Experimental Study on the Mechanical Properties of Tectonic Coal Using Reconstituted Coal Specimens

Abstract

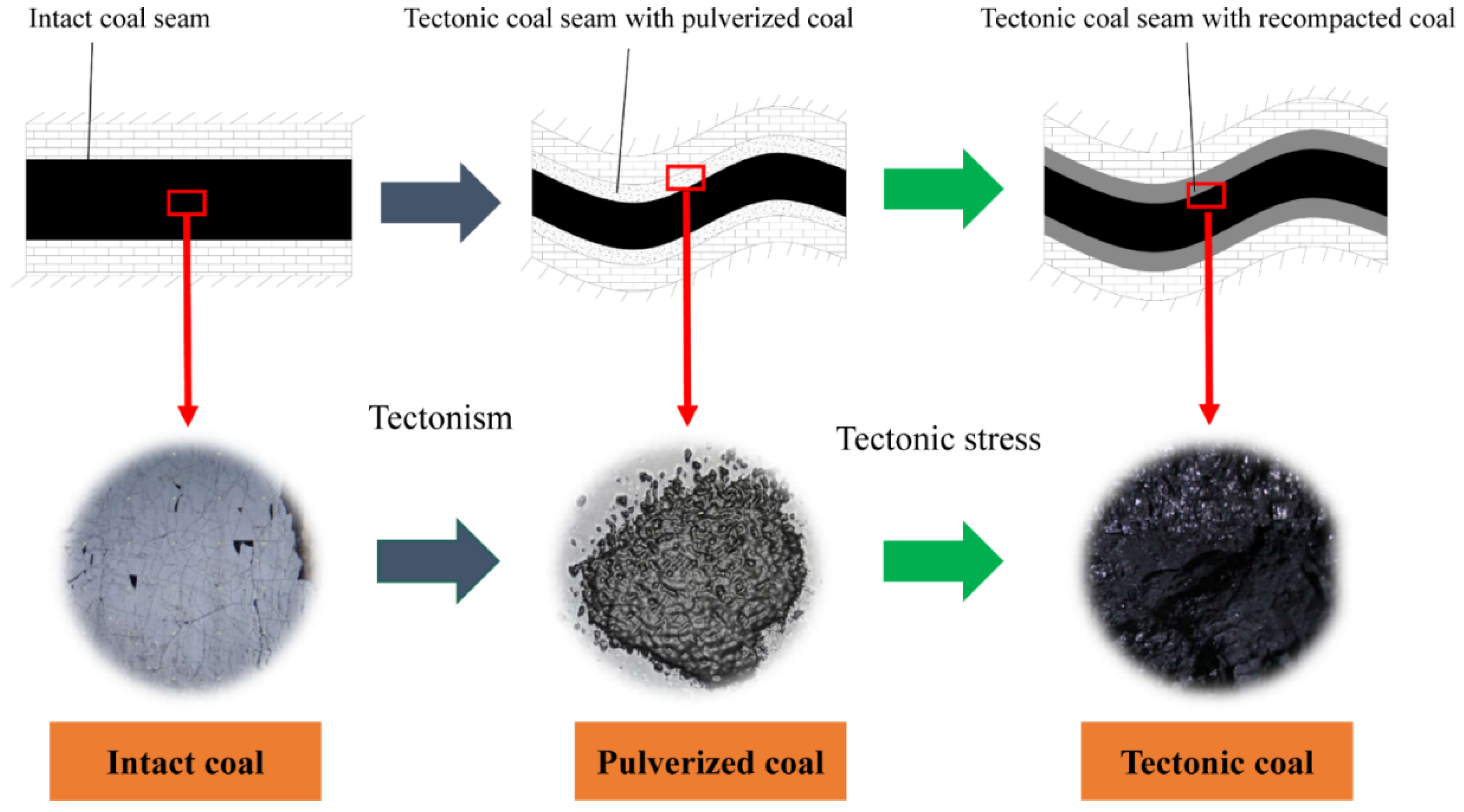

:1. Introduction

2. Reconstitution of Tectonic Coal Specimens

2.1. Basic Physical Parameters of Coal Sample

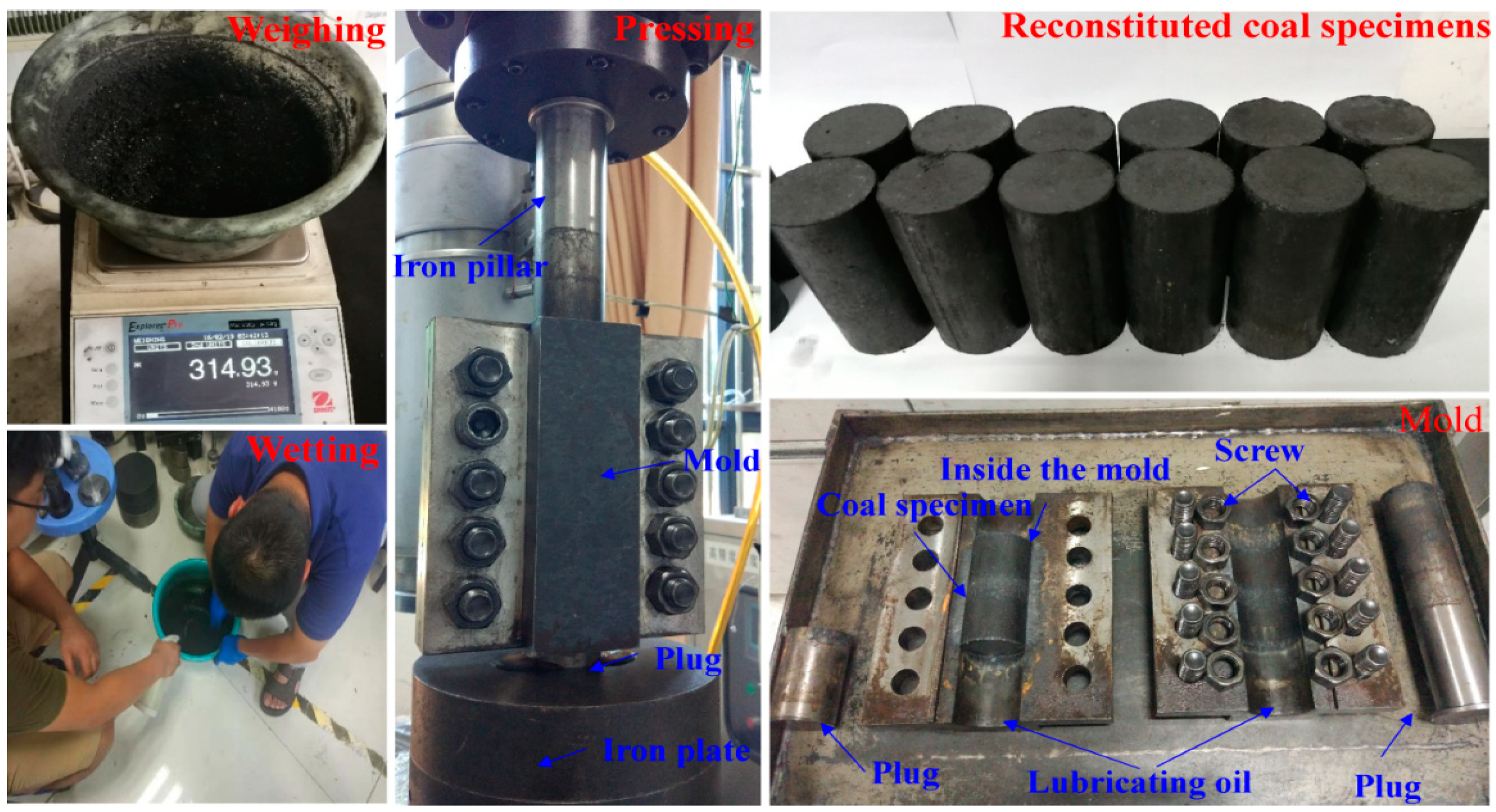

2.2. Reconstitution Equipment and Process

- (1)

- Weighing: the first step involves the weighing of a certain mass of pulverized tectonic coal particles. As for its quality, it should be adjusted repeatedly to ensure that the size of each reconstituted coal specimen is the standard size (Φ50 × 100 mm).

- (2)

- Wetting: a certain amount of distilled water is injected into the coal sample and evenly mixed by hand. During the reconstitution process, the distilled water can act as a binder.

- (3)

- Reconstituting: the wet coal particles are placed into the high–pressure–resistant mold, and a heavy press is used to provide external force to reconstitute the coal specimen. After the targeted force is achieved, the force is maintained for 12 h.

- (4)

- Demolding: after reconstitution, the screw of the mold is loosened, and the coal specimen is removed from the mold. To ensure a successful demolding, some lubricating oil can be applied on the inner surface of the mold before reconstitution.

- (5)

- Vacuum drying: the coal specimen is placed in a vacuum oven, and it is dried at 60 °C for 48 h.

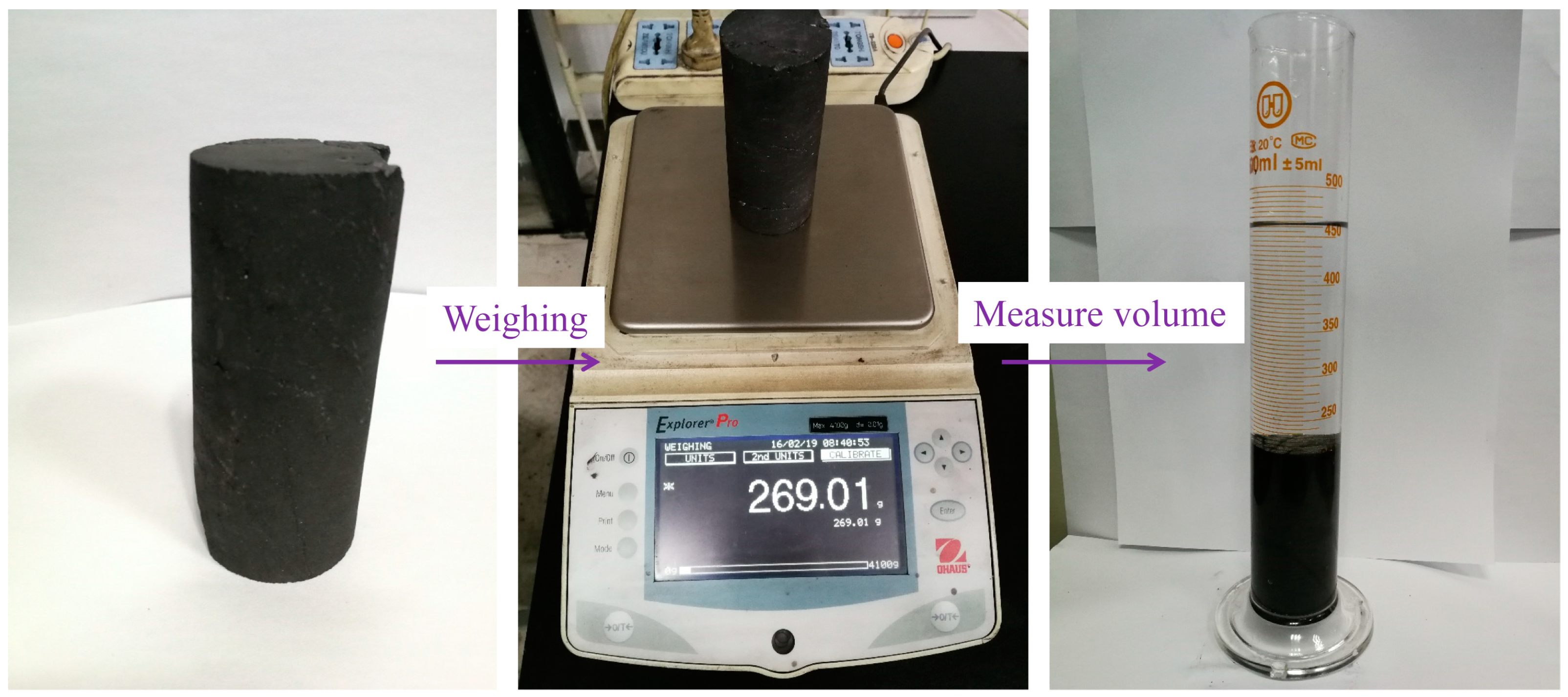

2.3. Investigation of the Compaction Degree

2.3.1. Internal Structural Characteristics

2.3.2. Density and Permeability Data

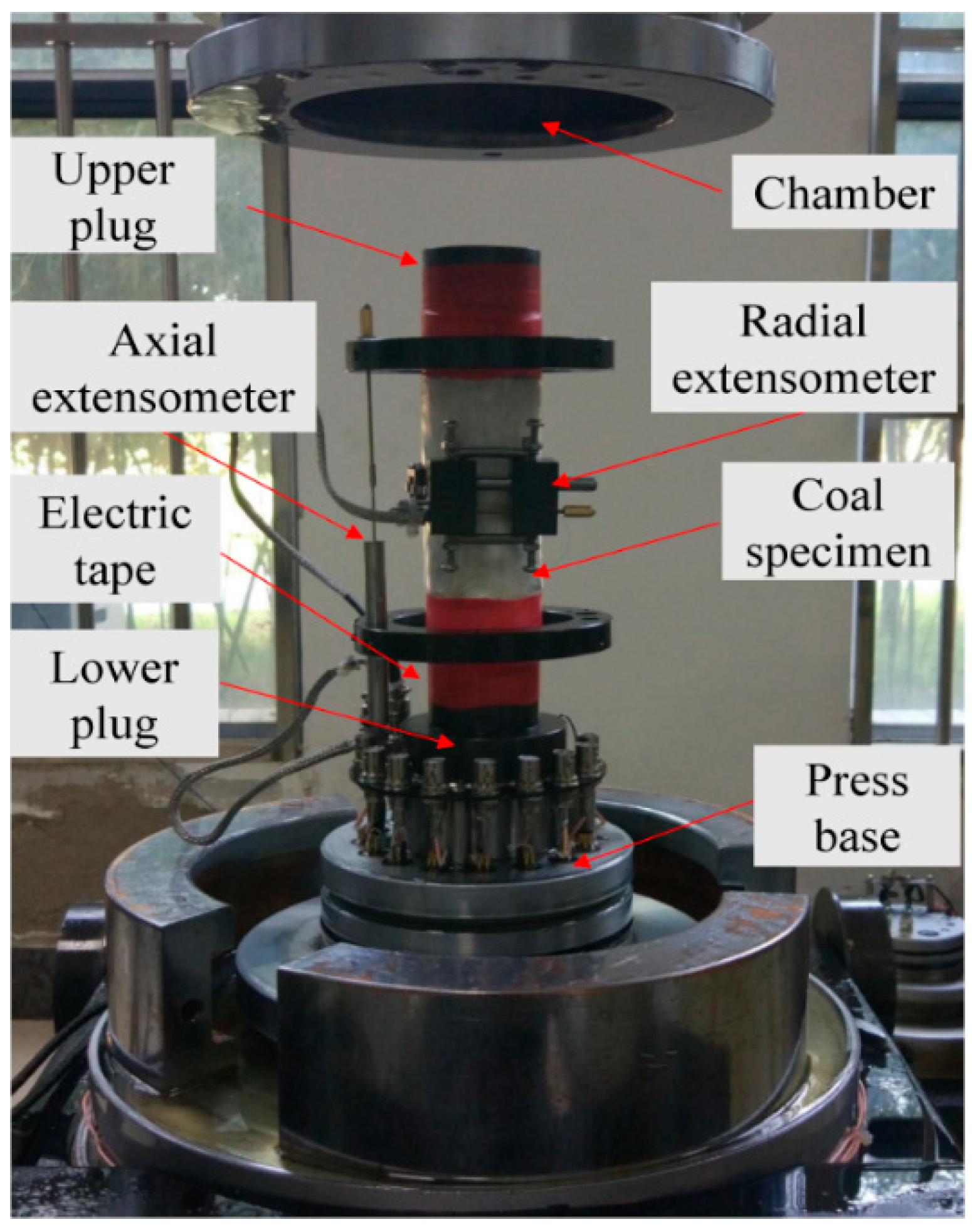

3. Mechanical Properties of Tectonic Coal

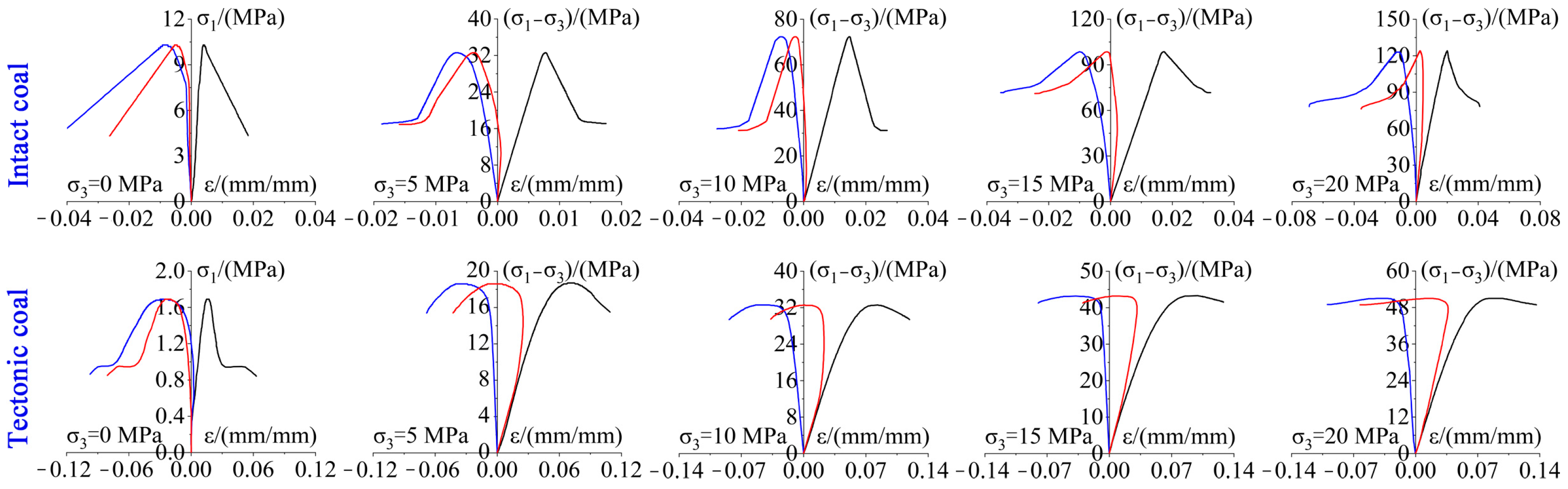

3.1. Total Stress–Strain Curve

3.2. Deformation and Strength Properties

3.2.1. Deformation Property

3.2.2. Strength Property

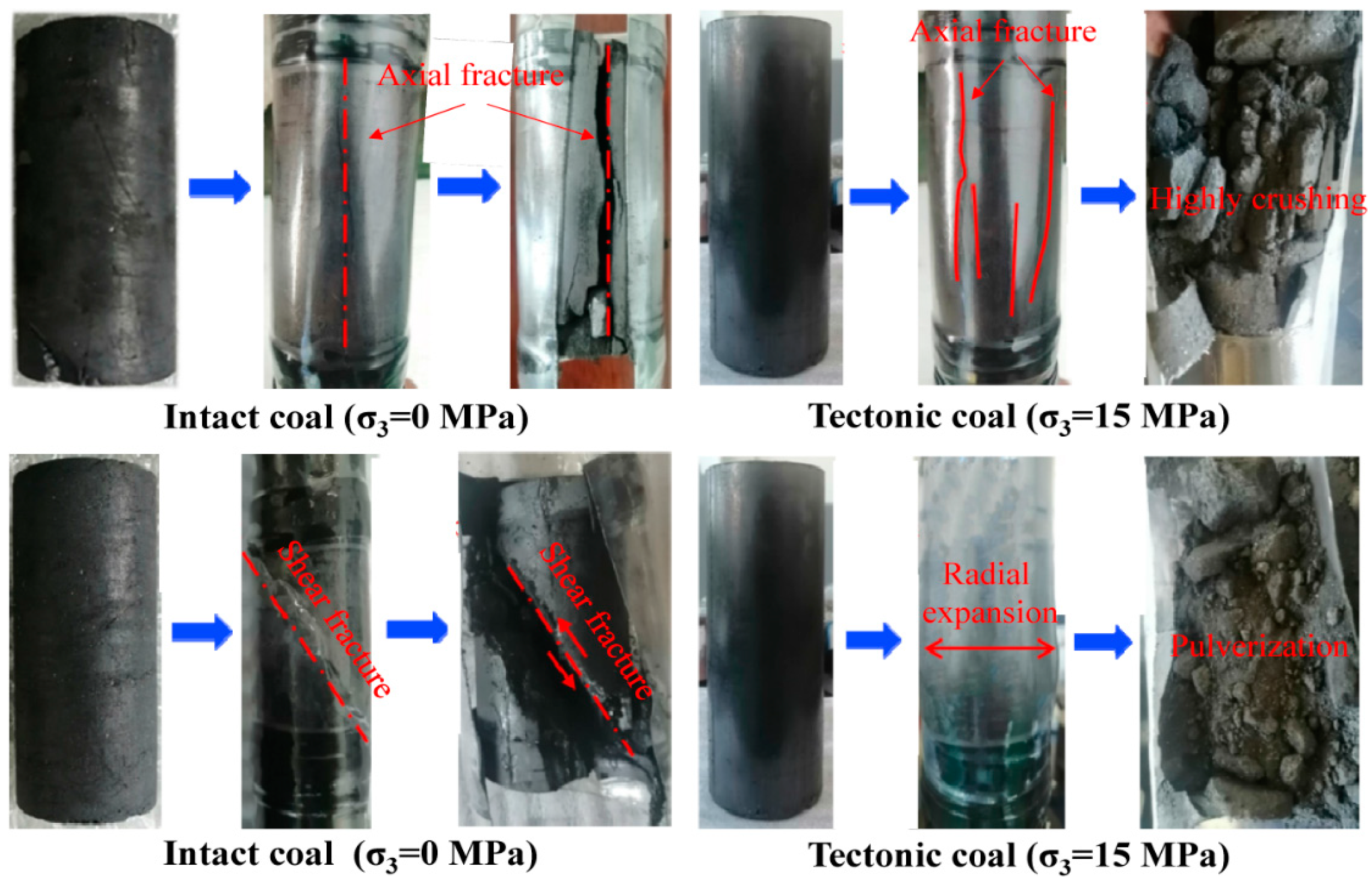

3.3. Post–Peak Failure Mode and Mechanism

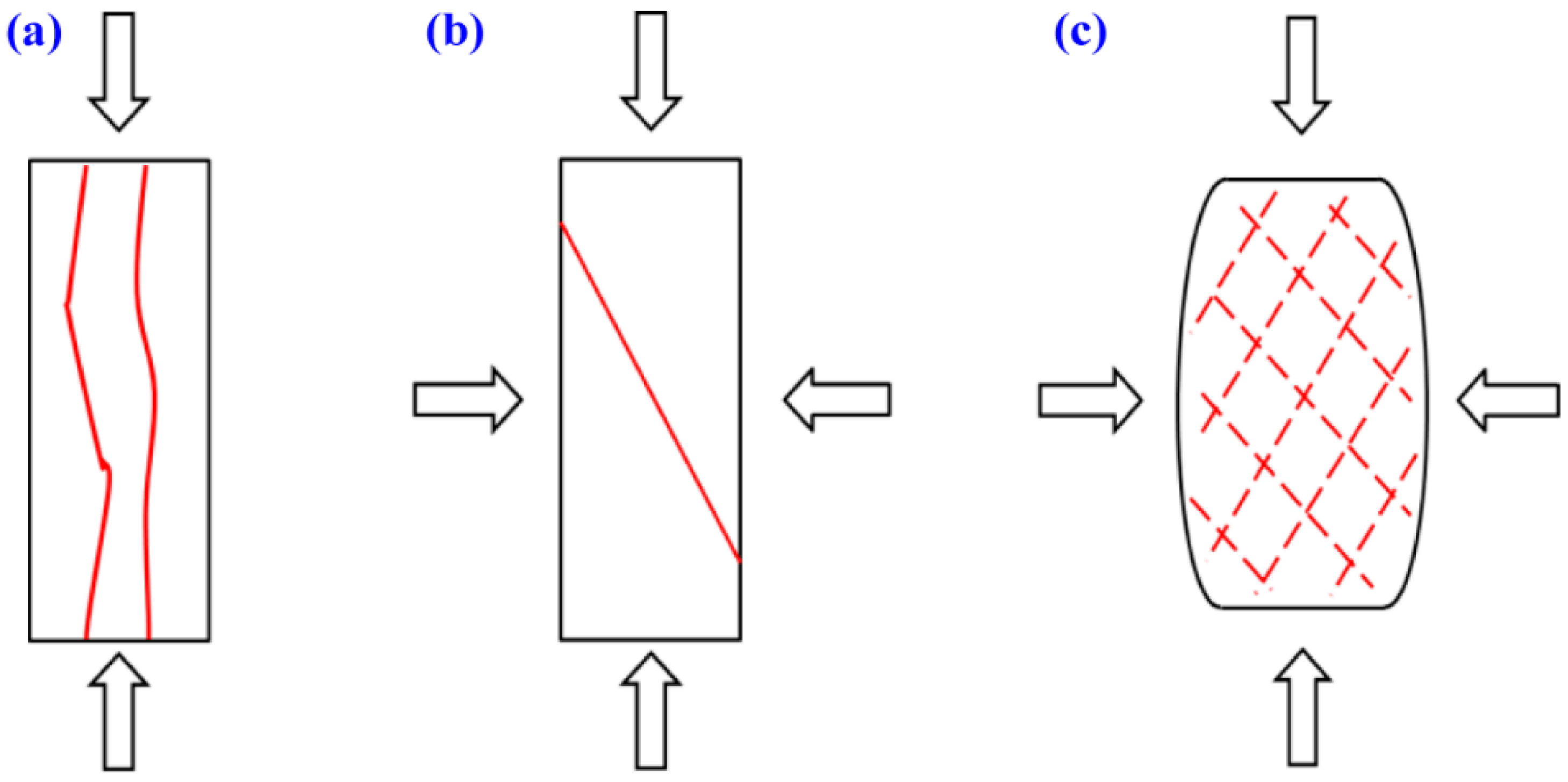

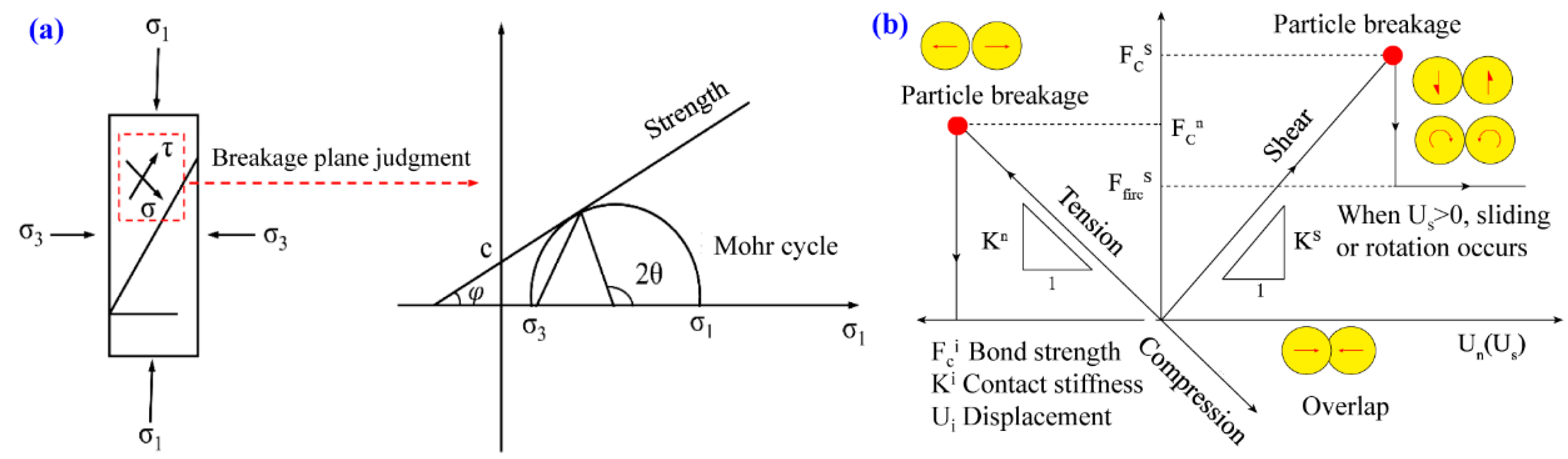

3.3.1. Post–Peak Failure Mode

3.3.2. Post–Peak Failure Mechanism

3.4. Failure Angle Evolution of Intact Coal

4. Conclusions

- (1)

- Increasing the external stress is an effective method to improve the compaction degree of the reconstructed coal sample. With the increase in the external force, the inner cracks close, the specimen density increases, and the specimen permeability decreases. When the external force is increased to 550 KN, the specimen density increases to 1.38 m3/t, and its permeability decreases to 0.00824 mD under the field stress level. Density and permeability measurement results are fairly close to field permeability data. Therefore, for the Sijiazhuang coal, a 550 KN external force can be used to reconstitute the tectonic coal specimen.

- (2)

- Compared with intact coal, tectonic coal exhibits a low elastic modulus but a high stress sensitivity due to its particle aggregation property. Its average elastic modulus is only 22.08% of that of tectonic coal. Moreover, with the increase in the confining pressure from 5 to 20 MPa, the elastic modulus of intact coal increases by just 8.70%, while that of tectonic coal increases by 1.14 times. In addition, tectonic coal also exhibits a low strength and weak cohesive properties due to the fact that its cohesion is only provided by the mechanical biting force between the coal particles. Its cohesion is only 43.47% of that of intact coal.

- (3)

- Tectonic coal and intact coal present different post–peak failure modes under the triaxial compression stress path. Typical shear failure occurs in intact coal at the most unfavorable plane under the coupling effect of normal stress and shear stress, while multiple shear failure occurs in tectonic coal due to its particle aggregation property. In addition, the failure angle of intact coal decreases with the increase in confining pressure. As the confining pressure increases from 5 to 20 MPa, the failure angle decreases from 69° to 46°.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Y.P.; Pan, Z.J. Reservoir properties of Chinese tectonic coal: A review. Fuel 2020, 260, 116350. [Google Scholar] [CrossRef]

- Li, D.Q. Underground hydraulic mining of thin sub–layer as protective coal seam in coal mines. Int. J. Min. Sci. Technol. 2014, 67, 145–154. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, Y.P.; Deng, C.B.; Shu, L.Y.; Pan, Z.J.; Yuan, L.; Wang, L.; Liu, Q.Q. A novel in–seam borehole discontinuous hydraulic flushing technology in the driving face of soft coal seams: Enhanced gas extraction mechanism and field Application. Rock Mech. Rock Eng. 2022, 55, 885–907. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.Q.; Fu, X.H.; Zhao, Y.; Gao, Y.B.; Yang, W. Modeling coupled gas flow and geomechanics process in stimulated coal seam by hydraulic flushing. Int. J. Rock Mech. Min. 2021, 142, 104769. [Google Scholar] [CrossRef]

- Skoczylas, N.; Dutka, B.; Sobczyk, J. Mechanical and gaseous properties of coal bri–quettes in terms of outburst risk. Fuel 2014, 134, 45–52. [Google Scholar] [CrossRef]

- Li, X.; Yin, G.Z.; Zhang, H.; Wang, W. Experimental study of mechanical properties of outburst coal containing gas under triaxial compression. Chin. J. Rock Mechan Eng. 2010, 29, 3350–3358. [Google Scholar]

- Dong, J.; Cheng, Y.P.; Hu, B.; Hao, C.M. Experimental study of the mechanical properties of intact and tectonic coal via compression of a single particle. Powder Technol. 2018, 325, 412–419. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Cheng, Y.P.; Jin, K.; Tu, Q.Y.; Zhao, W.; Zhang, R. Effect of confining pressure un–loading on strength reduction of soft coal in borehole stability analysis. Environ. Earth Sci. 2017, 76, 173. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, H.; Yin, G. Experiments on triaxial mechanical properties of soft coal containing gas. J. Chongqing Univ. 2013, 36, 103–109. [Google Scholar]

- Liu, Q. Damage and Permeability Evolution Mechanism for Dual−Porosity Coal under Multiple Stress Paths and Its Application; China University of Mining and Technology: Xuzhou, China, 2015; (In Chinese with English Abstract). [Google Scholar]

- Lu, S.; Wang, L.; Qin, L.M. Analysis on adsorption capacity and adsorption thermos dynamic characteristics of different metamorphic degree coals. Coal Sci. Technol. 2014, 42, 130–135, (In Chinese with English Abstract). [Google Scholar]

- Lin, J.; Cheng, Y.P.; Ren, T.; Liu, Q.Q. New insights into failure behavior of tectonic coal under triaxial conditions using reconstituted coal specimens. Rock Mech. Rock Eng. 2021, 55, 1361–1374. [Google Scholar] [CrossRef]

- Tu, Q.; Cheng, Y.P.; Ren, T.; Wang, Z.Y.; Lin, J.; Lei, Y. Role of tectonic coal in coal and gas outburst behavior during coal mining. Rock Mech. Rock Eng. 2019, 52, 4619–4635. [Google Scholar] [CrossRef]

- Gao, D.Y.; Sang, S.X.; Liu, S.Q.; Wu, J.; Geng, J.S.; Wang, T.; Sun, T.M. Experimental study on the deformation behaviour, energy evolution law and failure mechanism of tectonic coal subjected to cyclic loads. Int. J. Min. Sci. Technol. 2022, 32, 1301–1313. [Google Scholar] [CrossRef]

- Li, Y.B.; Zhang, Y.G.; Zhang, Z.M.; Jiang, B. Experimental study on gas desorption of tectonic coal at initial stage. J. China Coal Soc. 2013, 38, 15–20, (In Chinese with English Abstract). [Google Scholar]

- Cheng, X.; Wang, Z.; Li, Z. Features of gas diffusion in tectonic coal with different particle sizes by new model of dynamic diffusion coefficient. J. Saf. Sci. Technol. 2016, 12, 88–93, (In Chinese with English Abstract). [Google Scholar]

- Zhang, H.; Cheng, Y.P.; Liu, Q.Q.; Yuan, L.; Dong, J.; Wang, L.; Qi, Y.X.; Wang, W. A novel in–seam borehole hydraulic flushing gas extraction technology in the heading face: Enhanced permeability mechanism, gas flow characteristics, and application. J. Nat. Gas Sci. Eng. 2017, 46, 498–514. [Google Scholar] [CrossRef]

- Tu, Q.Y.; Xue, S.; Cheng, Y.P.; Zhang, W.; Shi, G.F.; Zhang, G.S. Experimental study on the guiding effect of tectonic coal for coal and gas outburst. Fuel 2021, 309, 122087. [Google Scholar] [CrossRef]

- Chen, Z.; Pan, Z.; Liu, J.; Connell, L.D.; Elsworth, D. Effect of the effective stress coefficient and sorption–induced strain on the evolution of coal permeability: Experimental observations. Int. J. Greenhouse Gas Control 2011, 5, 1284–1293. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, Y.; Ren, T.; Zhou, H.; Liu, Q.Q. Permeability distribution characteristics of protected coal seams during unloading of the coal body. Int. J. Rock Mech. Min. Sci. 2014, 71, 105–116. [Google Scholar] [CrossRef]

- Connell, L.D. A new interpretation of the response of coal permeability to changes in pore pressure, stress and matrix shrinkage. Int. J. Coal Geol. 2016, 162, 169–182. [Google Scholar] [CrossRef]

- Zhang, R. Research on the Stress Relief and Permeability Increase Mechanism and High–Efficiency Gas Drainage Method on a Composite Coal Seam; China University of Mining and Technology: Xuzhou, China, 2019; (In Chinese with English Abstract). [Google Scholar]

- Ma, X.D.; Rudnicki, J.W.; Haimson, B.C. Failure characteristics of two porous sandstones subjected to true triaxial stresses: Applied through a novel loading path. J. Geophys. Res.—Solid Earth 2017, 122, 2525–2540. [Google Scholar] [CrossRef]

- Zhou, H.; Cheng, J.; Lu, J.J.; Jiang, Y.; Meng, F.Z. A new rock brittleness evaluation index based on the internal friction angle and class I stress–strain curve. Rock Mech. Rock Eng. 2018, 51, 2309–2316. [Google Scholar] [CrossRef]

| Coal | Proximate Analysis | f Value | ΔP (mmHg) | Gas Adsorption Constant | ||||

|---|---|---|---|---|---|---|---|---|

| Mad | Aad | Vdaf | Fcad | VL (m3/t) | PL (MPa) | |||

| Intact | 2.96 | 5.86 | 10.72 | 84.31 | 1.32 | 28.6 | 35.75 | 1.41 |

| Tectonic | 2.64 | 8.32 | 8.64 | 83.68 | 0.18 | 41.3 | 41.58 | 1.27 |

| Coal | σ3 (MPa) | E (MPa) | Eav (MPa) | μ (Dimensionless) | μav (Dimensionless) |

|---|---|---|---|---|---|

| Intact | 0 | 1364 | 2939 | 0.35 | 0.33 |

| 5 | 3196 | 0.31 | |||

| 10 | 3268 | 0.38 | |||

| 15 | 3392 | 0.30 | |||

| 20 | 3474 | 0.33 | |||

| Tectonic | 0 | 363 | 649 | 0.33 | 0.35 |

| 5 | 478 | 0.35 | |||

| 10 | 632 | 0.36 | |||

| 15 | 753 | 0.33 | |||

| 20 | 1021 | 0.38 |

| Coal | Internal Friction Angle (°) | Cohesion (MPa) |

|---|---|---|

| Intact | 38.46 | 4.21 |

| Tectonic | 34.28 | 1.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, S.; Zhang, L.; Deng, C. Experimental Study on the Mechanical Properties of Tectonic Coal Using Reconstituted Coal Specimens. Sustainability 2023, 15, 8066. https://doi.org/10.3390/su15108066

Wang Y, Wang S, Zhang L, Deng C. Experimental Study on the Mechanical Properties of Tectonic Coal Using Reconstituted Coal Specimens. Sustainability. 2023; 15(10):8066. https://doi.org/10.3390/su15108066

Chicago/Turabian StyleWang, Yubo, Suifang Wang, Lemei Zhang, and Cunbao Deng. 2023. "Experimental Study on the Mechanical Properties of Tectonic Coal Using Reconstituted Coal Specimens" Sustainability 15, no. 10: 8066. https://doi.org/10.3390/su15108066