employees | Full-time employees from 5 to less than 75 | 1 | 14.3 |

| Full-time employees from 75 to not exceeding 200 | 4 | 57.1 | |

| Full-time employees of 200 and above | 2 | 28.6 | |

| Why does your organization purchase coal? | Electricity | 3 | 75.0 |

| Boiler | 1 | 25.0 | |

| Would your organization buy bio-coal for your business operations and/or to generate energy/fuel for your key processes in the short term? | Maybe | 7 | 100 |

| Yes | 0 | 0 | |

| No | 0 | 0 | |

| Would your organization buy bio-coal for your business operations and/or to generate energy/fuel for your key processes in the longer term (2 years or more)? | Maybe | 7 | 100 |

| Yes | 0 | 0 | |

| No | 0 | 0 |

| Ranking | Item |

|---|---|

| 1 | Heat/energy/calorific value (most important) |

| 2 | Information on energy efficiency |

| 3 | Emissions |

| 3 | Reduction of environmental pollutants |

| 4 | Biodegradability (least important) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, A.; Gill, A.; Lim, D.L.K.; Kasmaruddin, A.; Miri, T.; Chakrabarty, A.; Chai, H.H.; Selvarajoo, A.; Massawe, F.; Abakr, Y.A.; et al. Feasibility of Bio-Coal Production from Hydrothermal Carbonization (HTC) Technology Using Food Waste in Malaysia. Sustainability 2022, 14, 4534. https://doi.org/10.3390/su14084534

Singh A, Gill A, Lim DLK, Kasmaruddin A, Miri T, Chakrabarty A, Chai HH, Selvarajoo A, Massawe F, Abakr YA, et al. Feasibility of Bio-Coal Production from Hydrothermal Carbonization (HTC) Technology Using Food Waste in Malaysia. Sustainability. 2022; 14(8):4534. https://doi.org/10.3390/su14084534

Chicago/Turabian StyleSingh, Ajit, Andrew Gill, David Lian Keong Lim, Agustina Kasmaruddin, Taghi Miri, Anita Chakrabarty, Hui Hui Chai, Anurita Selvarajoo, Festo Massawe, Yousif Abdalla Abakr, and et al. 2022. "Feasibility of Bio-Coal Production from Hydrothermal Carbonization (HTC) Technology Using Food Waste in Malaysia" Sustainability 14, no. 8: 4534. https://doi.org/10.3390/su14084534

APA StyleSingh, A., Gill, A., Lim, D. L. K., Kasmaruddin, A., Miri, T., Chakrabarty, A., Chai, H. H., Selvarajoo, A., Massawe, F., Abakr, Y. A., Mateva, K. I., Ng, W. P. Q., Serifi, O., Mackenzie, C., Mohamad, M., Kang, H.-S., Goh, P. S., Lim, J. W., & Chan, Y. J. (2022). Feasibility of Bio-Coal Production from Hydrothermal Carbonization (HTC) Technology Using Food Waste in Malaysia. Sustainability, 14(8), 4534. https://doi.org/10.3390/su14084534