Traceability Models and Traceability Systems to Accelerate the Transition to a Circular Economy: A Systematic Review

Abstract

:1. Introduction

2. Research Questions

3. Eligibility Criteria

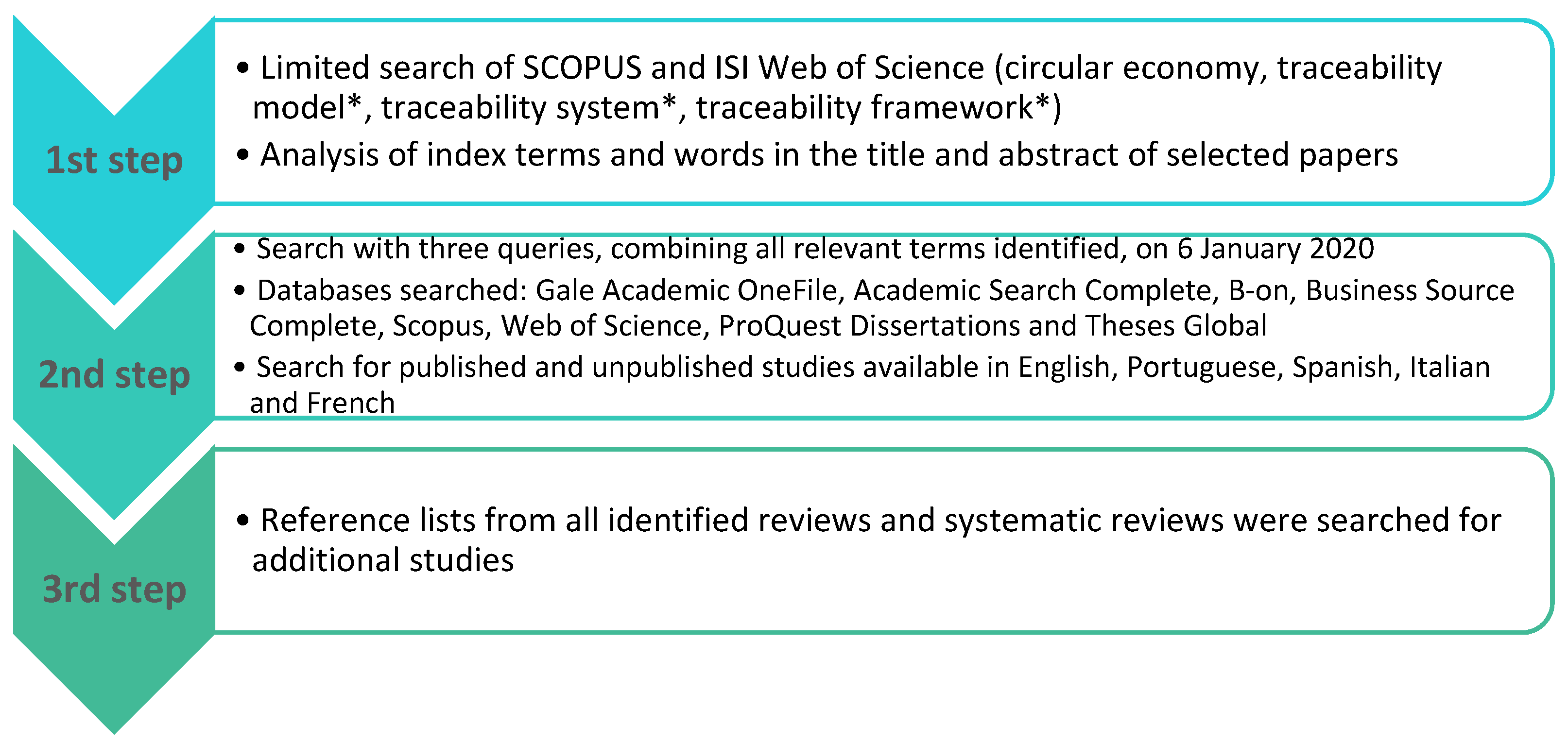

4. Methods

5. Results

5.1. Study Selection

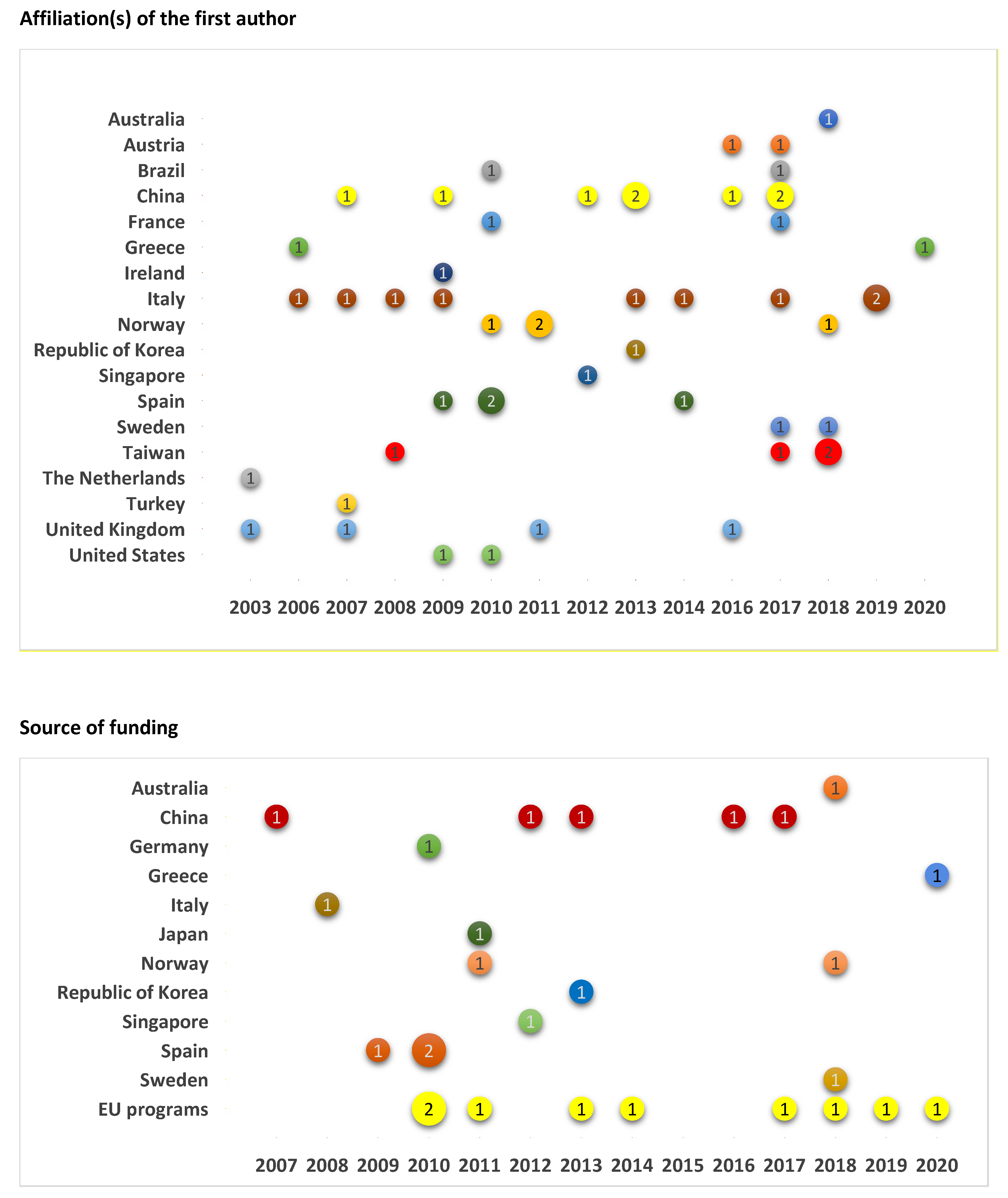

5.2. General Characteristics of the Included Studies

5.3. Methodological Options of the Included Studies

5.4. Traceable Entities

5.5. Interventions as Proposals on Traceability Models and Traceability Systems

5.5.1. Studies on Traceability Models or Modeling Traceability

Content and Dimensions of the Interventions

Requirements

Standards and Regulations

Ontologies

Technologies

5.5.2. Studies on Traceability Systems or the Components of Traceability Systems

Content and Dimensions of the Interventions

Requirements

Standards and Regulations

Ontologies

Technologies

5.6. Comparators

5.7. Context

5.7.1. Studies Reporting Traceability Models or Modeling Traceability

5.7.2. Studies Reporting on Traceability Systems or the Components of Traceability Systems

5.8. Outcomes of the Interventions

6. Discussion

6.1. To What Extent and in What Way Have the Use of Traceability Models and Traceability Systems Been Linked to a CE?

6.2. What Are the Structural and Methodological Characteristics of the Studies on Traceability Models and Traceability Systems, Namely, When Linked to a CE?

6.3. Which Level or Levels Do Traceability Models and Traceability Systems Cover and in What Way, Especially When Related to a CE?

6.4. What Agents or Stakeholders Are Expected to Have a Role in the Development and Implementation of Traceability Models and Traceability Systems, Especially When Related to a CE?

6.5. To What Extent and In What Way Are Ontologies Being Used, Especially When Related to a CE?

6.6. Do Traceability Models and Traceability Systems Reflect the Relevant Standards, Regulation and Indicators, and Consider Environmental, Social and Economic Perspectives, Especially When Related to a CE?

6.7. What Are the Technologies Being Proposed or Used to Implement Traceability Models and Traceability Systems and What Can We Expect from Their Use, Especially When Related to a CE?

6.8. What Are the Enabling Factors and the Challenges Related to the Development and Implementation of Traceability Models and Traceability Systems, Especially When Related to a CE?

6.9. Limitations of the Included Studies

6.10. Limitations of the Review

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ATF | AMPLE Traceability Framework |

| BPMN | Business Process Modeling and Notation |

| CE | Circular Economy |

| CPS | Cyber-Physical System |

| ebXML | Electronic Business XML |

| EPC | Electronic Product Code |

| EPCIS | EPC Information Services |

| EPCDS | EPC Discovery Services |

| EU | European Union |

| GPS | Global Positioning System |

| GSC | Global Supply Chain |

| GS1 | Global Standards 1 |

| IoT | Internet of Things |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LNG | Liquefied Natural Gas |

| MESCO | Meat Supply Chain Ontology |

| PL | Production Logistics |

| QR | Quick Response |

| RCBTS | RFID-based Cattle/Beef Traceability System |

| RFID | Radio Frequency Identification |

| SC | Supply Chain |

| SCM | Supply Chain Management |

| SME | Small and Medium Enterprises |

| SOAP | Simple Object Access Protocol |

| SQL | Structured Query Language |

| SR | Systematic Review |

| SW | Software |

| TM | Traceability Model |

| TMs | Traceability Models |

| TS | Traceability System |

| TSs | Traceability Systems |

| UML | Unified Modelling Language |

| XML | Extensible Markup Language |

| Acronyms | |

| QCRI | Qatar Computing Research Institute |

Appendix A

- First query: Search string on Scopus.

- Second query: Search string on Scopus.

- Third query: Search string on Scopus.

References

- Ellen MacArthur Foundation (EMF). Completing the picture: How the circular economy tackles climate change. Ellen MacArthur Found. Mater. Econ. 2019, 3, 1–62. [Google Scholar]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- EMF. Towards the circular economy: An economic and business rationale for an accelerated transition. Ellen MacArthur Found. Rethink. Futur. 2013, 1, 1–98. [Google Scholar]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- EU Circular Cooperation Hub. Strategic Research and Innovation Agenda on Circular Economy—CICERONE. 2020. Available online: https://cicerone-h2020.eu/wp-content/uploads/2020/09/Circular-Economy-SRIA-2020.pdf (accessed on 14 May 2021).

- INEC & ORÉE. Major Circular Economy Networks in Europe. Available online: https://institut-economie-circulaire.fr/wp-content/uploads/2020/03/majorcirculareconomynetworks.pdf (accessed on 14 May 2021).

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, I. An overview of the challenges and trade-offs in closing the loop of post-consumer plastic waste (PCPW): Focus on recycling. J. Hazard. Mater. 2019, 380, 120887. [Google Scholar] [CrossRef] [PubMed]

- Johansson, N.; Henriksson, M. Circular economy running in circles? A discourse analysis of shifts in ideas of circularity in Swedish environmental policy. Sustain. Prod. Consum. 2020, 23, 148–156. [Google Scholar] [CrossRef]

- Junestrand, S. Towards a Circular Economy in the Built Environment: Blockchain as a Solution for Supply Chain Transparency. Available online: https://medium.com/@stefanjunestrand/towards-a-circular-economy-in-the-built-environment-blockchain-as-a-solution-for-supply-chain-79027a584123 (accessed on 28 April 2018).

- Pishchulov, G.V.; Richter, K.K.; Pakhomova, N.V.; Tsenzharik, M.K. A circular economy perspective on sustainable supply chain management: An updated survey. J. Econ. Stud. 2018, 34, 267–297. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 9000:2015(en) Quality management systems—Fundamentals and vocabulary. Geneva Int. Organ. Stand. 2015, 4, 53. [Google Scholar]

- Global Traceability Standard (GS1). GS1’s Framework for the Design of Interoperable Traceability Systems for Supply Chains. 2017. Available online: https://www.gs1.org/sites/default/files/docs/traceability/GS1_Global_Traceability_Standard_i2.pdf (accessed on 28 April 2018).

- Bosona, T.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- GS1. GS1 Standards Document—Business Process and System Requirements for Full Supply Chain Traceability. Global Traceability Standard. 2012. Available online: https://www.gs1.org/docs/traceability/Global_Traceability_Standard.pdf (accessed on 28 April 2018).

- Kim, H.M.; Fox, M.S.; Gruninger, M. Ontology of quality for enterprise modelling. In Proceedings of the 4th IEEE Workshop on Enabling Technologies: Infrastructure for Collaborative Enterprises (WET ICE ’95), Berkeley Springs, WV, USA, 20–22 April 1995; pp. 105–116. [Google Scholar]

- Moe, T. Traceability in food manufacturing can range from in-house traceability in production plants to traceability in whole or part of the production chain from raw material to consumer. Trends Food Sci. Technol. 1998, 9, 211–214. [Google Scholar] [CrossRef]

- BS 8001:2017; Framework for Implementing the Principles of the Circular Economy in Organizations—Guide. British Standards Institution (BSI): London, UK, 2017.

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001: 2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- EMF (Ellen MacArthur Foundation). Circularity Indicators: An Approach to measuring Circularity—Project Overview. 2015. Available online: https://emf.thirdlight.com/link/yybss1obhtdv-ub419h/@/preview/1?o (accessed on 28 April 2018).

- Behrens, A.; Taranic, I.; Rizos, V. Resource Efficiency Indicators for Policy-Making—CEPS Working Document. 2015. Available online: http://aei.pitt.edu/69666/1/WD415.pdf (accessed on 28 April 2018).

- EASAC. Indicators for a circular economy. EASAC Policy Rep. 2016, 30, 1–43. [Google Scholar]

- Sánchez, B.B.; Alcarria, R.; Martín, D.; Robles, T. TF4SM: A framework for developing traceability solutions in small manufacturing companies. Sensors 2015, 15, 29478–29510. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neuhaus, F.; Vizedom, A.; Baclawski, K.; Bennett, M.; Dean, M.; Denny, M.; Grüninger, M.; Hashemi, A.; Longstreth, T.; Obrst, L.; et al. Towards ontology evaluation across the life cycle: The ontology summit 2013. Appl. Ontol. 2013, 8, 179–194. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Koberg, E.; Longoni, A. A systematic review of sustainable supply chain management in global supply chains. J. Clean. Prod. 2019, 207, 1084–1098. [Google Scholar] [CrossRef]

- Benoît, C.; Norris, G.A.; Valdivia, S.; Ciroth, A.; Moberg, A.; Bos, U.; Prakash, S.; Ugaya, C.; Beck, T. The guidelines for social life cycle assessment of products: Just in time! Int. J. Life Cycle Assess. 2010, 15, 156–163. [Google Scholar] [CrossRef]

- Mhatre, P.; Panchal, R.; Singh, A.; Bibyan, S. A systematic literature review on the circular economy initiatives in the European Union. Sustain. Prod. Consum. 2021, 26, 187–202. [Google Scholar] [CrossRef]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; PRISMA-P Group. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015: Elaboration and explanation. BMJ 2015, 349, 1–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ouzzani, M.; Hammady, H.; Fedorowicz, Z.; Elmagarmid, A. Rayyan—A web and mobile app for systematic reviews. Syst. Rev. 2016, 5, 210. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 International Conference on Service Systems and Service Management, Dalian, China, 16–18 June 2017; pp. 1–6. [Google Scholar]

- Wang, J.; Chi, H.L.; Shou, W.; Chong, H.Y.; Wang, X. A coordinated approach for supply-chain tracking in the liquefied natural gas industry. Sustainability 2018, 10, 4822. [Google Scholar] [CrossRef] [Green Version]

- Parreño-Marchante, A.; Alvarez-Melcon, A.; Trebar, M.; Filippin, P. Advanced traceability system in aquaculture supply chain. J. Food Eng. 2014, 122, 99–109. [Google Scholar] [CrossRef]

- Terzi, S.; Panetto, H.; Morel, G.; Garetti, M. A holonic metamodel for product traceability in Product Lifecycle Management. Int. J. Prod. Lifecycle Manag. 2007, 2, 253–289. [Google Scholar] [CrossRef]

- Ruiz-Garcia, L.; Steinberger, G.; Rothmund, M. A model and prototype implementation for tracking and tracing agricultural batch products along the food chain. Food Control 2010, 21, 112–121. [Google Scholar] [CrossRef] [Green Version]

- Anquetil, N.; Kulesza, U.; Mitschke, R.; Moreira, A.; Royer, J.-C.; Rummler, A.; Sousa, A. A model-driven traceability framework for software product lines. Softw. Syst. Model. 2010, 9, 427–451. [Google Scholar] [CrossRef] [Green Version]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016. [Google Scholar]

- Chen, R. An intelligent value stream-based approach to collaboration of food traceability cyber physical system by fog computing. Food Control 2017, 71, 124–136. [Google Scholar] [CrossRef]

- Hsu, Y.C.; Chen, A.P.; Wang, C.H. A RFID-enabled traceability system for the supply chain of live fish. In Proceedings of the 2008 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008; pp. 81–86. [Google Scholar]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. Business process reengineering of a supply chain and a traceability system: A case study. J. Food Eng. 2009, 93, 13–22. [Google Scholar] [CrossRef]

- Conti, M.; Orcioni, S. Cloud-based sustainable management of electrical and electronic equipment from production to end-of-life. Int. J. Qual. Reliab. Manag. 2019, 36, 98–119. [Google Scholar] [CrossRef]

- Karlsen, K.M.; Sørensen, C.F.; Forås, F.; Olsen, P. Critical criteria when implementing electronic chain traceability in a fish supply chain. Food Control 2011, 22, 1339–1347. [Google Scholar] [CrossRef]

- Kumar, V.; Hallqvist, C.; Ekwall, D. Developing a Framework for Traceability Implementation in the Textile Supply Chain. Systems 2017, 5, 33. [Google Scholar] [CrossRef]

- Ngai, E.W.T.; Cheng, T.C.E.; Lai, K.H.; Chai, P.Y.F.; Choi, Y.S.; Sin, R.K.Y. Development of an RFID-based traceability system: Experiences and lessons learned from an aircraft engineering company. Prod. Oper. Manag. 2007, 16, 554–568. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.; Fu, Z.; Wang, Z.; Xu, M.; Zhang, X. Development and evaluation on a RFID-based traceability system for cattle/beef quality safety in China. Food Control 2013, 31, 314–325. [Google Scholar] [CrossRef]

- Bezerra, A.C.; Pandorfi, H.; Gama, R.M.; de Carvalho, F.F.R.; Guiselini, C. Development of a traceability model applied to goat and sheep meat production. Eng. Agric. 2017, 37, 1062–1072. [Google Scholar] [CrossRef] [Green Version]

- Kang, Y.S.; Lee, Y.H. Development of generic RFID traceability services. Comput. Ind. 2013, 64, 609–623. [Google Scholar] [CrossRef]

- Bertolini, M.; Bevilacqua, M.; Massini, R. FMECA approach to product traceability in the food industry. Food Control 2006, 17, 137–145. [Google Scholar] [CrossRef]

- Pizzuti, T.; Mirabelli, G.; Sanz-Bobi, M.A.; Goméz-Gonzaléz, F. Food Track & Trace ontology for helping the food traceability control. J. Food Eng. 2014, 120, 17–30. [Google Scholar]

- Thakur, M.; Hurburgh, C.R. Framework for implementing traceability system in the bulk grain supply chain. J. Food Eng. 2009, 95, 617–626. [Google Scholar] [CrossRef]

- Lavelli, V. High-warranty traceability system in the poultry meat supply chain: A medium-sized enterprise case study. Food Control 2013, 33, 148–156. [Google Scholar] [CrossRef]

- Muñoz-Gea, J.P.; Malgosa-Sanahuja, J.; Manzanares-Lopez, P.; Sanchez-Aarnoutse, J.C. Implementation of traceability using a distributed RFID-based mechanism. Comput. Ind. 2010, 61, 480–496. [Google Scholar] [CrossRef]

- Tu, M.; Lim, M.K.; Yang, M.F. IoT-based production logistics and supply chain system—Part 1 modeling IoT-based manufacturing IoT supply chain. Ind. Manag. Data Syst. 2018, 118, 65–95. [Google Scholar] [CrossRef]

- Tu, M.; Lim, M.K.; Yang, M.F. IoT-based production logistics and supply chain system—Part 2 IoT-based cyber-physical system: A framework and evaluation. Ind. Manag. Data Syst. 2018, 118, 96–125. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Liu, G.; Liu, L.; Lai, X.; Xu, G. IoT-based tracking and tracing platform for prepackaged food supply chain. Ind. Manag. Data Syst. 2017, 117, 1906–1916. [Google Scholar] [CrossRef]

- Thakur, M.; Sørensen, C.F.; Bjørnson, F.O.; Forås, E.; Hurburgh, C.R. Managing food traceability information using EPCIS framework. J. Food Eng. 2011, 103, 417–433. [Google Scholar] [CrossRef]

- Jansen-Vullers, M.H.; van Dorp, C.A.; Beulens, A.J.M. Managing traceability information in manufacture. Int. J. Inf. Manag. 2003, 23, 395–413. [Google Scholar] [CrossRef]

- Pizzuti, T.; Mirabelli, G.; Grasso, G.; Paldino, G. MESCO (MEat Supply Chain Ontology): An ontology for supporting traceability in the meat supply chain. Food Control 2017, 72, 123–133. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, X.; Moga, L.M.; Neculita, M. Modeling and implementation of the vegetable supply chain traceability system. Food Control 2013, 30, 341–353. [Google Scholar] [CrossRef]

- Thakur, M.; Donnelly, K.A.M. Modeling traceability information in soybean value chains. J. Food Eng. 2010, 99, 98–105. [Google Scholar] [CrossRef]

- Xu, D.F.; Li, Q.; Jun, H.B.; Browne, J.; Chen, Y.L.; Kiritsis, D. Modelling for product information tracking and feedback via wireless technology in closed-loop supply chains. Int. J. Comput. Integr. Manuf. 2009, 22, 648–670. [Google Scholar] [CrossRef]

- Bechini, A.; Cimino, M.G.C.A.; Marcelloni, F.; Tomasi, A. Patterns and technologies for enabling supply chain traceability through collaborative e-business. Inf. Softw. Technol. 2008, 50, 342–359. [Google Scholar] [CrossRef]

- Olsen, P.; Aschan, M. Reference method for analyzing material flow, information flow and information loss in food supply chains. Trends Food Sci. Technol. 2010, 21, 313–320. [Google Scholar] [CrossRef]

- Sundberg, P.; Hermansson, S.; Tullin, C.; Öhman, M. Traceability of bulk biomass: Application of radio frequency identification technology on a bulk pellet flow. Biomass Bioenergy 2018, 118, 149–153. [Google Scholar] [CrossRef]

- Da Silva, D.L.; Corrêa, P.L.P.; Najm, L.H. Requirements analysis for a traceability system for management wood supply chain on Amazon forest. In Proceedings of the 2010 Fifth International Conference on Digital Information Management (ICDIM), Thunder Bay, ON, Canada, 5–8 July 2010; pp. 87–94. Available online: https://icdim.org/icdim2010/default.php (accessed on 28 April 2018).

- Zhang, Y.; Jiang, P.; Huang, G.; Qu, T.; Zhou, G.; Hong, J. RFID-enabled real-time manufacturing information tracking infrastructure for extended enterprises. J. Intell. Manuf. 2012, 23, 2357–2366. [Google Scholar] [CrossRef] [Green Version]

- Kelepouris, T.; Pramatari, K.; Doukidis, G. RFID-enabled traceability in the food supply chain. Ind. Manag. Data Syst. 2007, 107, 183–200. [Google Scholar] [CrossRef]

- Shi, J.; Li, Y.; He, W.; Sim, D. SecTTS: A secure track & trace system for RFID-enabled supply chains. Comput. Ind. 2012, 63, 574–585. [Google Scholar]

- Olsen, P.; Borit, M. The components of a food traceability system. Trends Food Sci. Technol. 2018, 77, 143–149. [Google Scholar] [CrossRef] [Green Version]

- Wong, E.Y.C.; Wong, W.H. The development of reusable luggage tag with the internet of things for mobile tracking and environmental sustainability. Sustainability 2016, 9, 58. [Google Scholar] [CrossRef] [Green Version]

- Parlikad, A.K.; Mcfarlane, D.; Fleisch, E.; Gross, S.V. The Role of Product Identity in End-of-Life Decision Making. In Auto-ID Center White Paper, Auto-Id Centre Institute for Manufacturing, University of Cambridge, Mill Lane, Cambridge, cb2 1rx, United Kingdom; MIT: Cambridge, MA, USA, 2003; Available online: https://www.alexandria.unisg.ch/21457/ (accessed on 28 April 2018).

- Segura-Velandia, D.M.S.; Kaur, N.; Whittow, W.G.; Conway, P.P.; West, A.A. Towards industrial internet of things: Crankshaft monitoring, traceability and tracking using RFID. Robot. Comput. Integr. Manuf. 2016, 41, 66–77. [Google Scholar] [CrossRef] [Green Version]

- Ouertani, M.Z.; Baïna, S.; Gzara, L.; Morel, G. Traceability and management of dispersed product knowledge during design and manufacturing. Comput. Aided Des. 2011, 43, 546–562. [Google Scholar] [CrossRef] [Green Version]

- Folinas, D.; Manikas, I.; Manos, B. Traceability data management for food chains. Br. Food J. 2006, 108, 622–633. [Google Scholar] [CrossRef]

- United Nations Economic Commission For Europe. Traceability for Sustainable Trade: A Framework to design Traceability Systems for Cross Border Trade (ECE/TRADE/429); United Nations Economic Commission For Europe: New York, NY, USA; Geneva, Switzerland, 2016. [Google Scholar]

- Ergen, E.; Akinci, B.; Sacks, R. Tracking and locating components in a precast storage yard utilizing radio frequency identification technology and GPS. Autom. Constr. 2007, 16, 354–367. [Google Scholar] [CrossRef]

- Martínez-Sala, A.S.; Egea-López, E.; García-Sánchez, F.; García-Haro, J. Tracking of Returnable Packaging and Transport Units with active RFID in the grocery supply chain. Comput. Ind. 2009, 60, 161–171. [Google Scholar] [CrossRef] [Green Version]

- Papetti, A.; Marconi, M.; Rossi, M.; Germani, M. Web-based platform for eco-sustainable supply chain management. Sustain. Prod. Consum. 2019, 17, 215–228. [Google Scholar] [CrossRef]

- Plakas, G.; Ponis, S.T.; Agalianos, K.; Aretoulaki, E. Reverse Logistics of End-of-Life Plastics Using Industrial IoT and LPWAN Technologies—A Proposed Solution for the Bottled Water Industry. Procedia Manuf. 2020, 51, 1680–1687. [Google Scholar] [CrossRef]

- Li, L.; Paudel, K.P.; Guo, J. Understanding Chinese farmers ’ participation behavior regarding vegetable traceability systems. Food Control 2021, 130, 108325. [Google Scholar] [CrossRef]

- De Monteiro, D.M.; Caswell, J.A. The Economics of Implementing Traceability in Beef Supply Chains: Trends in Major Producing and Trading Countries; University of Massachusetts: Amherst, MA, USA, 2004. [Google Scholar]

- Corallo, A.; Latino, M.E.; Menegoli, M.; Striani, F. The awareness assessment of the Italian agri-food industry regarding food traceability systems. Trends Food Sci. Technol. 2020, 101, 28–37. [Google Scholar] [CrossRef]

- Mattevi, M.; Jones, J.A. Food supply chain: Are UK SMEs aware of concept, drivers, benefits and barriers, and frameworks of traceability? Br. Food J. 2016, 118, 1107–1128. [Google Scholar] [CrossRef]

- Nikolaou, I.E.; Tsagarakis, K.P. An introduction to circular economy and sustainability: Some existing lessons and future directions. Sustain. Prod. Consum. 2021, 28, 600–609. [Google Scholar] [CrossRef]

- Alexandris, G.; Katos, V.; Alexaki, S.; Hatzivasilis, G. Blockchains as Enablers for Auditing Cooperative Circular Economy Networks. In Proceedings of the 2018 IEEE 23rd International Workshop on Computer Aided Modeling and Design of Communication Links and Networks (CAMAD), Barcelona, Spain, 17–19 September 2018. [Google Scholar]

- Öhgren, A.; Sandkuhl, K. Do SME need ontologies? Results from a survey among small and medium-sized enterprises. In Proceedings of the Tenth International Conference on Enterprise Information Systems—ISAS, Barcelona, Spain, 12–16 June 2008; ISAS, 2008; Volume 1, pp. 104–111. Available online: https://www.scitepress.org/Papers/2008/17042/17042.pdf (accessed on 28 April 2018).

- Acerbi, F.; Sassanelli, C.; Terzi, S.; Taisch, M. A Systematic Literature Review on Data and Information Required for Circular Manufacturing Strategies Adoption. Sustainability 2021, 13, 2047. [Google Scholar] [CrossRef]

- Sauter, E.; Lemmens, R.; Pauwels, P. CEO & CAMO Ontologies: A Circulation Medium for Materials in the Construction Industry. In Proceedings of the 6th International Symposium on Life-Cycle Civil Engineering, IALCCE 2018, Ghent, Belgium, 28–31 October 2018; Caspeele, R., Taerwe, L., Frangopol, D.M., Eds.; CRC Press: London, UK, 2019; pp. 1645–1652. [Google Scholar]

- Cullot, N.; Parent, C.; Spaccapietra, S.; Vangenot, C. Ontologies: A contribution to the DL/DB debate. In Proceedings of the 1st InternationalWorkshop on the Semantic Web and Databases, 29th International Conference on Very Large DataBases, Berlin, Germany, 7–8 September 2003; pp. 99–119. [Google Scholar]

- Polverini, D. Regulating the circular economy within the ecodesign directive: Progress so far, methodological challenges and outlook. Sustain. Prod. Consum. 2021, 27, 1113–1123. [Google Scholar] [CrossRef]

- Bo, X.; Jia, M.; Xue, X.; Tang, L.; Mi, Z.; Wang, S.; Cui, W.; Chang, X.; Ruan, J.; Dong, G.; et al. Effect of strengthened standards on Chinese ironmaking and steelmaking emissions. Nat. Sustain. 2021, 4, 811–820. [Google Scholar] [CrossRef]

- Thiesse, F.; Floerkemeier, C.; Harrison, M.; Michahelles, F.; Roduner, C. Technology, Standards, and Real-World Deployments of the EPC Network. In IEEE Internet Computing; IEEE, 2009; Volume 13, pp. 36–43. Available online: https://www.proquest.com/docview/197338167 (accessed on 28 April 2018).

- Pérez, J.J.B.; Queiruga-Dios, A.; Martínez, V.G.; del Rey, Á.M. Traceability of ready-to-wear clothing through blockchain technology. Sustainability 2020, 12, 7491. [Google Scholar] [CrossRef]

- Wang, B.; Luo, W.; Zhang, A.; Tian, Z.; Li, Z. Blockchain-enabled circular supply chain management: A system architecture for fast fashion. Comput. Ind. 2020, 123, 103324. [Google Scholar] [CrossRef]

- Zhu, P.; Hu, J.; Zhang, Y.; Li, X. A blockchain based solution for medication anti-counterfeiting and traceability. IEEE Access 2020, 8, 184256–184272. [Google Scholar] [CrossRef]

- Böckel, A.; Nuzum, A.; Weissbrod, I. Blockchain for the Circular Economy: Analysis of the Research-Practice Gap. Sustain. Prod. Consum. 2021, 25, 525–539. [Google Scholar] [CrossRef]

- Oliveira, J.; Lima, J.E.; da Silva, D.; Kuprych, V.; Faria, P.M.; Teixeira, C.; Cruz, E.F.; da Cruz, A.M.R. Traceability system for quality monitoring in the fishery and aquaculture value chain. J. Agric. Food Res. 2021, 5, 100169. [Google Scholar] [CrossRef]

- Pawson, R.; Greenhalgh, T.; Harvey, G.; Walshe, K. Realist review—A new method of systematic review designed for complex policy interventions. J. Health Serv. Res. Policy 2005, 10 (Suppl. 1), 21–34. [Google Scholar] [CrossRef]

| Study | Author(s) | Title | Affiliation(s) of the First Author | Source of Funding |

|---|---|---|---|---|

| Tian, 2017 [33] | Feng Tian | A supply chain traceability system for food safety, based on HACCP, blockchain and Internet of Things | Department of Information Systems and Operations, Vienna University of Economics and Business, Vienna, Austria | None declared. |

| Wang et al., 2018 [34] | Jun Wang, Hung-Lin Chi, Wenchi Shou, Heap-Yih Chong and Xiangyu Wang | A coordinated approach for supply-chain tracking in the liquefied natural gas industry | Australasian Joint Research Centre for Building Information Modelling, School of Design and the Built Environment, Curtin University, Perth | Australia. |

| Parreño-Marchante et al., 2014 [35] | Alfredo Parreño-Marchante, Alejandro Alvarez-Melcon, Mira Trebar, Piero Filippin | Advanced traceability system in aquaculture supply chain | Universidad Politécnica de Cartagena, Cartagena, Spain | European Union. |

| Terzi et al., 2007 [36] | Sergio Terzi, Hervé Panetto, Gérard Morel, Marco Garetti | A holonic metamodel for product traceability in product lifecycle management | University of Bergamo, Department of Industrial Engineering, Italy | None declared. |

| Ruiz-Garcia et al., 2010 [37] | Ruiz-Garcia, L., Steinberger, G., and Rothmund, M. | A model and prototype implementation for tracking and tracing agricultural batch products along the food chain | Laboratorio de Propiedades Físicas y Tecnologías Avanzadas en Agroalimentación, Universidad Politécnica de Madrid, Madrid, Spain | Spain. Germany. |

| Anquetil et al., 2010 [38] | Nicolas Anquetil, Uirá Kulesza, Ralf Mitschke, Ana Moreira, Jean-Claude Royer, Andreas Rummler, André Sousa | A model-driven traceability framework for software product lines | ASCOLA, EMN-INRIA, Nantes, France | European Union. |

| Tian, 2016 [39] | Feng Tian | An agri-food supply chain traceability system for China based on RFID and blockchain technology | Department of Information Systems and Operations, Vienna University of Economics and Business, Vienna, Austria | None declared. |

| Chen, 2017 [40] | Rui-Yang Chen | An intelligent value stream-based approach to collaboration of a food traceability cyber-physical system by fog computing | Department of Business Administration, Aletheia University, Taiwan | None declared. |

| (Hsu, Chen, & Wang, 2008) Hsu et al., 2008 [41] | Yu-Chia Hsu, An-Pin Chen, Chun-Hung Wang | An RFID-enabled traceability system for the supply chain of live fish | Institute of Information Management, National Chiao Tung University, Taiwan Mackay Medicine, Nursing and Management College, Taiwan | None declared. |

| Bevilacqua et al., 2009 [42] | M. Bevilacqua, F.E. Ciarapica, G. Giacchetta | Business process reengineering of a supply chain and a traceability system: a case study | Dipartimento di Energetica, Università Politecnica delle Marche, Ancona, Italy | None declared. |

| Conti and Orcioni, 2019 [43] | Massimo Conti and Simone Orcioni | Cloud-based sustainable management of electrical and electronic equipment from production to end-of-life | Department of Information Engineering, Universita Politecnica delle Marche, Ancona, Italy | European Union. |

| Karlsen et al., 2011 [44] | K.M. Karlsen, C.F. Sørensen, F. Forås, P. Olsen | Critical criteria when implementing electronic chain traceability in a fish supply chain | Norwegian Institute of Fisheries and Aquaculture Research (Nofima), Tromsø, Norway | Norway. |

| Kumar et al., 2017 [45] | Vijay Kumar, Carina Hallqvist and Daniel Ekwall | Developing a framework for traceability implementation in the textile supply chain | University of Borås, Allégatan 1, 503 32 Borås, Sweden ENSAIT/GEMTEX, Roubaix, France Université Lille 1 Sciences et Technologies, Villeneuve-d’Ascq, France College of Textile and Clothing Engineering, Soochow University, Suzhou, China | European Union. |

| Ngai et al., 2007 [46] | E. W. T. Ngai, T. C. E. Cheng, Kee-hung Lai, P. Y. F. Chai, Y. S. Choi, R. K. Y. Sin | Development of an RFID-based traceability system: experiences and lessons learned from an aircraft engineering company | The Hong Kong Polytechnic University, Hung Hom, Kowloon, Hong Kong SAR, PR China | Hong Kong, China. |

| Feng et al., 2013 [47] | Jianying Feng, Zetian Fu, Zaiqiong Wang, Mark Xu, Xiaoshuan Zhang | Development and evaluation of an RFID-based traceability system for cattle/beef quality safety in China | College of Engineering, China Agricultural University, Beijing 100083, PR China | China. |

| Bezerra et al., 2017 [48] | Alan C. Bezerra, Heliton Pandorfi, Rafael M. Gama, Francisco F. R. De Carvalho, Cristiane Guiselini | Development of a traceability model applied to goat and sheep meat production | Universidade Federal Rural de Pernambuco—Unidade Acadêmica de Serra Talhada/ Serra Talhada—PE, Brasil | None declared. |

| Kang and Lee, 2013 [49] | Yong-Shin Kang, Yong-Han Lee | Development of generic RFID traceability services | u-SCM Research Center, Dongguk University—Seoul, Republic of Korea | Republic of Korea. |

| Bertolini et al., 2006 [50] | Massimo Bertolini, Maurizio Bevilacqua, Roberto Massini | FMECA approach to product traceability in the food industry | Dipartimento di Ingegneria Industriale, Universita‘ degli Studi di Parma, Italy | None declared. |

| Pizzuti et al., 2014 [51] | Teresa Pizzuti, Giovanni Mirabelli, Miguel Angel Sanz-Bobi, Fernando Goméz-Gonzaléz | Food Track and Trace ontology for helping the food traceability control | Dipartimento di Ingegneria Meccanica, Energetica e Gestionale, Università della Calabria, Italy | None declared. |

| Thakur and Hurburgh, 2009 [52] | Maitri Thakur, Charles R. Hurburgh | Framework for implementing traceability system in the bulk grain supply chain | Department of Agricultural and Biosystems Engineering, Iowa State University, United States | None declared. |

| Lavelli, 2013 [53] | V. Lavelli | High-warranty traceability system in the poultry meat supply chain: a medium-sized enterprise case study | DeFENS e Department of Food, Environmental and Nutritional Sciences, Università degli Studi di Milano, Milano, Italy | None declared. |

| Muñoz-Gea et al., 2010 [54] | Juan Pedro Muñoz-Gea, Josemaria Malgosa-Sanahuja, Pilar Manzanares-Lopez, Juan Carlos Sanchez-Aarnoutse | Implementation of traceability using a distributed RFID-based mechanism | Department of Information Technologies and Communications, Polytechnic University of Cartagena, Cartagena, Spain | Spain. |

| Tu et al., 2018a [55] | Mengru Tu, Ming K. Lim, Ming-Fang Yang | IoT-based production logistics and supply chain system—Part 1: modeling IoT-based manufacturing supply chain | Department of Transportation Science, National Taiwan Ocean University, Keelung, Taiwan | None declared. |

| Tu et al., 2018b [56] | Mengru Tu, Ming Lim, Ming-Fang Yang | IoT-based production logistics and supply chain system—Part 2: IoT-based cyber-physical system: a framework and evaluation | Department of Transportation Science, National Taiwan Ocean University, Keelung, Taiwan | None declared. |

| Li et al., 2017 [57] | Zhi Li, Guo Liu, Layne Liu Xinjun Lai, Gangyan Xu | IoT-based tracking and tracing platform for prepackaged food supply chain | Guangdong Provincial Key Lab of Computer Integrated Manufacturing System, Guangdong University of Technology, Guangzhou, China | China. |

| Thakur et al., 2011 [58] | Maitri Thakur, Carl-Fredrik Sørensen, Finn Olav Bjørnson, Eskil Forås, Charles R. Hurburgh | Managing food traceability information using EPCIS framework | Aquaculture Technology, SINTEF Fisheries and Aquaculture, Trondheim, Norway | Unclear, it seems to be the European Union and Japan. |

| Jansen-Vullers et al., 2003 [59] | M.H. Jansen-Vullers, C.A. van Dorp, A.J.M. Beulens | Managing traceability information in manufacture | Department of Technology Management, Eindhoven University of Technology (TU/e), Eindhoven, The Netherlands | None declared. |

| Pizzuti et al., 2017 [60] | Teresa Pizzuti, Giovanni Mirabelli, Giovanni Grasso, Giulia Paldino | MESCO (meat supply chain ontology): an ontology for supporting traceability in the meat supply chain | Dipartimento di Ingegneria Meccanica, Energetica e Gestionale, Università della Calabria, Italy | None declared. |

| Hu et al., 2013 [61] | Jinyou Hu, Xu Zhang, Liliana Mihaela Moga, Mihaela Neculita | Modeling and implementation of the vegetable supply chain traceability system | College of Engineering, China Agricultural University, Beijing 100083, PR China | Unclear, at least partially by the European Union. |

| Thakur and Donnelly, 2010 [62] | Maitri Thakur, Kathryn A.-M. Donnelly | Modeling traceability information in soybean value chains | Department of Agricultural and Biosystems Engineering, Iowa State University, Ames, IA 50011, United States Department of Industrial and Manufacturing Systems Engineering, Iowa State University, Ames, IA 50011, United States | Unclear. |

| Xu et al., 2009 [63] | D. F. Xu, Q. Li, H.-B. Jun, J. Browne, Y. L. Chen, D. Kiritsis | Modeling for product information tracking and feedback via wireless technology in closed-loop supply chains | Department of Automation, Tsinghua University, Beijing, China CIMRU, National University of Ireland, Galway, Ireland | Unclear. |

| Bechini et al., 2008 [64] | Alessio Bechini, Mario G.C.A. Cimino, Francesco Marcelloni, Andrea Tomasi | Patterns and technologies for enabling supply chain traceability through collaborative e-business | Dipartimento di Ingegneria dell’Informazione: Elettronica, Informatica, Telecomunicazioni, University of Pisa, Pisa, Italy | Italy. |

| Olsen and Aschan, 2010 [65] | Petter Olsen and Michael Aschan | Reference method for analyzing material flow, information flow and information loss in food supply chains | Nofima Market, Muninbakken, Breivik, Tromsø, Norway | European Union. |

| Sundberg et al., 2018 [66] | Peter Sundberg, Sven Hermansson, Claes Tullin, Marcus Öhman | Traceability of bulk biomass: Application of radio frequency identification technology on a bulk pellet flow | RISE Research Institutes of Sweden, Department of Energy and Circular Economy, Borås, Sweden Energy Engineering, Division of Energy Science, Luleå University of Technology, Luleå, Sweden | Sweden. |

| da Silva et al., 2010 [67] | Daniel Lins da Silva, Pedro Luiz Pizzigatti Corrêa, Leandro Halle Najm | Requirements analysis for a traceability system for the management of the wood supply chain in the Amazon forest | Electrical Engineering Digital Systems, Engineering School of USP, Brazil | None declared. |

| Zhang et al., 2012 [68] | Yingfeng Zhang, Pingyu Jiang, George Huang, Ting Qu, Guanghui Zhou, Jun Hong | RFID-enabled real-time manufacturing information tracking infrastructure for extended enterprises | Key Laboratory of Contemporary Design and Integrated Manufacturing Technology, Ministry of Education, Northwestern Polytechnical University, Xi’an, China State Key Laboratory for Manufacturing Systems Engineering, School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an, China | China. |

| Kelepouris et al., 2007 [69] | Thomas Kelepouris, Katerina Pramatari and Georgios Doukidis | RFID-enabled traceability in the food supply chain | Auto-ID Lab, Institute for Manufacturing, University of Cambridge, Cambridge, UK. | None declared. |

| Shi et al., 2012 [70] | Jie Shi, Yingjiu Li, Wei He, Darren Sim | SecTTS: a secure track and trace system for RFID-enabled supply chains | School of Information Systems, Singapore Management University, Stamford Road, Singapore. | Singapore. |

| Olsen and Borit [71] | Petter Olsen, Melania Borit | The components of a food traceability system | Nofima, Muninbakken 9–13, Breivika, Tromsø, Norway. | European Union. Norway. |

| Wong and Wong, 2016 [72] | Eugene Y. C. Wong and W. H. Wong | The development of a reusable luggage tag with the Internet of Things for mobile tracking and environmental sustainability | Department of Supply Chain and Information Management, Hang Seng Management College, Hong Kong (China). | Hong Kong, China. |

| Parlikad et al., 2003 [73] | Ajith Kumar Parlikad, Duncan McFarlane, Elgar Fleisch, Sandra Gross | The role of product identity in end-of-life decisionmaking | AUTO-ID Centre Institute for Manufacturing, University of Cambridge, Cambridge, United Kingdom | None declared. |

| Segura-Velandia et al., 2016 [74] | Diana M. Segura-Velandia, Navjot Kaur, William G. Whittow, Paul P.Conway, Andrew A.West | Toward the industrial Internet of Things: Crankshaft monitoring, traceability and tracking using RFID | Wolfson School of Mechanical and Manufacturing Engineering and Loughborough University, England, UK. | Unclear. |

| Ouertani et al., 2011 [75] | M.Z. Ouertani, S. Baïna, L. Gzara, G. Morel | Traceability and management of dispersed product knowledge during design and manufacturing | Department of Engineering, University of Cambridge, UK. | None declared. |

| Folinas et al., 2006 [76] | Dimitris Folinas, Ioannis Manikas and Basil Manos | Traceability data management for food chains | Department of Applied Informatics, University of Macedonia, Thessaloniki, Greece. | None declared. |

| UNECE, 2016 [77] | Markus Pikart and Andrew Baxter | Traceability for sustainable trade—a framework to design traceability systems for cross-border trade | United Nations Economic Commission for Europe (UNECE). | None declared. |

| Ergen et al., 2007 [78] | Esin Ergen, Burcu Akinci, Rafael Sacks | Tracking and locating components in a precast storage yard utilizing radio frequency identification technology and GPS | Department of Civil Engineering, Istanbul Technical University, Istanbul, Turkey. | Unclear. |

| Martínez-Sala et al., 2009 [79] | Alejandro S. Martínez-Sala, Esteban Egea-Lopez, Felipe Garcia-Sanchez, Joan Garcıa-Haro | Tracking of returnable packaging and transport units with active RFID in the grocery supply chain | Polytechnic University of Cartagena (UPCT), Cuartel Antigones, Cartagena, Spain. | Spain. |

| Papetti et al., 2019 [80] | Alessandra Papetti, Marco Marconi, Marta Rossi, Michele Germani | Web-based platform for eco-sustainable supply chain management | Department of Industrial Engineering and Mathematical Sciences, Università Politecnica delle Marche, Ancona, Italy. | Unclear. |

| Plakas et al., 2020 [81] | G. Plakas, S. T. Ponis, K. Agalianos, E. Aretoulaki | Reverse logistics of end-of-life plastics using industrial IoT and LPWAN technologies—a proposed solution for the bottled water industry | School of Mechanical Engineering, National Technical University Athens, Athens, Greece | European Union. Greece. |

| Study | Traceability, Tracking, and Related Concepts | Supply Chain Management and Integration | Environmental and Lifecycle Management | Technology | Information Modeling, SW Development, Systems Architecture, Distributed and Cloud Computing | Processes and Processes’ Representation | Requirements | International Initiatives, Regulations and Standards | Intertwine of Physical and Computational Elements | Ontologies | Security |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [33] | X | X | |||||||||

| [34] | X | X | |||||||||

| [35] | X | X | X | ||||||||

| [36] | X | X | X | X | X | X | |||||

| [37] | X | X | |||||||||

| [38] | X | X | |||||||||

| [39] | X | ||||||||||

| [40] | X | X | X | X | |||||||

| [41] | X | X | |||||||||

| [42] | X | X | |||||||||

| [43] | X | X | |||||||||

| [44] | X | X | X | ||||||||

| [45] | X | X | X | ||||||||

| [46] | X | ||||||||||

| [47] | X | ||||||||||

| [48] | X | ||||||||||

| [49] | X | X | X | X | X | ||||||

| [50] | X | ||||||||||

| [51] | X | X | |||||||||

| [52] | X | X | X | X | |||||||

| [53] | X | X | |||||||||

| [54] | X | X | X | ||||||||

| [55] | X | X | X | X | X | X | |||||

| [56] | X | X | X | X | X | ||||||

| [57] | X | X | X | ||||||||

| [58] | X | X | |||||||||

| [59] | X | X | X | ||||||||

| [60] | X | ||||||||||

| [61] | X | X | |||||||||

| [62] | X | ||||||||||

| [63] | X | X | X | ||||||||

| [64] | X | X | |||||||||

| [65] | X | X | |||||||||

| [66] | X | X | |||||||||

| [67] | X | X | |||||||||

| [68] | X | ||||||||||

| [69] | X | X | X | X | |||||||

| [70] | X | X | X | ||||||||

| [71] | X | ||||||||||

| [72] | X | X | |||||||||

| [73] | X | ||||||||||

| [74] | X | X | |||||||||

| [75] | X | X | |||||||||

| [76] | X | ||||||||||

| [77] | X | ||||||||||

| [78] | X | ||||||||||

| [79] | X | X | |||||||||

| [80] | X | X | |||||||||

| [81] | X | X |

| Group of Studies | Study Number |

|---|---|

| Studies reporting on traceability models or modeling traceability | [36,38,45,48,51,52,55,58,59,60,62,63,64,65,67,69,73,75,76,77] |

| Studies reporting on traceability systems or the components of traceability systems | [33,34,35,37,38,39,40,41,42,43,44,46,47,48,49,50,53,54,56,57,61,66,68,70,71,72,74,78,79,80,81] |

| Study | Conceptual | Design | Technology Development | Implementation | Evaluation |

|---|---|---|---|---|---|

| [33] | X | ||||

| [34] | X | X | Feasibility study | Feasibility study | |

| [35] | X | Feasibility study | |||

| [36] | X | X | Simulation | ||

| [37] | X | X | Prototype | Test of prototype | |

| [38] | X | X | X | Instantiation | |

| [39] | X | ||||

| [40] | X | X | X | Experiment | Experiment |

| [41] | X | X | X | ||

| [42] | X | ||||

| [43] | X | X | X | ||

| [44] | X | Feasibility study | |||

| [45] | X | ||||

| [46] | X | X | X | ||

| [47] | X | X | X | X | |

| [48] | X | X | |||

| [49] | X | X | X | Evaluation through simulation | |

| [50] | X | ||||

| [51] | X | X | Suggestion for validation | ||

| [52] | X | ||||

| [53] | X | X | Evaluation through simulation | ||

| [54] | X | X | |||

| [55] | X | X | Proof of concept | ||

| [56] | X | Prototype in laboratory | Prototype in laboratory | ||

| [57] | X | X | X | ||

| [58] | X | X | Proposal for model evaluation | ||

| [59] | X | X | |||

| [60] | X | X | X | X | Test of an ontology |

| [61] | X | X | X | X | |

| [62] | X | X | X | ||

| [63] | X | X | Case study | Case study | |

| [64] | X | X | X | Prototype | |

| [65] | X | X | Suggestion for proof of concept | ||

| [66] | X | Feasibility study | |||

| [67] | X | X | |||

| [68] | X | X | X | ||

| [69] | X | ||||

| [70] | X | X | X | X | Test of prototype |

| [71] | X | ||||

| [72] | X | X | Feasibility study | ||

| [73] | X | ||||

| [74] | X | Feasibility study | |||

| [75] | X | X | X | Case study | Tools validation |

| [76] | X | ||||

| [77] | X | ||||

| [78] | X | X | X | X | |

| [79] | X | X | |||

| [80] | X | X | X | X | |

| [81] | X |

| Traceable Entities/Units within the Group of Studies Reporting on Traceability Models or Modeling Traceability | Study Specifics Where Appropriate (Study Number: Page Where Needed) |

|---|---|

| Undefined or unclear about traceable entity/unit | [36,51,52,63,65,67,76] |

| Not defined, but “object” was consistently used when modeling and a clear instantiation was provided in the running examples | Dehumidifiers and associated critical parts [55] |

| Meat products and packaged products [60] | |

| Generic terms used | traceable items [69] |

| traceable unit [58] | |

| product [73] | |

| traceable assets [77] | |

| Inconsistent use of terms | [48] |

| Clearly identified | traceable artifacts (in SW product lines) [38] |

| product knowledge during the design and manufacturing phases [75] | |

| Different granularity or different nature of the entity to be tracked/raced | Along the production process [59] |

| Along the supply chain [45,62,64] | |

| Traceable Entities/Units within the Group of Studies Reporting on Traceability Systems or Components of Traceability Systems | Study Specifics Where Appropriate (Study Number: Page Where Needed) |

| Undefined or unclear about traceable entity/unit | [33,39,42,48,49,54,57,61,68,70,80,81] |

| Not defined, but clear the entity being tracked/traced from the text | [41,43,46,50,52,56,66,72,74,78,79,81] |

| Identified | Tracking objects (steel columns and beams from a real construction project; a vehicle during shipping and delivery; construction materials in site logistics) [34] |

| “traceable unit” (batch of fish in cages and polystyrene boxes) [35] (pp. 102–103) | |

| “TRU, just called a batch in the system” [37] (p. 116) | |

| traceable artifacts [38] | |

| “various traceable objects with smart devices” [40] (p. 130) | |

| Traceable materials [53] | |

| Traceable resource unit (TRU) (a trade unit, a logistic unit or a production unit) [71] | |

| Traceable unit as a function [47] | |

| Different granularity or different nature of the entity to be tracked/traced | Along the supply chain [44] |

| Along the production process [50] |

| Intervention | Description (Study Number: Page Where Needed) |

|---|---|

| Developed some sort of data/information model | “… a reference metamodel” where a “product holon” is defined”, mainly focused on defining the information part for ensuring product traceability and using the UML (unified modeling language) formalism as the modeling methodology [36] (p. 2) |

| “… a metamodel for a repository of traceability links” in software product lines, using MOF 2.0 (meta-object facility) [38] (p. 2) | |

| A basic “general traceability model applied to goat and sheep meat production” [48] (p. 1064) | |

| A reference model allowing the exploration of the “model-part of the bill of lots and/or batches”, the “model-part of operations and variables” and “the integration of these two model-parts” [59] (pp. 405–408) | |

| An “Auto-ID Enabled Product Information Model” for end-of-life decision making [73] (p. 17) | |

| Modeled traceability infrastructures or frameworks or frameworks with tracking capabilities | A framework for traceability implementation based on traceability requirements and utilizing IDEF-0 (integrated computer-aided manufacturing (ICAM) definition Part 0) model to show its implementation at an actor level, illustrating the integration of the different supply chain actors using a unified modeling language (UML) sequential diagram and the extensible markup language (XML) [45] |

| A framework for traceability implementation in the bulk grain supply chain, based on the usage requirements of the traceability system from each actor involved, an IDEF-0 model for developing and implementing an internal traceability system at a grain elevator and electronic data interchange (EDI) and XML (extensible markup language) for information interchange [52] | |

| A unified modeling framework with a hierarchical-modeling approach (ontology-modeling layer, process-modeling layer and object-modeling layer) to support the modeling and design of IoT systems for product logistics supply chain systems (PLSCS), to reduce system modeling and design complexity while achieving high system reusability and maintainability and allowing to track both product and parts [55] | |

| Basic modeling of service-oriented architecture, including requirements analysis, for a wood supply chain [67] | |

| An information infrastructure for RFID-enabled traceability that would provide an interface based on web-services technology for integration with the global EPC network and that would be cost-effective for an SME supply chain [69] | |

| A “traceability framework that would support the tracing and sharing of product knowledge throughout the product development phase of its lifecycle, i.e. product design and product manufacturing”, and that addresses the contextual, the conceptual, the logical, the physical, the out-of-context and the functioning system levels [75] (p. 547) | |

| A generic framework for traceability data management for food chains, based on requirements elicitation and “the implementation of XML (extensible markup language) technology” [76] (p. 622) | |

| A framework to design traceability systems for cross border trade, encompassing a number of components, namely, “policy claim, entry point, entry point conditions, exit point, exit point conditions, transformation rules and audit agency” [77] (pp. 9–10) | |

| Developed modeling methodologies or models for information analysis and management in supply chains | A methodology for modeling traceability information using the EPCIS framework and UML statecharts, where a state-transition model with emphasis on identifying both traceability transitions and food safety and quality data is developed [58] |

| A model for information capture at various stages in the soybean chain [62] | |

| A process-mapping reference method for analyzing material flow, information flow and information loss in food supply chains [65] | |

| Modeled closed-loop product information tracking and feedback | A model based on a 3-level approach to the closed-loop supply chain (CLSC) aimed at modeling the system level, the process level and the information and data level, considering the beginning of life (BoL), the middle of life (MoL) and the end of life (EoL) of a product and modeling for product information tracking and feedback via wireless technology (closed-loop product information (CLPI) tracking and feedback (TAF)) [63] |

| Developed ontologies for supporting traceability | MESCO (meat supply chain ontology), specific to the meat supply chain [60] |

| Food Track and Trace ontology, generic to food supply chain [51] | |

| Discussed a methodology for managing relevant aspects specific to traceability | Methodologies such as traceability semantics, scalability, information management, lot identification, integration, business process interoperability and standards for inter-enterprise business collaboration [64] |

| Actors | Study Number |

|---|---|

| Small and medium enterprises | [36] |

| Software analysts, architects, developers | [38] |

| “actors” | [64] |

| “users” | [65] |

| Parties intervening in a supply chain | [51,52,69] |

| Parties intervening in a supply chain, including the consumer | [45,55,58,59,60,62,63,67,76] |

| Those active in a product life cycle | [73] |

| Those active in the product development cycle of a company | [75] |

| Regulatory, monitoring and enforcement entities, namely: internal policies, regulation and accreditation entities, governmental agencies | [45] |

| The Observatory, which was responsible for the management of the traceability system and the recall activities | [51] |

| Public authorities | [59] |

| Government, regulatory and audit agencies and inspectors | [67,77] |

| International and Global Initiatives and Systems, Regulations and Standards | Study Number |

|---|---|

| EPCglobal standards, broadly mentioned | [69] |

| GS1 standards, broadly mentioned | [58] |

| EPC (electronic product code) standards | [64] |

| EPCIS (electronic product code information services) standards | [58] |

| IEC 62264 | [36] |

| ISO standards such as STEP (ISO 10303), Mandate (ISO 15531), PLCS (ISO 10303-239) | [36] |

| ISO 9001:2000 and ISO 9000 | [64] |

| Food-related initiatives such as the EC Directive 178/2002, Codex Alimentarius Classification of Food and Animal Feeds, Eurocode2 Food Coding System, CIAA Food Categorization, USDA National Nutrient Database for Standard Reference | [51] |

| XML (extensible markup language) | [36,45,63] |

| ebXML (electronic business XML) | [64] |

| PML (physical markup language) | [36] |

| OWL (ontology web language) | [51,60] |

| UML (unified modeling language) | [62] |

| Methods and Tools | Study Number |

|---|---|

| MOF 2.0 (meta object facility) | [38] |

| Eclipse modeling framework (EMF) | [38] |

| Aspect-oriented software development (AOSD) | [38] |

| Web ontology language (OWL) | [51] |

| Pellet reasoner | [51] |

| Protégé | [51,60] |

| Ontology-based database access (OBDA) | [51] |

| UML | [36,38,45,52,55,58,62,64,65,75] |

| EPC and EPCglobal technologies | [36,58,64,69,76] |

| IDEF-0 (integrated computer-aided manufacturing (ICAM) definition Part 0) | [45,52] |

| Bill of Lots (BoL), Bill of Materials (BoM) | [59] |

| Gozinto graphs | [59] |

| Petri Net | [55,65] |

| Business process modeling and notation (BPMN) | [51] |

| Service-oriented architecture (SOA) | [64] |

| RFID | [55,58,63,64,69,73,76] |

| IoT | [55] |

| Physical markup language (PML) | [36,64,73,76] |

| Extensible markup language (XML) | [36,45,52,62,63,64,76] |

| ebXML | [64] |

| Extensible style-sheet language (XSL) | [76] |

| Electronic data interchange (EDI) | [52,62] |

| Intervention | Description (Study Number: Page Where Needed) |

|---|---|

| Proposed traceability or/and tracking systems | A supply chain traceability system for real-time food tracing based on HACCP (hazard analysis and critical control points), blockchain and the Internet of Things [33] |

| “… a framework of a coordinated approach towards SCM in LNG construction that integrates different tracking technologies”, including supply-chain tracking for general-material management, supply-chain tracking for project specific-material management and a supply chain control platform [34] (p. 2) | |

| A traceability system for the aquaculture supply chain, based on RFID readers, sensors and data input devices, a set of capture and query applications, a traceability repository that is used to store the relevant traceability data, and the set of web services that provide the product information to the customer [35] | |

| A system based on web service technologies for tracking and tracing agricultural batch products along the processing chain [37] | |

| A traceability framework for software product lines, composed of a trace repository containing all the specific data necessary to a certain use case for tracing activities (ATF Core), an open and flexible GUI platform (ATF Front-end) and ATF Plugins [38] | |

| An agri-food supply chain traceability system for China, based on RFID and blockchain technology [39] | |

| An intelligent value stream-based food traceability cyber-physical system by fog computing [40] | |

| An RFID-enabled traceability system for live fish supply chain [41] | |

| An RFID-based traceability system for cattle/beef quality safety in China, based on business processes modeling and users’ requirements identification, modeling traceability information acquisition and transmission, design and implementation of the breeding management system, the slaughter and processing management system and the traceability information retrieval system [47] | |

| A traceability system for goat and sheep meat production, composed of a web server, with the database management system in structured query language (MySQL) and programming language in a hypertext preprocessor (PHP) [48] | |

| A high-warranty traceability system for the poultry meat supply chain [53] | |

| An IoT-based platform for the real-time tracking and tracing of the prepackaged food supply chain (five layers: perception layer, data layer, service layer, application layer, and users layer [57] | |

| A traceability system for the vegetable supply chain [61] | |

| A secure track and trace system for RFID-enabled supply chains, based on the EPCglobal network and where the EPCDS is semi-trusted and can be outsourced to the cloud to provide a more scalable and reliable service to users [70] | |

| An integrated cyber-physical system for the tracking of a reusable luggage tag, including RFID-related components, a database management system and a mobile app [72] | |

| An RFID system architecture for crankshaft monitoring, traceability and tracking detailing the system hardware and software architectures [74] | |

| An RFID- and GPS-based system for tracking and locating components in a precast storage yard [78] | |

| A system for tracking returnable packaging and transport units with active RFID in the grocery supply chain, including the RFID framework, the middleware framework and the control and customer framework [79] | |

| Proposed traceability services or the components of traceability systems | A novel set of generic RFID traceability services (TS) with embedded algorithms that would allow multiple aggregations of products into containers and would work efficiently by invoking EPCISs in parallel [49] |

| A “mechanism for automatically obtaining the supply network associated with a specific product using the EPCglobal Network” [54] (p. 480) | |

| Proposals where a traceability/tracking capability was a component/module of a larger system | A cloud-based system for the management of the waste of electric and electronic equipment (WEEE) from production to end-of-life, including tracking the entire working life of an electronic appliance and tracing all the single components of the electronic products [43] |

| An IoT-based production logistics and supply chain cyber-physical system, including tracking and tracing capabilities [56] | |

| An RFID-enabled real-time manufacturing information tracking infrastructure for extended enterprises to implement real-time visibility and interoperability during manufacturing execution, addressing information tracking and real-time traceability, visibility and interoperability [68] | |

| A web-based platform for eco-sustainable supply chain management, capable of simultaneously assessing the environmental impacts of production while effectively tracking products through the supply chain [80] | |

| A “technology solution aiming to provide tracking information at the disposed-of product unit instead of the transportation unit (bin) where most of the existing IoT applications seem to focus” [81] (p. 1683) | |

| Proposed methodologies to analyze, and sometimes improve, traceability systems or part of it | The reengineering of a supply chain and introduction of a traceability system [42] |

| Applying the FMECA approach to product traceability in the food industry, by using FMEA (Failure Mode and Effects Analysis) to identify the main causes for effectiveness or efficiency loss during a product’s history information recovery and CA (Criticality Analysis) to assess the risk, in terms of occurrence and severity, involved in each failure mode previously recognized [50] | |

| Evaluating the applicability of radio frequency identification technology on a bulk pellet flow [66] | |

| A structure for describing and analyzing a traceability system [71] | |

| addressed critical criteria when implementing electronic chain traceability | Critical criteria when implementing electronic chain traceability in a fish supply chain [44] |

| discussed experiences and lessons learned | Lessons from developing an RFID-based traceability system for an aircraft engineering company [46] |

| Actors | Study Number |

| Actors in a supply chain | [37,39,41,42,44,47,49,54,56,57,61,72,80] |

| Actors in a supply chain, including consumers or costumers | [40,53,79] |

| Researchers, members of the project, experts or consultants | [34,35,38,42,46,50,56,61] |

| Authorities that could include governments, regulators and certification bodies | [33,34,39] |

| The authors simply invoked a European Directive | [43] |

| Actors intervening directly in the study, namely, logistic operators in the company, consultants, researchers | [46] |

| Actors intervening directly in the study, namely, processers | [48] |

| Actors intervening directly in the study, namely, company actors, experts | [50] |

| Actors intervening directly in the study, namely, energy plant, supplier | [66] |

| Actors intervening directly in the study, namely, users in a company | [68] |

| Actors intervening directly in the study, namely, decision-makers and RFID designers | [74] |

| Actors intervening directly in the study, namely, manufacturers, workers, and clients | [78] |

| Actors implied; mentioned as “stakeholders” | [81] |

| International and Global Initiatives and Systems, Regulations and Standards | Study Number: Page Where Needed |

|---|---|

| EPCglobal Architecture Framework | [35,49] |

| EAN.UCC system and Chinese EAN.UCC System | [61] |

| EPCglobal standards | [40] |

| EPCglobal network standards | [54,70] |

| GS1 standards | [35,42,44,54,61,71] |

| US Military standard, MIL-STD-1629A (1980) | [50] |

| Criticality number (CN) based on US MIL-STD-1629A | [50] |

| Global trade item code (GTIN) | [61] |

| GS1 serialized global trade identification number (SGTIN) | [71] |

| EPCIS (electronic product code information services) | [35,40,49,54] |

| UPC (universal product code) standard for barcodes | [80] |

| ISO/IEC15693-3 | [47] |

| ISO 22005 | [53,71] |

| ISO 12875/12877 | [71] |

| European Commission, Commission Regulation (EC) No 2065/2001 | [35] |

| European Commission, 2002. Regulation (EC) No 178/2002 | [37,42,71] |

| European Committee for Standardization Workshop Agreement (CWA) 14660 | [44] |

| United States: FDA Food Safety Modernization Act (2007) | [71] |

| Tracecore, a standard describing information exchanges between software systems | [44] |

| Open Geospatial Consortium (OGC) standards such as GML (geographic markup language) | [37] |

| WS*-standards | [54] |

| Extensible access control markup language (XACML) | [54] |

| Extensible markup language (XML) | [40,54] |

| Web service security (WSS) standard | [54] |

| IETF X.509v3 standards for digital certificates | [54] |

| Unified modeling language (UML) | [61] |

| MQ telemetry transport (MQTT) protocol | [81] |

| LoRaWAN communication protocol | [81] |

| User datagram protocol/internet protocol (UDP/IP) | [81] |

| Extended producer responsibility (EPR) mentioned as “a policy approach” | [81] (p. 1685) |

| Study | Topic A | Topic B | Topic C | Topic D | Topic E |

|---|---|---|---|---|---|

| [33] | X | X | X | X | X |

| [34] | X | X | X | ||

| [35] | X | X | X | X | X |

| [37] | X | X | X | ||

| [38] | X | X | X | X | X |

| [39] | X | X | X | X | |

| [40] | X | X | X | X | X |

| [41] | X | X | X | X | |

| [42] | X | ||||

| [43] | X | X | X | X | |

| [44] | X | ||||

| [46] | X | X | X | X | |

| [47] | X | X | X | X | |

| [48] | X | X | X | ||

| [49] | X | X | X | X | X |

| [50] | X | ||||

| [53] | X | ||||

| [54] | X | X | X | X | X |

| [56] | X | X | X | X | X |

| [57] | X | X | X | X | X |

| [61] | X | X | X | ||

| [66] | X | X | |||

| [68] | X | X | X | ||

| [70] | X | X | X | ||

| [71] | X | X | |||

| [72] | X | X | X | X | |

| [74] | X | X | |||

| [78] | X | X | X | ||

| [79] | X | X | X | X | X |

| [80] | X | X | X | X | X |

| [81] | X | X |

| Comparator | Study Number: Page Where Needed |

|---|---|

| Not declared | [37,40,42,47,48,49,50,53,57,61,68,80] |

| Unclear | [35,44,71] |

| Not explicit | [33] |

| Alternatives mentioned or discussed but not detailly and rigorously compared—using barcode, passive RFID, active RFID, GPS tags or paper-based instructions, or a combination of some of them, in offsite fabrication and construction site logistics | [34] |

| Centralized traceability systems mentioned or discussed, but not in detail or rigorously compared | [39] |

| Traditional ways of managing production information in companies mentioned or discussed, but not in detail or rigorously compared | [41,46] |

| Technologies that are mentioned but not fully compared to the actual proposal | [72,74,78] |

| Studies and solutions from other identified but not adequately compared | [43,54] |

| Qualitative information provided regarding how their solutions performed when compared to other systems | [70,79,81] |

| All studies only deal with 1-to-1 traceability links | [38] |

| “… conducted emulation experiments to evaluate the performance and benefits of adopting an IoT-based CPS for PL management.” and compared the performance between a model employing M2M (machine to machine) distributed intelligence and a model without such technology because IoT and M2M “tackle different problems facing a production enterprise” | [56] (p. 11) |

| “… performing three separate trials investigating the technological aspects where RFID tags were traced along a biomass fuel supply chain”, but results from the three pilots performed cannot be compared between themselves and were not compared to usual practices in the industry | [66] (p. 150) |

| IndustriesAddressed | Study Number |

| Industry-independent solutions, even if most of them placed an emphasis on food-related industries and supply chains | [36,55,58,59,63,64,65,69,73,75] |

| Food: live goat and sheep sector | [48] |

| Food: the bulk grain supply chain in the United States | [52] |

| Food: the meat supply chain | [60] |

| Food: soybean value chains | [62] |

| Food: the general food supply chain | [51] |

| Food: fresh, non-processed food products supply chains | [76] |

| The software industry, in particular, software product line engineering | [38] |

| The textile and apparel sector, a very challenging industry with globally dispersed actors in the supply chain | [45] |

| The supply chain of wood from the Brazilian Amazon rainforest | [67] |

| Cross-border trade and environments | [77] |

| Levels and Connections Between Levels Addressed | Study Number |

| Single companies and supply chains | [45,48,52,60,62,64,76] |

| The supply chain level | [51,67,77] |

| Material and information flow in supply chains | [65,69] |

| Merging product and product information through the entire lifecycle of the product | [36] |

| Software product lines | [38] |

| A product supply chain monitored throughout its lifecycle with an emphasis on the information required to manage the end-of-life | [73] |

| Manufacturing processes, supply chain, goods and information flows | [58] |

| Manufacturing processes, bill-of-lots, bill-of-materials | [59] |

| Integrating product knowledge during design and manufacturing | [75] |

| Production logistics and supply chains in the real world and three layers when modeling (ontology, process, objects), in an information space composed of the object, business entity, location, time, process informatics | [55] |

| Three levels of a closed-loop supply chain (CLSC) (system, process, information and data) and considering beginning of life (BOL), middle of life (MOL) and end-of-life (EOL) of a product | [63] |

| Enablers and Motivators | Description | Study Number |

| Standards | Taking into account existing standardization initiatives | [36] |

| The need for standardization of information exchange semantics | [45,64] | |

| The need for explicit semantics and contexts in the information content that is to be shared across product lifecycle management (PLM) applications | [75] | |

| Regulations | Regulations from governments, formulating guidelines for various actors and for the minimum of required traceability | [45] |

| Business- and market-related motivators | The need to deal with increasing risks inherent to participation in global markets and supply chains | [45] |

| The need to answer the market’s need for safety and fight against counterfeiting products and parts | [55] | |

| Dynamically knowing the characteristics of raw materials, semi-finished and finished products | [59] | |

| Stakeholders | Identifying and addressing the needs, expectations, motivations and limitations of diverse stakeholders, such as companies, governments, audit agencies and final consumers | [65,67,69,73,76,77] |

| Technological aspects | Aspects related to methods, software, or hardware, such as using clear categorization and modeling methods and a core traceability metamodel | [38] |

| Building flexible core IoT design models | [55] | |

| Using a product-embedded information device (PEID) to realize the whole scenario for closed-loop product information (CLPI) tracking and feedback | [63] | |

| Using XML, SOAP and ebXML to achieve interoperability and data integration. | [64] | |

| Challenges | Description | Study Number |

| Heterogeneity | Entailed in managing information coming from different systems | [36] |

| Dealing with the number and complexity of artifacts and diversity of software processes | [38] | |

| Dealing with all stages of production | [52] | |

| Heterogeneity in field processes | [67] | |

| Adopting appropriate technology and maintaining the system at all levels of the supply chain | [45] | |

| The diversity of operations and properties each firm may use for a specific traceable resource unit | [69] | |

| The diversity of the participants involved | [55] | |

| Security and privacy | Security and privacy issues | [36] |

| Standards | Lack of common standards in an industry | [51] |

| Non-consideration of standards for information exchange at the level of the supply chain | [59] | |

| Not supporting certification systems, such as ISO and EMAS | [59] | |

| Semantic inconsistencies | Semantic inconsistencies between diverse sources of information | [63] |

| Lack of agreement on a concept’s meaning and relationships between terms, worsened by current enterprise information systems | [51] | |

| Limitations of ontology-based approaches | [75] | |

| The need for new ontologies in some domains, including food traceability | [51] | |

| Difficulties with the identification and evaluation of existing conditions | Before the development of a traceability framework | [65] |

| Difficulties including information requirements for the whole product lifecycle | [63] | |

| Limitations in modeling | Imitations of modeling methods, namely, the inability to model information process flows | [52] |

| Lack of architecture design methods for IoT application development | [55] | |

| Lack of high level of abstractions to specify high-level IoT system behaviors and lack of common software architecture to account for different IoT environments and diverse software modules | [55] | |

| Difficulty in representing the dynamic behavior of IoT systems through a traditional process-modeling scheme | [55] | |

| Technology limitations | Limitations such as difficulties in dealing with high volumes of information when tags are attached at item level | [69] |

| The inability of available product data management or product life-cycle management systems to manage and use product knowledge generated in all phases of the product lifecycle | [75] | |

| Challenges in obtaining the required performance level at each specific domain covered by the traceability system | [64] | |

| Business and markets issues | Issues especially when SMEs are involved, namely, a lack of workforce skills to implement and maintain a traceability system | [45,76] |

| Confidentiality of business processes | [45] | |

| Narrow profit margins in some businesses | [76] | |

| Cost-effectiveness of traceability systems adoption | [69] | |

| The concept of transformation in bulk product traceability | [62] | |

| The information gap among entities due to unwillingness or inability to share information and fragmentation of supply chains | [76] | |

| Governmental intervention and regulations | Governmental intervention and regulatory bodies’ mandates | [77] |

| Industries Addressed | Study Number: Page Where Needed |

|---|---|

| Industry-independent solutions | [49,54,56,68,70] |

| The food sector in general, where consistency in terminology and standardization are in need | [71] |

| The whole food supply chain | [33,39,40] |

| The seafood sector, where many SMEs still work with paper-based systems | [35] |

| Live fish supply chains in Taiwan | [41] |

| A fresh fish supply chain | [44] |

| Agriculture food chain | [37] |

| Agro-food, in particular companies involved in the production of “fourth range vegetable products.” | [42] (p. 14) |

| The cattle/beef sector | [47] |

| The goat and sheep industry | [48] |

| The durum wheat past production process of an Italian company | [50] |

| The poultry meat industry | [53] |

| The prepackaged food sector | [57] |

| Vegetable supply chains in China | [61] |

| The grocery market with fresh fruit and vegetables | [79] |

| The software industry | [38] |

| The liquefied natural gas (LNG) industry, where poor coordination and fragmented practices harm productivity and performance | [34] |

| The electrical and electronic equipment (EEE) sector, where an integrated cloud-based WEEE management system with real-time tracking capabilities would make the EOL treatment of electronic equipment easier | [43] |

| An aircraft engineering company implementing an RFID-based traceability system | [46] |

| The energy industry, using pellets as fuel | [66] |

| Air travel sector and IoT for mobile tracking with reusable luggage tags | [72] |

| Automated manufacturers of automotive parts | [74] |

| The construction sector, where little research has been conducted on RFID technology for tracking components | [78] |

| The leather shoe sector, where specific rules, ontologies, and systems are needed to guarantee effective data sharing and collaboration between partners in the production network | [80] |

| Bottled water manufacturers | [81] |

| Levels and Connections Between Levels Addressed | Study Number |

| The supply chain | [33,34,35,37,39,40,41,42,47,57,66] |

| Single companies and the supply chains in which they are involved | [44,56,61,70,80] |

| Supply networks | [54] |

| Production chains | [43] |

| Overall real-time manufacturing information tracking infrastructure of extended enterprises | [68] |

| Company level | [46,53,72,78] |

| Internal processes of a company | [50] |

| Production lines | [74] |

| Processes, company and supply chain levels | [71] |

| Distribution cycle of fresh fruit and vegetables, including forward and backward paths | [79] |

| Software product lines | [38] |

| Levels unclear | [48,49,81] |

| Enablers and Motivators | Description | Study Number |

|---|---|---|

| Business- and market-related motivators | The need to assure food safety and trust in the sector | [33,39,42] |

| The need to deal with the high agri-food loss ratio in China | [39] | |

| The need to assure proper management of large and complex LNG supply chains | [34] | |