State Estimation of Membrane Water Content of PEMFC Based on GA-BP Neural Network

Abstract

:1. Introduction

2. Dynamic Model of the PEMFC

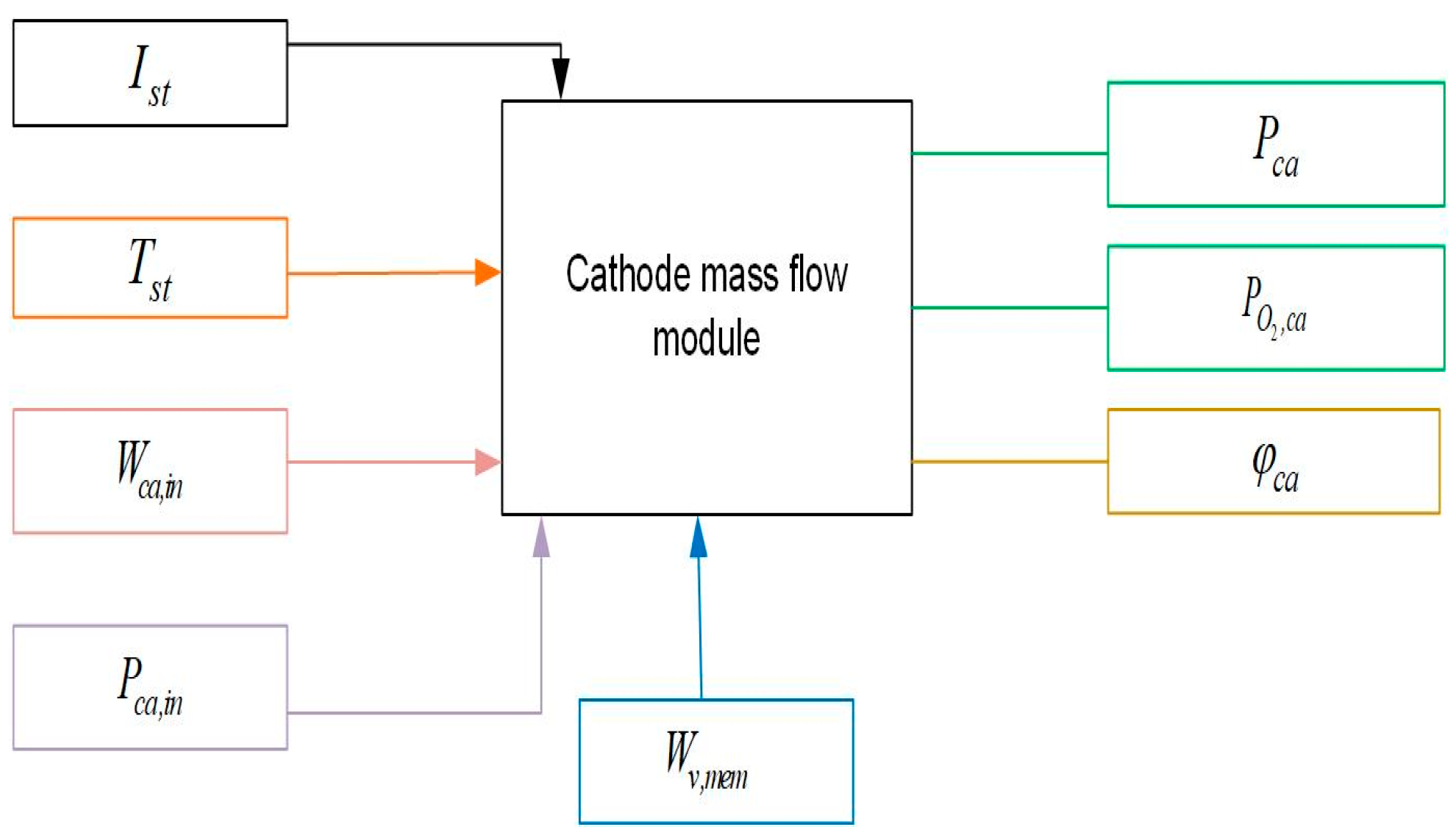

2.1. Cathode Mass Flow Sub-Model

2.2. Anode Mass Flow Sub-Model

- The anode input flow rate can be adjusted in time by a valve to minimize the pressure difference between the cathode and the anode.

- The temperature of the reaction gas stream is equal to the reactor temperature.

- The pressure, temperature, and humidity of the anode output stream are the same as those in the anode flow channel, respectively.

2.3. PEM Water Content Sub-Model

2.4. Output Voltage Sub-Model

3. Simulink Dynamic Modelling and Simulation of the PEMFC

3.1. Dynamic Simulation Model of the PEMFC

3.2. Dynamic Characteristics of the Membrane Water Content

3.3. Dynamic Characteristics of the PEMFC Output Voltage

3.3.1. Output Voltage Characteristics of the PEMFC with Drying Membrane

3.3.2. Output Voltage Characteristics of the PEMFC with 100% Humidified Membrane

4. GA-BP Based Estimation of the Water Content in the PEM

4.1. Estimation of Membrane Water Content Based on GA-BP Neural Network

4.1.1. Basic Principles of GA-BP Neural Network

4.1.2. GA-BP Based State Estimation of PEM Water Content

- (1)

- Initialize the program. Clear the environment variables.

- (2)

- Read the data. Collect reliable data as training and test samples for the neural network and save them in column form to a table.

- (3)

- Divide the training set and the test set. The total number of samples is 3264, the first 2300 data for training and the next 964 data for prediction on the trained model.

- (4)

- Data normalization. In this paper, the data are mapped to the interval of [0, 1], and the normalization can eliminate the differences of the magnitude, prevent the gradient explosion, and improve the performance of the neural network and lead to the better accuracy of the prediction.

- (5)

- Construction of neural network. The configuration of network parameters is carried out, and the optimal number of nodes is found by using the trial-and-error method. The initial population number of GA is set to 10, the number of evolutionary end generations is 60, the crossover probability is 0.8, and the variation probability is 0.1.

- (6)

- Population initialization. Code function is established to generate a random population and encode the variables needed for each individual in the population, which assigns them with an initial value. Fun function is developed to initialize the weights and thresholds of the BP neural network, and train the network using the encoded individual with the best adaptation. The function also records the best and average adaptation in each generation of evolution.

- (7)

- Iteratively solve the optimal initial threshold and weights. Establish the select function, cross function, mutation function and test function respectively to select new individuals using roulette, selection, crossover, and variation operations on individuals, test the feasibility of individuals, and judge whether the thresholds and weights are over-bounded.

- (8)

- Evolution. The worst individuals in each generation are eliminated, and the best adaptation and average adaptation in each evolutionary generation are recorded.

- (9)

- GA-BP neural network training. The train function is invoked to train and simulate the network for testing.

- (10)

- GA-BP neural network test. Simulation and inverse normalization are performed with the trained model, and finally the predicted and desired outputs are compared and the associated error values are calculated.

4.2. Results of Water Content Estimation with the GA-BP Neural Network

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviations | |

| BP | back propagation |

| GA | genetic algorithm |

| LS-SVM | least squares support vector machine |

| MAE | mean absolute error |

| MSE | mean square error |

| PEMFC | proton exchange membrane fuel cell |

| RMSE | root mean square error |

| Subscripts | |

| a | air |

| act | active |

| an | anode |

| ca | cathode |

| con | concentration |

| fuel cell stack | |

| gen | generation |

| H2 | hydrogen |

| i | index or position |

| in | inlet |

| j | position |

| l | liquid |

| max | maximum |

| mem | membrane |

| min | minimum |

| N2 | nitrogen |

| ohm | ohmic |

| SOC | state of charge |

| out | outlet |

| O2 | oxygen |

| reacted | electrochemical reacted |

| sat | saturation |

| st | stack |

| w | water |

| v | vapor |

| 0 | standard state |

| Parameters and variables | |

| number of current iterations | |

| current density, A cm−2 | |

| mass, kg | |

| water drag coefficient | |

| random number | |

| mass fraction | |

| molar fraction | |

| area, m2 | |

| open circuit voltage, V | |

| Faraday constant, 96,485.3 C mol−1 | |

| number of evolution | |

| current, A | |

| molar flow (mol s−1) | |

| pressure, pa | |

| ideal gas constant (8.31 J mol−1 K−1) | |

| temperature, K | |

| voltage (V) or volume (m3) | |

| gas mass flow rate, kg s−1 | |

| water content | |

| M | molar mass |

| water drag coefficient | |

References

- Yang, X.; Sun, J.; Jiang, G.; Sun, S.; Shao, Z.; Yu, H.; Duan, F.; Yang, Y. Experimental study on critical membrane water content of proton exchange membrane fuel cells for cold storage at −50 °C. Energies 2021, 14, 4520. [Google Scholar] [CrossRef]

- Xing, L.; Chang, H.; Zhu, R.; Wang, T.; Zou, Q.; Xiang, W.; Tu, Z. Thermal analysis and management of proton exchange membrane fuel cell stacks for automotive vehicle. Int. J. Hydrog. Energy 2021, 46, 32665–32675. [Google Scholar] [CrossRef]

- Ferahtia, S.; Rezk, H.; Ghoniem, R.M.; Fathy, A.; Alkanhel, R.; Ghonem, M.M. Optimal energy management for hydrogen economy in a hybrid electric vehicle. Sustainability 2023, 15, 3267. [Google Scholar] [CrossRef]

- Cai, G.; Liang, Y.; Liu, Z.; Liu, W. Design and optimization of bio-inspired wave-like channel for a PEM fuel cell applying genetic algorithm. Energy 2020, 192, 116670. [Google Scholar] [CrossRef]

- Wang, Y.; Seo, B.; Wang, B.; Zamel, N.; Jiao, K.; Adroher, X.C. Fundamentals, materials, and machine learning of polymer electrolyte membrane fuel cell technology. Energy AI 2020, 1, 100014. [Google Scholar] [CrossRef]

- Luo, Z.; Chang, Z.; Zhang, Y.; Liu, Z.; Li, J. Electro-osmotic drag coefficient and proton conductivity in Nafion® membrane for PEMFC. Int. J. Hydrog. Energy 2010, 7, 3120–3124. [Google Scholar] [CrossRef]

- Xiong, S.; Wu, Z.; Li, W.; Li, D.; Zhang, T.; Lan, Y.; Zhang, X.; Ye, S.; Peng, S.; Han, Z.; et al. Improvement of temperature and humidity control of proton exchange membrane fuel cells. Sustainability 2021, 13, 10578. [Google Scholar] [CrossRef]

- Li, X.; Deng, Z.; Wei, D.; Xu, C.; Cao, G. Parameter optimization of thermal-model-oriented control law for PEM fuel cell stack via novel genetic algorithm. Energy Conv. Manag. 2011, 52, 3290–3300. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, L.; Jiao, J. Modelling of humidity dynamics for open-cathode proton exchange membrane fuel cell. World Electr. Veh. J. 2021, 12, 106. [Google Scholar] [CrossRef]

- Pei, P.; Yue, L.; Xu, H.; Zi, W. A review on water fault diagnosis of PEMFC associated with the pressure drop. Appl. Energy 2016, 173, 366–385. [Google Scholar] [CrossRef]

- Shimpalee, S.; Beuscher, U.; Van Zee, J.W. Analysis of GDL flooding effects on PEMFC performance. Electrochim. Acta 2007, 52, 6748–6754. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, X.; Martin, J.; Wang, H.; Zhang, J.; Shen, J.; Wu, S.; Mérida, W. A review of PEM fuel cell durability: Degradation mechanisms and mitigation strategies. J. Power Sources 2008, 184, 104–119. [Google Scholar] [CrossRef]

- Espinoza-Andaluz, M.; Santana, J.; Andersson, M.P. Empirical correlations for the performance of a PEFC considering relative humidity of fuel and oxidant gases. Int. J. Hydrog. Energy 2020, 45, 29763–29773. [Google Scholar] [CrossRef]

- Khan, S.S.; Shareef, H.; Ibrahim, A.A. Improved semi-empirical model of proton exchange membrane fuel cell incorporating fault diagnostic feature. J. Mod. Power Syst. Clean Energy 2021, 9, 1566–1573. [Google Scholar] [CrossRef]

- Dotelli, G.; Ferrero, P.; Stampino, P.G.; Latorrata, S.; Toscani, S. Diagnosis of PEM fuel cell drying and flooding based on power converter ripple. IEEE Trans. Instrum. Meas. 2014, 63, 2341–2348. [Google Scholar] [CrossRef] [Green Version]

- Gorgun, H.; Arcak, M.; Barbir, F. An algorithm for estimation of membrane water content in PEM fuel cells. J. Power Sources 2006, 157, 389–394. [Google Scholar] [CrossRef]

- Bellows, R.J.; Lin, M.Y.; Arif, M.; Thompson, A.K.; Jacobson, D.L. Neutron imaging technique for in situ measurement of water transport gradients within Nafion in polymer electrolyte fuel cells. J. Electrochem. Soc. 1999, 146, 1099–1103. [Google Scholar] [CrossRef]

- Qu, S.; Li, X.; Ke, C.; Shao, Z.; Yi, B. Experimental and modeling study on water dynamic transport of the proton exchange membrane fuel cell under transient air flow and load change. J. Power Sources 2010, 195, 6629–6636. [Google Scholar] [CrossRef]

- Chen, X.; Wen, J.; Li, X.; Li, Y. SOH prediction of lithium battery based on IC curve feature and BP neural network. Energy 2022, 261, 125234. [Google Scholar]

- Mao, X.; Song, S.; Ding, F. Optimal BP neural network algorithm for state of charge estimation of lithium-ion battery using PSO with Levy flight. J. Energy Storage 2022, 49, 104139. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, Y.; Long, S.; Jin, X.; Li, J.; Shen, W. A branch current estimation and correction method for a parallel connected battery system based on dual BP neural networks. Green Energy Intell. Transp. 2022, 1, 100029. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, Z.; Huang, L. SoC estimation of lithium battery based on improved BP neural network. Energy Procedia 2017, 105, 4153–4158. [Google Scholar] [CrossRef]

- Pukrushpan, J.T. Modeling and Control of Fuel Cell Systems and Fuel Processors; University of Michigan: Ann Arbor, MI, USA, 2003. [Google Scholar]

- Jiao, J.; Chen, F. Humidity estimation of vehicle proton exchange membrane fuel cell under variable operating temperature based on adaptive sliding mode observation. Appl. Energy 2022, 313, 118779. [Google Scholar] [CrossRef]

- Nguyen, T.V.; White, R.E. A water and heat management model for proton-exchange membrane fuel cells. J. Electrochem. Soc. 1993, 140, 2178–2186. [Google Scholar] [CrossRef]

- Sonntag, R.E.; Borgnakke, C.; Wylen, G.J.V. Fundamentals of Thermodynamics, 5th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1998. [Google Scholar]

- Liso, V.; Araya, S.S.; Olesen, A.C.; Nielsen, M.P.; Kær, S.K. Modeling and experimental validation of water mass balance in a PEM fuel cell stack. Int. J. Hydrog. Energy 2016, 41, 3079–3092. [Google Scholar] [CrossRef]

- Springer, T.E.; Zawodzinski, T.A.; Gottesfeld, S. Polymer electrolyte fuel cell model. J. Electrochem. Soc. 1991, 138, 2334–2342. [Google Scholar] [CrossRef]

- Pukrushpan, J.T.; Stefanopoulou, A.G.; Peng, H. Control of fuel cell breathing. IEEE Control Syst. 2004, 24, 30–46. [Google Scholar]

- Zeng, T.; Zhang, C.Z.; Hu, M.; Chen, Y.; Yuan, C.F.; Chen, J.; Zhou, A. Modelling and predicting energy consumption of a range extender fuel cell hybrid vehicle. Energy 2018, 165, 187–197. [Google Scholar] [CrossRef]

| Symbol | Definition | Value |

|---|---|---|

| Number of cells | 381 | |

| Faraday constant | 96,485 | |

| Molar mass of oxygen | 0.032 | |

| Molar mass of nitrogen | 0.028 | |

| Molar mass of gaseous water | 0.01802 | |

| Ideal gas constant for gaseous water | 461.5 | |

| Effective area of fuel cell | 232 | |

| Ideal gas constants for hydrogen | 4124.3 | |

| PEM thickness | 0.01275 | |

| Parameter | 2 |

| Item | Value (LS-SVM) | Value (GA-BP) |

|---|---|---|

| MSE | 0.215 | 0.0226 |

| MAE | 0.32809 | 0.1256 |

| RMSE | 0.4588 | 0.1506 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, H.; Chen, J.; Wang, K.; Wang, F.; Jin, G.; Chen, F. State Estimation of Membrane Water Content of PEMFC Based on GA-BP Neural Network. Sustainability 2023, 15, 9094. https://doi.org/10.3390/su15119094

Huo H, Chen J, Wang K, Wang F, Jin G, Chen F. State Estimation of Membrane Water Content of PEMFC Based on GA-BP Neural Network. Sustainability. 2023; 15(11):9094. https://doi.org/10.3390/su15119094

Chicago/Turabian StyleHuo, Haibo, Jiajie Chen, Ke Wang, Fang Wang, Guangzhe Jin, and Fengxiang Chen. 2023. "State Estimation of Membrane Water Content of PEMFC Based on GA-BP Neural Network" Sustainability 15, no. 11: 9094. https://doi.org/10.3390/su15119094

APA StyleHuo, H., Chen, J., Wang, K., Wang, F., Jin, G., & Chen, F. (2023). State Estimation of Membrane Water Content of PEMFC Based on GA-BP Neural Network. Sustainability, 15(11), 9094. https://doi.org/10.3390/su15119094