1. Introduction

The foundation is one of the crucial components of structures as it stabilizes the building system and transfers the whole load to the soil. Generally, there are two types of foundations: shallow and deep. The cost of foundation construction ranges from 10% to 15% of the project’s total cost [

1]. The foundation types are usually chosen based on the designers’ and builders’ experience and judgment, with little consideration of the structure’s specific engineering–geological conditions and features. A suitable foundation type is chosen by considering several variables, including the engineering–geological conditions, climatic influence, groundwater levels, unique features of the structure, and the builder’s technological skills [

2]. In addition, Turskis et al. [

3], pointed out that the expected cost of the foundation and the project duration may influence the decision of foundation selection, which in turn influences the project’s scope, schedule, bonding conditions, and maximum and minimum deviations from the volume of work.

An effective method to establish a suitable solution is supported by multi-criteria decision-making (

MCDM) or multi-attribute decision-making methods (MADM [

4,

5]. Several methods support

MCDM, including Value Engineering (

VE), Analytical Hierarchy Process (

AHP), Function Analysis System Technique (

FAST), Stepwise Weight Assessment Ratio Analysis (

SWARA), and Weighted Aggregated Sum Product Assessment (

WASPAS).

First, the

VE approach aims to provide the required facility at the lowest cost while preserving performance consistency, dependability, and maintainability. Achieving a balance between cost, punctuality, and quality is challenging, given current construction practices. The Society of American Value Engineers refers to

VE as a systematic application that precisely defines and provides the desired function at the lowest cost [

6]. The

VE increases the product’s value by altering and improving functions. Value improvement is the

VE’s primary objective. The

VE states that value is the ratio of sum function and quality to cost [

6]. Elhegazy [

7] stated the importance of the

VE in the design, ongoing operation, and maintenance of multistory buildings.

Second, the

AHP methodology, introduced by Saaty [

8], addresses hierarchical challenges by minimizing the number of complex judgments. As a result, the

AHP aids in determining a decision’s subjective and objective components. The

AHP also uses an effective method to reduce any potential bias in judgment. Finally, the pairwise method has been used to evaluate the criteria and user choices, transforming the

AHP into a flexible and powerful tool for final ranking.

Third, the FAST is a graphical representation of a product, system, or entity’s functions that uses the relationships of how and why they are presented. FAST allows the evaluation of existing or suggested processes in terms of their effectiveness in achieving the targeted service or function. In the context of foundation selection, FAST can be performed to develop the selection criteria with a focus on the attributes of the primary function of the foundation.

Fourth, the

SWARA technique, developed by Keršulienė et al. [

9] is more straightforward to use than other

MCDM tools for assessing and weighing selection criteria. Finally, the

WASPAS is one of the

MCDM methods, and it combines the weighted sum model (

WSM) and weighted product model (

WPM) to provide more accuracy than its components [

9].

A suitable foundation may significantly impact the project’s progress and the stages of construction. However, limited prior research efforts are addressing the issue of foundation selection using

MCDM. Prior studies were limited to one type of foundation [

10] or a few types of foundations [

3]. In addition, previous studies did not consider the flexibility of the architectural design and the water table issues in the decision-making of the foundation type.

In this paper, the methods mentioned above (AHP, FAST, SWARA, and WASPAS) were integrated and incorporated into the VE concept (which is expressed as (Quality + Function)/Cost) to develop a framework for selecting appropriate foundation types. According to the type of construction project and subsoil conditions, 45 cases were generated, and six cases were considered in the paper. Developing the framework involved reviewing international standards, reviewing the literature, and conducting expert interviews to shortlist the most critical criteria and then classifying them into four main sub-functions of foundations. Based on the evaluation of foundation construction experts, the selected significant criteria were defined based on FAST analysis, including the four main sub-functions: safety, buildability, adaptable architectural design, and environmental impact. According to the FAST analysis, the significant criteria were distributed as follows; five criteria were safety-related, two criteria for both adaptable architectural design and environmental impact and one criterion for buildability. The weight of the ten criteria was then determined for the six cases by experts using the SWARA approach. The alternative foundations’ quality weight was then defined using WASPAS. After calculating the life cycle cost of each alternative foundation for the six cases, the VE was calculated for each alternative foundation.

3. Methodology

The research approach used to establish the proposed framework is described in this section.

Figure 1 represents the framework flowchart process. The methodology consists of six steps; where data collection was performed first. Then, identifying and selecting the significant criteria was accomplished using

FAST analysis and carrying out expert interviews. Subsequently, the weights for the selected criteria were determined using the

SWARA method. Next, calculating quality weight per foundation alternative was executed using the

WASPAS method. After that, an estimation of the life cycle cost per foundation alternative was performed by interviewing experts. Finally, the

VE was computed for each alternative; the higher the value of the

VE, the better the alternative.

3.1. Collecting Data

Requirements and demands in selecting the foundation types were collected. In this stage, books [

26,

27,

28,

29], reports [

30], and standards [

31,

32] were all thoroughly searched. Additionally, several meetings with three foundation construction experts were held to review the criteria that were collected by the above sources and to select the common foundation design criteria. The task’s outcome was also to create a strategy and implementation process for the proposed framework. The foundation design criteria are displayed in

Table 2. These criteria were classified based on function into six groups—safety, buildability, water table issues, site location condition, adaptable architectural design, and environmental impacts.

It should be noted that the function of “Adaptable architectural design” with its criteria (less top surface area foundation and more embedment depth) was added based on the results of interviews with construction industry experts. In addition, environmental impact was added based on the study by Gispert et al. [

9]. The function has two criteria: less thermal emission and less influence on the groundwater table.

3.2. Identify Critical Criteria

The criteria mentioned above are considered in design of the different foundation types and types of external loading and subsoil conditions.

Table 3 shows the list of foundation types that cover the shallow and deep foundations. The list includes special foundations in industrial activities such as rigid, frame with top slab, and frame with bottom slab machine foundation. In terms of loading,

Table 3 comprises a wide range of loading that may occur on a foundation such as; column loading (vertical, inclined, eccentric loading); loading variation with time (cyclic loading, transient loading, seismic loading, impulse loading); and loading that is soil induced (lateral loading, sliding loading, and overturning loading). The soil type is generally classified according by grain size into gravel, sand, silt, and clay, as shown in

Table 3.

The most common load is vertical loading which divides with foundation area and generates the vertical applied stress. In this paper, three types of projects were considered low-rise buildings, high-rise buildings, and bridge projects. These projects cover low and high applied vertical stress and different construction conditions. Considering three project types and the subsoil types, 45 cases were created, as shown in

Table 4. The paper was limited to cases 4–9. This was because these cases are common in real-life settings.

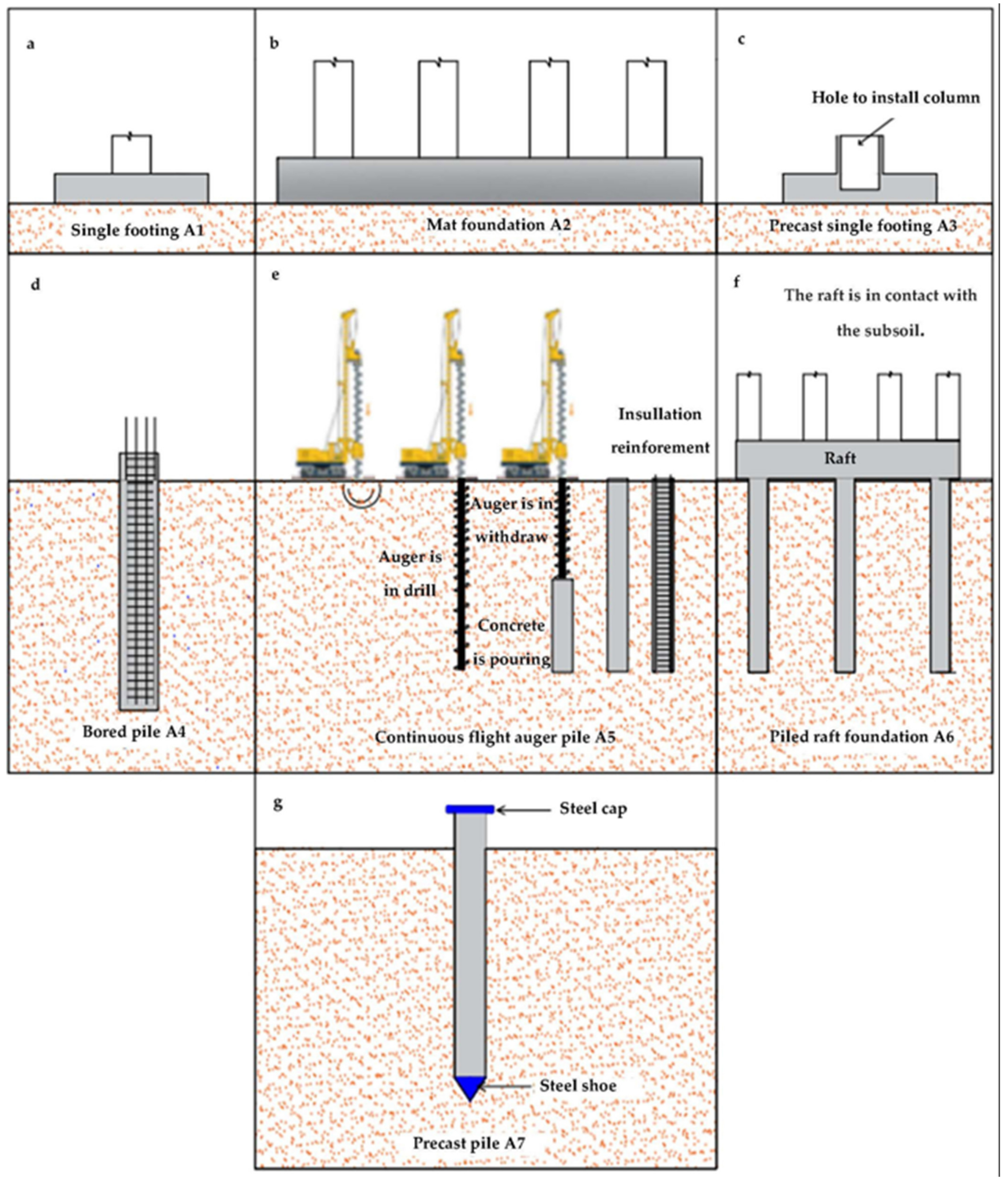

The most common foundation types that were considered as an alternative foundation were single footing (

A1), mat foundation (

A2), single precast footing (

A3), bored pile (

A4), continuous flight auger pile (

A5), piled raft (

A6), and precast pile (

A7), as shown in

Figure 2. On the other hand, the criteria of the four functions (safety, buildability, flexibility of architectural design, and environmental impact) were more safety, more bearing capacity (

C1), less total settlement (

C2), less differential settlement (

C3), more resistance to punching force (

C4), more resistance to liquefaction (

C5), ease of installation (

C6), less top surface area of a foundation, more embedment depth, (

C8), less thermal emission during construction (

C9), and less influence on the groundwater table (

C10). The functions with their criteria are shown in

Figure 3.

3.3. Determine Criteria Weight (CW) for the Selected Criteria for Each Case

The steps of

SWARA were applied for each case, according to the study of [

8].

Step 1: The ten criteria in relative importance were prioritized by experts in foundation construction, in which the most important criterion was the first, while the criterion with the lowest importance was the last.

Step 2: The degree of importance of the previous criterion (j − 1) to the current criterion (j) was recorded and obtained (Sj). It should be noted that the Sj value for the first criterion is a unit.

Step 3: Add a unit to

Sj and obtain

Kj with set

K1 with the unit, as in Equation (1).

Step 4: Divide

Kj−1 by

Kj for each criterion

qi with

q1 set as a unit. It was shown in Equation (2)

Step 5: Normalize qj by ∑qj and obtain CWj.

Table 5 shows examples of the

SWARA computation for low-rise buildings resting on either loose or dense sand.

3.4. Determine Criteria Quality Weights (CQW) Using WASPAS

For the

WASPAS computation, procedures were utilized such as: the criteria quality weights

CQWij were firstly set by the three experts. A Likert scale was used to scale the criteria per alternative foundation, where very low strength was represented by one, and very high strength was represented by 5. Therefore, three

CQW matrices (matrix per expert) were developed, and the average

CQW matrix was computed. Then, the averaged

CQWij value was normalized and the (

) obtained, where the method for normalizing a value was the Linear Scale Transformation Max Method (

LSTMM) [

20]. In this study, the

can be computed using Equation (3):

the

ranged from 0.2 to 1.0. After that, the quality weight

QWi of the alternative foundation was computed per each case using Equation (4) depending on the normalized criteria quality weight (

) and criteria weight (

CW).

3.5. Evaluate the LCC for Each Foundation Alternative

The

LCC had to be assessed for each foundation alternative to quantify

VE.

LCC is the construction cost and the value of the foundations after their life span is neglected. The

LCC can be affected by many variable factors that are difficult to solve in an exact equation. To simplify the issue of

LCC, the

LCC of the foundation alternative was evaluated by the three experts for each case (cases 4–9). The Likert scale was utilized to describe the cost; a Likert scale of one and five represents low and very high costs, respectively. Then, the foundation alternative’s life cycle cost (

LCCi) normalized the maximum life cycle cost (

LCCmax). By the end of this step the

LCC required normalizing for the next step and comparative purpose.

Table 6 shows the Likert scale and normalization of the

LCC of low-rise building foundation alternatives resting on loose sand.

3.6. Determine VE and Decide the Best Alternative Foundations

This study has developed a transparent methodology for applying

VE to select the most valuable foundation. The most suitable foundation alternative should represent the maximum quality score and the minimum

LCC. The

QW and

LCC were computed in the last two steps. Hence, the

VE can be computed using Equation (5) [

33] as;

The higher the value of VE, the more preferable the foundation’s alternative in the given case.

5. Application of the Introduced Framework in a Case Study

The purpose of using a real-life case study was to validate the application of the introduced framework for foundation type selection. The case study was a bridge project with a length of 930 m that was constructed in the

Almaather district of Riyadh City, Saudi Arabia, as shown in

Figure 5. The bridge is located at the intersection of two major roads in Riyadh. The purpose of the bridge is to mitigate crowded movement. The bridge includes six main lanes and four service lanes. The bridge aims to raise the efficiency of the intersection, provide smooth movement in the north and south, reduce congestion at traffic lights, and ease movement towards the health, service, and commercial destinations surrounding the bridge. In addition, as a constraint, the two roads should be open to traffic during the bridge construction project. The subsoil was limestone, with a groundwater

Table 9 meter below ground. The rock’s condition is beyond the scope of the paper. Due to the significant stiffness and strength of any rock compared to soil, the limestone can be assumed to be dense sand to adapt to the ground conditions with the paper framework. Five foundation alternatives were chosen for this case study based on the project type and subsoil condition.

Calculating Normalized QW and LCC

Because the case study was a bridge assumed to be constructed on dense sand, the ten criteria weights of case 9 were considered. Furthermore, QW was calculated using Equation (5) depending on

CW and

. The results of these calculations are shown in

Table 12. Regarding the

LCC, the

LCC values of the foundation alternatives that rested on dense sand were utilized. The

QW,

LCC, and

VE were presented in

Table 13 for the case study.

The five alternatives’ VE values were computed and compared. The VE values of the mat foundation, bored pile, continuous flight auger pile, piled raft, and precast pile were 5.48, 5.32, 5.75, 5.29, and 5.32, respectively. The continuous-flight auger is the best applicable foundation for the case study. On the other hand, the mat foundation is more suitable than the bored and precast pile foundations. The worst foundation option was piled raft foundation. This result may be because a piled raft foundation combines the high construction costs of pile and mat.

The foundation constructed in the case study was a bored pile foundation. However, the appropriate foundation of the paper is the continuous flight auger pile. In addition, the bored pile is the third-order selection for the bridge foundation, resting on the dense sand. For discussion of the contradiction between the real-life selection and paper results, the sub-ground condition of the case study was limestone; however, the continuous-flight auger is more suitable for sand than rock soil. Moreover, the framework of the paper that applied to the case study assumed that the subsoil was dense sand (case 9, as shown in

Table 4). Since the sub ground condition was rock, the mat foundation is preferable for construction on the rock condition than deep foundations (

A4,

A5, and

A7) due to relatively low construction cost. The reason for the selection of bored piles for the case study may be due to the nature of the project: the crossroads where the bridge project was constructed could not be halted during construction, and the mat foundation takes a significant construction area which may stop the crossroads working for traffic. The results of the framework selection in the case study were presented to the experts in the deep foundation construction industry. The first expert agreed with the results of the framework regardless of the type of deep foundation, he stated that the function of the construction site obliges the consulting company to choose deep foundations to avoid suspending the traffic service at the site during the construction of the foundations. On the other hand, the second expert did not agree with the findings of the conceptual framework for the selection of institutions. He explained that the reason for choosing the deep foundations in the case study is not in the nature of the construction site but may be due to the lack of local experience in the company that designed the foundations. He added that most of the design companies in the Kingdom of Saudi Arabia are foreign companies that lack local experience in the construction sites in general and the nature of the land that will be built on, and therefore work to raise the safety factor in their designs, which results in what is called an overestimate in the design.

7. Conclusions

The appropriate foundation may be essential to the project’s progress and influences the construction project stages. The traditional method of selecting the type of foundation only focused on the safety function. It did not consider other functions that may significantly influence the decision of the foundation selection. This paper considered four functions: safety, buildability, flexibility architectural design, and environmental impact. Most of the criteria were listed and categorized into the four functions after reviewing the international standards, a literature review, and expert interviews. Forty-five examples were developed based on the project types (low-rise building, high-rise building, and bridge) and soil types, but the study was only able to use six of them. Based on the expert interviews and using FAST analysis, the significant criteria were reduced to ten criteria (five for safety, one for buildability, two for adaptable architectural design, and two for environmental impact). Experts used the SWARA approach to determine the weights of the ten criteria for the six cases. The alternative foundations’ quality weight was defined using WASPAS. The alternative foundations that were considered in the paper were single footing, mat foundation, precast footing, bored pile, continuous flight auger pile, piled raft, and precast pile. Based on calculating the LCC and QW of each alternative foundation for the six cases, the VE was estimated for each alternative foundation. The main results are summarized as follows:

The adaptable architectural design criteria have more weight than the safety criteria when selecting a foundation for a bridge project.

The environmental impact criteria for high-rise building projects have more influence on foundation selection than for low-rise building projects.

Regarding the results of the framework application in the case study, the framework suggests the continuous flight auger pile as an appropriate selection. However, the foundation constructed in the case study was a bored pile foundation. The slight difference may be attributed to the need for more local experience.

This paper has highlighted that safety standards are not the only aspects to consider when choosing the appropriate foundation type, especially in bridge or high-rise building projects. However, the adaptability of architectural design criteria must be considered in selecting an appropriate foundation for bridge projects. In addition, factors such as project type and work size which are related to subsoil condition and buildability functions might affect the economic cost of foundation construction. The environmental impact has an insignificant influence, and is limited to only two criteria in semi-arid regions. Different environmental criteria may be created and considered in humid and cold regions. Therefore, future research should be carried out to consider that criterion in the selection process. This study intends to improve the adaptability of architectural design and the environmental impact of future structures and building codes in the construction industry.