Planning an Integrated Stockyard–Port System for Smart Iron Ore Supply Chains via VND Optimization

Abstract

:1. Introduction

1.1. Related Work

| Acronym | Explanation | Ref. |

|---|---|---|

| CB | Conveyor Belt | - |

| CD | Car Dumper | - |

| IOSpT | Iron Ore Stockyard-Planning Terminal | [14] |

| MILP | Mixed-Integer Linear Programming | [13,14,29] |

| MIP | Mixed-Integer Programming | [28,30] |

| RE | Reclaimer | - |

| SR | Stacker–Reclaimer | - |

| ST | Stacker | - |

| SY | Stockyard | - |

| SB | Ship Berth | - |

| VND | Variable Neighborhood Descent | [31], this work |

1.2. Formulation of the Iron Ore Stockyard Planning Terminal Problem

- Objective Function: minimizing the elapsed time between the port’s first ship arrival and the completion of the transshipment operation of the last ship leaving the port;

- Constraints: the lengths and velocity of the stacking and reclaiming conveyor belts, and the number and volume of stockyards used for stacking and reclaiming.

1.3. Contributions

- The design of abstracted graph representations to capture the main concepts of a real stockyard–port system;

- The graph representation that allows a robust and effective implementation of a VND metaheuristic that optimizes the stockyard–port NP-hard planning problem;

- The proposal of a novel, flexible, and fast Deterministic Simulation Algorithm (DSA) to generate solutions and calculate the objective function;

- A description of a hybrid method combining the VND metaheuristic with the DSA. The hybrid method was used to determine the minimum total time spent to complete the stockyard–port planning process;

- The application of the hybrid approach to analyze a real stockyard–port system, using real data from its conveyor belts, stockpiles, berths, and ships.

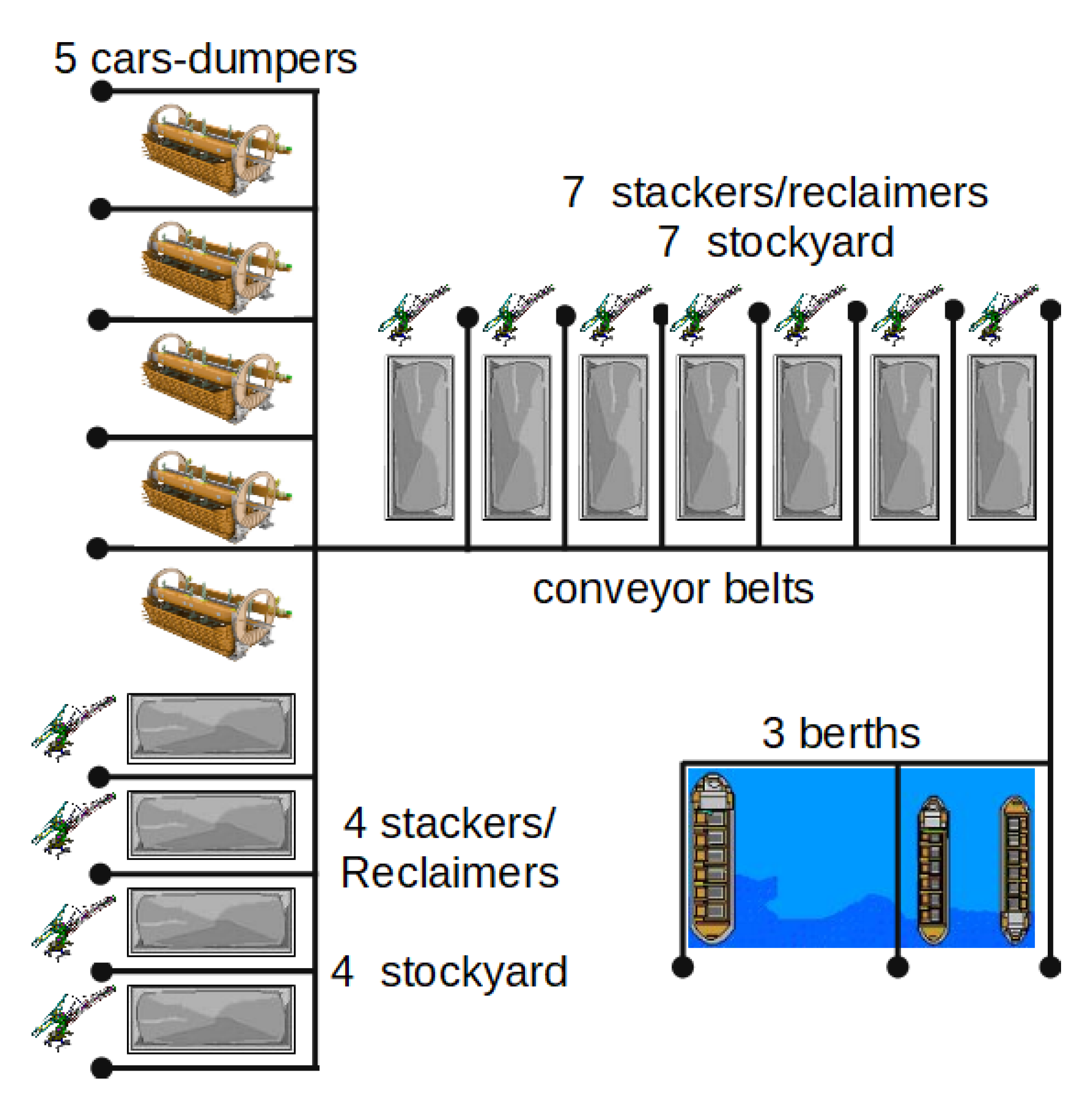

2. Features of the Stockyard–Port System

2.1. Iron Ore Unloading Terminal

2.2. Stockyards

2.3. Stockpiles

2.4. Routes

2.5. Stacking

2.6. Reclaiming

2.7. Berths

2.8. Ships

3. The Developed Simulation Algorithm

- Identify the technical reports with relevant information such as the characteristics and operational data of the stockyard–port system;

- Use electronic spreadsheets for data mining of technical reports;

- Validate the extracted data according to comparison with other sources of information, and verify consistency and precision;

- Generate data input files in the proper format to be used in the developed simulation software;

- Compare the data obtained in the simulation with the information extracted from the technical report to validate the model;

- Perform additional analysis to identify trends or patterns in the simulation results.

3.1. The Proposed Deterministic Simulation Algorithm

3.2. Pseudocode of the Deterministic Simulation Algorithm

| Algorithm 1: DSA(, , , , ) |

|

4. The Proposed VND Metaheuristic

- Strategies to achieve an optimal solution through “efficient” search spaces with neighborhood structures;

- Usage of solutions found during the optimum search to generate other solutions;

- Intensification that seeks to find a great location and diversification that aims to leave the great location (disturbance).

| Algorithm 2: VND(Qn, Qb, Qp, Qe) |

|

5. Results and Discussion

5.1. Experiments for the First Scenario (11 Stockyards, 3 Berths, and 10 h of Conveyor Belt Operation per Day)

5.2. Experiments for the Second Scenario (15 Stockyards, 5 Berths, and 10 h of Conveyor Belt Operation per Day)

5.3. Increasing the Capacity of Conveyor Belts

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Issaoui, Y.; Khiat, A.; Bahnasse, A.; Ouajji, H. Toward smart logistics: Engineering insights and emerging trends. Arch. Comput. Methods Eng. 2021, 28, 3183–3210. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Marinagi, C.; Reklitis, P.; Trivellas, P.; Sakas, D. The Impact of Industry 4.0 Technologies on Key Performance Indicators for a Resilient Supply Chain 4.0. Sustainability 2023, 15, 5185. [Google Scholar] [CrossRef]

- Khan, Y.; Su’ud, M.B.M.; Alam, M.M.; Ahmad, S.F.; Ahmad Ayassrah, A.Y.A.B.; Khan, N. Application of Internet of Things (IoT) in Sustainable Supply Chain Management. Sustainability 2023, 15, 694. [Google Scholar] [CrossRef]

- Filipov, V.; Vasilev, P. Manufacturing operations management—The smart backbone of Industry 4.0. Int. Sci. Conf. Ind. 4.0 2016, 1, 71–76. [Google Scholar]

- De Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Nota, G.; Nota, F.D.; Peluso, D.; Toro Lazo, A. Energy efficiency in Industry 4.0: The case of batch production processes. Sustainability 2020, 12, 6631. [Google Scholar] [CrossRef]

- Csalódi, R.; Süle, Z.; Jaskó, S.; Holczinger, T.; Abonyi, J. Industry 4.0-driven development of optimization algorithms: A systematic overview. Complexity 2021, 2021, 6621235. [Google Scholar] [CrossRef]

- Xu, J.; Huang, E.; Hsieh, L.; Lee, L.H.S.; Chen, C.H. Simulation optimization in the era of Industrial 4.0 and the Industrial Internet. J. Simul. 2020, 10, 310–320. [Google Scholar] [CrossRef]

- Iris, Ç.; Lam, J.S.L. A review of energy efficiency in ports: Operational strategies, technologies and energy management systems. Renew. Sustain. Energy Rev. 2020, 112, 170–182. [Google Scholar] [CrossRef]

- Leal Gomes Leite, J.M.; Arruda, E.F.; Bahiense, L.; Marujo, L.G. Modeling the integrated mine-to-client supply chain: A survey. Int. J. Mining Reclam. Environ. 2020, 34, 247–293. [Google Scholar] [CrossRef]

- Koch, B.; Mehendiratta, V. Solving the Sotckyard Optimization Trilemma. Mining Magazine. Available online: https://www.miningmagazine.com/tag/stockyard (accessed on 23 January 2023).

- Ago, M.; Nishi, T.; Konishi, M. Simultaneous optimization of storage allocation and routing problems for belt-conveyor transportation. J. Adv. Mech. Des. Syst. Manuf. 2007, 1, 250–261. [Google Scholar] [CrossRef]

- Servare, M.W.J., Jr.; Rocha, H.R.D.O.; Salles, J.L.F.; Perron, S. A Linear Relaxation-Based Heuristic for Iron Ore Stockyard Energy Planning. Energies 2020, 13, 5232. [Google Scholar] [CrossRef]

- Boland, N.; Gulczynski, D.; Savelsbergh, M. A stockyard planning problem. EURO J. Transp. Logist. 2012, 1, 197–236. [Google Scholar] [CrossRef]

- Boland, N.; Gulczynski, D.; Jackson, M.P.; Savelsbergh, M.W.P.; Tam, M.K. Improved stockyard management strategies for coal export terminals at Newcastle. In Proceedings of the 19th International Congress on Modelling and Simulation, Perth, Australia, 12–16 December 2011; pp. 718–724. [Google Scholar]

- Hanoun, S.; Khan, B.; Johnstone, M.; Nahavandi, S.; Creighton, D. An effective heuristic for stockyard planning and machinery scheduling at a coal handling facility. In Proceedings of the 11th IEEE International Conference on Industrial Informatics (INDIN), Bochum, Germany, 29–31 July 2013; pp. 206–211. [Google Scholar]

- Belov, G.; Boland, N.; Savelsbergh, M.W.; Stuckey, P.J. Local search for a cargo assembly planning problem. In Proceedings of the 11th International Conference, CPAIOR, Cork, Ireland, 19–23 May 2014; pp. 159–175. [Google Scholar]

- Belov, G.; Boland, N.; Savelsbergh, M.W.P.; Stuckey, P.J. Exploration of models for a cargo assembly planning problem. arXiv 2015, arXiv:1504.00445. [Google Scholar]

- Savelsbergh, M.; Smith, O. Cargo assembly planning. EURO J. Transp. Logist. 2015, 4, 321–354. [Google Scholar] [CrossRef]

- Menezes, G.C.; Mateus, G.R.; Ravetti, M.G. A branch and price algorithm to solve the integrated production planning and scheduling in bulk ports. Eur. J. Oper. Res. 2017, 258, 926–937. [Google Scholar] [CrossRef]

- Moreno, E.; Rezakhah, M.; Newman, A.; Ferreira, F. Linear models for stockpiling in open-pit mine production scheduling problems. Eur. J. Oper. Res. 2017, 260, 212–221. [Google Scholar] [CrossRef]

- Le, V.T.; Johnstone, M.; Zhang, J.; Khan, B.; Creighton, D.; Hanoun, S.; Nahavandi, S. Complex simulation of stockyard mining operations. In Advances in Global Optimization; Springer: Cham, Switzerland, 2015; pp. 529–537. [Google Scholar]

- Bai, X.; Zhao, Y.; Liu, Y. A novel approach to study real-time dynamic optimization analysis and simulation of complex mine logistics transportation hybrid system with belt and surge links. Discret. Dyn. Nat. Soc. 2015, 2015, 601578. [Google Scholar] [CrossRef]

- Van Vianen, T.; Ottjes, J.; Lodewijks, G. Belt conveyor network design using simulation. J. Simul. 2016, 10, 157–165. [Google Scholar] [CrossRef]

- Balzary, J.; Mohais, A. Consideration for multi-objective metaheuristic optimisation of large iron ore and coal supply chains, from resource to market. In Advances in Applied Strategic Mine Planning; Springer: Cham, Switzerland, 2018; pp. 297–316. [Google Scholar]

- Gao, Z.; Sun, D.; Zhao, R.; Dong, Y. Ship-unloading scheduling optimization for a steel plant. Inf. Sci. 2021, 544, 214–226. [Google Scholar] [CrossRef]

- Sun, D.; Meng, Y.; Tang, L.; Liu, J.; Huang, B.; Yang, J. Storage space allocation problem at inland bulk material stockyard. Transp. Res. Part E Logist. Transp. Rev. 2020, 134, 101856. [Google Scholar] [CrossRef]

- Silva, A.; Beneteli, T.A.P.; Silva, L.; Pessin, G.; Euzébio, T.A.M.; Cota, L.P. A mixed-integer linear programming model for the stockpiles blending problem in a nickel mine. Int. J. Min. Miner. Eng. 2022, 13, 93–118. [Google Scholar] [CrossRef]

- Tang, X.; Jin, J.G.; Shi, X. Stockyard storage space allocation in large iron ore terminals. Comput. Ind. Eng. 2022, 164, 107911. [Google Scholar] [CrossRef]

- Hansen, P.; Mladenović, N.; Brimberg, J.; Pérez, J.A.M. Variable neighborhood search. Comput. Oper. Res. 2019, 24, 57–97. [Google Scholar]

- Holmes, R.J.; Lu, Y.; Lu, L. Introduction: Overview of the global iron ore industry. In Iron Ore; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–56. [Google Scholar]

- Santos, M.S.; Pinto, T.V.; Júnior, Ê.L.; Cota, L.P.; Souza, M.J.; Euzébio, T.A. Simheuristic-based decision support system for efficiency improvement of an iron ore crusher circuit. Eng. Appl. Artif. Intell. 2020, 94, 103789. [Google Scholar] [CrossRef]

- Pereira, F.G.G.; Cruz, J.P.G.; Botter, R.C.; Robles, L.T. Optimization model for integrated port terminal management. Trends Marit. Technol. Eng. 2022, 2, 75–83. [Google Scholar]

- Guze, S. Graph theory approach to the vulnerability of transportation networks. Algorithms 2019, 12, 270. [Google Scholar] [CrossRef]

- Gendreau, M.; Potvin, J.Y. Handbook of Metaheuristics; Springer: Berlin/Heidelberg, Germany, 2010; Volume 2. [Google Scholar]

| CD | A | B | C | D | E | F | G | H | I | J | K | SB1 | SB2 | SB3 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CD | 0 | 0.025 | 0.046 | 0.025 | 0.024 | 0.045 | 0.02 | 0.046 | 0.046 | 0.045 | 0.046 | 0.038 | 0 | 0 | 0 |

| A | 0.025 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.024 | 0.024 | 0.024 |

| B | 0.046 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.027 | 0.027 | 0.027 |

| C | 0.025 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.050 | 0.050 | 0.050 |

| D | 0.024 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.031 | 0.031 | 0.031 |

| E | 0.045 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.030 | 0.030 | 0.030 |

| F | 0.02 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.034 | 0.034 | 0.034 |

| G | 0.046 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.053 | 0.053 | 0.053 |

| H | 0.046 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.022 | 0.022 | 0.022 |

| I | 0.045 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.016 | 0.016 | 0.016 |

| J | 0.046 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.051 | 0.051 | 0.051 |

| K | 0.038 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.025 | 0.025 | 0.025 |

| SB1 | 0 | 0.024 | 0.027 | 0.050 | 0.031 | 0.030 | 0.034 | 0.053 | 0.022 | 0.016 | 0.051 | 0.025 | 0 | 0 | 0 |

| SB2 | 0 | 0.024 | 0.027 | 0.050 | 0.031 | 0.030 | 0.034 | 0.053 | 0.022 | 0.016 | 0.051 | 0.025 | 0 | 0 | 0 |

| SB3 | 0 | 0.024 | 0.027 | 0.050 | 0.031 | 0.030 | 0.034 | 0.053 | 0.022 | 0.016 | 0.051 | 0.025 | 0 | 0 | 0 |

| Ships | CB (CR to SY) | CB (SY to SB) | Berths | Output |

|---|---|---|---|---|

| 0 | 0 | 0 | 0 | NA |

| 0 | 0 | 0 | 1 | r/e |

| 0 | 0 | 1 | 0 | NA |

| 0 | 0 | 1 | 1 | c |

| 0 | 1 | 0 | 0 | NA |

| 0 | 1 | 0 | 1 | r/e |

| 0 | 1 | 1 | 0 | c |

| 0 | 1 | 1 | 1 | c |

| 1 | 0 | 0 | 0 | r/e |

| 1 | 0 | 0 | 1 | r/e |

| 1 | 0 | 1 | 0 | r/e |

| 1 | 0 | 1 | 1 | c |

| 1 | 1 | 0 | 0 | c |

| 1 | 1 | 0 | 1 | c |

| 1 | 1 | 1 | 0 | c |

| 1 | 1 | 1 | 1 | c |

| A | B | C | D | E | F | G | H | I | J | K |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 |

| 0 | 0 | 0 | maintenance |

| 0 | 0 | 1 | “Pa” |

| 0 | 1 | 0 | “Ca” |

| 0 | 1 | 1 | “Va” |

| 1 | 0 | 0 | “Pa” and “Ca” |

| 1 | 0 | 1 | “Pa” and “Va” |

| 1 | 1 | 0 | “Va” and “Ca” |

| 1 | 1 | 1 | “Pa”, “Ca”, and “Va” |

| A | B | C | D | E | F | G | H | I | J | K | SB 1 | SB 2 | SB 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 |

| Nomenclature | Description |

|---|---|

| set of ships and their attributes | |

| demand of each ship | |

| set of berths | |

| set of stockyards and their attributes | |

| set of conveyor belts and their attributes | |

| binary set with the availability configuration of stockyards and berths | |

| binary set with the availability configuration of stacking conveyor belts | |

| binary set with the availability configuration of reclaiming conveyor belts | |

| weighted matrix of stacking and reclaiming times | |

| current demand | |

| current stockyard | |

| time involved in the current stacking operation | |

| time involved in the current docking operation | |

| time involved in the current reclaiming operation | |

| time involved in the current unberthing operation | |

| H | planning time (objective function) |

| 11 Stockyards/3 Berths/10 h/VND | ||||||

|---|---|---|---|---|---|---|

| Ships | Best Time Initial Solution (h) | Best Time Best Solution (h) | Average Time Initial Solution (h) | Average Time Best Solution (h) | Relative Error Best Solution (%) | Average Computational Time (s) |

| 10 | 58.95 | 54.97 | 92.43 | 65.14 | 17.63 | 0.99 |

| 50 | 302.14 | 260.22 | 481.30 | 275.30 | 4.09 | 4.19 |

| 100 | 555.49 | 479.27 | 1178.46 | 519.79 | 8.10 | 6.29 |

| 500 | 4461.22 | 2485.64 | 5863.22 | 2658.96 | 5.81 | 40.28 |

| 1000 | 6819.10 | 4730.70 | 10,399.56 | 5338.05 | 6.33 | 64.59 |

| 15 Stockyards/5 Berths/10 h/VND | ||||||

|---|---|---|---|---|---|---|

| Ships | Best Time Initial Solution (h) | Best Time Best Solution (h) | Average Time Initial Solution (h) | Average Time Best Solution (h) | Relative Error Best Solution (%) | Average Computational Time (s) |

| 10 | 58.56 | 53.69 | 77.6293 | 60.18 | 16.61 | 3.71 |

| 50 | 293.31 | 195.61 | 353.88 | 202.08 | 4.13 | 11.57 |

| 100 | 590.532 | 372.82 | 772.56 | 415.79 | 6.30 | 22.58 |

| 500 | 3129.749 | 2158.54 | 5045.83 | 2268.02 | 5.02 | 103.25 |

| 1000 | 6131.69 | 3976.82 | 6822.69 | 4200.44 | 4.43 | 190.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopes, Á.D.O.; Rocha, H.R.O.; Servare Junior, M.W.J.; Moraes, R.E.N.; Silva, J.A.L.; Salles, J.L.F. Planning an Integrated Stockyard–Port System for Smart Iron Ore Supply Chains via VND Optimization. Sustainability 2023, 15, 8970. https://doi.org/10.3390/su15118970

Lopes ÁDO, Rocha HRO, Servare Junior MWJ, Moraes REN, Silva JAL, Salles JLF. Planning an Integrated Stockyard–Port System for Smart Iron Ore Supply Chains via VND Optimization. Sustainability. 2023; 15(11):8970. https://doi.org/10.3390/su15118970

Chicago/Turabian StyleLopes, Álvaro D. O., Helder R. O. Rocha, Marcos W. J. Servare Junior, Renato E. N. Moraes, Jair A. L. Silva, and José L. F. Salles. 2023. "Planning an Integrated Stockyard–Port System for Smart Iron Ore Supply Chains via VND Optimization" Sustainability 15, no. 11: 8970. https://doi.org/10.3390/su15118970

APA StyleLopes, Á. D. O., Rocha, H. R. O., Servare Junior, M. W. J., Moraes, R. E. N., Silva, J. A. L., & Salles, J. L. F. (2023). Planning an Integrated Stockyard–Port System for Smart Iron Ore Supply Chains via VND Optimization. Sustainability, 15(11), 8970. https://doi.org/10.3390/su15118970