Research on Bamboo Furniture Design Based on D4S (Design for Sustainability)

Abstract

:1. Introduction

2. Literature Review

2.1. Research on the Concept of Sustainable Design

2.2. Research on Bamboo Furniture

2.3. Research on the Use of D4S Theory in Furniture Design

3. Materials

3.1. Characteristics of Bamboo

3.2. The Processing Process of Bamboo Materials

4. Methods

4.1. Goals and Strategies of Sustainable Design

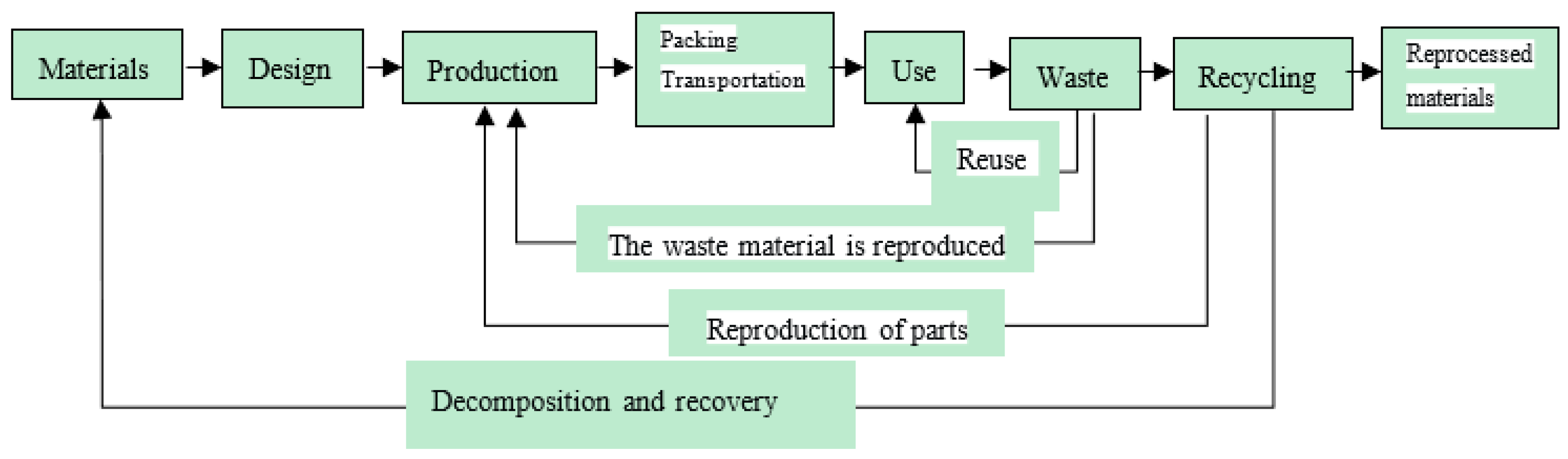

4.2. Furniture Design Based on the Life Cycle of Bamboo

4.2.1. Design Strategy to Address Mechanical Property Changes

4.2.2. Design Strategies to Cope with Color Texture Changes

4.2.3. Design Strategies to Address Bamboo Cracking and Destruction

4.2.4. Design Strategy to Cope with the Convenience of Packaging and Transportation

4.2.5. Design Strategies for Bamboo Recycling

4.3. Sustainable Bamboo Furniture Design Based on “Human-Material-Environment” Relationship

5. Results and Discussion

5.1. Program Design Ideas

5.1.1. Design Methods Used

5.1.2. Design Strategies Adopted

5.1.3. Design Practice

5.2. Design Evaluation

6. Conclusions

- (1)

- By studying the basic theory of D4S, the methods and modes of bamboo furniture design that can be directly and effectively applied are summarized. First of all, the main design methods are based on bamboo life cycle analysis, which adopt a modular, standardized, multifunctional design. Secondly, the model of sustainable product design is established. The main steps are to set up a sustainable design team, collect sustainable design data, design sustainable product plans, make decisions on sustainable product design, establish a sustainable design enterprise alliance, and formulate sustainable design criteria for the industry;

- (2)

- The article provides a general analysis of bamboo furniture and clarifies the advantages, disadvantages, and positive development prospects of bamboo furniture. With the increasing demand for environmentally friendly furniture and improvements in the production process, bamboo furniture breaks through the traditional shape and structure design, and new bamboo furniture emerges to provide more choices for people. Through our case study of bamboo furniture products, we learned that current bamboo furniture products are uneven and lack a design sense. In addition, although bamboo is environmentally friendly, bamboo furniture is not necessarily environmentally friendly. Thus, we proposed the D4S bamboo furniture design strategy, including a systematic and localized approach, which will play a very important role in guiding the sustainable design of bamboo furniture;

- (3)

- The article concludes by inviting professionals to evaluate existing bamboo furniture products using a design checklist, which is professionally scored in three stages: design solution, solution execution, and disposal, and make a judgement based on the scores. This was used as an evaluation method applicable to D4S bamboo furniture product design to judge the sustainability of bamboo furniture product design.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Modarress, B.; Ansari, A.; Ansari, A. Sustainable Development and Ecological Deficit in the United Arab Emirates. Sustainability 2020, 12, 6180. [Google Scholar] [CrossRef]

- Aykut, S.C.; Maertens, L. The climatization of global politics: Introduction to the special issue. Int. Politics 2021, 58, 501–518. [Google Scholar] [CrossRef]

- Bouraiou, A.; Necaibia, A.; Boutasseta, N.; Mekhilef, S.; Dabou, R.; Ziane, A.; Sahouane, N.; Attoui, I.; Mostefaoui, M.; Touaba, O. Status of renewable energy potential and utilization in Algeria. J. Clean. Prod. 2020, 246, 119011. [Google Scholar] [CrossRef]

- Dlamini, L.C.; Fakudze, S.; Makombe, G.G.; Muse, S.; Zhu, J. Bamboo as a valuable resource and its utilization in historical and modern-day China. BioResources 2021, 17, 1926–1938. [Google Scholar] [CrossRef]

- Gan, J.; Chen, M.; Semple, K.; Liu, X.; Dai, C.; Tu, Q. Life cycle assessment of bamboo products: Review and harmonization. Sci. Total Environ. 2022, 849, 157937. [Google Scholar] [CrossRef] [PubMed]

- Muhammad Suandi, M.E.; Amlus, M.H.; Hemdi, A.R.; Abd Rahim, S.Z.; Ghazali, M.F.; Rahim, N.L. A Review on Sustainability Characteristics Development for Wooden Furniture Design. Sustainability 2022, 14, 8748. [Google Scholar] [CrossRef]

- Bumgardner, M.S.; Nicholls, D.L. Sustainable Practices in Furniture Design: A Literature Study on Customization, Biomimicry, Competitiveness, and Product Communication. Forests 2020, 11, 1277. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Zhang, X.; Zeng, S. Research on Sustainable Furniture Design Based on Waste Textiles Recycling. Sustainability 2023, 15, 3601. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Ioras, F. The sustainability of the Asian wooden furniture industry. Holz. Als. Roh. Werkst. 2003, 61, 233–237. [Google Scholar] [CrossRef]

- Siti Suhaily, S.; Islam, M.N.; Asniza, M.; Rizal, S.; Abdul Khalil, H.P.S. Physical, mechanical and morphological properties of laminated bamboo hybrid composite: A potential raw material for furniture manufacturing. Mater. Res. Express 2020, 7, 7. [Google Scholar] [CrossRef]

- Sun, Y.; Gong, J.; Liu, H.; Fang, C. Axial Compression Behaviors of Columns Fabricated from Bamboo Oriented Strand Boards. Forests 2022, 13, 1817. [Google Scholar] [CrossRef]

- Xiong, X.; Ma, Q.; Yuan, Y.; Wu, Z.; Zhang, M. Current situation and key manufacturing considerations of green furniture in China: A review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Corsini, L.; Moultrie, J. What Is Design for Social Sustainability? A Systematic Literature Review for Designers of Product-Service Systems. Sustainability 2021, 13, 5963. [Google Scholar] [CrossRef]

- Rocha, C.S.; Antunes, P.; Partidário, P. Design for sustainability models: A multiperspective review. J. Clean. Prod. 2019, 234, 1428–1445. [Google Scholar] [CrossRef]

- Schoenmaker, D. Principles of Sustainable Finance; Oxford University Press: Oxford, UK, 2019. [Google Scholar]

- Silvestre, B.S.; Ţîrcă, D.M. Innovations for sustainable development: Moving toward a sustainable future. J. Clean. Prod. 2019, 208, 325–332. [Google Scholar] [CrossRef]

- Wojtkowiak, D.; Cyplik, P. Operational Excellence within Sustainable Development Concept-Systematic Literature Review. Sustainability 2020, 12, 7933. [Google Scholar] [CrossRef]

- Navarrete, S.D.S.; Borini, F.M.; Avrichir, I. Environmental upgrading and the United Nations Sustainable Development Goals. J. Clean. Prod. 2020, 264, 121563. [Google Scholar] [CrossRef]

- Leong, B.D.; Lee, B.Y.H. Future Shade of Green: Introduction to the Practice of “Product Design for Sustainability”. J. Zhuangshi 2013, 242, 31–38. [Google Scholar]

- Filimonova, I.V.; Provornaya, I.V.; Komarova, A.V.; Zemnukhova, E.A.; Mishenin, M.V. Influence of economic factors on the environment in countries with different levels of development. Energy Rep. 2020, 6, 27–31. [Google Scholar] [CrossRef]

- Ghabbour, S.I. United Nations International Conference on Population and Development (ICPD), held in the International Conference Centre, Cairo, Egypt, during 5–13 September 1994. Environ. Conserv. 2009, 21, 283–284. [Google Scholar] [CrossRef]

- Moro, S.R.; Cauchick-Miguel, P.A.; Campos, L.M.S. Product-service systems towards eco-effective production patterns: A Lean-Green design approach from a literature review. Total Qual. Manag. Bus. Excell. 2019, 32, 1046–1064. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, L.; Fung, K.Y.; Bakshi, B.R.; Ng, K.M. Sustainable product design: A life-cycle approach. Chem. Eng. Sci. 2020, 217, 115508. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Remmen, A. A framework for sustainable value propositions in product-service systems. J. Clean. Prod. 2019, 223, 25–35. [Google Scholar] [CrossRef]

- Meier, H.; Roy, R.; Seliger, G. Industrial Product-Service Systems—IPS 2. CIRP Ann. 2010, 59, 607–627. [Google Scholar] [CrossRef]

- Piligrimienė, Ž.; Banytė, J.; Dovalienė, A.; Gadeikienė, A.; Korzilius, H. Sustainable Consumption Patterns in Different Settings. Eng. Econ. 2021, 32, 278–291. [Google Scholar] [CrossRef]

- Yates, L. Sharing, households and sustainable consumption. J. Consum. Cult. 2016, 18, 433–452. [Google Scholar] [CrossRef]

- Tamang, M.; Nandy, S.; Srinet, R.; Das, A.K.; Padalia, H. Bamboo Mapping Using Earth Observation Data: A Systematic Review. J. Indian Soc. Remote Sens. 2022, 50, 2055–2072. [Google Scholar] [CrossRef]

- Fadrique, B.; Santos-Andrade, P.; Farfan-Rios, W.; Salinas, N.; Silman, M.; Feeley, K.J. Reduced tree density and basal area in Andean forests are associated with bamboo dominance. For. Ecol. Manag. 2021, 480, 118648. [Google Scholar] [CrossRef]

- Du, H.; Mao, F.; Li, X.; Zhou, G.; Xu, X.; Han, N.; Sun, S.; Gao, G.; Cui, L.; Li, Y.; et al. Mapping Global Bamboo Forest Distribution Using Multisource Remote Sensing Data. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2018, 11, 1458–1471. [Google Scholar] [CrossRef]

- Feng, X.; Tan, S.; Dong, Y.; Zhang, X.; Xu, J.; Zhong, L.; Yu, L. Mapping Large-Scale Bamboo Forest Based on Phenology and Morphology Features. Remote Sens. 2023, 15, 515. [Google Scholar] [CrossRef]

- Ferreira, E.; Kalliola, R.; Ruokolainen, K. Bamboo, climate change and forest use: A critical combination for southwestern Amazonian forests? Ambio 2020, 49, 1353–1363. [Google Scholar] [CrossRef] [PubMed]

- Qi, S.; Song, B.; Liu, C.; Gong, P.; Luo, J.; Zhang, M.; Xiong, T. Bamboo Forest Mapping in China Using the Dense Landsat 8 Image Archive and Google Earth Engine. Remote Sens. 2022, 14, 762. [Google Scholar] [CrossRef]

- Muhammad, A.; Rahman, M.R.; Hamdan, S.; Sanaullah, K. Recent developments in bamboo fiber-based composites: A review. Polym. Bull. 2018, 76, 2655–2682. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Sun, W.; Zhao, Y.; Wang, X.; Liu, X.; Li, Y. Bamboo flattening technique: A literature and patent review. Eur. J. Wood Wood Prod. 2021, 79, 1035–1048. [Google Scholar] [CrossRef]

- Luo, B.; Ahmed, S.; Long, C. Bamboos for weaving and relevant traditional knowledge in Sansui, Southwest China. J. Ethnobiol. Ethnomed. 2020, 16, 63. [Google Scholar] [CrossRef]

- Huang, D. Know “bamboo”. ZHUANGSHI 2011, 11, 36–41. [Google Scholar]

- Han, X.; Lou, Z.; Yuan, C.; Wu, X.; Liu, J.; Weng, F.; Li, Y. Study on the Effect of Two-Step Saturated Steam Heat Treatment Process on the Properties of Reconstituted Bamboo. J. Renew. Mater. 2022, 10, 3313–3334. [Google Scholar] [CrossRef]

- Yang, L.; Lou, Z.; Han, X.; Liu, J.; Wang, Z.; Zhang, Y.; Wu, X.; Yuan, C.; Li, Y. Fabrication of a novel magnetic reconstituted bamboo with mildew resistance properties. Mater. Today Commun. 2020, 23, 101086. [Google Scholar] [CrossRef]

- Zhao, K.; Wei, Y.; Chen, S.; Hang, C.; Zhao, K. Experimental investigation of the long-term behavior of reconstituted bamboo beams with various loading levels. J. Build. Eng. 2021, 36, 102107. [Google Scholar] [CrossRef]

- Gu, Y.; Zhang, J. Tensile Properties of Natural and Synthetic Rattan Strips Used as Furniture Woven Materials. Forests 2020, 11, 1299. [Google Scholar] [CrossRef]

- Kremensas, A.; Vaitkus, S.; Vėjelis, S.; Członka, S.; Kairytė, A. Hemp shivs and corn-starch-based biocomposite boards for furniture industry: Improvement of water resistance and reaction to fire. Ind. Crops Prod. 2021, 166, 113477. [Google Scholar] [CrossRef]

- Yasir, M.; Majid, A.; Yasir, M.; Qudratullah, H. Promoting environmental performance in manufacturing industry of developing countries through environmental orientation and green business strategies. J. Clean. Prod. 2020, 275, 123003. [Google Scholar] [CrossRef]

- Sun, X. Green and ecological interior design based on network processor and embedded system. Microprocess. Microsyst. 2021, 82, 103911. [Google Scholar] [CrossRef]

- Li, H.; Wen, K.-H. Research on Design of Stalk Furniture Based on the Concept and Application of Miryoku Engineering Theory. Sustainability 2021, 13, 3652. [Google Scholar] [CrossRef]

- Gao, X.; Zhu, D.; Fan, S.; Rahman, M.Z.; Guo, S.; Chen, F. Structural and mechanical properties of bamboo fiber bundle and fiber/bundle reinforced composites: A review. J. Mater. Res. Technol. 2022, 19, 1162–1190. [Google Scholar] [CrossRef]

- Kadivar, M.; Gauss, C.; Ghavami, K.; Savastano, H., Jr. Densification of Bamboo: State of the Art. Materials 2020, 13, 4346. [Google Scholar] [CrossRef]

- Zhu, Y.; Huang, J.; Wang, K.; Wang, B.; Sun, S.; Lin, X.; Song, L.; Wu, A.; Li, H. Characterization of Lignin Structures in Phyllostachys edulis (Moso Bamboo) at Different Ages. Polymers 2020, 12, 187. [Google Scholar] [CrossRef]

- Wi, S.G.; Lee, D.S.; Nguyen, Q.A.; Bae, H.J. Evaluation of biomass quality in short-rotation bamboo (Phyllostachys pubescens) for bioenergy products. Biotechnol. Biofuels 2017, 10, 127. [Google Scholar] [CrossRef]

- Akoto, D.; Denich, M.; Partey, S.; Frith, O.; Kwaku, M.; Mensah, A.; Borgemeister, C. Socioeconomic Indicators of Bamboo Use for Agroforestry Development in the Dry Semi-Deciduous Forest Zone of Ghana. Sustainability 2018, 10, 2324. [Google Scholar] [CrossRef]

- Huang, Y.; Qi, Y.; Zhang, Y.; Yu, W. Progress of Bamboo Recombination Technology in China. Adv. Polym. Technol. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Mofidi, A.; Abila, J.; Ng, J.T.M. Novel Advanced Composite Bamboo Structural Members with Bio-Based and Synthetic Matrices for Sustainable Construction. Sustainability 2020, 12, 2485. [Google Scholar] [CrossRef]

- Tsolakis, N.; Niedenzu, D.; Simonetto, M.; Dora, M.; Kumar, M. Supply network design to address United Nations Sustainable Development Goals: A case study of blockchain implementation in Thai fish industry. J. Bus. Res. 2021, 131, 495–519. [Google Scholar] [CrossRef]

- Chen, F.-H.; Ho, S.-J. Designing a Board Game about the United Nations’ Sustainable Development Goals. Sustainability 2022, 14, 11197. [Google Scholar] [CrossRef]

- Campbell, D.A. An Update on the United Nations Millennium Development Goals. J. Obstet. Gynecol. Neonatal. Nurs. 2017, 46, e48–e55. [Google Scholar] [CrossRef]

- Pryshlakivsky, J.; Searcy, C. Life Cycle Assessment as a decision-making tool: Practitioner and managerial considerations. J. Clean. Prod. 2021, 309, 127344. [Google Scholar] [CrossRef]

- Athar, M.; Shariff, A.M.; Buang, A. A review of inherent assessment for sustainable process design. J. Clean. Prod. 2019, 233, 242–263. [Google Scholar] [CrossRef]

- Wang, F.; Shao, Z.; Wu, Y.; Wu, D. The toughness contribution of bamboo node to the Mode I interlaminar fracture toughness of bamboo. Wood Sci. Technol. 2013, 48, 1257–1268. [Google Scholar] [CrossRef]

- Wang, X.; Liang, D.; Deng, W. Surface grading of bamboo strips using multi-scale color texture features in eigenspace. Comput. Electron. Agric. 2010, 73, 91–98. [Google Scholar] [CrossRef]

- Designers Use Sharp Skewers to Create Soft ‘Dandelions’. Available online: https://www.sohu.com/a/481513783_121124644 (accessed on 26 March 2023).

- Wan, Q.; Hu, Q.; Chen, B.; Fang, H.; Ke, Q.; Song, S. Study on the Visual Cognition of Laminated Bamboo Furniture. For. Prod. J. 2021, 71, 84–91. [Google Scholar] [CrossRef]

- Glavič, P. Updated Principles of Sustainable Engineering. Processes 2022, 10, 870. [Google Scholar] [CrossRef]

| Principles | Specific Instructions |

|---|---|

| Integral | Starting from the whole, we minimize the consumption and waste in the activities of design, production, sales, and usage to achieve the purpose of protecting energy resources. |

| Harmony | From the concept of harmony, through optimal design, we create a harmonious relationship between humans, machines, the environment, and society to achieve the purpose of harmonious coexistence. |

| Circulation | From the purpose of recycling, we can preserve, expand renewable resources and make reasonable use of nonrenewable resources, and extend their service life to achieve recycling through recycling design. |

| Innovation | From the sustainable design method, the existing product design is going to achieve innovation in terms of function, shape, structure, practicality, and cultural connotation. |

| Material | Physical and Mechanical Properties |

|---|---|

| Bamboo | Density 0.81 g/cm3, coefficient of dry shrinkage 0.255%, tensile strength 184.27 MPa, flexural strength 108.52 MPa, compressive strength 65.39 MPa |

| Wood (oak) | Density 0.572 g/cm3, dry shrinkage coefficient 0.392%, tensile strength 153.55 MPa, flexural strength 139.6 MPa, compressive strength 64.7 MPa |

| Plastic (PVC) | Density 0.9–2.3 g/cm3, hardness ≥ 85 HR, tensile strength ≥ 36.8 MPa, bending modulus of elasticity ≥ 1961 MPa, Vicat softening point 83 °C, oxygen index 35% |

| Steel | Density 1.15 g/cm3, tensile strength ≥ 300 MPa, compressive shrinkage strength ≥ 140 MPa, modulus of elasticity ≥ 30 GPa |

| Type | Figure | Description |

|---|---|---|

| Round bamboo furniture |  | The number and scale of enterprises specializing in the production of round bamboo furniture is small, and the output of individual family-type workshops accounts for the majority of the total output of such furniture. The non-disassembled structure of round bamboo furniture not only wastes raw materials but is also not conducive to quality control and product standardization, serialization, and disassembly, and leads to low production efficiency, high transportation costs, and a small product circulation. |

| Bamboo composite furniture |  | Bamboo laminated timber is produced with a certain hydrothermal carbonization treatment, and the finished product is well sealed, which can effectively prevent insect infiltration and mildew. Compared with wooden furniture, bamboo has strong physical and mechanical properties, and through a variety of applications of the material and rich color changes, it forms a diversity of styles to meet the needs of consumers at different levels. |

| Bamboo reconstituted furniture |  | Heavy bamboo is pressed and produced using a special process, sometimes involving high temperature, and has a very high density, super hardness, and static bending strength. Due to the restructuring of the fiber structure of bamboo, the external problem of deformation is completely solved. The bending is achieved in one piece and it can be a natural replacement for high-grade mahogany without any trace of articulation. |

| Bamboo bent and glued furniture |  | Bamboo bent and glued furniture mainly involves the use of bamboo, bamboo veneer, bamboo thin wood, and other materials, through the multilayer bending and gluing process. |

| D4S Bamboo Furniture Design Check Results | |||

|---|---|---|---|

| Evaluation date | 4 October 2022 | Sustainability rating | Level 2 |

| Inspection items | Inspection content | Inspection result score | Total number of people selected |

| Design Solution Phase | ① Maximum utilization of the characteristics of bamboo material | 1 2 3 4 5 | 40 |

| ② Maximum compliance with user needs | 1 2 3 4 5 | 42 | |

| ③ Maximize business benefits | 1 2 3 4 5 | 38 | |

| ④ No follow-up or corresponding efforts are required to ensure greenness | 1 2 3 4 5 | 35 | |

| ⑤ Limited impact on the environment throughout the life cycle | 1 2 3 4 5 | 34 | |

| Program Implementation Phase | ① Use recyclable materials | 1 2 3 4 5 | 45 |

| ② Use as few materials as possible | 1 2 3 4 5 | 43 | |

| ③ Easy to recycle | 1 2 3 4 5 | 44 | |

| ④ Conform to production standards | 1 2 3 4 5 | 46 | |

| ⑤ Lightweight processing and production | 1 2 3 4 5 | 40 | |

| ⑥ Reduce the application of auxiliary materials such as ink, adhesive, bleach, dye, lamination, etc. | 1 2 3 4 5 | 39 | |

| ⑦ Packaging materials are environmental protection materials | 1 2 3 4 5 | 34 | |

| ⑧ Product environmental protection certification qualified | 1 2 3 4 5 | 46 | |

| ⑨ Systematic, overall beauty, and localization strategies are implemented | 1 2 3 4 5 | 44 | |

| Disposal Phase | ① Recycled | 1 2 3 4 5 | 46 |

| ② Recycling | 1 2 3 4 5 | 45 | |

| ③ Continuously consumed | 1 2 3 4 5 | 42 | |

| ④ Naturally, degraded | 1 2 3 4 5 | 48 | |

| Inspection Items | Inspection Content | Radar Chart of Examination Results Scores |

|---|---|---|

| Design Solution Phase | ① Maximum utilization of the characteristics of bamboo material |  |

| ② Maximum compliance with user needs | ||

| ③ Maximize business benefits | ||

| ④ No follow-up or corresponding efforts are required to ensure greenness | ||

| ⑤ Limited impact on the environment throughout the life cycle | ||

| Through the radar chart analysis, it can be intuitively seen that the experts, professors, furniture product designers, and business leaders were most satisfied with this solution because most people use the characteristics of bamboo wood to design furniture products with strong practicality. | ||

| Program Implementation Phase | ① Use recyclable materials |  |

| ② Use as few materials as possible | ||

| ③ Easy to recycle | ||

| ④ Conform to production standards | ||

| ⑤ Lightweight processing and production | ||

| ⑥ Reduce the application of auxiliary materials such as ink, adhesive, bleach, dye, lamination. | ||

| ⑦ Packaging materials are environmental protection materials | ||

| ⑧ Product environmental protection certification qualified | ||

| ⑨ Systematic, overall beauty, and localization strategies are implemented | ||

| Through the analysis, it can be intuitively seen that the packaging material score of bamboo furniture was relatively low, which is not conducive to sustainable use. It is easy to waste packaging materials and, therefore, this needs further improvement. | ||

| Disposal Phase | ① Recycled |  |

| ② Recycling | ||

| ③ Continuously consumed | ||

| ④ Naturally, degraded | ||

| According to the analysis, the most important feature of the bamboo furniture was its natural degradation properties, and that it is easy to recycle and reuse; however, achieving sustainable consumption still requires the efforts of many parties. | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, W.; Lin, H.; Jiang, M. Research on Bamboo Furniture Design Based on D4S (Design for Sustainability). Sustainability 2023, 15, 8832. https://doi.org/10.3390/su15118832

Deng W, Lin H, Jiang M. Research on Bamboo Furniture Design Based on D4S (Design for Sustainability). Sustainability. 2023; 15(11):8832. https://doi.org/10.3390/su15118832

Chicago/Turabian StyleDeng, Wenxin, Hong Lin, and Mu Jiang. 2023. "Research on Bamboo Furniture Design Based on D4S (Design for Sustainability)" Sustainability 15, no. 11: 8832. https://doi.org/10.3390/su15118832

APA StyleDeng, W., Lin, H., & Jiang, M. (2023). Research on Bamboo Furniture Design Based on D4S (Design for Sustainability). Sustainability, 15(11), 8832. https://doi.org/10.3390/su15118832