Mechanical Properties, Durability, and Structural Applications of Rubber Concrete: A State-of-the-Art-Review

Abstract

:1. Introduction

2. Static Properties of Rubber Concrete

2.1. Compressive Strength

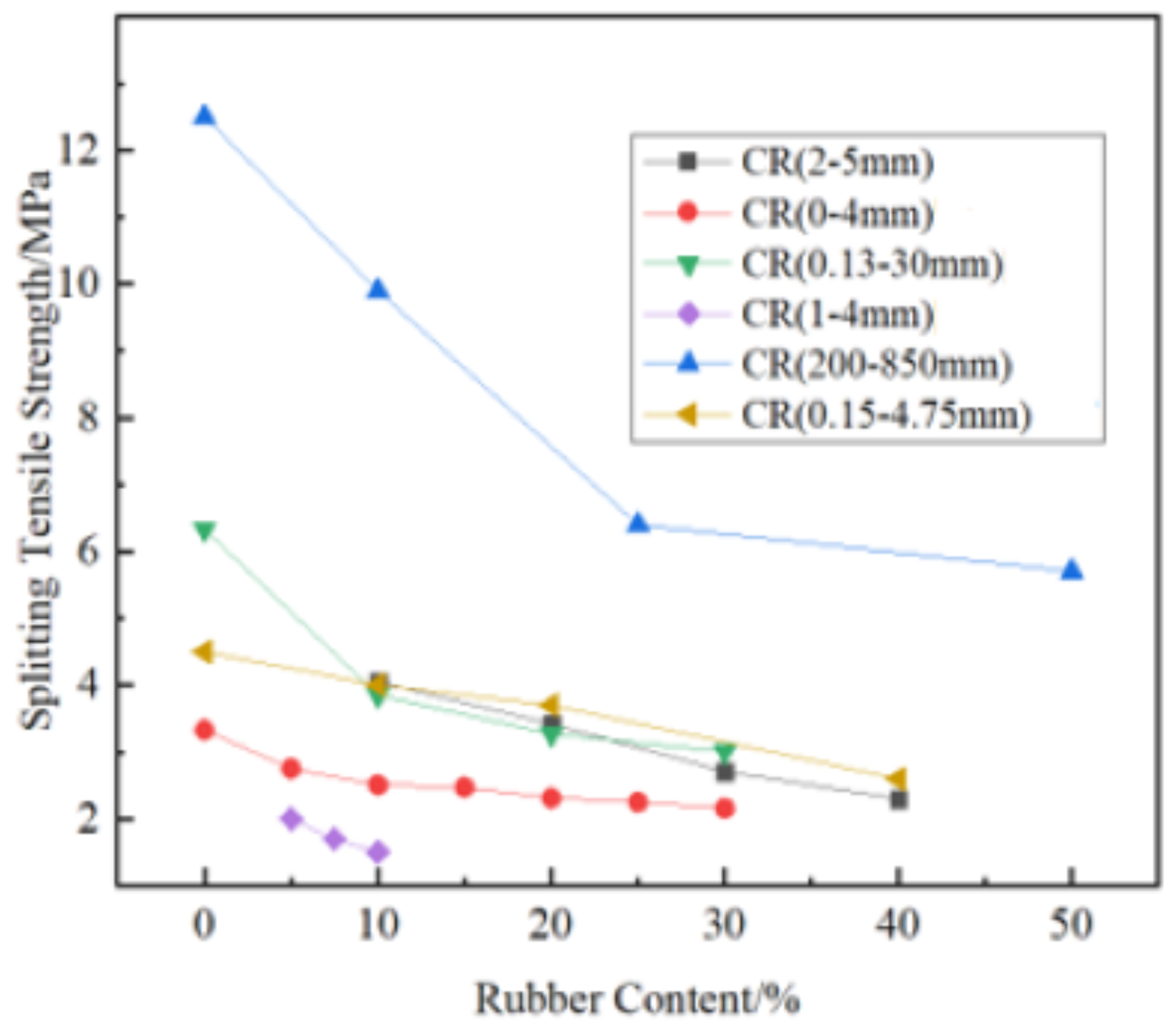

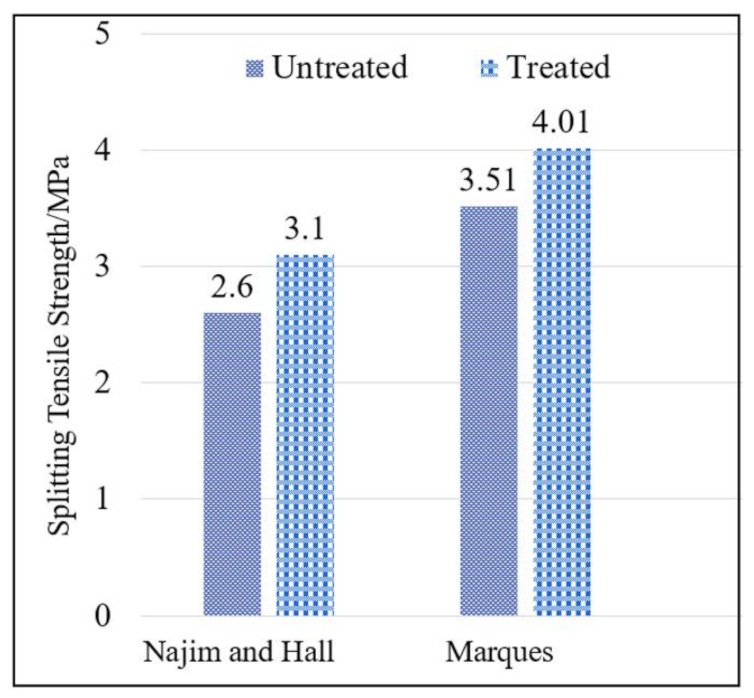

2.2. Tensile Strength

2.3. Flexural Strength

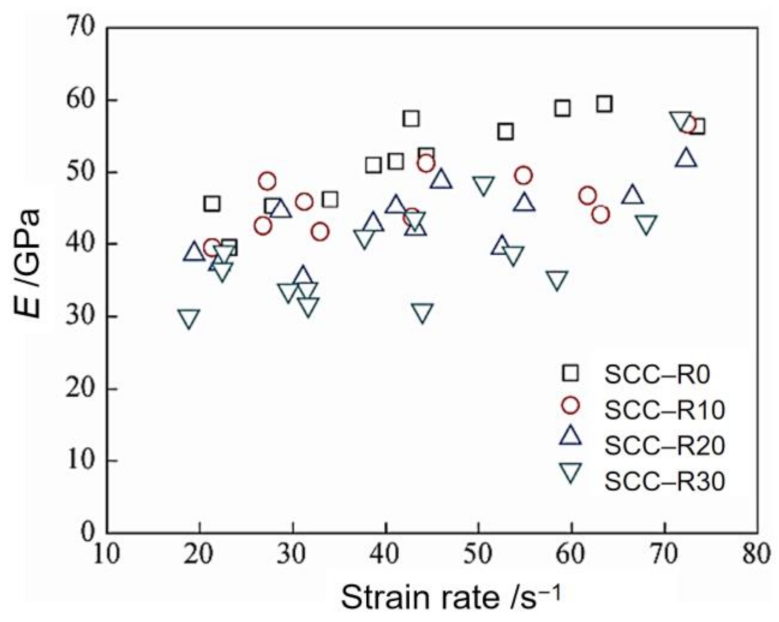

2.4. Modulus of Elasticity

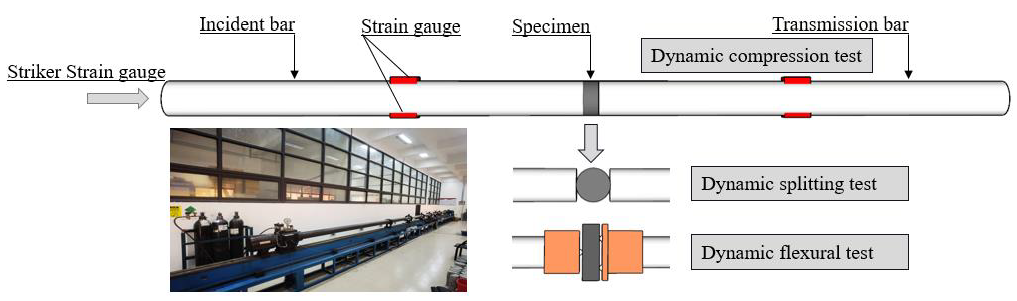

3. Dynamic Properties of Rubber Concrete

3.1. Test Method

3.1.1. Hopkinson Compression Bar Test

3.1.2. Drop Hammer Impact Test

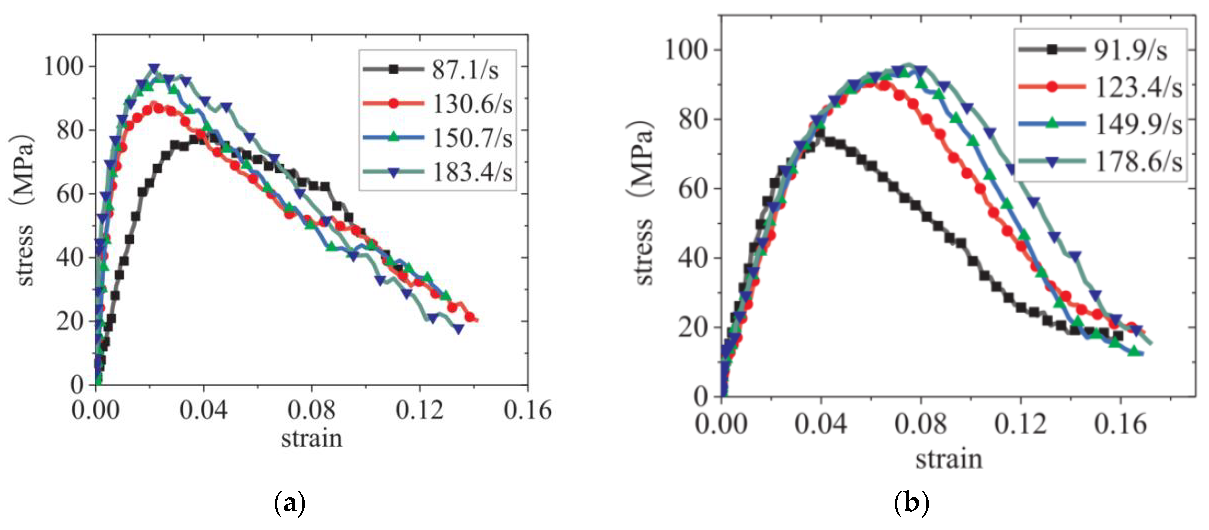

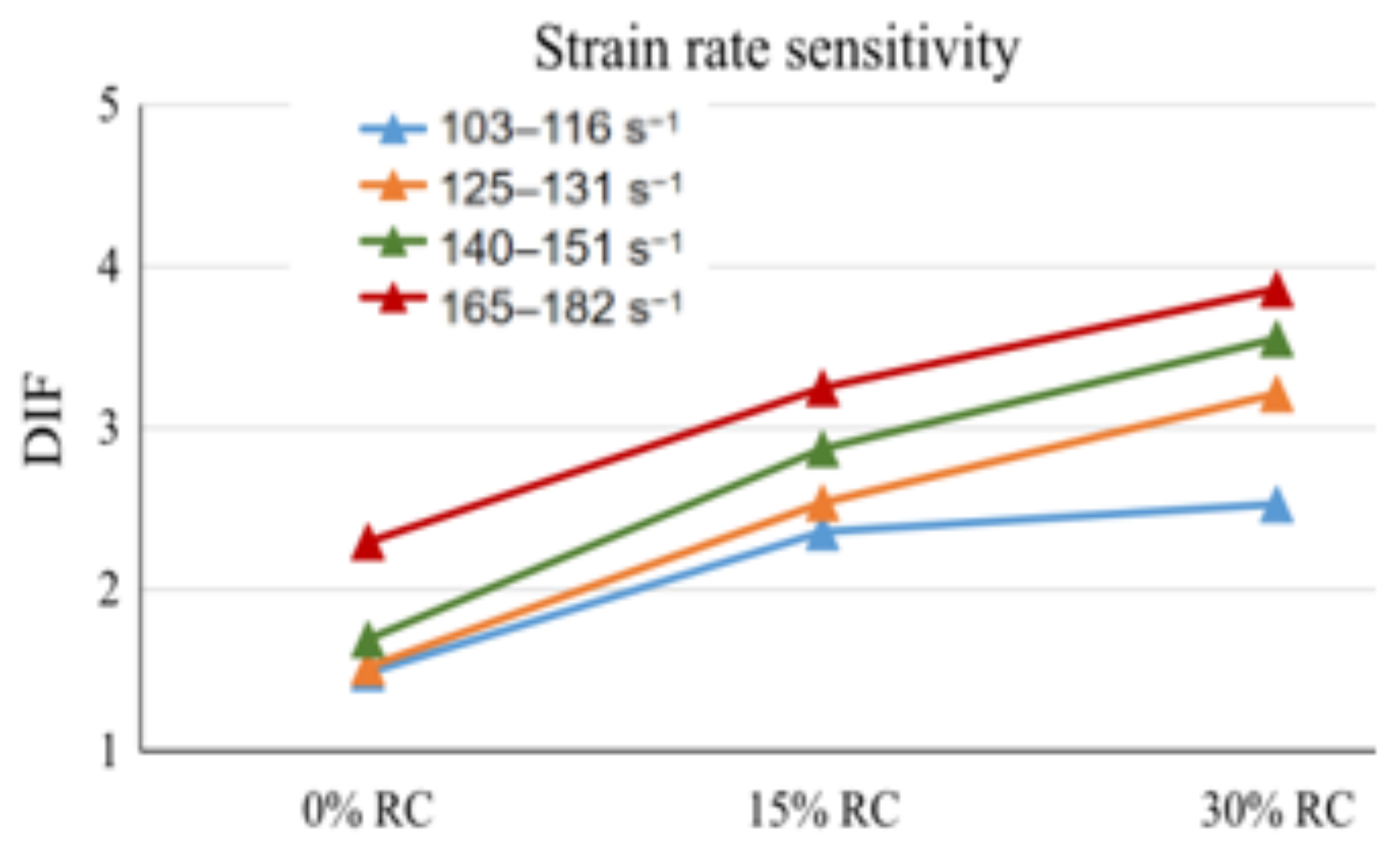

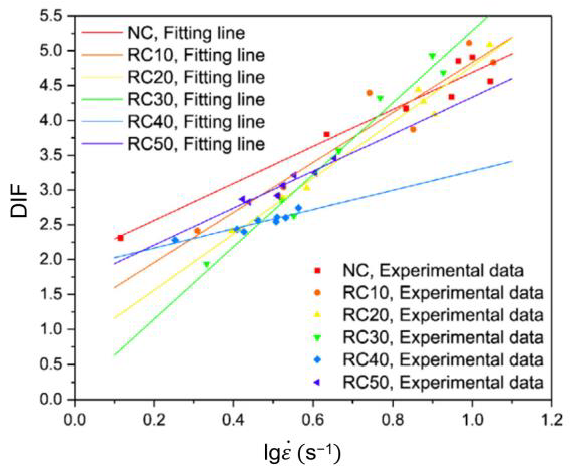

3.2. Dynamic Compressive Property

3.3. Dynamic Splitting Tensile Property

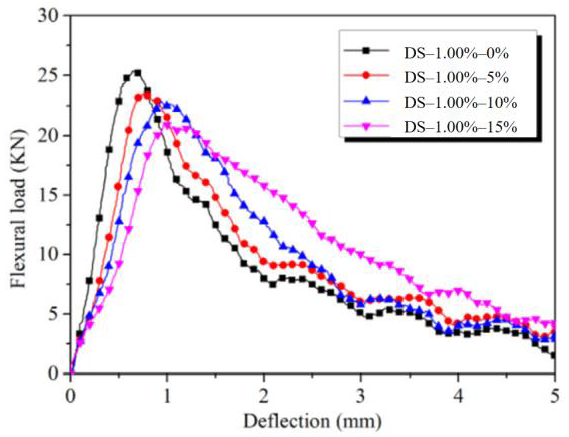

3.4. Dynamic Flexural Property

4. Durability of Rubber Concrete

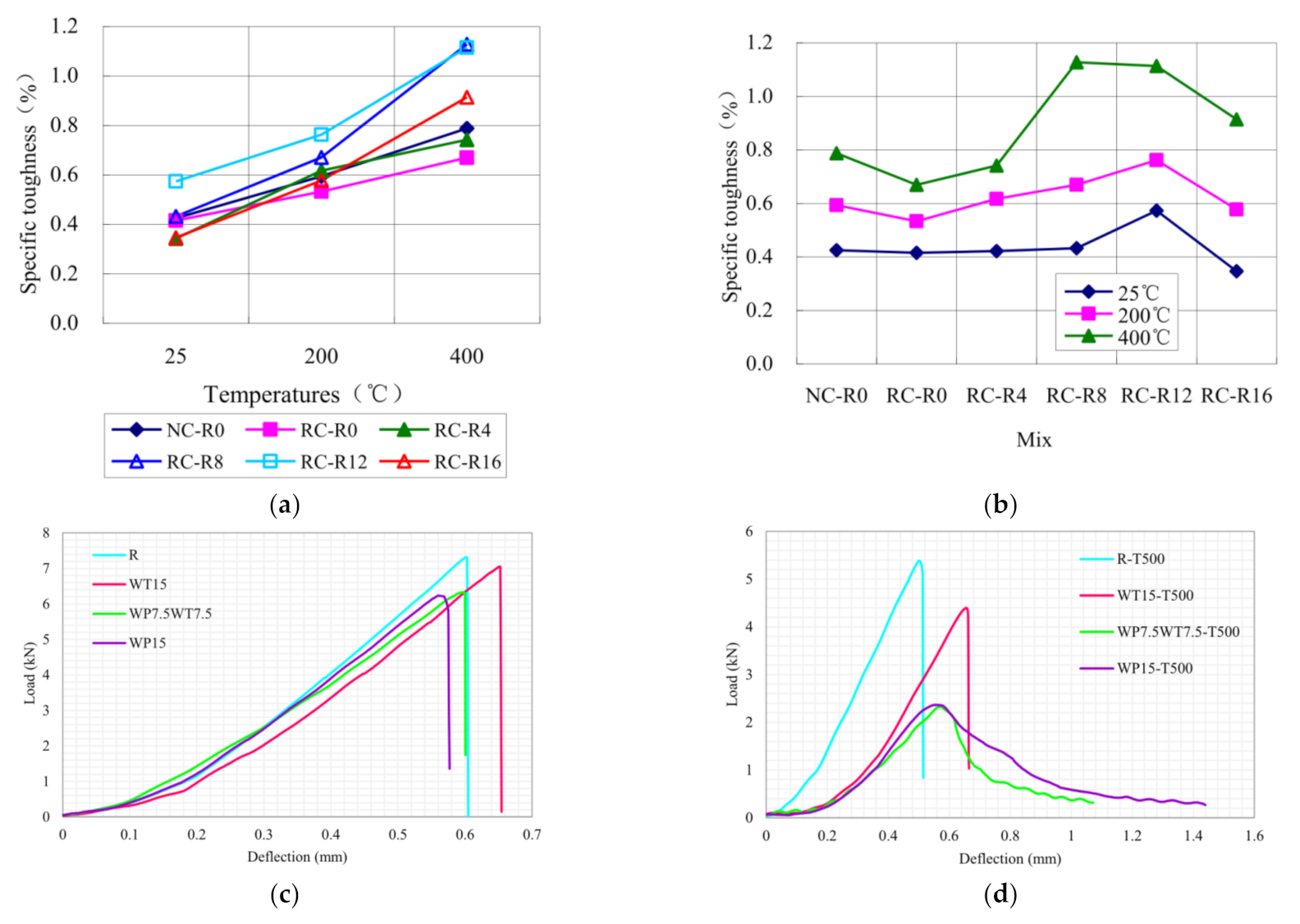

4.1. Heat Resistance

4.2. Impermeability

4.3. Freeze–thaw Resistance

5. Structural Performance of Rubber Concrete Component

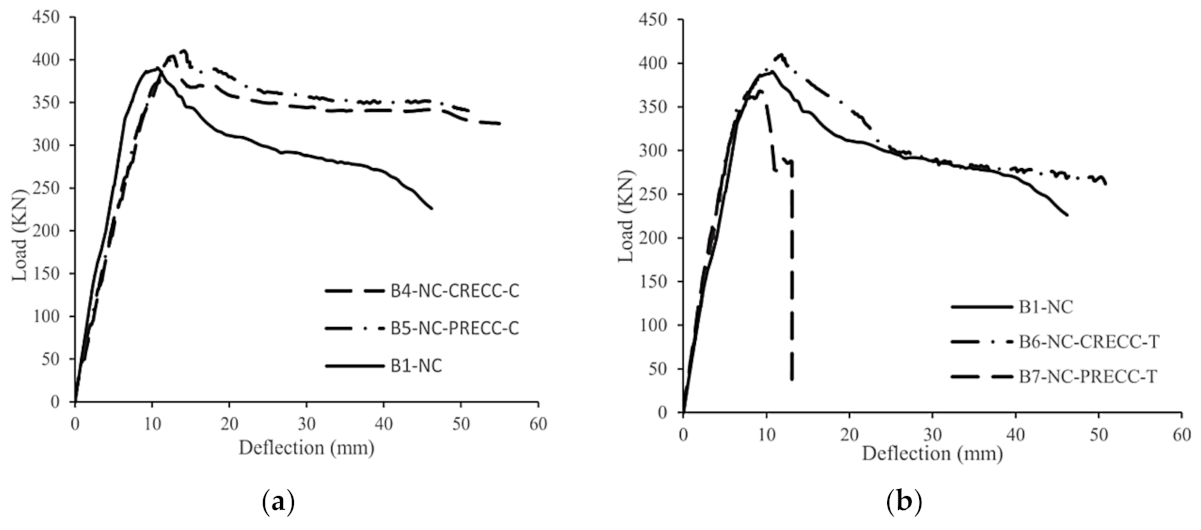

5.1. Beams and Slabs

5.2. Columns and Walls

5.3. Beam–Column Joints

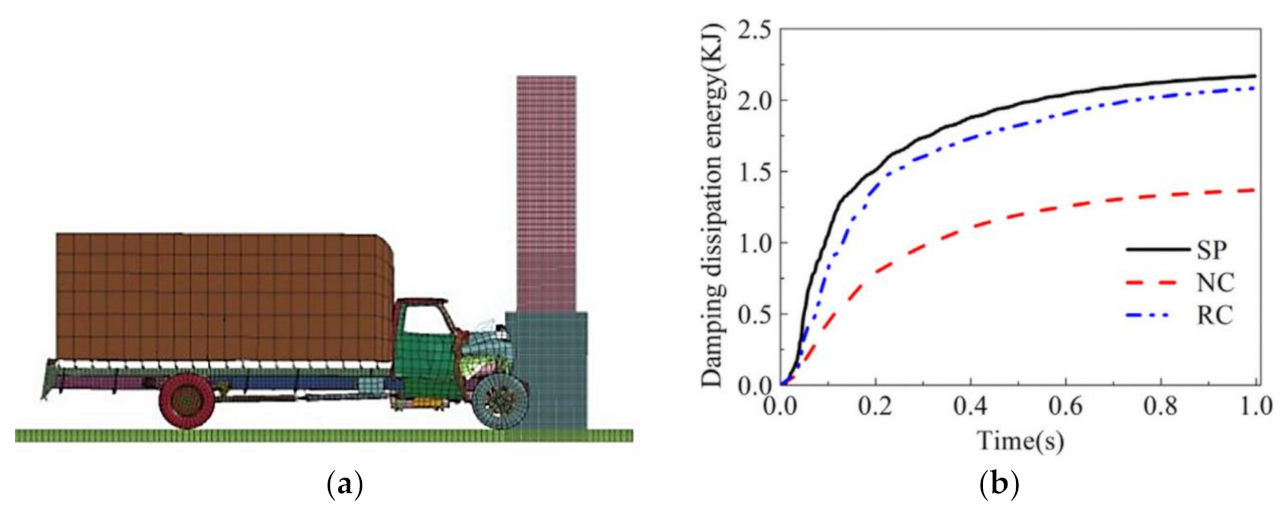

5.4. Collision and Explosion Elements

6. Conclusions

- (1)

- Rubber particles reduce the static mechanical properties of concrete; however, the incorporation of rubber enhances the concrete specimen’s ductility and plastic deformation ability. This improvement is attributed to the high elasticity, toughness, and energy absorption effect of rubber in concrete. The RC incorporating a rubber content of lower than 30% presents good mechanical and environmental performances.

- (2)

- Under dynamic loading, rubber concrete exhibits significant strain rate effects, affecting compressive strength, splitting tensile strength, and bending strength. The failure of rubber concrete under a dynamic load is associated with the formation of micro-cracks. However, rubber concrete exhibits high cracking resistance under high loading rates, decelerating the damage accumulation rate and enhancing the hysteretic deformation effect of the material.

- (3)

- In comparison to NC, RC is more sensitive to strain rate changes, and the DIF of RC is higher than that of NC at the same strain rate. The higher the rubber content (less than 30%), the stronger the impact energy absorption capacity. The strength of concrete significantly decreases when the rubber content exceeds 30%, which, in turn, results in a reduction in the material’s strain rate sensitivity and impact energy absorption.

- (4)

- Upon increasing the rubber content, significant improvements in impact energy dissipation and dynamic damping can be observed. However, the outcomes of the tests varied due to the distinct parameters, including concrete type, sample size, drop weight, and height. Nevertheless, the number of impacts resulting in the first crack (N1) and final failure (N2) both increased by more than five-fold with rubber content (0 to 30%), indicating an increase in the impact load absorption capacity and ductility.

- (5)

- Rubber, a high-quality thermal insulation and hydrophobic material, performs an essential function in filling pores, conducting heat, and mitigating matrix deformation in concrete by its elastic deformation ability. This property enhances the permeability resistance of concrete materials and their capacity to withstand extreme temperatures, including heat and freeze–thaw resistance.

- (6)

- The energy dissipation capacity and ductility of different structural elements, in which rubber particles replace part of the fine aggregate, are improved under a static load. The brittleness index is reduced and the failure mode gradually changes from brittle to more flexible behavior. The addition of rubber particles in the mixture seems to act as a spring, delaying crack expansion.

- (7)

- Rubber also improves the cyclic and dynamic performances of reinforced concrete structural members, such as beams, columns, walls, and beam–column joints. The damping ratio and energy consumption of the CRC column with a rubber content of 20% increases by 13% and 150%, respectively, compared to the CC column. Rubber has potential advantages in structural applications in high-risk earthquake zones due to its good damping and energy absorption characteristics.

- (8)

- The addition of rubber particles to concrete has shown promising results. Rubber concrete members, such as piers and columns (rubber content 0 to 30%), exhibit greater ultimate strain and energy consumption levels under collision and explosion loads, roughly two times greater than that of ordinary concrete members, indicating that rubber concrete can be used in applications requiring resistance to impacts and collisions, such as road guardrails, piers, and structures bearing expansion devices or explosion loads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Description |

| RGPC | Rubberized geopolymer concrete |

| TC | Traditional concrete |

| SFRRC | Steel fiber-reinforced rubberized concrete |

| SFRC | Steel fiber-reinforced concrete |

| SCRC | Self-compacting rubberized concrete |

| ECC | Engineered cementitious composite |

| SBR | Styrene butadiene rubber |

| CR | Crumb rubber |

| SFRRuC | Steel fiber-reinforced rubberized concretes |

| PUM | Polyurethane-based polymer mortar |

| UCS | Unconfined compressive strength |

| RCS | Rubberized cement–soil |

| SCC | Self-compacting concrete |

| RCFRP | Fiber-reinforced rubber concrete |

| RMSCC | Rubber-modified self-compacting concrete |

| CFST | Concrete-filled steel tube |

| RTP | Recycled-tire polymers |

| PFRC | Polypropylene fiber-reinforced concrete |

| FRGARC | Fiber-reinforced grouted aggregate rubberized concrete |

| CC | Conventional concrete |

| CRC | Crumbed rubber concrete |

| NC | Normal concrete |

| RECC | Rubberized engineered cementitious composite |

| ECC-CR | ECC crumb rubber |

| RC | Rubberized concrete |

| RuC | Rubberized concrete |

| GTRC | Ground tire rubber concrete |

References

- Li, P.; Khan, M.A.; Galal, A.M.; Awan, H.H.; Zafar, A.; Javed, M.F.; Qayyum, S.; Malik, M.; Wang, F. Sustainable use of chemically modified tyre rubber in concrete: Machine learning based novel predictive model. Chem. Phys. Lett. 2022, 793, 139478. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.-F. Application of waste tire rubber and recycled aggregates in concrete products: A new compression casting approach. Resour. Conserv. Recycl. 2021, 167, 105353. [Google Scholar] [CrossRef]

- Aslani, F. Mechanical Properties of Waste Tire Rubber Concrete. J. Mater. Civ. Eng. 2016, 28, 4015152. [Google Scholar] [CrossRef]

- Roychand, R.; Gravina, R.J.; Zhuge, Y.; Ma, X.; Youssf, O.; Mills, J.E. A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr. Build. Mater. 2019, 237, 117651. [Google Scholar] [CrossRef]

- Li, L.-J.; Tu, G.-R.; Lan, C.; Liu, F. Mechanical characterization of waste-rubber-modified recycled-aggregate concrete. J. Clean. Prod. 2016, 124, 325–338. [Google Scholar] [CrossRef]

- Chen, B.; Guo, L.; Sun, W. Fatigue Performance and Multiscale Mechanisms of Concrete Toughened by Polymers and Waste Rubber. Adv. Mater. Sci. Eng. 2014, 2014, 684207. [Google Scholar] [CrossRef]

- Hernández-Olivares, F.; Barluenga, G.; Bollati, M.; Witoszek, B. Static and dynamic behaviour of recycled tyre rubber-filled concrete. Cem. Concr. Res. 2002, 32, 1587–1596. [Google Scholar] [CrossRef]

- Yu, Z.; Tang, R.; Li, F.; Hu, Y.; Liu, G.; Qin, Y.; Huang, Q. Experimental study and failure criterion analysis on combined compression-shear performance of rubber concrete (RC) with different rubber replacement ratio. Constr. Build. Mater. 2021, 288, 123105. [Google Scholar] [CrossRef]

- He, L.; Cai, H.; Huang, Y.; Ma, Y.; Van Den Bergh, W.; Gaspar, L.; Valentin, J.; Vasiliev, Y.E.; Kowalski, K.J.; Zhang, J. Research on the properties of rubber concrete containing surface-modified rubber powders. J. Build. Eng. 2021, 35, 101991. [Google Scholar] [CrossRef]

- Si, R.; Guo, S.; Dai, Q. Durability performance of rubberized mortar and concrete with NaOH-Solution treated rubber particles. Constr. Build. Mater. 2017, 153, 496–505. [Google Scholar] [CrossRef]

- Yang, G.; Chen, X.; Xuan, W.; Chen, Y. Dynamic compressive and splitting tensile properties of concrete containing recycled tyre rubber under high strain rates. Sādhanā 2018, 43, 178. [Google Scholar] [CrossRef]

- Long, G.C.; Li, N.; Xue, Y.; Xie, Y.J. Mechanical properties of self-compacting concrete incorporating rubber particles under impact load. J. Chin. Ceram. Soc. 2016, 44, 1081–1090. [Google Scholar]

- Pham, T.M.; Chen, W.; Khan, A.M.; Hao, H.; Elchalakani, M.; Tran, T.M. Dynamic compressive properties of lightweight rubberized concrete. Constr. Build. Mater. 2019, 238, 117705. [Google Scholar] [CrossRef]

- Lai, D.; Demartino, C.; Xiao, Y. High-strain rate compressive behavior of Fiber-Reinforced Rubberized Concrete. Constr. Build. Mater. 2021, 319, 125739. [Google Scholar] [CrossRef]

- Feng, L.; Chen, X.; Zhang, J.; Chen, C. Experimental and mesoscopic investigation of self-compacting rubberized concrete under dynamic splitting tension. J. Build. Eng. 2022, 57, 104942. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Wang, H.; Zhang, M. Behaviour of recycled tyre polymer fibre reinforced concrete under dynamic splitting tension. Cem. Concr. Compos. 2020, 114, 103764. [Google Scholar] [CrossRef]

- Feng, W.; Liu, F.; Yang, F.; Li, L.; Jing, L. Experimental study on dynamic split tensile properties of rubber concrete. Constr. Build. Mater. 2018, 165, 675–687. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Reyes, J.; Feliu, J.; Hernández, M. Influence of scrap rubber addition to Portland I concrete composites: Destructive and non-destructive testing. Compos. Struct. 2005, 71, 439–446. [Google Scholar] [CrossRef]

- Huang, L.; Su, L.; Xie, J.; Lu, Z.; Li, P.; Hu, R.; Yang, S. Dynamic splitting behaviour of ultra-high-performance concrete confined with carbon-fibre-reinforced polymer. Compos. Struct. 2022, 284, 115155. [Google Scholar] [CrossRef]

- Cai, H.; Yuan, B.; Yang, F.; Chen, L.; Feng, W.; Liang, Y. Dynamic three-point flexural performance of unsaturated polyester polymer concrete at different curing ages. J. Build. Eng. 2021, 45, 103449. [Google Scholar] [CrossRef]

- Feng, W.; Liu, F.; Yang, F.; Li, L.; Jing, L.; Chen, B.; Yuan, B. Experimental study on the effect of strain rates on the dynamic flexural properties of rubber concrete. Constr. Build. Mater. 2019, 224, 408–419. [Google Scholar] [CrossRef]

- Yang, G.; Chen, X.; Guo, S.; Xuan, W. Dynamic Mechanical Performance of Self-compacting Concrete Containing Crumb Rubber under High Strain Rates. KSCE J. Civ. Eng. 2019, 23, 3669–3681. [Google Scholar] [CrossRef]

- Mo, J.; Zeng, L.; Liu, Y.; Ma, L.; Liu, C.; Xiang, S.; Cheng, G. Mechanical properties and damping capacity of polypropylene fiber reinforced concrete modified by rubber powder. Constr. Build. Mater. 2020, 242, 118111. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Abu Bakar, B.H.; Akil, H.M.; Ismail, H. Performance of Rubberized and Hybrid Rubberized Concrete Structures under Static and Impact Load Conditions. Exp. Mech. 2012, 53, 377–384. [Google Scholar] [CrossRef]

- Gupta, T.; Patel, K.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Prediction of mechanical properties of rubberised concrete exposed to elevated temperature using ANN. Measurement 2019, 147, 106870. [Google Scholar] [CrossRef]

- Wang, J.; Du, B. Experimental studies of thermal and acoustic properties of recycled aggregate crumb rubber concrete. J. Build. Eng. 2020, 32, 101836. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Mezreb, K.; Laidoudi, B.; Quéneudec, M. Thermal conductivity of cement composites containing rubber waste particles: Experimental study and modelling. Constr. Build. Mater. 2008, 22, 573–579. [Google Scholar] [CrossRef]

- Marques, A.; Correia, J.; de Brito, J. Post-fire residual mechanical properties of concrete made with recycled rubber aggregate. Fire Saf. J. 2013, 58, 49–57. [Google Scholar] [CrossRef]

- Pham, T.M.; Lim, Y.Y.; Malekzadeh, M. Effect of pretreatment methods of crumb rubber on strength, permeability and acid attack resistance of rubberised geopolymer concrete. J. Build. Eng. 2021, 41, 102448. [Google Scholar]

- Khern, Y.C.; Paul, S.C.; Kong, S.Y.; Babafemi, A.J.; Anggraini, V.; Miah, J.; Šavija, B. Impact of Chemically Treated Waste Rubber Tire Aggregates on Mechanical, Durability and Thermal Properties of Concrete. Front. Mater. 2020, 7, 90. [Google Scholar] [CrossRef]

- Assaggaf, R.A.; Al-Dulaijan, S.U.; Maslehuddin, M.; Al-Amoudi, O.S.B.; Ahmad, S.; Ibrahim, M. Effect of different treatments of crumb rubber on the durability characteristics of rubberized concrete. Constr. Build. Mater. 2022, 318, 126030. [Google Scholar] [CrossRef]

- Wang, J.; Guo, Z.; Yuan, Q.; Zhang, P.; Fang, H. Effects of ages on the ITZ microstructure of crumb rubber concrete. Constr. Build. Mater. 2020, 254, 119329. [Google Scholar] [CrossRef]

- Alsaif, A.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Durability of steel fibre reinforced rubberised concrete exposed to chlorides. Constr. Build. Mater. 2018, 188, 130–142. [Google Scholar] [CrossRef]

- Hua, L.; Xiao, F.; Li, Y.; Huang, H.; Zhao, K.; Yu, K.; Hettiarachchi, C. A potential damage mechanism of rubberized cement under freeze-thaw cycle. Constr. Build. Mater. 2020, 252, 119054. [Google Scholar] [CrossRef]

- Grinys, A.; Augonis, A.; Daukšys, M.; Pupeikis, D. Mechanical properties and durability of rubberized and SBR latex modified rubberized concrete. Constr. Build. Mater. 2020, 248, 118584. [Google Scholar] [CrossRef]

- Alsaif, A.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Freeze-thaw resistance of steel fibre reinforced rubberised concrete. Constr. Build. Mater. 2018, 195, 450–458. [Google Scholar] [CrossRef]

- Jiang, W.; Zhu, H.; Haruna, S.I.; Shao, J.; Yu, Y.; Wu, K. Mechanical properties and freeze–thaw resistance of polyurethane-based polymer mortar with crumb rubber powder. Constr. Build. Mater. 2022, 352, 129040. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J. Effect of freeze–thaw cycles on the resilient moduli and unconfined compressive strength of rubberized recycled concrete aggregate as pavement base/subbase. Transp. Geotech. 2020, 27, 100477. [Google Scholar] [CrossRef]

- Mendis, A.S.; Al-Deen, S.; Ashraf, M. Flexural shear behaviour of reinforced Crumbed Rubber Concrete beam. Constr. Build. Mater. 2018, 166, 779–791. [Google Scholar] [CrossRef]

- AbdelAleem, B.H.; Hassan, A.A. Use of rubberized engineered cementitious composite in strengthening flexural concrete beams. Eng. Struct. 2022, 262, 114304. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.E. Experimental investigations of reinforced rubberized concrete structural members. J. Build. Eng. 2017, 10, 149–165. [Google Scholar] [CrossRef]

- Li, D.; Xiao, J.; Zhuge, Y.; Mills, J.E.; Senko, H.; Ma, X. Experimental study on crumb rubberised concrete (CRC) and reinforced CRC slabs under static and impact loads. Aust. J. Struct. Eng. 2020, 21, 294–306. [Google Scholar] [CrossRef]

- He, S.; Zhou, W.; Jiang, Z.; Zheng, C.; Mo, X.; Huang, X. Structural performance of perforated steel plate-CFST arch feet in concrete girder-steel arch composite bridges. J. Constr. Steel. Res. 2023, 201, 107742. [Google Scholar] [CrossRef]

- He, S.; Xu, Y.; Zhong, H.; Mosallam, A.S.; Chen, Z.; Huang, X. Investigation on interfacial anti-sliding behavior of high strength steel-UHPC composite beams. Compos. Struct. 2023, 316, 117036. [Google Scholar] [CrossRef]

- Son, K.S.; Hajirasouliha, I.; Pilakoutas, K. Strength and deformability of waste tyre rubber-filled reinforced concrete columns. Constr. Build. Mater. 2011, 25, 218–226. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Karimi, A.; Gholampour, A. Pre-and post-heating behavior of concrete-filled steel tube stub columns containing steel fiber and tire rubber. Structures 2020, 27, 2346–2364. [Google Scholar] [CrossRef]

- Moustafa, A.; Gheni, A.; ElGawady, M.A. Shaking-Table Testing of High Energy–Dissipating Rubberized Concrete Columns. J. Bridg. Eng. 2017, 22, 4017042. [Google Scholar] [CrossRef]

- Youssf, O.; ElGawady, M.A.; Mills, J.E. Experimental investigation of crumb rubber concrete columns under seismic loading. Structures 2015, 3, 13–27. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Youssf, O.; Mills, J.; Xiao, J. Structural behaviour of composite panels made of profiled steel sheets and foam rubberised concrete under monotonic and cyclic shearing loads. Thin-Walled Struct. 2020, 151, 106726. [Google Scholar] [CrossRef]

- Sadek, D.M.; El-Attar, M.M. Structural behavior of rubberized masonry walls. J. Clean. Prod. 2015, 89, 174–186. [Google Scholar] [CrossRef]

- Chu, L.; Wang, S.; Li, D.; Zhao, J.; Ma, X. Cyclic behaviour of beam-column joints made of crumb rubberised concrete (CRC) and traditional concrete (TC). Case Stud. Constr. Mater. 2021, 16, e00867. [Google Scholar] [CrossRef]

- Ganesan, N.; Raj, B.; Shashikala, A.P. Behavior of self-consolidating rubberized concrete beam-column joints. ACI Mater. J. 2013, 110, 697. [Google Scholar]

- AbdelAleem, B.H.; Hassan, A.A. Effect of combining steel fibers with crumb rubber on enhancing the behavior of beam-column joints under cyclic loading. Eng. Struct. 2019, 182, 510–527. [Google Scholar] [CrossRef]

- AbdelAleem, B.H.; Ismail, M.K.; Hassan, A.A. Structural Behavior of Rubberized Engineered Cementitious Composite Beam-Column Joints under Cyclic Loading. ACI Struct. J. 2020, 117. [Google Scholar]

- Gil-Martín, L.; Rodríguez-Suesca, A.; Fernández-Ruiz, M.; Hernández-Montes, E. Cyclic behavior of RC beam-column joints with epoxy resin and ground tire rubber as partial cement replacement. Constr. Build. Mater. 2019, 211, 659–674. [Google Scholar] [CrossRef]

- Liu, B.; Yang, S.; Li, W.; Zhang, M. Damping dissipation properties of rubberized concrete and its application in anti-collision of bridge piers. Constr. Build. Mater. 2019, 236, 117286. [Google Scholar] [CrossRef]

- Atahan, A.O.; Sevim, U.K. Testing and comparison of concrete barriers containing shredded waste tire chips. Mater. Lett. 2008, 62, 3754–3757. [Google Scholar] [CrossRef]

- Pham, T.M.; Zhang, X.; Elchalakani, M.; Karrech, A.; Hao, H.; Ryan, A. Dynamic response of rubberized concrete columns with and without FRP confinement subjected to lateral impact. Constr. Build. Mater. 2018, 186, 207–218. [Google Scholar] [CrossRef]

- Yu, Y.; Jin, Z.; Zhu, H.; Song, H. Effect of rubber particles on impact resistance of concrete at a temperature of −20 °C. Arch. Civ. Mech. Eng. 2021, 21. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Li, D.; Chen, Y.; Xiang, Z. Enhancement of Dynamic Damping in Eco-Friendly Railway Concrete Sleepers Using Waste-Tyre Crumb Rubber. Materials 2018, 11, 1169. [Google Scholar] [CrossRef]

- Yang, F.; Feng, W.; Liu, F.; Jing, L.; Yuan, B.; Chen, D. Experimental and numerical study of rubber concrete slabs with steel reinforcement under close-in blast loading. Constr. Build. Mater. 2019, 198, 423–436. [Google Scholar] [CrossRef]

- Feng, W.; Chen, B.; Yang, F.; Liu, F.; Li, L.; Jing, L.; Li, H. Numerical study on blast responses of rubberized concrete slabs using the Karagozian and Case concrete model. J. Build. Eng. 2020, 33, 101610. [Google Scholar] [CrossRef]

- Alwesabi, E.A.; Abu Bakar, B.; Alshaikh, I.M.; Akil, H. Impact resistance of plain and rubberized concrete containing steel and polypropylene hybrid fiber. Mater. Today Commun. 2020, 25, 101640. [Google Scholar] [CrossRef]

- Aslani, F.; Khan, M. Properties of High-Performance Self-Compacting Rubberized Concrete Exposed to High Temperatures. J. Mater. Civ. Eng. 2019, 31, 4019040. [Google Scholar] [CrossRef]

- Guo, Y.-C.; Zhang, J.-H.; Chen, G.-M.; Xie, Z.-H. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; Ipek, S.; Asaad, D.S. Influence of waste rubber utilization on the fracture and steel–concrete bond strength properties of concrete. Constr. Build. Mater. 2015, 101, 1113–1121. [Google Scholar] [CrossRef]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Hossain, F.Z.; Shahjalal; Islam, K.; Tiznobaik, M.; Alam, M.S. Mechanical properties of recycled aggregate concrete containing crumb rubber and polypropylene fiber. Constr. Build. Mater. 2019, 225, 983–996. [Google Scholar] [CrossRef]

- Chen, A.; Han, X.; Chen, M.; Wang, X.; Wang, Z.; Guo, T. Mechanical and stress-strain behavior of basalt fiber reinforced rubberized recycled coarse aggregate concrete. Constr. Build. Mater. 2020, 260, 119888. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T. Properties of rubberized concretes containing silica fume. Cem. Concr. Res. 2004, 34, 2309–2317. [Google Scholar] [CrossRef]

- Abdelmonem, A.; El-Feky, M.; Nasr, E.-S.A.; Kohail, M. Performance of high strength concrete containing recycled rubber. Constr. Build. Mater. 2019, 227, 116660. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Najim, K.B.; Hall, M.R. Crumb rubber aggregate coatings/pretreatments and their effects on interfacial bonding, air entrapment and fracture toughness in self-compacting rubberised concrete (SCRC). Mater. Struct. 2013, 46, 2029–2043. [Google Scholar] [CrossRef]

- Marques, A.C.; Akasaki, J.L.; Trigo, A.P.M.; Marques, M.L. Influence of the surface treatment of tire rubber residues added in mortars. Rev. IBRACON Estruturas Mater. 2008, 1, 113–120. [Google Scholar] [CrossRef]

- Bisht, K.; Ramana, P. Evaluation of mechanical and durability properties of crumb rubber concrete. Constr. Build. Mater. 2017, 155, 811–817. [Google Scholar] [CrossRef]

- Hilal, N.N. Hardened properties of self-compacting concrete with different crumb rubber size and content. Int. J. Sustain. Built Environ. 2017, 6, 191–206. [Google Scholar] [CrossRef]

- Choudhary, S.; Chaudhary, S.; Jain, A.; Gupta, R. Valorization of waste rubber tyre fiber in functionally graded concrete. Mater. Today Proc. 2020, 32, 645–650. [Google Scholar] [CrossRef]

- Liu, R.; Li, H.; Jiang, Q.; Meng, X. Experimental investigation on flexural properties of directional steel fiber reinforced rubberized concrete. Structures 2020, 27, 1660–1669. [Google Scholar] [CrossRef]

- Li, L.; Ruan, S.; Zeng, L. Mechanical properties and constitutive equations of concrete containing a low volume of tire rubber particles. Constr. Build. Mater. 2014, 70, 291–308. [Google Scholar] [CrossRef]

- Atahan, A.; Yücel, A. Crumb rubber in concrete: Static and dynamic evaluation. Constr. Build. Mater. 2012, 36, 617–622. [Google Scholar] [CrossRef]

- Li, D.; Zhuge, Y.; Gravina, R.; Mills, J.E. Compressive stress strain behavior of crumb rubber concrete (CRC) and application in reinforced CRC slab. Constr. Build. Mater. 2018, 166, 745–759. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, L.; Pan, W.; Wang, W.; Guan, Q.; Zhai, S.; Liu, L.; Zhang, Y. Study on evaluation of elastic modulus of crumb rubber concrete in meso-scale. Constr. Build. Mater. 2022, 331, 127247. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, T.; Huang, B.; Zhou, Y.; Ye, J. Ultra-lightweight high ductility cement composite incorporated with low PE fiber and rubber powder. Constr. Build. Mater. 2021, 312, 125430. [Google Scholar] [CrossRef]

- Huang, Z.; Sui, L.; Wang, F.; Du, S.; Zhou, Y.; Ye, J. Dynamic compressive behavior of a novel ultra-lightweight cement composite incorporated with rubber powder. Compos. Struct. 2020, 244, 112300. [Google Scholar] [CrossRef]

- Xiong, C.; Li, Q.; Lan, T.; Li, H.; Long, W.; Xing, F. Sustainable use of recycled carbon fiber reinforced polymer and crumb rubber in concrete: Mechanical properties and ecological evaluation. J. Clean. Prod. 2020, 279, 123624. [Google Scholar] [CrossRef]

- Yang, R.; Xu, Y.; Chen, P.; Wang, J. Experimental study on dynamic mechanics and energy evolution of rubber concrete under cyclic impact loading and dynamic splitting tension. Constr. Build. Mater. 2020, 262, 120071. [Google Scholar] [CrossRef]

- Lindholm, U. Some experiments with the split hopkinson pressure bar∗. J. Mech. Phys. Solids 1964, 12, 317–335. [Google Scholar] [CrossRef]

- ACI 544-18; Guide for Specifying, Mixing, Placing, and Finishing Steel Fiber Reinforced Concrete. American Concrete Institute (ACI): Farmington Hills, MI, USA, 2018.

- Xu, J.; Yao, Z.; Yang, G.; Han, Q. Research on crumb rubber concrete: From a multi-scale review. Constr. Build. Mater. 2019, 232, 117282. [Google Scholar] [CrossRef]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Yan, Z.-W.; Jia, J.-F.; Ozbakkaloglu, T.; Liu, Y. Dynamic compressive behavior of concrete confined with unidirectional natural flax FRP based on SHPB tests. Compos. Struct. 2021, 259, 113233. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Abu Bakar, B.; Ismail, H.; Akil, H. Effect of partial replacement of sand by recycled fine crumb rubber on the performance of hybrid rubberized-normal concrete under impact load: Experiment and simulation. J. Clean. Prod. 2013, 59, 284–289. [Google Scholar] [CrossRef]

- Hameed, A.S.; Shashikala, A. Suitability of rubber concrete for railway sleepers. Perspect. Sci. 2016, 8, 32–35. [Google Scholar] [CrossRef]

- Youssf, O.; Hassanli, R.; Mills, J.E. Mechanical performance of FRP-confined and unconfined crumb rubber concrete containing high rubber content. J. Build. Eng. 2017, 11, 115–126. [Google Scholar] [CrossRef]

- Eltayeb, E.; Ma, X.; Zhuge, Y.; Youssf, O.; Mills, J. Influence of rubber particles on the properties of foam concrete. J. Build. Eng. 2020, 30, 101217. [Google Scholar] [CrossRef]

- Murali, G.; Poka, L.; Parthiban, K.; Haridharan, M.K.; Siva, A. Impact Response of Novel Fibre-Reinforced Grouted Aggregate Rubberized Concrete. Arab. J. Sci. Eng. 2019, 44, 8451–8463. [Google Scholar] [CrossRef]

- Li, H.-L.; Xu, Y.; Chen, P.-Y.; Ge, J.-J.; Wu, F. Impact Energy Consumption of High-Volume Rubber Concrete with Silica Fume. Adv. Civ. Eng. 2019, 2019, htpps. [Google Scholar] [CrossRef]

- Noaman, A.T.; Abu Bakar, B.H.; Akil, H. Influence of Crumb Rubber on Impact Energy of Steel Fiber Concrete Beams. Appl. Mech. Mater. 2015, 802, 196–201. [Google Scholar] [CrossRef]

- Donga, P.D.; Shah, D.; Bhavsar, J.K. Impact resistance of waste rubber fiber silica fume concrete. J. Civ. Eng. Environ. Technol. 2016, 3, 274–279. [Google Scholar]

- Elchalakani, M. High strength rubberized concrete containing silica fume for the construction of sustainable road side barriers. Structures 2015, 1, 20–38. [Google Scholar] [CrossRef]

- Wang, F.; Ping, X.; Zhou, J.; Kang, T. Effects of crumb rubber on the frost resistance of cement-soil. Constr. Build. Mater. 2019, 223, 120–132. [Google Scholar] [CrossRef]

| Reference | Objective | Concrete | Rubber Type | Rubber Content (%) | Key Findings |

|---|---|---|---|---|---|

| Gupta et al. [25] | Dynamic compressive properties | RC | Fibers (2–5 mm wide, up to 20 mm long) | 0, 5, 10, 15, 20, 25 | Under ambient temperature, dynamic modulus of elasticity decreases as rubber increases. |

| Huang et al. [84] | Dynamic compressive properties | RULCC | Particles (380 μm) | 5, 10, 20 | Dynamic compressive strength decreases as rubber content increases. |

| Xiong et al. [85] | Dynamic compressive properties | RFRRC | 0, 10 | RFRRC possesses good flexural toughness, ductility, and impact resistance. | |

| Pham et al. [13] | Dynamic compressive properties | RUC | Crumbs (1–3 mm, 3–5 mm, and 5–10 mm wide) | 0, 15, 30 | Absorbed energy of rubber concrete is 54–79% higher than normal concrete. |

| Lai et al. [14] | Dynamic compressive properties | FRRC | Crumbs (1–3 mm wide) | 30 | Ratio of dynamic compressive strength to DIF increases with the strain rate. |

| Feng et al. [15] | Dynamic splitting tensile property | SCRC | Particles (4.75 mm) | 5, 10, 15 | Dynamic splitting tensile strength decreases as rubber content increases. |

| Chen et al. [16] | Dynamic splitting tensile property | FRC | 0.1, 0.2, 0.4, 0.8 | RTP fibers enhance the splitting tensile properties of rubber concrete under various strain rates. | |

| Feng et al. [17] | Dynamic splitting tensile property | RC | Particles (0.85 mm) | 0, 10, 20, 30, 40, 50 | Rubber particles have a toughening effect on the concrete. |

| Yang et al. [86] | Dynamic splitting tensile property | RC | Particles (0.36–1.26 mm) | Rubber concrete exhibits better compression energy dissipation than splitting. | |

| Feng et al. [21] | Dynamic flexural property | RC | Particles (0.85 mm) | 0, 10, 20, 30, 40, 50 | Rubber concrete is more sensitive to strain rate than normal concrete. |

| Mo et al. [23] | Dynamic flexural property | PFRC | Particles (380 μm) | Rubber powder improves PFRC damping capacity. | |

| Al-Tayeb et al. [24] | Dynamic flexural property | RC | 5, 10, 20 | The static peak bending load always decreases with increase in rubber in the mix. |

| Rubber Content (%) | η | λ | a | b |

|---|---|---|---|---|

| 0 | 1.1199 | 0.9063 | 0.639 | 0.796 |

| 10 | 1.01412 | 0.9213 | 0.895 | 0.927 |

| 20 | 1.1813 | 1.0156 | 0.972 | 0.855 |

| 30 | 1.2535 | 0.8614 | 1.100 | 0.831 |

| 40 | 0.9307 | 1.1061 | 0.957 | 0.740 |

| 50 | 1.0918 | 1.4550 | 0.619 | 0.804 |

| Reference | Objective | Concrete | Rubber Type | Rubber Content (%) | Key Findings |

|---|---|---|---|---|---|

| Wang et al. [26] | Thermal performance | RCC | Particles (0.1–4, 5–10 mm) | 10, 20, 30 | Concrete with a rubber content of 20% possesses the highest thermal resistance and energy absorption. |

| Benazzouk et al. [27] | Thermal performance | CRA | Particles (smaller than 1 mm) | 10, 20, 30, 40, 50 | Rubber particles increase concrete thermal conductivity. |

| Aslani et al. [64] | Thermal performance | SCRC | Particles (2–10 mm) | 10, 20, 30, 40 | Crumb rubber as an aggregate enhances deformation and energy absorption but decreases workability. |

| Pham et al. [29] | Impermeability | GPC | Particles (0–14 mm) | 0, 10, 20, 30 | Water absorption of concrete increases with increase in rubber content. |

| Khern et al. [30] | Impermeability | REF | Particles (0–15 mm) | 8, 10, 20, 30 | Impermeability of concrete with 5% Ca(ClO)2 treated rubber is better than those with 20% NaOH and water. |

| Assaggaf et al. [31] | Impermeability | CRC | Particles (0.3–2.36 mm) | 2, 8, 16, 24, 40 | Water absorption of CRC treated with NaOH, KMnO4, and cement slurry is lower than untreated CRC. |

| Alsaif et al. [33] | Impermeability | SFRRuC | Particles (0–20 mm) | 0, 30, 60 | Penetration depth of chloride ion increases with rubber content. |

| Grinys et al. [35] | Freeze–thaw resistant | SBR, RC | Particles (0–2 mm) | 5 | Concrete with certain rubber has high closed porosity and good freeze–thaw durability. |

| Alsaif et al. [36] | Freeze–thaw resistant | SFRRuC, SFRC, RC | Particles (CR:0–10 mm, FR: 0–6 mm) | 30, 60 | SFRRuC can withstand 56 freeze–thaw cycles without internal damage or mechanical property degradation. |

| Jiang et al. [37] | Freeze–thaw resistant | PUM | Particles (0–2.5 mm) | 0–15 | Rubber improves concrete bending toughness and frost resistance. |

| Saberian et al. [38] | Freeze–thaw resistant | RCA | Particles (0.5 mm) | 0.5, 1, 2 | Freezing and thawing affect frost resistance of rubber concrete. |

| Wang et al. [101] | Freeze–thaw resistant | RCS | Particles (0.25 and 0.5 mm) | 0, 5, 10, 15, 20 | Compressive strength of rubber concrete peaks at the 6th to 9th cycles and then gradually decreases. |

| Reference | Test Description | Components | Concrete Type | Rubber Ratio (%) | Key Findings |

|---|---|---|---|---|---|

| Mendis et al. [39] | Two-point bending test | Concrete beam (100 × 200 × 2200 mm) | CRC | 5, 11, 21 | Shear capacity of CRC beam is 2–10% lower than NC beam. |

| Abdel Aleem et al. [40] | Four-point bending test | Concrete beam (100 × 200 × 2200 mm) | RECC | 20 | Rubberized ECC beam possesses higher deformability and resistance than the NC beam. |

| Hassanli et al. [41] | Cyclic bending test | Concrete beam (130 × 200 × 2800 mm) | NRC | 6, 12, 18 | Ultimate displacement of NRC beams is 27.9% higher than NC beams. |

| Li et al. [42] | Impact test four-point bending test | Concrete slab (550 × 10 × 2200 mm) | CRC | 5, 10, 15, 20 | Impact resistance of CRC is 5% (CRC5), 9% (CRC10), 15% (CRC15), and 12% (CRC20), respectively, higher than TC. |

| Son et al. [44] | Compression test | Concrete-filled column (300 × 200 × 1600 mm) | CRC | 2.7–5.4 | Rubber concrete offers good energy dissipation capacity and ductility, making it suitable for seismic applications. |

| Nematzadeh et al. [44] | Compression test | CFST column (89 × 188 mm) | CFST | 5, 10 | Rubber decreases the compressive strength of CFSTs. |

| Moustafa et al. [47] | Seismic test | Concrete column (300 × 1800 mm) | RC | 20 | The lateral drift and energy dissipated capacity of the rubber concrete column are 12.5% and 16.5%, respectively, higher than the NC column. |

| Youssef et al. [48] | Reversed cyclic loads | Concrete column (240 × 1325 mm) | CRC | 20 | Hysteretic damping ratio and energy dissipation of the CRC columns increase by 13% and 150%, respectively. |

| Eltayeb et al. [49] | Cyclic shearing test | Steel-concrete composite slab (600 × 600 × 100 mm) | FRC | 8.5, 17% | FRC slabs with 8.5% and 17% rubber contents produce 10.3% and 8% higher resistance than their counterparts, respectively. |

| Chu et al. [51] | Cyclic bending test | Beam–column joints (400 × 400 × 2700 mm) | CRC | 15 | Post-energy dissipation ability of CRC improved by 10%. |

| Ganesan et al. [52] | Cyclic bending test | Beam–column joints (150 × 200 × 1000 mm) | SCRC, SFSRC | 15 | Rubber and steel fibers enhance the concrete’s load-carrying capacity and crack resistance. |

| AbdelAleem et al. [53] | Cyclic bending test | Beam–column joints (250 × 250 × 1000 mm) | SCC-CR | 0–25 | The optimum percentage of CR is 15%. |

| AbdelAleem et al. [54] | Cyclic bending test | Beam–column joints (250 × 250 × 1000 mm) | ECC-CR | 5, 10, 15 | Rubber increases ECC’s energy dissipation and ductility by 4%, 11%, 23% and 8%, 15%, and 18%, respectively |

| Gil-Martín et al. [55] | Cyclic bending test | Beam–column joints (250 × 250 × 1500 mm) | GTRC | 5 | Rubber concrete exhibits good structural behavior. |

| Feng et al. [60] | Blast test | Concrete slab (200 × 200 × 100 mm) | RC | 10, 30 | Blast resistance of rubber concrete is superior to that of NC. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Jiang, Z.; Chen, H.; Chen, Z.; Ding, J.; Deng, H.; Mosallam, A.S. Mechanical Properties, Durability, and Structural Applications of Rubber Concrete: A State-of-the-Art-Review. Sustainability 2023, 15, 8541. https://doi.org/10.3390/su15118541

He S, Jiang Z, Chen H, Chen Z, Ding J, Deng H, Mosallam AS. Mechanical Properties, Durability, and Structural Applications of Rubber Concrete: A State-of-the-Art-Review. Sustainability. 2023; 15(11):8541. https://doi.org/10.3390/su15118541

Chicago/Turabian StyleHe, Shaohua, Zheng Jiang, Huanwei Chen, Zhiliang Chen, Jianming Ding, Haidong Deng, and Ayman S. Mosallam. 2023. "Mechanical Properties, Durability, and Structural Applications of Rubber Concrete: A State-of-the-Art-Review" Sustainability 15, no. 11: 8541. https://doi.org/10.3390/su15118541

APA StyleHe, S., Jiang, Z., Chen, H., Chen, Z., Ding, J., Deng, H., & Mosallam, A. S. (2023). Mechanical Properties, Durability, and Structural Applications of Rubber Concrete: A State-of-the-Art-Review. Sustainability, 15(11), 8541. https://doi.org/10.3390/su15118541