1. Introduction

Sustainable management of forests and halting deforestation are among the targets of Sustainable Development Goal (SDG) 15. There is an alarming decline in the proportion of the forest area to the world’s total land area from 31.9% in 2000 to 31.2% in 2020, where a significant decrease took place in Latin America and Sub-Saharan Africa [

1]. In Kenya, the loss of primary forests reached 7.6% from 2002 to 2020, which was driven, among others, by the demand for cheap energy [

2,

3].

The share of bioenergy generated from traditional biomass, such as charcoal and firewood, has hardly changed over the last 25 years and accounts for approximately 60% of the total energy use in Kenya [

4,

5]. As the world’s third-largest producer of black tea [

2,

6], the Kenyan tea industry requires around one million tons of firewood every year [

7], mainly to reduce the moisture content of the tea leaves [

5,

8,

9]. The high demand for fuelwood by rural communities and industry has led to deforestation and the depletion of trees as a natural resource [

3].

The Government of Kenya addressed this issue by imposing a forest harvesting moratorium firstly in 2018. Due to the moratorium, the supply of wood materials has been adversely affected, causing scarcity and increased market prices for wood products. Tea factories, which are firewood dependent, suffered additional expenditures in their production and, consequently, a decline in profits [

10]. Therefore, they seek to invest in alternative energy sources.

Several studies have already investigated alternative energy sources for the tea sector [

8,

9,

11,

12]. Wind energy can be economically viable in several locations of tea factories in Kenya, although this solution addresses the electricity demand and does not offer firewood replacement [

8]. Different solar drying technologies were investigated to dry different types of tea, which can improve its color and aroma ss [

11]. However, the study did not provide insights on the feasibility of installing the technology in certain geographical settings [

11]. A study in India [

9] investigated different renewable energy technologies, i.e., solar, wind, hydropower, and bioenergy waste. The authors proposed a solar-biomass hybrid system for the drying and withering process [

9]. Briquettes from rice husks and tea waste are also promising for tea industry application, although further studies are required to determine the optimum combustion properties [

12]. There are also challenges to implementing these technologies in the tea sector. To name a few, the harvesting and transportation of biomass are energy-intensive, and storage space is needed; solar and wind energy is influenced by their diurnal and stochastic nature. Thus an appropriate site selection is important, and hydropower suffers from seasonal climatic changes that influence the water availability [

9].

The tea factories in Kenya recognized the potential of biomass residues to substitute firewood in their processes. Kenya has a promising bioenergy opportunity from crop residues, for example, husks and bagasse, from the ongoing agricultural production such as maize, cassava, and sugarcane [

5]. Briquettes have been introduced in several tea factories through cofiring, i.e., mixing firewood and briquettes in the boilers. However, this potential is not yet widely used. Recent reports suggest that operational problems, cost intensity, and the distance from briquette factories to tea factories can be some of the factors hindering the briquette use [

7,

10]. A review of the briquette sector in East Africa identified several factors impeding the advancement of the briquette use, namely the lack of specific regulations relating to briquettes, limited access to financing options, insufficient marketing and distribution strategies, and inconsistent supply of raw materials [

13]. Furthermore, feedstock availability, lack of technical capacity, high cost of briquettes [

14], lack of awareness, limited fiscal incentives, and lack of an overarching institutional framework [

15] can be other challenges in implementation. However, to the best of our knowledge, no study has attempted to look specifically at the factors that influence the application of briquettes made of crop residues (hereinafter referred to as biomass briquettes) to be used as a substitution for firewood in the tea industry.

Against this background, this research aims to identify the drivers and barriers to substituting firewood with biomass briquettes in the Kenyan tea industry. We focus on the substitution potential and synthesizing the drivers and barriers within the PESTEL (political, economic, social, technological, environmental, and legal) framework in combination with a SWOT (strengths, weaknesses, opportunities, and threats) analysis. The contribution of this study includes a strategic recommendation to promote the sustainable use of biomass briquettes for industrial purposes, particularly in the tea industry, and an understanding of the use of a combined SWOT/PESTEL analysis in the bioenergy sector.

The article is organized into five sections.

Section 1 provides the theoretical and contextual background.

Section 2 presents the scope and methods of the study.

Section 3 presents the results of the substitution potential and the SWOT/PESTEL analysis.

Section 4 discusses the main drivers and barriers to the substitution. Lastly,

Section 5 defines the conclusions of the study and provides recommendations for future research.

2. Materials and Methods

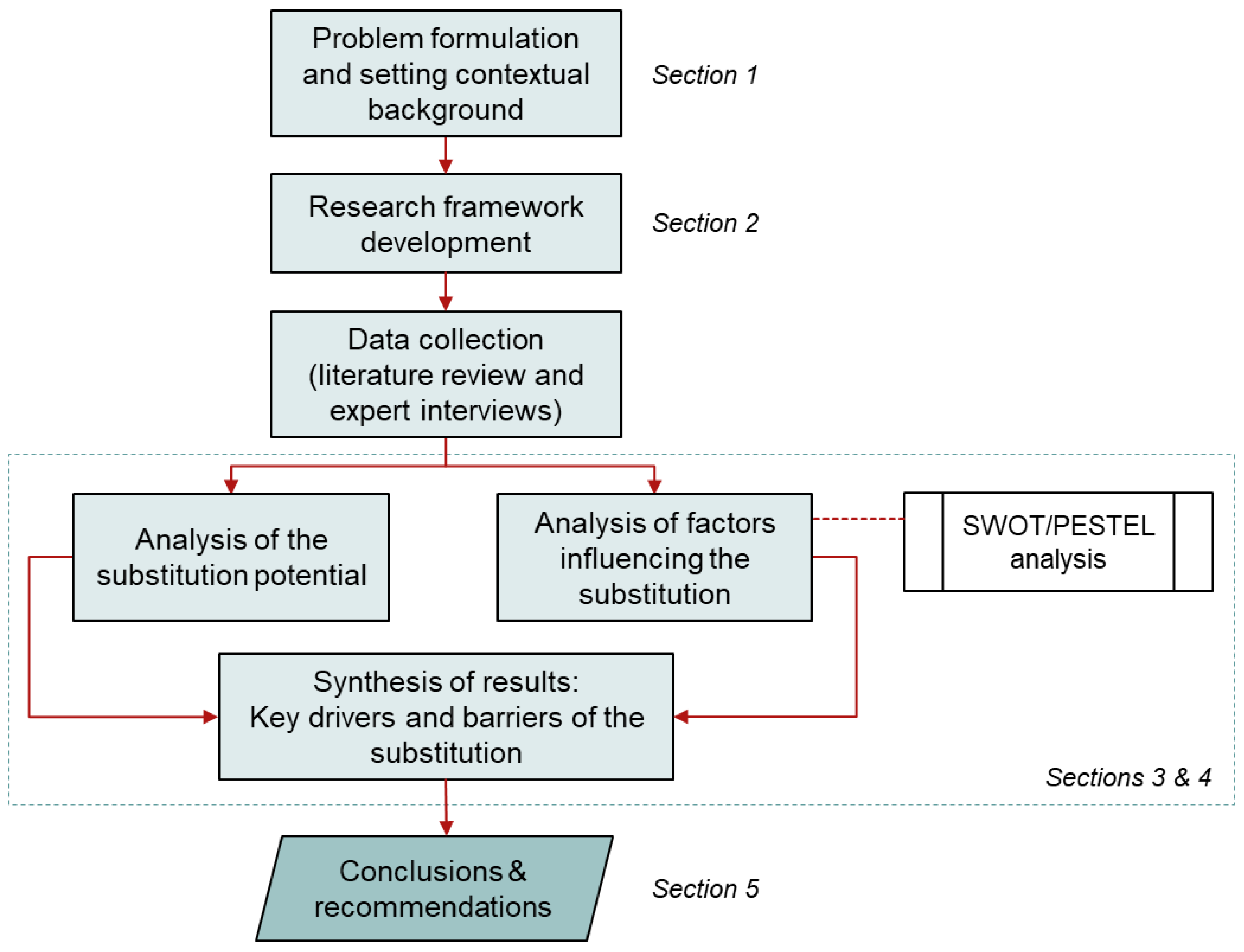

The design of the study is illustrated in

Figure 1. The first part is to analyze the substitution potential, and the second part is to identify the factors influencing the substitution using a combined SWOT/PESTEL analysis based on expert interviews. The results are synthesized to determine the drivers and barriers of the substitution.

The study scope was set within the value chain of firewood and biomass briquette production (

Figure 2). This chart was used as an orientation to determine the internal and external factors of the substitution.

2.1. Study Area

The tea industry in Kenya is operated by the tea estates (involving large plantations) and the smallholder farmers organized by the Kenya Tea Development Agency (KTDA). KTDA is a private holding company, managing an overall 70 factories on behalf of more than 635,000 farmers who have an ownership stake in the factories [

16]. Tea is grown in 19 counties located within the West and East of Rift in Kenya, where KTDA operates plantations and factories in 16 counties [

16]. Over 60% of the country’s tea production comes from KTDA [

17,

18]. This study, therefore, focuses on the tea factories managed by KTDA.

The study was conducted at the country level. A map (

Figure 3) was created by plotting the location data of biomass briquette factories, tea factories, and sugar factories to provide an overview of the geographical information. Only a limited number of briquette factories are shown on the map as the data are scarce. Information on agricultural land and tree plantations is included in the map. The data used to plot the map are provided in the

Supplementary Materials.

2.2. Analysis of Substitution Potential

2.2.1. Biomass Residues Potential

Kenya has potential for biomass residues coming from agricultural products such as sugarcane, maize, potato, cassava, and banana, which are among the country’s top ten commodities [

19]. The types of biomass residue can be differentiated according to where they are found. Residues such as stalks, stems, straws, and leaves are most likely to be left in the field; thus, they are called field-based residue (F). Meanwhile, residues such as husks, cobs, peelings, nutshells, bagasse, and pulp are typically generated after processing (P), for example, at a milling facility.

Biomass residue potential refers to the number of biomass residues available to be processed into briquettes and the potential energy that can be generated from the residues. The amount of residue was calculated by multiplying the annual crop production quantity by its average RPR (residue-to-product ratio) value (Equation (1)). RPR is a measure of how much residue is generated per mass unit of product [

20]. RPR values of a crop might be influenced by its geographic location, crop yield, weather conditions, and moisture content at the time of sampling [

21]. The theoretical energy potential refers to the analytical calculations of energy to be generated from the biomass residues based on their characteristics. It was estimated by multiplying the residue quantity by its calorific value (CV) (Equation (2)). Obtaining RPR values that are specific to Kenya is difficult without actually collecting primary data from the field and processing facilities. We adopted the RPR values and CVs from previous studies in Kenya and other countries, as summarized in

Table A1 and

Table A2 of

Appendix A.

This study considered three aspects in selecting the biomass residues to be further analyzed, namely (1) the abundance of quantity based on the latest data of produced crops, (2) the results of the previous studies [

5,

20,

22], and (3) the consultations with briquette companies in Kenya. The four most promising crops selected for analysis were sugarcane, maize, potato, and banana. Additionally, coffee and rice were included in the analysis despite their relatively small production. This is because several briquette companies are using coffee and rice husks, either as the main raw material or as fillers. Sawdust (i.e., residue from sawmills) is also commonly used in the briquette industry for its high calorific value and is therefore included in the analysis.

2.2.2. Energy Demand in Tea Factories

Energy demand in this study refers to the thermal energy required for the withering and drying processes, which comes from burning firewood in the boilers. The amount of firewood consumed in the tea factories varies according to their production capacity. This study assumed an average annual firewood consumption per factory to be 16,000 m

3 per year [

23] and the total consumption by all KTDA tea factories to be 900,000 m

3 [

24]. Since there is no certification scheme in place to measure the moisture content, the density of firewood was assumed. Based on the range of 393–550 kg/m

3 [

7,

24,

25], we assumed the density of 460 kg/m

3, which results in an equivalent of 414,000 tons of dry firewood demand. This can generate up to 5,796,000 GJ of heat energy, assuming a CV of 14 MJ/kg. The initiative to replace 20–30% firewood with briquettes means that the energy amount required from briquettes would range between 1,159,200 and 1,738,800 GJ.

Table A3 of

Appendix A provides a list of assumptions used for the calculation.

2.2.3. Briquette Production

A study in Kenya [

7] suggested that the level of briquette supply and cost factors may make it unattractive for tea factories to switch from firewood to biomass briquettes. Therefore, this study examined the briquette production and the costs of purchasing briquettes in comparison to firewood.

ISO 16559:2014 standard defines biomass briquette as “densified biofuel made with or without additives in pre-determined geometric form with at least two dimensions (length, width, height) of more than 25 mm, produced by compressing biomass.” Briquetting is the process of compacting residues into a solid product to increase the energy density of the materials, where higher densification leads to less moisture content and higher calorific value compared to its raw materials [

26,

27,

28].

There are two types of briquettes, i.e., carbonized and non-carbonized. Carbonized briquettes are made from biomass that has undergone pyrolysis, and the feedstock is mixed with a binding agent before being pressed to form briquettes [

15]. This type of briquette is preferred for cooking in households as it can light quickly. Non-carbonized briquettes are processed directly from biomass sources through various casting and pressing processes (i.e., densification) and are mainly for industrial use [

29]. Non-carbonized briquettes are more favorable for industrial purposes because they can burn for a longer duration.

2.2.4. Energy Cost Estimation

This study examined the production capacity and product prices, excluding tax and other costs, based on the data from the literature [

7,

10] and interviews with briquette producers. The exclusion of other costs was due to the variance of delivery costs and the data scarcity. A sensitivity analysis of the costs of adopting briquettes at different substitution rates in the tea factories and different CVs was conducted. CV is a sensitive parameter to the costs; the higher the CV of briquettes, the more competitive briquettes are to replace firewood as there will be more energy that can be delivered. The sensitivity analysis was carried out to show the importance of having a more standardized CV for briquette products so that the amount of energy to be delivered by briquettes can be ensured. The CV variation was based on the existing data in the literature [

24] and the value reported by the briquette companies interviewed for the study (

Table A4).

2.3. SWOT/PESTEL Analysis

SWOT analysis is commonly used in strategic planning to evaluate an organization, a project, or a business activity based on the internal factors (strengths and weaknesses) and external factors (opportunities and threats) [

30]. It has been applied by researchers in the area of energy planning, including the topic of drivers and barriers to renewable energy development [

31] and sustainable transition to renewable energy [

32]. The SWOT analysis identified and systematically categorized the results into two groups: internal and external factors. Internal factors are those over which the system has control over it and are divided into favorable and unfavorable ones. The favorable internal factors were considered

strengths, while the unfavorable internal factors were seen as

weaknesses. With the same logic, the favorable external factors were grouped under

opportunities, whereas the unfavorable external factors fell under the

threats category.

A PESTEL analysis was carried out complementary to the SWOT analysis by initially focusing on the key external factors affecting the substitution. It reviewed the macro environment of the transition from firewood to biomass briquettes. PESTEL analysis reflected the political, economic, social, technological, environmental, and legal factors to evaluate the biomass briquettes’ potential to substitute firewood in the tea industry. This approach was used to identify the drivers and barriers to the adoption of alternative energy technologies [

33] and to analyze the biofuel energy industry in Europe [

34].

The combination of SWOT and PESTEL analyses allows for a more thorough and more accurate analysis of a complex system and its multidimensional interactions with the environment [

35]. Even though the initial purpose of PESTEL analysis was to comprehend the macro environment of the substitution, the expert interviews revealed that the PESTEL categories were also reflected within the internal factors. Applying a PESTEL analysis to both internal and external factors has been shown in a case study of reconstructing a water intake structure [

35]. The SWOT/PESTEL analysis in this study followed the algorithm as illustrated in

Figure 4.

The identified factors were categorized according to the political (P), economic (Ec), social (S), technological (T), environmental (En), and legal (L) aspects. Then, they were classified into four SWOT groups based on the logic of internal/external and favorable/unfavorable toward the substitution. In some cases, one factor may indicate multiple SWOT/PESTEL aspects as it is not always easy to allocate one factor to only one category.

Eleven experts were interviewed for this study; five were directors of briquette companies, one was at a managerial position in KTDA, and one was from KEBS (Kenya Bureau of Standards, a government agency dealing with national standards in Kenya), two were from NGOs, one researcher, and one consultant. Nine interviews were recorded, while two were not due to technical issues. There are in total of 365 min of audio recording. All data are confidential and can only be used for academic purposes.

The interviews were evaluated through thematic analysis, a technique for identifying, analyzing, and interpreting patterns of meaning, called

themes, within qualitative data [

36]. This method was chosen for its flexible nature in terms of research questions, sample sizes, data collection methods, and approaches to generating themes [

37]. A thematic analysis starts with familiarizing with the data through an iterative process of transcribing the interview recordings into a text form, reading and rereading the transcriptions to comprehend the entirety of the information, and noting down the initial ideas [

37]. The raw data were transformed into a standardized format for analysis by identifying and labeling recurrent words and concepts, called

codes, which are the smallest units of analysis relevant to the research questions [

37,

38]. From line-by-line coding of the raw data, the generated

codes were grouped logically to build

themes as patterns of meaning, known as

categorization [

38]. These steps were also performed iteratively, repeatedly returning to the raw data and adjusting the labeling of

codes and

themes. The result of this process is not only a summary of data content but also its interpretation and meaning extracted from the raw data.

4. Discussion

4.1. Opportunities as the Driving Force

The drivers for the substitution are found mainly as opportunities in the environmental and political aspects. These include the scarcity of firewood and the difficulties faced by KTDA in acquiring nearby land and planting and growing eucalyptus trees. When the forest harvesting moratorium was enforced, briquette demand increased as the tea factories were pushed to diversify their energy sources. The potential resource availability to make briquettes from residues is also an opportunity for substitution. An appealing aspect of using biomass briquettes is that the raw materials are renewable and derived from otherwise discarded residues. Many local entrepreneurs recognized this potential; by transforming bagasse, sawdust, coffee husks, and rice husks into briquettes. Residues from maize, potato, and banana can further be explored for briquette production in the country.

Politically, the drivers could be better supported by consistent government policies to conserve the forest and promote the use of more biomass residues. Some forms of incentives for both the tea factories and briquette companies were proposed by the experts interviewed in this study. For the tea factories, the support can be in the form of tax holidays and accelerated depreciation so that they can invest in boilers to accommodate more biomass briquettes. Similarly, for briquette companies, a tax holiday to acquire high-quality briquetting equipment was proposed. Additionally, the external push and support from development organizations motivated by sustainability concerns can also further drive the substitution. Such organizations have the vision and resources to bring forward initiatives that may not be the main business interests of the tea factories.

4.2. Internal Weaknesses as Barriers to Substitution

Different from the drivers, which mostly are external factors, the barriers to substitution are mainly the internal weaknesses of the briquette product itself. The main barrier discovered was the cost competitiveness. Briquettes are typically more expensive than firewood. In the tea sector, firewood is accessible with a zero-rated tax, while briquettes are subject to 16% VAT. It makes it difficult for briquettes to compete as the production costs are higher than firewood. The experts see the need to advocate for necessary changes in current Kenya’s bioenergy strategy and policies to improve the cost competitiveness of biomass briquettes as a firewood replacement. This may include the VAT exemption for briquettes (to be made zero-rated) and financial incentives for the importation of production equipment (as applied to solar and wind technologies).

The supply issue is found as a weakness for the substitution. It includes the quantity and continuity of briquette supply, the production process, and handling. Fetching a sufficient amount of certain raw materials, such as sawdust and coffee husks, is problematic. Meanwhile, for abundant feedstock such as bagasse, the drying process remains heavily reliant on sun-drying. It is debatable whether briquettes are easier to handle than firewood. On the one hand, firewood needs more space to season; a large amount of firewood should be stored under a shed in the factory’s vicinity for up to six months, whereas briquettes are more compact and require less space for storage. Briquettes, on the other hand, are made of residues that can disintegrate if the environment is not conducive to their physical properties. The tea-growing regions are typically wet, which is not ideal for briquettes.

The lack of awareness and knowledge is likely to cause a slow adoption process. Improving the awareness and knowledge level both in the tea and briquette sectors supposedly can expedite the transition. This includes the awareness of existing technical standards adopted by KEBS, which should be widely communicated to all stakeholders. Establishing a quality assurance system for biomass briquettes will increase the tea factories’ confidence in incorporating briquettes into their operations. More organized product testing and certification can be introduced. Additionally, a continuous effort to develop more skilled human resources is a prerequisite to expanding the staged cofiring strategy.

The experts had different views regarding the readiness and willingness of the tea factories to switch to biomass briquettes. On the one hand, a group of experts considered that there is no urgency to switch as firewood is still available and cheaper than briquettes. Partially replacing firewood means they have to change some processes to accommodate the inclusion of briquettes. This will influence the boiler operation, handling, storage, and, most importantly, the costs. On the other hand, the remaining experts were convinced that the tea factories were ready to cofire and that shifting from firewood was inevitable. A staged cofiring can alleviate the burden of incremental costs associated with cofiring. The increasing number of factories that participate in the cofiring initiative can be seen as an indication that the willingness to transition is more a driver than a barrier.

4.3. Limitations

The findings of this article confirm the results of a previous study regarding barriers to using briquettes [

13,

14], although both studies did not specifically discuss the use of briquettes in the tea industry. Despite the best efforts to ensure the validity and reliability of the findings, some limitations might lead to inaccuracies in the results concluded in this study. This study was highly reliant on secondary data, including the RPR values, that is scarce in Kenya. The cost analysis conducted in this study did not take into account factors other than the product price. Overall, the outcomes of this work should be regarded as preliminary results that must be further refined as more data are incorporated.

5. Conclusions

The tea industry in Kenya could be a prime target for a big energy transition away from firewood and towards biomass briquettes, considering the high value of tea as an export commodity and the high energy demand in its production. Trifold objectives to improve the tea production process, utilize renewable energy, as well as to conserve the forests would be a strategic move. On the supply side, briquette production capacity can still increase if more generated residues are optimally utilized. This can be accomplished by deploying a more efficient manufacturing process, such as mechanical drying, or, in the long run, by using residues that are currently underutilized.

This study revealed several factors that positively influence the substitution. The main drivers include firewood scarcity, biomass resource availability, and external push from development organizations to integrate briquettes through cofiring. The study also concluded the main barriers to substitution are the cost competitiveness, insufficient and non-continuous supply of briquettes, as well as the still lacking awareness and knowledge regarding briquette technology.

The combined SWOT/PESTEL framework worked well in identifying the drivers and barriers factors of an energy transition effort. Defining the system boundary is important to determine the internal and external factors. However, sometimes one factor cannot be fully attributed to only one category, and it may relate to the others. Such a correlation was not part of this paper, thus offering future research potential. The use of primary data in terms of RPR, CV, briquette production capacity, and prices would be beneficial for conducting feasibility studies. A field study on RPR values in Kenya will be valuable to obtain a more accurate picture of residues characteristics specific to the country.

This study has identified the main drivers and barriers to firewood substitution with biomass briquettes in a broad sense. Further research efforts can be further pursued on this topic. These include implementing a comprehensive monitoring system in the tea factories with cofiring to allow for empirical assessment of the energy use, a cost-benefit analysis of the substitution, and case studies on briquette factories supplying to tea factories to show the feasibility of the substitution.