Soil Erosion Due to Defective Pipes: A Hidden Hazard Beneath Our Feet

Abstract

:1. Background

1.1. Internal Soil Erosion

1.2. Internal Soil Erosion in Embankment Dams

1.3. Soil Erosion in Urban Environments

2. Soil Erosion Due to Defective Pipes (SEDP): Experimental Studies

2.1. Hydraulic Conditions

2.2. Pipe Conditions: Pipe Defect and Pipe Depth

2.2.1. Pipe Defect Characteristics

2.2.2. Pipe Depth

2.3. Soil Properties

2.4. Other Influencing Factors

2.4.1. Nearby Pipes

2.4.2. Fluidization

3. Soil Erosion Due to Defective Pipes (SEDP): Numerical Studies

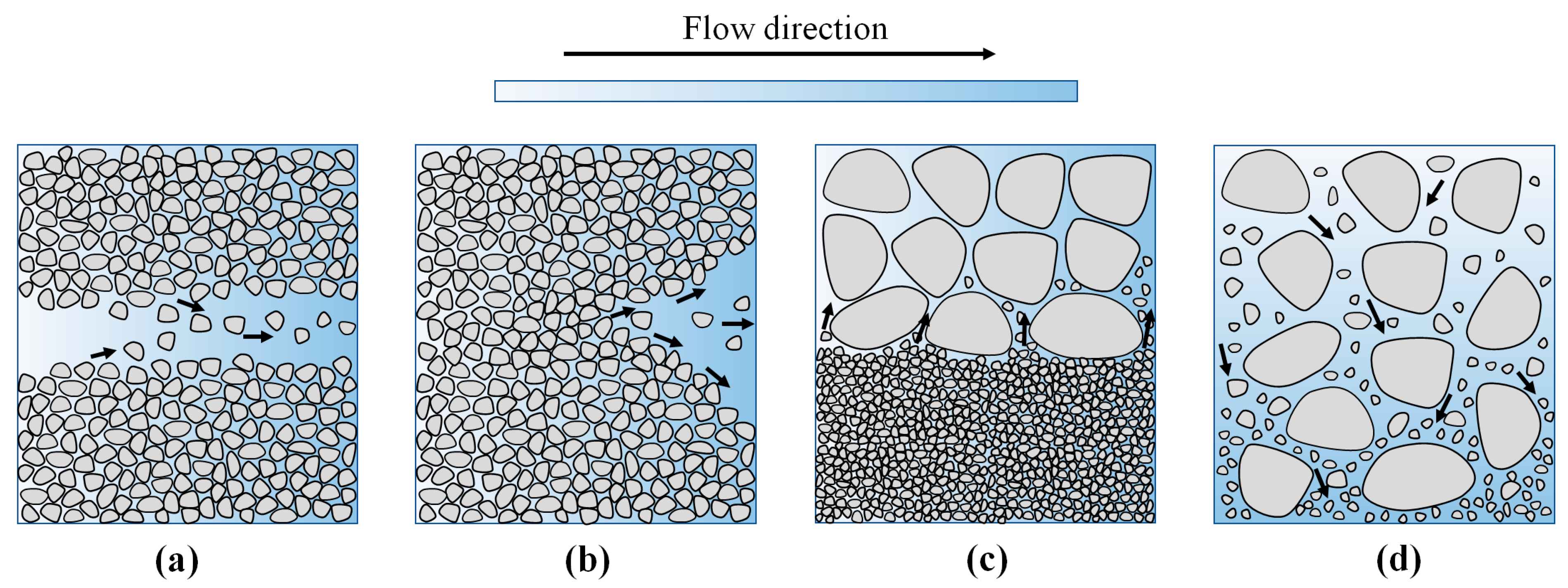

4. Discussion on the Potential Mechanisms of SEDP

5. Gaps in Current Knowledge and Needed Research

5.1. Lack of Extensive Studies and Repeatability

5.2. SEDP Mechanisms

5.3. SEDP Scenarios

5.4. Initial Hydraulic Conditions

5.5. Unsaturated Aspects

5.6. Fluidization

5.7. Scale Effects

5.8. Numerical Modelling

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lal, R. Soil erosion by wind and water: Problems and prospects. In Soil Erosion Research Methods; Routledge: London, UK, 2017; pp. 1–10. ISBN 0203739353. [Google Scholar]

- Dubey, A.A.; Ravi, K.; Shahin, M.A.; Dhami, N.K.; Mukherjee, A. Bio-composites treatment for mitigation of current-induced riverbank soil erosion. Sci. Total Environ. 2021, 800, 149513. [Google Scholar] [CrossRef] [PubMed]

- Briaud, J.-L.; Govindasamy, A.V.; Shafii, I. Erosion charts for selected geomaterials. J. Geotech. Geoenviron. Eng. 2017, 143, 4017072. [Google Scholar] [CrossRef]

- Foster, M.; Fell, R.; Spannagle, M. The statistics of embankment dam failures and accidents. Can. Geotech. J. 2000, 37, 1000–1024. [Google Scholar] [CrossRef]

- Bernatek-Jakiel, A.; Poesen, J. Subsurface erosion by soil piping: Significance and research needs. Earth-Sci. Rev. 2018, 185, 1107–1128. [Google Scholar] [CrossRef]

- Cooper, A.H. Halite karst geohazards (natural and man-made) in the United Kingdom. Environ. Geol. 2002, 42, 505–512. [Google Scholar] [CrossRef]

- Farrant, A.R.; Cooper, A.H. Karst geohazards in the UK: The use of digital data for hazard management. Q. J. Eng. Geol. Hydrogeol. 2008, 41, 339–356. [Google Scholar] [CrossRef]

- Delle Rose, M.; Federico, A.; Parise, M. Sinkhole genesis and evolution in Apulia, and their interrelations with the anthropogenic environment. Nat. Hazards Earth Syst. Sci. 2004, 4, 747–755. [Google Scholar] [CrossRef]

- Gutiérrez, F. Sinkhole hazards. In Oxford Research Encyclopedia of Natural Hazard Science; Oxford University Press: Oxford, UK, 2016. [Google Scholar]

- Foster, M.A. The Probability of Failure of Embankment Dams by Internal Erosion and Piping. Ph.D. Thesis, The University of New South Wales, Sydney, Australia, 1999. [Google Scholar]

- Fell, R.; Wan, C.F.; Cyganiewicz, J.; Foster, M. Time for development of internal erosion and piping in embankment dams. J. Geotech. Geoenviron. Eng. 2003, 129, 307–314. [Google Scholar] [CrossRef]

- Fell, R. Geotechnical Engineering of Dams; CRC Press: Boca Raton, FL, USA, 2005; ISBN 0415889324. [Google Scholar]

- Robbins, B.A.; Griffiths, D. V Internal erosion of embankments: A review and appraisal. In Proceedings of the Rocky Mountain Geo-Conference 2018, Golden, CO, USA, 2 November 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 61–75. [Google Scholar]

- Stéphane Bonelli, F.N. Front Matter. In Erosion in Geomechanics Applied to Dams and Levees; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. i–xix. ISBN 9781118577165. [Google Scholar]

- USACE. Internal Erosion Risks for Embankments and Foundations; Bureau of Reclamation, US Department of the INTERIOR: Denver, CO, USA, 2015. [Google Scholar]

- Fry, J.J. Lessons on internal erosion in embankment dams from failures and physical models. In Proceedings of the 8th International Conference on Scour and Erosion (ICSE8), Oxford, UK, 12–15 September 2016; pp. 41–58. [Google Scholar]

- Fannin, R.J.; Slangen, P. On the distinct phenomena of suffusion and suffosion. Géotech. Lett. 2014, 4, 289–294. [Google Scholar] [CrossRef]

- ASTM D4647-93; Standard Test Method for Identification and Classification of Dispersive Clay Soils by the Pinhole Test. ASTM International: West Conshohocken, PA, USA, 2006.

- Wan, C.F.; Fell, R. Investigation of rate of erosion of soils in embankment dams. J. Geotech. Geoenviron. Eng. 2004, 130, 373–380. [Google Scholar] [CrossRef]

- Briaud, J.-L.; Ting, F.C.K.; Chen, H.C.; Cao, Y.; Han, S.W.; Kwak, K.W. Erosion function apparatus for scour rate predictions. J. Geotech. Geoenviron. Eng. 2001, 127, 105–113. [Google Scholar] [CrossRef]

- Richards, K.S.; Reddy, K.R. True Triaxial Piping Test Apparatus for Evaluation of Piping Potential in Earth Structures. 2010. Available online: https://hdl.handle.net/10027/7288 (accessed on 1 April 2023).

- Davies, J.P.; Clarke, B.A.; Whiter, J.T.; Cunningham, R.J. Factors influencing the structural deterioration and collapse of rigid sewer pipes. Urban Water 2001, 3, 73–89. [Google Scholar] [CrossRef]

- Tohda, J.; Hachiya, M. Response and design of buried pipelines subjected to differential ground settlement. In Proceedings of the 16th International Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12–16 September 2005; IOS Press: Amsterdam, The Netherlands, 2005; pp. 1659–1662. [Google Scholar]

- Mukunoki, T.; Kumano, N.; Otani, J.; Kuwano, R. Visualization of three dimensional failure in sand due to water inflow and soil drainage from defective underground pipe using X-ray CT. Soils Found. 2009, 49, 959–968. [Google Scholar] [CrossRef]

- Ssozi, E.N.; Reddy, B.D.; Van Zyl, J.E. Numerical investigation of the influence of viscoelastic deformation on the pressure-leakage behavior of plastic pipes. J. Hydraul. Eng. 2016, 142, 4015057. [Google Scholar] [CrossRef]

- Buttrick, D.; Van Schalkwyk, A. Hazard and risk assessment for sinkhole formation on dolomite land in South Africa. Environ. Geol. 1998, 36, 170–178. [Google Scholar] [CrossRef]

- Shamet, R.; Nam, B.H. Geotechnical Investigation of karst sinkholes using an empirically-based CPT raveling chart. Transp. Geotech. 2021, 31, 100648. [Google Scholar] [CrossRef]

- Nam, B.H.; Kim, Y.J.; Youn, H. Identification and quantitative analysis of sinkhole contributing factors in Florida’s Karst. Eng. Geol. 2020, 271, 105610. [Google Scholar] [CrossRef]

- Tufano, R.; Guerriero, L.; Annibali Corona, M.; Bausilio, G.; Di Martire, D.; Nisio, S.; Calcaterra, D. Anthropogenic sinkholes of the city of Naples, Italy: An update. Nat. Hazards 2022, 112, 2577–2608. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J.; Kwak, T.-Y.; Chung, C.-K. Logistic regression model for sinkhole susceptibility due to damaged sewer pipes. Nat. Hazards 2018, 93, 765–785. [Google Scholar] [CrossRef]

- Laura, F. Tucson—Sewer Collapse; Pima County Wastewater Management Department: Pima County, AZ, USA, September 2022; Available online: http://www.sewerhistory.org/photosgraphics/tanfo-sewer-collapse-september-2002/ (accessed on 1 June 2017).

- Hannagan, C. Syracuse Officials Fear April Storm Created More Sinkholes. 2011. Available online: http://www.syracuse.com/news/index.ssf/2011/05/syracuse_officials_fear_april.html (accessed on 1 September 2021).

- The Associated Press. Officials: Drilled Hole in Pipe May Have Caused Sinkhole. 2017. Available online: http://www.dailymail.co.uk/wires/ap/article-4088896/Officials-Drilled-hole-pipe-caused-sinkhole.html (accessed on 1 September 2021).

- Tang, Y. Mechanisms of Soil Erosion Due to Defective Sewer Pipes. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2017. [Google Scholar]

- Hewage, S.R.I.; Renuka, S. Erosion Potential of Pipe Embedment Materials through Defective Sewer Pipes; Swinburne University of Technology: Melbourne, Australia, 2019. [Google Scholar]

- Kuwano, R.; Horii, T.; Kohashi, H.; Yamauchi, K. Defects of sewer pipes causing cave-in’s in the road. In Proceedings of the 5th International Symposium on New Technologies for Urban Safety of Mega Cities in Asia, Phuket, Thailand, 16–17 November 2006; pp. 16–17. [Google Scholar]

- Gordon, J.R. An Investigation into Freezing and Bursting Water Pipes in Residential Construction; School of Architecture-Building Research Council, University of Illinois at at Urbana-Champaign: Champaign, IL, USA, 1996. [Google Scholar]

- Xu, G.; Qi, J.; Jin, H. Model test study on influence of freezing and thawing on the crude oil pipeline in cold regions. Cold Reg. Sci. Technol. 2010, 64, 262–270. [Google Scholar] [CrossRef]

- Zare, M.; Wilkinson, S.; Potangaroa, R. Earthquake damage in wastewater systems and post-earthquake repair methods; limitation and practice. In Proceedings of the Australian Earthquake Engineering Society Conference, Rowland Flat, Australia, 18–20 November 2011. [Google Scholar]

- Nair, G.S.; Dash, S.R.; Mondal, G. Review of pipeline performance during earthquakes since 1906. J. Perform. Constr. Facil. 2018, 32, 4018083. [Google Scholar] [CrossRef]

- Mukunoki, T.; Kumano, N.; Otani, J. Image analysis of soil failure on defective underground pipe due to cyclic water supply and drainage using X-ray CT. Front. Struct. Civ. Eng. 2012, 6, 85–100. [Google Scholar] [CrossRef]

- Guo, S.; Shao, Y.; Zhang, T.; Zhu, D.Z.; Zhang, Y. Physical modeling on sand erosion around defective sewer pipes under the influence of groundwater. J. Hydraul. Eng. 2013, 139, 1247–1257. [Google Scholar] [CrossRef]

- Sato, M.; Kuwano, R. Influence of location of subsurface structures on development of underground cavities induced by internal erosion. Soils Found. 2015, 55, 829–840. [Google Scholar] [CrossRef]

- Indiketiya, S.; Jegatheesan, P.; Rajeev, P. Evaluation of defective sewer pipe–induced internal erosion and associated ground deformation using laboratory model test. Can. Geotech. J. 2017, 54, 1184–1195. [Google Scholar] [CrossRef]

- Tang, Y.; Zhu, D.Z.; Chan, D.H. Experimental study on submerged sand erosion through a slot on a defective pipe. J. Hydraul. Eng. 2017, 143, 4017026. [Google Scholar] [CrossRef]

- Karoui, T.; Jeong, S.-Y.; Jeong, Y.-H.; Kim, D.-S. Experimental study of ground subsidence mechanism caused by sewer pipe cracks. Appl. Sci. 2018, 8, 679. [Google Scholar] [CrossRef]

- Indiketiya, S.; Jegatheesan, P.; Rajeev, P.; Kuwano, R. The influence of pipe embedment material on sinkhole formation due to erosion around defective sewers. Transp. Geotech. 2019, 19, 110–125. [Google Scholar] [CrossRef]

- Kwak, T.Y.; Woo, S.I.; Kim, J.; Chung, C.-K. Model test assessment of the generation of underground cavities and ground cave-ins by damaged sewer pipes. Soils Found. 2019, 59, 586–600. [Google Scholar] [CrossRef]

- Basak, N.; Sarkar, G. Study on the effect of slot size on soil erosion due to defective pipe in wet condition. In Proceedings of the International Conference on Planning, Architecture and Civil Engineering, Singapore, 27–28 May 2019; pp. 1–5. [Google Scholar]

- Ali, H.; Choi, J. Risk prediction of sinkhole occurrence for different subsurface soil profiles due to leakage from underground sewer and water pipelines. Sustainability 2019, 12, 310. [Google Scholar] [CrossRef]

- Kwak, T.-Y.; Woo, S.-I.; Chung, C.-K.; Kim, J. Experimental assessment of the relationship between rainfall intensity and sinkholes caused by damaged sewer pipes. Nat. Hazards Earth Syst. Sci. 2020, 20, 3343–3359. [Google Scholar] [CrossRef]

- Zhang, D.-M.; Du, W.-W.; Peng, M.-Z.; Feng, S.-J.; Li, Z.-L. Experimental and numerical study of internal erosion around submerged defective pipe. Tunn. Undergr. Space Technol. 2020, 97, 103256. [Google Scholar] [CrossRef]

- Khudhair, H.; Nile, B.K.; Al-Baidhani, J.H. Evaluation the effect of pressure head and soil type on erosion and subsidence of soil due to defective sewers. Kerbala J. Eng. Sci. 2020, 1–12. [Google Scholar]

- Mohamed, H.I.; Rabey, S.H.; Darweesh, M.S. Laboratory investigation of ground surface settlement caused by erosion around a leaking pipe. J. Pipeline Syst. Eng. Pract. 2022, 13, 4021080. [Google Scholar] [CrossRef]

- Guo, S.; Zhu, D.Z. Soil and groundwater erosion rates into a sewer pipe crack. J. Hydraul. Eng. 2017, 143, 6017008. [Google Scholar] [CrossRef]

- Tang, Y.; Chan, D.H.; Zhu, D.Z. A coupled discrete element model for the simulation of soil and water flow through an orifice. Int. J. Numer. Anal. Methods Geomech. 2017, 41, 1477–1493. [Google Scholar] [CrossRef]

- The Water Services Association of Australia (WSAA). Product Specifications for Products and Materials, version 2; Water Services Association Australia: Docklands, Melbourne, Australia, 2018. [Google Scholar]

- Indiketiya, S.; Jegatheesan, P.; Pathmanathan, R.; Kuwano, R. Effect of pipe defect size and maximum particle size of bedding material on associated internal erosion. In Physical Modelling in Geotechnics; CRC Press: Boca Raton, FL, USA, 2018; pp. 803–808. ISBN 0429438648. [Google Scholar]

- Rogers, C.J. Sewer Deterioration Studies: The Background to the Structural Assessment Procedure in the Sewerage Rehabilitation Manual; Water Research Centre: Swindon, UK, 1986. [Google Scholar]

- AS 1726:2017; Geotechnical Site Investigations. Standards Association of Australia: Homebush, NSW, Australia, 2017.

- Ministry of Environment of Korea. Technical Standard for Construction of Sewer Pipes; Ministry of Environment of Korea: Sejong-si, Republic of Korea, 2010. [Google Scholar]

- Japan Road Association. Earth Works Manual; Japan Road Association: Tokyo, Japan, 1990. [Google Scholar]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2011.

- Long, Y.-Y.; Tan, Y. Soil arching due to leaking of tunnel buried in water-rich sand. Tunn. Undergr. Space Technol. 2020, 95, 103158. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, G.; Tian, X.; Li, C.; Cheng, H. Experimental study on city road collapse under vibrating load. Shock. Vib. 2020, 2020, 6074658. [Google Scholar] [CrossRef]

- Sato, M.; Kuwano, R. Effects of buried structures on the formation of underground cavity. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 18 July 2011; pp. 1769–1772. [Google Scholar]

- Alsaydalani, M.O.A.; Clayton, C.R.I. Internal fluidization in granular soils. J. Geotech. Geoenviron. Eng. 2014, 140, 4013024. [Google Scholar] [CrossRef]

- He, Y.; Zhu, D.Z.; Zhang, T.; Shao, Y.; Yu, T. Experimental observations on the initiation of sand-bed erosion by an upward water jet. J. Hydraul. Eng. 2017, 143, 6017007. [Google Scholar] [CrossRef]

- Helal, E. Experimental evaluation of changes in channel bed morphology due to a defective pressure flow pipe. J. Irrig. Drain. Eng. 2019, 145, 4019022. [Google Scholar] [CrossRef]

- Zhao, A.; Ma, Y.; Liu, J.; Li, Y.; Zhong, Q.; Yuan, H.; Fu, M. Morphological Characteristics of Overlying Soil Eroded by Leakage Gas from Buried Pipelines. J. Pipeline Syst. Eng. Pract. 2021, 12, 4021063. [Google Scholar] [CrossRef]

- Cividini, A.; Bonomi, S.; Vignati, G.C.; Gioda, G. Seepage-induced erosion in granular soil and consequent settlements. Int. J. Geomech. 2009, 9, 187–194. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, X.; Wu, D.; Di, H. Mathematical modeling of slurry infiltration and particle dispersion in saturated sand. Transp. Porous Media 2018, 124, 91–116. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, F.; Zhang, H.; Zhang, L.; Zhang, J. Influences of internal erosion on infiltration and slope stability. Bull. Eng. Geol. Environ. 2019, 78, 1815–1827. [Google Scholar] [CrossRef]

- Vardoulakis, I.; Papanastasiou, P.; Stavropoulou, M. Sand erosion in axial flow conditions. Transp. Porous Media 2001, 45, 267–280. [Google Scholar] [CrossRef]

- Chetti, A.; Benamar, A.; Hazzab, A. Modeling of particle migration in porous media: Application to soil suffusion. Transp. Porous Media 2016, 113, 591–606. [Google Scholar] [CrossRef]

- Steeb, H.; Diebels, S.; Vardoulakis, I. Modeling internal erosion in porous media. In Computer Applications in Geotechnical Engineering; Geo-Institute: Reston, VA, USA, 2007; pp. 1–10. [Google Scholar]

- Yerro, A.; Rohe, A.; Soga, K. Modelling internal erosion with the material point method. Procedia Eng. 2017, 175, 365–372. [Google Scholar] [CrossRef]

- Esmaeilpour, M.; Ghanbarian, B.; Liang, F.; Liu, H.-H. Scale-dependent permeability and formation factor in porous media: Applications of percolation theory. Fuel 2021, 301, 121090. [Google Scholar] [CrossRef]

- Wang, X.; Tang, Y.; Huang, B.; Hu, T.; Ling, D. Review on numerical simulation of the internal soil erosion mechanisms using the discrete element method. Water 2021, 13, 169. [Google Scholar] [CrossRef]

- Cheng, K.; Wang, Y.; Yang, Q. A semi-resolved CFD-DEM model for seepage-induced fine particle migration in gap-graded soils. Comput. Geotech. 2018, 100, 30–51. [Google Scholar] [CrossRef]

- Zhang, F.; Li, M.; Peng, M.; Chen, C.; Zhang, L. Three-dimensional DEM modeling of the stress–strain behavior for the gap-graded soils subjected to internal erosion. Acta Geotech. 2019, 14, 487–503. [Google Scholar] [CrossRef]

- Scholtès, L.; Hicher, P.-Y.; Sibille, L. Multiscale approaches to describe mechanical responses induced by particle removal in granular materials. C. R. Méc. 2010, 338, 627–638. [Google Scholar] [CrossRef]

- Fascetti, A.; Oskay, C. Multiscale modeling of backward erosion piping in flood protection system infrastructure. Comput. Civ. Infrastruct. Eng. 2019, 34, 1071–1086. [Google Scholar] [CrossRef]

- Al Kaabi, M.R.; Sousa, R.L. Studying the effects of gypsum karst cavities in tunneling. In Tunnels and Underground Cities: Engineering and Innovation meet Archaeology, Architecture and Art; CRC Press: Boca Raton, FL, USA, 2019; pp. 5275–5284. ISBN 0429424442. [Google Scholar]

- Meguid, M.A.; Kamel, S. A three-dimensional analysis of the effects of erosion voids on rigid pipes. Tunn. Undergr. Space Technol. 2014, 43, 276–289. [Google Scholar] [CrossRef]

- Zi, H.; Ding, Z.; Ji, X.; Liu, Z.; Shi, C. Effect of voids on the seismic vulnerability of mountain tunnels. Soil Dyn. Earthq. Eng. 2021, 148, 106833. [Google Scholar] [CrossRef]

- Zhang, J.-X.; Zhang, N.; Zhou, A.; Shen, S.-L. Numerical evaluation of segmental tunnel lining with voids in outside backfill. Undergr. Space 2022, 7, 786–797. [Google Scholar] [CrossRef]

- Tang, Y.; Zhu, D.Z.; Chan, D.H. Modeling Soil Loss by Water Infiltration through Sewer Pipe Defects. In Proceedings of the World Environmental and Water Resources Congress 2018: Hydraulics and Waterways, Water Distribution Systems Analysis, and Smart Water, Minneapolis, MN, USA, 3–7 June 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 254–262. [Google Scholar]

- Xiong, H.; Wu, H.; Bao, X.; Fei, J. Investigating effect of particle shape on suffusion by CFD-DEM modeling. Constr. Build. Mater. 2021, 289, 123043. [Google Scholar] [CrossRef]

- Stanford University. National Performance of Dams Program (NPDP) at the Department of Civil and Environmental Engineering at Stanford University (2018) Dam Failures in the U.S. 2018. Available online: https://npdp.stanford.edu/sites/default/files/reports/npdp_dam_failure_summary_compilation_v1_2018.pdf (accessed on 1 September 2021).

- Fry, J.-J.; Vogel, A.; Royet, P.; Courivaud, J.-R. Dam failures by erosion: Lessons from ERINOH data bases. In Proceedings of the ICSE6, Paris, France, 27–31 August 2012; pp. 273–280. [Google Scholar]

- Ma, G.; Bui, H.H.; Lian, Y.; Tran, K.M.; Nguyen, G.D. A five-phase approach, SPH framework and applications for predictions of seepage-induced internal erosion and failure in unsaturated/saturated porous media. Comput. Methods Appl. Mech. Eng. 2022, 401, 115614. [Google Scholar] [CrossRef]

| Researchers | Varied Parameter(s) | Test Box (mm) | Main Findings |

|---|---|---|---|

| Mukunoki et al. [24] | Defect shape; defect size; hydraulic load application 1 | Cylinder 1; 130 × 100 | Cyclic hydraulic loading causes larger ground subsidence than monotonic loading (for the same type of backfill soil). |

| Mukunoki et al. [41] | Defect size; relative density; particle size; | Cylinder; 130 × 100 | Relative density plays a crucial role in SEDP, and backfill with low relative density is more susceptible to SEDP. The ratio between mean particle size (D50) and defect size is significant when predicting the erodibility of soils. Curvature and uniformity coefficients are also important parameters when prediction soil erosion. |

| Guo et al. [42] | Particle size; water head; defect size; backfill height | Rectangular 2; 500 × 500 × 600 Cylinder; 480 × 500 | Particle and defect size had a major influence on the SEDP rate 3, while water head (hw) and backfill height (hs) had a major impact on the cavity formation geometry. |

| Sato and Kuwano [43] | Other subsurface pipe locations; soil type | Rectangular; 300 × 200 × 80 | If another subsurface pipe exists overhead the pipe with the defect, this only changes the cavity formation shape. This shape depends closely on the relative location of both pipes (the defective and the non-defective one) |

| Indiketiya et al. [44] | Hydraulic load application | Rectangular; 800 × 400 × 100 | Particles less than 0.3 mm are highly susceptible to erosion through 5 mm openings of embedment material with a maximum particle size of 4.75 mm.When the water table is below the void, the void is stable. When the water table is between the void ceiling and the defect, the void ceiling is stable; meanwhile, when the void is submerged, it becomes unstable. |

| Tang et al. [45] | Particle size; slot position; slot size; water level | Rectangular; 500 × 500 × 80 | The ratio between sand volumetric flow rate (qs) and water volumetric flow rate (qw) is linearly proportional. Also, the relationship between qs/qw and the particle-defect size ratio is exponentially proportional. |

| Karoui et al. [46] | Water head; hydraulic load application | Rectangular; 400 × 300 × 140 | They measured pore pressure near the defect and found it fluctuates as the cavity forms or expands. |

| Indiketiya et al. [47] | Soil type; slot size; hydraulic load application | Rectangular; 800 × 400 × 100 | When the backfill material is finer, the onset of cavity formation occurs faster (i.e., it happens at the earlier cycles) than with coarser backfill. |

| Kwak et al. [48] | Soil type; relative density | Rectangular; 1400 × 900 × 100 | Uniformly graded soils are more susceptible to soil erosion and sinkhole formation than non-uniformly graded soils. |

| Basak and Sarkar [49] | Water head; slot size; slot location | Rectangular; 600 × 500 × 120 | The soil erosion rate is highest when the slot (defect) is located on top of the pipe. |

| Ali and Choi [50] | Soil type; defect location; hydraulic load application | Rectangular; 700 × 600 × 330 | Developed a sinkhole/ground settlement risk index as a function of soil type, hydraulic load and defect location. However, the number of tests done was very limited. |

| Kwak et al. [51] | Hydraulic load application (rainfall intensity) | Rectangular; 1400 × 900 × 100 | Rainfall intensity dramatically impacts ground subsidence during and after rainfall and sinkhole occurrence. |

| Zhang et al. [52] | Hydraulic head; defect shape | Rectangular; 400 × 750 × 200 | In gaped graded backfill, the loss of fines is mostly seen above the defect beyond the onset region. A higher hydraulic head leads to a higher risk of collapse. |

| Khudhair et al. [53] | Soil type; water head | Rectangular; 700 × 490 × 100 | Determined two parameters strongly influenced the soil erosion process and subsidence: water head and soil type. Water pressure was directly proportional to the volume of eroded material, and clayey soil was highly susceptible to subsidence but not soil erosion. |

| Mohamed et al. [54] | Water head; defect location; defect size; soil type | Rectangular; 1500 × 750 × 1000 | The ground subsidence shape and dimensions (maximum settlement and width) depend on the defect location, size, water head, and soil type. When the soil type is finer, the ground subsidence is more pronounced. |

| Researchers | Defect Size (mm) | Defect Shape | Defect Location | Pipe Depth 1 (mm) |

|---|---|---|---|---|

| Mukunoki et al. [24] | 5 × 5; 2.5 × 10; 5 × 50; 5 × 78.5 | Square, rectangle, straight | Top of the pipe, on the circumference of the pipe | 100 |

| Mukunoki et al. [41] | 2.1 and 5 | Straight | on the circumference of the pipe | 100 |

| Guo et al. [42] | 10 and 20 | Circular | Top of the pipe | 100, 200, 300, and 400 |

| Tang et al. [45] | 3 and 9 | Straight | Top, side and horizontal of the pipe | 250 and 300 |

| Indiketiya et al. [47] | 10 × 60; 20 × 60; 30 × 60 | Rectangle | Top of the pipe | 400 |

| Basak and Sarkar [49] | 3 and 5 | Straight | Top, side and horizontal of the pipe | 100 |

| Ali and Choi [50] | - | Artificially created crack with no particular shape or dimensions | Bottom and top | 40 |

| Zhang et al. [52] | 5 and 5 × 10 | Circular and waist-shaped | Top of the pipe | 500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dastpak, P.; Sousa, R.L.; Dias, D. Soil Erosion Due to Defective Pipes: A Hidden Hazard Beneath Our Feet. Sustainability 2023, 15, 8931. https://doi.org/10.3390/su15118931

Dastpak P, Sousa RL, Dias D. Soil Erosion Due to Defective Pipes: A Hidden Hazard Beneath Our Feet. Sustainability. 2023; 15(11):8931. https://doi.org/10.3390/su15118931

Chicago/Turabian StyleDastpak, Pooya, Rita L. Sousa, and Daniel Dias. 2023. "Soil Erosion Due to Defective Pipes: A Hidden Hazard Beneath Our Feet" Sustainability 15, no. 11: 8931. https://doi.org/10.3390/su15118931

APA StyleDastpak, P., Sousa, R. L., & Dias, D. (2023). Soil Erosion Due to Defective Pipes: A Hidden Hazard Beneath Our Feet. Sustainability, 15(11), 8931. https://doi.org/10.3390/su15118931