Numerical Analysis of the Structural and Flow Rate Characteristics of the Fuel Injection Pump in a Marine Diesel Engine

Abstract

1. Introduction

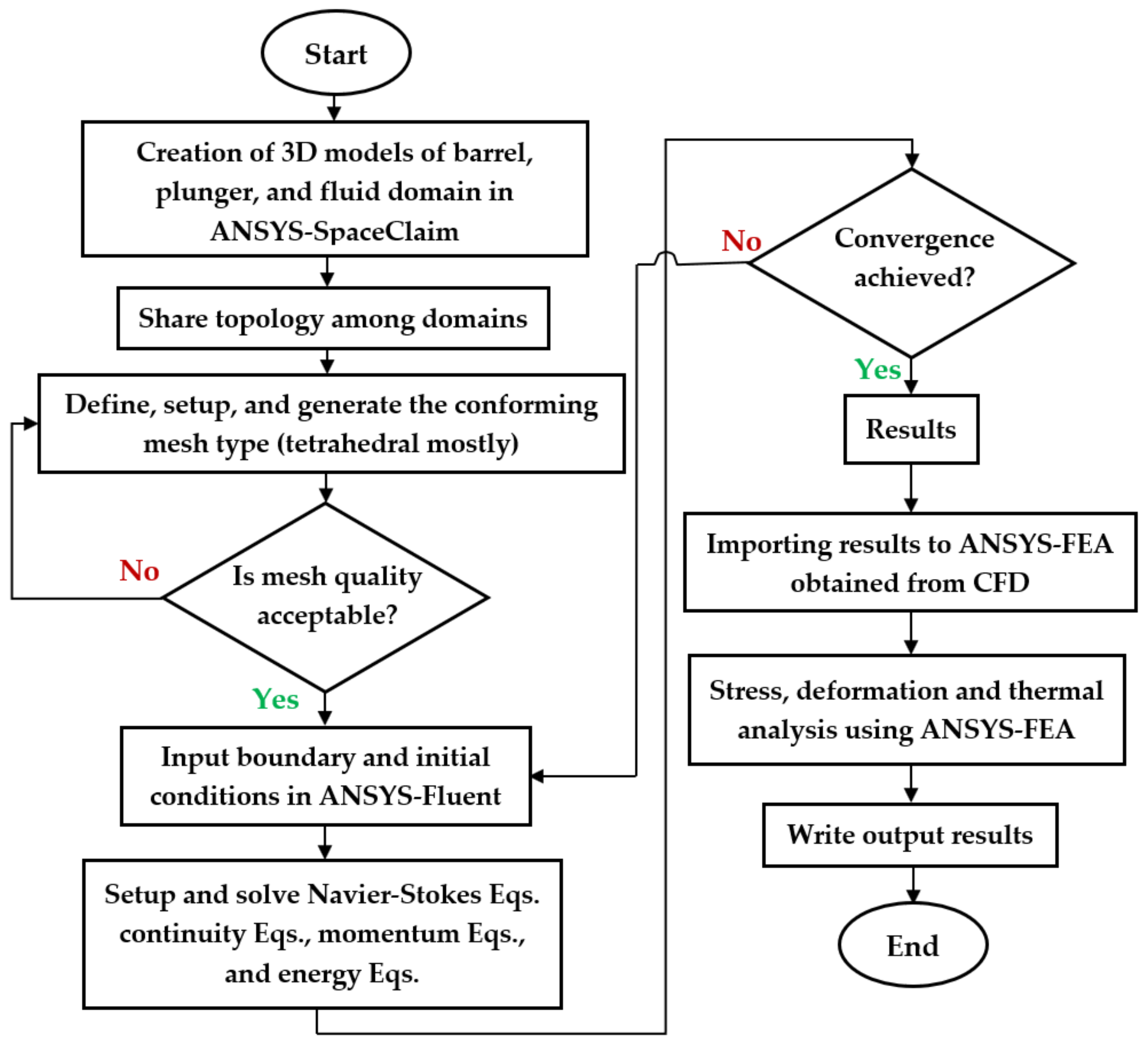

2. Methodology

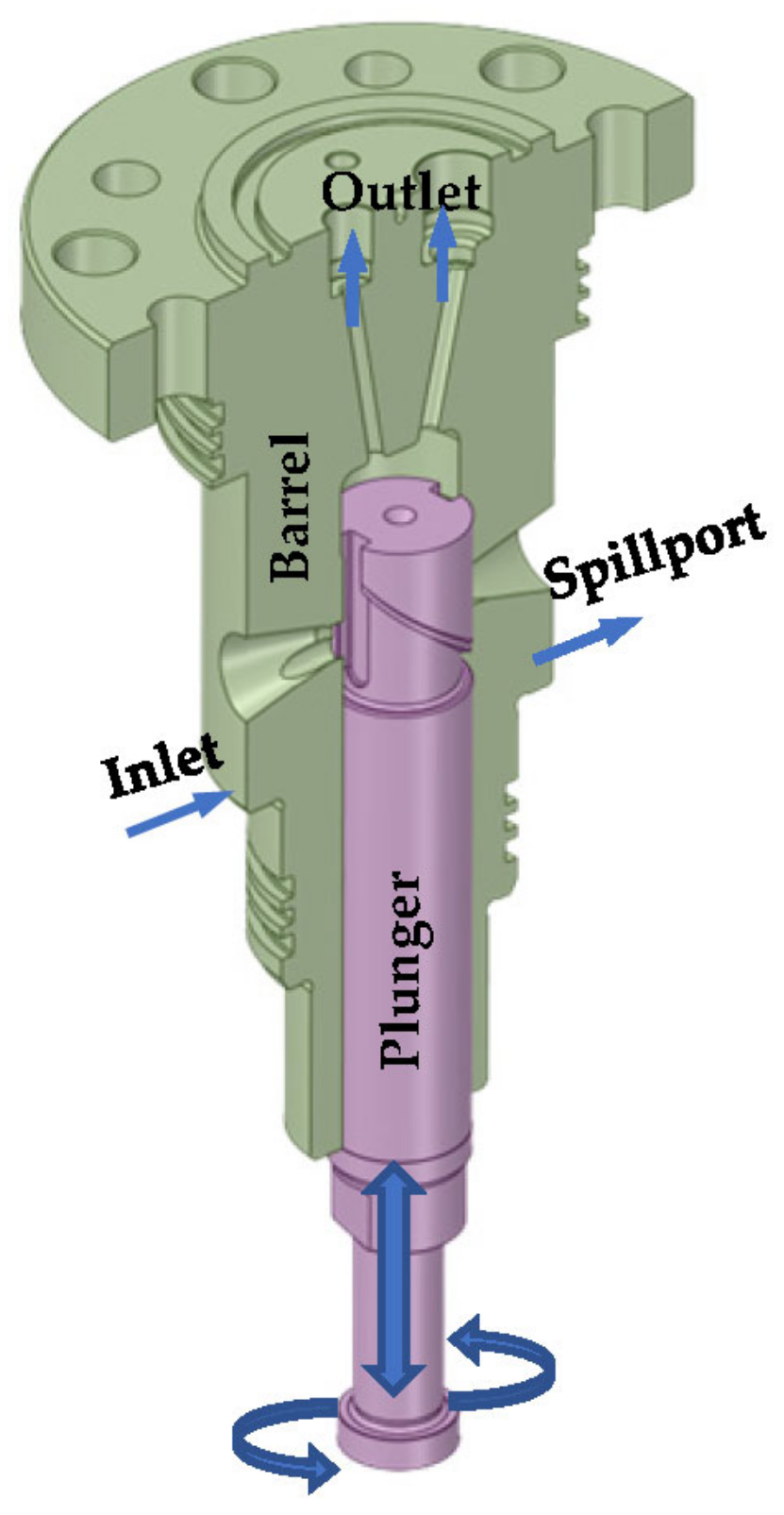

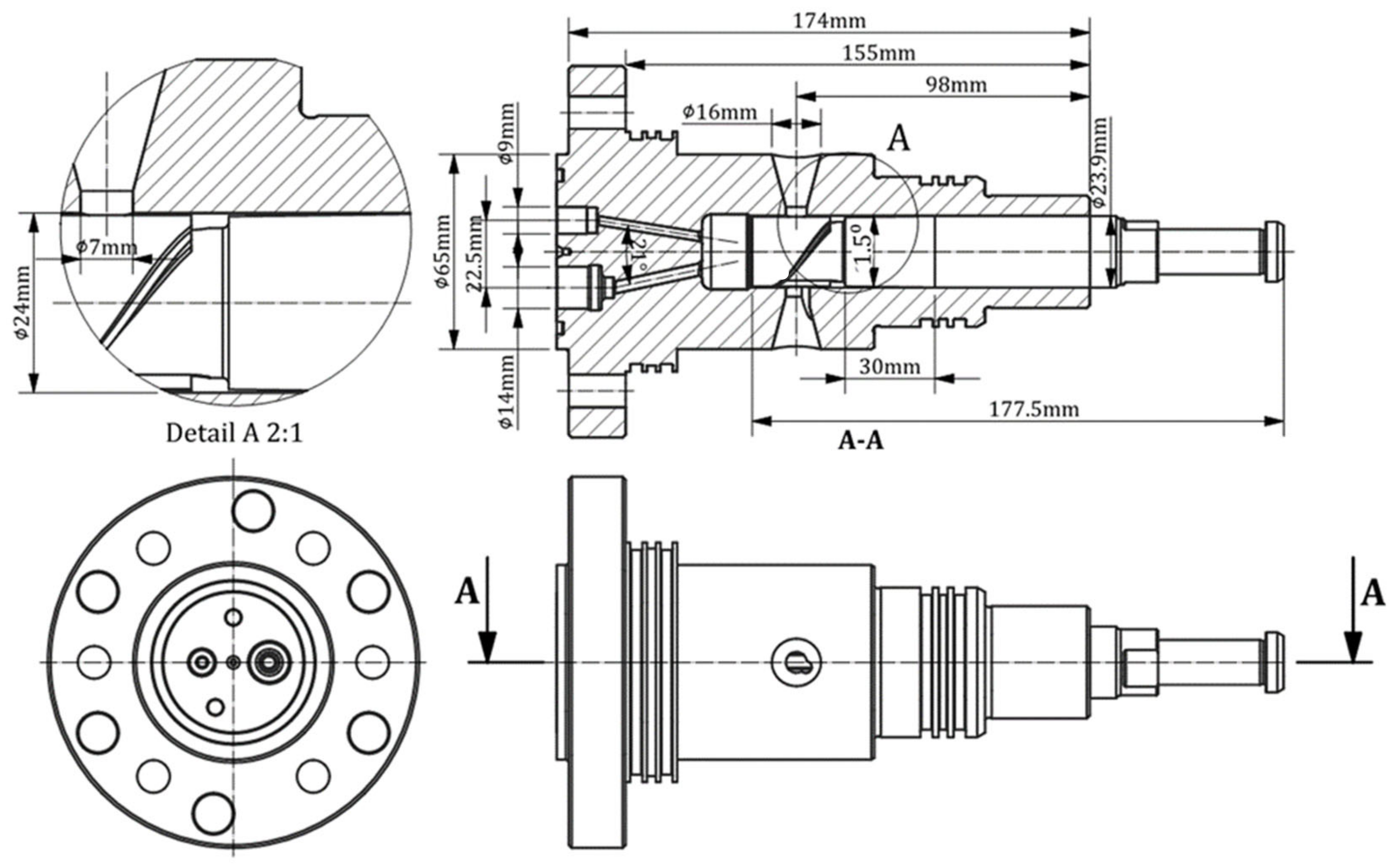

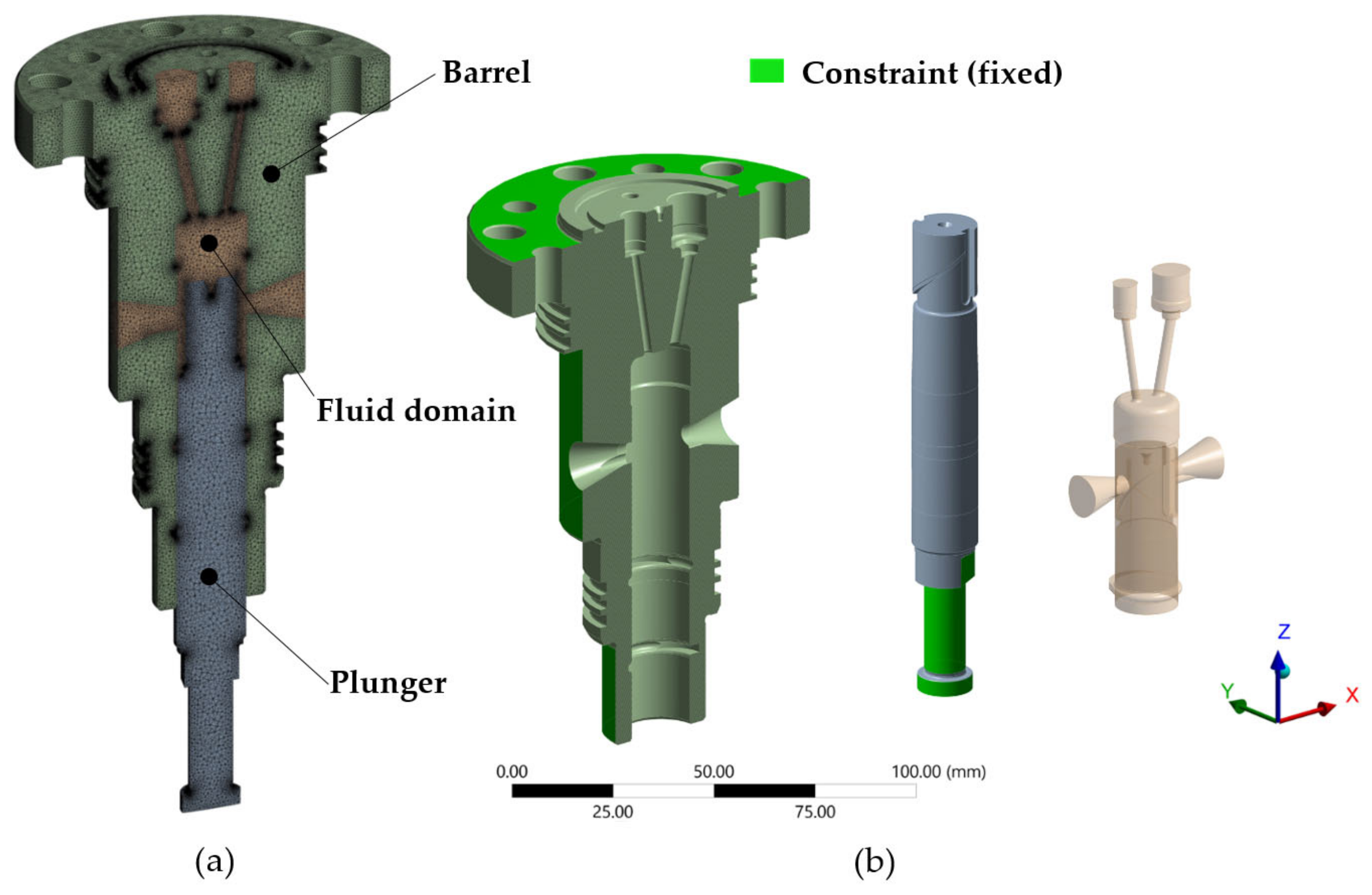

2.1. Three-Dimensional Numerical Model of High-Pressure Marine Fuel Injection Pump

2.2. Computational Fluid–Solid Thermal Coupling Theory and Governing Equations for Marine Fuel Injection Pump

- k equation:

- ε equation:

- and:

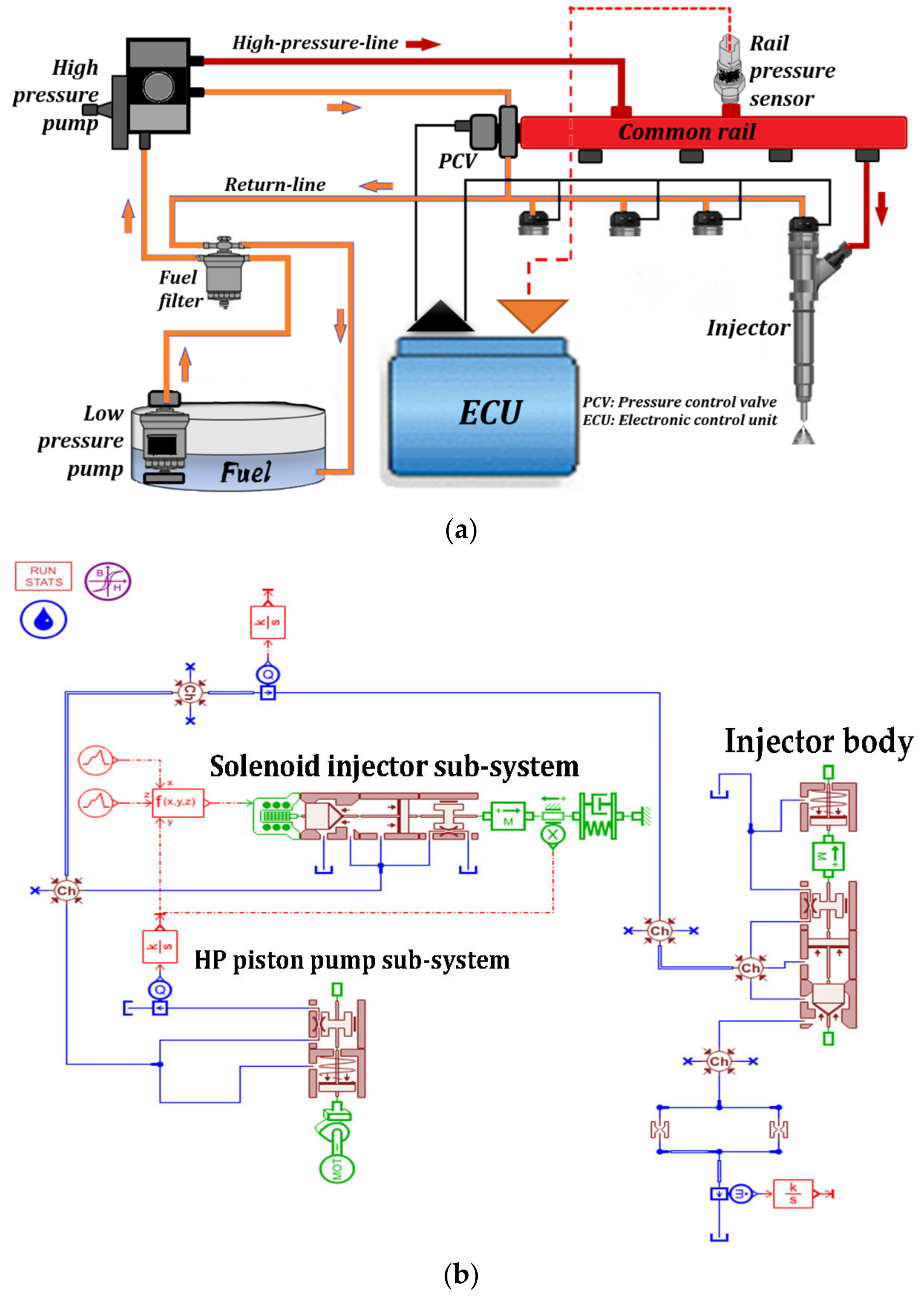

2.3. Description and Modeling of High-Pressure Common Rail Fuel Injection System in AMESim

2.4. Solution Method

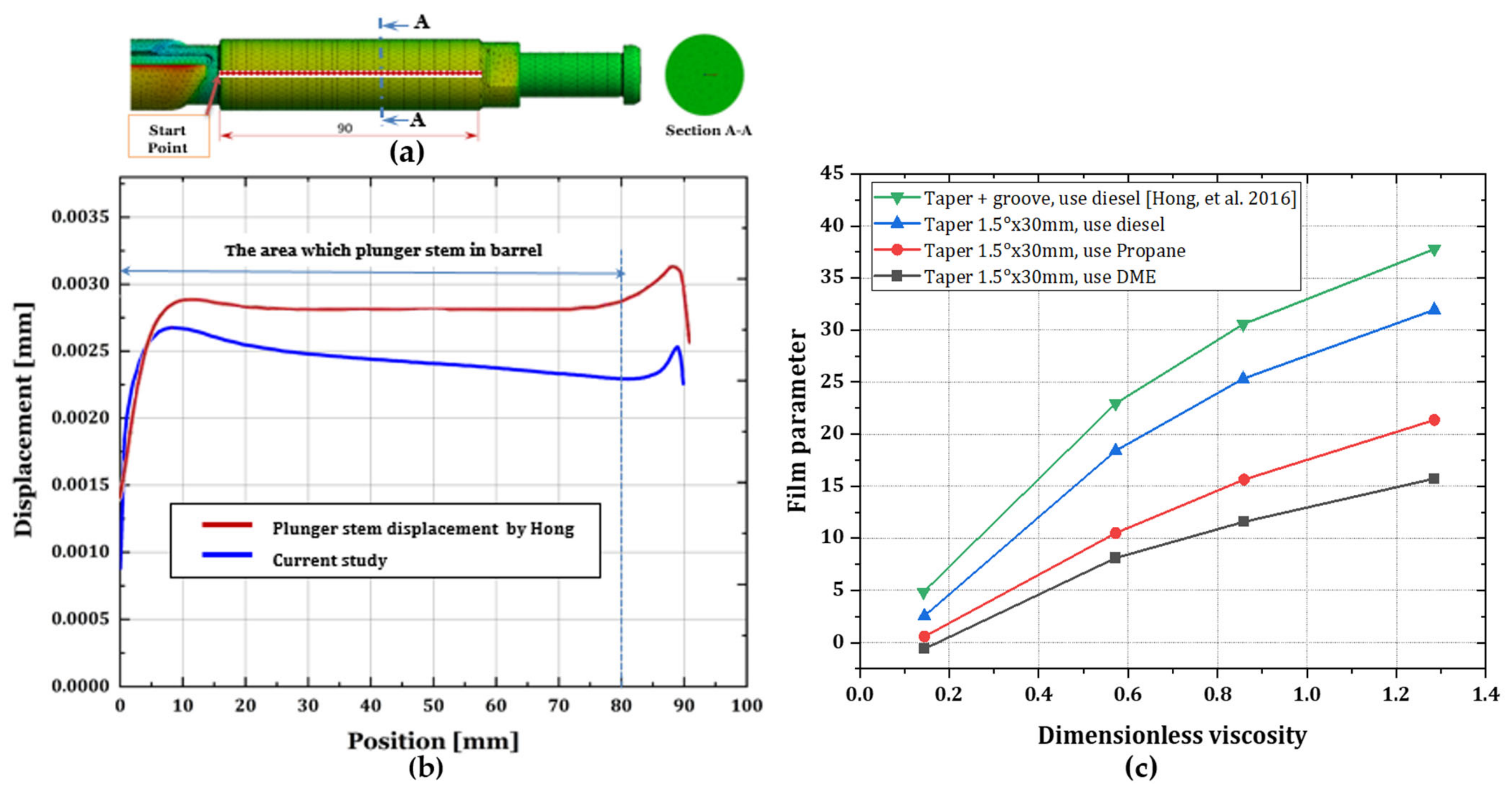

2.5. Grid Independence Test and Model Validation

3. Results

4. Discussion

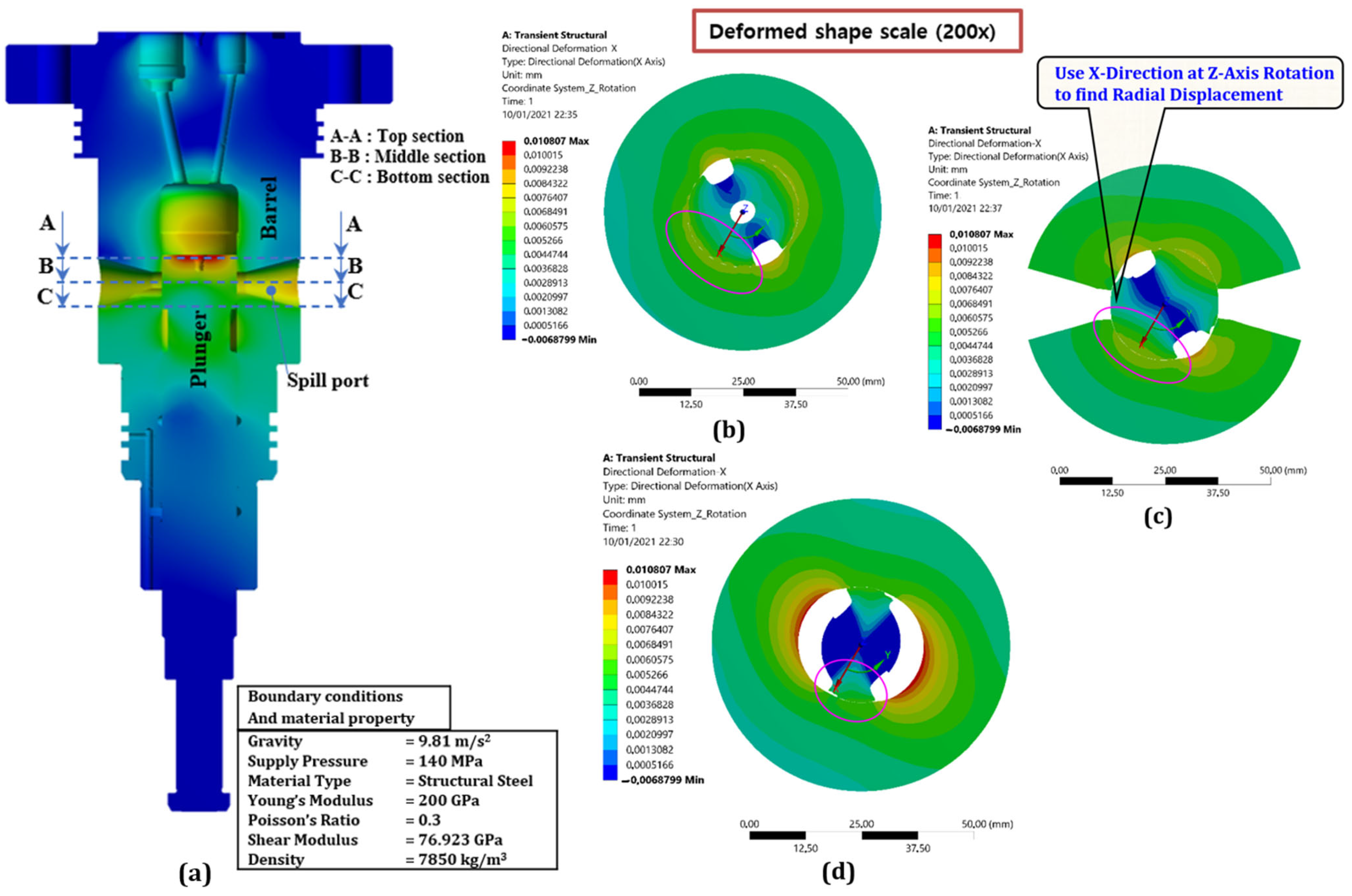

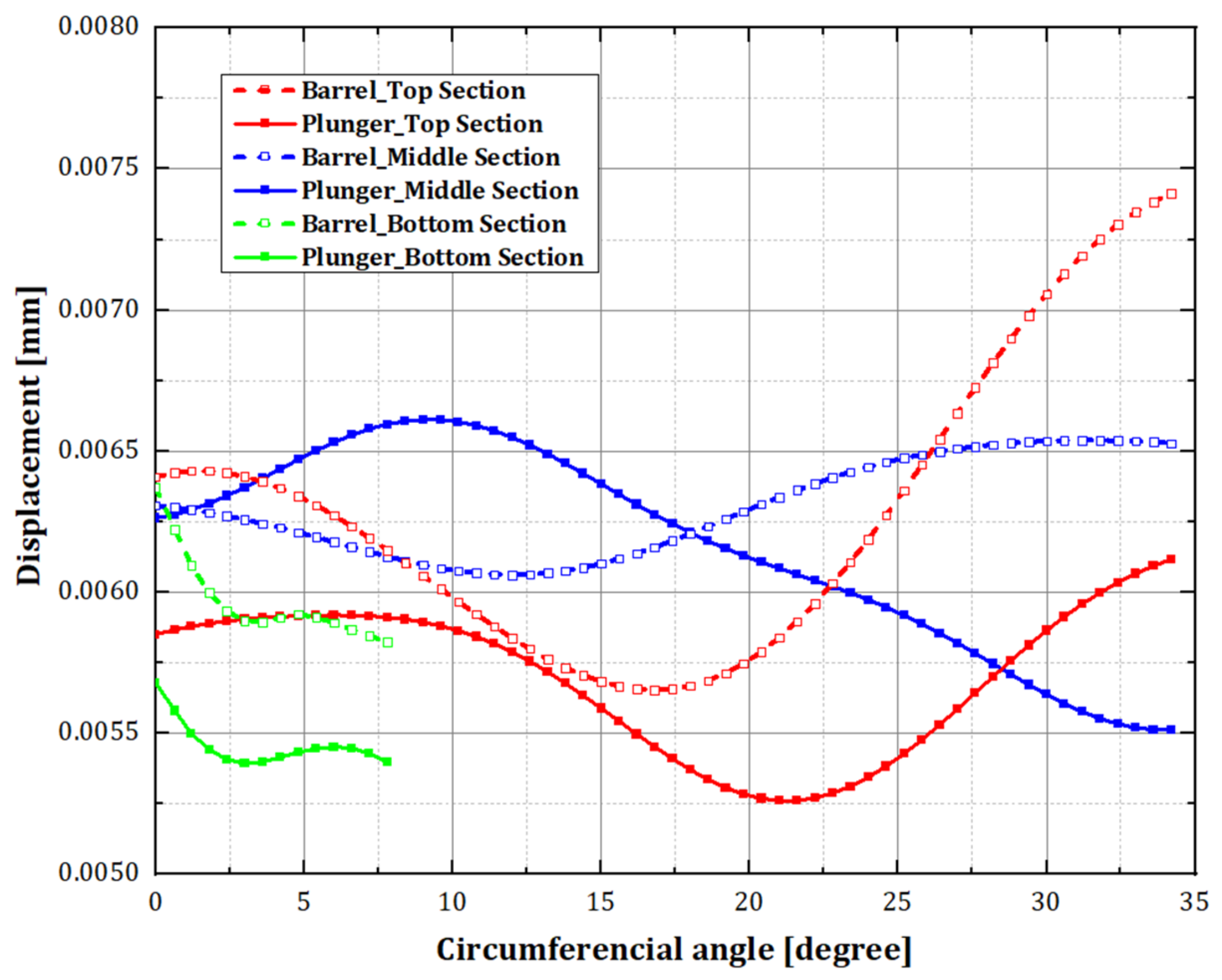

4.1. Effect of Fuel Pressure on Plunger Deformation

4.2. The Effect of Taper and Clearance of Plunger Stem on Film Parameters

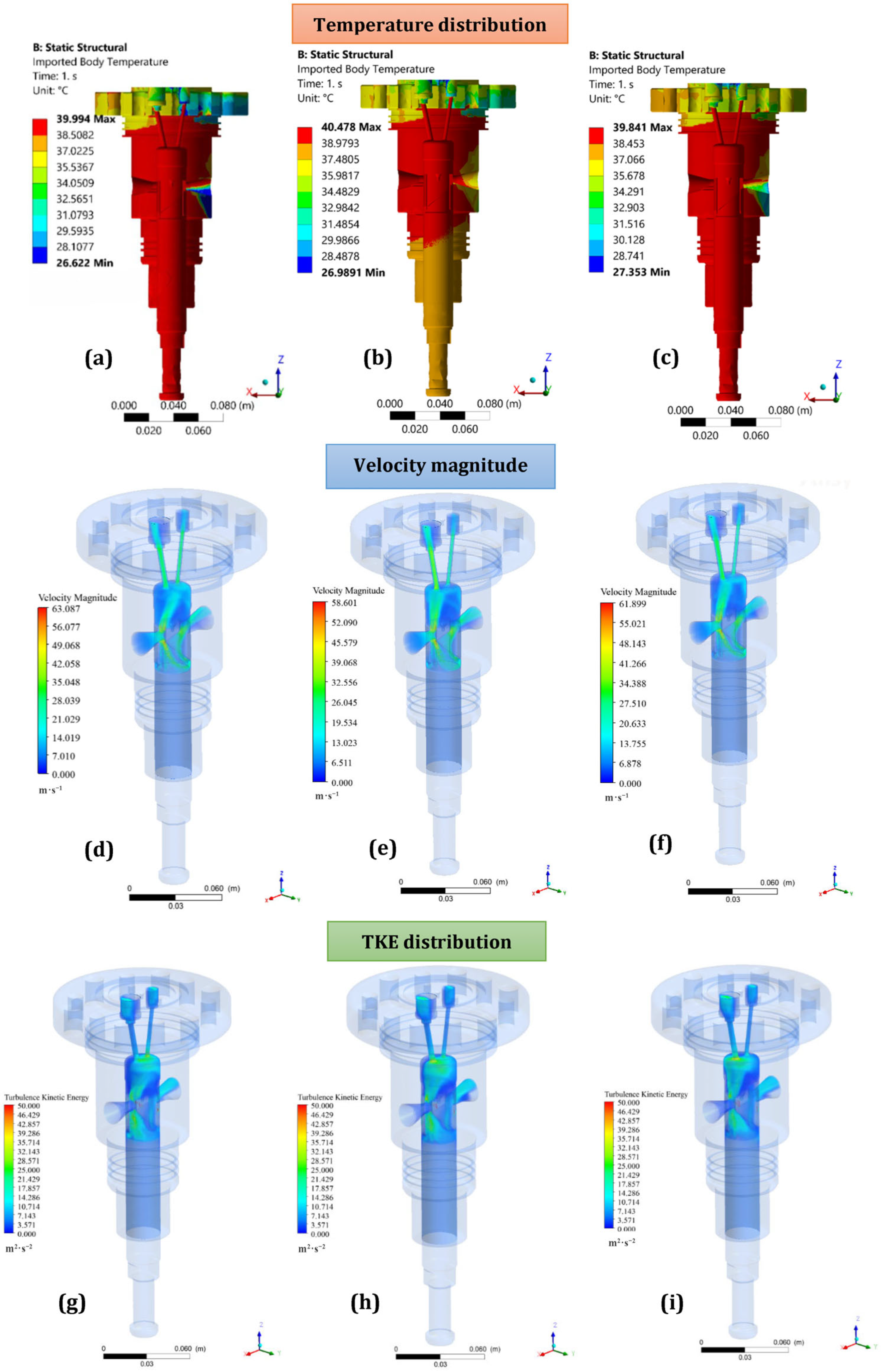

4.3. The Thermal Effect, Fluid Velocity, and Turbulence Kinetic Energy of the Fuel Pump

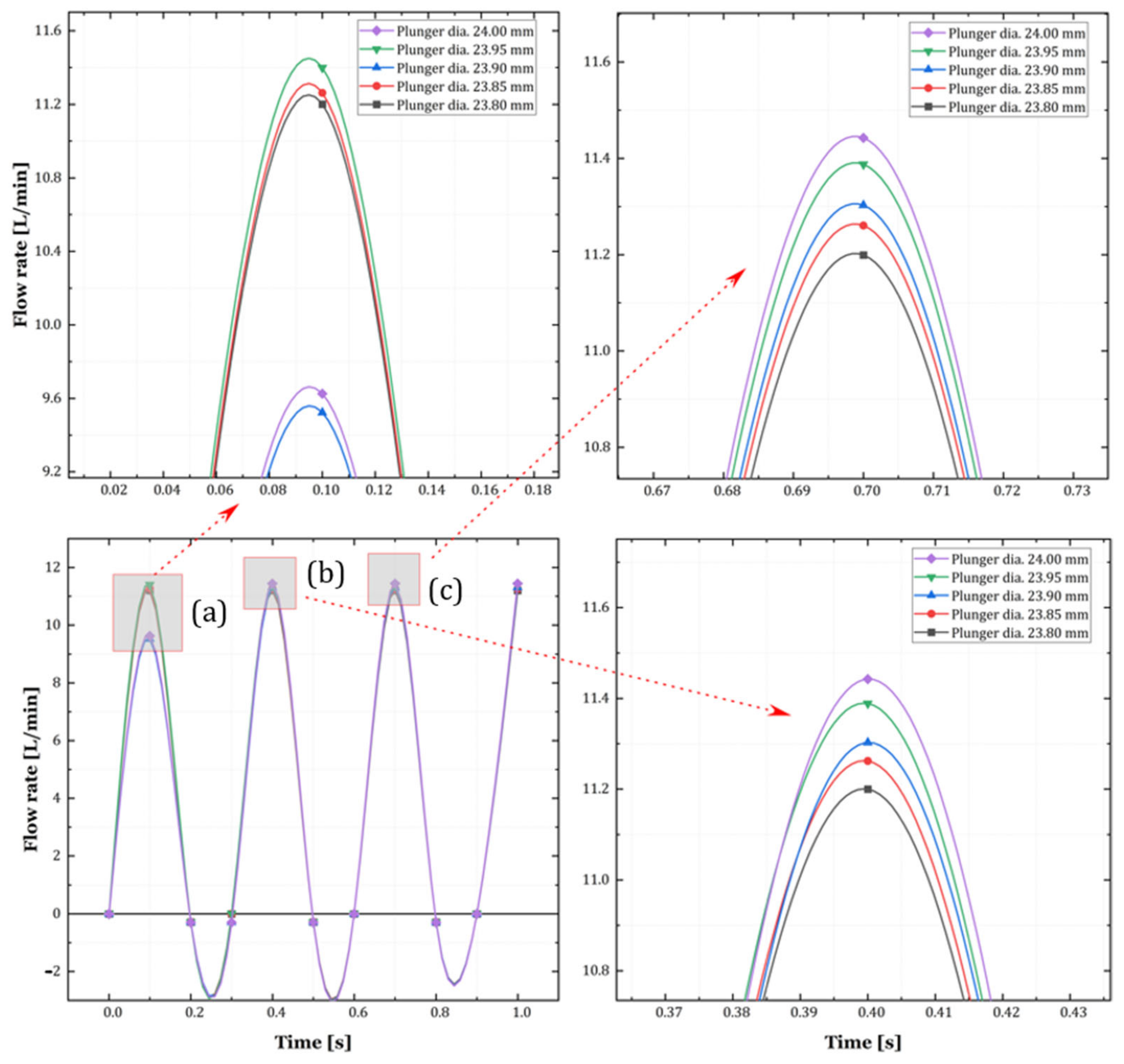

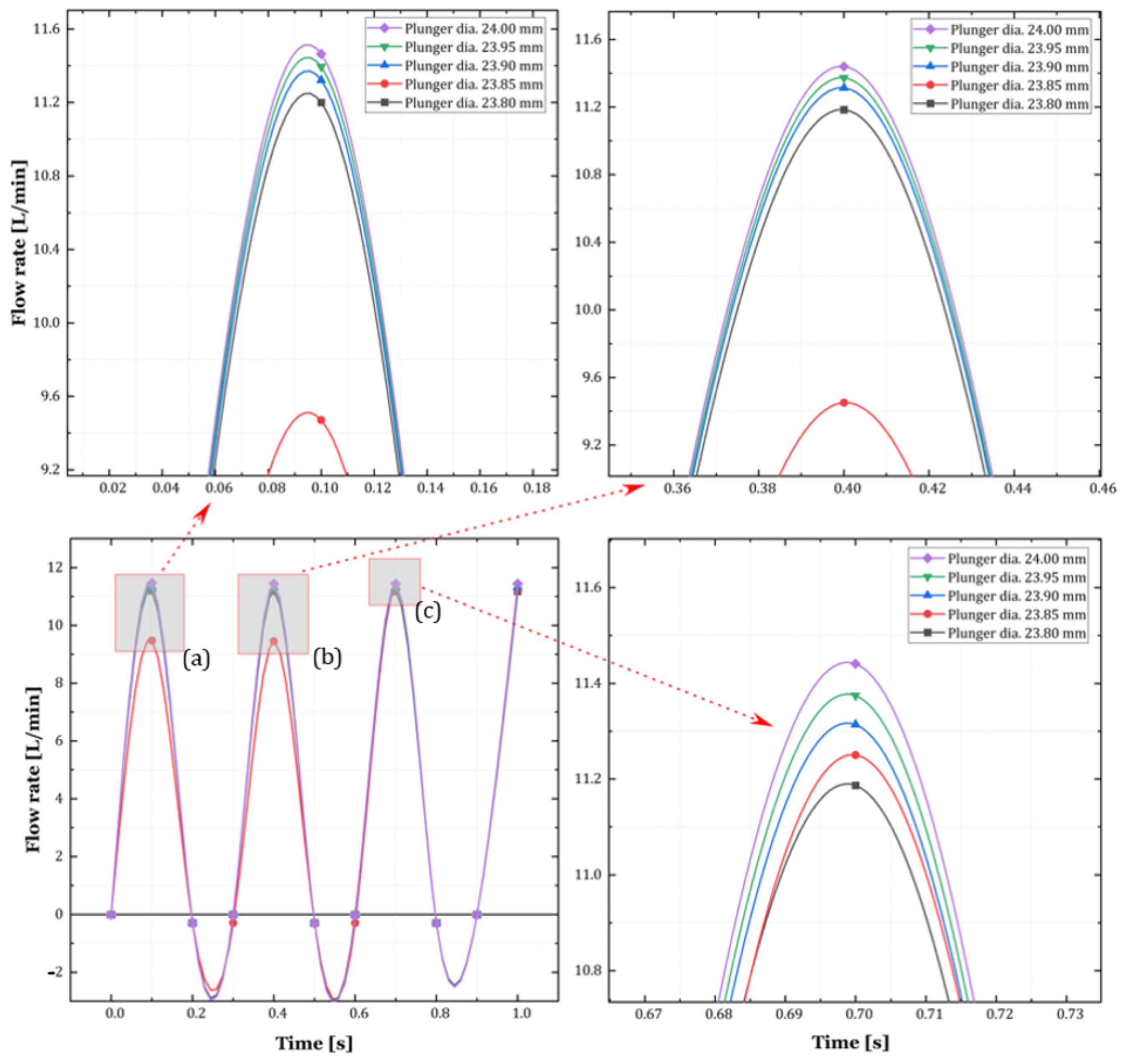

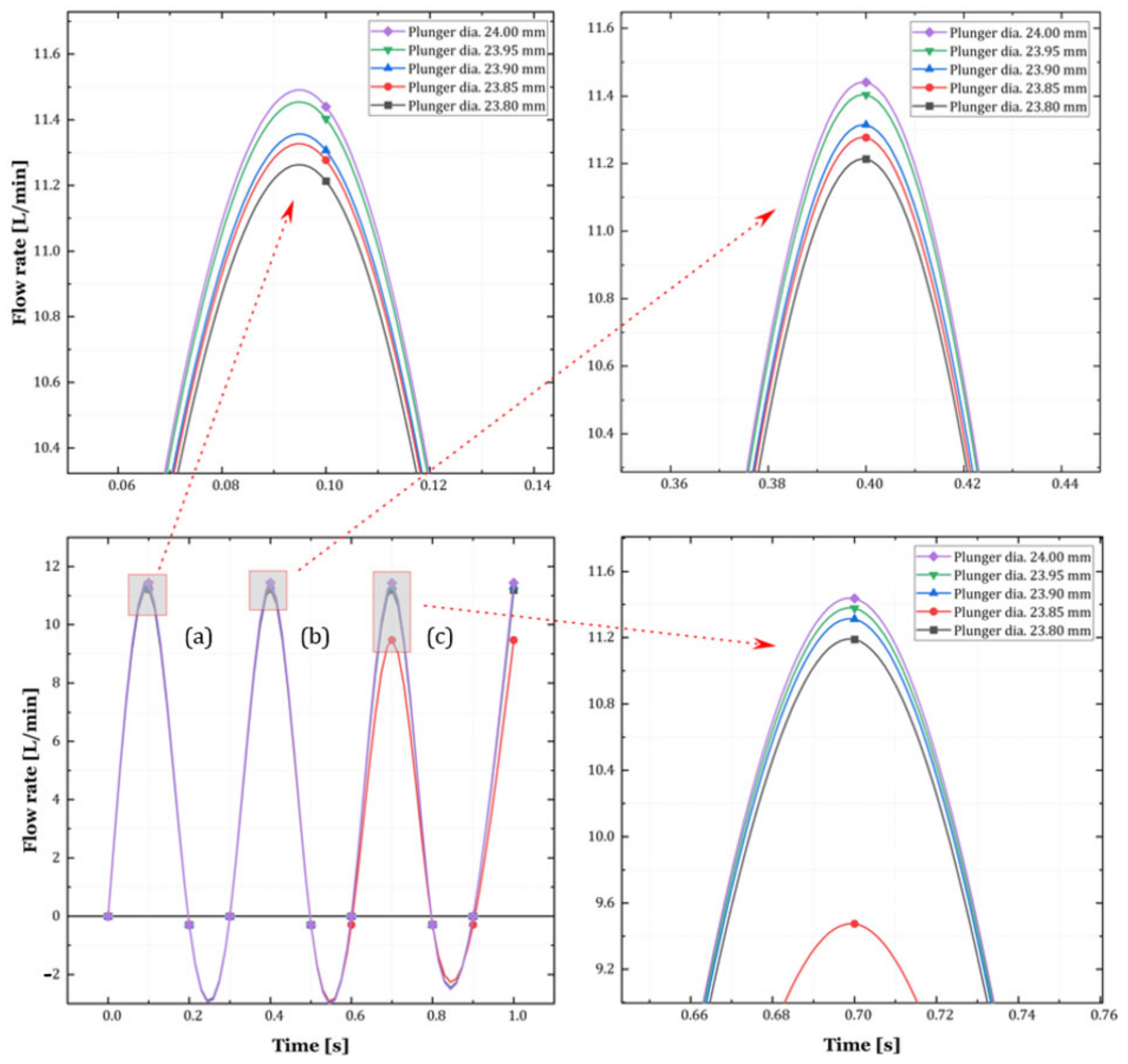

4.4. Effect of Both Differences in Fuels and Plunger Diameters on the Flow Rate Characteristics of the Fuel Pump

4.5. The Influence of Fuel Type on Performance Requirements, Environmental Concerns, and Economic Considerations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | |

| CFD | Computational fluid dynamics |

| CPU | Central processing unit |

| DME | Dimethyl ether |

| FEM | Finite element method |

| RAM | Random access memory |

| RPM | Revolution per minutes |

| TKE | Turbulence kinetic energy |

| Symbols | |

| c | Clearance (mm) |

| Cp | Specific heat at constant pressure (J/kg·°C) |

| d | Displacement (mm) |

| e | Eccentricity (mm) |

| F | Force (N) |

| g | Gravitational acceleration (m·s−2) |

| H | Dimensionless film thickness |

| Hm | |

| k | Heat conductivity coefficient (W/m°C) |

| Mo | Moment at point O |

| P | Supply pressure (MPa) |

| R | Dimensionless plunger radius |

| Rq | Root mean square deviation |

| Rq1 | Root mean square deviation of plunger |

| Rq2 | Root mean square deviation of barrel |

| ∆t | Time interval (s) |

| Ε | Eccentricity ratio (e/c) |

| T | Temperature (°C) |

| t | Time (s) |

| ° | Degree |

| Q | Mean flow rate (L/min) |

| µ | Fluid viscosity (Pa·s) |

| ρ | Density (kg/m3) |

| v | Velocity vector (m/s) |

| α | Thermal expansion coefficient of (/°C) |

| λ | Film parameter |

References

- Wang, Z.; Hu, S.; Ji, H.; Wang, Z.; Liu, X. Analysis of lubricating characteristics of valve plate pair of a piston pump. Tribol. Int. 2018, 126, 49–64. [Google Scholar] [CrossRef]

- Bejger, A.; Drzewieniecki, J.B. The use of acoustic emission to diagnosis of fuel injection pumps of marine diesel engines. Energies 2019, 12, 4661. [Google Scholar] [CrossRef]

- Wang, G.; Zhong, L.; He, X.; Lei, Z.; Hu, G.; Li, R.; Wang, Y. Dynamic behavior of reciprocating plunger pump discharge valve based on fluid structure interaction and experimental analysis. PLoS ONE 2015, 10, e0140396. [Google Scholar] [CrossRef]

- Lan, Q.; Bai, Y.; Fan, L.; Gu, Y.; Wen, L.; Yang, L. Investigation on fuel injection quantity of low-speed diesel engine fuel system based on response surface prediction model. Energy 2020, 211, 118946. [Google Scholar] [CrossRef]

- Hong, S.H.; Lee, B.; Cho, Y. Improvement of lubrication characteristics in the reciprocating fuel pump of marine diesel engines. J. Mech. Sci. Technol. 2016, 30, 5225–5232. [Google Scholar] [CrossRef]

- Bejger, A.; Drzewieniecki, J.B. A new method of identifying the limit condition of injection pump wear in self-ignition engines. Energies 2020, 13, 1601. [Google Scholar] [CrossRef]

- Hong, S.H. A New Clearance Design Method for Reciprocating Fuel Pumps of Medium-Speed Diesel Engines. Tribol. Trans. 2018, 61, 773–783. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, H.; Yu, Y.; Yang, J.; He, Y. Establishment of a real-time simulation of a marine high-pressure common rail system. Energies 2021, 14, 5481. [Google Scholar] [CrossRef]

- Bao, H.-y.; Wang, C.-l.; Lu, F.-x. Temperature impact analysis of star gear bearing inner ring based on under-race lubrication passage. J. Mech. Sci. Technol. 2020, 34, 5271–5278. [Google Scholar] [CrossRef]

- Zhao, B.; Dai, X.D.; Zhang, Z.N.; Xie, Y.B. Numerical study of the effects on clearance joint wear in flexible multibody mechanical systems. Tribol. Trans. 2015, 58, 385–396. [Google Scholar] [CrossRef]

- Hong, S.H. A literature review of lacquer formation in medium-speed and low-speed engines. J. Mech. Sci. Technol. 2016, 30, 5651–5657. [Google Scholar] [CrossRef]

- Hong, S.-H. Improvement of Lubrication Characteristics in Fuel Injection Pump for Medium-Speed Diesel Engines: Part I-Application of Profile Shape. J. Korean Soc. Tribol. Lubr. Eng. 2015, 31, 205–212. [Google Scholar] [CrossRef]

- Lei, D.; Huang, X.; Zhang, H.; Yao, M.; Chen, R.; Liu, J. Optimization and Application of Reciprocating Direct-Drive Electric Submersible Plunger Pump Lifting System in the Xinjiang Oilfield. Open Chem. Eng. J. 2019, 13, 68–80. [Google Scholar] [CrossRef]

- Hong, S.H. Application of Spiral Grooves in Fuel Pump for Medium-Speed Diesel Engines. Tribol. Trans. 2018, 61, 532–538. [Google Scholar] [CrossRef]

- Borghi, M. Hydraulic locking-in spool-type valves: Tapered clearances analysis. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2005, 215, 157–168. [Google Scholar] [CrossRef]

- Ma, X.; Wang, Q.J.; Lu, X.; Mehta, V.S. A transient hydrodynamic lubrication model for piston/cylinder interface of variable length. Tribol. Int. 2018, 118, 227–239. [Google Scholar] [CrossRef]

- Xiang, C.; Guo, F.; Jia, X.; Wang, Y.; Huang, X. Thermo-elastohydrodynamic mixed-lubrication model for reciprocating rod seals. Tribol. Int. 2019, 140, 105894. [Google Scholar] [CrossRef]

- Dhar, S.; Vacca, A. A novel FSI–thermal coupled TEHD model and experimental validation through indirect film thickness measurements for the lubricating interface in external gear machines. Tribol. Int. 2015, 82, 162–175. [Google Scholar] [CrossRef]

- Van Emden, E.; Venner, C.H.; Morales-Espejel, G.E. A challenge to cavitation modeling in the outlet flow of an EHL contact. Tribol. Int. 2016, 102, 275–286. [Google Scholar] [CrossRef]

- Venner, C.H.; Wang, J.; Lubrecht, A.A. Central film thickness in EHL point contacts under pure impact revisited. Tribol. Int. 2016, 100, 1–6. [Google Scholar] [CrossRef]

- Masjedi, M.; Khonsari, M.M. An engineering approach for rapid evaluation of traction coefficient and wear in mixed EHL. Tribol. Int. 2015, 92, 184–190. [Google Scholar] [CrossRef]

- Meng, F.M.; Zhang, L.; Liu, Y.; Li, T.T. Effect of compound dimple on tribological performances of journal bearing. Tribol. Int. 2015, 91, 99–110. [Google Scholar] [CrossRef]

- Li, Y.; Ji, Z.; Yang, L.; Zhang, P.; Xu, B.; Zhang, J. Thermal-fluid-structure coupling analysis for valve plate friction pair of axial piston pump in electrohydrostatic actuator (EHA) of aircraft. Appl. Math. Model. 2017, 47, 839–858. [Google Scholar] [CrossRef]

- Najjari, M.; Guilbault, R. Formula derived from particle swarm optimization (PSO) for optimum design of cylindrical roller profile under EHL regime. Mech. Mach. Theory 2015, 90, 162–174. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, L.; Feng, J.; Qiao, L.; Yu, C.; Shi, W.; Ding, C.; Zang, Y.; Chang, C.; Xiong, Y.; et al. A comparative investigation on the effect of different nanofluids on the thermal performance of two-phase closed thermosyphon. Int. J. Heat Mass Transf. 2020, 149, 119189. [Google Scholar] [CrossRef]

- Zhou, T.; Zhao, Y.; Rao, Z. Fundamental and estimation of thermal contact resistance between polymer matrix composites: A review. Int. J. Heat Mass Transf. 2022, 189, 122701. [Google Scholar] [CrossRef]

- Gong, S.; Li, X.; Sheng, M.; Liu, S.; Zheng, Y.; Wu, H.; Lu, X.; Qu, J. High Thermal Conductivity and Mechanical Strength Phase Change Composite with Double Supporting Skeletons for Industrial Waste Heat Recovery. ACS Appl. Mater. Interfaces 2021, 13, 47174–47184. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, K.; Zou, Z.; Zhong, L.; Akkurt, N.; Feng, J.; Xiong, Y.; Han, J.; Wang, J.; Du, Y. A new type of two-supply, one-return, triple pipe-structured heat loss model based on a low temperature district heating system. Energy 2021, 218, 119569. [Google Scholar] [CrossRef]

- Xu, Q.; Feng, J.; Zhang, S. Combined effects of different temperature and pressure loads on the “L”-type large-diameter buried pipeline. Int. J. Heat Mass Transf. 2017, 111, 953–961. [Google Scholar] [CrossRef]

- Xu, Q.; Zou, Z.; Chen, Y.; Wang, K.; Du, Z.; Feng, J.; Ding, C.; Bai, Z.; Zang, Y.; Xiong, Y. Performance of a novel-type of heat flue in a coke oven based on high-temperature and low-oxygen diffusion combustion technology. Fuel 2020, 267, 117160. [Google Scholar] [CrossRef]

- Ding, B.; Feng, W.C.; Fang, J.; Li, S.Z.; Gong, L. How natural convection affect cooling performance of PCM heat sink. Int. J. Heat Mass Transf. 2022, 184, 122272. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The Numerical Computation of Turbulent Flows. In Numerical Prediction of Flow, Heat Transfer, Turbulence and Combustion; Elsevier: Amsterdam, The Netherlands, 1983; pp. 96–116. [Google Scholar] [CrossRef]

- Bardina, J.E.; Huang, P.G.; Coakley, T.J. Turbulence Modeling Validation, Testing, and Development. 1997. Available online: https://ntrs.nasa.gov/citations/19970017828 (accessed on 20 September 2022).

- Canonsburg, T.D. ANSYS Fluent Tutorial Guide; ANSYS: Canonsburg, PA, USA, 2013; Volume 15317, pp. 724–746. [Google Scholar]

- Shih, T.H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Memon, A.A.; Sheikh, S.; Siddique, M.; Ishtiyaque, S. Di-Methyl Ether (DME) Prospective in Terms of Conventional Fuels in Pakistan from Gasification of Aboriginal Coal Di-Methyl Ether (DME) Prospective in Terms of Conventional Fuels in Pakistan from Gasification of Aboriginal Coal. J. Appl. Emerg. Sci. 2018, 7, 156–165. [Google Scholar]

- Hayer, F.; Bakhtiary-Davijany, H.; Myrstad, R.; Holmen, A.; Pfeifer, P.; Venvik, H.J. Synthesis of dimethyl ether from syngas in a microchannel reactor-Simulation and experimental study. Chem. Eng. J. 2011, 167, 610–615. [Google Scholar] [CrossRef]

- Wang, H.P.; Zheng, D.; Tian, Y. High pressure common rail injection system modeling and control. ISA Trans. 2016, 63, 265–273. [Google Scholar] [CrossRef]

- Qian, D.; Liao, R.; Xiang, J.; Sun, B.; Wang, S. Thermal fluid-structure interaction analysis on the piston/cylinder interface leakage of a high-pressure fuel pump for diesel engines. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 791–798. [Google Scholar] [CrossRef]

- Kacem, S.H.; Jemni, M.A.; Driss, Z.; Abid, M.S. The effect of H2 enrichment on in-cylinder flow behavior, engine performances and exhaust emissions: Case of LPG-hydrogen engine. Appl. Energy 2016, 179, 961–971. [Google Scholar] [CrossRef]

- Aditya Wardana, M.K.; Lim, O. A study effects of injection pressure and wall temperature on the mixing process of NOx and NH3 in Selective Catalytic Reduction system. J. Mechatron. Electr. Power Veh. Technol. 2020, 11, 45. [Google Scholar] [CrossRef]

- Yosri, M.R.; Ho, J.Z.; Meulemans, M.; Talei, M.; Gordon, R.L.; Brear, M.J.; Cosby, D.; Lacey, J.S. Large-eddy simulation of methane direct injection using the full injector geometry. Fuel 2021, 290, 120019. [Google Scholar] [CrossRef]

| Design Parameters | Value | Unit |

|---|---|---|

| Gravity | 9.81 | m·s−2 |

| Supply pressure | 140 | MPa |

| Material type (Barrel and plunger) | Structural steel | |

| Young’s modulus | 200 | GPa |

| Poisson’s ratio | 0.3 | |

| Shear modulus | 76.923 | GPa |

| Density | 7850 | kg/m3 |

| The inlet of fuel mass flow rate | 0.012774 | kg/s |

| Properties | Diesel | Propane | DME | Unit |

|---|---|---|---|---|

| Chemical formula | C12H23 | C3H8 | C2H6O | |

| Molar mass | 170 | 44.09 | 46.08 | g/mole |

| Carbon contents | 86 | 89 | 52.05 | mass% |

| Hydrogen contents | 14 | 18 | 13 | mass% |

| Boiling point | 180–370 | −45 | −25 | °C |

| Self-ignition | 250 | 365 | 235 | °C |

| Cetane number | 57.8 | 5 | 55 | |

| Liquid density at 200 °C | 830 | 501 | 668 | kg/m3 |

| Liquid kinematics viscosity | 3 | 1.571 | 0.184 | cSt |

| Lower heating value | 43,200 | 46,360 | 28,430 | kJ/kg |

| Design Parameters | Value | Unit |

|---|---|---|

| Plunger diameters | 23.80, 23.85, 23.90, 23.95, and 24.00 | mm |

| Motor speed | 2000 | RPM |

| Inlet fuel flow rate | 3.31449 | L/min |

| Supply pressure | 140 | MPa |

| No. | Grid Number | Grid Size (mm) | Displacement (mm) |

|---|---|---|---|

| 1 | 13,882,457 | 1.4 | 0.00269 |

| 2 | 13,996,005 | 1.3 | 0.00268 |

| 3 | 14,146,254 | 1.2 | 0.00267 |

| 4 | 14,363,772 | 1.1 | 0.00266 |

| 5 | 14,633,400 | 1.0 | 0.00266 |

| Maximum clearance reduction at head | 0.0007 mm |

| Maximum clearance reduction at stem | 0.268 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Binyamin, B.; Lim, O. Numerical Analysis of the Structural and Flow Rate Characteristics of the Fuel Injection Pump in a Marine Diesel Engine. Sustainability 2023, 15, 8948. https://doi.org/10.3390/su15118948

Binyamin B, Lim O. Numerical Analysis of the Structural and Flow Rate Characteristics of the Fuel Injection Pump in a Marine Diesel Engine. Sustainability. 2023; 15(11):8948. https://doi.org/10.3390/su15118948

Chicago/Turabian StyleBinyamin, Binyamin, and Ocktaeck Lim. 2023. "Numerical Analysis of the Structural and Flow Rate Characteristics of the Fuel Injection Pump in a Marine Diesel Engine" Sustainability 15, no. 11: 8948. https://doi.org/10.3390/su15118948

APA StyleBinyamin, B., & Lim, O. (2023). Numerical Analysis of the Structural and Flow Rate Characteristics of the Fuel Injection Pump in a Marine Diesel Engine. Sustainability, 15(11), 8948. https://doi.org/10.3390/su15118948