Performance Improvement of Flux Switching Permanent Magnet Wind Generator Using Magnetic Flux Barrier Design

Abstract

:1. Introduction

2. Topology Selection

3. Flux Barrier Design and Optimization

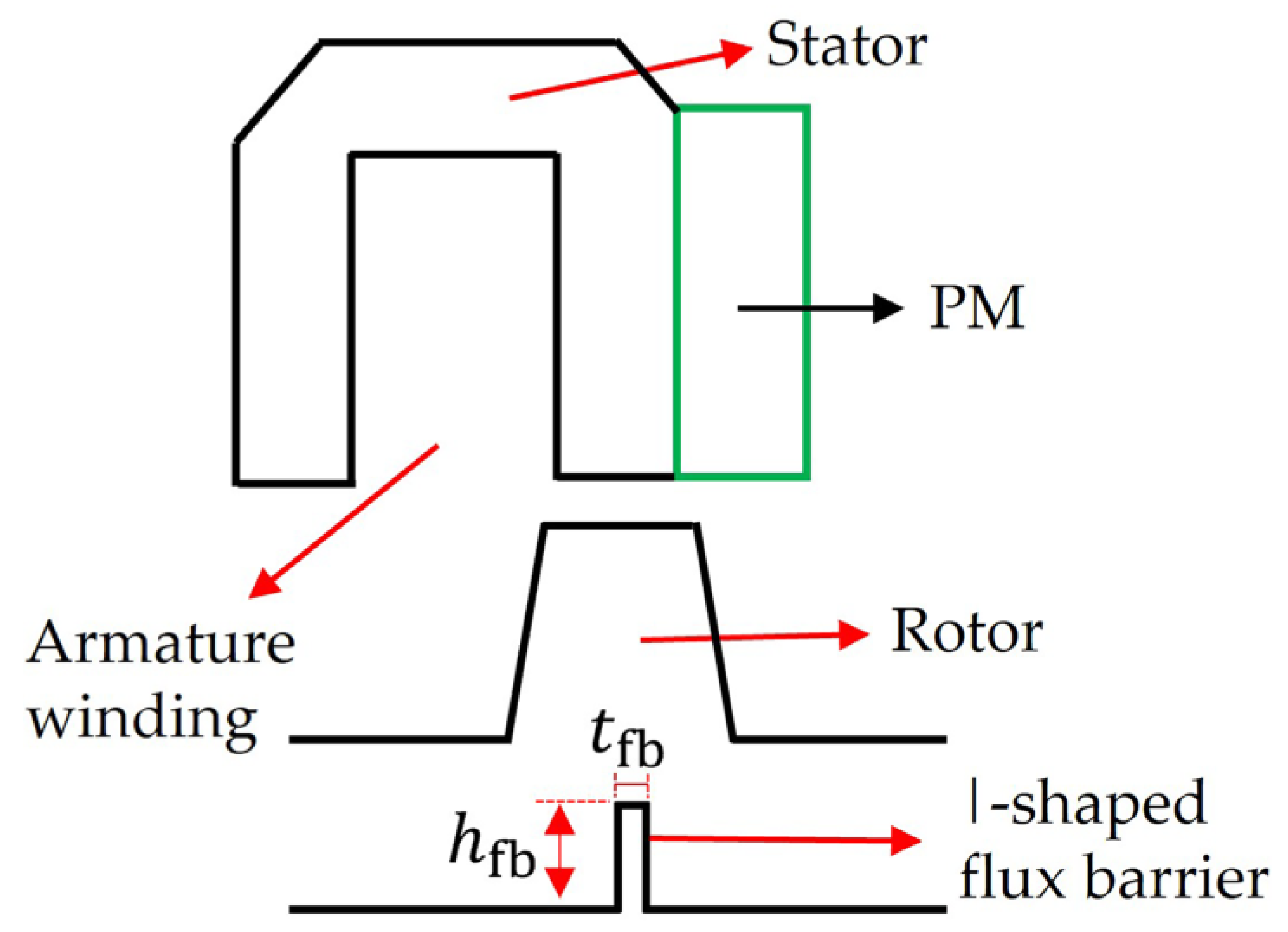

3.1. Design of Flux Barrier

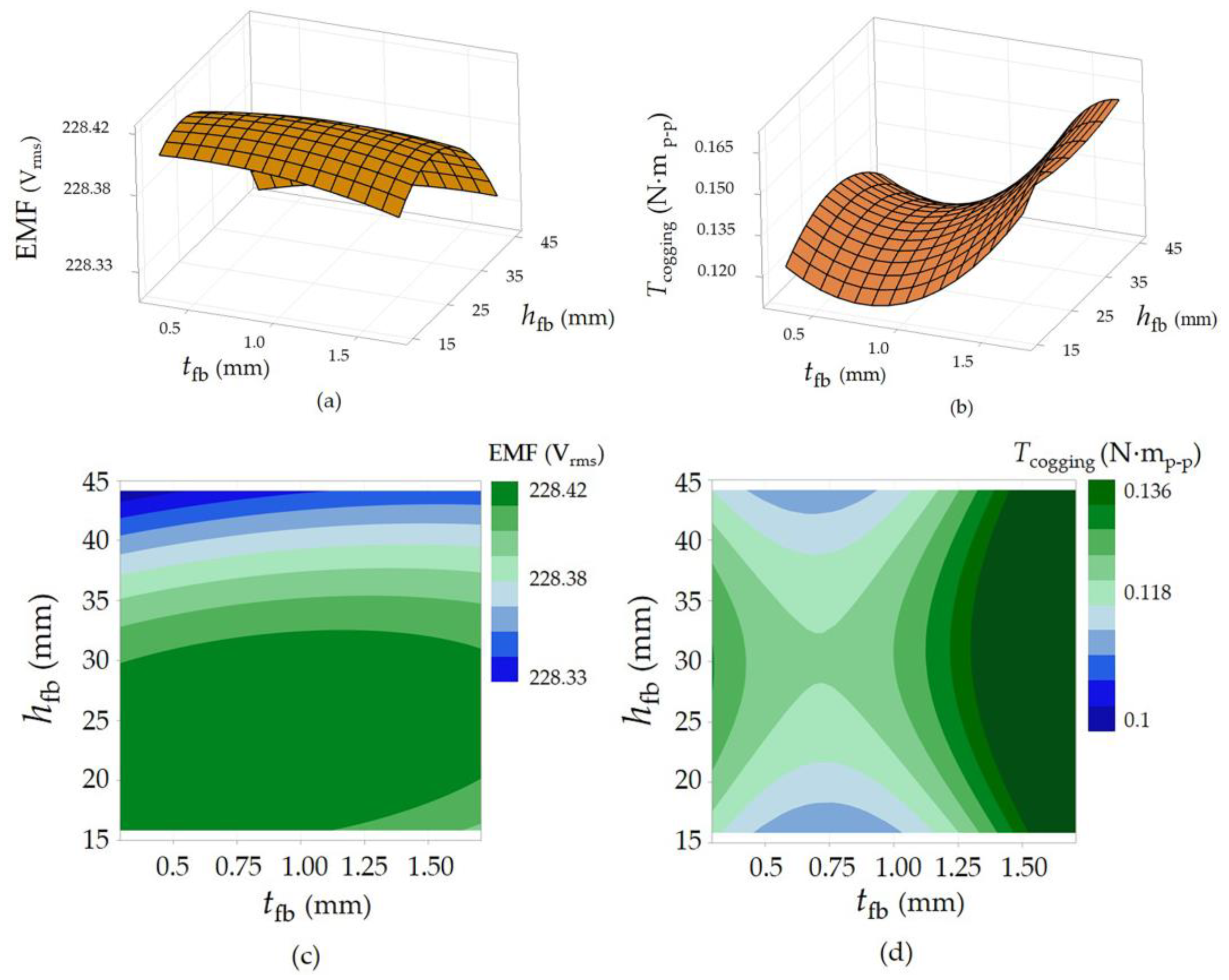

3.2. Optimization of |-Shaped Flux Barrier Using Response Surface Methodology

4. Electromagnetic Performance Comparison

4.1. No-Load Performance

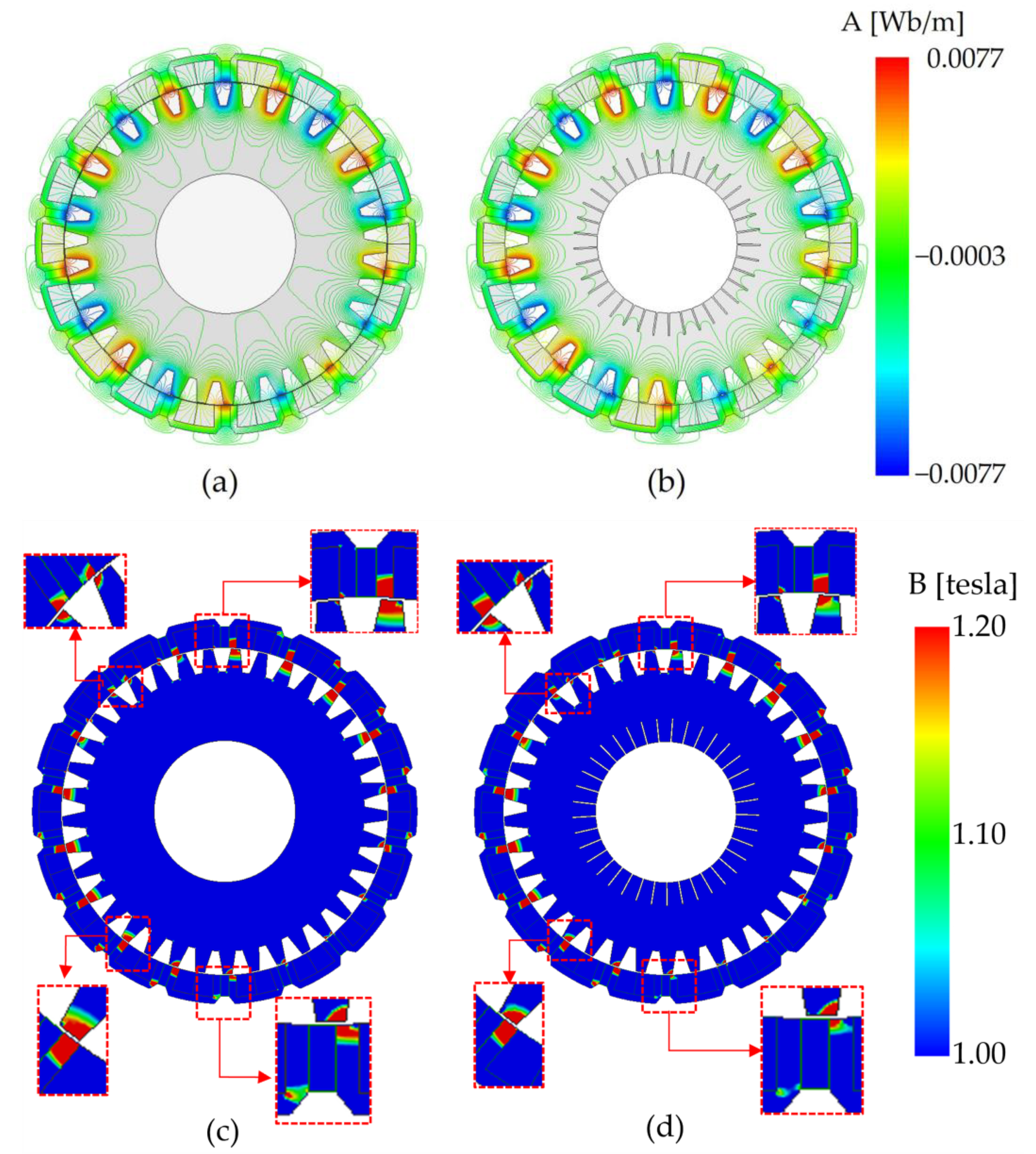

4.1.1. PM Flux Line Distribution

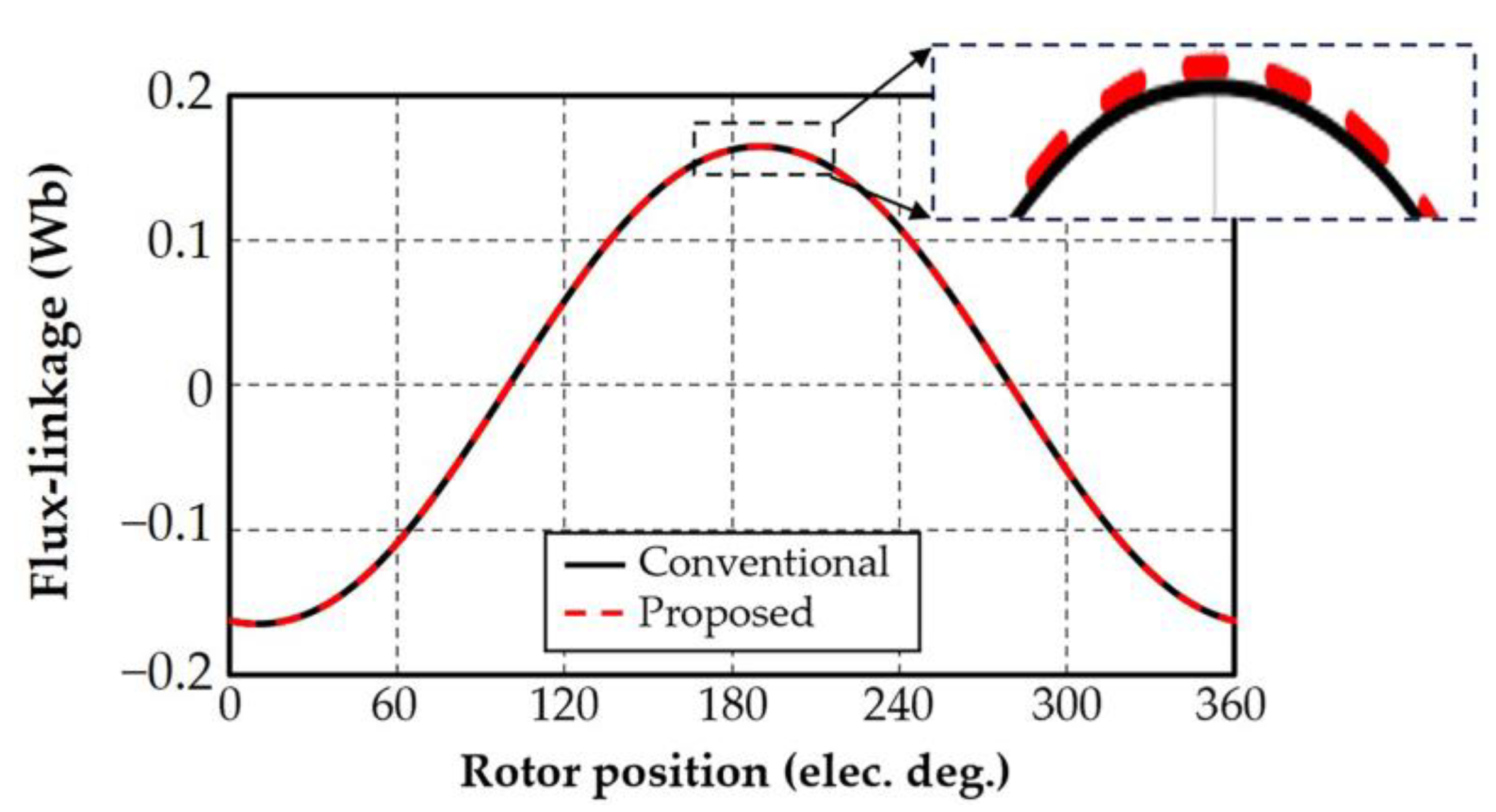

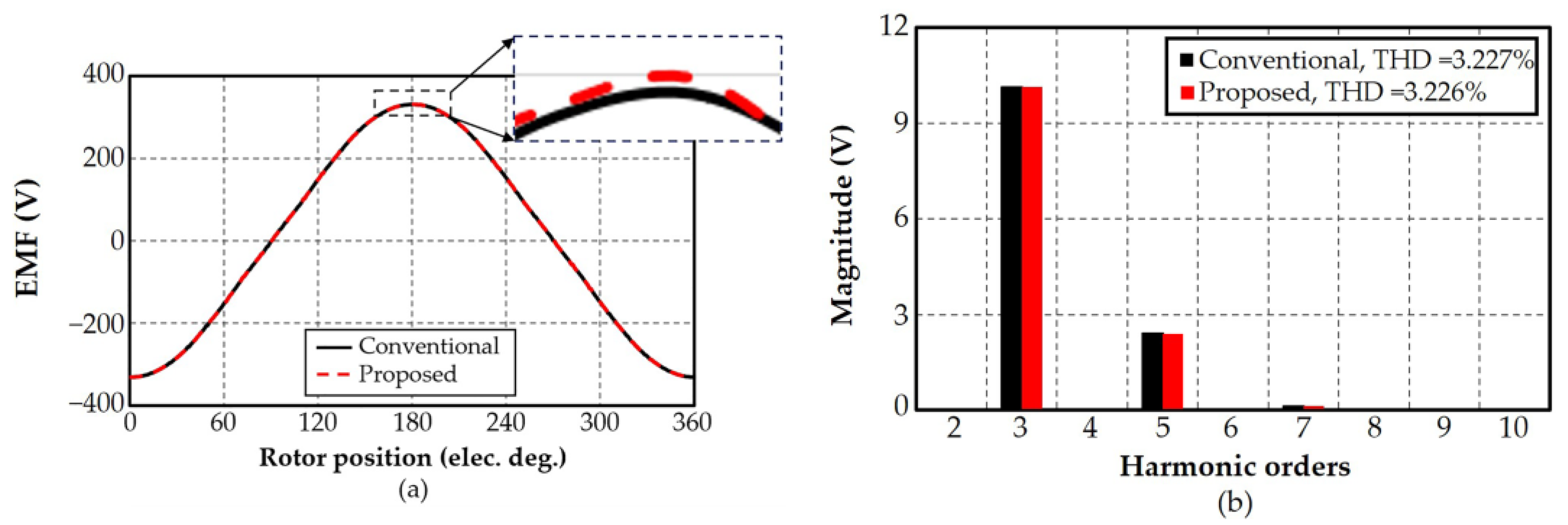

4.1.2. Open-Circuit PM Flux-Linkage and Electromotive Force

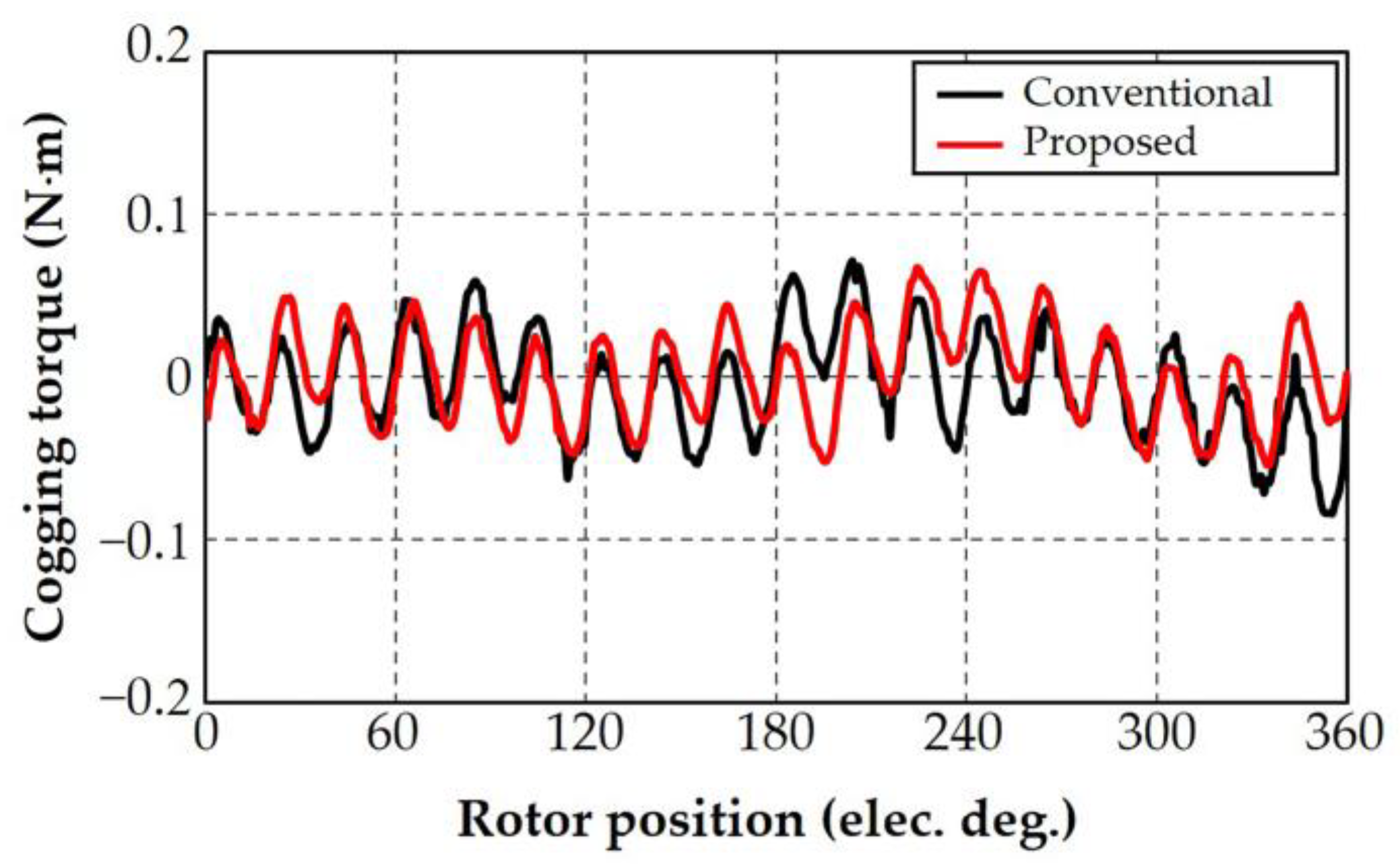

4.1.3. Cogging Torque

4.2. On-Load Performance

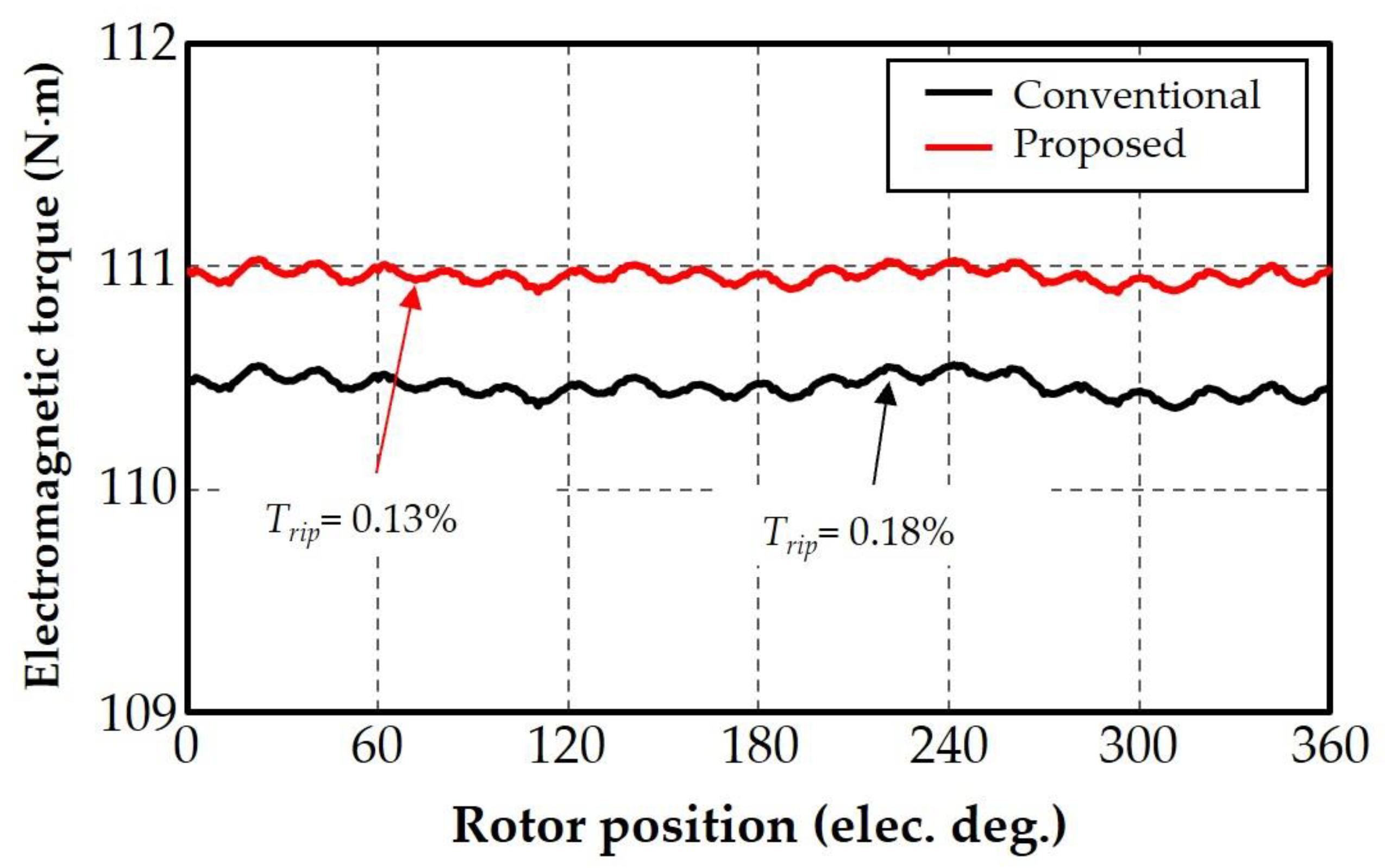

4.2.1. Electromagnetic Torque

4.2.2. Losses and Efficiency

4.3. Comparison to the Existing Radial-Flux PM Wind Generators

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, R.; Lu, M.; Member, S. Comparison Between Linear Induction Motor and Linear Flux-Switching Permanent-Magnet Motor for Railway Transportation. IEEE Trans. Ind. Electron. 2019, 66, 9394–9405. [Google Scholar] [CrossRef]

- Brisset, S.; Vizireanu, D.; Brochet, P. Design and Optimization of a Nine-Phase Axial-Flux PM Synchronous Generator with Concentrated Winding for Direct-Drive Wind Turbine. IEEE Trans. Ind. Appl. 2008, 44, 707–715. [Google Scholar] [CrossRef]

- Zaitsev, I.; Bereznychenko, V.; Bajaj, M.; Taha, I.B.M.; Belkhier, Y.; Titko, V.; Kamel, S. Calculation of Capacitive-Based Sensors of Rotating Shaft Vibration for Fault Diagnostic Systems of Powerful Generators. Sensors 2022, 22, 1634. [Google Scholar] [CrossRef]

- Zhu, X.; Fan, D.; Mo, L.; Chen, Y.; Quan, L. Multiobjective Optimization Design of a Double-Rotor Flux-Switching Permanent Magnet Machine Considering Multimode Operation. IEEE Trans. Ind. Electron. 2019, 66, 641–653. [Google Scholar] [CrossRef]

- Belkhier, Y.; Shaw, R.N.; Bures, M.; Islam, M.R.; Bajaj, M.; Albalawi, F.; Ghoneim, S.S. Robust interconnection and damping assignment energy-based control for a permanent magnet synchronous motor using high order sliding mode approach and nonlinear observer. Energy Rep. 2022, 8, 1731–1740. [Google Scholar] [CrossRef]

- Cao, R.; Mi, C.; Cheng, M. Quantitative Comparison of Flux-Switching Permanent-Magnet Motors with Interior Permanent Magnet Motor for EV, HEV, and PHEV Applications. IEEE Trans. Magn. 2012, 48, 2374–2384. [Google Scholar] [CrossRef]

- Yuan, J.; Meng, D.; Lian, G.; Zhang, J.; Li, H.; Ban, F. The Stator Slot-Type Optimization of Electrical Excitation Flux-Switching Motor and Its Maximum Torque/Copper Loss Control. IEEE Trans. Appl. Supercond. 2019, 29, 2–6. [Google Scholar] [CrossRef]

- Wang, P.; Member, S.; Hua, W.; Member, S.; Zhang, G.; Wang, B.; Cheng, M. Principle of Flux-Switching PM Machine by Magnetic Field Modulation Theory Part II: Electromagnetic Torque Generation. IEEE Trans. Ind. Electron. 2022, 69, 2437–2446. [Google Scholar] [CrossRef]

- Shi, Y.; Jian, L.; Wei, J.; Shao, Z.; Li, W.; Chan, C.C. A New Perspective on the Operating Principle of Flux-Switching Permanent-Magnet Machines. IEEE Trans. Ind. Electron. 2016, 63, 1425–1437. [Google Scholar] [CrossRef]

- Zhu, X.; Hua, W.; Wang, W.; Huang, W. Analysis of Back-EMF in Flux-Reversal Permanent Magnet Machines by Air Gap Field Modulation Theory. IEEE Trans. Ind. Electron. 2019, 66, 3344–3355. [Google Scholar] [CrossRef]

- Sriwannarat, W.; Seangwong, P.; Lounthavong, V.; Khunkitti, S.; Siritaratiwat, A.; Khunkitti, P. An Improvement of Output Power in Doubly Salient Permanent Magnet Generator Using Pole Configuration Adjustment. Energies 2020, 13, 4588. [Google Scholar] [CrossRef]

- Lounthavong, V.; Sriwannarat, W.; Siritaratiwat, A.; Khunkitti, P. Optimal Stator Design of Doubly Salient Permanent Magnet Generator for Enhancing the Electromagnetic Performance. Energies 2019, 12, 3201. [Google Scholar] [CrossRef]

- Chen, H.; El-Refaie, A.M.; Demerdash, N.A.O. Flux-Switching Permanent Magnet Machines: A Review of Opportunities and Challenges-Part II: Design Aspects, Control, and Emerging Trends. IEEE Trans. Energy Convers. 2020, 35, 699–713. [Google Scholar] [CrossRef]

- Sriwannarat, W.; Khunkitti, P.; Janon, A.; Siritaratiwat, A. An Improvement of Magnetic Flux Linkage in Electrical Generator Using the Novel Permanent Magnet Arrangement. Acta Phys. Pol. A 2018, 133, 642–644. [Google Scholar] [CrossRef]

- Shao, L.; Hua, W.; Zhu, Z.Q.; Tong, M.; Zhao, G.; Yin, F.; Wu, Z.; Cheng, M. Influence of Rotor-Pole Number on Electromagnetic Performance in 12-Phase Redundant Switched Flux Permanent Magnet Machines for Wind Power Generation. IEEE Trans. Ind. Appl. 2017, 53, 3305–3316. [Google Scholar] [CrossRef]

- Li, F.; Hua, W.; Tong, M.; Zhao, G.; Cheng, M. Nine-Phase Flux-Switching Permanent Magnet Brushless Machine for Low-Speed and High-Torque Applications. IEEE Trans. Magn. 2015, 51, 4–7. [Google Scholar]

- Ullah, W.; Khan, F.; Hussain, S. Investigation of Inner/Outer Rotor Permanent Magnet Flux Switching Generator for Wind Turbine Applications. IEEE Access 2021, 9, 149110–149117. [Google Scholar] [CrossRef]

- Ullah, W.; Khan, F.; Hussain, S. A Novel Dual Rotor Permanent Magnet Flux Switching Generator for Counter Rotating Wind Turbine Applications. IEEE Access 2022, 10, 16456–16467. [Google Scholar] [CrossRef]

- Ullah, W.; Khan, F.; Hussain, S. A Comparative Study of Dual Stator with Novel Dual Rotor Permanent Magnet Flux Switching Generator for Counter Rotating Wind Turbine Applications. IEEE Access 2022, 10, 8243–8261. [Google Scholar] [CrossRef]

- Seangwong, P.; Chamchuen, S.; Fernando, N.; Siritaratiwat, A.; Khunkitti, P. A Novel Six-Phase V-Shaped Flux-Switching Permanent Magnet Generator for Wind Power Generation. Energies 2022, 15, 9608. [Google Scholar] [CrossRef]

- Barcaro, M.; Bianchi, N.; Magnussen, F. Rotor Flux-Barrier Geometry Design to Reduce Stator Iron Losses in Synchronous IPM Motors under FW Operations. IEEE Trans. Ind. Appl. 2010, 46, 1950–1958. [Google Scholar] [CrossRef]

- Yamazaki, K.; Kumagai, M.; Ikemi, T.; Ohki, S. A Novel Rotor Design of Interior Permanent-Magnet Synchronous Motors to Cope with Both Maximum Torque and Iron-Loss Reduction. IEEE Trans. Ind. Appl. 2013, 49, 2478–2486. [Google Scholar] [CrossRef]

- Luo, J.; Zhao, W.; Ji, J.; Zheng, J.; Zhang, Y.; Ling, Z.; Mao, J. Reduction of Eddy-Current Loss in Flux-Switching Permanent-Magnet Machines Using Rotor Magnetic Flux Barriers. IEEE Trans. Magn. 2017, 53, 3–7. [Google Scholar] [CrossRef]

- Sanada, M.; Hiramoto, K.; Morimoto, S.; Takeda, Y. Torque Ripple Improvement for Synchronous Reluctance Motor Using an Asymmetric Flux Barrier Arrangement. IEEE Trans. Ind. Appl. 2004, 40, 1076–1082. [Google Scholar] [CrossRef]

- Yamazaki, K.; Kato, Y.; Ikemi, T.; Ohki, S. Reduction of Rotor Losses in Multilayer Interior Permanent-Magnet Synchronous Motors by Introducing Novel Topology of Rotor Flux Barriers. IEEE Trans. Ind. Appl. 2014, 50, 3185–3193. [Google Scholar] [CrossRef]

- Choi, G.; Jahns, T.M. Reduction of Eddy-Current Losses in Fractional-Slot Concentrated-Winding Synchronous PM Machines. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Zhao, W.; Pan, X.; Ji, J.; Xu, L.; Zheng, J. Analysis of PM Eddy Current Loss in Four-Phase Fault-Tolerant Flux-Switching Permanent-Magnet Machines by Air-Gap Magnetic Field Modulation Theory. IEEE Trans. Ind. Electron. 2020, 67, 5369–5378. [Google Scholar] [CrossRef]

- Naseh, M.; Hasanzadeh, S.; Dehghan, S.M.; Rezaei, H.; Al-Sumaiti, A.S. Optimized Design of Rotor Barriers in PM-Assisted Synchronous Reluctance Machines with Taguchi Method. IEEE Access 2022, 10, 38165–38173. [Google Scholar] [CrossRef]

- Pan, Z.; Yang, K.; Wang, X. Optimal Design of Flux-Barrier to Improve Torque Performance of IPMSM for Electric Spindle. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; pp. 773–778. [Google Scholar] [CrossRef]

- Nissayan, C.; Seangwong, P.; Chamchuen, S.; Fernando, N.; Siritaratiwat, A.; Khunkitti, P. Modeling and Optimal Configuration Design of Flux-Barrier for Torque Improvement of Rotor Flux Switching Permanent Magnet Machine. Energies 2022, 15, 8429. [Google Scholar] [CrossRef]

- Sayed, E.; Yang, Y.; Bilgin, B.; Bakr, M.H.; Emadi, A. A Comprehensive Review of Flux Barriers in Interior Permanent Magnet Synchronous Machines. IEEE Access 2019, 7, 149168–149181. [Google Scholar] [CrossRef]

- Ishikawa, K.; Kitagawa, W.; Takeshita, T. Shape Optimization of Flux Barriers in IPMSM by Using Polygon Model Method with GP. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Berlin, Germany, 2–5 September 2014; pp. 1403–1408. [Google Scholar] [CrossRef]

- Bianchi, N.; Bolognani, S.; Bon, D.; Pré, M.D. Rotor Flux-Barrier Design for Torque Ripple Reduction in Synchronous Reluctance and PM-Assisted Synchronous Reluctance Motors. IEEE Trans. Ind. Appl. 2009, 45, 921–928. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.; Lin, H. Investigation of Torque Improvement Mechanism in Emerging Switched Flux PM Machines. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 1860–1869. [Google Scholar] [CrossRef]

- Yang, H.; Li, Y.; Lin, H.; Zhu, Z.Q.; Lyu, S. Principle Investigation and Performance Comparison of Consequent-Pole Switched Flux PM Machines. IEEE Trans. Transp. Electrif. 2021, 7, 766–778. [Google Scholar] [CrossRef]

- Shao, L.; Hua, W.; Li, F.; Soulard, J.; Zhu, Z.Q.; Wu, Z.; Cheng, M. A Comparative Study on Nine- and Twelve-Phase Flux-Switching Permanent-Magnet Wind Power Generators. IEEE Trans. Ind. Appl. 2019, 55, 3607–3616. [Google Scholar] [CrossRef]

- Hazir, E.; Ozcan, T. Response Surface Methodology Integrated with Desirability Function and Genetic Algorithm Approach for the Optimization of CNC Machining Parameters. Arab. J. Sci. Eng. 2019, 44, 2795–2809. [Google Scholar] [CrossRef]

- Zhao, W.; Ma, A.; Ji, J.; Chen, X.; Yao, T. Multiobjective Optimization of a Double-Side Linear Vernier PM Motor Using Response Surface Method and Differential Evolution. IEEE Trans. Ind. Electron. 2020, 67, 80–90. [Google Scholar] [CrossRef]

- Tlali, P.M.; Wang, R.; Member, S.; Gerber, S.; Botha, C.D.; Kamper, M.J.; Member, S. Design and Performance Comparison of Vernier and Conventional PM Synchronous Wind Generators. IEEE Trans. Ind. Appl. 2020, 56, 2570–2579. [Google Scholar] [CrossRef]

- Kamper, M.J.; Member, S. Design and Performance Evaluation of PM Vernier Generator Technology for a Small-Scale Uncontrolled Passive Wind Generator System. IEEE Trans. Ind. Appl. 2022, 58, 4657–4667. [Google Scholar]

- Nasiri-zarandi, R.; Ajamloo, A.M. Design Optimization of a Transverse Flux Halbach-Array PM Generator for Direct Drive Wind Turbines. IEEE Trans. Energy Convers. 2020, 35, 1485–1493. [Google Scholar] [CrossRef]

- Seangwong, P.; Siritaratiwat, A.; Sriwannarat, W.; Fernando, N. Design of Doubly Salient Permanent Magnet Generator for Output Power Enhancement Using Structural Modification. J. Appl. Comput. Mech. 2021, 7, 2171–2178. [Google Scholar] [CrossRef]

| Indicators (Unit) | Conventional | |-Shaped | T-Shaped | ⊥-Shaped |

|---|---|---|---|---|

| EMF (Vrms) | 228.41 | 228.38 | 227.68 | 226.98 |

| Cogging torque (N·mp-p) | 0.16 | 0.128 | 0.179 | 0.129 |

| Parameters | Unit | Conventional | |-Shaped |

|---|---|---|---|

| Number of phases | phase | 9 | |

| Number of stator pole | pole | 18 | |

| Number of rotor pole | pole | 37 | |

| Lamination length | mm | 148 | |

| Stator outer radius | mm | 130.8 | |

| Rotor outer radius | mm | 110.38 | |

| Rotor inner radius | mm | 48 | |

| Stator pole arc | degree | 2.625 | |

| Air gap length | mm | 0.8 | |

| PM type | - | NdFeB | |

| Remanence of PM | T | 1.2 | |

| PM arc | degree | 3.25 | |

| PM length | mm | 14.5 | |

| Rotor pole arc | degree | 3.25 | |

| Rotor yoke arc | degree | 6.825 | |

| Rotor pole height | mm | 15.41 | |

| Cut delta length | mm | 6.4 | |

| Stator yoke | mm | 4.57 | |

| Number of turns per phase | turn | 168 | |

| Shaft material | - | Non-magnetic | |

| Rated speed | mm | 500 | |

| Flux barrier height, hfb | mm | - | 15.86 |

| Flux barrier thickness, tfb | mm | - | 1.00 |

| Design Parameters | Range |

|---|---|

| Height of flux barrier, hfb (mm) | 15–40 |

| Thickness of flux barrier, tfb (mm) | 0.5–1.5 |

| Parameters (Unit) | Conventional | Proposed |

|---|---|---|

| EMF (Vrms) | 228.41 | 228.41 |

| Cogging torque (N⋅mp-p) | 0.160 | 0.122 |

| Rated current (A) | 3.5 | |

| Output voltage (Vrms) | 170.61 | 171.40 |

| Average torque (N⋅m) | 110.46 | 110.96 |

| Torque ripple (%) | 0.18 | 0.13 |

| Output power (W) | 5374.06 | 5399.23 |

| Core loss (W) | 129.74 | 129.05 |

| Copper loss (W) | 155.95 | |

| Eddy-current loss (W) | 17.17 | 8.37 |

| Efficiency (%) | 94.51 | 94.70 |

| References | Output Power per Machine Volume (kW/m3) | Cogging Torque per Machine Volume (N·mp-p/m3) |

|---|---|---|

| Proposed structure | 683.0 | 15.43 |

| [20] | 1004.3 | 7.85 |

| [15] | 1004.1 | 51.49 |

| [36] | 939.7 | 50.20 |

| [16] | 768.2 | 1229.14 |

| [39] | 692.6 | 74.66 |

| [40] | 636.2 | 159.06 |

| [18] | 606.1 | 446.56 |

| [41] | 432.9 | 816.11 |

| [42] | 217.9 | 19,038.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torn, V.; Seangwong, P.; Fernando, N.; Siritaratiwat, A.; Khunkitti, P. Performance Improvement of Flux Switching Permanent Magnet Wind Generator Using Magnetic Flux Barrier Design. Sustainability 2023, 15, 8867. https://doi.org/10.3390/su15118867

Torn V, Seangwong P, Fernando N, Siritaratiwat A, Khunkitti P. Performance Improvement of Flux Switching Permanent Magnet Wind Generator Using Magnetic Flux Barrier Design. Sustainability. 2023; 15(11):8867. https://doi.org/10.3390/su15118867

Chicago/Turabian StyleTorn, Vanna, Pattasad Seangwong, Nuwantha Fernando, Apirat Siritaratiwat, and Pirat Khunkitti. 2023. "Performance Improvement of Flux Switching Permanent Magnet Wind Generator Using Magnetic Flux Barrier Design" Sustainability 15, no. 11: 8867. https://doi.org/10.3390/su15118867

APA StyleTorn, V., Seangwong, P., Fernando, N., Siritaratiwat, A., & Khunkitti, P. (2023). Performance Improvement of Flux Switching Permanent Magnet Wind Generator Using Magnetic Flux Barrier Design. Sustainability, 15(11), 8867. https://doi.org/10.3390/su15118867