Effects of High Temperature Treatments on Strength and Failure Behavior of Sandstone under Dynamic Impact Loads

Abstract

1. Introduction

2. Materials and Methods

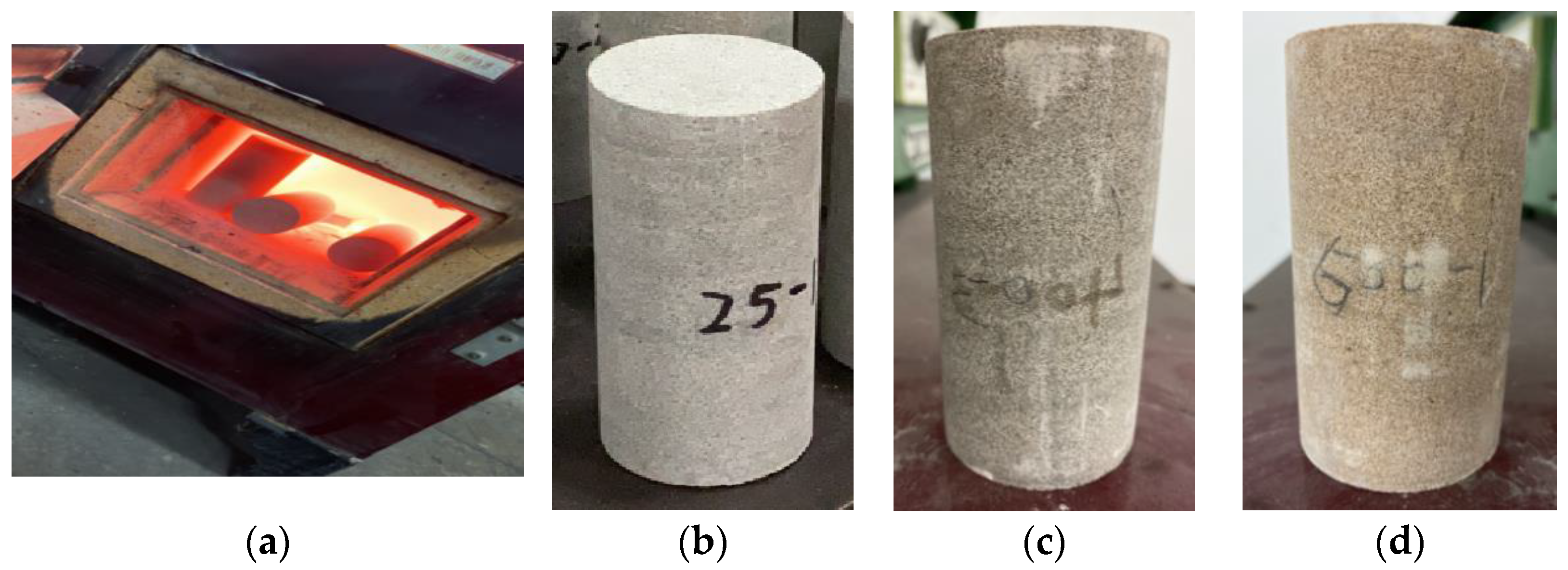

2.1. Specimens Preparation

2.2. Testing Procedures

2.3. Statistical Analysis Methods

3. Results and Analysis

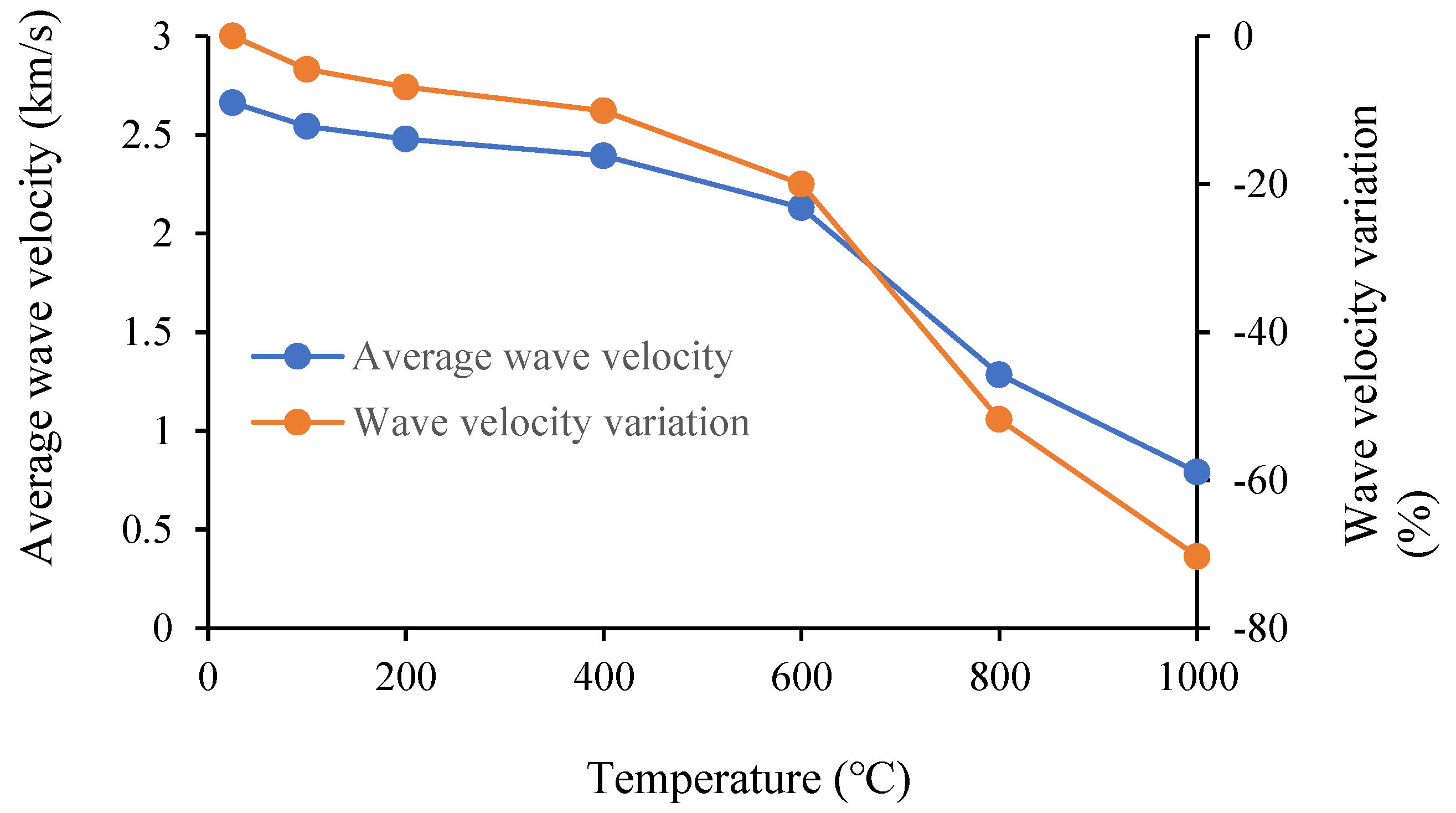

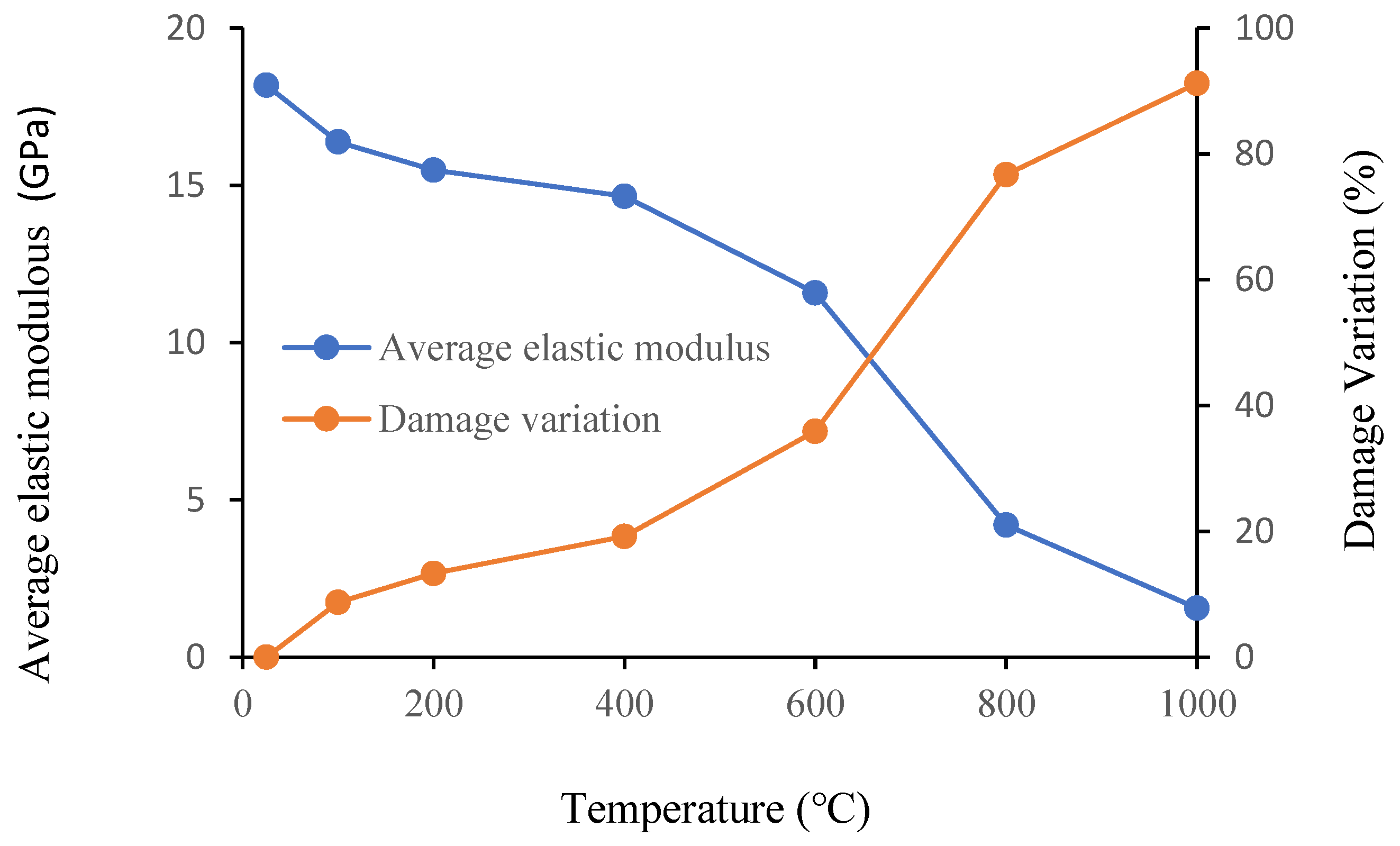

3.1. Physical and Damage Effects

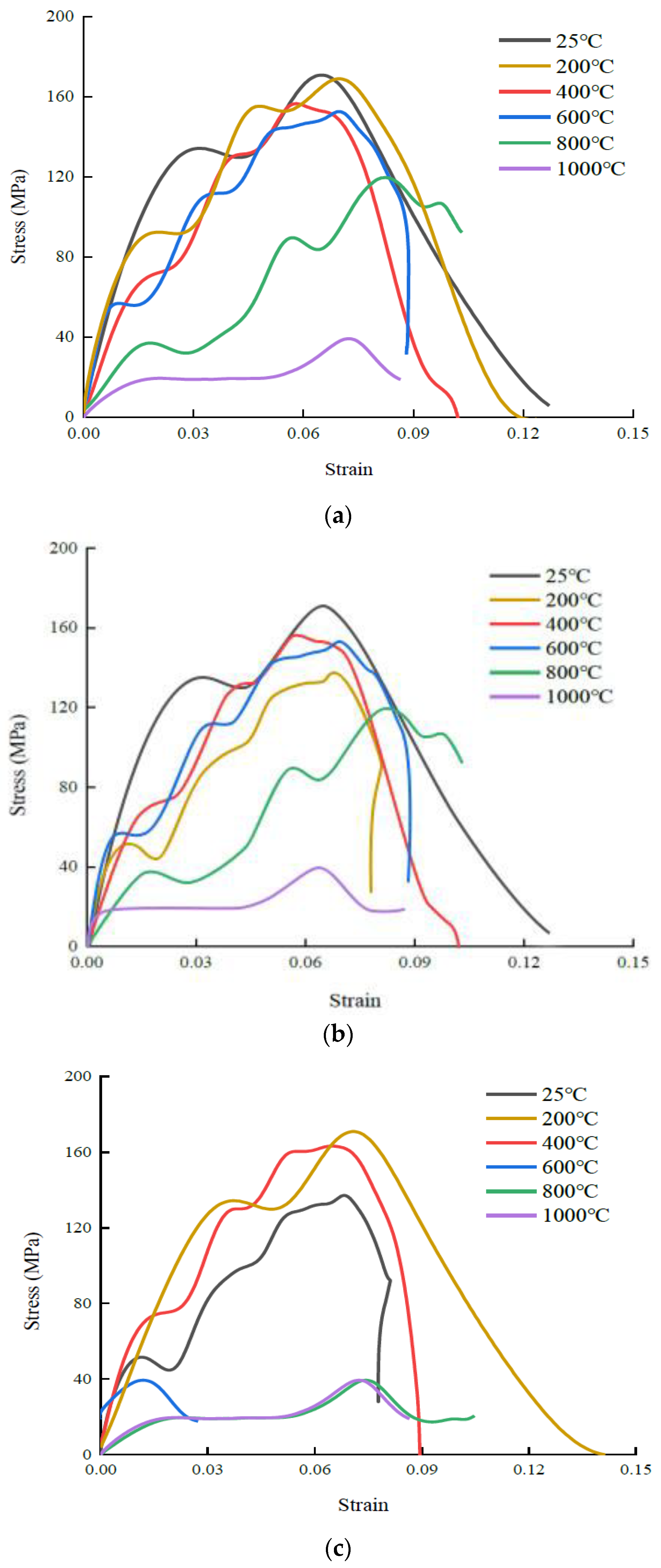

3.2. SHPB Testing Results

4. Discussions

5. Conclusions

- With the increase of heating temperature, the average density, average wave velocity, and average elastic modulus all showed a decreasing trend and the highest decreasing rates occurred at temperature between 600 °C and 800 °C.

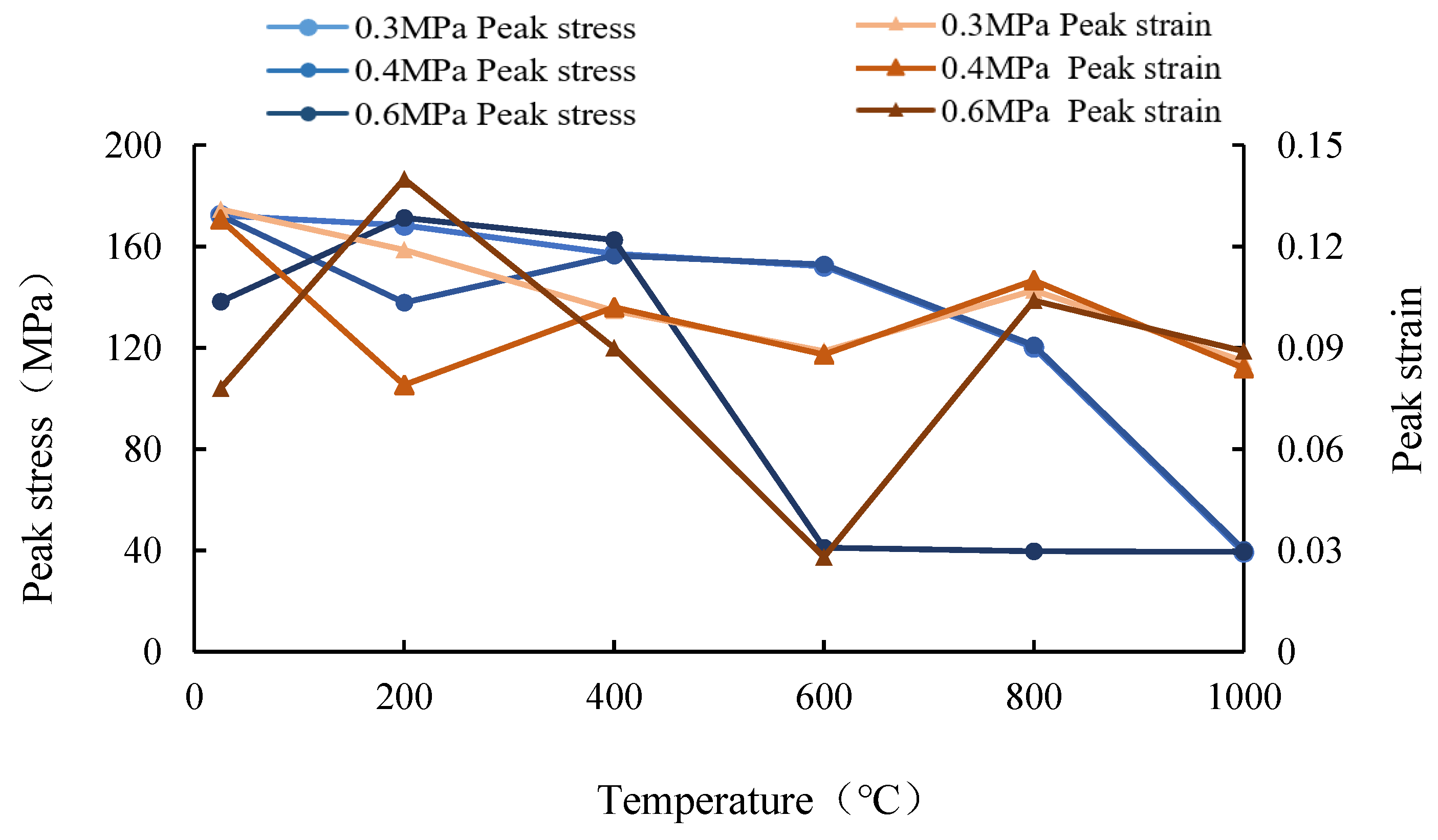

- The temperature treatment and impact loads had obvious effects on dynamic mechanical properties and damage degree of the specimens. Under the action of high temperature and impact load, the average peak stress and modulus decreased with increase of temperature, and peak stress decreased fastest in the range from 600 °C to 1000 °C.

- It was suggested that when the temperature was below 600 °C, the separation of adsorbed water and interlayer water as well as thermal expansion of clay minerals mainly occurred. The microcracks generated led to the slight deterioration of the specimens. When the temperature was above 600 °C, a large number of micro internal cracks were generated, leading to seriously deteriorated and decreased bearing capacities.

- The obtained results provided a certain theoretical basis for deep mine exploitation, especially for the mines with high temperature.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferrero, A.M. The shear strength of reinforced rock joints. Int. J. Rock Mech. Min. Sci. 1995, 32, 595–605. [Google Scholar] [CrossRef]

- Hutchinson, J.D.; Deiderichs, M.S. Cablebolting in Underground Mines; BiTech: Richmond, BC, Canada, 1996. [Google Scholar]

- Bieniawski, Z.T. Mechanism of brittle fracture of rock: Part II—Experimental studies. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 407–423. [Google Scholar] [CrossRef]

- Li, D.; Li, Y.; Chen, J.; Masoumi, H. An analytical model for axial performance of rock bolts under constant confining pressure based on continuously yielding criterion. Tunn. Undergr. Space Technol. 2021, 113, 103955. [Google Scholar] [CrossRef]

- Hoek, E.; Bieniawski, Z.T. Brittle fracture propagation in rock under compression. Int. J. Fract. Mech. 1965, 1, 137–155. [Google Scholar] [CrossRef]

- Li, X.S.; Li, Y.C.; Wu, S.S. Experimental Investigation into the Influences of Weathering on the Mechanical Properties of Sedimentary Rocks. Geofluids 2020, 2020, 12. [Google Scholar] [CrossRef]

- Basu, A.; Celestino, T.B.; Bortolucci, A.A. Evaluation of rock mechanical behaviors under uniaxial compression with reference to assessed weathering grades. Rock Mech. Rock Eng. 2009, 42, 73–93. [Google Scholar] [CrossRef]

- Li, D.Y.; Wong, L.N.Y. The Brazilian Disc Test for Rock Mechanics Applications: Review and New Insights. Rock Mech. Rock Eng. 2013, 46, 269–287. [Google Scholar] [CrossRef]

- Li, D.; Shirani Faradonbeh, R.; Lv, A.; Wang, X.; Roshan, H. A data-driven field-scale approach to estimate the permeability of fractured rocks. Int. J. Min. Reclam. Environ. 2022, 36, 671–687. [Google Scholar] [CrossRef]

- Wu, S.S.; Ramandi, H.L.; Chen, H.H.; Crosky, A.; Hagan, P.; Saydam, S. Mineralogically influenced stress corrosion cracking of rockbolts and cable bolts in underground mines. Int. J. Rock Mech. Min. Sci. 2019, 119, 109–116. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, X.; Li, J.; Wang, Z. Investigation for Influences of Seepage on Mechanical Properties of Rocks Using Acoustic Emission Technique. Geofluids 2020, 2020, 6693920. [Google Scholar] [CrossRef]

- Li, D.; Cai, M.; Masoumi, H. A constitutive model for modified cable bolts exhibiting cone shaped failure mode. Int. J. Rock Mech. Min. Sci. 2021, 145, 104855. [Google Scholar] [CrossRef]

- Li, X.; Li, Q.; Hu, Y.; Teng, L.; Yang, S. Evolution characteristics of mining fissures in overlying strata of stope after converting from open-pit to underground. Arab. J. Geosci. 2021, 14, 2795. [Google Scholar] [CrossRef]

- Chen, J.; Zeng, B.; Liu, L.; Tao, K.; Zhao, H.; Zhang, C.; Zhang, J.; Li, D. Investigating the anchorage performance of full-grouted anchor bolts with a modified numerical simulation method. Eng. Fail. Anal. 2022, 141, 106640. [Google Scholar] [CrossRef]

- Wu, S.S.; Li, J.P.; Guo, J.P.; Shi, G.B.; Gu, Q.H.; Lu, C.W. Stress corrosion cracking fracture mechanism of cold-drawn high-carbon cable bolts. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2020, 769, 10. [Google Scholar] [CrossRef]

- Tapponnier, P.; Brace, W.F. Development of stress-induced microcracks in Westerly Granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1976, 13, 103–112. [Google Scholar] [CrossRef]

- Kang, H.; Wu, Y.; Gao, F.; Lin, J.; Jiang, P. Fracture characteristics in rock bolts in underground coal mine roadways. Int. J. Rock Mech. Min. Sci. 2013, 62, 105–112. [Google Scholar] [CrossRef]

- Wei, S.J.; Yang, Y.S.; Su, C.D.; Cardosh, S.R.; Wang, H. Experimental Study of the Effect of High Temperature on the Mechanical Properties of Coarse Sandstone. Appl. Sci. 2019, 9, 2424. [Google Scholar] [CrossRef]

- Dong, L.-j.; Tao, Q.; Hu, Q.-c. Influence of temperature on acoustic emission source location accuracy in underground structure. Trans. Nonferrous Met. Soc. China 2021, 31, 2468–2478. [Google Scholar] [CrossRef]

- Chen, J.; Liu, L.; Zeng, B.; Tao, K.; Zhang, C.; Zhao, H.; Li, D.; Zhang, J. A constitutive model to reveal the anchorage mechanism of fully bonded bolts. Rock Mech. Rock Eng. 2023, 56, 1–19. [Google Scholar] [CrossRef]

- Windsor, C.R. Rock reinforcing systems. Int. J. Rock Mech. Min. Sci. 1997, 34, 919–951. [Google Scholar] [CrossRef]

- He, Q.; Li, Y.; Li, D.; Zhang, C. Microcrack fracturing of coal specimens under quasi-static combined compression-shear loading. J. Rock Mech. Geotech. Eng. 2020, 12, 1014–1026. [Google Scholar] [CrossRef]

- Gong, B.; Jiang, Y.J.; Yan, P.; Zhang, S.H. Discrete element numerical simulation of mechanical properties of methane hydrate-bearing specimen considering deposit angles. J. Nat. Gas Sci. Eng. 2020, 76, 17. [Google Scholar] [CrossRef]

- David, C.; Menéndez, B.; Darot, M.J.I.J.o.R.M.; Sciences, M. Influence of stress-induced and thermal cracking on physical properties and microstructure of La Peyratte granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1999, 36, 433–448. [Google Scholar] [CrossRef]

- Rosenberg, Z.; Dawicke, D.; Strader, E.; Bless, S.J. A new technique for heating specimens in split-Hopkinson-bar experiments using induction-coil heaters. Exp. Mech. 1986, 26, 275–278. [Google Scholar] [CrossRef]

- Mardoukhi, A.; Mardoukhi, Y.; Hokka, M.; Kuokkala, V.T.J.R.M.; Engineering, R. Effects of Test Temperature and Low Temperature Thermal Cycling on the Dynamic Tensile Strength of Granitic Rocks. Rock Mech. Rock Eng. 2021, 54, 443–454. [Google Scholar] [CrossRef]

- Chiddister, J.L.; Malvern, L.E.J.E.M. Compression-impact testing of Aluminum at elevated temperatures. Exp. Mech. 1963, 3, 81–90. [Google Scholar] [CrossRef]

- Price, D.G.; Knill, J.L. A study of the tensile strength of isotropic rocks. In Proceedings of the 1st ISRM Congress, Lisbon, Portugal, 25 September–1 October 1966. [Google Scholar]

- Kumar, A.J.G. The Effect of Stress Rate and Temperature on the Strength of Basalt and Granite. Geophysics 1968, 33, 501–510. [Google Scholar] [CrossRef]

- Friedman, M.; Perkins, R.; Green, S. Observation of brittle-deformation features at the maximum stress of westerly granite and solenhofen limestone. Int. J. Rock Mech. Min. Sci. 1976, 33, 177–186. [Google Scholar] [CrossRef]

- Li, X.; Peng, J.; Xie, Y.; Li, Q.; Zhou, T.; Wang, J.; Zheng, W. Influence of High-Temperature Treatment on Strength and Failure Behaviors of a Quartz-Rich Sandstone under True Triaxial Condition. Lithosphere 2022, 2022, 3086647. [Google Scholar] [CrossRef]

- Wu, G.; Wang, Y.; Swift, G.; Chen, J. Laboratory Investigation of the Effects of Temperature on the Mechanical Properties of Sandstone. Geotech. Geol. Eng. 2013, 31, 809–816. [Google Scholar] [CrossRef]

- Ding, Q.L.; Feng, J.; Mao, X.; Ma, D.; Yu, B.; Song, S. Experimental Investigation of the Mechanical Behavior in Unloading Conditions of Sandstone After High-Temperature Treatment. Rock Mech. Rock Eng. 2016, 49, 2641–2653. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, W.; Mao, X. Experimental research on mechanical properties of sandstone at high temperature. J. Min. Saf. Eng. 2007, 24, 293–297. [Google Scholar]

| Bar Diameter | Incident Bar Length | Transmission Bar Length | Poisson’s Ratio | Elastic Modulus | Longitudinal Wave Velocity |

|---|---|---|---|---|---|

| 100 mm | 5000 (mm) | 3000 (mm) | 0.28 | 210 (GPa) | 4910 (m/s) |

| Specimen ID | Mass (g) | Diameter (mm) | Height (mm) | Density (g/cm3) | Average Density (g/cm3) | Temperature (°C) |

|---|---|---|---|---|---|---|

| 25-1 25-2 25-3 | 469.82 469.69 464.67 | 48.34 48.65 48.88 | 97.34 98.74 98.65 | 2.630 2.560 2.510 | 2.567 | 25 |

| 100-1 100-2 100-3 | 469.07 469.60 469.29 | 49.80 47.79 48.22 | 99.30 99.11 98.45 | 2.425 2.640 2.610 | 2.558 | 100 |

| 200-1 200-2 200-3 | 465.24 467.52 460.97 | 47.88 48.89 49.11 | 98.34 98.74 97.99 | 2.627 2.522 2.482 | 2.543 | 200 |

| 400-1 400-2 400-3 | 464.62 465.18 466.94 | 48.35 48.66 48.98 | 99.13 97.65 98.55 | 2.551 2.562 2.514 | 2.542 | 400 |

| 600-1 600-2 600-3 | 467.32 468.11 466.49 | 48.32 49.32 49.74 | 96.36 97.49 99.10 | 2.645 2.514 2.422 | 2.527 | 600 |

| 800-1 800-2 800-3 | 458.97 468.44 469.92 | 48.99 47.74 49.95 | 99.77 98.12 98.60 | 2.440 2.668 2.432 | 2.513 | 800 |

| 1000-1 1000-2 1000-3 | 468.02 469.57 469.59 | 50.11 49.55 49.07 | 97.82 98.43 98.60 | 2.425 2.473 2.517 | 2.472 | 1000 |

| Specimen ID | Wave Velocity (km/s) | Average (km/s) | Variation (%) | Elastic Modulus (GPa) | Average (GPa) | Damage Variation (%) |

|---|---|---|---|---|---|---|

| 25-1 25-2 25-3 | 2.666 2.624 2.695 | 2.662 | 0 | 18.69 17.63 18.23 | 18.18 | 0 |

| 100-1 100-2 100-3 | 2.645 2.439 2.545 | 2.543 | −4.5 | 18.50 14.96 15.69 | 16.38 | 8.7 |

| 200-1 200-2 200-3 | 2.439 2.563 2.433 | 2.478 | −6.9 | 14.51 17.53 14.40 | 15.48 | 13.3 |

| 400-1 400-2 400-3 | 2.398 2.411 2.369 | 2.393 | −10.1 | 13.94 15.35 14.65 | 14.65 | 19.2 |

| 600-1 600-2 600-3 | 1.898 2.242 2.252 | 2.131 | −20.0 | 9.46 12.68 12.59 | 11.58 | 35.9 |

| 800-1 800-2 800-3 | 1.263 1.295 1.295 | 1.284 | −51.8 | 4.07 4.30 4.22 | 4.20 | 76.7 |

| 1000-1 1000-2 1000-3 | 0.745 0.904 0.724 | 0.791 | −70.3 | 1.35 2.02 1.32 | 1.56 | 91.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Lei, Y.; Yang, Y.; Cheng, P.; Wang, Z.; Wu, S. Effects of High Temperature Treatments on Strength and Failure Behavior of Sandstone under Dynamic Impact Loads. Sustainability 2023, 15, 794. https://doi.org/10.3390/su15010794

Guo J, Lei Y, Yang Y, Cheng P, Wang Z, Wu S. Effects of High Temperature Treatments on Strength and Failure Behavior of Sandstone under Dynamic Impact Loads. Sustainability. 2023; 15(1):794. https://doi.org/10.3390/su15010794

Chicago/Turabian StyleGuo, Jinping, Yanzi Lei, Yanguang Yang, Ping Cheng, Zhao Wang, and Saisai Wu. 2023. "Effects of High Temperature Treatments on Strength and Failure Behavior of Sandstone under Dynamic Impact Loads" Sustainability 15, no. 1: 794. https://doi.org/10.3390/su15010794

APA StyleGuo, J., Lei, Y., Yang, Y., Cheng, P., Wang, Z., & Wu, S. (2023). Effects of High Temperature Treatments on Strength and Failure Behavior of Sandstone under Dynamic Impact Loads. Sustainability, 15(1), 794. https://doi.org/10.3390/su15010794