1. Introduction

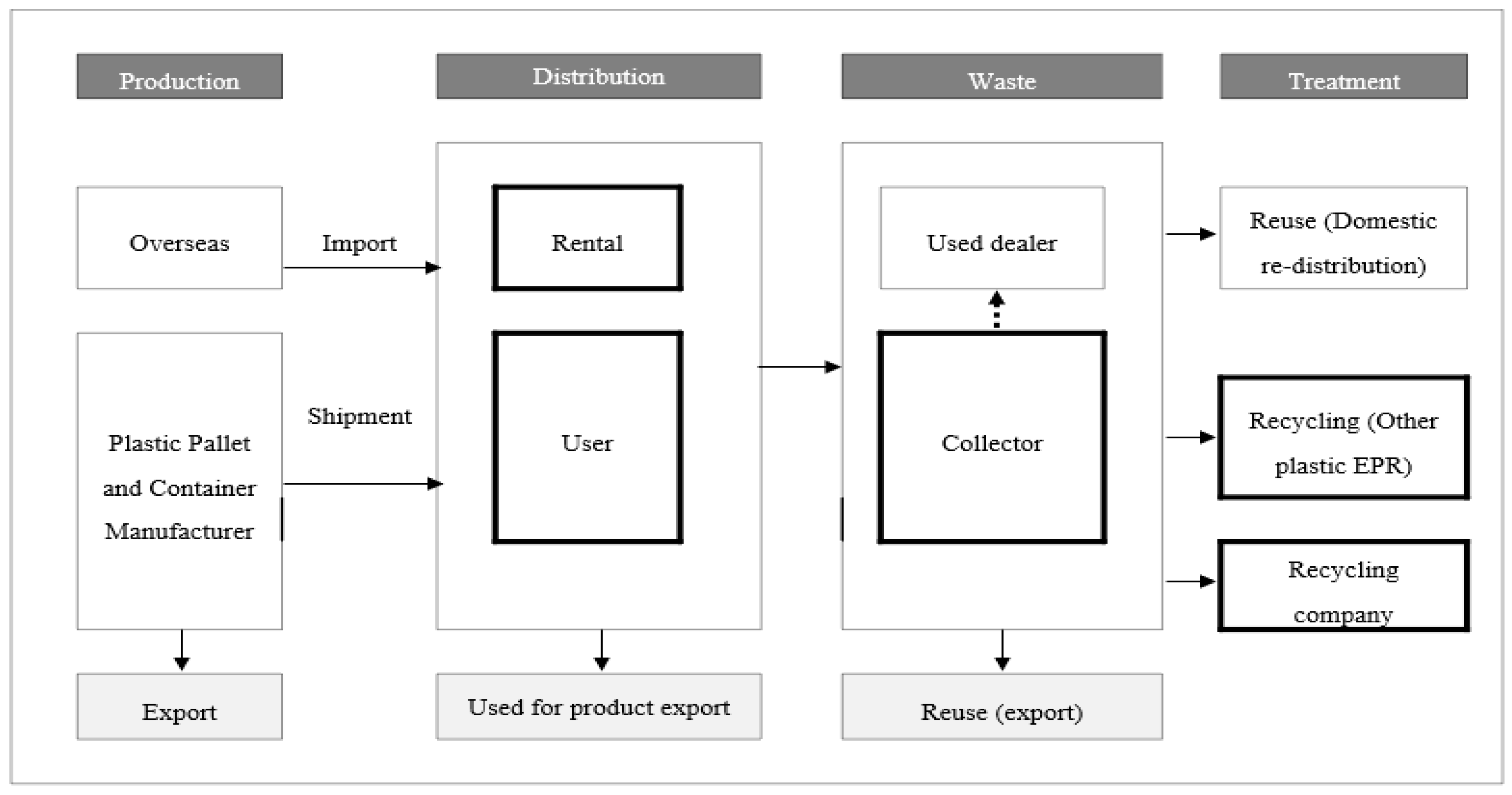

Pallets and containers are industrial materials that are reused repeatedly as transportation tools (

Figure 1). Ownership is not transferred; they are used only for transportation [

1]. The uses of pallets and containers are very diverse, from agriculture, fishery, and livestock industries to manufacturing and distribution industries, as well as logistics companies; they are generated as waste through the selling or disposing of pallets and containers when they are damaged or lose their value over a certain period [

2,

3].

Plastic pallets and containers have been gaining in popularity because of their durability and light weight [

1]. They are mainly made of a single material: HDPE (High Density Polyethylene) or PP (Polypropylene). A heavy pallet made of HDPE is a product with specialized durability that can be used multiple times, mainly for domestic distribution purposes, and it takes a considerable amount of time to be generated as waste. On the other hand, lightweight pallets made of PP are mainly used for disposable or export purposes, and are mass-produced and discarded in a short period of time after use.

However, as multi-use transport containers, the characteristics of pallets generated as waste are very different depending on their degree of use and management [

4,

5,

6]. When lost items occur during use, it is difficult to trace them. However, since pallets and containers are traded at high prices, they are collected by private collectors and, after a certain period, are often brought into the recycling system to be used as raw materials for original products(

Figure 2).

The recycling system for pallets and containers consists of crushing by intermediate processing companies and recycling companies that manufacture and sell pallets.

Although the mandatory recycling rate of pallets and containers is on a continuous upward trend, there is a limit to increasing the recycling rate, despite the recycling efforts of the industry. Moreover, Korea is trying to manage pallets and containers via EPR (Extended Producer Responsibility). In the case of conversion to items subject to EPR, it is necessary to analyze the characteristics of pallets and containers generated as waste to calculate the MRR (Mandatory recycling rate). The number of pallets and containers generated as waste is generally proportional shipment, but they are a rental-oriented returnable product. It is difficult to determine the characteristics of waste generation only. In addition, since the time at which waste is generated differs depending on the use (material) of each product, it is not reasonable to estimate the amount of waste generated in the current year based on the amount shipped from the previous year.

There are many studies on the average lifespan and LCA (Life Cycle Assessment) of pallets and containers [

7,

8,

9]. In related studies, the lifetime is usually determined by the number of times the pallet is used (1–100 cycle) [

10]. Additionally, the life expectancy of plastic pallets is known to be around 10 years [

11]. However, no studies have been conducted on the actual lifespan of each item or material.

Research related to the development and application of waste generation estimation methods can be divided into methods using replacement cycles [

12], methods using domestic shipment [

12], generation calculation methods considering annual disposal rates [

13], and estimation methods using life curves [

14].

When a product is shipped, the distribution representing the time during which the product can operate normally without failure is called the ‘Weibull distribution (life distribution)’; moreover, pallets and containers can be broken or damaged, in which case, they are discarded [

15]. By using PDF (probability density function), it is possible to know the time it takes for a percentage of a product to fail, and the time it takes for 100% of a product to fail corresponds to the total lifespan. If the annual failure rate of a product is known during its lifetime, it is possible to estimate the annual failure rate by multiplying the product release by the annual failure rate.

PDF is used as a method of estimating the amount of waste generated while considering the durability period of waste, and it is sometimes corrected by considering the discharge characteristics. According to a standard useful life and useful life range table of assets by industry, pallets and containers have different useful life ranges, ranging from 5 to 10 years on average, depending on the industry; however, waste does not occur after a specific point in time. This tends to happen gradually.

As such, PDF is a function used to indicate, in the form of a ratio, how much of the same product produced at a specific point in time is discarded over time until its use has ended and it has been disposed of. It expresses the characteristics and is used as a necessary tool for estimating the amount of waste generated. For example, after a product is shipped, a% will fail after 1 year, b% after 2 years, and c% after 3 years (breakage), and if a + b + c = 100, the life of the product is 3 years, meaning it will fail within 3 years.

As a method of estimating the generation amount, the generation amount of electrical and electronic waste products was estimated using PDF by taking the life data of the product as a factor [

16]. Additionally, the PDF was calculated and the discharge rate. The amount of waste generated by general refrigerators was estimated [

17].

The purpose of this study was to calculate the lifespan of pallets and containers for each material using PDF, and to estimate the amount of waste generated each year by multiplying the release amount each year using PDF. These results can be used to objectively estimate waste generation in the future when pallet and container products begin to be managed as EPR items. When the characteristics of each material (PE, PP) are reflected, more rational and detailed management will be possible.

2. Methods

For the quality management of pallets or containers, a molding mark is applied to the product. A molding mark is placed on the product to show the manufacturing year. As this is used, in this paper, the lifespan was investigated using the difference between the manufacturing year and the survey year. In the example given in

Figure 3, the left side of the square table shows the manufacturing year (12) and the upper side shows the manufacturing month (4); this means that it was manufactured in April 2012, and if there are multiple dots, the most recently displayed date is when the product was made. Using the data on the amount of product in the shipment and the lifespan of products brought into recycling companies, it is possible to know what percentage of the products in the years after shipment is brought into recycling companies.

Therefore, to calculate the PDF of pallets and containers, the date of manufacture of the loaded items was checked via an on-site survey of pallet and container recycling companies. The field survey companies selected 3 companies with the largest number of pallets and containers for recycling to secure many samples and ensure representativeness. The number of samples, used as lifespan data, was 1555 HDPE pallets, 562 HDPE containers, and 132 PP pallets. The PDF parameters (scale parameter and shape parameter) were derived for each item and material using MINITAB, which can perform PDF. However, pallets and containers brought into recycling companies are collected in large quantities. In other words, they are collected at the source and discharged in batches when the economic feasibility of collection is secured. Because of these characteristics, even if a recycling company can have representativeness, there is a limit, making it difficult to confirm that a sample has representativeness.

PDF was performed using Micro soft Excel (2022) and a PDF parameter, and the PDF (P(t)), which indicates the rate at which lifespan ends by time (t), was multiplied by the amount shipped by item and material(waste generation by year was estimated). The amount of product in the shipment was used for KPCA (Korea Pallet and Container Association) using internal data on the pallets and containers.

The lifespan function is calculated; here,

f(t) is the probability density function and represents the discard rate in year

t, λ is the shape parameter,

β is the scale parameter, and

t is the usage time.

, t: year.

If the life distribution follows the Weibull distribution,

MTTF (Mean Time to Failure) is calculated using Formula (2).

The theoretical

waste generation in a specific year (

n) is affected by all pallets shipped before the

lifespan from year

`n, and the calculation Formula (3) is as follows.

As for the lifespan, we tried to apply the maximum lifespan rather than the average lifespan. This is because waste is generated even after the average lifespan. Therefore, it was applied as a year with a PDF of X ≤ 0.0000%, and the adjusted lifespan of the pallets (PE) was 40 years, the pallets (PP) was 28 years, the containers (PE) was 39 years, and the containers (PP) was 26 years.

The amount of product in the shipment was obtained to estimate the amount of waste generated, and the recycling performance was obtained to calculate the mandatory recycling rate from 2010 to 2020 by requesting KPCA. To estimate the amount of waste generated by 2027, we applied the Excel Trend function to the amount of product in the shipment and recycling performance, and the level of mandatory recycling was calculated using this.

Figure 4 shows the research process.

3. Results

3.1. Calculation of Probability Density Function by Item and Material

The Anderson–Darling (A–D) statistic was used to measure how well the corresponding lifetime data followed a specific distribution, and the smaller this metric was, the more accurately the suitability of the distribution could be judged. The A–D statistical values of the Weibull distribution (the exponential distribution) were 9.586 (10.214) for pallets (PE), 8.591 (8.615) for pallets (PP), 2.835 (3.151) for containers (PE), and 6.893 (7.112) for containers (PP). The A–D values were calculated for the Weibull distribution and the exponential distribution. As a result, a Weibull distribution with a relatively small value was found to have relatively high suitability, so it was determined that both the pallets and the containers followed the Weibull distribution, and the probability density function was calculated. The Weibull distribution implies that the failure rate increases as the product ages over time based on realistic assumptions. On the other hand, considering that a case where the failure rate of a product is constant over time is used when it can be explained in the form of an exponential function rather than a Weibull distribution, the result is considered valid.

As a result of calculating the PDF parameter using MINITAB for each item, the scale parameters of HDPE pallets and PP pallets were 1.69732 and 1.03902, and the shape parameters were 10.7294 and 3.2628, respectively. The scale parameters of the HDPE and PP containers were 3.02085 and 3.63126, respectively, and the shape parameters were 18.4226 and 13.4772, respectively.

The shape parameter β of the Weibull distribution can model the properties of the lifetime distribution. Herein, 0 < β < 1 indicates that failures occur predominantly in the early stages of product life; β = 1, means that the failure rate remains constant and models the “actual service life”; β = 1.5 indicates premature failure after a certain period; β = 2 means that the risk of failure after wear increases steadily over the life of the product; and 3 ≤ β ≤ 4 models the final period of a product’s lifetime when failures occur most frequently after rapid wear.

The PDF was calculated as follows using each shape parameter and scale parameter. The scale parameter of containers is larger than that of pallets, which means that containers have a more even life distribution than pallets. If the shape parameter value is less than 1, it represents a decreasing failure rate, and if it is greater than 1, it represents an increasing failure rate function. As a result of calculating MTTF using Equation (2), that of the pallet (PE) was 9.6 years, that of the pallet (PP) was 3.2 years, that of the container (PE) was 16.5 years, and that of the container (PP) was 12.2 years (

Table 1). This means that containers have a longer lifespan than pallets, and by material, PP has a shorter lifespan than PE.

The PDF results of pallets and containers by lifespan are shown in

Figure 5. That of pallets (PP) decreases rapidly, and that of items other than pallets (PP) show a tendency to gradually decrease after initially increasing the waste generation rate. By material, pallets have a higher waste generation rate in the initial stage than containers. By material, the waste generation rate of PP is initially higher than that of PE. The reason the P(t) of pallets (PP) differs from that of other items is that pallets (PP) are used as a disposable product.

The reliability function (r(t)) results of pallets and containers are shown in

Figure 6. This is a measure indicating the probability that an object’s lifespan will be longer than t years, and it has a characteristic that decreases as time increases.

By product, pallets are generated as waste faster than containers. This seems to be because pallets are used for stronger loads and are handled more roughly than containers. By material, it can be confirmed that PP is generated as waste faster than PE. This is because PP is more prone to breakage than PE.

A total of 50% of pallets (PE) were generated as waste within about 8–9 years, and pallets (PP) within 2–3 years. In total, 50% of containers (PE) were generated as waste within about 15–16 years, and containers (PP) within about 11–12 years. Looking at the years in which the most waste was generated, pallets (PE) took less than 6 years, and pallets (PP) after manufacturing less than 1 year. Waste generation occurred after 16 years for containers (PE) and 12 years for containers (PP). This is because pallets and containers have very different life cycles depending on their management strategy and usage [

4,

5].

Even if the material is the same, it can be confirmed that the lifespan of a container is higher than that of the pallet. This is considered to reflect their usage characteristics; pallets are mainly used for the loading and unloading of materials, whereas containers are mainly used for storage. The difference in the lifespan of each material seems to occur because PP has weaker strength than PE [

18].

3.2. Estimation of Waste Generation by Item

The waste generation amount calculated considering the waste generation characteristics of wasted pallets gradually increased from 71,811 tons in 2010, and was predicted to reach a total of 207,586 tons in 2027 (

Figure 7). This is an increase of 67.5% to 75.1% compared to the shipment, and this maximum waste generation rate could be the basis for applying a value of 75.1%. Additionally, the recycling rate is 21.9% compared to the amount of waste generated (

Table 2).

However, there is a need to consider that the amount recovered is reduced as the wasted pallets are exported or resold as used. During the site survey, there was an opinion that most of the waste flows into second-hand stores because recycling companies receive treatment fees and bring in waste, while second-hand companies purchase them. In addition, even if the pallet (PP) is released for domestic use, it is often used for export and is not discharged as waste in the country. Although radio frequency identification (RFID) trackers are increasingly being used on pallet pullers, allowing them to collect data on the lifecycle and location of pallets in the supply chain [

19], pallets are freely exchanged in the market, so the intensity of use cannot be accurately estimated. Pallets can also be repaired during their life cycle to extend their service life [

6]. In other words, even if they are discarded, it is believed that the actual amount brought into the recycling company will inevitably be smaller. Therefore, although the lifetime of a pallet can be predicted using PDF, it is difficult to view it as the amount of waste that can be recycled.

In addition, it appears that the gap between the amount of waste generated and the amount that can be recycled continues to widen. This may be due to the high volume of shipments in the past.

The waste generation amount calculated considering the waste generation characteristics of containers is predicted to increase gradually from 13,280 tons in 2010 to a total of 54,331 tons in 2027 (

Figure 8). This is an increase of 26.9–69.2% compared to the shipment (

Table 3). Compared to pallets, containers have a smaller difference in the amount of waste generated and recycled. This seems to be because containers are mostly used for domestic consumption. However, it is considered that the actual amount that can be recycled is smaller, as the containers are introduced to second-hand companies rather than being discarded; moreover, in the field survey, it was found that various plastic packaging materials are managed as EPR items in Korea. They commented that it is customary for recyclers to recycle pallets or containers, which are single materials, to achieve the mandatory recycling rate. Additionally, it is understood that a portion of this is used by other companies or randomly selected to be used for other purposes, and some is identified as being collected by better factories over time and reaching the recycling market.

4. Conclusions

To establish an efficient waste management plan, it is important to accurately predict future waste generation, and generation estimation is the basis for the development of existing waste management infrastructure and sustainable development and optimization.

In this study, the concept of reliability was introduced based on the lifespan data of pallets and containers brought into recycling companies, to calculate their average lifespan and waste generation. The Mean Time to Failure among pallets was 9.6 years for PE and 3.2 years for PP, and among containers was 16.5 years for PE and 12.2 years for PP. These are basic data for management using the EPR system for pallets and containers. In previous studies, there was no classification of pallet and container materials, and there have been no studies on lifespan, but this study calculated the amount of waste generated according to the characteristics of each material.

However, it was found that it was difficult to estimate the actual amount of waste generated using only PDF, because it was introduced to second-hand businesses, shipped domestically but used for export, or recovered from other EPR plastic product recycling companies. Additionally, since the target items were brought into the recycling company at different times, were not used for the same purpose, and were obtained through a single inspection, correction of the data may be required to predict their lifespan. Additionally, although the estimated generation amount of wasted pallets is expected to increase, continuous monitoring is necessary as the recyclable amount may decrease as the circulation logistics system is improved.

In the future, if the method proposed in this study and additional research to create a Material Flow Diagram are conducted, it is expected that it will be possible to calculate a realistically recyclable waste generation number for pallets and containers. Based on the method proposed in this study, it is expected that it will be used to gain important basic data for waste management, as it is possible to calculate the amount of recycled pallets and containers and the required level of budget. Additionally, when comprehensively considering the characteristics of repeated use and the function of industrial logistics equipment, plastic pallets and containers are not subject to EPR; however, in terms of deposits, considering that related industries autonomously manage waste and rebuild the system for recycling, it is necessary to see the degree to which they are recycled.