1. Introduction

Rice is an utmost essential food crop. Around 80% people in the world consume rice [

1]. Solar energy is one of the alternative sources of energy both industrial and commercial applications, where this energy is abundantly available [

2]. Solar drying is the superior and economical drying method for dehydrating the agricultural produce namely paddy, maize, sunflower seeds, fruits and vegetables etc. [

3]. In our routine life various new technologies have been applied to increase the drying performance of the dryer. Various dryers had been designed, fabricated and tested its performance for different produce. Each dryer is different in shape, size and is fabricated for a particular product [

4]. Drying of agricultural produce is necessary post harvesting process, which is used to increase the quality and reduce the losses of the produce during storage and milling. The transportation cost of the produce becomes less because removing the moisture from the produce result in less weight and occupies less area [

5,

6,

7,

8,

9]. It forbids biological deterioration, prevents mold growth, fermentation, sprouting and discoloration of the agricultural produce. The agricultural produce can be stored for longer periods, at low moisture content under specified conditions. Drying the agricultural produce under specified value of humidity and temperature of air helps to dry the produce quickly to require moisture content and maintain the noble grade of the produce [

10].

Solar dryer was widely classified in three types in consonance with the solar radiation received by the produce namely direct, indirect and mixed mode solar dryer. As reported by the air movement in the systems, the solar dryers are categorized into active solar dryer (forced convection) and passive solar dryer (natural convection). In the passive solar dryers, the flow of air occurs due to the buoyancy effect, while in active solar dryers the air flow is produced by the external devices such as fans or blowers operated either by electricity/solar module. It occupies less area, saves the drying time and improves the produce quality [

11,

12]. The velocity of the drying air had great impact in the drying kinetics of the agricultural produce [

13]. The passive dryers are simple in construction, less expensive and easy to maintain where the drying mechanisms are firmly dependent on temperature variance, so the pressure drop arise in each drying bed. The mixed mode solar dryer has been noble in the speed of drying compared to direct and indirect mode of drying [

14].

The performance of the solar dryer can be enhanced by accumulating surplus energy in peak hours and utilizing that energy in off–sun hours and inadequate solar energy hours. The specified material is used to store the solar energy in the form of latent heat, sensible heat and combination of both [

15]. The newly harvested paddy grains have moisture content of 18–26% in wet basis [

16,

17]. At Present the main goal is to design and fabricate a dryer with less utilization of the power and superior quality of dried product [

18]. Now a day many methods are available for drying of paddy grains such as fluidized bed drying and thin layer drying [

19,

20,

21,

22,

23]. It is concluded that the cross flow continuous fluidized bed drying method is almost effective and efficient method to dry many agricultural produces [

12,

21,

24,

25,

26]. Normally fixed bed or movable bed such as belt conveyor is used in the solar dryer to dry the agricultural produce [

27].

2. Literature Review

Ref. [

28] developed an indirect mode of solar dryer incorporated with phase change material for dehydrating the valerianajatamansi rhizomes (medicinal herb) from 89% to 9% in 5 days. Ref. [

17] analyzed the performance of oscillating bed solar dryer for dehydrating the non-parboiled paddy grains with various combinations of bed cover and reflecting mirror. The results showed that combined reflecting mirror and bed cover gave the best drying performance. Ref. [

29] fabricated a mixed mode solar dryer for reducing the moisture of 3 kg grapes from 81.4% to 18.6% was achieved in 4 days.

Ref. [

30] fabricated a simple and economic solar dryer. The dryer can dry the paddy grains from initial water content of 24% to final water content of 14%. This dryer saved 50% drying time against the open sun drying. Ref. [

31] investigated a small scale solar seed dryer for drying crops such as maize and beans etc.

Ref. [

32] developed a photovoltaic powered solar grain dryer and tested its performance. The dryer was able to dry 90 kg of maize from 33.3% (d.b) to less than 20% (d.b) moisture content in a single day. Ref. [

33] developed a dryer and analyzed the drying characteristics of paddy grains using single and combined heating sources such as electrical, solar and biomass.

Ref. [

34] fabricated an indirect solar dryer to dry plantain fillets. The results indicated that the collector and dryer efficiencies were 46.4 and 78.73%, respectively. The removal of moisture and final moisture were 77.5 and 15.75%, respectively. The average drying rate of plantain fillets was 0.184 kg/h. [

35] constructed a forced convection solar dryer in addition to evacuated tube collector to dry Amla from initial moisture in the range of 83.6 and 84.3% to final moisture in the range of 0.1 and 0.6% within 5 to 7 whereas open sun drying takes 13 to 15 h to achieve this result. The efficiency of the fabricated dryer changes from 38.61 to 43.7% but the efficiency of open sun drying changes from 12.5 to 14.15%.

Ref. [

25] designed and built a solar dryer integrated with porous sensible heat storage medium (Pebble) and tested its performance to dry curry leaves. The curry leaves were dried in 5 h in solar dryer. ReshaTaide and Deshmukh, (2018) constructed a natural convection mixed-mode solar dryer for drying vegetables such as chili and bitter gourd. Drying rate of chili and bitter gourd are found to be 10.75 and 14.6 g/h, respectively. Thermal efficiency of solar collector was 38% and drying efficiency of solar dryer was 15%. Ref. [

36] had constructed and analyzed a forced convection mixed mode solar dryer to dry 15 kg of turmeric. The drying time could be decreased up to 7 days by using this solar dryer compared to a conventional method which required 13–15 days.

In this present work, dual pass oscillating inclined bed solar dryer has been developed and studied its performance at the constant bed tilt of 0.5° with various frequencies of oscillations of drying chamber such as 1.25, 1.75 and 2.25 Hz.

The main purpose of developed this dryer is to remove the moisture from the agricultural produce such as non-parboiled paddy grains, Sunflower seeds and Groundnuts etc. Using this model the farmer can dry their agricultural produce with minimum time and affordable cost. In this paper we used non-parboiled paddy grains as the produce and tested the dryer performance by various frequencies such as 1.25, 1.75 and 2.25 Hz with bed tilt of 0.5°.

3. Description about the Experimental Model

The drying model was constructed at Madhurapuri, near Thuraiyur (76°48′ N, 13°11′ E) in Trichy district, Tamilnadu state, India.

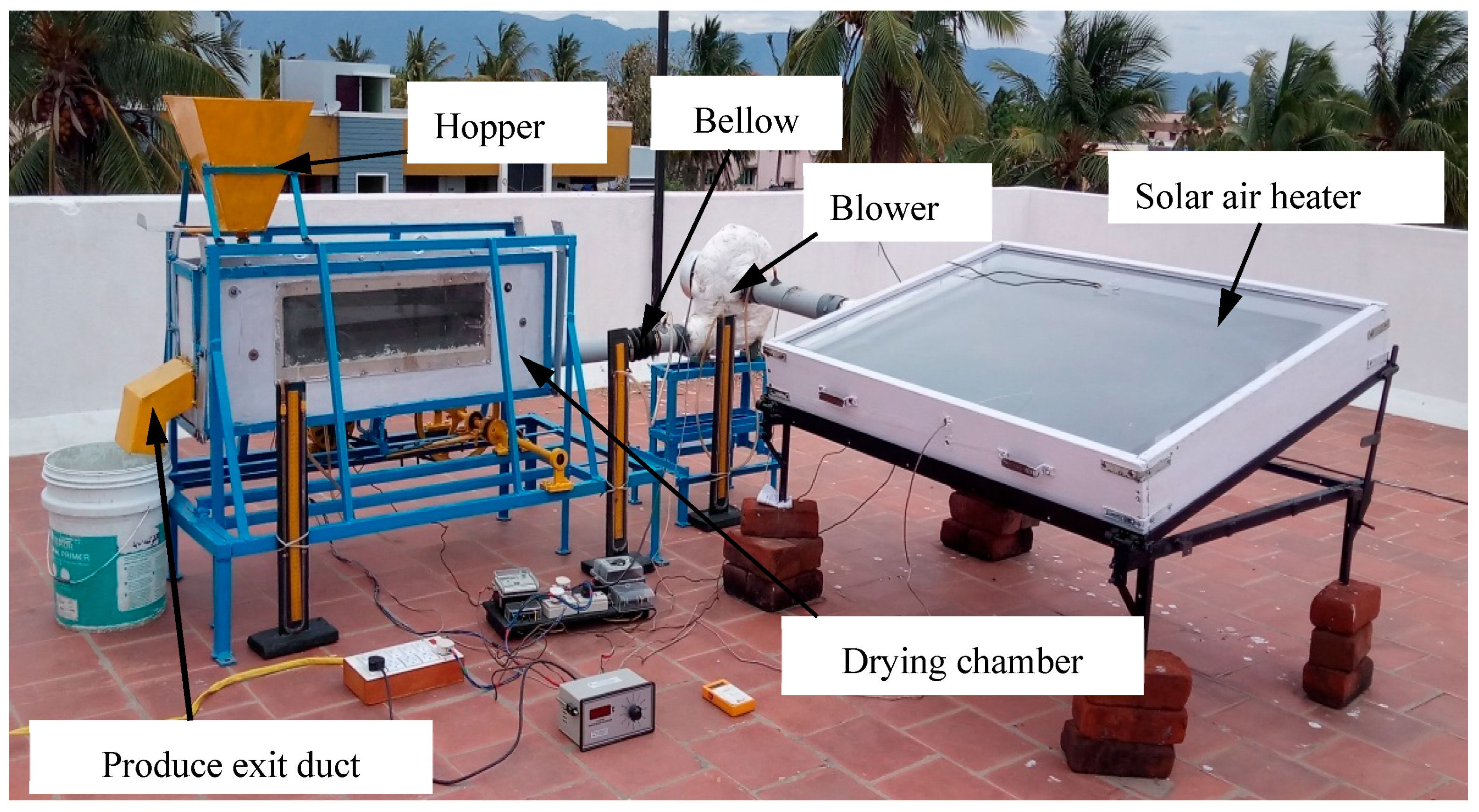

Figure 1 indicates the photographic view of dual pass inclined oscillating bed solar dryer. It comprises an insulated blower, dual pass flat plate solar collector, oscillating drying chamber with two perforated trays, hopper, bellow, PVC pipes and bed motor. The dual pass flat plate solar collector contains transparent glass plate, absorber plate and bottom plate. A 4 mm thick glass plate is located at 35 mm on top of the absorber plate for transferring the sun light on the absorber plate. A thin aluminum sheet called as absorber plate of thickness 0.87 mm with area of 1.152 m

2 is painted in dull black colour for absorbing more solar radiation. Ceramic wool insulated with a thin galvanized iron sheet and 18 mm thick wooden plank are fixed at 35 mm underneath the absorber plate is called as a back plate for reducing the bottom heat loss. These three plates are inserted in the wooden frame so that it makes a dual pass air flow passage. The flat plate solar collector has been placed on the metal frame such that the frame makes an angle of 13° with the ground. An insulated trapezium shape metal duct and PVC pipes are used to connect the blower with the solar collector.

The blower supplies 0.0506 kg/s of hot air from the solar collector to the drying chamber through a black rubber bellow. The blower is connected with the drying chamber through the rubber bellow which is used to avoid the blower with oscillation of the drying chamber. The drying chamber is made up wooden box; consisting of two perforated trays and a grains outlet duct. The perforated trays are black coated galvanized iron sheet metal having 31,600 holes of diameter 1.5 mm each to allow the hot air from bottom to top of the drying chamber for drying the grains. The perforated trays are arranged at 0.5° tilt with the horizontal to facilitate the motion of the grains from entry to exit of the drying chamber as shown in

Figure 2. The drying chamber was suspended by four flat belts with the bed frame for oscillation. The oscillating system comprises of A.C. motor of the capacity of 184 W, driver pulley, V-belt, driven wheel, eccentric cam and cam shaft. The cam was installed on the cam shaft connected with driven wheel. The power was given to the driven wheel through the V-belt by the bed motor.

The drying chamber was oscillated with different frequency of 1.25, 1.75 and 2.25 Hz by changing the diameter of the motor pulley is given in

Table 1. The hopper is a trapezium shape of metal box made in mild steel sheet and located at one side of the top of the drying chamber for storing and feeding the grains continuously to one end of the top perforated tray. The grains flow rate from the hopper to the top perforated tray was maintained constantly by adjusting the metal strap at the hopper bottom. The grains outlet duct is used to collect the dried grains at the other end of the bottom tray. The high temperature with low relative humidity of hot air enters the bottom side of the drying chamber and moves in the upward direction. The hot air first contacts the paddy grains in the bottom tray along the perforated holes in the bottom tray losing some of its heat and gaining some of the moisture from the grains. Then it further moves up losing some of its heat and gaining some of the moisture from the grains in the top tray. The hot air leaves from the top tray with low temperature and high relative humidity due to absorbing the moisture from the grains. The drying chamber and oscillating system are supported by the bed frame.

4. Experimental Approach

The experiments were conducted in the present dryer model between 7.30 a.m. and 5 p.m. from 22 to 24 June 2017. The drying chamber was given three different oscillations of 1.25, 1.75 and 2.25 Hz. In the beginning of experiments, 45 kg of non–parboiled paddy grains were taken with the initial moisture value of 19% (w.b). Every half an hour 2.5 kg of paddy grains were taken in the hopper for drying. When the experiments started, the atmospheric air was admitted into the flat plate collector and changed into hot air by receiving the heat from the absorber plate. The blower sucked the hot air from the flat plate collector and delivered into the bottom of the drying chamber through the rubber bellow. The hopper supplies a constant mass flow rate 0.08333 kg/min of the grains to the top perforated tray by adjusting the metal strap at the bottom of the hopper. The oscillation was given to the drying chamber by the oscillating mechanism to furnish uniform rolling and sliding movement of the grains on the perforated trays resulting thin layer of the grains formed on the perforated tray. Initially the paddy grains moved on the top perforated tray from one end to other end and then moved down to one end of the bottom tray. The grains further move to another end of the bottom tray and sent out through the grains outlet duct.

Owing to the sliding and rolling motion of the grains on the perforated trays, the hot air contacts all the surfaces of the grains resulting in the fast elimination of moistures from the grains. The following observations were taken at every half an hour such as wind velocity, solar radiation, energy meter readings of bed motor and blower, percentage of moisture available in the paddy grains before putting the hopper and after received from the dryer, temperature and relative humidity of air at various places such as entry, middle and exit of the drying chamber, entry and exit of the flat plate solar collector and at atmosphere, weight of dried produce received from the dryer.

5. Mathematical Calculation

The performance of the present dryer depends upon the thermal and Pick-up efficiency of the solar dryer [

22,

32] which determines amount of moisture dehydrated from the grains. The experimental datas obtained by the present dryer is given in

Table 2.

The dryer thermal efficiency was determined as the ratio of amount of heat energy used to remove the water content in the grains to the amount of heat energy contained by the hot air at the entry of the drying chamber; mathematically it is given by [

32],

Thermal efficiency of the dryer

Pick-up efficiency was calculated as the quantity of moisture extracted from the grains by the amount of heat energy given through the hot air. It is expressed mathematically by [

32],

Pick–up efficiency

The frequency of oscillation of drying chamber in Hz .

Where,

D1, D2—Diameter of the driver and driven pulley.

N—Speed of the bed motor in rpm (750 rpm).

6. Results and Discussion

Figure 3 shows the power consumed by the bed motor and blower of the solar dryer at various oscillating frequency of the drying chamber for the consecutive three experimental days. It is obvious from the above figure that the bed motor and blower consumed less electrical power between 11 and 15 h compared to remaining hours of the experimental day. The availability of solar radiation was quite high between 11 and 15 h resulting in the fast removal of moisture from the grains. Therefore the grains are weighing less and moving down very fast on the perforated trays. It is seen from the above figure when the frequency of oscillation of drying chamber increases, the power consumption of the blower decreases. Since at high frequency of oscillation, the grains move down at relatively high speed in the bed trays. So that accumulation of grains on the bed trays becomes less, resulting in less back pressure developed inside the drying chamber. When the frequency of oscillation of drying chamber increases, the power consumption of the bed motor also increases, because higher the frequency, higher the current consumed. The bed motor consumed less electrical power of 68 W at 13 h with the frequency of oscillation of 1.25 Hz. When the frequency of oscillation is increased to 1.75 and 2.25 Hz, the minimum electrical power consumed by the bed motor is 70 and 77 W, respectively, at 13 h. The blower consumed less electrical power of 120 W at 13 h at the oscillating frequency of 2.25 Hz. When the frequency of oscillation is decreased to 1.75 and 1.25 Hz, the blower consumes the minimum electrical power of 122 and 123 W, respectively, at 13 h.

The actual mass of dried grains collected from the dryer at every half an hour with various frequency of oscillation of the drying chamber is presented in

Figure 4. It is seen from the above figure when the frequency of oscillation of drying chamber increases, the mass of dried grains collected from the dryer also increases. When the oscillating frequency of the drying chamber is high, the speed of the grains on the bed is also high. Therefore, more dried grains are received at outlet of the drying chamber. When the frequency of oscillation of the drying chamber is constant the more dried grains are collected from the dryer between 12.5 and 13 h compared to morning and evening session. Since at that time the solar radiation was high and the high amount of moisture was eliminated from the grains resulting in less weight of the grain and moving fast in the bed trays. The paddy grains of 0.556 kg are left behind in the bed trays as residual mass after the experimental period when the frequency of oscillation is 1.25 Hz. The high quantity of dried grains collected from the dryer was 3.105 kg between 12.5 h and 13 h at the oscillating frequency of 2.25 Hz. When the frequency of oscillation is decreased to 1.75 and 1.25 Hz, the high quantity of dried grains received from the dryer is 3.099 and 3.068 kg, respectively.

Figure 5 indicates the minimum and maximum accepted level of moisture content and the change in percentage of moisture content of the dried paddy grains at various frequency of oscillation of the drying chamber. When the drying chamber was oscillated at the frequency of 1.25, 1.75 and 2.25 Hz, the accepted level of 12–14% of moisture content of the paddy grains was obtained from 9 to 17 h, 9 to 16.5 h and 9.5 to 16 h, respectively. It is notice from the above figure, when the oscillated frequency increases, the duration of accepted level of paddy grains obtained decreases, because of the high speed of the paddy grains in the bed tray, so that the contact time between hot air and grains were reduced, resulting in less amount of moisture was removed from the grains.

The change in dryer thermal efficiency at various frequency of oscillation of drying chamber is presented in

Figure 6. It is notice from the above figure when the frequency of oscillation decreases the dryer thermal efficiency increases, because at less frequency of oscillation the grains contact more time with hot air losing more amount of moisture to the hot air. The dryer thermal efficiency was less value in morning and evening session and more value at middle of the session at 13 h [

1,

18,

37,

38,

39,

40,

41]. So, the dryer thermal efficiency curve starts from low value in morning and maximum value in middle of the session and then decreases in evening session. The maximum dryer thermal efficiency was attained at 13 h in all the cases due to availability of high solar radiation resulting in high temperature of air. So that more amount of moisture was extracted from the paddy grains. The maximum dryer thermal efficiency of 44.47% is obtained at 13 h at the frequency of oscillation of 1.25 Hz. When the frequency of oscillation is increased to 1.75 and 2.25 Hz, the maximum thermal efficiency is 43.39% and 41.39%, respectively [

42,

43,

44,

45,

46,

47].

Figure 7 shows the variation in pick–up efficiency of the hot air in the dryer at various frequency of oscillation of the drying chamber. It is notice from the above figure when the frequency of oscillation decreases, the pick-up efficiency of air increases. Since at less frequency of oscillation, the paddy grains move slowly in the bed trays and contact more time with the hot air, so the air pick-up more moisture from the grains. The pick-up efficiency of air was less value at morning and evening session and more value at middle of the session at 13 h. Therefore, the pick-up efficiency curve increases from morning to middle session and then decreases in evening session [

48,

49,

50,

51]. The maximum pick–up efficiency was attained at 13 h in all the cases due to availability of high solar radiation resulting in high temperature with less relative humidity of hot air. Therefore, more quantity of moisture was extracted from the paddy grains. The maximum pick–up efficiency of 80.41% is obtained at 13 h at the frequency of oscillation of 1.25 Hz. When the frequency of oscillation is increased to 1.75 and 2.25 Hz, the maximum pick–up efficiency is 79.19% and 76.21%, respectively.

Table 3 gives the performance enhancement of this present dryer model with the existing dryer model.

7. Conclusions

The performance of the dual–pass oscillating bed solar dryer had been analyzed at constant bed tilt of 0.5° with various frequency of oscillation of the drying chamber such as 1.25, 1.75 and 2.25 Hz to dry non-parboiled paddy grains. From the above experiment, the following conclusions are made. It is obvious from the above discussion, the frequency of oscillation of 1.25 Hz has given best result based on dryer thermal efficiency, pick-up efficiency and moisture removal, but 0.556 kg of paddy grains are left behind in the bed tray as residual mass after17 h. At 1.75 Hz frequency, the values of efficiency and moisture removal are good and also there is no residual mass on the bed tray. At 2.25 Hz frequency, the grains move fast on the bed, resulting in less efficiencies and moisture removal compared to 1.75 and 1.25 Hz. Therefore, the optimum drying behavior of dual–pass oscillating bed solar dryer was obtained at the frequency of oscillation of 1.75 Hz with bed tilt of 0.5° to dry non–parboiled paddy grains.

In future the other agricultural produce such as sunflower seeds and groundnuts can be used to analyze the performance of this model and also the photo voltaic cell can be used instead of A.C. power supply to reduce the cost of electricity.

Author Contributions

Conceptualization, G.P.A., S.T., P.K., V.A., S.S., P.R., S.A.K. and C.A.S.; Formal analysis, P.K., V.A., S.S. and M.A.; Investigation, G.P.A., S.T., V.A. and M.A.; Methodology, G.P.A.; Resources, M.A.; Software, M.A.; Supervision, S.T.; Validation, P.R., S.A.K. and C.A.S.; Writing—original draft, G.P.A., S.T., P.K. and V.A.; Writing—review & editing, S.S., P.R., S.A.K. and C.A.S. All authors have read and agreed to the published version of the manuscript.

Funding

This paper is funded by UniversitiSainsMalaysiaRUiGrant1001/ PAERO/ 8014108 and 1001/ PAERO/ 8014120.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University (KKU) for funding this research through the Research Group Program Under the Grant Number: R.G.P.2/133/43.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Tdi | Entry air temperature of drying chamber (°C) |

| Tdo | Exit air temperature of drying chamber (°C) |

| Ta | Temperature of atmospheric air (°C) |

| Tci | Collector entry air temperature (°C) |

| Tco | Collector exit air temperature (°C) |

| Cpa | Specific heat capacity of atmospheric air (kJ/kgK) |

| Mass flow rate of air (kg/s) |

| Mass flow rate of moisture evaporated from the grains (kg/s) |

| hfg | Latent heat of water evaporization (kJ/kg) |

| mw | Mass of the moisture evaporated in time interval ‘dt’ (kg) |

| Wai | Absolute humidity of air at entry of the drying chamber (kg of water vapour/kg of dry air) |

| Wao | Absolute humidity of air at exit of the drying chamber (kg of water vapour/kg of dry air) |

| RH | Relative humidity (%) |

| ηD | Thermal efficiency of dryer (%) |

| ηp | Pick-up efficiency of the hot air (%) |

| Ac | Cross sectional area the solar collector (m2) |

| Pb | Power used by the blower (kW) |

| Pm | Power used by the bed motor (kW) |

| I | Solar radiation (W/m2) |

References

- Yadollahinia, A.R.; Omid, M.; Rafiee, S. Design and fabrication of experimental dryer for studying agricultural products. Int. J. Agric. Biol. 2008, 10, 61–65. [Google Scholar]

- Singh, S.; Kumar, S. New approach for thermal testing of solar dryer: Development of generalized drying characteristic curve. Sol. Energy 2012, 86, 1981–1991. [Google Scholar] [CrossRef]

- Umesh, T.; Karale, S.R. A review paper on solar dryer. Int. J. Eng. Res. Appl. 2013, 3, 896–902. [Google Scholar]

- Shanmugam, V.; Natarajan, E. Experimental study of regenerative desiccant integrated solar dryer with and without reflective mirror. Appl. Therm. Eng. 2007, 27, 1543–1551. [Google Scholar] [CrossRef]

- Afriyie, J.; Nazha, M.; Rajakaruna, H.; Forson, F. Experimental investigations of a chimney-dependent solar crop dryer. Renew. Energy 2009, 34, 217–222. [Google Scholar] [CrossRef]

- Bal, L.M.; Satya, S.; Naik, S.; Meda, V. Review of solar dryers with latent heat storage systems for agricultural products. Renew. Sustain. Energy Rev. 2010, 15, 876–880. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Ruslan, M.; Alghoul, M.; Sulaiman, M. Review of solar dryers for agricultural and marine products. Renew. Sustain. Energy Rev. 2010, 14, 1–30. [Google Scholar] [CrossRef]

- Kumar, R.; Chauhan, R.; Sethi, M.; Sharma, A.; Kumar, A. Experimental investigation of effect of flow attack angle and thermo hydraulic performance of air flow in a rectangular channel with discrete V—pattern baffle on the heated plate. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Leon, M.A.; Kumar, S.; Bhattacharya, S. A comprehensive procedure for performance evaluation of solar food dryers. Renew. Sustain. Energy Rev. 2002, 6, 367–393. [Google Scholar] [CrossRef]

- Sharma, V.K.; Colangelo, A.; Spagna, G. Experimental investigation of different solar dryers suitable for fruit and vegetable drying. Renew. Energy 1995, 6, 413–424. [Google Scholar] [CrossRef]

- Beigi, M.; Tohidi, M.; Torki-Harchegani, M. Exergetic analysis of deep-bed drying of rough rice in a convective dryer. Energy 2017, 140, 374–382. [Google Scholar] [CrossRef]

- Rahimi, A.; Sami, S.; Etesami, N. Economical optimization of an indirect solar cabinet dryer based on mathematical modeling. Environ. Eng. Manag. J. 2014, 13, 2615–2623. [Google Scholar] [CrossRef]

- Na Abou, M.M.; Madougou, S.; Boukar, M. Effect of Drying Air Velocity on Drying Kinetics of Tomato Slices in a Forced-Convective Solar Tunnel Dryer. J. Sustain. Bioenergy Syst. 2019, 9, 64–78. [Google Scholar] [CrossRef] [Green Version]

- Simate, I. Optimization of mixed-mode and indirect-mode natural convection solar dryers. Renew. Energy 2003, 28, 435–453. [Google Scholar] [CrossRef]

- Agrawal, A.; Sarviya, R. A review of research and development work on solar dryers with heat storage. Int. J. Sustain. Energy 2014, 35, 583–605. [Google Scholar] [CrossRef]

- Arul, G.P.; Shanmugam, S.; Veerappan, A.; Kumar, P. Performance analysis of double-pass oscillating bed solar dryer for drying of non-parboiled paddy grains. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 41, 418–426. [Google Scholar] [CrossRef]

- Kumar, P.; Shanmugam, S.; Veerappan, A. An Experimental Study on Drying of Non-parboiled Paddy Grains Using an Oscillating Bed Solar Dryer. Energy Eng. 2011, 108, 69–80. [Google Scholar] [CrossRef]

- Yogendra, S.D.; PydiSetty, Y. Drying kinetics, exergy and energy analyses of kodo millet grains and fenugreek seeds using wall heated fluidized bed dryer. Energy 2018, 151, 799–811. [Google Scholar] [CrossRef]

- Jain, D.; Jain, R.K. Performance evaluation of an inclined multi-pass solar air heater with in-built thermal storage on deep-bed drying application. J. Food Eng. 2004, 65, 497–509. [Google Scholar] [CrossRef]

- Rao, P.S.; Bal, S.; Goswami, T. Modelling and optimization of drying variables in thin layer drying of parboiled paddy. J. Food Eng. 2007, 78, 480–487. [Google Scholar] [CrossRef]

- Shanmugam, S.; Kumar, P.; Veerappan, A. Modeling and Experimental Studies on Oscillating Inclined-Bed Solar Dryer. J. Sol. Energy Eng. 2013, 135, 031009. [Google Scholar] [CrossRef]

- Supranto; Sopian, K.; Daud, W.; Othman, M.; Yatim, B. Design of an experimental solar assisted dryer for palm oil fronds. Renew. Energy 1999, 16, 643–646. [Google Scholar] [CrossRef]

- Srzednicki, G.S.; Hou, R.; Driscoll, R.H. Development of a control system for in-store drying of paddy in Northeast China. J. Food Eng. 2006, 77, 368–377. [Google Scholar] [CrossRef]

- Resha, T.; Deshmukh, S.J. Design, fabrication and performance analysis of a mixed mode solar dryer for drying vegetables. Int. J. Latest Trends Eng. Technol. 2018, 9, 51–56. [Google Scholar]

- Ronak Jain, R.; Pandikesavan, M.; Raghul Kumar, T.; Sakthivel, U. Experimental analysis of curry leaves drying using an indirect solar dryer. SSRG Int. J. Mech. Eng. 2017, 29–33. [Google Scholar]

- Shanmugam, S.; Kumar, P. Performance of an Oscillating Bed Solar Dryer for Sunflower Seeds. Energy Sources Part A Recovery Util. Environ. Eff. 2013, 35, 282–289. [Google Scholar] [CrossRef]

- Shanmugam, S.; Kumar, P.; Veerappan, A.R. Thermal performance of solar dryer with oscillating–bed solar dryer for non–parboiled paddy grains. Energy Sources Part A Recovery Util. Environ. Eff. 2014, 36, 1877–1885. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Chauhan, R.; Kumar, R.; Sethi, M.; Rana, A. Experimental investigation of an indirect solar dryer integrated with phase change material for drying valeriana jatamansi (medicinal herb). Case Stud. Therm. Eng. 2017, 10, 302–314. [Google Scholar] [CrossRef]

- Pardhi, C.B.; Bhagoria, J.L. Development and performance evaluation of mixed-mode solar dryer with forced convection. Int. J. Energy Environ. Eng. 2013, 4, 23. [Google Scholar] [CrossRef] [Green Version]

- Sidrah, A.; Manzoor, A.; Aftab, W. Design development and performance evaluation of a small scale solar assisted paddy dryer for on farm processing. J. Food Processing Technol. 2015, 6, 1–6. [Google Scholar]

- Gavhale, M.; Kawale, S.; Nagpure, R.; Mujbaile, V.N.; Sawarkar, N.S. Design and development of solar seed dryer. Int. J. Innov. Sci. Eng. Technol. 2015, 2, 1005–1010. [Google Scholar]

- Mumba, J. Design and development of a solar grain dryer incorporating photovoltaic powered air circulation. Energy Convers. Manag. 1996, 37, 615–621. [Google Scholar] [CrossRef]

- Manikantan, M.R.; Barnwal, P.; Goyal, R.K. Drying characteristics of paddy in an integrated dryer. J. Food Sci. Technol. 2014, 51, 813–819. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adelaja, A.O.; Babatope, B.I. Analysis and Testing of a Natural Convection Solar Dryer for the Tropics. J. Energy 2013, 2013, 479894. [Google Scholar] [CrossRef] [Green Version]

- Umayal Sundari, A.R.; Neelamegam, P.; Subramanian, C.V. Performance evaluation of a forced convection solar dryer with evacuated tube collector for drying Amla. Int. J. Eng. Technol. 2013, 5, 2853–2858. [Google Scholar]

- Avesahemad, S.N.; Husainy, S.P.; Gouri, W. Experimental investigation of mixed mode forced convection solar dryer for turmeric (Curcuma Longa). Asian Rev. Mech. Eng. 2018, 7, 1–6. [Google Scholar]

- Gad, M.; Ağbulut, Ü.; El-Shafay, A.; Panchal, H.; Emara, K.; Al-Mdallal, Q.M.; Afzal, A. Experimental and numerical assessment of the rotary bed reactor for fuel-processing and evaluation of produced oil usability as fuel substitute. Case Stud. Therm. Eng. 2022, 29, 101710. [Google Scholar] [CrossRef]

- Yıldız, G.; Ergün, A.; Gürel, A.E.; Ceylan, I.; Ağbulut, Ü.; Eser, S.; Afzal, A.; Saleel, C. Exergy, sustainability and performance analysis of ground source direct evaporative cooling system. Case Stud. Therm. Eng. 2022, 31, 101810. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Elibol, E.; Demirci, T.; Sarıdemir, S.; Gürel, A.E.; Rajak, U.; Afzal, A.; Verma, T.N. Synthesis of graphene oxide nanoparticles and the influences of their usage as fuel additives on CI engine behaviors. Energy 2022, 244, 122603. [Google Scholar] [CrossRef]

- Khandal, S.V.; Ağbulut, Ü.; Afzal, A.; Sharifpur, M.; Razak, K.A.; Khalilpoor, N. Influences of hydrogen addition from different dual-fuel modes on engine behaviors. Energy Sci. Eng. 2022, 10, 881–891. [Google Scholar] [CrossRef]

- Saleh, B.; Madhukesh, J.K.; Kumar, R.S.V.; Afzal, A.; Abdelrhman, Y.; Aly, A.A.; Gowda, R.J.P. Aspects of magnetic dipole and heat source/sink on the Maxwell hybrid nanofluid flow over a stretching sheet. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022. [Google Scholar] [CrossRef]

- Shaik, S.; Maduru, V.R.; Kontoleon, K.J.; Arıcı, M.; Gorantla, K.; Afzal, A. Building glass retrofitting strategies in hot and dry climates: Cost savings on cooling, diurnal lighting, color rendering, and payback timeframes. Energy 2022, 243, 123106. [Google Scholar] [CrossRef]

- Islam, T.; Nguyen, A.V.; Afzal, A. Bubble’s rise characteristics in shear-thinning xanthan gum solution: A numerical analysis. J. Taiwan Inst. Chem. Eng. 2022, 132, 104219. [Google Scholar] [CrossRef]

- Yaliwal, V.; Banapurmath, N.; Soudagar, M.E.M.; Afzal, A.; Ahmadi, P. Effect of manifold and port injection of hydrogen and exhaust gas recirculation (EGR) in dairy scum biodiesel—low energy content gas-fueled CI engine operated on dual fuel mode. Int. J. Hydrogen Energy 2022, 47, 6873–6897. [Google Scholar] [CrossRef]

- Al Rashdi, S.A.; Sudhir, C.; Basha, J.S.; Saleel, C.A.; Soudagar, M.E.M.; Yusuf, A.A.; El-Shafay, A.; Afzal, A. A case study on the electrical energy auditing and saving techniques in an educational institution (IMCO, Sohar, Oman). Case Stud. Therm. Eng. 2022, 31, 101820. [Google Scholar] [CrossRef]

- Murugan, M.; Saravanan, A.; Elumalai, P.; Kumar, P.; Saleel, C.A.; Samuel, O.D.; Setiyo, M.; Enweremadu, C.C.; Afzal, A. An overview on energy and exergy analysis of solar thermal collectors with passive performance enhancers. Alex. Eng. J. 2022, 61, 8123–8147. [Google Scholar] [CrossRef]

- Aigba, P.A.; Emovon, I.; Samuel, O.D.; Enweremadu, C.C.; Abdeljawad, T.; Al-Mdallal, Q.M.; Afzal, A. Exergetic Assessment of Waste Gas to Energy in a Novel Integrated NGL Recovery and Power Generation Plant. Front. Energy Res. 2022, 9, 1–23. [Google Scholar] [CrossRef]

- Saleh, B.; Sundar, L.S.; Aly, A.A.; Ramana, E.V.; Sharma, K.V.; Afzal, A.; Abdelrhman, Y.; Sousa, A.C.M. The Combined Effect of Al2O3 Nanofluid and Coiled Wire Inserts in a Flat-Plate Solar Collector on Heat Transfer, Thermal Efficiency and Environmental CO2 Characteristics. Arab. J. Sci. Eng. 2022, 1–28. [Google Scholar] [CrossRef]

- Samuel, O.D.; Samuel, O.D.; Waheed, M.A.; Waheed, M.A.; Taheri-Garavand, A.; Taheri-Garavand, A.; Verma, T.N.; Verma, T.N.; Dairo, O.U.; Dairo, O.U.; et al. Prandtl number of optimum biodiesel from food industrial waste oil and diesel fuel blend for diesel engine. Fuel 2021, 285, 119049. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.; RezaSafaeibcd, M.; Afzale, A.; Raju, V.D.; Ahmeda, W.; Banapurmath, N.; Hossainh, N.; Bashiri, S.; Anjum Badruddinjk, I.; et al. Effect of Sr@ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2021, 215, 119094. [Google Scholar] [CrossRef]

- Afzal, A.; Samee, A.M.; Jilte, R.; Islam, T.; Manokar, A.M.; Razak, K.A. Battery thermal management: An optimization study of parallelized conjugate numerical analysis using Cuckoo search and Artificial bee colony algorithm. Int. J. Heat Mass Transf. 2021, 166, 120798. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).