Collapsibility Mechanisms and Water Diffusion Morphologies of Loess in Weibei Area

Abstract

:1. Introduction

2. Project Overview and Water Immersion Test

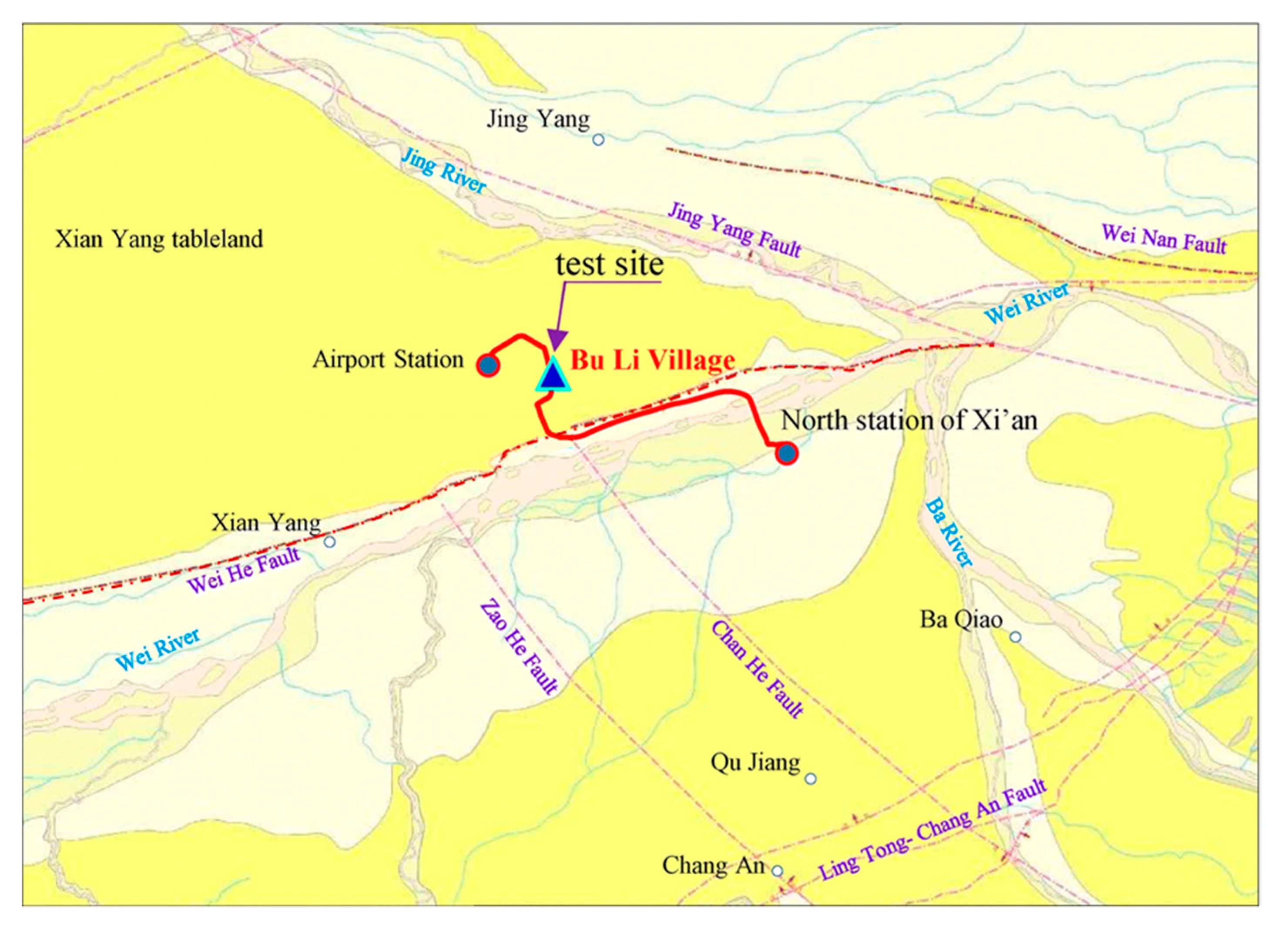

2.1. Field Test Site Selection

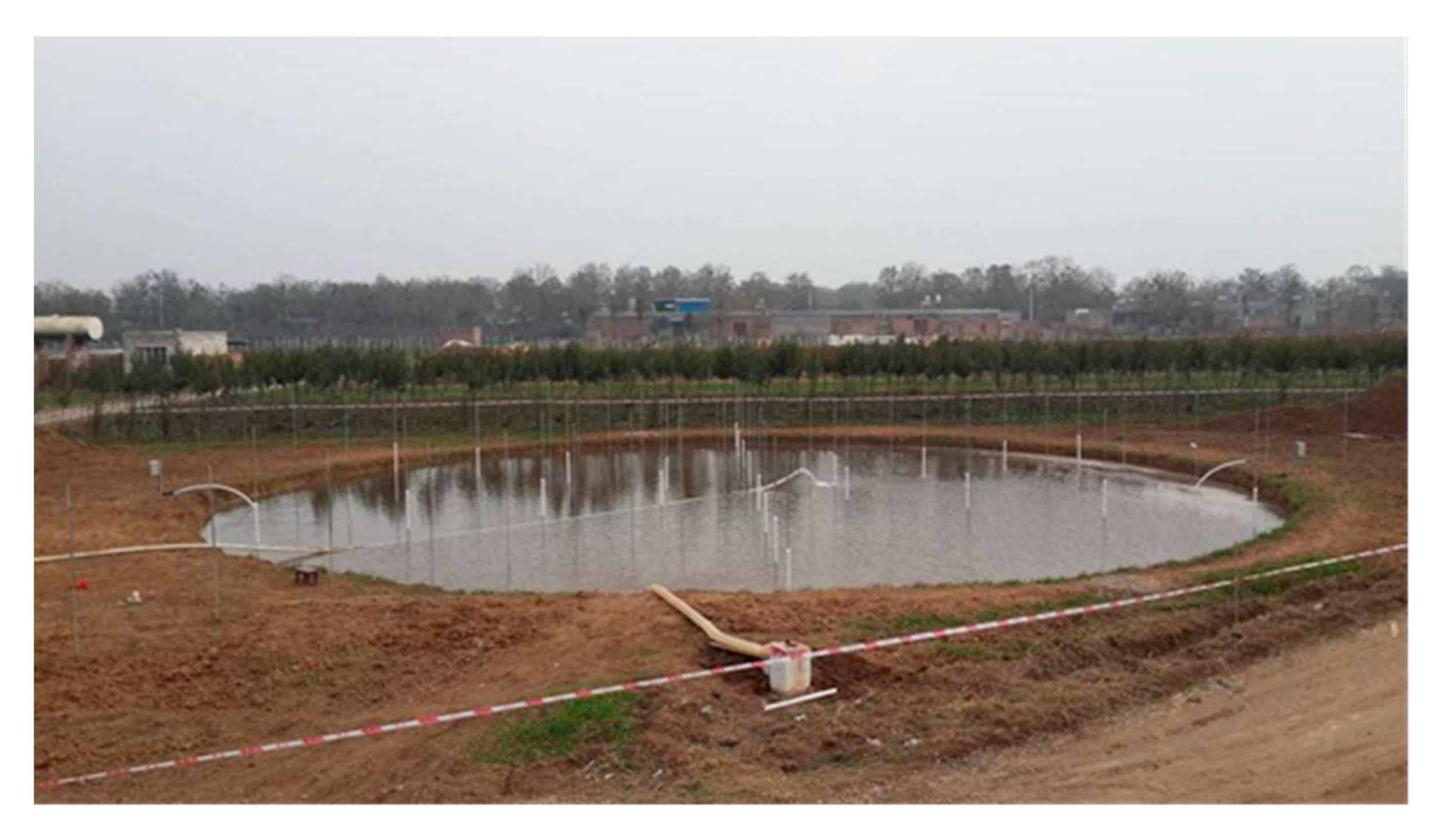

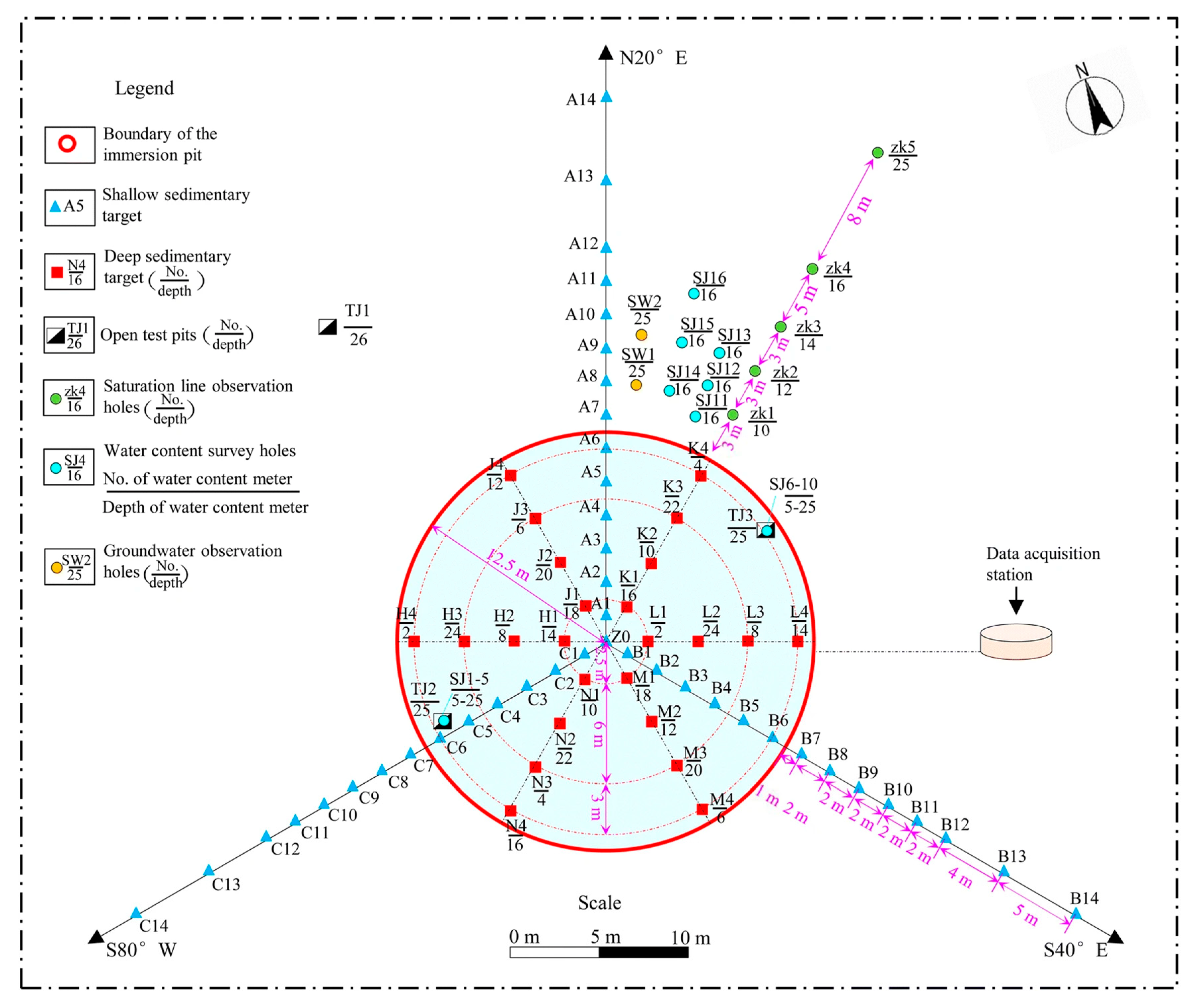

2.2. Field Test Scheme

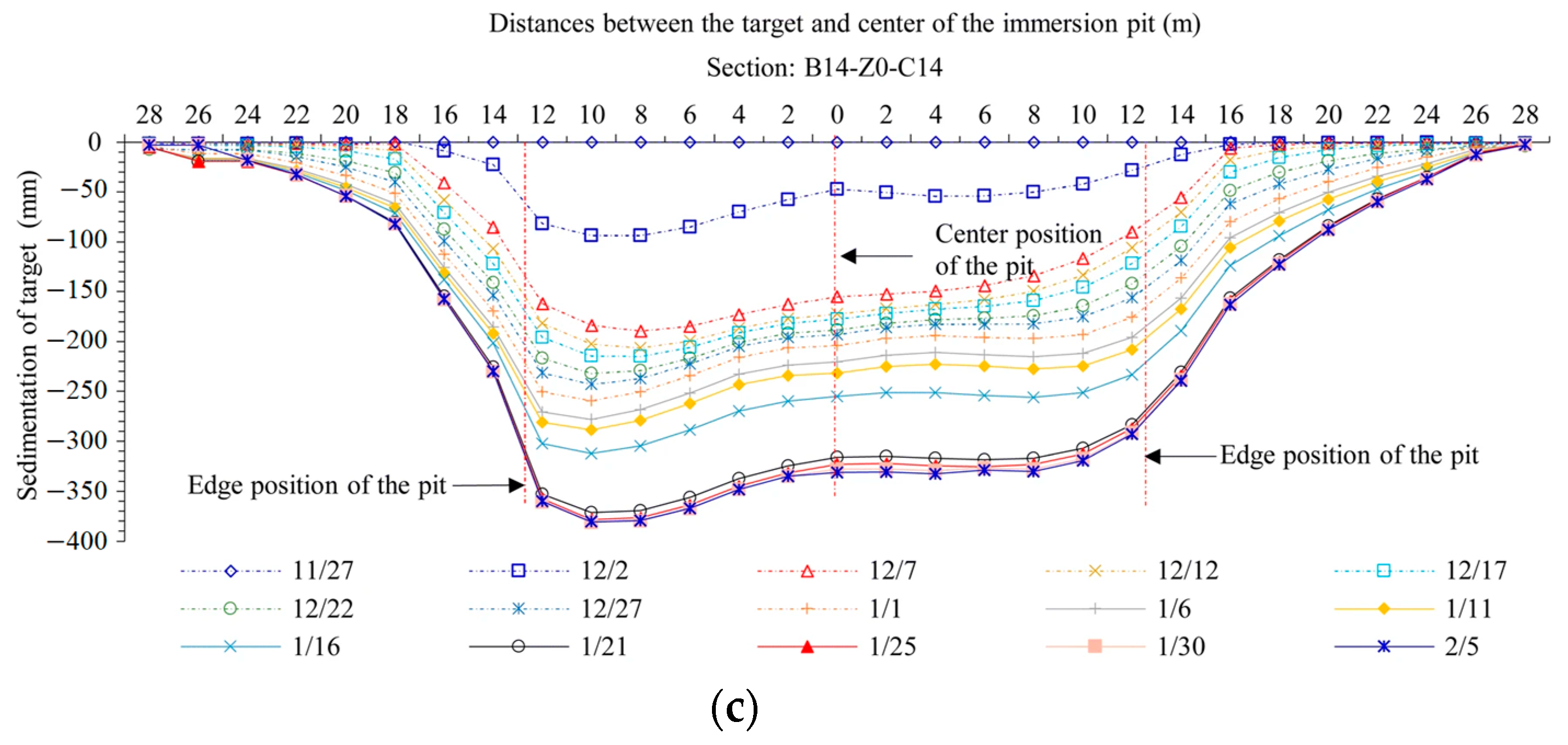

2.3. Test Results and Analysis

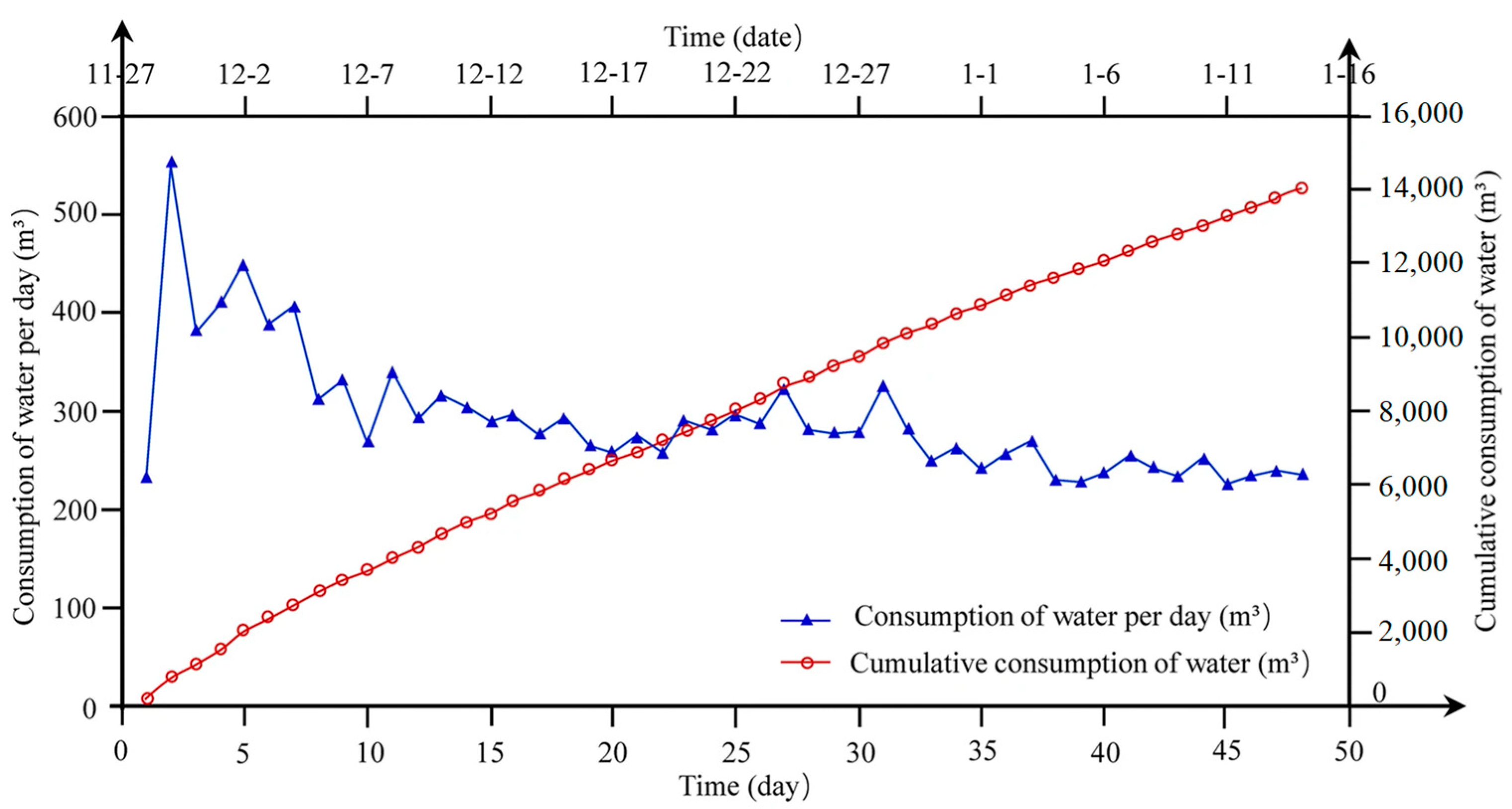

2.3.1. Water Consumption

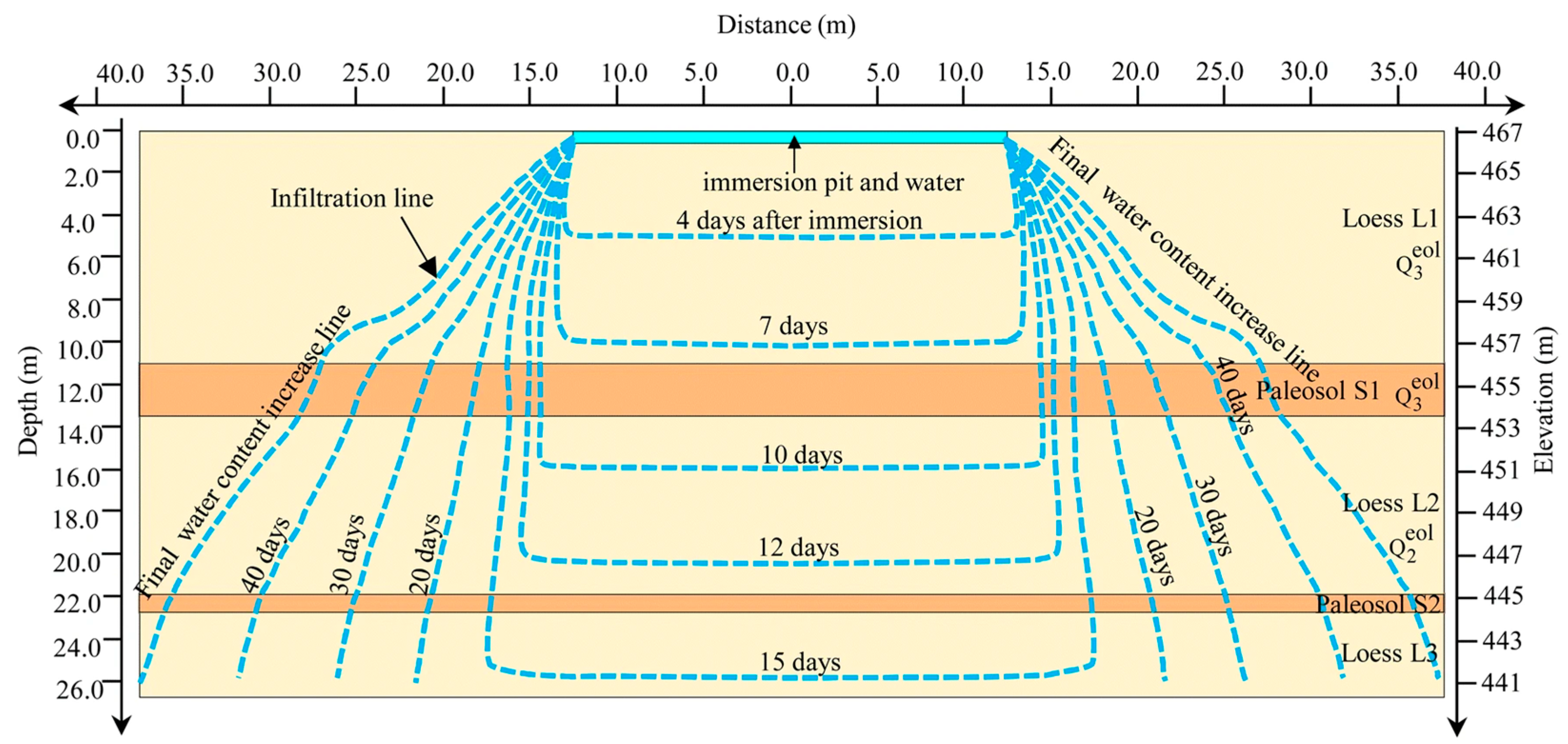

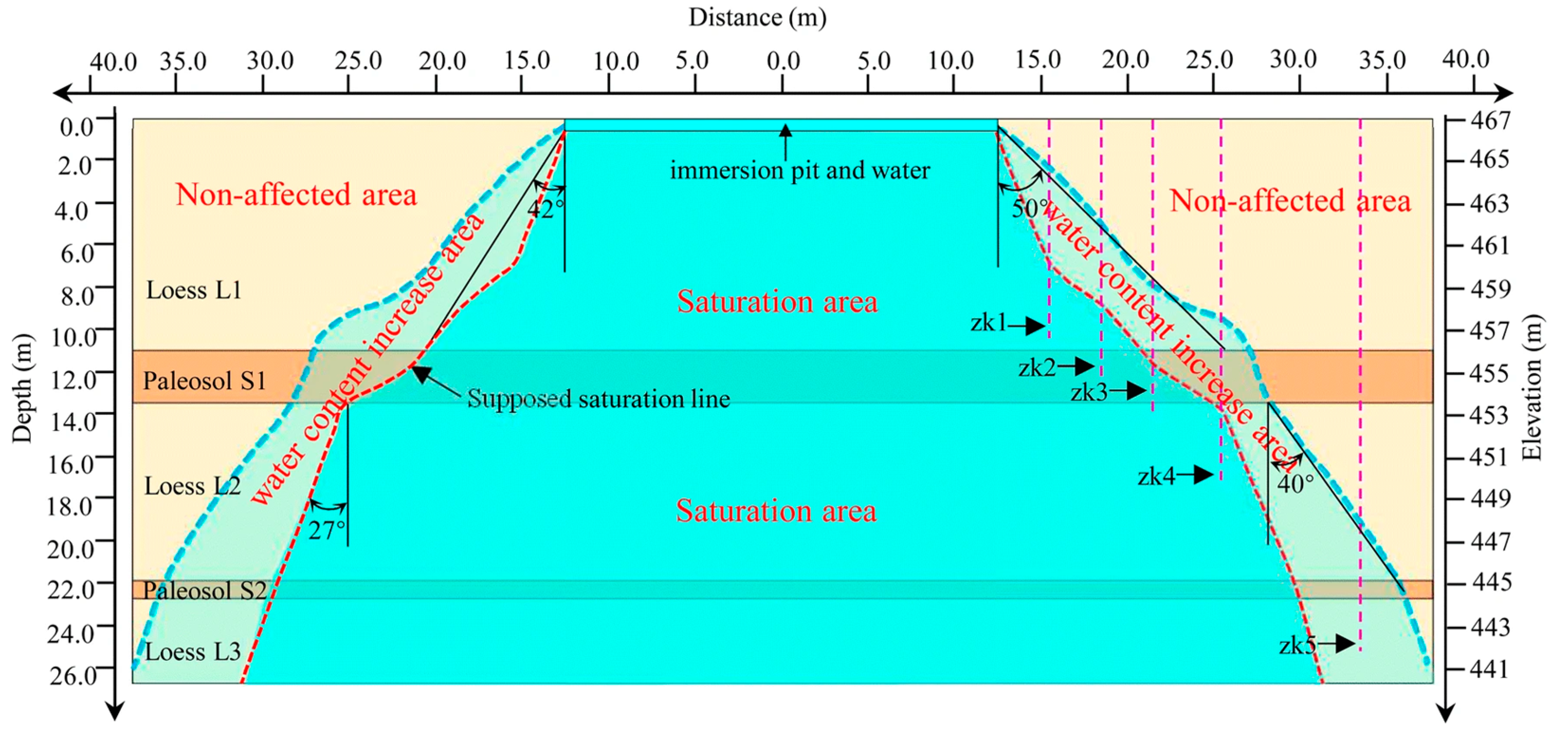

2.3.2. Characteristics of the Seepage Field

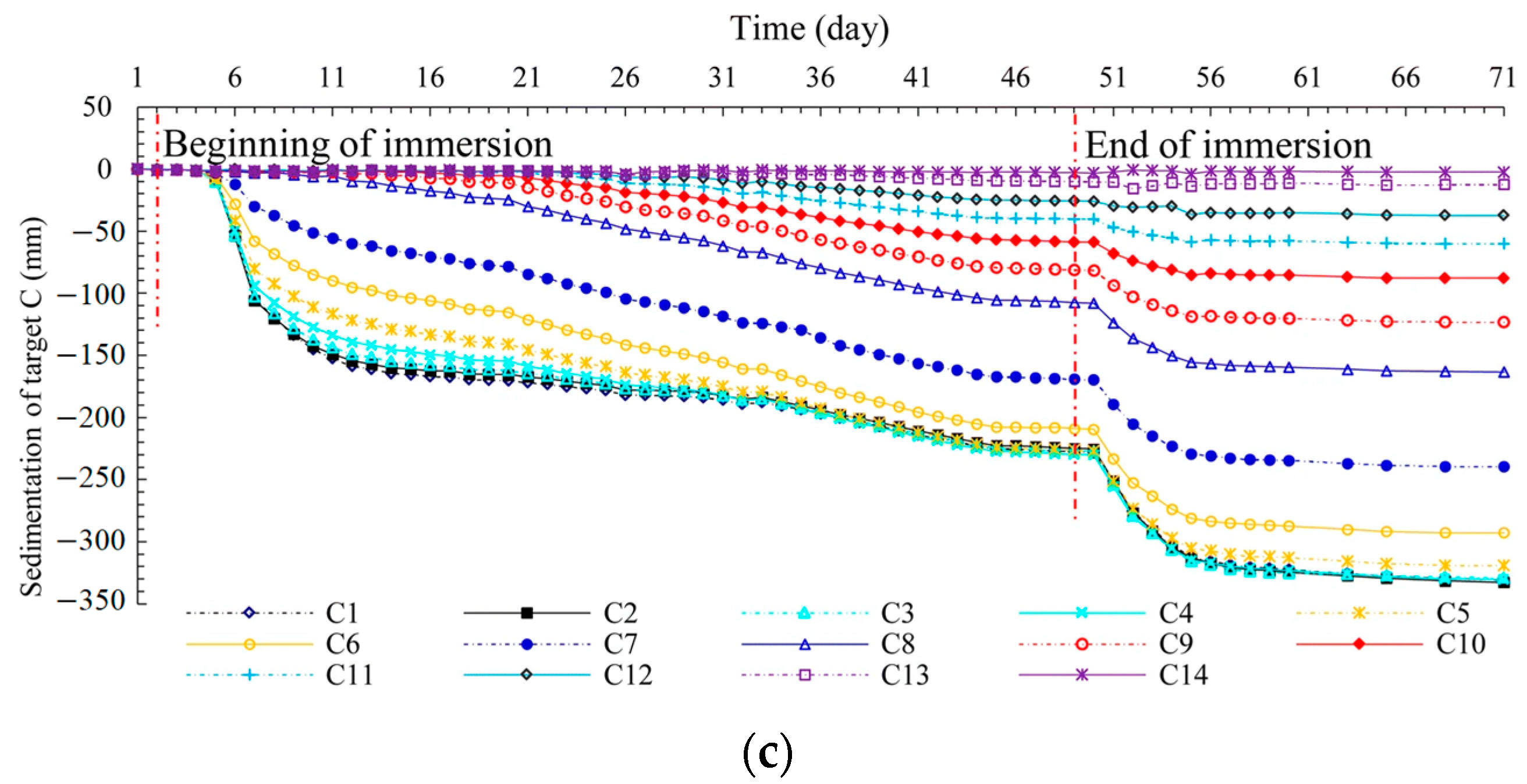

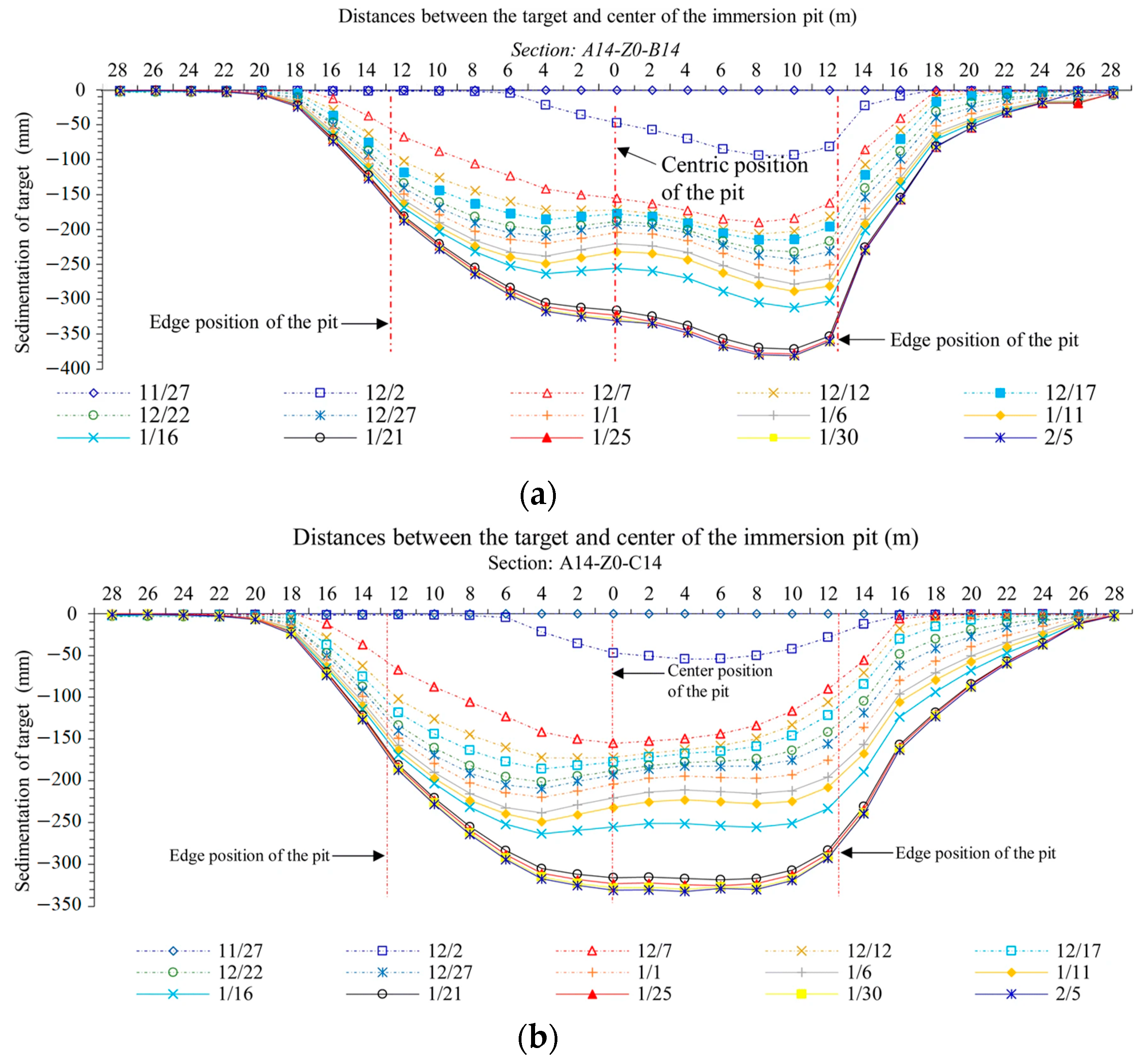

2.3.3. Loess Collapsibility Evaluation

3. Microscopic Collapsibility Mechanism

3.1. Natural Moisture Content and Void Ratio

3.2. Material Composition of Loess

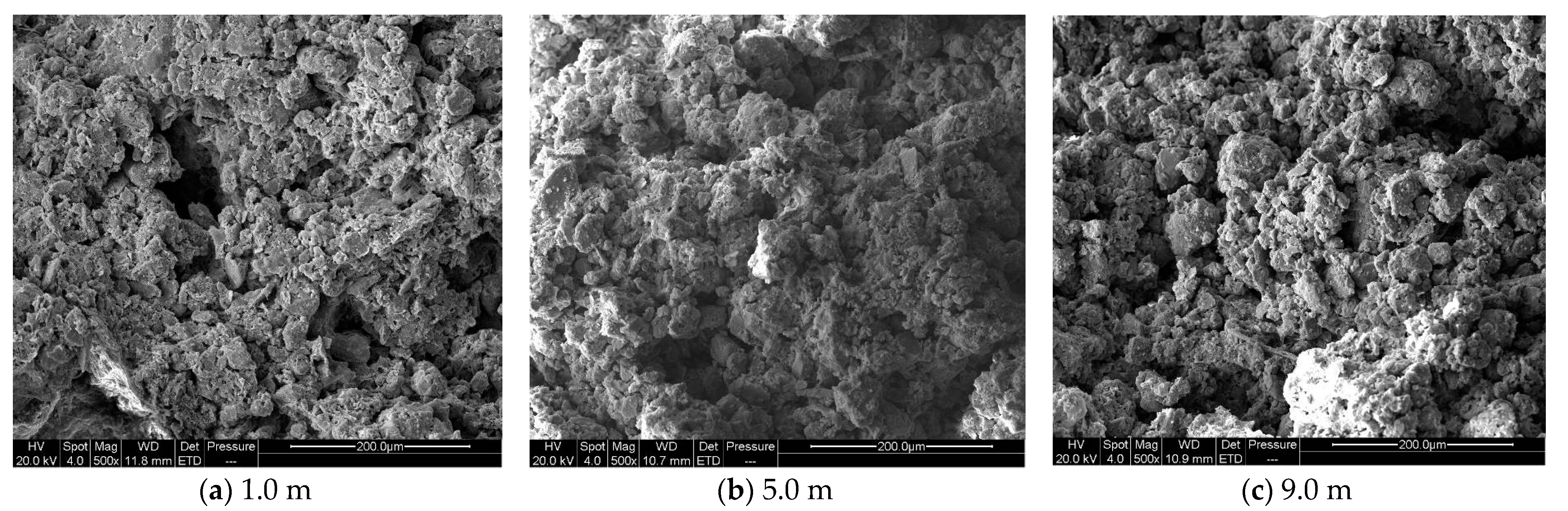

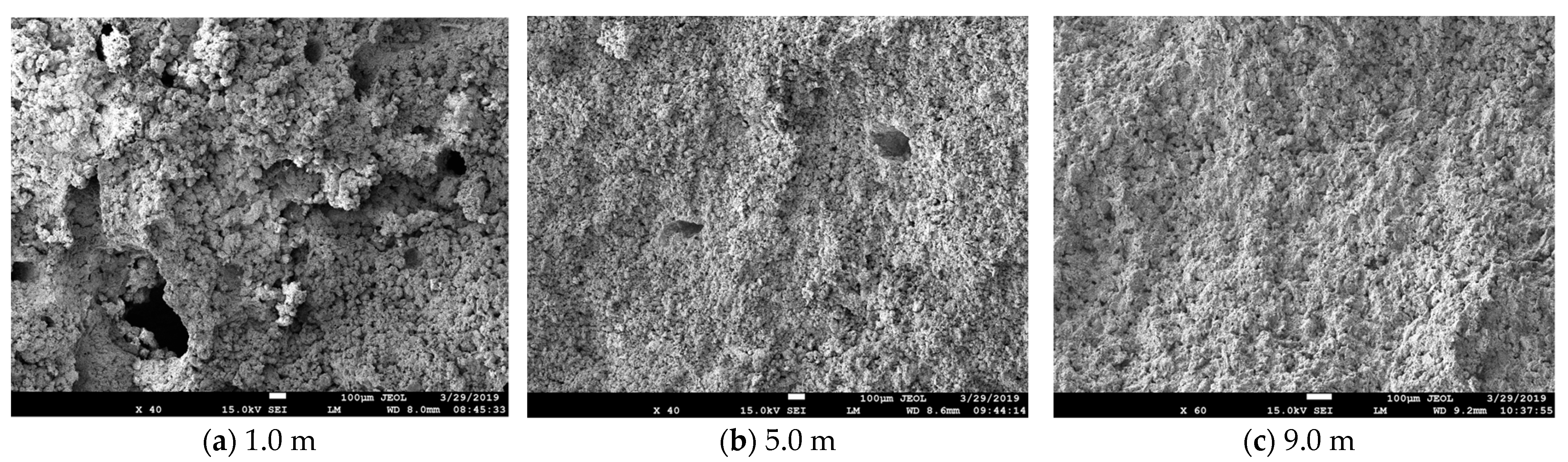

3.3. Microstructure Evolution of Loess

3.4. Collapsible Mechanisms of Loess

4. Water Diffusion Morphology in Collapsible Loess

4.1. Numerical Modeling

4.1.1. Principles and Method

4.1.2. Design Parameters

4.1.3. Model Size

4.1.4. Boundary Conditions

4.1.5. Model Verification

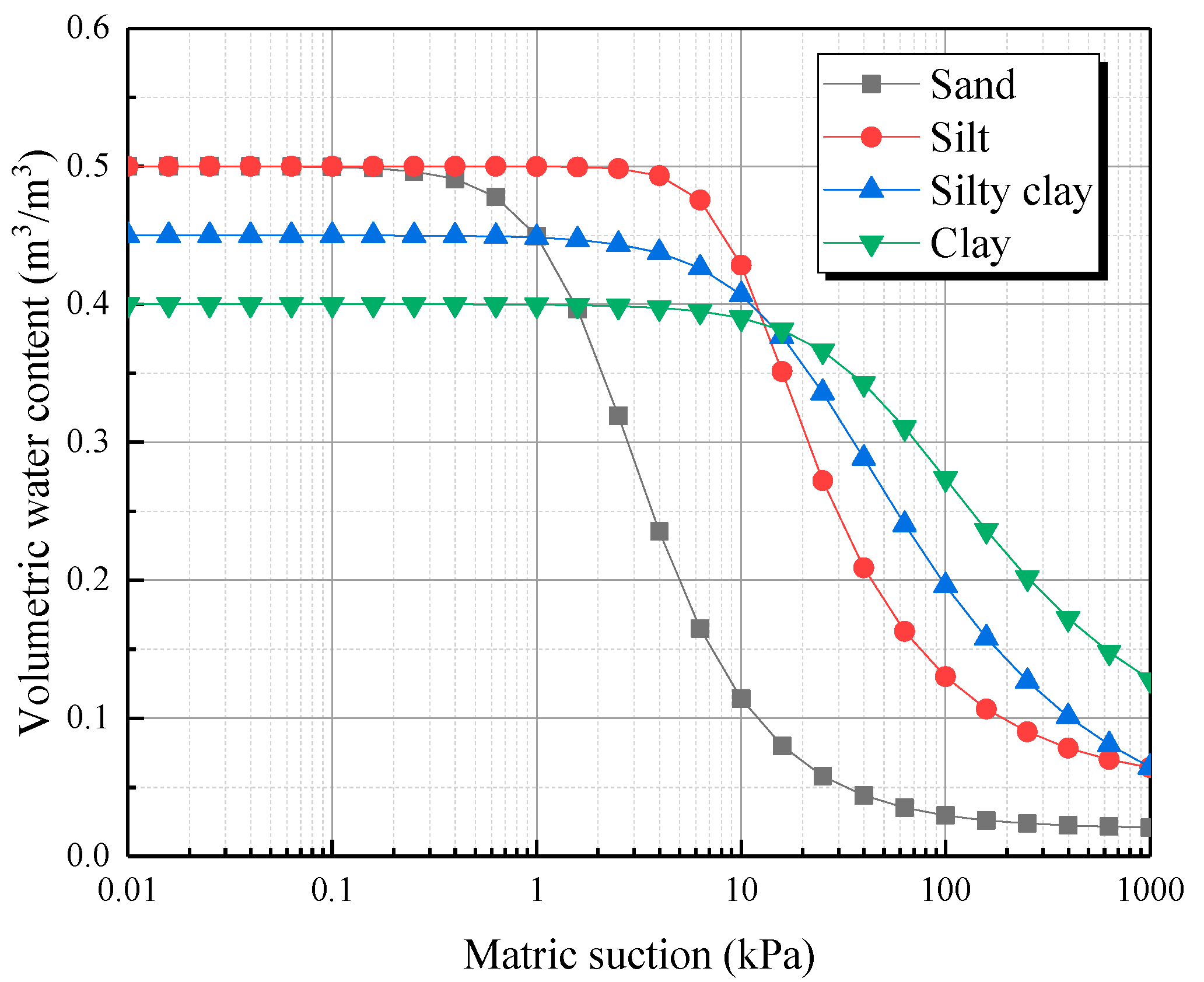

4.2. Soil–Water Characteristic Curves

4.3. Simulation Results and Analysis

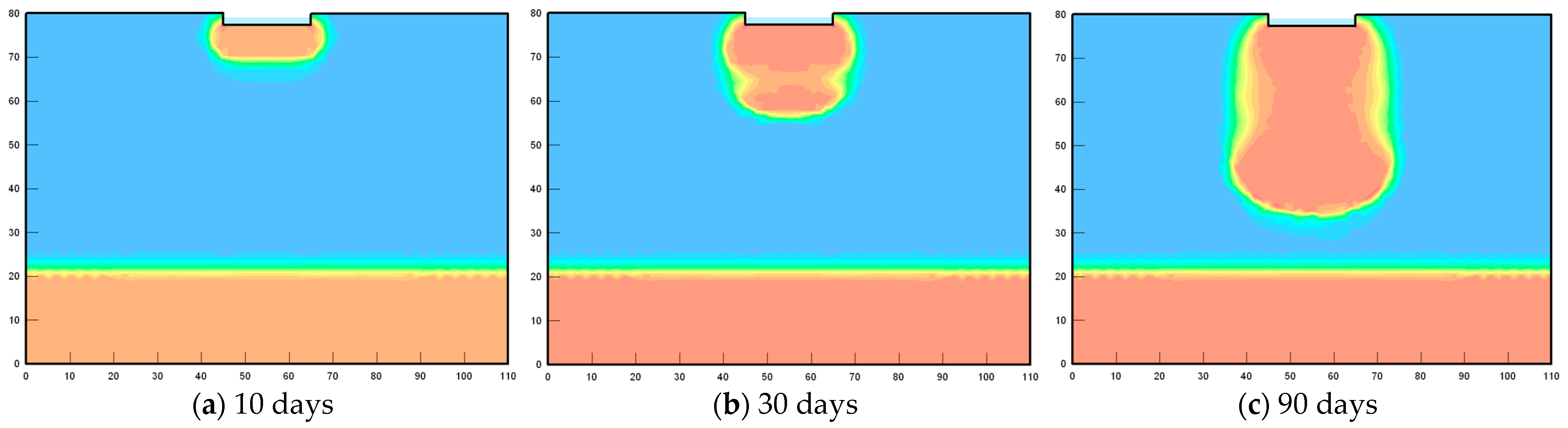

4.3.1. Effect of Foundation Lithology

4.3.2. Effect of Initial Water Content

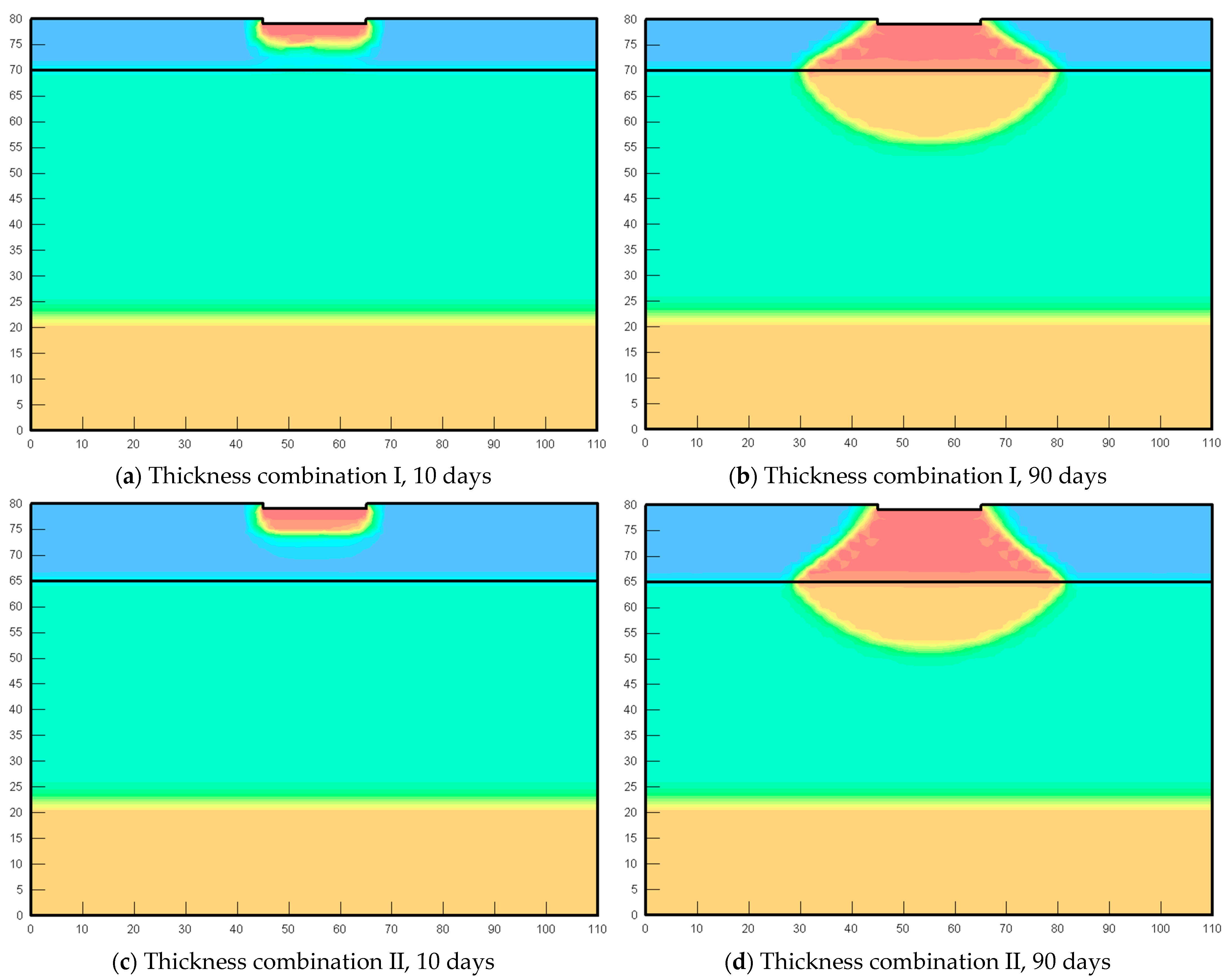

4.3.3. Effect of Stratum Combination

- (1)

- Double-layer stratum combination

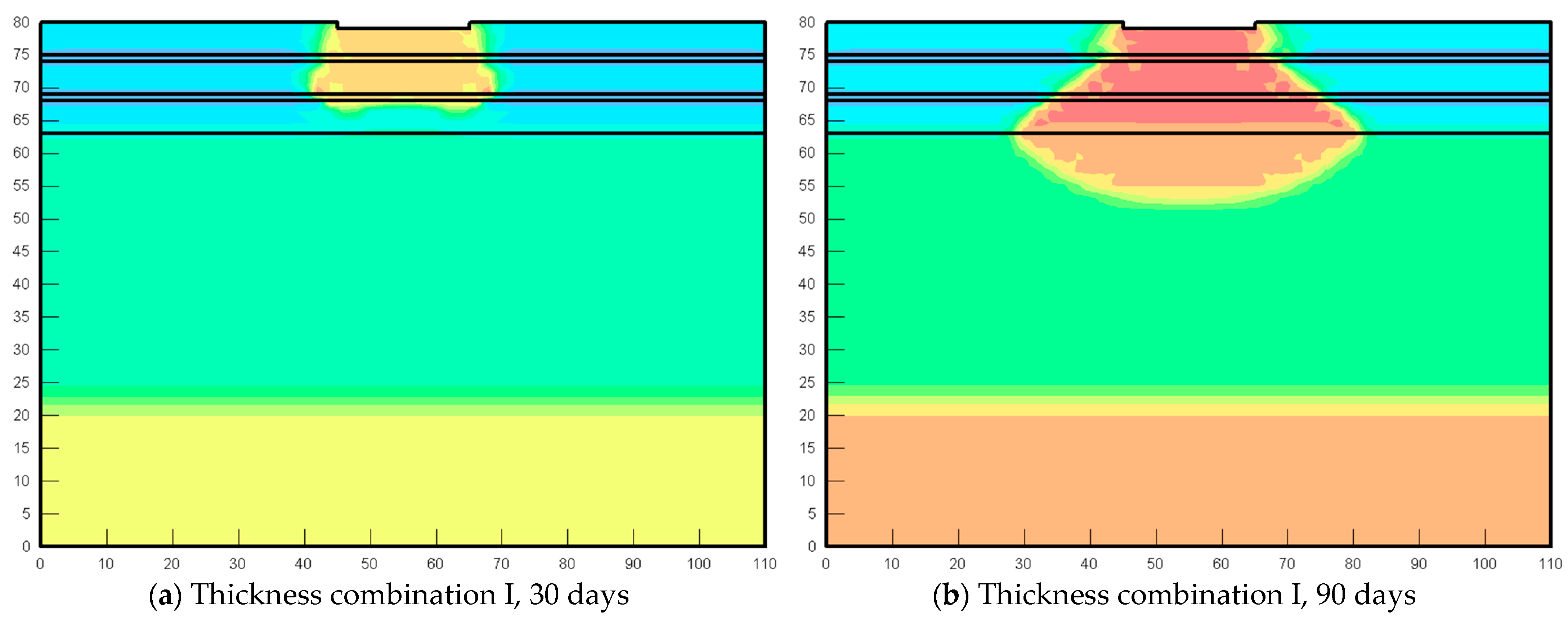

- (2)

- Multi-layer stratum combination

4.4. Classification of Water Diffusion Morphology

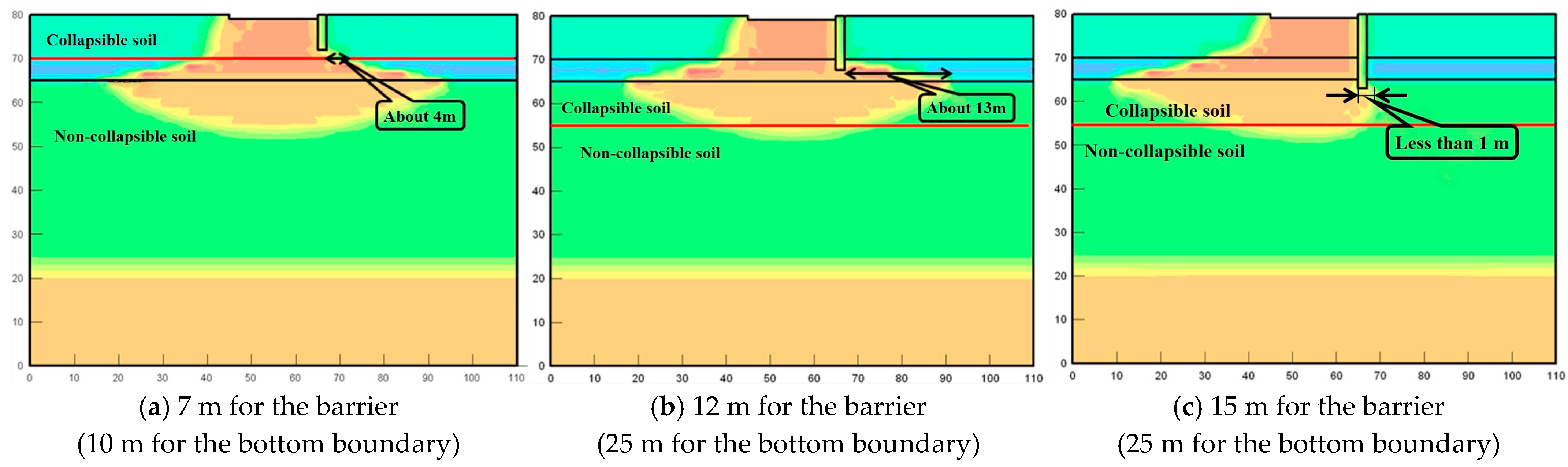

5. Optimization of Collapsible Loess Foundation

5.1. Optimization Scheme

5.2. Evaluation of the Proposed Barrier Scheme

5.2.1. Effect of the Proposed Scheme

5.2.2. Analysis of Combination Scheme

6. Conclusions

- The water diffusion morphology in the loess was an inverted funnel shape, and the scope of saturation and the infiltration line were 30.5 m and 37.5 m from the central axis of the pit at a depth of 25 m, respectively. The measured maximum consolidation settlement was approximately 380.5 mm.

- The void ratio and natural moisture content of loess exhibited a positive and negative correlation with the collapsibility coefficient, respectively, and the concept of collapsibility potential was put forward. The expansion of clay minerals and the dissolution of soluble salts during wetting were the critical reasons for the failure of loess skeleton and cementing materials.

- The water diffusion morphologies in various stratum combinations were classified, and a water-barrier measure of “inverted box shape” was proposed to prevent loess from water immersion, whose feasibility and applicability were verified. The optimal depths of the vertical barrier were recommended to be set at the maximum inflection point in the water diffusion morphology or the main action layer.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Liu, F.; Ma, F.; Wang, M.; Bai, X.; Zheng, Y.; Yin, H.; Zhang, G. Collapsibility, composition, and microstructure of loess in China. Can. Geotech. J. 2016, 53, 673–686. [Google Scholar] [CrossRef]

- Yang, H.; Xie, W.-L.; Liu, Q.-Q.; Zhu, R.-S.; Liu, Y.-Y. Three-stage collapsibility evolution of Malan loess in the Loess Plateau. Catena 2022, 217, 106482. [Google Scholar] [CrossRef]

- Xie, D. Exploration of some new tendencies in research of loess soil mechanics. Chin. J. Geotech. Eng. 2001, 1, 3–13. [Google Scholar]

- Wang, L.; Shi, Y.; Liu, X. Loess Dynamics; Seismological Press: Beijing, China, 2003. [Google Scholar]

- Houston, S.L.; Houston, W.N.; Zapata, C.E.; Lawrence, C. Geotechnical engineering practice for collapsible soils. Geotech. Geol. Eng. 2001, 19, 333–355. [Google Scholar] [CrossRef]

- Rogers, C.D.F.; Dijkstra, T.A.; Smalley, I.J. Hydroconsolidation and subsidence of loess: Studies from China, Russia, North America and Europe: In memory of Jan Sajgalik. Eng. Geol. 1994, 37, 83–113. [Google Scholar] [CrossRef]

- Garakani, A.A.; Haeri, S.M.; Khosravi, A.; Habibagahi, G. Hydro-mechanical behavior of undisturbed collapsible loessial soils under different stress state conditions. Eng. Geol. 2015, 195, 28–41. [Google Scholar] [CrossRef]

- Li, P.; Li, T.L.; Wang, H.; Liang, Y. Soil-water characteristic curve and permeability prediction on Childs & Collis-Geroge model of unsaturated loess. Rock Soil Mech. 2013, 34, 184–189. [Google Scholar]

- Ma, Y.; Wang, J.; Peng, S.; Li, B. Relationships between physical-mechanical and collapsibility of loess soil and its prediction model. Bull. Soil Water Conserv. 2016, 36, 120–128. [Google Scholar]

- Zhang, W.; Zhang, A.; Chen, J.; Liu, Y. Effect of moisture content and density on collapsibility coefficient of Ili loess. J. Northwest A F Univ.-Nat. Sci. Ed. 2017, 45, 211–220. [Google Scholar]

- Deng, L.S.; Fan, W.; Yin, Y.P.; Cao, Y.B. Case study of a collapse investigation of loess sites covered by very thick loess-paleosol interbedded strata. Int. J. Geomech. 2018, 11, 05018009. [Google Scholar] [CrossRef]

- Lu, Q.; Liu, Y.; Peng, J.; Li, L.; Fan, W.; Liu, N.; Sun, K.; Liu, R. Immersion test of loess in ground fissures in Shuanghuaishu, Shaanxi province, China. Bull. Eng. Geol. Environ. 2020, 79, 2299–2312. [Google Scholar] [CrossRef]

- Liu, B.; Xie, Y.; Yu, Y. In-situ testing study on infiltration in unsaturated loess. J. Eng. Geol. 2004, 24, 4156–4160. [Google Scholar]

- Yang, J.; Wang, J.; Li, K.; Zhao, J.; Chao, J. Experimental study on site test pit immersion in loess tableland section of Xi’an North-airport intercity railway. J. China Railw. Soc. 2022, 44, 107–115. [Google Scholar]

- Miao, T.D.; Wang, Z.G. Deformation mechanism of collapsible loess in consideration of the microstructure instability. Catena Suppl. 1991, 20, 93–105. [Google Scholar]

- Sha, A.; Chen, K. Relationship between collapsibility and microstructure of compacted loess. J. Chang’an Univ. Nat. Sci. Ed. 2006, 26, 1–4. [Google Scholar]

- Tang, L. Synthetic effect of microstructure and uneven suction on loess subsidence. Rock Soil Mech. 2003, 11, 30–35. [Google Scholar]

- Yang, Y. Study of the mechanism of loess collapse. Sci. China Ser. B Chem. Life Sci. Earth Sci. 1989, 5, 604–617. [Google Scholar]

- Derbyshire, E. Genesis and Properties of Collapsible Soils; Springer Science & Business Media: New York, NY, USA, 2012; Volume 468. [Google Scholar]

- Xie, W.-L.; Li, P.; Zhang, M.-S.; Cheng, T.-E.; Wang, Y. Collapse behavior and microstructural evolution of loess soils from the Loess Plateau of China. J. Mt. Sci. 2018, 15, 1642–1657. [Google Scholar] [CrossRef]

- Wang, J.-D.; Li, P.; Ma, Y.; Vanapalli, S.K.; Wang, X.-G. Change in pore-size distribution of collapsible loess due to loading and inundating. Acta Geotech. 2020, 15, 1081–1094. [Google Scholar] [CrossRef]

- Shao, X.; Zhang, H.; Tan, Y. Collapse behavior and microstructural alteration of remolded loess under graded wetting tests. Eng. Geol. 2018, 233, 11–22. [Google Scholar] [CrossRef]

- Ayadat, T.; Hanna, A. Design of foundations built on a shallow depth (less than 4 m) of Egyptian macro-porous collapsible soils. Open J. Geol. 2013, 3, 209–215. [Google Scholar] [CrossRef]

- Jefferson, I.; Rogers, C.; Evstatiev, D.; Karastanev, D. Treatment of Metastable Loess Soils: Lessons from Eastern Europe; Elsevier Geo-engineering Book Series; Elsevier: Amsterdam, The Netherlands, 2005; Volume 3, pp. 723–762. [Google Scholar]

- Zhang, S.J.; Huang, X.F.; Zhu, Y.P. Foundation treatment depth and reasonable control on remnant collapse in area of dead weight collapse loess with great thickness. Rock Soil Mech. 2013, 34, 344–350. [Google Scholar]

- Yuan, K.; Ni, W.; Lü, X.; Zhu, M.; Wang, H.; Nie, Y. Mechanical properties and microstructure evolution of Malan loess. Quatern. Int. 2022, 637, 74–84. [Google Scholar] [CrossRef]

- Nie, Y.; Ni, W.; Tuo, W.; Wang, H.; Yuan, K.; Zhao, Y. Microstructure and compressibility evolution of sulfate saline compacted loess under drying-wetting cycles. Quatern. Int. 2022, 625, 96–106. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Q.; Qian, H.; Qu, W.; Li, M. Microstructure and permeability evolution of remolded loess with different dry densities under saturated seepage. Eng. Geol. 2021, 282, 105875. [Google Scholar] [CrossRef]

- Wei, Y.; Fan, W.; Ma, G. Characteristics of microstructure and collapsible mechanism of Malan Loess Plateau, China. J. Earth Sci. Environ. 2022, 44, 581–592. [Google Scholar]

- Ren, Z.; Pan, J.; Li, Z.; Xiao, P.; Shen, Z.; Jia, L.; Li, X. The Interaction of Aeolian Sand and Slope on Runoff and Soil Loss on a Loess Slope via Simulated Rainfall under Laboratory Conditions. Water 2023, 15, 888. [Google Scholar] [CrossRef]

- Zhu, Y.; Ishikawa, T.; Subramanian, S.S.; Luo, B. Simultaneous analysis of slope instabilities on a small catchment-scale using coupled surface and subsurface flows. Eng. Geol. 2020, 275, 105750. [Google Scholar] [CrossRef]

- Pato, F.J.; Aranda, M.S.; Navarro, G.P. A 2D finite volume simulation tool to enable the assessment of combined hydrological and morphodynamical processes in mountain catchments. Adv. Water Resour. 2020, 141, 103617. [Google Scholar] [CrossRef]

- Yuan, S.; Sun, B.; Han, G.; Duan, W.; Wang, Z. Application and Prospect of Curtain Grouting Technology in Mine Water Safety Management in China: A Review. Water 2022, 14, 4093. [Google Scholar] [CrossRef]

- Van Genuchten, M.T.A. Closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Lu, N.; Willian, J.L. Unsaturated Soil Mechanics; John Wiley & Sons, Inc.: New York, NY, USA, 2004. [Google Scholar]

- Xia, J. Soil Mechanics and Engineering Geology; Zhejiang University Press: Hangzhou, China, 2012. [Google Scholar]

- Xiong, X.; Shi, Z.; Xiong, Y.; Peng, M.; Ma, X.; Zhang, F. Unsaturated slope stability around the Three Gorges Reservoir under various combinations of rainfall and water level fluctuation. Eng. Geol. 2019, 261, 105231. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Department of the People’s Republic of China. GB50025-2018 Standard for Building Construction in Collapsible Loess Regions; China Construction Industry Press: Beijing, China, 2018. [Google Scholar]

| Layer | Age | Stratigraphic Characteristics | ||

|---|---|---|---|---|

| Color | Condition | Collapsibility | ||

| Plain fill (1-2) | Q4ml | Light yellow~ brown yellow | — | Slight collapse |

| New loess (3-1-1) | Q3eol | Brown yellow | Mainly hard plastic, local plastic | Moderate collapse ~ severe collapse |

| Paleosol (3-2-1) | Q3el | Maroon | Mainly hard plastic, local plastic | Moderate collapse |

| Old loess (4-1-1) | Q2eol | Brown yellow | Mainly hard plastic, local plastic | Moderate collapse |

| Paleosol (4-2-1) | Q2el | Maroon | Plastic | Slight collapse |

| Number | Particle Size (%) | ||

|---|---|---|---|

| Sand >0.05 mm | Silt 0.05~0.005 mm | Clay <0.005 mm | |

| 6 | 1~12 | 66~77 | 11~23 |

| Average | 7 | 74 | 19 |

| Illite and Montmorillonite | Kaolinite and Chlorite | Quartz | Anorthose and Albite | Calcite | Dolomite, Pyrite, and Siderite | Collapsible Characteristic | |

|---|---|---|---|---|---|---|---|

| Range | 7.5~10 | 8~9.5 | 46~53 | 14~19 | 13~14 | 1~2 | Self-weight Collapsible site |

| Average | 9 | 9 | 49 | 17 | 13.5 | 1.5 |

| Number | Water-Soluble Salt Content (%) | ||

|---|---|---|---|

| Soluble Salt | Moderately Soluble Salt | Insoluble Salt | |

| 6 | 0.05~0.12 | 0.18~0.23 | 12.3~16.7 |

| Average | 0.08 | 0.20 | 14.3 |

| Geomorphic Unit | Geological Information | Depth | Microstructure Characteristics | ||

|---|---|---|---|---|---|

| Particle Arrangement | Pore Structure | Particle Cementation | |||

| Loess tableland | 3-1-1 New loess | 1.0 m before immersion | Bracket | Bracketed-micropore | Bracketed-micropore semi-cemented structure |

| 1.0 m after immersion | Bracket-inlaid | Inlaid-micropore | Inlaid-micropore semi-cemented structure | ||

| 5.0 m before immersion | Bracket | Bracketed-micropore | Bracketed-micropore semi-cemented structure | ||

| 5.0 m after immersion | Inlaid | Inlaid-micropore | Inlaid-micropore semi-cemented structure | ||

| 9.0 m before immersion | Bracket | Bracketed-micropore | Bracketed-micropore semi-cemented structure | ||

| 9.0 m after immersion | Inlaid | Inlaid-micropore | Inlaid-micropore semi-cemented structure | ||

| Lithology Characteristic | Silt | Silty Clay |

|---|---|---|

| Initial water content by volume | 0.27 | 0.11/0.15/0.27/0.35 |

| Thickness Combination | Stratum Combination (Lithology Characteristic) | ||

|---|---|---|---|

| I/m | II/m | A | B |

| 10 | 15 | Silt (collapsible) | Silt (collapsible) |

| 5 | 5 | Silty clay (aquitard) | Sand (permeable) |

| 65 | 60 | Clay (non-collapsible) | Clay (non-collapsible) |

| Thickness Combination | Stratum Combination (Lithology Characteristic) | ||

|---|---|---|---|

| I/m | II/m | A | B |

| 5 | 10 | Silt (collapsible) | Silt (collapsible) |

| 1 | 1 | Silty clay (aquitard) | Sand (permeable) |

| 5 | 2.5 | Silt (collapsible) | Silt (collapsible) |

| 1 | 1 | Silty clay (aquitard) | Sand (permeable) |

| 5 | 2.5 | Silt (collapsible) | Silt (collapsible) |

| 63 | 63 | Silty clay (aquitard) | Silty clay (aquitard) |

| Types of Soil | Clay | Silty Clay | Silt | Silty Sand |

|---|---|---|---|---|

| Permeability coefficient k (cm/s) | <10−7 | 10−5~10−6 | 10−4~10−5 | 10−3~10−4 |

| Types of Stratum Combination | Bottom Boundary of Collapsibility | Morphology Characteristic |

|---|---|---|

| Single layer | Middle of infiltration region | Ellipse shape |

| Underpart of infiltration region | Pear shape | |

| Double layer with aquitard as the lower layer | Aquitard | Bowl shape |

| Underpart of infiltration region | Inverted funnel | |

| Double layer with a permeable lower layer | Ladder shape | |

| Underpart of infiltration region | Long axe shape | |

| Multi-layer with aquitard as middle layers | First aquitard | Bowl shape |

| Underpart of infiltration region | Multi-layer cone shape | |

| Multi-layer with permeable middle layers | First permeable layer | Ladder shape |

| Underpart of infiltration region | Long axe shape |

| Types of Stratum Combination | Thickness of the Collapsible Soil/m | Vertical Depths of the Barrier/m | Horizontal Diffusion Ranges of Water/m |

|---|---|---|---|

| Double layer with aquitard as the lower layer | 10 | 0 | 16 * |

| 3 | 13 * | ||

| 7 | 10 * | ||

| Double layer with a permeable lower layer | 10 | 0 | 5 * |

| 5 | 4 * | ||

| 7 | 4 * | ||

| Double layer with aquitard as the lower layer | 25 | 10 | 3 * |

| 12 m (2 m below the aquitard) | 2 * | ||

| 15 m (the depth of the aquitard) | <1 | ||

| 17 | <1 | ||

| 20 | <1 | ||

| Double layer with a permeable lower layer | 25 | 10 | 14 * |

| 12 m (2 m below the permeable layer) | 13 * | ||

| 15 m (the depth of the permeable layer) | 4 * | ||

| 17 | 1 * | ||

| 20 | <1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, Y.; Zhang, C.; Zhao, J. Collapsibility Mechanisms and Water Diffusion Morphologies of Loess in Weibei Area. Sustainability 2023, 15, 8573. https://doi.org/10.3390/su15118573

Lv Y, Zhang C, Zhao J. Collapsibility Mechanisms and Water Diffusion Morphologies of Loess in Weibei Area. Sustainability. 2023; 15(11):8573. https://doi.org/10.3390/su15118573

Chicago/Turabian StyleLv, Yuanqiang, Changliang Zhang, and Jingang Zhao. 2023. "Collapsibility Mechanisms and Water Diffusion Morphologies of Loess in Weibei Area" Sustainability 15, no. 11: 8573. https://doi.org/10.3390/su15118573