Study on the Effect of Bio-Based Materials’ Natural Degradation in the Environment

Abstract

:1. Introduction

- d2w®—biodegradable plastic technology: plastics manufactured under the d2w® technology could be considered as “oxo-biodegradable”, since they require oxygen and UV exposure for the degradation process to start. However, this technology is described as a two-stage process, in which, firstly, ordinary plastic, at the end of its useful life and in the presence of oxygen, is turned into a material with a different molecular structure, while, in the second stage, it is no longer a plastic, but a material that is biodegradable (by bacteria and fungi) in the open environment [9].

- Cocoa paper: newly developed material that is the result of an innovative technology that reuses scrap shells from the processing of cocoa and transforms them into paper with remarkable quality and with a natural texture [10]. Alongside being plastic-free, it is recyclable and biodegradable and waste material is used in its production, making cocoa paper a circular economy product.

2. Materials and Methods

2.1. Biodegradation Analysis of PLA and Other Bio-Based Materials in Different Environments

- (a)

- PLA spoon (4 cm × 2 cm and 4 cm × 0.5 cm samples);

- (b)

- d2w® biodegradation technology bag (5 cm × 3 cm samples);

- (c)

- Cocoa paper tray (5 cm × 6 cm and 5 cm × 3 cm samples);

- (d)

- PLA filament (11 cm × 0.2 cm samples).

- (a)

- Soil;

- (b)

- Baltic Sea sand;

- (c)

- Medium-grain sand;

- (d)

- Saltwater with 0.7% concentration of salt.

- Temperature: In each environment, the temperature was around 20 °C (ambient temperature), with slight changes between the winter and spring season.

- Salt concentration: The salt concentration in the saltwater environment was 0.7%, which corresponds to the one found in the Baltic Sea, Poland.

- Moisture content of each material: The moisture content of each material was also determined with the following formula:

2.2. Home Composting Simulation of PLA and Other Bio-Based Materials in Small-Scale Electric Composter Unit

2.3. Determination of Calorific Value of PLA and Bio-Based Materials

2.4. Determination of Carbon and Hydrogen Content

2.5. Determination of Chlorine Content of PLA and Bio-Based Materials

3. Results

3.1. Initial Values of Tested Materials

3.2. PLA and Bio-Based Materials’ Properties and Ecotoxicity Results

3.3. Degradation Rates in Different Environments

3.4. Home Composting of PLA and Bio-Based Materials in Small-Scale Electric Composter Unit

4. Discussion

- (a)

- Material properties and ecotoxicity

- (b) Biodegradation rate

- (c) Biodegradation in compost

- (a)

- Physical and chemical properties: the type of bioplastic must be specified, as well as information about its environmental claims, which must be truthful and accurate, and end-of-life recommendations based on the consumer’s access to them.

- (b)

- Information from life cycle assessment: from the waste management options that the product might have.

- (c)

- Availability of the waste management technologies: as shown in Figure 4, there might be adequate technology or a complete lack of it; however, there can also be only some of the proposed end-of-life options and the chosen one must be that of the lowest environmental impact.

- (d)

- Consumer’s behavior regarding waste management: the efficiency of the whole waste processing system can be increased from the sorting and collection phase; therefore, the public must have clear knowledge of the appropriate ways in which they should dispose of the bioplastic. This can be achieved with unambiguous and informative labelling as well as with education towards the public regarding the proper disposal of bioplastics.

- (1)

- Creation of guidelines for accurate environmental communication;

- (2)

- Proper communication of end-of-life options.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rutkowska, M.; Heimowska, A.; Krasowska, K.; Janik, H. Biodegradability of Polyethylene Starch Blends in Sea Water. Pol. J. Environ. Stud. 2002, 11, 267–271. [Google Scholar]

- Carus, M.; Dammer, L. Food or Non-Food: Which Agricultural Feedstocks Are Best for Industrial Uses? Ind. Biotechnol. 2013, 9, 171–176. [Google Scholar] [CrossRef]

- Agarwal, M.; Koelling, K.W.; Chalmers, J.J. Characterization of the Degradation of Polylactic Acid Polymer in a Solid Substrate Environment. Biotechnol. Prog. 1998, 14, 517–526. [Google Scholar] [CrossRef] [PubMed]

- Williams, D.F. Enzymic Hydrolysis of Polylactic Acid. Eng. Med. 1981, 10, 5–7. [Google Scholar] [CrossRef]

- Ho, K.-L.G.; Pometto, A.L.; Gadea-Rivas, A.; Briceño, J.A.; Rojas, A. Degradation of Polylactic Acid (PLA) Plastic in Costa Rican Soil and Iowa State University Compost Rows. J. Polym. Environ. 1999, 7, 173–177. [Google Scholar] [CrossRef]

- Intaraksa, P.; Rudeekit, Y.; Siriyota, P.; Leejarkpai, T. Comparative Study of the Bio-Disintegration Behavior of Polylactic Acid under Laboratory and Pilot-Scale Composting Conditions. Adv. Mater. Res. 2013, 747, 678–681. [Google Scholar] [CrossRef]

- Napper, I.E.; Thompson, R.C. Environmental Deterioration of Biodegradable, Oxo-biodegradable, Compostable, and Conventional Plastic Carrier Bags in the Sea, Soil, and Open-Air Over a 3-Year Period. Environ. Sci. Technol. 2019, 53, 4775–4783. [Google Scholar] [CrossRef] [PubMed]

- Cooper, T. Developments in Bioplastic Materials for Packaging Food, Beverages and Other Fast-Moving Consumer Goods; Woodhead Publishing Limited: Cambridge, UK, 2013. [Google Scholar] [CrossRef]

- Chemsec. d2w®—Biodegradable Plastic Technology. Marketplace. Available online: https://marketplace.chemsec.org/Alternative/d2w-Biodegradable-plastic-technology--490 (accessed on 12 August 2021).

- Ecopack. “Cocoa Paper Baking Moulds: Welcome to a New Generation of Food Packaging”, Greenearth Food Packaging Ltd. 2020. Available online: http://pdfs.findtheneedle.co.uk/50701.pdf (accessed on 11 August 2021).

- European Bioplastics. Bioplastics and the Circular Economy. 2016. Available online: https://docs.european-bioplastics.org/publications/pp/EUBP_PP_Circular_economy_package.pdf (accessed on 12 August 2021).

- Williams, M.; Gower, R.; Green, J.; Whitebread, E.; Lenkiewicz, Z.; Schröder, P. No Time to Waste: Tackling the Plastic Pollution Crisis Before It’s Too Late; Tearfund: Teddington, UK, 2019. [Google Scholar]

- Oklin. SMALL-SCALE GG-02. Available online: http://oklininternational.com/small-scale-composters/ (accessed on 11 August 2021).

- Green Tree. OKLIN Composters. Jestem Kompostowalny. Available online: https://www.greentree.com.pl/en/oklin-t35#! (accessed on 11 August 2021).

- Rahim, M.U.; Gao, X.; Wu, H. Determination of chlorine in solid fuels using an improved Eschka method. Fuel 2014, 129, 314–317. [Google Scholar] [CrossRef]

- Laußmann, C.; Land, U.; Münster, B.; Endres GH, J.; Hannover, F.; Giese, G.U.; Kitzler, A.-S.; Papierveredelung, A. Disposal of bio-polymers via energy recovery. Bioplastics Mag. 2010, 5, 42–43. [Google Scholar]

- Zhao, L.; Giannis, A.; Lam, W.-Y.; Lin, S.-X.; Yin, K.; Yuan, G.-A.; Wang, J.-Y. Characterization of Singapore RDF resources and analysis of their heating value. Sustain. Environ. Res. 2016, 26, 51–54. [Google Scholar] [CrossRef] [Green Version]

- Gerassimidou, S.; Velis, C.A.; Williams, P.T.; Castaldi, M.J.; Black, L.; Komilis, D. Chlorine in waste-derived solid recovered fuel (SRF), co-combusted in cement kilns: A systematic review of sources, reactions, fate and implications. Crit. Rev. Environ. Sci. Technol. 2020, 51, 140–186. [Google Scholar] [CrossRef]

- Siracusa, V. Microbial Degradation of Synthetic Biopolymers Waste. Polymers 2019, 11, 1066. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, H.; Chen, G.; Wang, J. Microplastics in the Marine Environment: Sources, Fates, Impacts and Microbial Degradation. Toxics 2021, 9, 41. [Google Scholar] [CrossRef] [PubMed]

- Kliem, S.; Kreutzbruck, M.; Bonten, C. Review on the Biological Degradation of Polymers in Various Environments. Materials 2020, 13, 4586. [Google Scholar] [CrossRef] [PubMed]

- Green Tree. Oklin GG02 Composting Machine. Sklep Green Tree. Available online: https://sklep.greentree.com.pl/maszyna-kompostujaca-oklin-gg02-p-99.html (accessed on 11 August 2021).

- European Bioplastics. Bioplastics–End-of-Life Options. Available online: http://www.bioplastics.guide/ref/bioplastics/end-of-life-options (accessed on 9 June 2021).

- Martin, R.T.; Camargo, L.P.; Miller, S.A. Marine-degradable polylactic acid. Green Chem. 2014, 16, 1768–1773. [Google Scholar] [CrossRef]

- Rogers, T. Everything You Need to Know About Polylactic Acid (PLA), Creative Mechanisms Blog, 7 October 2015. Available online: https://www.creativemechanisms.com/blog/learn-about-polylactic-acid-pla-prototypes (accessed on 3 March 2022).

- Boey, J.Y.; Mohamad, L.; Khok, Y.S.; Tay, G.S.; Baidurah, S. A Review of the Applications and Biodegradation of Polyhydroxyalkanoates and Poly(lactic acid) and Its Composites. Polymers 2021, 13, 1544. [Google Scholar] [CrossRef] [PubMed]

- European Bioplastics. Bioplastics—Furthering Efficient Waste Management; European Bioplastics: Berlin, Germany, 2015; pp. 1–4. [Google Scholar]

| No. of Sample | Soil (g) | Baltic Sea Sand (g) | Medium-Grain Sand (g) | Saltwater (g) | |

|---|---|---|---|---|---|

| Spoon | 1 | 4.407 | 4.3616 | 4.4138 | 2.7598 |

| 2 | 4.4226 | 4.4133 | 4.3619 | 1.1885 | |

| 3 | 4.4113 | 4.3587 | 4.4183 | 1.1007 | |

| Bag | 1 | 0.2195 | 0.1911 | 0.2255 | 0.0897 |

| 2 | 0.0710 | 0.0586 | 0.1618 | 0.0544 | |

| 3 | 0.1492 | 0.0944 | 0.0856 | 0.0708 | |

| Tray | 1 | 1.317 | 1.4372 | 1.3305 | 0.5216 |

| 2 | 1.2153 | 1.2422 | 1.1359 | 0.4655 | |

| 3 | 0.8626 | 1.4098 | 1.3448 | 0.4523 | |

| Filament | 1 | 2.2400 | 0.2978 | 0.3451 | 0.1353 |

| 2 | 0.7418 | 0.3155 | 0.2846 | 0.2508 | |

| 3 | 3.5854 | 0.3195 | 0.2566 | 0.1556 |

| Weight (g) | |||||||

| Determination of Calorific Value | Home Composting Simulation | ||||||

| Spoon | Tray | Filament | Spoon | Tray | Filament | Bag | |

| Sample 1 | 1.3456 | 1.0029 | 1.0342 | 4.3652 | 1.916 | 1.2118 | 0.4997 |

| Sample 2 | 1.0073 | 0.9354 | 1.0372 | ||||

| Sample 3 | 1.0049 | 1.0923 | 1.065 | ||||

| Weight (g) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Carbon and Hydrogen Content Determination | Chlorine Content Determination | ||||||||||

| Sample | Tray | Catalyst (Al2O3) | Spoon | Catalyst (Al2O3) | Filament | Catalyst (Al2O3) | Tray | Spoon | Filament | Bag | Blank |

| 1 | 0.2035 | 0.2338 | 0.2093 | 0.2042 | 0.2032 | 0.2088 | 0.9931 | 1.0048 | 1.0096 | 1.0432 | 4.0179 |

| 2 | 0.2025 | 0.2081 | 0.2078 | 0.2204 | 0.204 | 0.2074 | 1.0037 | 1.0001 | 1.0371 | 1.0066 | |

| 3 | 0.2054 | 0.2415 | 0.2137 | 0.2046 | 0.2066 | 0.2161 | 1.0005 | 1.0018 | 1.0035 | 1.0778 | |

| Cocoa Paper Tray | d2w® Biodegradation Technology Bag | PLA Spoon | PLA Filament | ||

|---|---|---|---|---|---|

| Ecotoxicity | Chlorine content (%) | 0.0475 | 0.2034 | 0.0471 | 0.0943 |

| Properties | Moisture content (%) | 6.0658 | 0.2224 | 3.0568 | 0.3694 |

| Calorific value (kJ/kg) | 14,868.283 | * | 13,369.126 | 18,730.730 | |

| Carbon content (%) | 41.176 | * | 35.262 | 52.237 | |

| Hydrogen content (%) | 5.413 | * | 4.759 | 4.765 |

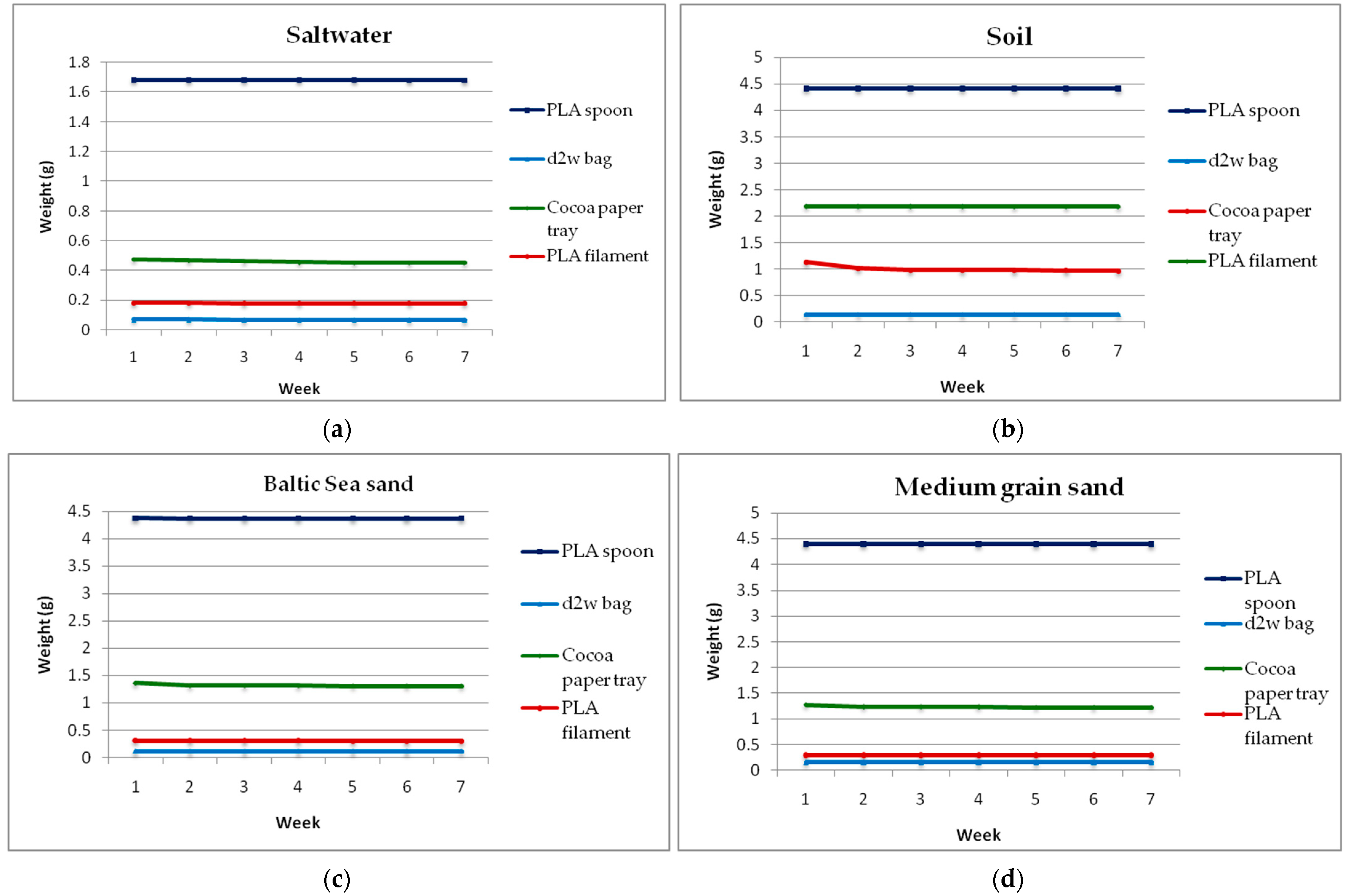

| Environments | Cocoa Paper Tray | d2w® Biodegradation Technology Bag | PLA Spoon | PLA Filament | |

|---|---|---|---|---|---|

| Biodegradation Rate | Soil (g/week) | 0.0155 | 0.0001 | 0.0006 | 0.001 |

| Baltic Sea sand (g/week) | 0.0057 | 0.0001 | 0.0006 | 0.0007 | |

| Medium-grain sand (g/week) | 0.0049 | 0.0005 | 0.0004 | 0.0002 | |

| Saltwater (g/week) | 0.0028 | 0.0006 | 0.0003 | 0.0001 |

| Final Weight (g) | Weight Loss (%) | |

|---|---|---|

| Bag | 0.0318 | 93.636 |

| Tray | - | 100.000 |

| Spoon | 0.7311 | 83.252 |

| Filament | 0.0817 | 93.258 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bogacka, M.; Salazar, G.L. Study on the Effect of Bio-Based Materials’ Natural Degradation in the Environment. Sustainability 2022, 14, 4675. https://doi.org/10.3390/su14084675

Bogacka M, Salazar GL. Study on the Effect of Bio-Based Materials’ Natural Degradation in the Environment. Sustainability. 2022; 14(8):4675. https://doi.org/10.3390/su14084675

Chicago/Turabian StyleBogacka, Magdalena, and Gildaiden Longinos Salazar. 2022. "Study on the Effect of Bio-Based Materials’ Natural Degradation in the Environment" Sustainability 14, no. 8: 4675. https://doi.org/10.3390/su14084675