Effect of Leak Geometry on Water Characteristics Inside Pipes

Abstract

:1. Introduction

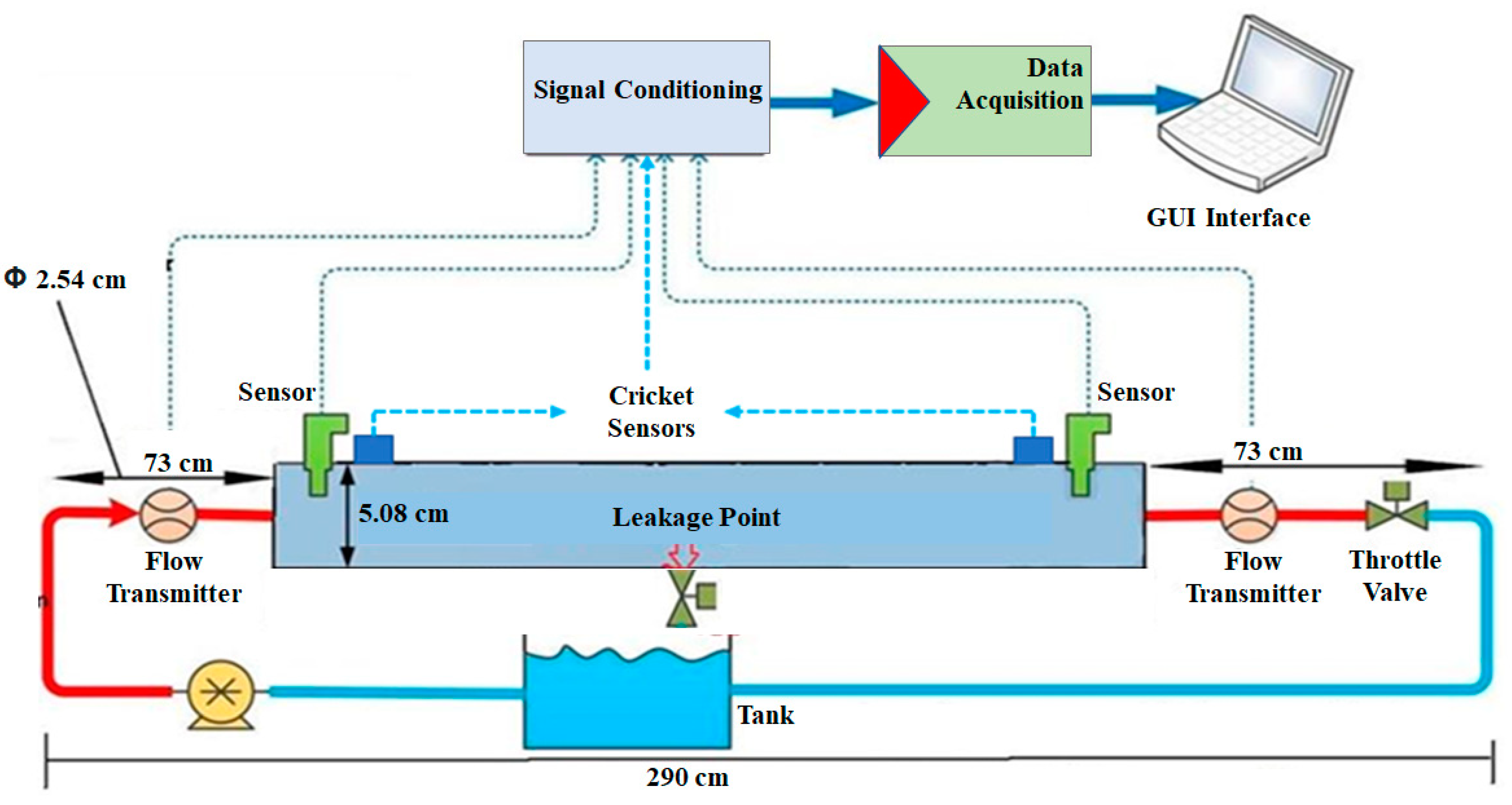

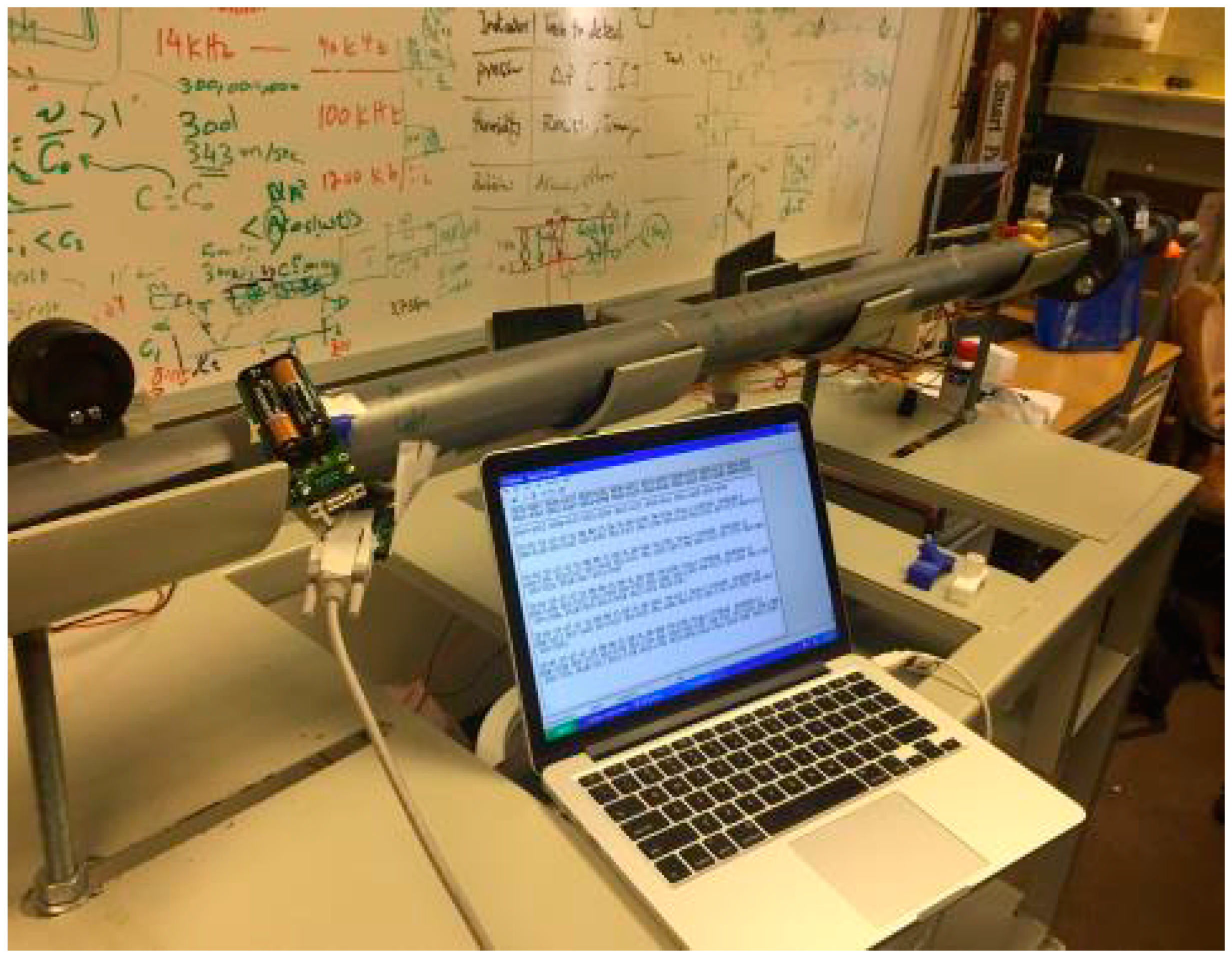

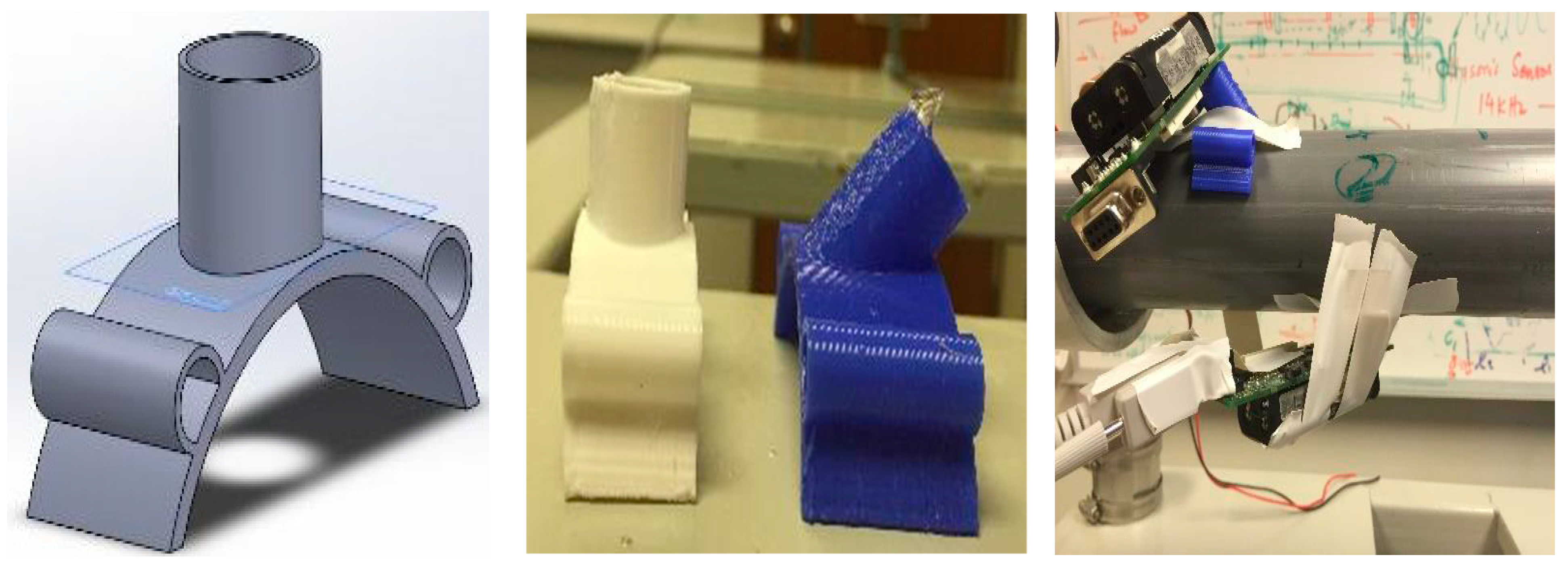

2. Experimental Setup & Numerical Model

2.1. Experimental Setup

2.2. Numerical Model

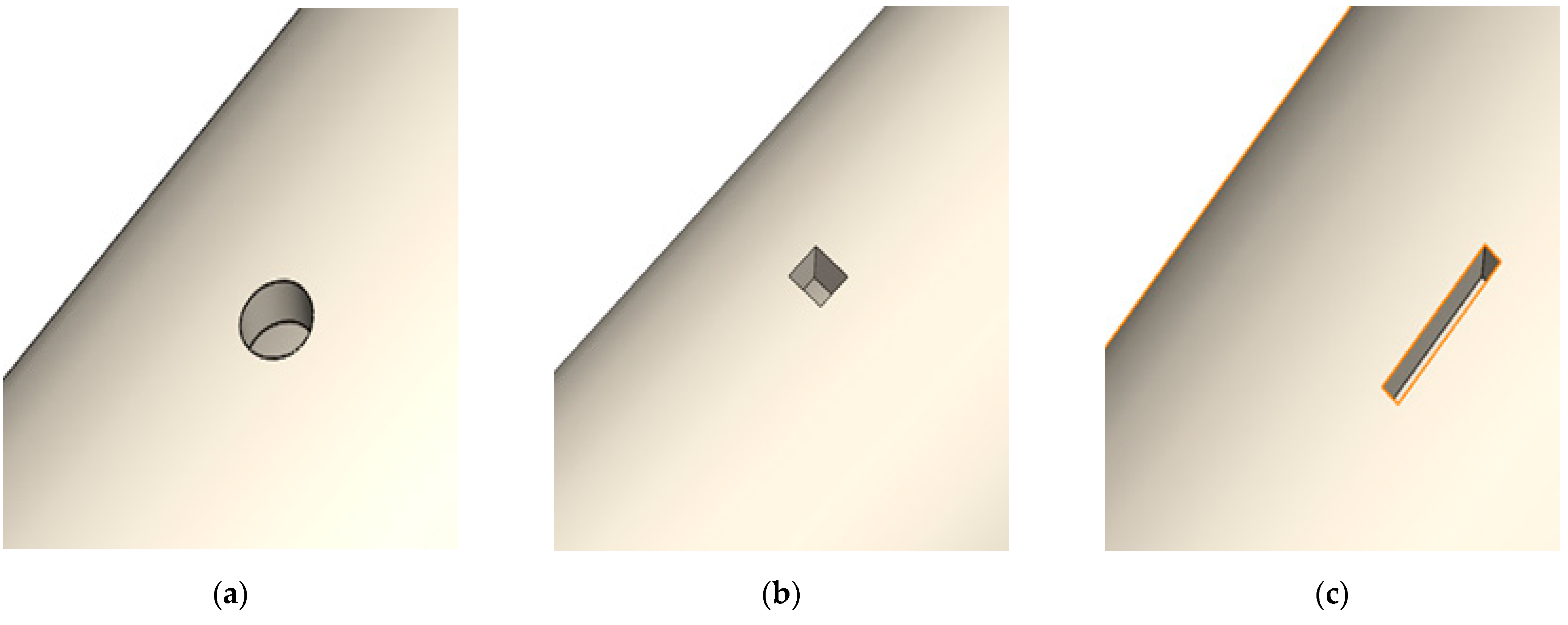

Geometry and Mesh Creation

3. Analysis & Results

3.1. Numerical Simulations

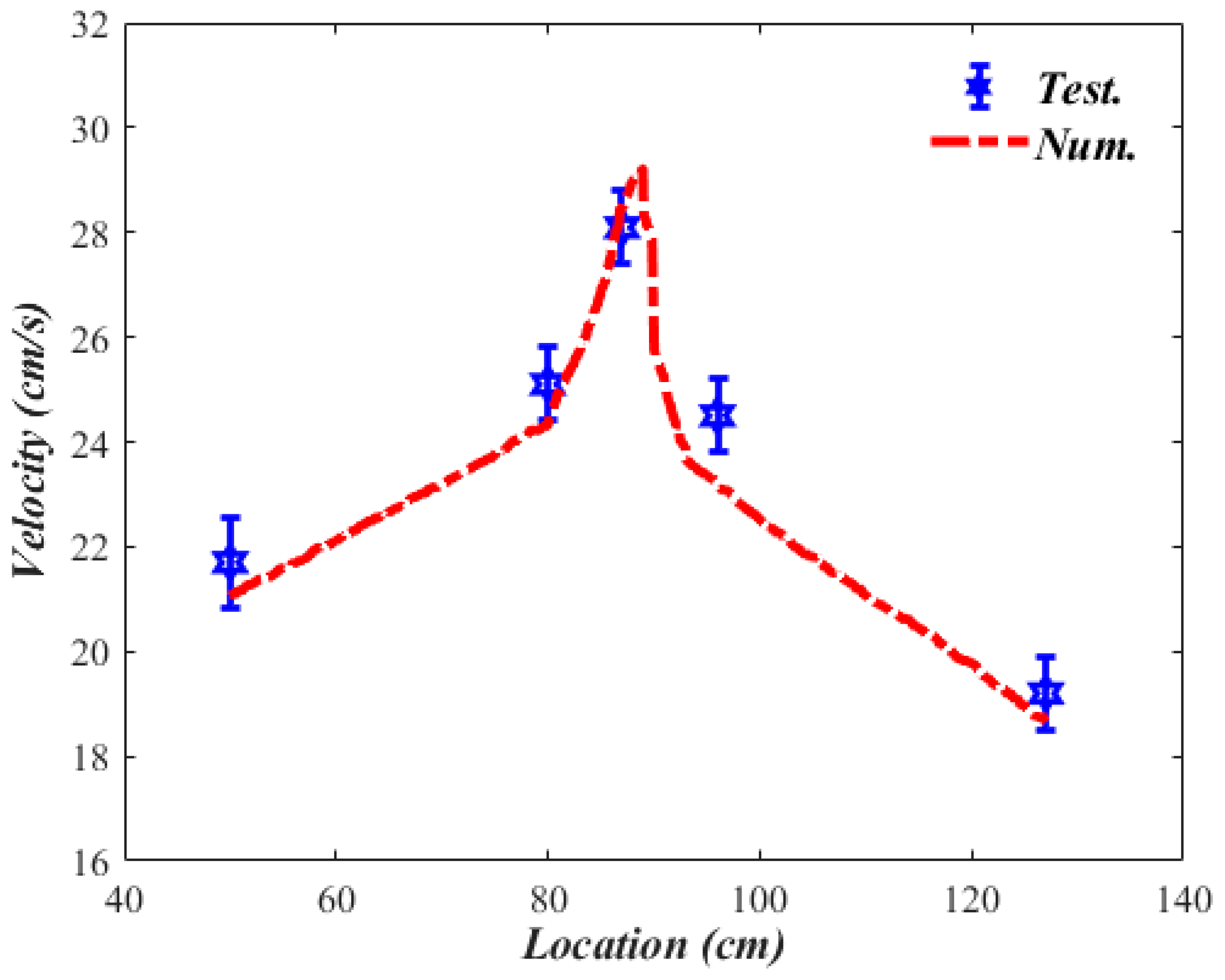

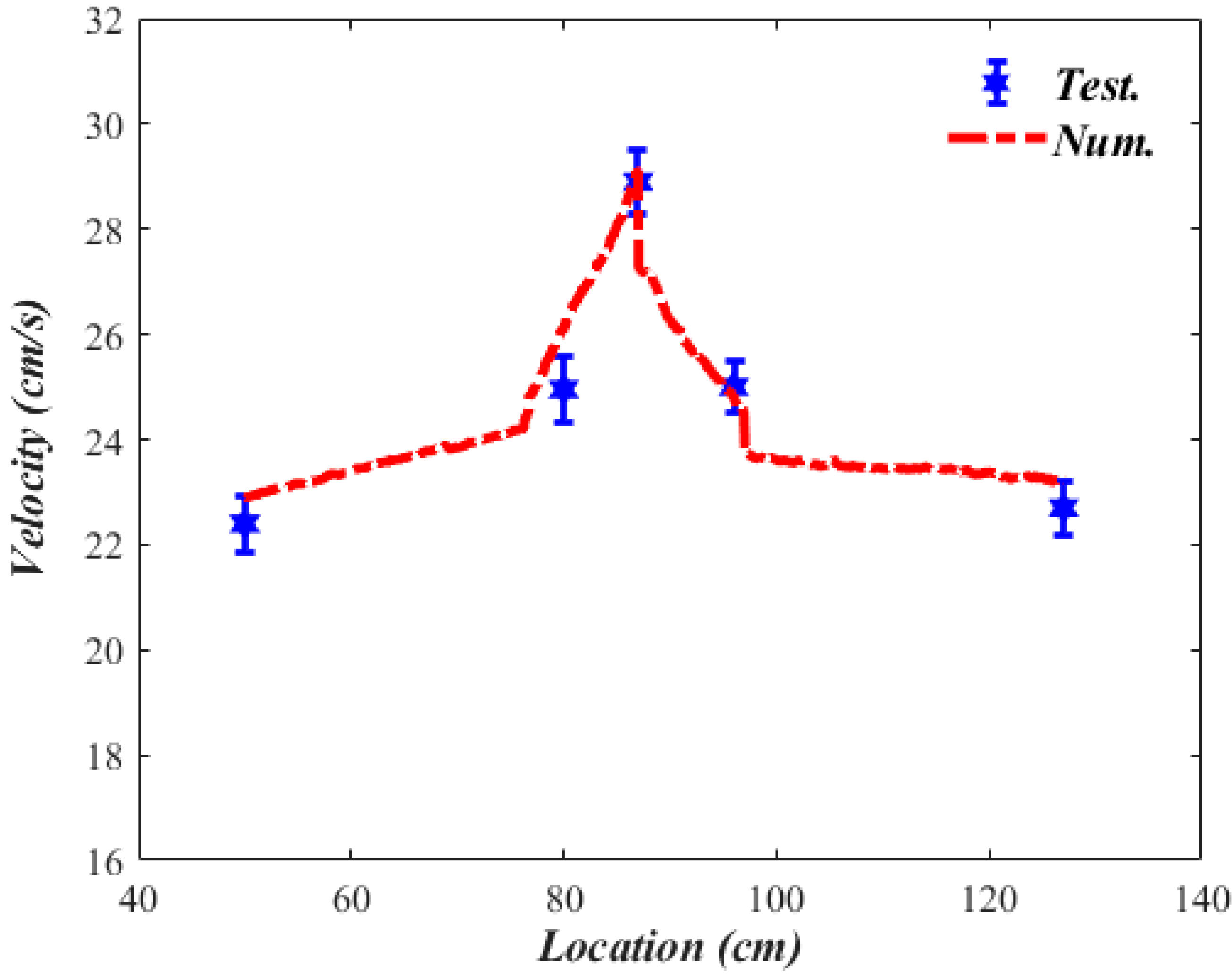

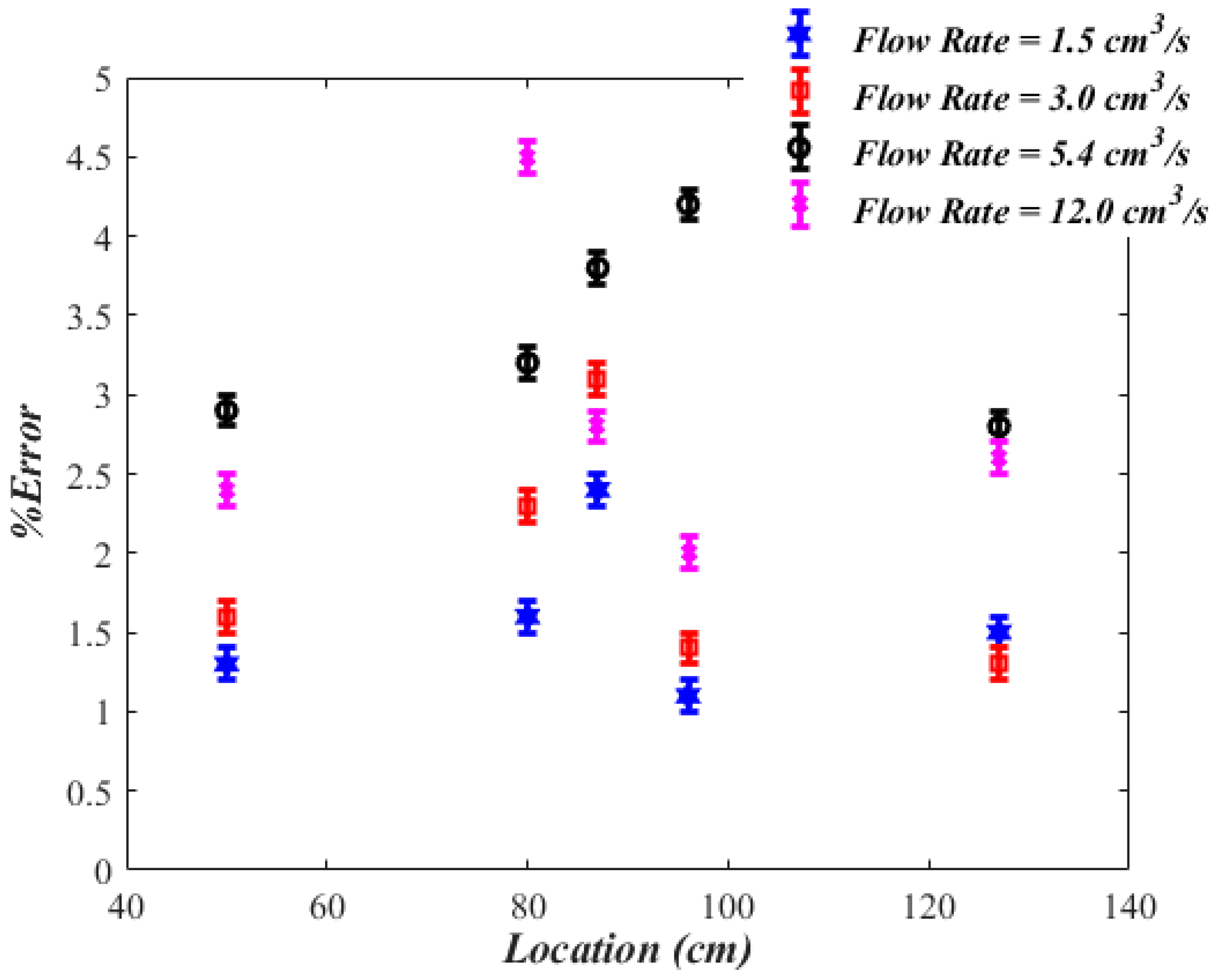

3.2. Comparisons between Experimental Results & Numerical Simulations

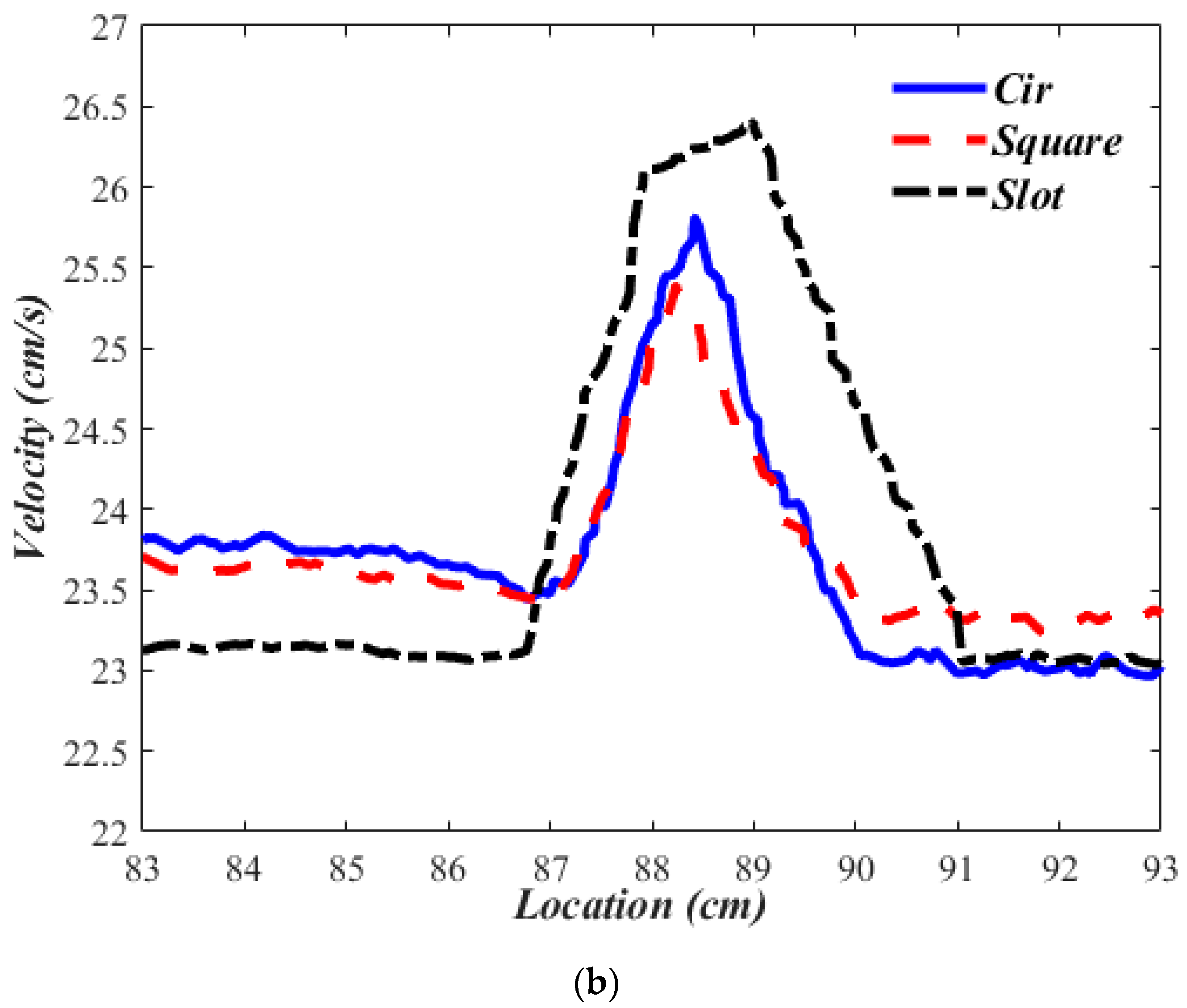

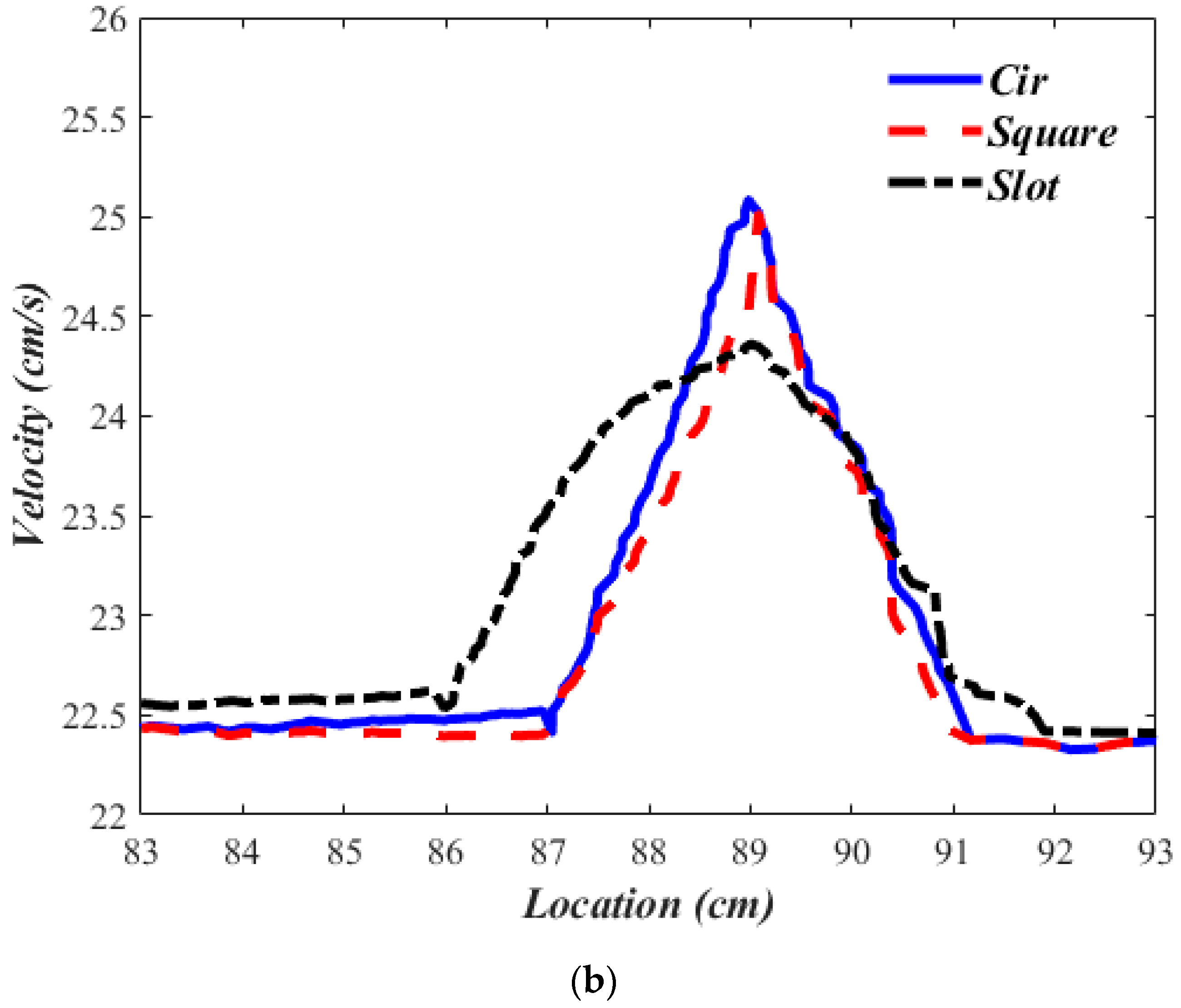

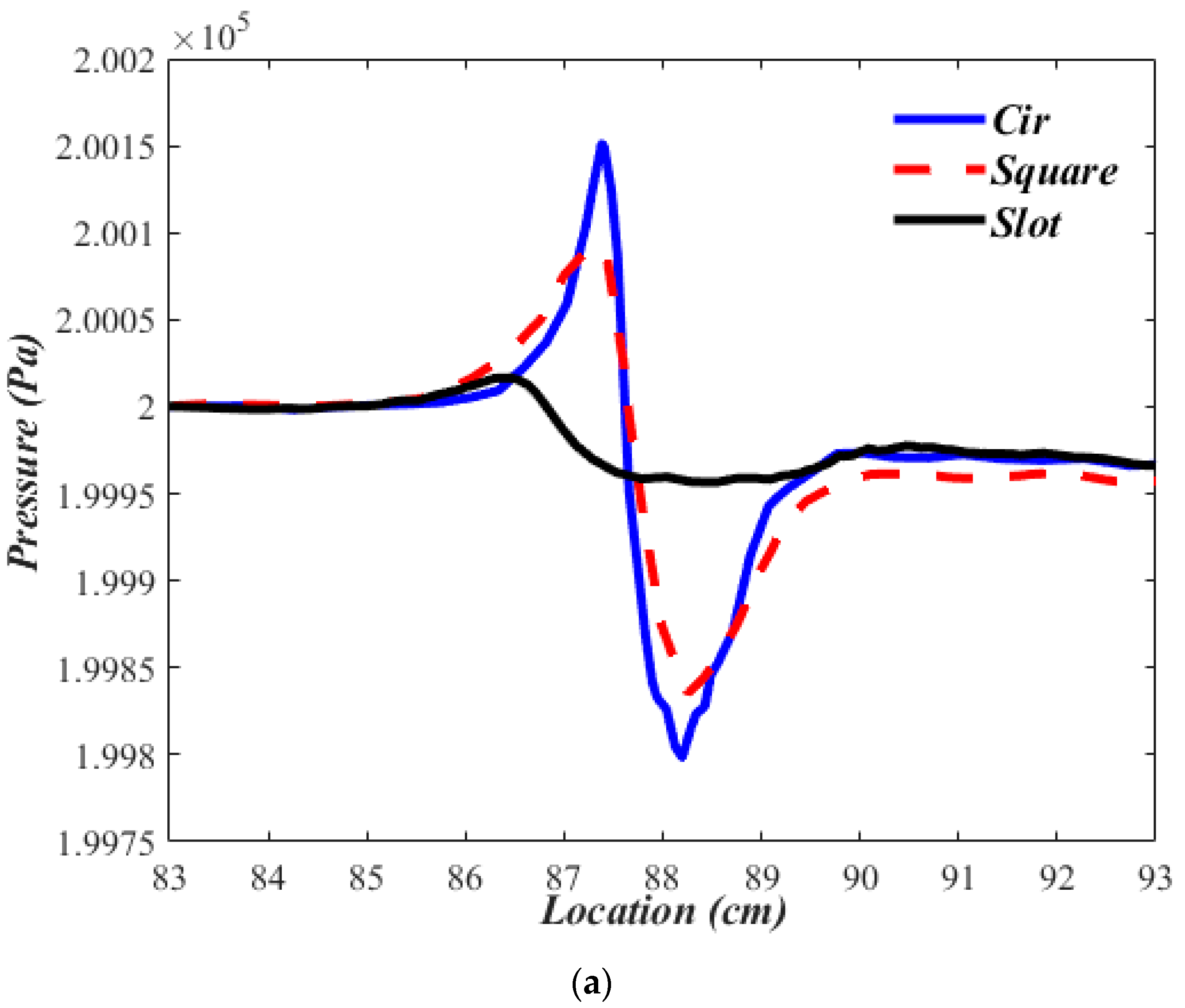

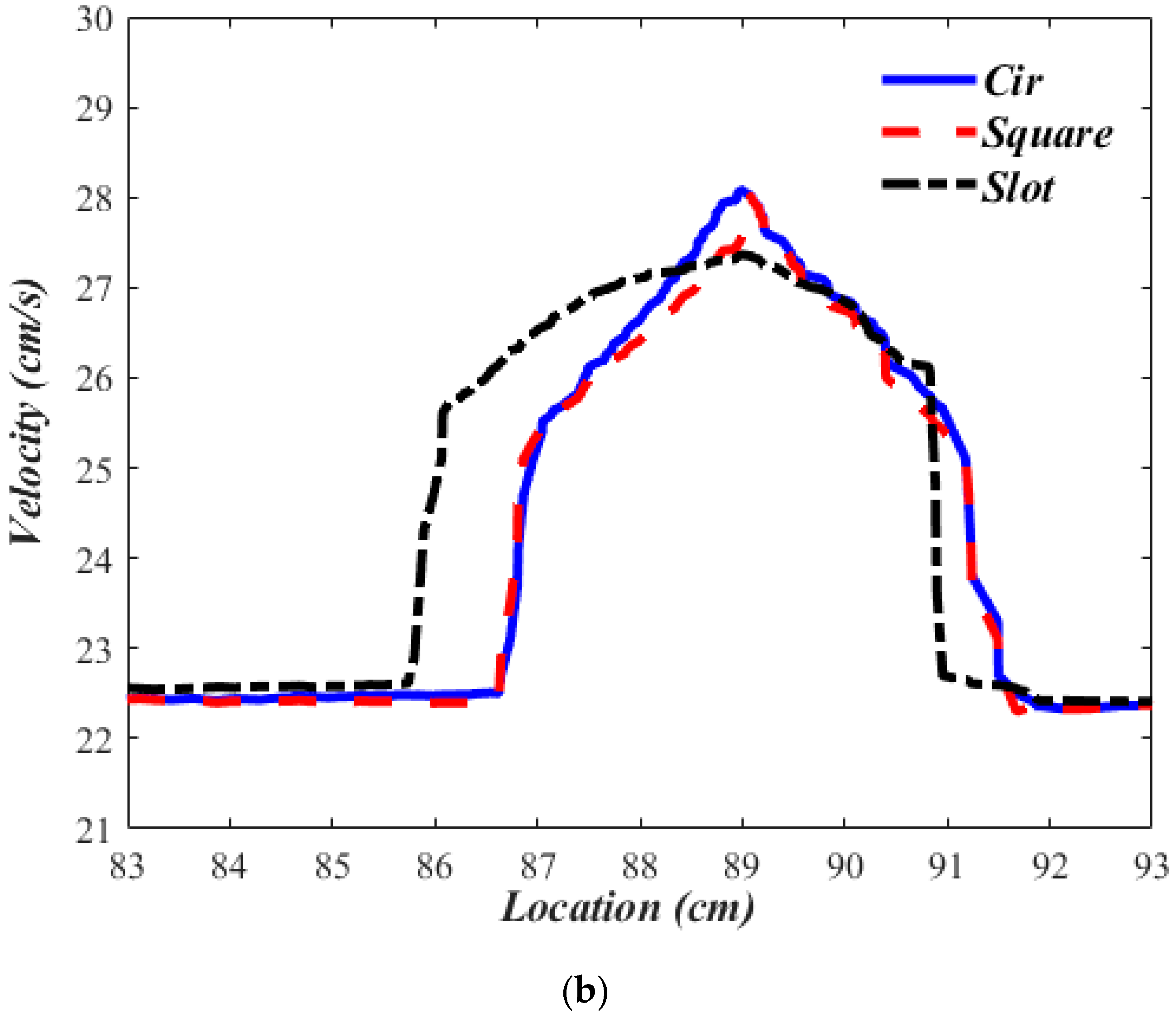

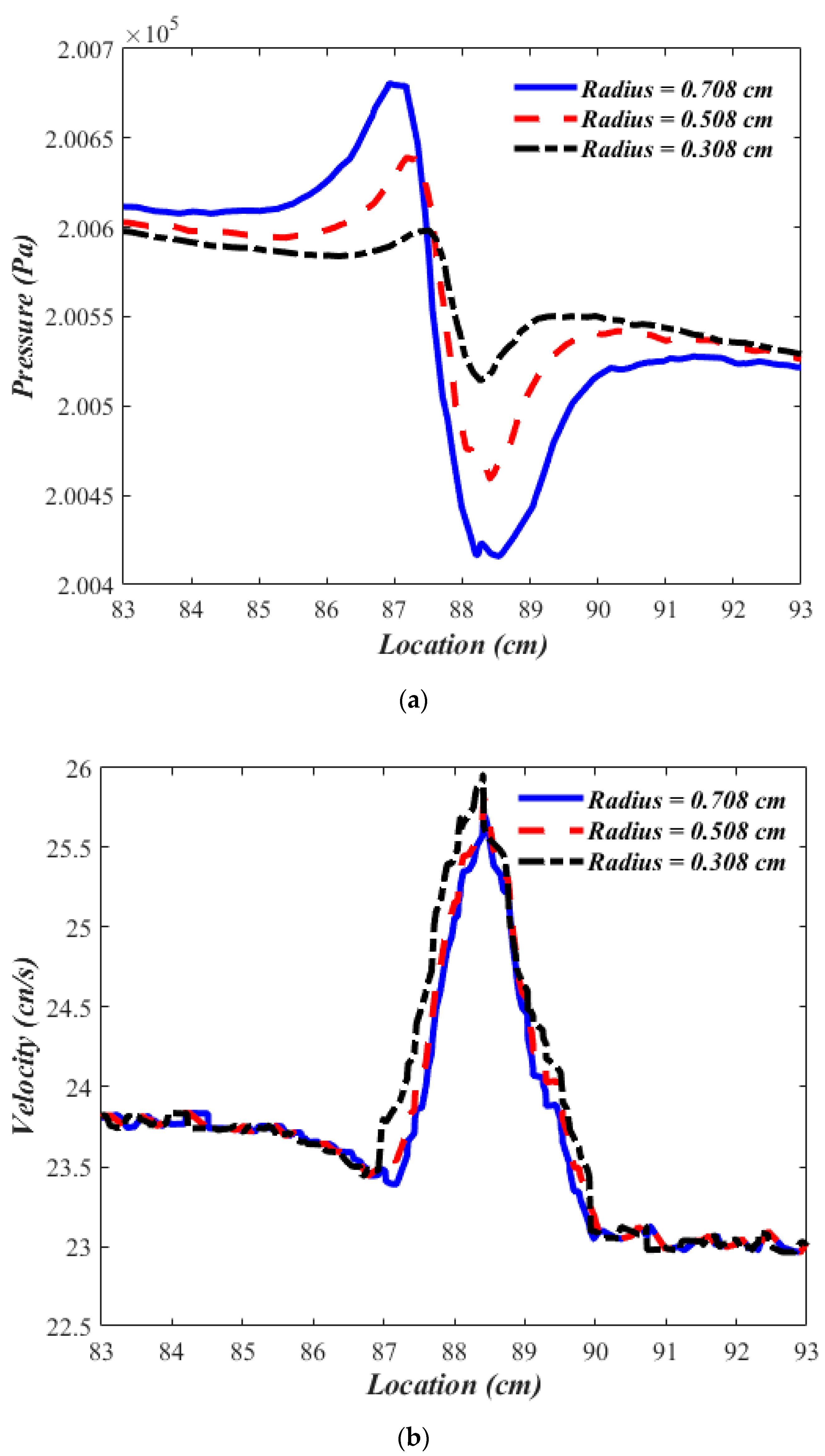

3.3. Pipe Geometry, Crack Geometry & Flow Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Da Silva, H.V.; Morooka, C.K.; Guilherme, I.R.; da Fonseca, T.C.; Mendes, J.R.P. Leak detection in petroleum pipelines using a fuzzy system. J. Pet. Sci. Eng. 2005, 49, 223–238. [Google Scholar] [CrossRef]

- Ishido, Y.; Takahashi, S. A new indicator for real-time leak detection in water distribution networks: Design and simulation validation. Procedia Eng. 2014, 89, 411–417. [Google Scholar] [CrossRef] [Green Version]

- Martini, A.; Troncossi, M.; Rivola, A. Vibration Monitoring as a Tool for Leak Detection in Water Distribution Networks. In Proceedings of the International Conference Surveillance 7, Chartres, France, 29–30 October 2013. [Google Scholar]

- Baroudi, U.; Al-Roubaiey, A.A.; Devendiran, A. Pipeline Leak Detection Systems and Data Fusion: A Survey. IEEE Access 2019, 7, 97426–97439. [Google Scholar] [CrossRef]

- El-Zahab, S.; Zayed, T. Leak detection in water distribution networks: An introductory overview. Smart Water 2019, 4, 5. [Google Scholar] [CrossRef] [Green Version]

- Liston, D.A.; Liston, J.D. Leak detection techniques. J. N. Engl. Water Work. Assoc. 1992, 106, 103–108. [Google Scholar]

- Hunaidi, O. Detecting Leaks in Water-Distribution Pipes. Inst. Res. Constr. 2000, 40, 1–6. [Google Scholar]

- Puust, R.; Kapelan, Z.; Savic, D.A.; Koppel, T. A review of methods for leakage management in pipe networks. Urban Water J. 2010, 7, 25–45. [Google Scholar] [CrossRef]

- Ayala-Cabrera, D.; Herrera, M.; Izquierdo, J.; Ocaña-Levario, S.J.; Pérez-García, R. GPR-based water leak models in water distribution systems. Sensors 2013, 13, 15912–15936. [Google Scholar] [CrossRef]

- Navarro, A.; Begovich, O.; Sanchez-Torres, J.D.; Besancon, G.; Murillo, J.A.P. Leak detection and isolation using an observer based on robust sliding mode differentiators. In Proceedings of the World Automation Congress Proceedings, Puerto Vallarta, Mexico, 24–28 June 2012. [Google Scholar]

- Torres, L.; Besançon, G.; Navarro, A.; Begovich, O.; Georges, D. Examples of pipeline monitoring with nonlinear observers and real-data validation. In Proceedings of the 8th International Multi-Conference on Systems, Signals & Devices, Sousse, Tunisia, 22–25 March 2011; pp. 1–6. [Google Scholar]

- Liu, Z.; Kleiner, Y. State of the art review of inspection technologies for condition assessment of water pipes. Meas. J. Int. Meas. Confed. 2013, 46, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Cataldo, A.; Cannazza, G.; De Benedetto, E.; Giaquinto, N. A new method for detecting leaks in underground water pipelines. IEEE Sens. J. 2012, 12, 1660–1667. [Google Scholar] [CrossRef]

- Choi, J.; Shin, J.; Song, C.; Han, S.; Park, D., II. Leak detection and location of water pipes using vibration sensors and modified ML prefilter. Sensors 2017, 17, 2104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bentoumi, M.; Chikouche, D.; Mezache, A.; Bakhti, H. Wavelet DT method for water leak-detection using a vibration sensor: An experimental analysis. IET Signal Process. 2017, 11, 396–405. [Google Scholar] [CrossRef]

- Asada, Y.; Kimura, M.; Azechi, I.; Iida, T.; Kubo, N. Transient damping method for narrowing down leak location in pressurized pipelines. Hydrol. Res. Lett. 2020, 14, 41–47. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Chen, S.; Li, J.; Jin, S. Leak detection monitoring system of long distance oil pipeline based on dynamic pressure transmitter. Meas. J. Int. Meas. Confed. 2014, 49, 382–389. [Google Scholar] [CrossRef]

- Chatzigeorgiou, D.; Youcef-Toumi, K.; Ben-Mansour, R. Design of a novel in-pipe reliable leak detector. IEEE/ASME Trans. Mechatronics 2015, 20, 824–833. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.W.; Li, Y.X.; Yan, Y.K.; Fu, J.T.; Zhang, Y.Q. A new leak location method based on leakage acoustic waves for oil and gas pipelines. J. Loss Prev. Process Ind. 2015, 35, 236–346. [Google Scholar] [CrossRef]

- Lang, X.; Li, P.; Cao, J.; Li, Y.; Ren, H. A small leak localization method for oil pipelines based on information fusion. IEEE Sens. J. 2018, 18, 6115–6122. [Google Scholar] [CrossRef]

- Lang, X.; Li, P.; Guo, Y.; Cao, J.; Lu, S. A multiple leaks’ localization method in a pipeline based on change in the sound velocity. IEEE Trans. Instrum. Meas. 2019, 69, 5010–5017. [Google Scholar] [CrossRef]

- Zeng, Y.; Luo, R. Numerical Analysis of Incompressible Flow Leakage in Short Pipes. In Proceedings of the 12th Pipeline Technology Conference, Berlin, Germany, 2–4 May 2017. [Google Scholar]

- Ali, S.; Kamran, M.A.; Khan, S. Effect of baffle size and orientation on lateral sloshing of partially filled containers: A numerical study. Eur. J. Comput. Mech. 2017, 26, 584–608. [Google Scholar] [CrossRef]

- Ali, S.; Khan, S.; Horoub, M.M.; Ali, S.; Albalasie, A.; Jamal, A. Effect of Baffles Location on the Rollover Stability of Partially Filled Road Container. In Proceedings of the 2020 2nd International Conference on Electrical, Communication, and Computer Engineering (ICECCE), Istanbul, Turkey, 12–13 June 2020; pp. 12–13. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Xu, M. An integrated detection and location model for leakages in liquid pipelines. J. Pet. Sci. Eng. 2019, 175, 852–867. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, F.; Yang, Z.; Li, G.; Zuo, J. Simulation of the transient characteristics of water pipeline leakage with different bending angles. Water 2019, 11, 1871. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Yang, L.; Ma, Y.; Yang, D.; Li, A.; Huang, L.; Zhan, Y. Simulation and application of a detecting rapid response model for the leakage of flammable liquid storage tank. Process Saf. Environ. Prot. 2020, 141, 390–401. [Google Scholar] [CrossRef]

- Karney, B.; Khani, D.; Halfawy, M.; Hunaidi, O. A Simulation Study on Using Inverse Transient Analysis for Leak Detection in Water Distribution Networks. J. Water Manag. Model. 2009, 399–416. [Google Scholar] [CrossRef] [Green Version]

- Jang, S.P.; Cho, C.Y.; Nam, J.H.; Lim, S.H.; Shin, D.; Chung, T.Y. Numerical study on leakage detection and location in a simple gas pipeline branch using an array of pressure sensors. J. Mech. Sci. Technol. 2010, 24, 983–990. [Google Scholar] [CrossRef]

- Hosseinalipour, S.M.H.; Aghakhani, H. Numerical & experimental study of flow from a leaking buried pipe in an unsaturated porous media. World Acad. Sci. Eng. Technol. 2011, 5, 859–864. [Google Scholar] [CrossRef]

- De Sousa, J.V.N.; Sodré, C.H.; de Lima, A.G.B.; de Farias Neto, S.R. Numerical Analysis of Heavy Oil-Water Flow and Leak Detection in Vertical Pipeline. Adv. Chem. Eng. Sci. 2013, 3, 9–15. [Google Scholar] [CrossRef] [Green Version]

- Ben-Mansour, R.; Habib, M.A.; Khalifa, A.; Youcef-Toumi, K.; Chatzigeorgiou, D. Computational fluid dynamic simulation of small leaks in water pipelines for direct leak pressure transduction. Comput. Fluids 2012, 57, 110–123. [Google Scholar] [CrossRef]

- Guo, X.L.; Yang, K.L.; Li, F.T.; Wang, T.; Fu, H. Analysis of first transient pressure oscillation for leak detection in a single pipeline. J. Hydrodyn. 2012, 24, 363–370. [Google Scholar] [CrossRef]

- Olegario, F.; Seleghim, P. Model Development and Numerical Simulation for Detecting Pre-Existing Leaks in Liquid Pipeline. In Proceedings of the 22nd International Congress of Mechanical Engineering (COBEM 2013), Ribeirão Preto, Brazil, 3–7 November 2013; pp. 6906–6915. [Google Scholar]

- Meniconi, S.; Brunone, B.; Ferrante, M.; Massari, C. Numerical and experimental investigation of leaks in viscoelastic pressurized pipe flow. Drink. Water Eng. Sci. 2013, 6, 11–16. [Google Scholar] [CrossRef] [Green Version]

- Xanthos, S.S.; Agathokleous, A.; Gagatsis, A.; Kranioti, S.; Christodoulou, S.E. Experimental and Numerical Investigation of Water-Loss in Water Distribution Networks. In Proceedings of the 2014 Intelligent Distribution for Efficient and Affordable Supplies [Water IDEAS 2014], Bologna, Italy, 22–24 October 2014; Available online: https://www.researchgate.net/profile/Symeon-Christodoulou/publication/267214360 (accessed on 15 March 2022).

- Liu, C.; Li, Y.; Meng, L.; Wang, W.; Zhao, F.; Fu, J. Computational fluid dynamic simulation of pressure perturbations generation for gas pipelines leakage. Comput. Fluids 2015, 119, 213–223. [Google Scholar] [CrossRef]

- De Sousa, C.A.; Romero, O.J. Influence of oil leakage in the pressure and flow rate behaviors in pipeline. Lat. Am. J. Energy Res. 2017, 4, 17–29. [Google Scholar] [CrossRef] [Green Version]

- Abdulshaheed, A.; Mustapha, F.; Ghavamian, A. A pressure-based method for monitoring leaks in a pipe distribution system: A Review. Renew. Sustain. Energy Rev. 2017, 69, 902–911. [Google Scholar] [CrossRef]

- Fu, H.; Yang, L.; Liang, H.; Wang, S.; Ling, K. Diagnosis of the single leakage in the fluid pipeline through experimental study and CFD simulation. J. Pet. Sci. Eng. 2020, 193, 107437. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, W.; Zhang, Y. Leakage position of pipeline on the underground diffusion of crude oil. IOP Conf. Ser. Earth Environ. Sci. 2019, 237, 32119. [Google Scholar] [CrossRef]

- Gong, J.; Lambert, M.F.; Zecchin, A.C.; Simpson, A.R. Experimental verification of pipeline frequency response extraction and leak detection using the inverse repeat signal. J. Hydraul. Res. 2016, 54, 210–219. [Google Scholar] [CrossRef] [Green Version]

- Duan, H.-F. Transient frequency response based leak detection in water supply pipeline systems with branched and looped junctions. J. Hydroinform. 2016, 19, 17–30. [Google Scholar] [CrossRef]

- Bohorquez, J.; Alexander, B.; Simpson, A.R.; Lambert, M.F. Leak Detection and Topology Identification in Pipelines Using Fluid Transients and Artificial Neural Networks. J. Water Resour. Plan. Manag. 2020, 146, 4020040. [Google Scholar] [CrossRef]

- Markey, B.; Yu, Y.; Ban, T.; Johal, G. Time-of-flight application for fluid flow measurement. Opt. Diagnostics Sens. IX 2009, 7186, 71860S. [Google Scholar] [CrossRef]

- Hadush, T. Flow in pipes. Fluid Mech. 2004, 1–25. [Google Scholar]

| Sample No. | Flow Rate (cm3/s) |

|---|---|

| 1 | 1.5 |

| 2 | 3 |

| 3 | 5.4 |

| 4 | 1.2 |

| 5 | 1 |

| The Flow Rate through Leak (dia 1.016 cm) (cm3/s) | Point 1 (50 cm) | Point 2 (83 cm) | Point 3 (89 cm) | Point 4 (96 cm) | Point 5 (127 cm) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test. (cm/s) | Num. (cm/s) | Test. (cm/s) | Num. (cm/s) | Test. (cm/s) | Num. (cm/s) | Test. (cm/s) | Num. (cm/s) | Test. (cm/s) | Num. (cm/s) | |

| 1.5 | 23.1 | 23.4 | 23.5 | 23.9 | 25.5 | 24.9 | 23.4 | 23.2 | 23.6 | 23.9 |

| 3 | 21.6 | 22.0 | 22.4 | 21.9 | 25.1 | 25.9 | 21.1 | 20.8 | 20.1 | 19.9 |

| 5.4 | 21.7 | 21.1 | 25.1 | 24.3 | 28.1 | 29.2 | 24.6 | 23.6 | 19.2 | 18.7 |

| 12 | 22.4 | 23.0 | 24.4 | 25.5 | 28.9 | 28.1 | 25.0 | 24.5 | 22.7 | 23.3 |

| Length (cm) | Diameter (cm) | Sample No. |

|---|---|---|

| 177 | 5.08 | 1 |

| 177 | 10.16 | 2 |

| Condition 2 | Condition 1 |

|---|---|

| Flow Rate = 5 × 102 cm3/s | Velocity = 2 × 102 cm/s |

| Pressure = 20 × 103 Pa | Pressure = 20 × 104 Pa |

| Dimensions | Crack Shape | Sample No. |

|---|---|---|

| 0.508 cm Radius | Circular | 1 |

| 0.9 cm × 0.9 cm | Square | 2 |

| 2.54 cm × 0.32 cm | Slot | 3 |

| Flow Conditions 1 (Pipe Diameter 5.08 cm) | Flow Conditions 2 (Pipe Diameter 5.08 cm) | Flow Conditions 1 (Pipe Diameter 10.16 cm) | Flow Conditions 2 (Pipe Diameter 10.16 cm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pressure (Pa) | Velocity (m/s) | Pressure (Pa) | Velocity (m/s) | Pressure (Pa) | Velocity (m/s) | Pressure (Pa) | Velocity (m/s) | |||||

| Min | Max | Max | Min | Max | Max | Min | Max | Max | Min | Max | Max | |

| Circular | 200459.3 | 200639 | 25.808 | 20015.91 | 20009.37 | 27.808 | 200167.9 | 200333.9 | 25.08 | 199798.4 | 200151.1 | 28.079 |

| Slot | 200490.7 | 200619 | 25.385 | 20015.85 | 20009.41 | 27.385 | 200152.1 | 200344.9 | 25.01 | 199835.5 | 200090 | 28.009 |

| Square | 200509.5 | 200621 | 26.4 | 20015.15 | 20013.44 | 28.4 | 200235.5 | 200295.7 | 24.36 | 199956.5 | 20016.7 | 27.364 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.; Hawwa, M.A.; Baroudi, U. Effect of Leak Geometry on Water Characteristics Inside Pipes. Sustainability 2022, 14, 5224. https://doi.org/10.3390/su14095224

Ali S, Hawwa MA, Baroudi U. Effect of Leak Geometry on Water Characteristics Inside Pipes. Sustainability. 2022; 14(9):5224. https://doi.org/10.3390/su14095224

Chicago/Turabian StyleAli, Sajid, Muhammad A. Hawwa, and Uthman Baroudi. 2022. "Effect of Leak Geometry on Water Characteristics Inside Pipes" Sustainability 14, no. 9: 5224. https://doi.org/10.3390/su14095224

APA StyleAli, S., Hawwa, M. A., & Baroudi, U. (2022). Effect of Leak Geometry on Water Characteristics Inside Pipes. Sustainability, 14(9), 5224. https://doi.org/10.3390/su14095224