A Spatial Water Footprint Assessment of Recycled Cotton T-Shirts: Case of Local Impacts in Selected China Provinces

Abstract

:1. Introduction

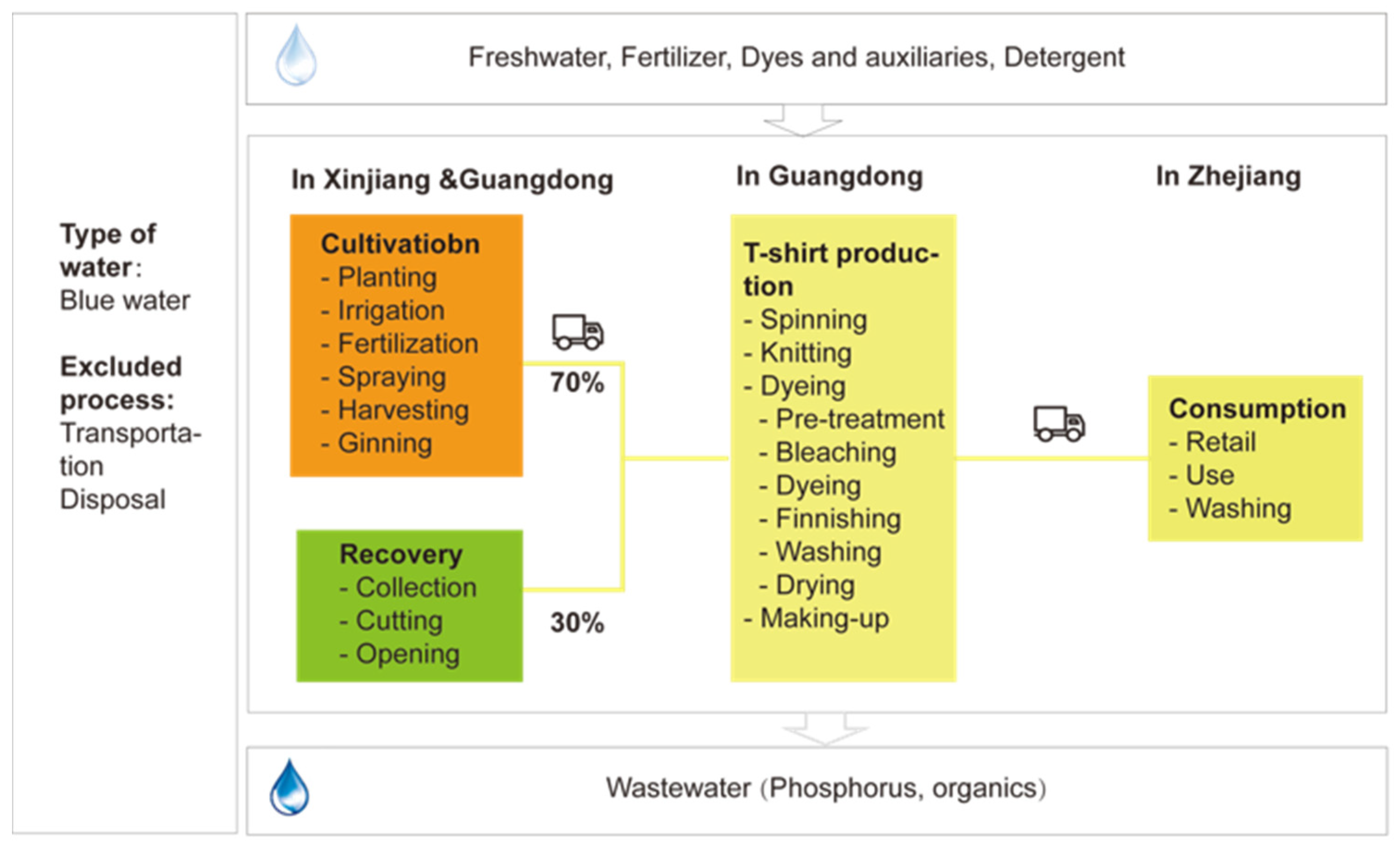

2. Materials and Methods

2.1. Data Collection

2.2. Water-Scarcity Footprint

2.3. Freshwater-Eutrophication Footprint

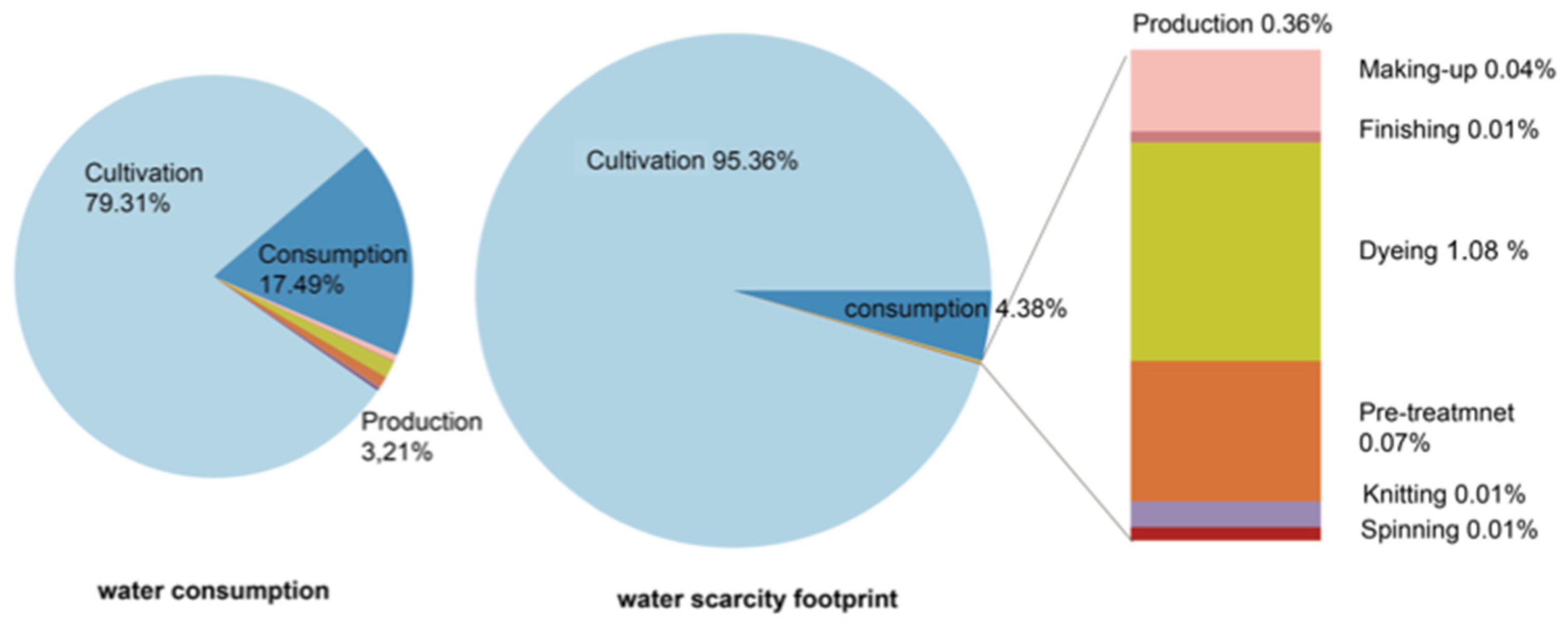

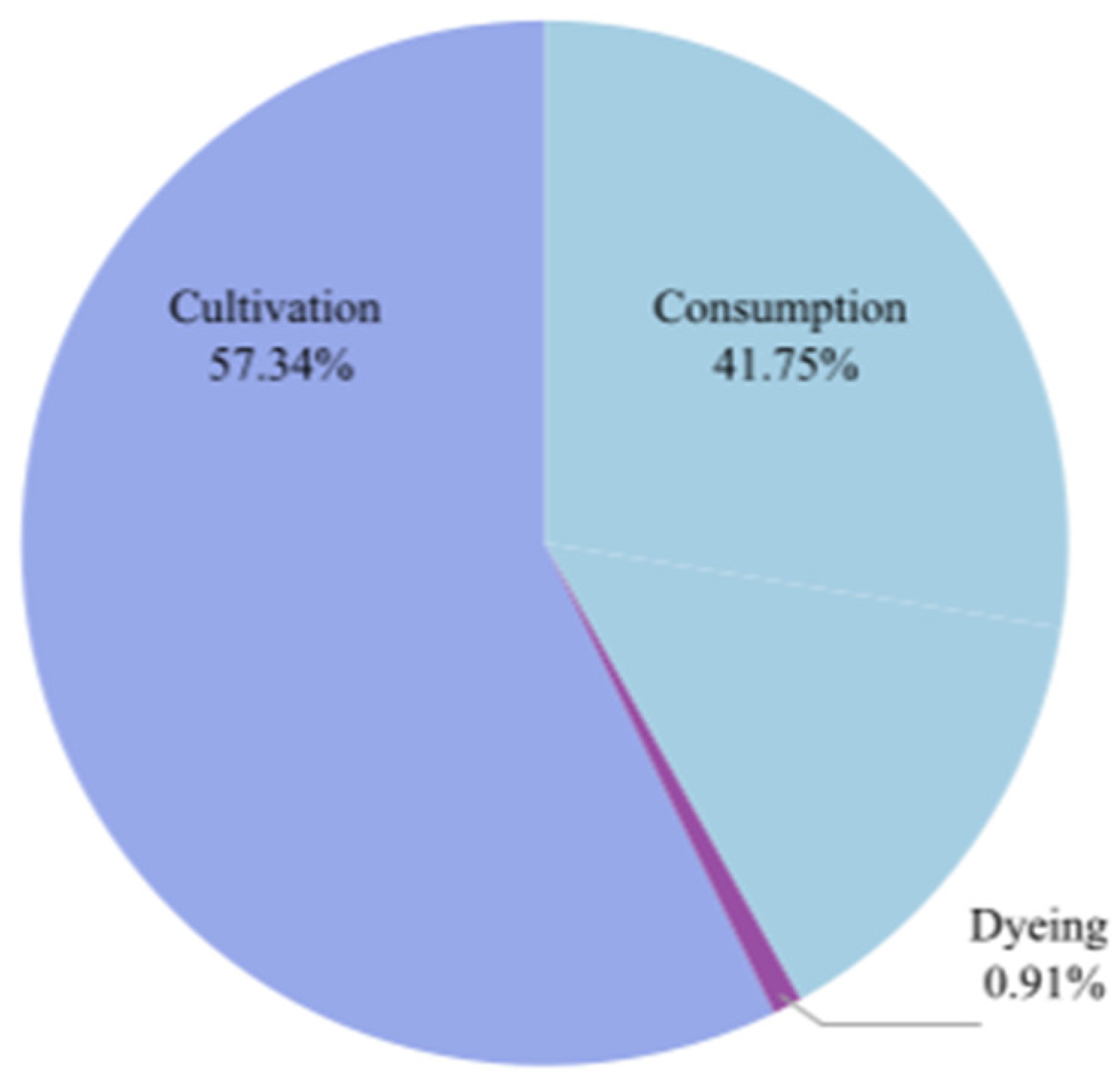

3. Results

Water Inventory Analysis

4. Discussion

4.1. Advantages of a Spatial Water-Footprint Method

4.2. Advantages of Recycling Scenarios

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chapagain, A.; Hoekstra, A.Y.; Savenije, H.H.G.; Gautam, R. The water footprint of cotton consumption. In Value of Water Research Report Series No. 18; Unesco-IHE Institute for Water Education: Delft, The Netherlands, 2005. [Google Scholar]

- Chapagain, A.K.; Hoekstra, A.Y.; Savenije, H.H.G.; Gautam, R. The water footprint of cotton consumption: An assessment of the impact of worldwide consumption of cotton products on the water resources in the cotton producing countries. Ecol. Econ. 2006, 60, 186–203. [Google Scholar] [CrossRef]

- FAO (FAOSTAT). FAOSTAT Database. 2014. Available online: http://www.fao.org/faostat/en/#data/RF (accessed on 1 November 2022).

- NBSC (National Bureau of Statistics of China). China Industry Statistics Yearbook; Chinese Statistics Press: Beijing, China, 2017. (In Chinese) [Google Scholar]

- Ghazinoory, S. Cleaner production in Iran: Necessities and priorities. J. Clean. Prod. 2005, 13, 755–762. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China. Available online: https://data.stats.gov.cn/easyquery.htm?cn=E0103&zb=A0D0Q®=650000&sj=2021 (accessed on 1 November 2022).

- Liu, Y.; Huang, H.; Zhu, L.; Zhang, C.; Ren, F.; Liu, Z. Could the recycled yarns substitute for the virgin cotton yarns: A comparative LCA. Int. J. Life Cycle Assess. 2020, 25, 2050–2062. [Google Scholar] [CrossRef]

- Laudes Foundation. Life Cycle Assessment of Cotton Cultivation Systems—Better Cotton, Conventional Cotton, and Organic Cotton. 2018. Available online: https://www.laudesfoundation.org/en/resources/4332environmentallcareportjune19.pdf (accessed on 1 November 2022).

- Roos, S.; Peters, G.M. Three methods for strategic product toxicity assessment—The case of the cotton T-shirt. Int. J. Life Cycle Assess. 2015, 20, 903–912. [Google Scholar]

- Levi Strauss & CO, 2015. The Life Cycle of a Jeans. Available online: https://www.levistrauss.com/wp-content/uploads/2015/03/Full-LCA-Results-Deck-FINAL.pdf (accessed on 1 November 2022).

- Zhang, Y.; Liu, X.; Xiao, R. Life cycle assessment of cotton T-shirts in China. Int. J. Life Cycle Assess. 2015, 20, 994–1004. [Google Scholar] [CrossRef]

- Keeble, J.J.; Topiol, S.; Berkeley, S. Using indicators to measure sustainability performance at a corporate and project level. J. Bus. Ethics 2003, 44, 149–158. [Google Scholar] [CrossRef]

- Alkaya, E.; Demirer, G.N. Sectoral assessment of the Turkish textile industry for the diffusion of sustainable production approach. J. Text. Inst. 2014, 106, 1212–1225. [Google Scholar] [CrossRef]

- Rajkishore, N.; Tarun, P.; Long, T.N. Sustainability in fashion and textiles: A survey from developing country. In Sustainable Technologies for Fashion and Textiles; Rajkishore, N., Ed.; Woodhead Publishing: Sawston, UK, 2020; pp. 3–30. [Google Scholar]

- Shen, B.; Zheng, J.H.; Chow, P.S.; Chow, K.Y. Perception of fashion sustainability in online community. J. Text. Inst. 2014, 105, 971–979. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Mazzuto, G.; Paciarotti, C. Environmental analysis of a cotton yarn supply chain. J. Clean. Prod. 2014, 82, 154–165. [Google Scholar] [CrossRef]

- Xie, K.; Cheng, F.; Zhao, W.; Xu, L. Micelle dyeing with low liquor ratio for reactive dyes using dialkyl maleic acid ester surfactants. J. Clean. Prod. 2011, 19, 332–336. [Google Scholar] [CrossRef]

- Kan, C.W.; Cheung, H.F.; Chan, Q. A study of plasma-induced ozone treatment on the colour fading of dyed cotton. J. Clean. Prod. 2016, 112, 3514–3524. [Google Scholar] [CrossRef]

- Hussain, T.; Wahab, A. A critical review of the current water conservation practices in textile wet processing. J. Clean. Prod. 2018, 198, 806–819. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Esteve-Turrillas, F.A.; de la Guardia, M. Environmental impact of Recover cotton in textile industry. Resour. Conserv. Recyc. 2017, 116, 107–115. [Google Scholar] [CrossRef]

- Farrant, L.; Olsen, S.I.; Wangel, A. Environmental benefits from reusing clothes. Int. J. Life Cycle Assess. 2010, 15, 726–736. [Google Scholar] [CrossRef]

- Ütebay, B.; Çelik, P.; Çay, A. Effects of cotton textile waste properties on recycled fibre quality. J. Clean. Prod. 2019, 222, 29–35. [Google Scholar] [CrossRef]

- Chapagain, A.K.; Hoekstra, A.Y. The water footprint of coffee and tea consumption in The Netherlands. Ecol. Econ. 2007, 64, 109–118. [Google Scholar] [CrossRef]

- Gerbens-Leenes, W.; Hoekstra, A.Y.; van der Meer, T.H. The water footprint of bioenergy. Proc. Natl. Acad. Sci. USA 2009, 106, 10219–10223. [Google Scholar] [CrossRef] [Green Version]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard; Earthscan: London, UK, 2011; Available online: https://waterfootprint.org/en/resources/publications/water-footprint-assessment-manual/ (accessed on 1 November 2022).

- Mekonnen, M.M.; Hoekstra, A.Y. The green, blue and grey water footprint of crops and derived crop products. Hydrol. Earth Syst. Sci. 2011, 15, 1577–1600. Available online: http://hdl.handle.net/10535/7177 (accessed on 1 November 2022). [CrossRef] [Green Version]

- Mekonnen, M.M.; Hoekstra, A.Y. A global assessment of the water footprint of farm animal products. Ecosystems 2012, 15, 401–415. [Google Scholar] [CrossRef] [Green Version]

- Pfister, S.; Koehler, A.; Hellweg, S. Assessing the environmental impacts of freshwater consumption in LCA. Environ. Sci. Technol. 2009, 43, 4098–4104. [Google Scholar] [CrossRef] [PubMed]

- Ridoutt, B.G.; Pfister, S. A revised approach to water footprinting to make transparent the impacts of consumption and production on global freshwater scarcity. Glob. Environ. Chang. 2010, 20, 113–120. [Google Scholar] [CrossRef]

- Boulay, A.M.; Bare, J.; De Camillis, C.; Döll, P.; Gassert, F.; Gerten, D.; Humbert, S.; Inaba, A.; Itsubo, N.; Lemoine, Y.; et al. Consensus building on the development of a stress-based indicator for LCA-based impact assessment of water consumption: Outcome of the expert workshops. Int. J. Life Cycle Assess. 2015, 20, 577–583. [Google Scholar] [CrossRef]

- ISO 14046:2014; Environmental Management—Water Footprint—Principles, Requirements and Guidelines. International Standard Organization: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/43263.html (accessed on 1 November 2022).

- Mutel, C.; Liao, X.; Patouillard, L.; Bare, J.; Fantke, P.; Frischknecht, R.; Hauschild, M.; Jolliet, O.; Maia de Souza, D.; Laurent, A.; et al. Overview and recommendations for regionalized life cycle impact assessment. J. Life Cycle Assess. 2018, 24, 856–865. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roy, P.O.; Azevedo, L.B.; Margni, M.; van Zelm, R.; Deschênes, L.; Huijbregts, M.A. Characterization factors for terrestrial acidification at the global scale: A systematic analysis of spatial variability and uncertainty. Sci. Total Environ. 2014, 500, 270–276. [Google Scholar] [CrossRef]

- Azevedo, L.B.; Henderson, A.D.; van Zelm, R.; Jolliet, O.; Huijbregts, M.A. Assessing the Importance of Spatial Variability versus Model Choices in Life Cycle Impact Assessment: The Case of Freshwater Eutrophication in Europe. Environ. Sci. Technol. 2013, 47, 3565–13570. [Google Scholar] [CrossRef]

- Bulle, C.; Margni, M.; Patouillard, L.; Boulay, A.M.; Bourgault, G.; De Bruille, V.; Cao, V.; Hauschild, M.; Henderson, A.; Humbert, S.; et al. IMPACT World+: A globally regionalized life cycle impact assessment method. Int. J. Life Cycle Assess. 2019, 24, 1653–1674. [Google Scholar] [CrossRef] [Green Version]

- Verones, F.; Hellweg, S.; Azevedo, L.; Chaudhary, A.; Cosme, N.; Fantke, P.; Goedkoop, M.; Hauschild, M.; Laurent, A.; Mutel, C.; et al. LC-IMPACT Version 0.5—A Spatially Differentiated Life Cycle Impact Assessment Approach. 2016. Available online: http://www.lc-impact.eu (accessed on 1 November 2022).

- Buxmann, K.; Koehler, A.; Thylmann, D. Water scarcity footprint of primary aluminium. Int. J. Life Cycle Assess. 2016, 21, 1605–1615. [Google Scholar] [CrossRef] [Green Version]

- Caldeira, C.; Quinteiro, P.; Castanheira, E.; Boulay, A.M.; Dias, A.C.; Arroja, L.; Freire, F. Water footprint profile of crop-based vegetable oils and waste cooking oil: Comparing two water scarcity footprint methods. J. Clean. Prod. 2018, 195, 1190–1202. [Google Scholar] [CrossRef]

- Hess, T.M.; Lennard, A.T.; Daccache, A. Comparing local and global water scarcity information in determining the water scarcity footprint of potato cultivation in Great Britain. J. Clean. Prod. 2015, 87, 666–674. [Google Scholar] [CrossRef]

- Ridoutt, B.; Hodges, D. From ISO14046 to water footprint labeling: A case study of indicators applied to milk production in south-eastern Australia. Sci. Total Environ. 2017, 599–600, 14–19. [Google Scholar] [CrossRef] [PubMed]

- Borsato, E.; Giubilato, E.; Zabeo, A.; Lamastra, L.; Criscione, P.; Tarolli, P.; Marinello, F.; Pizzol, L. Comparison of Water-focused Life Cycle Assessment and Water Footprint Assessment: The case of an Italian wine. Sci. Total Environ. 2019, 666, 1220–1231. [Google Scholar] [CrossRef] [PubMed]

- Zonderland-Thomassen, M.A.; Lieffering, M.; Ledgard, S.F. Water footprint of beef cattle and sheep produced in New Zealand: Water scarcity and eutrophication impacts. J. Clean. Prod. 2014, 73, 253–262. [Google Scholar] [CrossRef]

- Baydar, G.; Ciliz, N.; Mammdadov, A. Life cycle assessment of cotton textile products in Turkey. Resour. Conserv. Recyc. 2015, 104, 213–223. [Google Scholar] [CrossRef]

- CmiA, 2014, Life Cycle Assessment (LCA) of Cotton Made in Africa (CimA). PE International AG, Afriva. Available online: https://cottonmadeinafrica.org/wp-content/uploads/2020/03/Life-Cycle-Assessment-CmiA-2014.pdf (accessed on 1 November 2022).

- Cotton Inc. (Cotton Incorporated). The life Cycle Inventory & Life Cycle Assessment of Cotton Fibrt & Fabric. Cotton Foundation, America. 2016. Available online: https://cottoncultivated.cottoninc.com/wp-content/uploads/2017/01/2016-LCA-Executive-Summary.pdf (accessed on 1 November 2022).

- Textile Exchange. The Life Cycle Assessment (LCA) of Organic Cotton Fiber. Textile Exchange, America. 2014. Available online: https://store.textileexchange.org/wp-content/uploads/woocommerce_uploads/2019/04/LCA_of_Organic_Cotton-Fiber-Full_Report.pdf (accessed on 1 November 2022).

- Xuan, J.W.; Zheng, J.H.; Liu, Z.H. Calculation and analysis on water footprint of main crops in Xinjiang. Agric. Res. Arid Areas 2014, 32, 196–201. [Google Scholar]

- SBXUAR (Statistic Bureau of Xinjiang Uygur Autonomous Region). Xinjiang Statistics Yearbook; Chinese Statistics Press: Beijing, China, 2012. (In Chinese) [Google Scholar]

- CMEP (Chinese Ministry of Environmental Protection). Dataset for the First China Pollution Source Census; Chinese Environmental Science Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Huang, J.; Xu, C.C.; Ridoutt, B.G.; Wang, X.C.; Ren, P.A. Nitrogen and phosphorus losses and eutrophication potential associated with fertilizer application to cropland in China. J. Clean. Prod. J. 2017, 159, 171–179. [Google Scholar] [CrossRef]

- Scherer, L.; Pfister, S. Global biodiversity loss by freshwater consumption and eutrophication from Swiss food consumption. Environ. Sci. Technol. 2016, 50, 7019–7028. [Google Scholar] [CrossRef]

- Helmes, R.J.K.; Huijbregts, M.A.J.; Henderson, A.D.; Jolliet, O. Spatially explicit fate factors of phosphorous emissions to freshwater at the global scale. Int. J. Life Cycle Assess. 2012, 17, 646–654. [Google Scholar] [CrossRef] [Green Version]

- Tirado-Seco, P. Development of Damage Functions for Aquatic Eutrophication in Life Cycle Assessment; Université de Genève: Geneva, Switzerland, 2005. [Google Scholar]

- Luo, L.P.; Liu, X.J. Regional differences on typical crop water requirement and water footprint in China from a production perspective. Water Sav. Irrig. 2020, 1, 88–94. [Google Scholar]

- Günther, J.; Thevs, N.; Gusovius, H.J.; Sigmund, I.; Brückner, T.; Beckmann, V.; Abdusalik, N. Carbon and phosphorus footprint of the cotton production in Xinjiang, China, in comparison to an alternative fibre (Apocynum) from Central Asia. J. Clean. Prod. 2017, 148, 490–497. [Google Scholar] [CrossRef]

- Nike, 2018. FY 2018 Impact Report. Available online: https://s3-us-west-2.amazonaws.com/purpose-cms-production01/wp-content/uploads/2019/05/16054840/FY18-Nike-Impact-Report_Final2.pdf (accessed on 1 November 2022).

| Phase | Location | Phase | Water Consumption (t H2O) | Total Phosphorus (kg) | COD (kg) |

|---|---|---|---|---|---|

| Fiber production | Xinjiang | Cultivation | 1.07 | 0.25 × 10−2 | |

| Ginning | 1.19 × 10−3 | ||||

| T-shirt Production | Guangdong | Spinning | 1.71 × 10−3 | ||

| Knitting | 2.20 × 10−3 | ||||

| Pre-papering | 1.21 × 10−3 | ||||

| Dyeing | 1.88 × 10−2 | 0.25 × 10−1 | |||

| Finishing | 9.30 × 10−4 | ||||

| Making-up | 7.02 × 10−3 | ||||

| Consumption | Zhejiang | Use (45washes) | 0.24 | 1.1 × 10−3 | 0.78 × 10−1 |

| Function unit: 1 piece of eco T-shirt (180 g) | |||||

| Crop | Area | Blue Water (t) | Green Water (t) | Total (t) | Source |

|---|---|---|---|---|---|

| Seed cotton | Global | 1306 | 2282 | 3588 | Mekonnen and Hoekstra et al., 2011 [28] |

| soybean | Global | 70 | 2030 | 2107 | |

| corn | Global | 81 | 947 | 1028 | |

| Seed cotton | Brazil | 46 | 2575 | 2621 | Chapagain et al., 2006 [1] |

| China | 760 | 1258 | 2018 | ||

| Pakistan | 3860 | 1054 | 4914 | ||

| Turkey | 2812 | 288 | 3100 | ||

| USA | 576 | 1673 | 2249 | ||

| Uzbekistan | 4377 | 83 | 4460 | ||

| Functional unit: 1 ton of crop | |||||

| Type | Recycling T-Shirt (100% Recycling) | Eco T-Shirt (30% Recycling) | Conventional T-Shirt (No Recycling) |

|---|---|---|---|

| Water scarcity (t H2O eq) | 8.07 × 10−2 | 1.74 | 2.45 |

| Water eutrophication (PDF·m2·yr) | 4.04 × 10−3 | 9.47 × 10−3 | 1.18 × 10−2 |

| Phase | Location | Phase | Water Consumption (t H2O) | Water Scarcity Footprint (t H2O) | Water-Eutrophication Footprint (PDF·m2·yr−1) |

|---|---|---|---|---|---|

| Fiber production | Xinjiang | Cultivation | 1.07 | 1.66 | 5.43 × 10−3 |

| Ginning | 1.19 × 10−3 | 1.85 × 10−3 | |||

| T-shirt Production | Guangdong | Spinning | 1.71 × 10−3 | 1.78 × 10−4 | |

| Knitting | 2.20 × 10−3 | 2.29 × 10−4 | |||

| Pre-papering | 1.21 × 10−3 | 1.25 × 10−3 | |||

| Dyeing | 1.88 × 10−2 | 1.95 × 10−3 | 8.64 × 10−5 | ||

| Finishing | 9.30 × 10−4 | 9.65 × 10−5 | |||

| Making-up | 7.02 × 10−3 | 7.29 × 10−4 | |||

| Consumption | Zhejiang | Use (45 washes) | 0.24 | 7.63 × 10−2 | 3.95 × 10−3 |

| Function unit: 1 piece of eco T-shirt (180 g) | |||||

| Location | WSI | Water Eutrophication CF for COD | Water Eutrophication CF for P |

|---|---|---|---|

| Xinjiang | 0.9318 | 0.01547 | 2.1523 |

| Guangdong | 0.0625 | 0.0035 | 0.4853 |

| Zhejiang | 0.1942 | 0.0172 | 2.3917 |

| China * | 0.48 | 0.0231 | 3.2179 |

| Global * | 0.602 | 0.0797 | 11.0869 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Chen, F.; Zhu, L.; Li, Q.; Wang, X.; Wang, L. A Spatial Water Footprint Assessment of Recycled Cotton T-Shirts: Case of Local Impacts in Selected China Provinces. Sustainability 2023, 15, 817. https://doi.org/10.3390/su15010817

Chen S, Chen F, Zhu L, Li Q, Wang X, Wang L. A Spatial Water Footprint Assessment of Recycled Cotton T-Shirts: Case of Local Impacts in Selected China Provinces. Sustainability. 2023; 15(1):817. https://doi.org/10.3390/su15010817

Chicago/Turabian StyleChen, Shuang, Fangli Chen, Lisha Zhu, Qizheng Li, Xiaopeng Wang, and Laili Wang. 2023. "A Spatial Water Footprint Assessment of Recycled Cotton T-Shirts: Case of Local Impacts in Selected China Provinces" Sustainability 15, no. 1: 817. https://doi.org/10.3390/su15010817

APA StyleChen, S., Chen, F., Zhu, L., Li, Q., Wang, X., & Wang, L. (2023). A Spatial Water Footprint Assessment of Recycled Cotton T-Shirts: Case of Local Impacts in Selected China Provinces. Sustainability, 15(1), 817. https://doi.org/10.3390/su15010817