Measurement of China’s Building Energy Consumption from the Perspective of a Comprehensive Modified Life Cycle Assessment Statistics Method

Abstract

:1. Introduction

2. Literature Review

2.1. Scopes and Methods of Building Energy Consumption

2.2. Energy Consumption Analysis Based on the LCA

2.3. Summary of Literature Review

3. LCA-Based Calculation Model

3.1. Identification and Division

3.2. Data Collection

3.3. Building Energy Consumption

3.3.1. Building Energy Consumption of the Construction Industry

3.3.2. Building Energy Consumption of the Engineering Industry

- : energy consumption of industrial buildings,

- denotes total energy consumption of the ferrous metal mining industry,

- represents total energy consumption of the non-ferrous metal mining industry,

- denotes total energy consumption of the non-metallic ore mining industry,

- captures total energy consumption of the non-metallic mineral manufacturing industry,

- represents total energy consumption of the metal smelting and rolling processing industries,

- stands for total energy consumption of the non-ferrous metal smelting and rolling processing industries, and

- , , represent the ferrous/non-ferrous/non-metallic industries related to the ratio of building consumption. The detailed values of , , and over the years are summarized in Table 2.

3.3.3. Building Energy Consumption of the Transportation and Storage Industry

- represents building energy consumption of transportation and storage,

- denotes coal consumption of transportation and storage,

- captures electricity consumption of transportation and storage, and

- stands for building electricity consumption of transportation and warehousing. This paper takes 40% [38].

- denotes coal conversion coefficient and standard coal coefficient of raw coal. It is 0.7143 million tons of standard coal/ton (China Energy Statistics Yearbook).

- denotes electric power conversion coefficient, and the conversion coefficient of thermal power generation is 122.9 million tons/100 million kWh (China Energy Statistics Yearbook).

3.3.4. Building Energy Consumption in Wholesale, Retail, Accommodation, and Catering Industries

- represents building energy consumption in the wholesale, retail, accommodation, and catering industries,

- captures total energy consumption of the wholesale, retail, accommodation, and catering industries,

- denotes transportation energy consumption in the wholesale, retail, accommodation, and catering industries;

- represents gasoline consumption in the wholesale, retail, accommodation, and catering industries;

- stands for diesel consumption in the wholesale, retail, accommodation, and catering industries;

- is the standard coal coefficient of gasoline, which is 14,714 tons of standard coal/ton (China Energy Statistics Yearbook), and

- is the standard coal coefficient of diesel oil, which is 144.571 million tons of standard coal/10 thousand tons (China Energy Statistics Yearbook).

3.3.5. Building Energy Consumption in Other Related Industries

- represents other industries related to building energy consumption,

- stands for the total energy consumption of other industries,

- denotes the transportation energy consumption in other industries,

- represents the amount of gasoline consumed by other industries, and

- denotes diesel consumption in other industries.

3.3.6. Building Energy Consumption of Residential Consumption Part

- represents the building energy consumption contained in living consumption,

- denotes the total consumption of domestic energy,

- captures the gasoline consumption in daily consumption, and

- denotes the consumption of diesel in daily consumption.

3.3.7. The Heating Energy Consumption

- represents the building energy consumption of heating,

- denotes total steam heating,

- denotes total hot water heating, and

- is the thermal standard coal coefficient, which is 0.03412 million tons of standard coal/10,000 (China Energy Statistical Yearbook).

3.3.8. Building Energy Consumption Calculation Model

4. Results and Analysis

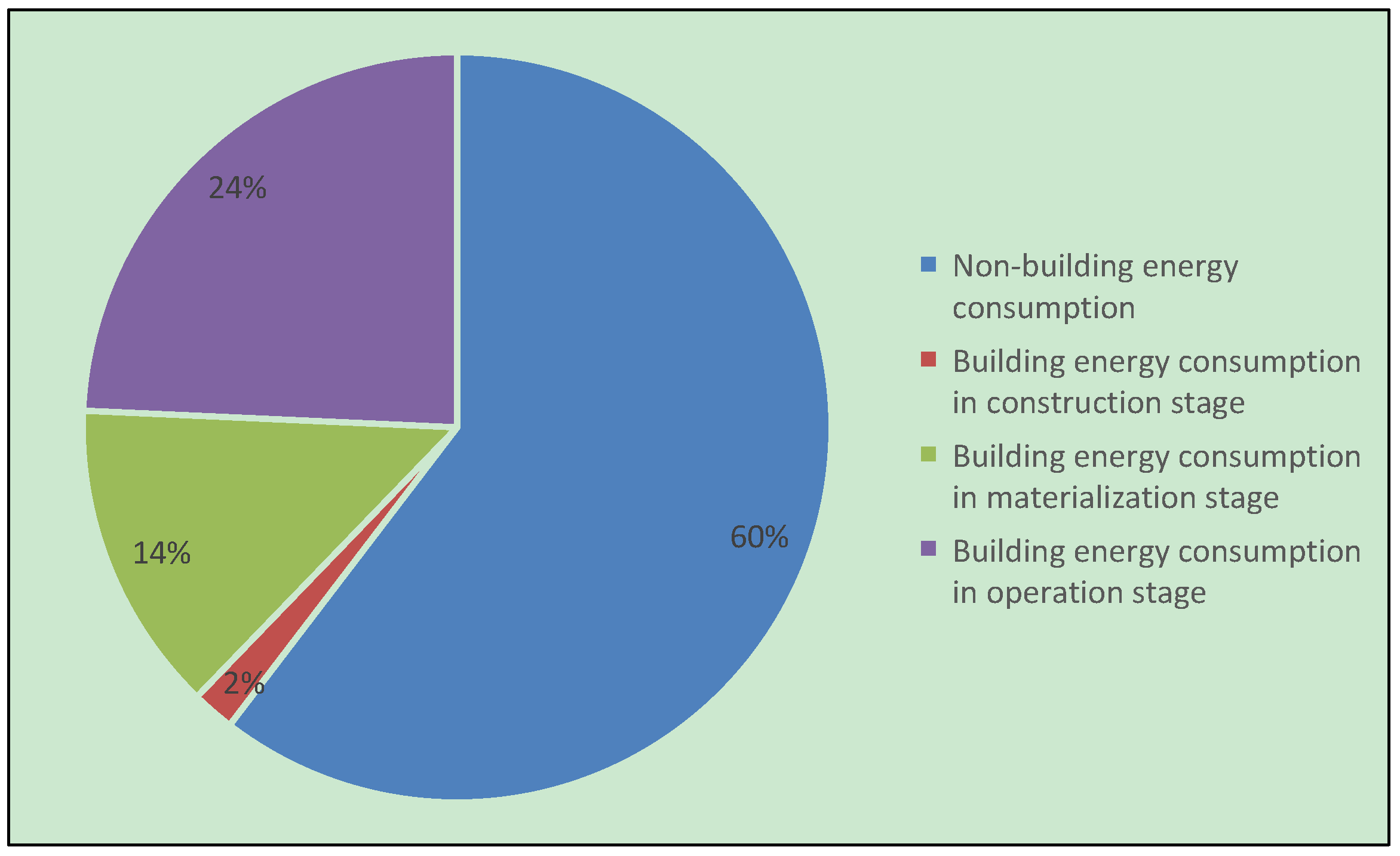

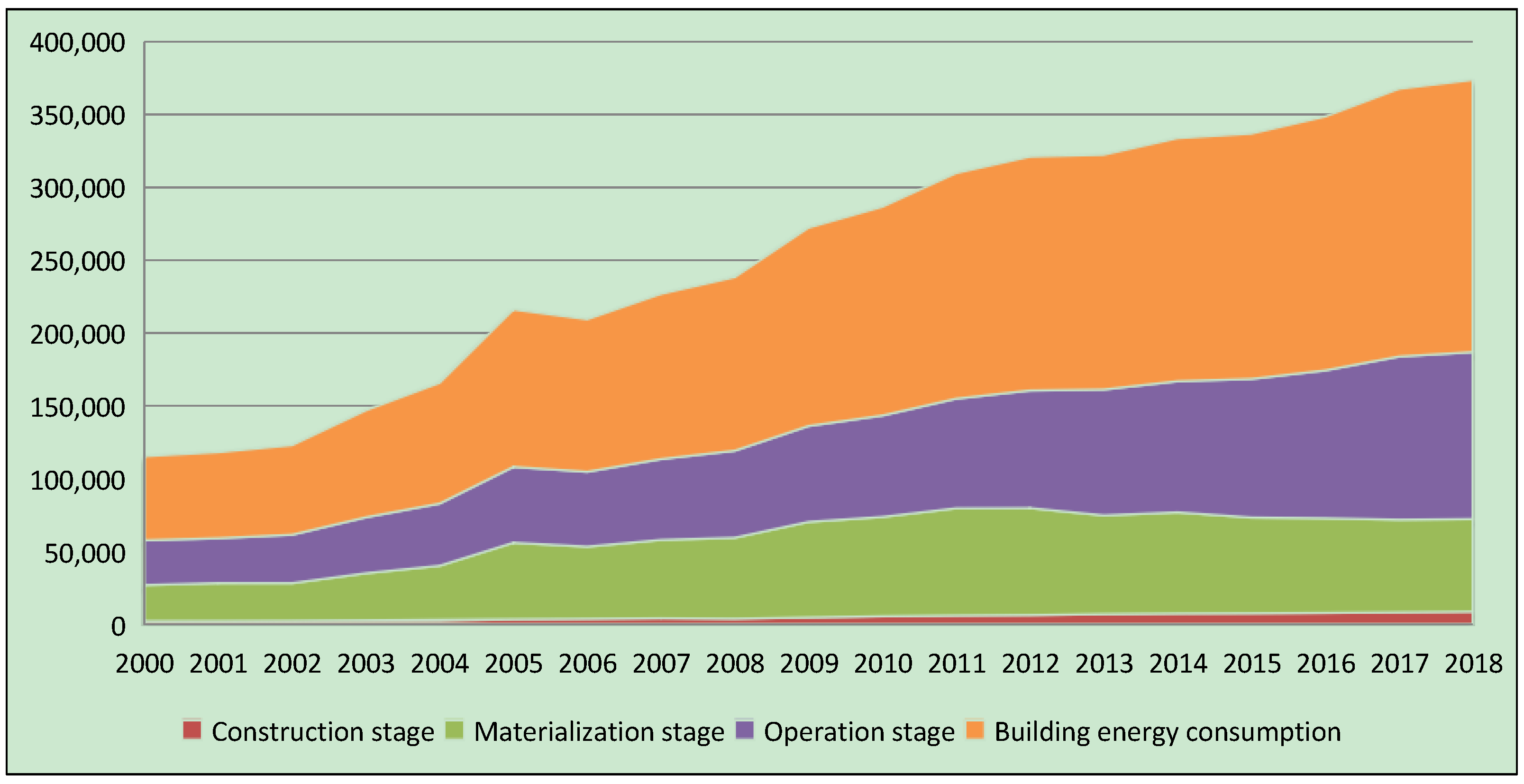

4.1. Current Situation of Building Energy Consumption in China

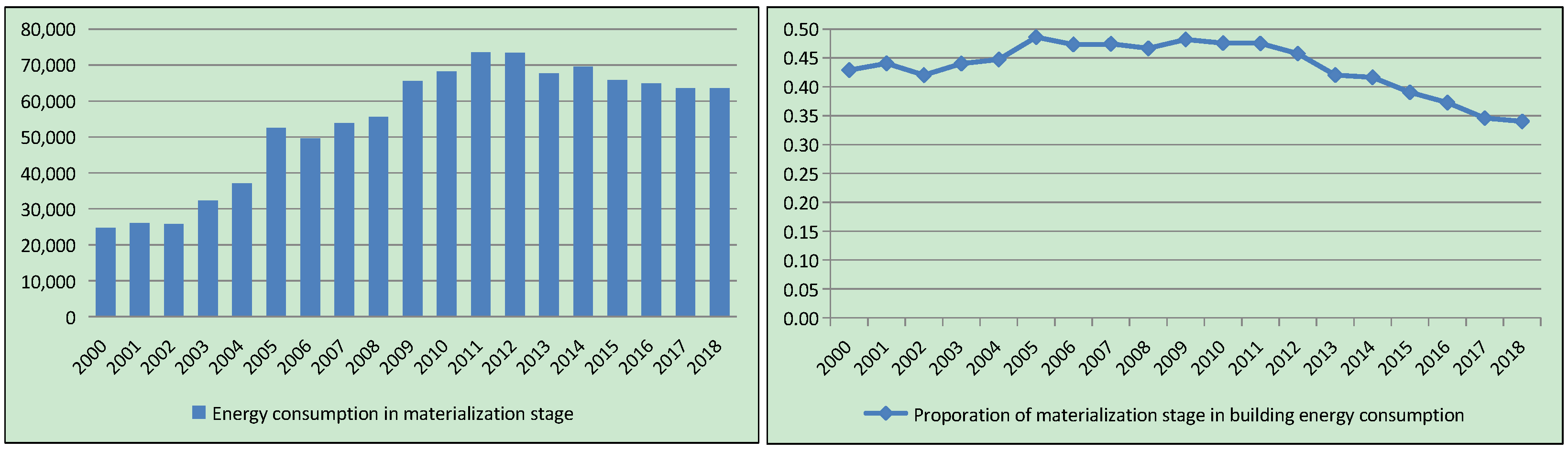

4.2. Energy Consumption in the Materialization Stage

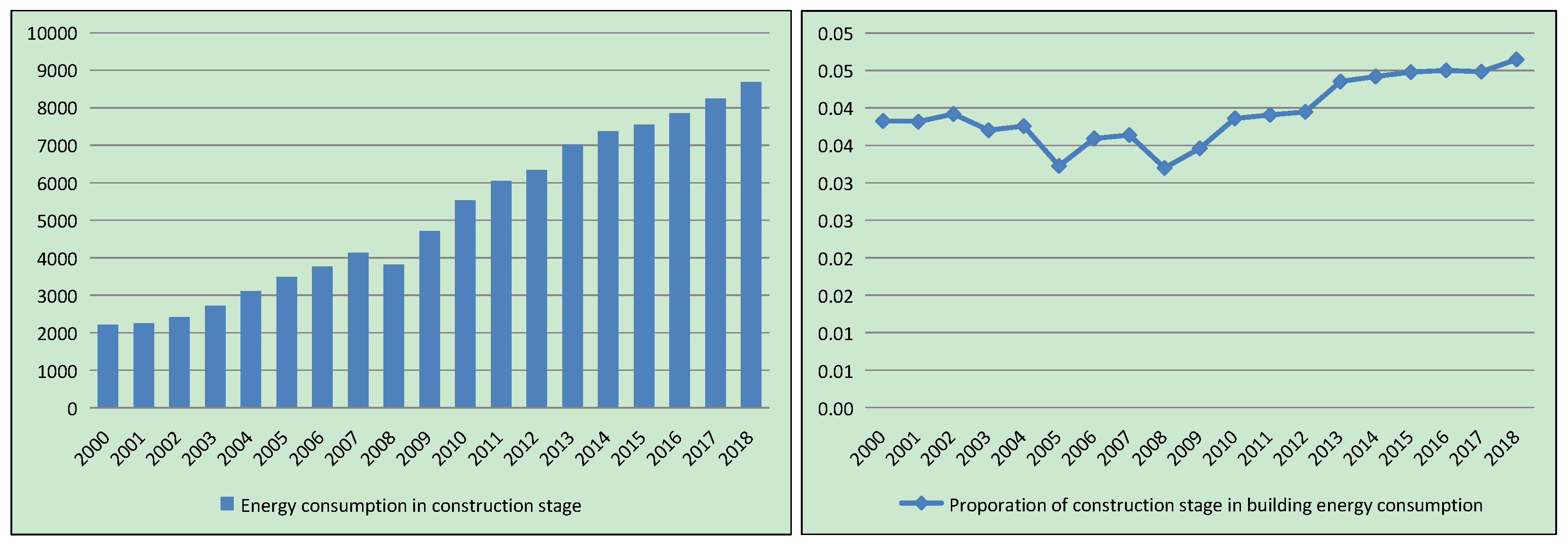

4.3. Energy Consumption in the Construction Stage

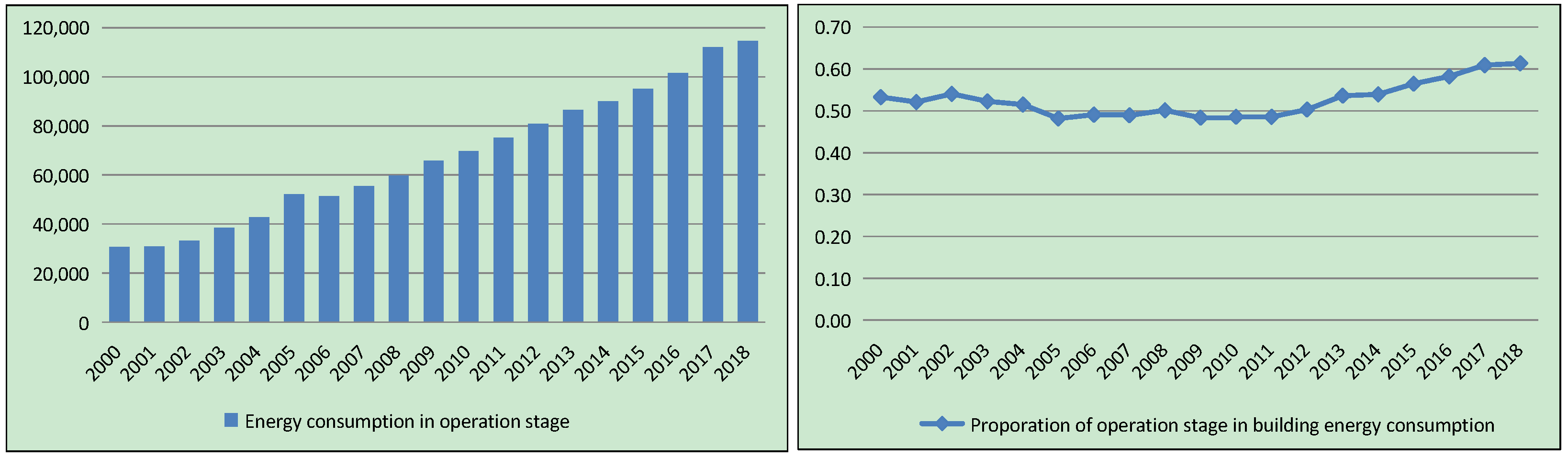

4.4. Energy Consumption in the Operation Stage

5. Optimization Strategies

5.1. Optimization Strategies for the Materialization Stage

- (1)

- Industrial restructuring. Backward capacity should be eliminated, especially in the industries of iron making, steel making, cement (clinker and grinding), and flat glass.

- (2)

- Transformation and innovation of energy-saving technology. Energy-saving technologies, such as waste heat and pressure utilization, energy system optimization, and energy saving of motor systems, should be applied to reconstruct engineering equipment.

- (3)

- Industrial energy saving. Energy efficiency benchmarking should be fully implemented in key energy-consuming industries, such as building materials, steel, electricity, and transportation. Energy management and control centers of industrial enterprises should also be established.

- (4)

- Prefabricated industries should be supported to promote the modernization of the construction industry. Equivalent replacement or decrement replacement of energy consumption should be applied to the new capacity of the steel and building material industries.

5.2. Optimization Strategies for the Construction Stage

- (1)

- Project management should be improved to reduce energy consumption. There still exists inefficiency or lack of regulation regarding the management of construction projects in China, resulting in accelerated mechanical aging, material damage, and unnecessary energy consumption. The immaturity of construction technology will not only lead to excessive energy consumption in the construction stage, but also lead to more energy consumption in the later operation stage.

- (2)

- Selection of suppliers within a short distance between the product inventories and the construction site should be considered to reduce energy consumption in transportation.

- (3)

- Adoption of green buildings. Full implementation of green building standards should be put into action for public welfare and large public buildings. Project capability and environmental impact assessment systems should be strictly implemented. For those regions that have not finished the energy-saving tasks, their new high energy consumption projects should be canceled or delayed.

5.3. Optimization Strategies for the Operation Stage

- (1)

- Architectural design determines the energy consumption in the operation stage. Through controllable design, eco-friendly or new energy-saving building materials can be selected for the new buildings, which will be an effective method to reduce the consumption of resources and energy, from the perspective of the life cycle. For existing buildings, reasonable energy-saving renovation should also be carried out.The technology of building information modelling (BIM) has been considered an ideal digital tool to function as the data repository of all information relating to the building lifecycle [50]. The Ministry of Housing and Urban-Rural Development issued the Construction Industry Information Development Outline from 2011 to 2015 in May 2011 and the Architectural Engineering Design Information Model Mapping Standard in 2019, aiming to strengthen the management of projects and standardize building industry data.

- (2)

- As energy consumption in the operation stage is to meet people’s requirements for normal study, work, and life, the most effective way is to strengthen the management of energy conservation, to implement demand-side management mechanisms of power, and to enhance people’s awareness of energy saving. Electricity and heat take most of the consumption energy in the building operation stage. For instance, reducing the usage of air conditioning is one of the most effective ways to save energy.

- (3)

- As coal is still the main energy source of power and heat, the energy consumption structure should be adjusted to reduce inefficient and carbon-intensive coal use in electric power and thermal power enterprises. Meanwhile, strategies of energy efficiency are essential in energy policy, which could be created using the various approaches employed for energy savings in buildings [51]. The supply of non-fossil fuels and natural gas should be increased in residents’ life or for the replacement of coal, with a strict replacement policy of equal or reduced coal consumption. Using the potentiality of electric vehicles toward the achievement of the zero-energy target extended to a buildings cluster level is also a measure to reduce coal burning, by exploiting renewable generation on and off-site [52].

- (4)

- The government can give publicity to the catalog of energy-efficient air conditioners, refrigerators, and other products. They can also make policies to guide the production, purchase, and use of energy-efficient products.

6. Conclusions and Management Insights

6.1. Conclusions

6.2. Management Insights

- (1)

- This paper helps with the understanding of Chinese building energy consumption in 2000–2018. Nowadays, China is more eager than ever to save energy and reduce carbon emissions. During 2020 to 2021, the Chinese government has emphasized many times their determination to make efforts to save energy and reduce carbon emissions in international conferences. In 2021, they have put forward their 14th Five-Year Plan, which clearly demonstrates control of the growth of coal consumption. By 2030, China’s civil construction area will exceed 70 billion square meters, their building industry will face a more severe situation of energy conservation. As building energy consumption still takes nearly 40% of their total energy consumption in recent years, the task of energy conservation in the building industry is quite urgent. In this case, the supervision intensity of the building industry has been enhanced. This forces building enterprises to put more attention into energy saving strategies.

- (2)

- Attention should be paid to the recovery and reuse of construction wastes. The reuse of metal, wood, and available wastes can greatly reduce the input of raw materials and reduce energy consumption. The application of construction waste recycling in prefabricated buildings should be encouraged. Certain preferential tax policies could be applied to the projects that use construction waste recycling. Additionally, intelligent sorting standards should be developed in order to improve the sorting efficiency of construction waste recycling enterprises.

- (3)

- A new finding is that although building energy consumption in the construction stage is only a small part of total building energy consumption and is often neglected, its growth is the fastest. Therefore, more attention should be paid to control its growth. Energy consumption in the construction stage is less affected by external factors. Improvement of construction technology, management, and design can be useful in energy-saving in the construction and operation stages. It is promising to use BIM to promote the construction industry, paving the way for energy saving and emission reduction in the whole building life cycle.

- (4)

- The application of hybrid renewable energy systems in ultra-low energy and near-zero energy buildings should be promoted. For example, the hybrid geothermal-photovoltaic system has been used for heating and cooling. Companies should pay more attention to research and development in this field.

- (5)

- The operation stage not only takes up most of a building’s energy consumption, it also makes the greatest contribution to the growth of Chinese buildings’ energy consumption from 2000 to 2018. Therefore, it is essential to control building energy consumption in the operation stage. Except for the design and application of new eco-friendly technology, an effective way to reduce building energy consumption in the operation stage may be to enhance people’s awareness of energy conservation in their daily life.

6.3. Future Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Luo, X.; Oyedele, L.; Owolabi, H.; Bilal, M.; Ajayi, A.; Akinade, O. Life cycle assessment approach for renewable multi-energy system: A comprehensive analysis. Energy Convers. Manag. 2020, 224, 113354. [Google Scholar] [CrossRef]

- Khan, H.R.; Awan, U.; Zaman, K.; Nassani, A.A.; Haffar, M.; Abro, M.M.Q. Assessing hybrid solar-wind potential for industrial decarbonization strategies: Global shift to green development. Energies 2021, 14, 7620. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, T.; Li, H.; Skitmore, M.; Su, B. A statistics-based method to quantify residential energy consumption and stock at the city level in China: The case of the Guangdong-Hong Kong-Macao Greater Bay Area cities. J. Clean. Prod. 2019, 251, 119637. [Google Scholar] [CrossRef]

- Ikram, M.; Sroufe, R.; Awan, U.; Abid, N. Enabling progress in developing economies: A novel hybrid decision-making model for green technology planning. Sustainability 2022, 14, 258. [Google Scholar] [CrossRef]

- Tabrizikahou, A.; Nowotarski, P. Mitigating the energy consumption and the carbon emission in the building structures by optimization of the construction processes. Energies 2021, 14, 3287. [Google Scholar] [CrossRef]

- Li, Y.; Han, M.; Liu, S.; Chen, G. Energy consumption and greenhouse gas emissions by buildings: A multi-scale perspective. Build. Environ. 2019, 151, 240–250. [Google Scholar] [CrossRef]

- Wen, Q.; Gu, J.; Hong, J.; Shen, G.; Yuan, M. Unfolding interregional energy flow structure of China’s construction sector based on province-level data. J. Environ. Manag. 2019, 253, 109693. [Google Scholar] [CrossRef]

- Chen, L.; Nan, G.; Li, M.; Feng, B.; Liu, Q. Manufacturer’s online selling strategies under spillovers from online to offline sales. J. Oper. Res. Soc. 2022. [Google Scholar] [CrossRef]

- Yu, H.; Huang, Z.; Pan, Y.; Long, W. Guidelines for Community Energy Planning; Springer Science and Business Media LLC: Berlin, Germany, 2020. [Google Scholar]

- Liu, B.; Wang, D.; Xu, Y.; Liu, C.; Luther, M. Vertical specialisation measurement of energy embodied in international trade of the construction industry. Energy 2018, 165, 689–700. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, Y.; Huang, F.; Zhong, Y.; Zhou, J. Forecasting the energy and economic benefits of photovoltaic technology in China’s rural areas. Sustainability 2021, 13, 8408. [Google Scholar] [CrossRef]

- Wei, Y.; Liao, H. Energy Economics: Energy Efficiency in China; Springer Science and Business Media LLC: Berlin, Germany, 2016. [Google Scholar]

- Xiao, Q.; Chen, L.; Xie, M.; Wang, C. Optimal contract design in sustainable supply chain: Interactive impacts of fairness concern and overconfidence. J. Oper. Res. Soc. 2021, 72, 1505–1524. [Google Scholar] [CrossRef]

- Awan, U.; Khattak, A.; Rabbani, S.; Dhir, A. Buyer-driven knowledge transfer activities to enhance organizational sustainability of suppliers. Sustainability 2020, 12, 2993. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Chen, X.; Shahrestani, M. Optimization of insulation thickness of external walls of residential buildings in hot summer and cold winter zone of China. Sustainability 2020, 12, 1574. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Rao, C.; Goh, M.; Yang, Z. Pricing strategies and profit coordination under a double echelon green supply chain. J. Clean. Prod. 2021, 278, 123694. [Google Scholar] [CrossRef]

- Guo, Y.; Bart, D. Optimization of design parameters for office buildings with climatic adaptability based on energy demand and thermal comfort. Sustainability 2020, 12, 3540. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Supply chain management for improved energy efficiency: Review and opportunities. Energies 2017, 10, 1618. [Google Scholar] [CrossRef] [Green Version]

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C.; Corrales, L.C.N. Development of a new green indicator and its implementation in a cyber-physical system for a green supply chain. Sustainability 2020, 12, 8629. [Google Scholar] [CrossRef]

- Sun, Y.; Haghighat, F.; Fung, B. A review of the-state-of-the-art in data-driven approaches for building energy prediction. Energy Build. 2020, 221, 110022. [Google Scholar] [CrossRef]

- Begum, S.; Xia, E.; Ali, F.; Awan, U.; Ashfaq, M. Achieving green product and process innovation through green leadership and creative engagement in manufacturing. J. Manuf. Technol. Manag. 2021. [Google Scholar] [CrossRef]

- Yuan, X.; Sun, X.; Zhao, W.; Mi, Z.; Wang, B.; Wei, Y. Forecasting China’s regional energy demand by 2030: A Bayesian approach. Resour. Conserv. Recycl. 2017, 127, 85–95. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Hybrid input-output analysis for life-cycle energy consumption and carbon emissions of China’s building sector. Build. Environ. 2016, 104, 188–197. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.; Guo, S.; Xue, F.; Zheng, W. Energy use embodied in China’s construction industry: A multi-regional input-output analysis. Renew. Sustain. Energy Rev. 2016, 53, 1303–1312. [Google Scholar] [CrossRef] [Green Version]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Degen, F.; Schütte, M. Life cycle assessment of the energy consumption and GHG emissions of state-of-the-art automotive battery cell production. J. Clean. Prod. 2022, 330, 129798. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life cycle analysis in the construction sector: Guiding the optimization of conventional Italian buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Chau, C.; Leung, T.; Ng, W. A review on life cycle assessment, life cycle energy assessment and life cycle carbon emissions assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Sartori, I.; Sandberg, N.; Brattebø, H. Dynamic building stock modelling: General algorithm and exemplification for Norway. Energy Build. 2016, 132, 13–25. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Du, G.; Zhang, Z.; Wang, P.; Xie, B. Life cycle analysis of energy consumption and CO2 emissions from a typical large office building in Tianjin, China. Build. Environ. 2017, 117, 36–48. [Google Scholar] [CrossRef]

- Zhang, Y.; He, C.; Tang, B.; Wei, Y. China’s energy consumption in the building sector: A life cycle approach. Energy Build. 2015, 94, 240–251. [Google Scholar] [CrossRef]

- Cheng, Z.; Shahmir, N.; Lu, T. BIM-based investigation of total energy consumption in delivering building products. Adv. Eng. Inform. 2018, 38, 370–380. [Google Scholar]

- Zhang, Y.; Yan, D.; Hu, S.; Guo, S. Modelling of energy consumption and carbon emission from the building construction sector in China, a process-based LCA approach. Energy Policy 2019, 134, 110949. [Google Scholar] [CrossRef]

- Zhou, N.; Lin, J. The reality and future scenarios of commercial building energy consumption in China. Energy Build. 2008, 40, 2121–2127. [Google Scholar] [CrossRef] [Green Version]

- Cai, W.; Wu, Y.; Zhong, Y.; Ren, H. China building energy consumption: Situation, challenges and corresponding measures. Energy Policy 2009, 37, 2054–2059. [Google Scholar] [CrossRef]

- McNeil, M.; Feng, W.; Can, S.; Khanna, N.; Ke, J.; Zhou, N. Energy efficiency outlook in China’s urban buildings sector through. Energy Policy 2016, 97, 532–539. [Google Scholar] [CrossRef] [Green Version]

- Basbagill, J.; Flager, F.; Lepech, M.; Fischer, M. Application of life-cycle assessment to early stage building design for reduced embodied environmental impacts. Build. Environ. 2013, 60, 81–92. [Google Scholar] [CrossRef]

- Huo, T.; Ren, H.; Zhang, X.; Cai, W.; Feng, W.; Zhou, N.; Wang, X. China’s energy consumption in the building sector: A Statistical Yearbook-Energy Balance Sheet based splitting method. J. Clean. Prod. 2018, 185, 665–679. [Google Scholar] [CrossRef]

- Abrahamse, W.; Steg, L.; Vlek, C.; Rothengatter, T. A review of intervention studies aimed at household energy conservation. J. Environ. Psychol. 2005, 25, 273–291. [Google Scholar] [CrossRef]

- Wenninger, S.; Kaymakci, C.; Wiethe, C. Explainable long-term building energy consumption prediction using QLattice. Appl. Energy 2022, 308, 118300. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.; Li, C.; Liu, G.; Wu, Z.; Zhong, X. An integrated framework for embodied energy quantification of buildings in China: A multi-regional perspective. Resour. Conserv. Recycl. 2018, 138, 183–193. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, G.; Xia, X.; Setunge, S.; Shi, L. A review of internal and external influencing factors on energy efficiency design of buildings. Energy Build. 2020, 216, 109944. [Google Scholar] [CrossRef]

- Motalebi, M.; Rashidi, A.; Nasiri, M.M. Optimization and BIM-based lifecycle assessment integration for energy efficiency retrofit of buildings. J. Build. Eng. 2022, 49, 104022. [Google Scholar] [CrossRef]

- SäYnäJoki, A.; Heinonen, J.; Junnila, S.; Horvath, A. Can life-cycle assessment produce reliable policy guidelines in the building sector? Environ. Res. Lett. 2017, 12, 013001. [Google Scholar] [CrossRef] [Green Version]

- Felmer, G.; Morales-Vera, R.; Astroza, R.; González, I.; Puettmann, M.; Wishnie, M. A lifecycle assessment of a low-energy mass-timber building and mainstream concrete alternative in central Chile. Sustainability 2022, 14, 1249. [Google Scholar] [CrossRef]

- Chen, J.; Guo, Y.; Su, H.; Ma, X.; Zhang, Z.; Chang, B. Empirical analysis of energy consumption transfer in China’s national economy from the perspective of production and demand. Environ. Sci. Pollut. Res. 2021, 28, 19202–19221. [Google Scholar] [CrossRef] [PubMed]

- Kwok, K.; Kim, J.; Chong, W.; Ariaratnam, S. Structuring a comprehensive carbon-emission framework for the whole life cycle of building, operation, and construction. J. Archit. Eng. 2016, 22, 04016006. [Google Scholar] [CrossRef]

- Yang, R.; Chen, W. Spatial correlation, influencing factors and environmental supervision mechanism construction of atmospheric pollution: An empirical study on SO2 emissions in China. Sustainability 2019, 11, 1742. [Google Scholar] [CrossRef] [Green Version]

- Marzouk, M.; Azab, S.; Metawie, M. BIM-based approach for optimizing life cycle costs of sustainable buildings. J. Clean. Prod. 2018, 188, 217–226. [Google Scholar] [CrossRef]

- Aldhshan, S.R.S.; Abdul Maulud, K.N.; Wan Mohd Jaafar, W.S.; Karim, O.A.; Pradhan, B. Energy consumption and spatial assessment of renewable energy penetration and building energy efficiency in Malaysia: A review. Sustainability 2021, 13, 9244. [Google Scholar] [CrossRef]

- Barone, G.; Buonomano, A.; Forzano, C.; Giuzio, G.F.; Palombo, A. Increasing self-consumption of renewable energy through the Building to Vehicle to Building approach applied to multiple users connected in a virtual micro-grid. Renew. Energy 2020, 159, 1165–1176. [Google Scholar] [CrossRef]

- Gao, M.; Yang, H.; Xiao, Q.; Goh, M. A novel method for carbon emission forecasting based on Gompertz’s law and fractional grey model: Evidence from American industrial sector. Renew. Energy 2022, 181, 803–819. [Google Scholar] [CrossRef]

- Rao, C.; He, Y.; Wang, X. Comprehensive evaluation of non-waste cities based on two-tuple mixed correlation degree. Int. J. Fuzzy Syst. 2021, 23, 369–391. [Google Scholar] [CrossRef]

| Articles | Scopes of the Building Energy Consumption | Whether the Calculation Covers Related Industries | Methods of Building Energy Consumption | LCA-Based Calculation Method |

|---|---|---|---|---|

| Hong et al. [42] | Materialization | No | Model-based | EIO-LCA |

| Zhang et al. [33] | Construction | No | Model-based | Process-LCA |

| Huo et al. [38] | Operation | Yes | Macro data | Hybrid-LCA |

| Zhang et al. [31] | Materialization | Yes | Macro data | Process-LCA |

| Construction | ||||

| Operation | ||||

| Zhang and Wang [23] | Construction | Yes | Macro data | Hybrid-LCA |

| Operation | ||||

| This paper | Materialization | Yes | Macro data | Process-LCA |

| Construction | ||||

| Operation |

| Year | 2000 | 2001 | 2002 | 2004 | 2005 | 2006 | 2007 | 2008 | 2009 |

| X | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.50 | 0.50 | 0.50 | 0.50 |

| Y | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.28 | 0.28 | 0.28 | 0.28 |

| Z | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 |

| Year | 2010 | 2011 | 2012 | 2014 | 2015 | 2016 | 2017 | 2018 | |

| X | 0.55 | 0.55 | 0.55 | 0.58 | 0.58 | 0.58 | 0.58 | 0.58 | |

| Y | 0.28 | 0.32 | 0.32 | 0.32 | 0.32 | 0.35 | 0.35 | 0.35 | |

| Z | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 |

| Year | Construction | Materialization | Operation | Building Energy Consumption | Proportion |

|---|---|---|---|---|---|

| 2000 | 2207 | 24,739.92 | 30,731.35 | 57,678.27 | 0.39 |

| 2001 | 2255.02 | 26,024.87 | 30,788.39 | 59,068.28 | 0.38 |

| 2002 | 2409.57 | 25,836.12 | 33,223.23 | 61,468.92 | 0.36 |

| 2003 | 2720.66 | 32,329.27 | 38,393.56 | 73,443.49 | 0.37 |

| 2004 | 3114.60 | 37,076.32 | 42,684.25 | 82,875.16 | 0.36 |

| 2005 | 3486 | 52,521.05 | 52,050.82 | 108,057.87 | 0.41 |

| 2006 | 3760.73 | 49,550.34 | 51,397.95 | 104,709.02 | 0.37 |

| 2007 | 4127.52 | 53,809.25 | 55,482.27 | 113,419.04 | 0.36 |

| 2008 | 3812.53 | 55,619.24 | 59,733.9 | 119,165.67 | 0.37 |

| 2009 | 4712 | 65,618.92 | 65,821.35 | 136,152.27 | 0.41 |

| 2010 | 5533 | 68,178.96 | 69,611.29 | 143,323.25 | 0.40 |

| 2011 | 6052 | 73,602.14 | 75,241.48 | 154,895.62 | 0.40 |

| 2012 | 6337 | 73,455.26 | 80,740.18 | 160,532.44 | 0.40 |

| 2013 | 7017 | 67,756.98 | 86,405.02 | 161,179.00 | 0.39 |

| 2014 | 7377 | 69,499.48 | 90,008.44 | 166,884.92 | 0.39 |

| 2015 | 7545 | 65,770.57 | 95,133.35 | 168,448.92 | 0.39 |

| 2016 | 7847 | 64,958.22 | 101,485.70 | 174,290.95 | 0.39 |

| 2017 | 8243 | 63,576.50 | 111,994.30 | 183,813.82 | 0.40 |

| 2018 | 8685 | 63,576.94 | 114,636.60 | 186,898.54 | 0.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Huang, J.; Ni, T.; Chen, L. Measurement of China’s Building Energy Consumption from the Perspective of a Comprehensive Modified Life Cycle Assessment Statistics Method. Sustainability 2022, 14, 4587. https://doi.org/10.3390/su14084587

Liu Q, Huang J, Ni T, Chen L. Measurement of China’s Building Energy Consumption from the Perspective of a Comprehensive Modified Life Cycle Assessment Statistics Method. Sustainability. 2022; 14(8):4587. https://doi.org/10.3390/su14084587

Chicago/Turabian StyleLiu, Qiurui, Juntian Huang, Ting Ni, and Lin Chen. 2022. "Measurement of China’s Building Energy Consumption from the Perspective of a Comprehensive Modified Life Cycle Assessment Statistics Method" Sustainability 14, no. 8: 4587. https://doi.org/10.3390/su14084587