Preparation and Photoelectric Properties of C-LaFeO3 Composites

Abstract

:1. Introduction

2. Experiment

2.1. Materials and Methodology

2.2. Synthesis of C-LaFeO3 Nanocomposites

2.3. Photocatalytic Measurements

2.4. Electrochemical Measurement

3. Results and Discussion

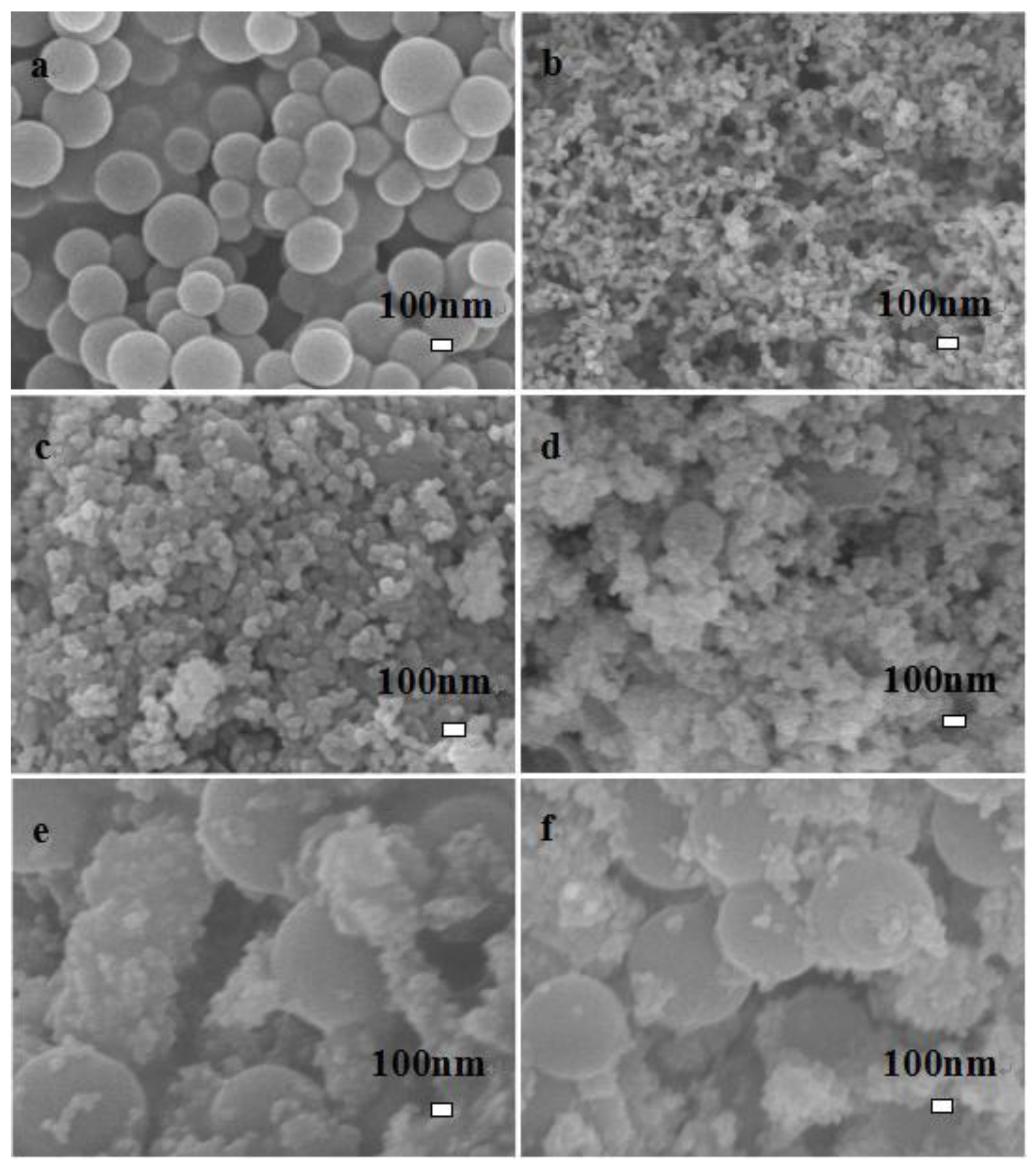

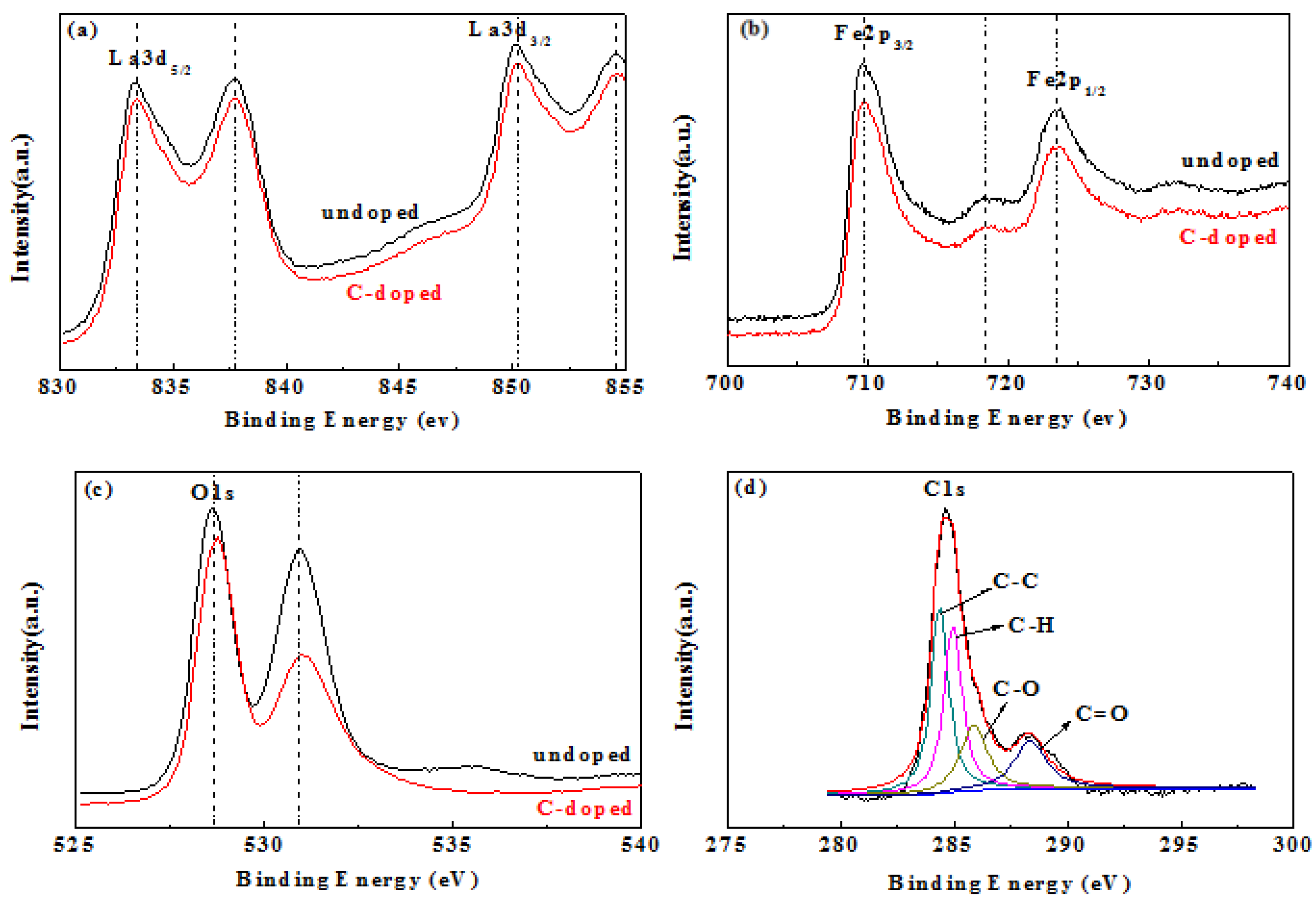

3.1. Structure and Morphology

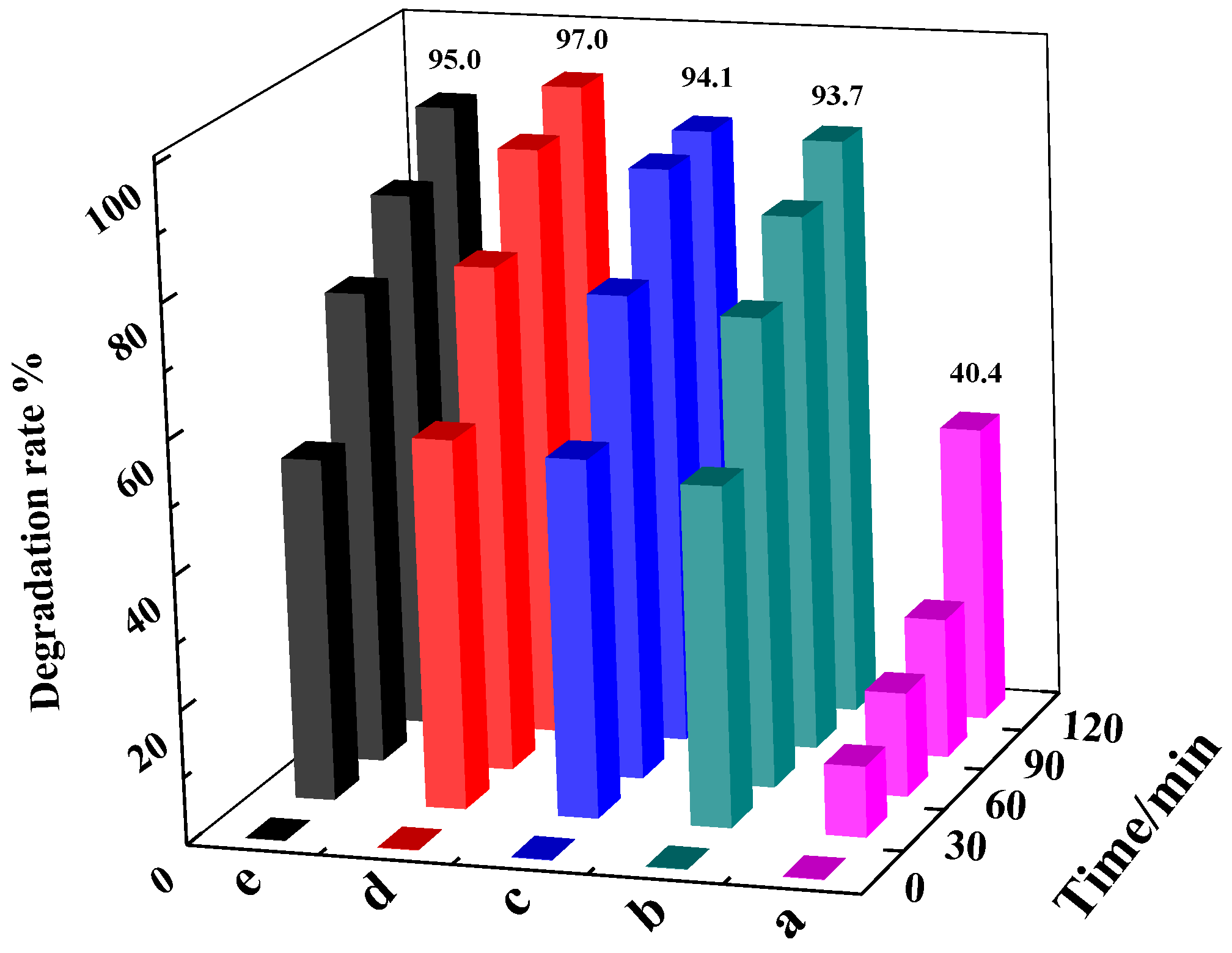

3.2. Photocatalytic Activity

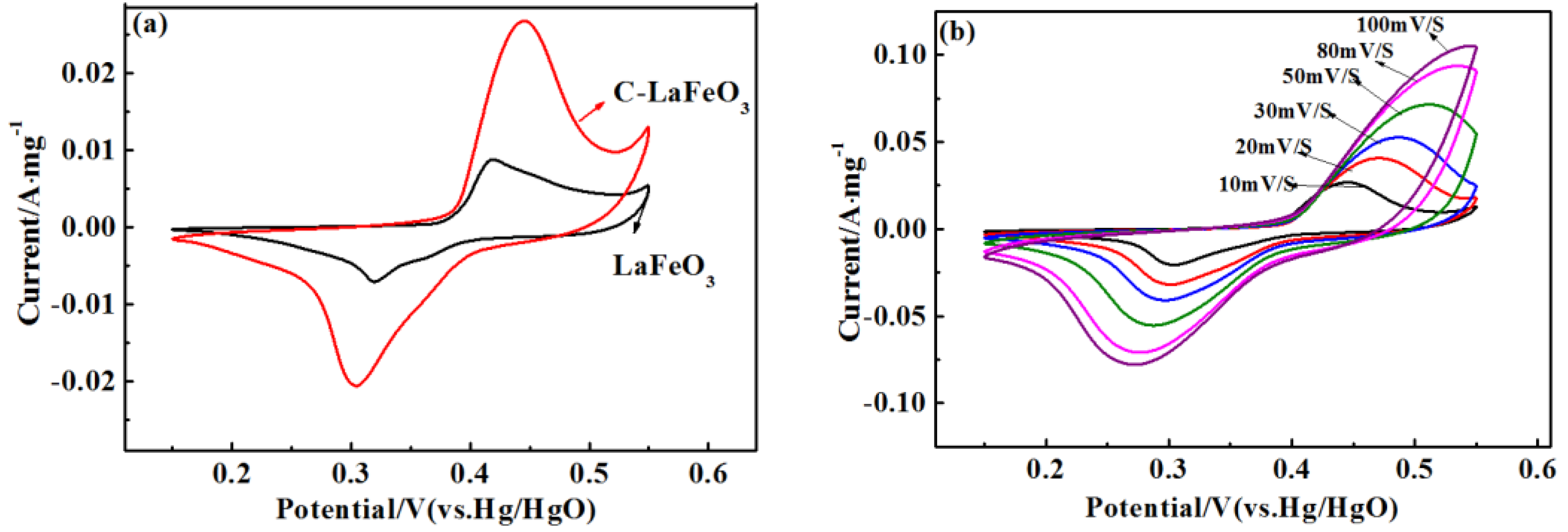

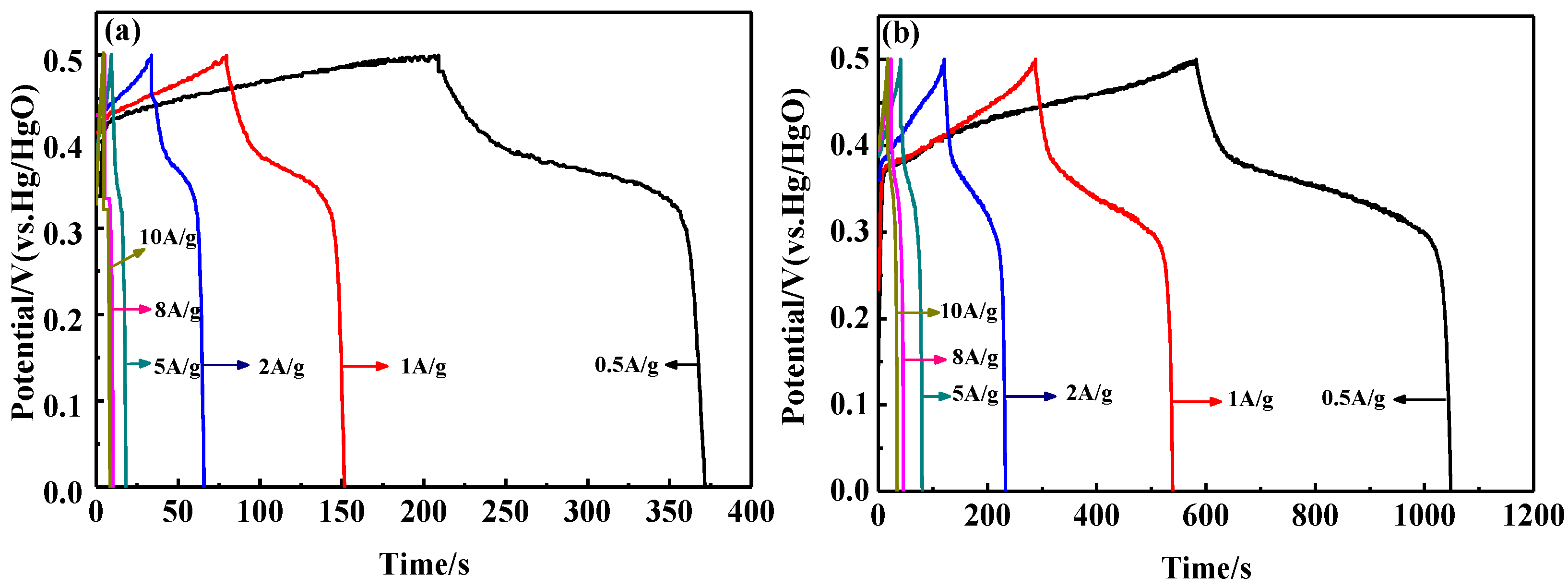

3.3. Electrochemical Performance

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, X.M.; Shang, Y.Y.; Liu, L.B.; Nie, W.; Fu, F. AgCl/Ag/LaFeO3 heterojunction with a prolonged charge lifetime and enhanced visible light catalytic property. J. Phys. Chem. Solids 2019, 127, 186–193. [Google Scholar] [CrossRef]

- Chen, Z.; Fan, T.; Zhang, Q.; He, J.W.; Fan, H.Q.; Sun, Y.F.; Yi, X.D.; Li, J.H. Interface engineering: Surface hydrophilic regulation of LaFeO3 towards enhanced visible light photocatalytic hydrogen evolution. J. Colloid Interface Sci. 2019, 536, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Humayun, M.; Qu, Y.; Raziq, F.; Yan, R.; Li, Z.J.; Zhang, X.L.; Jing, L.Q. Exceptional Visible-Light Activities of TiO2-Coupled N-Doped Porous Perovskite LaFeO3 for 2,4-Dichlorophenol Decomposition and CO2 Conversion. Environ. Sci. Technol. 2016, 50, 13600–13610. [Google Scholar] [CrossRef]

- Humayun, M.; Sun, N.; Raziq, F.; Zhang, X.L.; Yan, R.; Li, Z.J.; Qu, Y.; Jing, L.Q. Synthesis of ZnO/Bi-doped porous LaFeO3 nanocomposites as highly effiffifficient nano-photocatalysts dependent on the enhanced utilization of visible-light-excited electrons. Appl. Catal. B Environ. 2018, 231, 23–33. [Google Scholar] [CrossRef]

- Zhou, Y.J.; Lu, Z.; Li, J.W.; Xu, S.F.; Xu, D.; Wei, B. The electronic properties and structural stability of LaFeO3 oxide by niobium doping: A density functional theory study. Int. J. Hydrogen Energ. 2021, 46, 9193–9198. [Google Scholar] [CrossRef]

- Li, X.Y.; Li, Z.S.; Lu, C.Q.; Li, D.Y.; Li, Z.Q.; Gao, J.; Wei, J.L.; Li, K.Z. Enhanced performance of LaFeO3 oxygen carriers by NiO for chemical looping partial oxidation of methane. Fuel Process. Technol. 2022, 236, 107396. [Google Scholar] [CrossRef]

- Kumar, A.; Chandel, M.; Sharma, A.; Thakur, M.; Kumar, A.; Pathania, D.; Singh, L. Robust visible light active PANI/LaFeO3/CoFe2O4 ternary heterojunction for the photo-degradation and mineralization of pharmaceutical effluent: Clozapine. J. Environ. Chem. Eng. 2021, 9, 106159. [Google Scholar] [CrossRef]

- Iervolino, G.; Vaiano, V.; Sannino, D.; Rizzo, L.; Ciambelli, P. Production of hydrogen from glucose by LaFeO3 based photocatalytic process during water treatment. Int. J. Hydrogen Energ. 2016, 41, 959–966. [Google Scholar] [CrossRef]

- Li, M.; Liu, Z.W.; Wang, F.; Xuan, J.J. The inflfluence of the type of N dopping on the performance of bifunctional N-doped ordered mesoporous carbon electrocatalysts in oxygen reduction and evolution reaction. J. Energy Chem. 2017, 26, 422–427. [Google Scholar] [CrossRef] [Green Version]

- Chandel, M.; Thakur, M.; Sharma, A.; Pathania, D.; Kumar, A.; Singh, L. Chlorophyll sensitized (BiO)2CO3/ CdWO4/rGO nano-hybrid assembly for solar assisted photo-degradation of chlorzoxazone. Chemosphere 2022, 305, 135472. [Google Scholar] [CrossRef]

- Wang, Q.J.; Tan, Q.H.; Liu, Y.K. Enhanced ferromagnetism in N-doped BiFeO3: A first-principles prediction. J. Alloy. Compd. 2015, 644, 30–39. [Google Scholar] [CrossRef]

- Li, X.Z.; Shi, H.Y.; Yan, X.Y.; Zuo, S.X.; Zhang, Y.Y.; Chen, Q.; Yao, C.; Ni, C.Y. Rational construction of direct Z-scheme doped perovskite/palygorskite nanocatalyst for photo-SCR removal of NO: Insight into the effect of Ce incorporation. J. Catal. 2019, 369, 190–200. [Google Scholar] [CrossRef]

- Li, Z.S.; Lv, L.; Wang, J.S.; Ao, X.; Ruan, Y.J.; Zha, D.C.; Hong, G.; Wu, Q.H.; Lan, Y.C.; Wang, C.D.; et al. Engineering phosphorus-doped LaFeO3-δ perovskite oxide as robust bifunctional oxygen electrocatalysts in alkaline solutions. Nano Energy 2018, 47, 199–209. [Google Scholar] [CrossRef]

- Ma, Q.L.; Zhu, J.J.; Gleisner, R.; Yang, R.D.; Zhu, J.Y. Valorization of Wheat Straw Using a Recyclable Hydrotrope at Low Temperatures (≤90 °C). ACS Sustain. Chem. Eng. 2018, 6, 14480–14489. [Google Scholar] [CrossRef]

- Li, X.Z.; Shi, H.Y.; Zhu, W.; Zuo, S.X.; Lu, X.W.; Luo, S.P.; Li, Z.Y.; Yao, C.; Chen, Y.S. Nanocomposite LaFe1−xNixO3 /Palygorskite catalyst for photo-assisted reduction of NOx: Effect of Ni doping. Appl. Catal. B Environ. 2018, 231, 92–100. [Google Scholar] [CrossRef]

- Pan, F.; Zhang, W.D.; Ferronato, C.; Valverde, J.L.; Giroir-Fendler, A. Boosting propene oxidation activity over LaFeO3 perovskite catalysts by cobalt substitution. Appl. Catal. A Gen. 2022, 643, 118779. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Thakur, M.; Pathania, D.; Sharma, A. Fabrication of high visible light active LaFeO3/Cl-g-C3N4/RGO heterojunction for solar assisted photo-degradation of aceclofenac. J. Environ. Chem. Eng. 2022, 10, 108098. [Google Scholar] [CrossRef]

- Ji, F.; Li, J.; Cui, X.L.; Liu, J.; Bing, X.M.; Song, P. Hierarchical C-doped BiPO4/ZnCoAl-LDO hybrid with enhanced photocatalytic activity for organic pollutants degradation. Appl. Clay Sci. 2018, 162, 182–191. [Google Scholar] [CrossRef]

- Duan, Y.W.; Chen, X.W.; Zhang, X.X.; Xiang, W.; Wu, C.F. Inflfluence of carbon source on the anatase and brookite mixed phase of the C-doped TiO2 nanoparticles and their photocatalytic activity. Solid State Sci. 2018, 86, 12–18. [Google Scholar] [CrossRef]

- Kumar, A.; Pathania, D.; Gupta, N.; Raj, P.; Sharma, A. Photo-degradation of noxious pollutants from water system using Cornulaca monacantha stem supported ZnFe2O4 magnetic bio-nanocomposite. Sustain. Chem. Pharm. 2020, 18, 100290. [Google Scholar] [CrossRef]

- Wang, W.; Huang, R.J.; Dai, H.L.; Shan, Y.; Zhao, Y.Q.; Guo, S.B.; Huang, C.J.; Li, L.F. Tunable near-zero thermal expansion in the C-doped La(Fe, Si)13 compounds at cryogenic temperatures. Mater. Lett. 2019, 237, 26–28. [Google Scholar] [CrossRef]

- Liu, W.; Li, X.Z.; Chu, X.N.; Zuo, S.X.; Gao, B.Y.; Yao, C.; Li, Z.Y.; Chen, Y.S. Boosting photocatalytic reduction of nitrate to ammonia enabled by perovskite/biochar nanocomposites with oxygen defects and O-containing functional groups. Chemosphere 2022, 94, 133763. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhang, Y.N.; Liu, C.; Yuan, Z.T.; Yu, X.H.; Zhong, Y.; Zhan, Z.L. Microwave-Assisted Sol-Gel Modification of Al- or C-doped Li4Ti5O12 Samples as Anode Materials for Li-ion Batteries. Int. J. Electrochem. Sci. 2017, 12, 12009–12018. [Google Scholar] [CrossRef]

- Zubenko, D.; Singh, S.; Rosen, B.A. Exsolution of Re-alloy catalysts with enhanced stability for methane dry reforming. Appl. Catal. B Environ. 2017, 209, 711–719. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Wang, L.S.; Ma, Y.T.; Zheng, H.F.; Lin, L.; Zhang, Q.F.; Chen, Y.Z.; Qiu, Y.L.; Peng, D.L. Enhanced Microwave Absorption Properties by Tuning Cation Defificiency of Perovskite Oxides of Two-Dimensional LaFeO3/C Composite in X-Band. ACS Appl. Mater. Int. 2017, 9, 7601–7610. [Google Scholar] [CrossRef]

- Joula, M.H.; Farbod, M. Synthesis of uniform and size-controllable carbon nanospheres by a simple hydrothermal method and fabrication of carbon nanosphere super-hydrophobic surface. Appl. Surf. Sci. 2015, 347, 535–540. [Google Scholar] [CrossRef]

- Yang, J.; Hu, R.S.; Meng, W.W.; Du, Y.F. A novel p-LaFeO3/n-Ag3PO4 heterojunction photocatalyst for phenol degradation under visible light irradiation. Chem. Commun. 2016, 52, 2620–2623. [Google Scholar] [CrossRef]

- Ren, X.; Yang, H.T.; Gen, S.; Zhou, J.; Yang, T.Z.; Zhang, X.Q.; Cheng, Z.H.; Sun, S.H. Controlled growth of LaFeO3 nanoparticles on reduced graphene oxide for highly effiffifficient photocatalysist. Nanoscale 2016, 8, 752–756. [Google Scholar] [CrossRef]

- Wang, K.X.; Niu, H.L.; Chen, J.S.; Song, J.M.; Mao, C.J.; Zhang, S.Y.; Gao, Y.H. Immobilizing LaFeO3 nanoparticles on carbon spheres for enhanced heterogeneous photo-Fenton like performance. Appl. Surf. Sci. 2017, 404, 138–145. [Google Scholar] [CrossRef]

- Cao, E.S.; Yang, Y.Q.; Cui, T.T.; Zhang, Y.J.; Hao, W.T.; Sun, L.; Peng, H.; Deng, X. Effect of synthesis route on electrical and ethanol sensing characteristics for LaFeO3-nanoparticles by citric sol-gel method. Appl. Surf. Sci. 2017, 393, 134–143. [Google Scholar] [CrossRef]

- Deganello, F.; Testa, M.L.; Parola, V.L.; Longo, A.; Tavares, A.C. LaFeO3-based nanopowders prepared by a soft-hard templating approach: The effffect of silica texture. J. Mater. Chem. A 2014, 2, 8438–8447. [Google Scholar] [CrossRef]

- Li, Z.X.; Shen, Y.; Yang, C.; Lei, Y.C.; Guan, Y.H.; Lin, Y.H.; Liu, D.B.; Nan, C.W. Signifificant enhancement in the visible light photocatalytic properties of BiFeO3-graphene nanohybrids. J. Mater. Chem. A 2013, 1, 823–829. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Li, M.; Xu, M.; Li, X.; Gao, K. Preparation and Photoelectric Properties of C-LaFeO3 Composites. Sustainability 2023, 15, 715. https://doi.org/10.3390/su15010715

Li S, Li M, Xu M, Li X, Gao K. Preparation and Photoelectric Properties of C-LaFeO3 Composites. Sustainability. 2023; 15(1):715. https://doi.org/10.3390/su15010715

Chicago/Turabian StyleLi, Shudan, Man Li, Mingjian Xu, Xueying Li, and Kun Gao. 2023. "Preparation and Photoelectric Properties of C-LaFeO3 Composites" Sustainability 15, no. 1: 715. https://doi.org/10.3390/su15010715