1. Introduction

The deep integration of advanced information technology and mine production is leading the global mining industry into the era of intelligent mining [

1,

2,

3,

4,

5,

6]. Modern mines are no longer characterized solely by equipment automation and the Internet of Things (IoT); they also encompass intelligent management and decision-making approaches [

7,

8].

In underground mine scheduling, ensuring the precision and promptness of instructions and related data poses challenges due to various factors, including communication breakdowns, management inefficiencies, and equipment malfunctions. As a consequence, unresolved issues may arise, leading to a negative impact on production efficiency if not addressed promptly. To overcome these challenges, the underground mining industry urgently longs for a new management mode and tools within the context of intelligent mine construction. By incorporating intelligent management techniques and technologies, such as real-time data analytics, artificial intelligence, and machine learning, mining companies can better manage their resources, optimize their production schedules, and respond more quickly to unexpected events. This not only benefits the mining companies themselves, but it also contributes to the sustainable development of the industry coordinately.

Effective mining scheduling involves the allocation of production tasks for personnel, equipment, and materials according to shifts and types of work, as well as integrated planning and coordination to meet production objectives. Delays or interruptions in tasks can have a ripple effect that affects subsequent tasks and the entire production schedule, caused by equipment failure, safety hazards, environmental changes, operational errors, etc. These unplanned delays or interruptions are called “time wastes”, which are major causes of reduced productivity. By improving management practices, such as implementing effective management strategies and advanced technologies, mining companies can mitigate ‘time wastes’ and optimize their operations.

Short interval control is a scheduling management tool that monitors production progress by reducing supervision intervals. It is effective in underground mines by quickly responding to ‘time wastes’, minimizing adverse effects, and reducing productivity losses. By dividing traditional shift management into multiple short intervals and conducting progress control and scheduling optimization at each interval, short interval control enables continuous production improvement. Through rapid progress tracking and data analysis, adverse factors can be identified and eliminated to improve production efficiency. Short interval control facilitates a PDCA (Plan, Do, Check, and Act) cycle of mining operations, guiding future production by analyzing the current situation.

Short interval control originated in manufacturing and is still in its infancy in mining [

9]. Ade M. et al. (2012) [

10] introduced the concept of lean manufacturing to the Indian coal industry to increase productivity through waste reduction. They investigated drill bits data of five driller gangs in a month in Nagpur India and analyzed the elimination of waste activities and overall effective use of resources and more coal production to wheel the development. Howes R. et al. (2012) [

11] experimented with short interval control at the Chelopech Mine in Bulgaria and discussed its effectiveness in improving underground production management. Through appropriate optimization of management processes, they achieved production and efficiency goals. However, information transfer posed a bottleneck in practice, and how to apply intelligent software and hardware was not mentioned. Visser W. (2020) [

12] proposed a blueprint for operations management based on short interval control to improve mine performance, but its application method was still not resolved. Recently, mining service providers, such as ABB, Deswik, Hexagon, Sandvik, and Mobilaris [

13,

14,

15], have developed software and hardware solutions for short interval control, expanding its potential applications. However, further research into the change in functions of management triggered is still essential, which was neglected by them. The Global Mining Guidelines Group (GMG) [

16] published guidance on short interval control implementation in June 2019, outlining its use in underground mines. This guidance provides a basic framework for the implementation of short interval control. Traditional research on improving mining production efficiency mainly focuses on equipment improvement and process optimization, while neglecting systematic management. Therefore, based on the GMG guidance and experience of existing research, we proposed a lean scheduling framework for underground mines based on short interval control, which aims to integrate the management process, hardware systems, and optimization methods.

Despite the potential of short interval control to enable lean production in underground mines, challenges remain in achieving lean scheduling. Firstly, existing scheduling management typically makes decisions and reports hierarchically, lacking rapid feedback and response models. Therefore, a high-frequency scheduling mode should be established. Secondly, the adoption of underground wireless networks and intelligent terminals is relatively recent, and the concept of using information technology to solve scheduling problems is not yet fully matured. Finally, short interval control is a high-frequency scheduling approach that differs from traditional shift-based scheduling, requiring intelligent algorithms for decision-making.

For many years, intelligent and sustainable mining research has focused on equipment improvement and process optimization, usually for a specific function. Production management optimization research has been more on conceptual innovation, but less on specific implementation paths. However, in order to achieve systematic production efficiency improvements, management concept innovation must be combined with hardware, software, and optimization algorithm innovation. The existing research on short interval control mainly focuses on management concepts and management processes, but less on how to combine them with intelligence. The novelty of this paper is to adapt the lean production concept to the mining industry, optimize the scheduling process using short interval control, and propose a matching hardware architecture and decision support algorithm library implementation method. Overall, this paper proposes a lean scheduling framework for underground mines based on short interval control, aiming to solve the latency issue in current scheduling management. An important feature of this framework is the integration of digital twins and intelligent algorithms.

2. Mining Efficiency Improvement by Lean Production

2.1. Seven Wastes in Underground Mines

During the conversion of geological resources into ore products, mining activities can be categorized as value-added, non-value-added, and waste [

17,

18,

19]. Non-value-added activities can be further divided into essential and non-essential components.

The value-added activities directly increase the value of the product, which is essential to production and generating economic benefits. The value-added activities in mining include blasting, mucking, haulage, hoisting, and other related processes.

Non-value-added activities refer to processes that are essential for the completion of value-added activities, but which non-directly contribute to increasing the value of the product. In the context of mining, non-value-added activities include tasks, such as drift development, support, and ventilation, which are necessary for creating a safe and stable environment for the execution of value-added activities, such as blasting, mucking, haulage, and hoisting. While non-value-added activities may not generate economic benefits on their own, their proper execution is critical for the success of the mining operation integration.

In lean production, waste activities can be categorized as “seven wastes” or TIMWOOD, which include non-essential transportation (T), non-essential inventory (I), excessive motion (M), waiting (W), overproduction (O), overprocessing (O), and product defects (D) [

20,

21,

22]. Waste activities neither cause changes in the value of the product, nor are necessary to complete value-added activities. Hence, it is crucial to minimize the impact of waste activities through effective management. Minimizing waste activities is a key approach to achieving lean production in the mining industry.

Short interval control is a crucial tool for achieving lean production in mining, as it enables the improvement of the efficiency of value-added activities, reduces the time taken for non-value-added activities, and minimizes waste activities. The core principle of short interval control is to shorten the scheduling interval during production operations, enabling front-line personnel to summarize the tasks performed within a certain interval. By doing so, it becomes possible to swiftly identify factors that adversely impact production and make timely decisions and responses for the subsequent phase of production. This approach differs significantly from the traditional mining scheduling management method, which tends to rely on hierarchical decision-making processes and lacks the concept and model of rapid feedback and response.

2.2. Short Interval Control for Underground Mines

Short interval control is a method of monitoring progress and quality at high time frequencies based on production objectives and tasks at mining sites. The primary aim of using this approach in underground mine scheduling management is to increase the transparency of production progress, minimize the impact of uncontrollable factors, enhance the consistency between actual progress and the plan, and ensure the efficiency and continuity of each task. Short interval control enables front-line personnel to make quick and accurate decisions based on real-time data, leading to better overall performance and productivity.

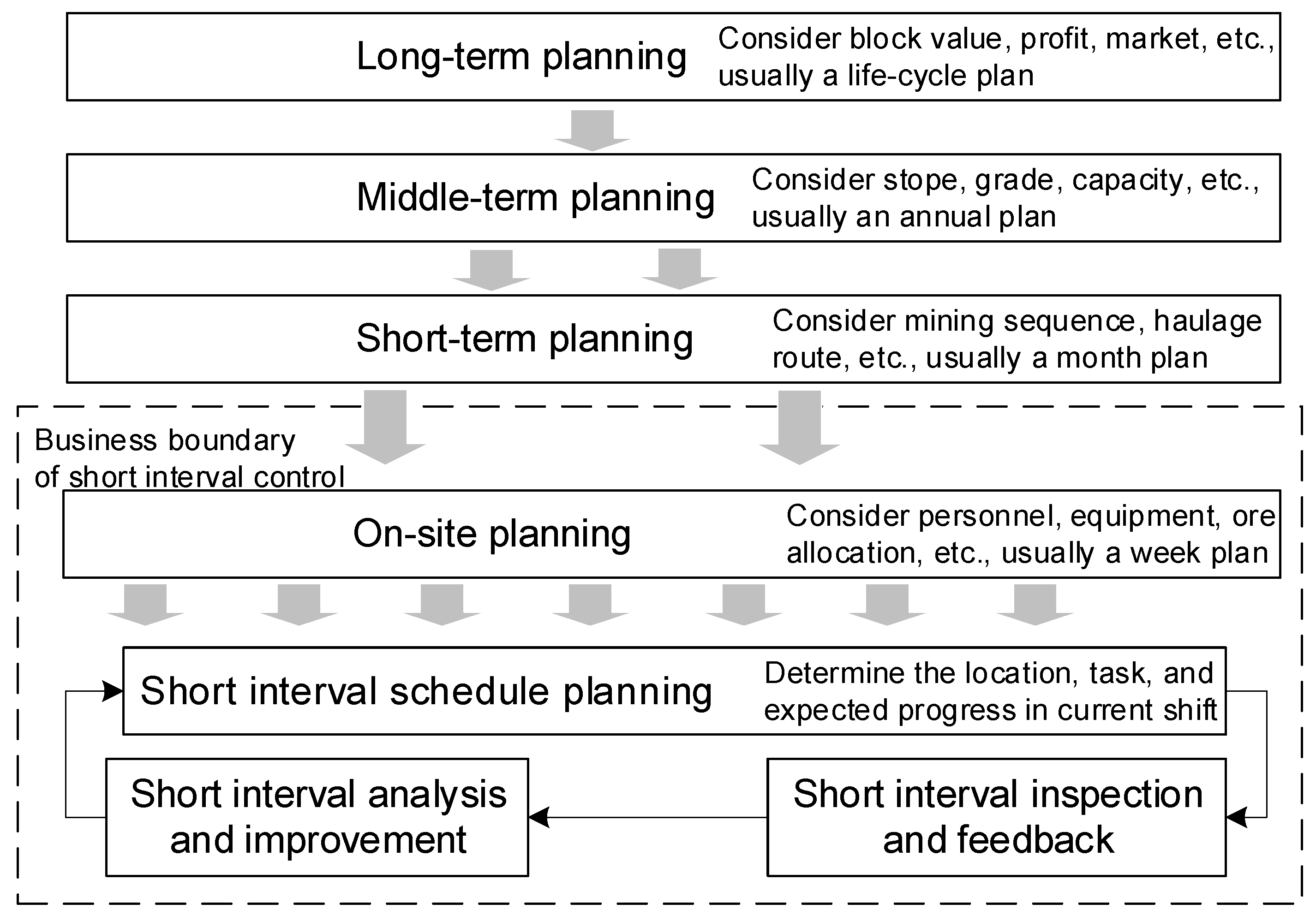

Short interval control for underground mines was a component of mine production management, and it still followed the mining planning process with long-term planning, medium-term planning, short-term planning, on-site planning, and execution. The primary process and business boundaries were shown in

Figure 1, including on-site planning, short interval schedule planning, short interval inspection and feedback, and short interval analysis and improvement.

2.3. Research Methods

To realize the combination of short interval control and intelligent mining, requirement analysis, process modeling, hardware framework design, algorithm library management, and platform development were used to achieve lean production in mines. The specific research process is shown in

Figure 2. The main idea was to analyze the management concept, build a scheduling framework, and finally realize the application.

3. Lean Scheduling Framework

3.1. Requirements for Lean Scheduling

Underground mine scheduling is a complex system engineering process that involves the integration of various technologies, including automation control, the Internet of Things (IoT), sensing, digital mining, machine learning, network communication, and mining operation management. The objective of this process is to analyze the deviation between the actual and planned schedule of mining equipment through information-awareness-driven means and seek a dynamic global collaborative optimization solution within short intervals. The following specific requirements must be achieved:

- ①

Status Sensing: This requirement entails the quantitative perception of the mining equipment and environment using intelligent sensing technology. Unmeasurable state parameters are extrapolated and predicted based on which overall state parameters and inter-individual state effects in physical space are derived.

- ②

Decision Optimization: This requirement is based on the sensing data, which deduces and analyzes the various possible decisions and their impacts. Multi-equipment, multi-system, and global optimization are considered to fully account for the operating conditions of each individual and finally realize the optimal decision for the objectives.

- ③

Cooperative Operation: This requirement entails the development of personalized operation instructions for each operation execution unit, according to the decision optimization results to ensure cooperative production. The way of issuing decision instructions, the way of executing equipment, and the temporal conflict relationship are fully considered, and a certain fault tolerance space is reserved for the instruction executing equipment to improve the overall robustness of the system.

3.2. Process Modeling

The business entities involved in short interval control in underground mines include the planning entity, the scheduling management entity, the on-site production management entity, and the operating entity. The planning entity, composed of engineers in the production technology department, is in charge of decomposing short-term plans and developing and releasing on-site plans. Meanwhile, the scheduling management entity, made up of schedule engineers in the control center, is tasked with assigning tasks, issuing orders, and conducting statistical analyses of production scheduling. In addition, the on-site production management entity, led by team leaders or section leaders, is responsible for overseeing the production and coordination of a specific mining area. Finally, the operating entity consists of front-line operators and equipment tasked with performing operational tasks.

3.2.1. On-Site Planning

The purpose of on-site planning is to develop a schedule and resource allocation plan within the framework of the short-term plan that can achieve the production target. The on-site plan arranges the limited personnel, equipment, and other resources scientifically and reasonably to the appropriate working face, enabling smooth alternating operations. This process prevents conflicts and idleness in equipment usage, improves mine production efficiency, and provides planning guidance for the realization of accurate scheduling. The specific process is shown in

Figure 3.

3.2.2. Short Interval Schedule Planning

Short interval schedule planning is used to develop a task and resource allocation plan within the framework of the on-site plan, implement responsibility to the operating entity, and provide guidance for on-site operation. The specific process is shown in

Figure 4. Short interval schedule planning uses the on-site plan as a guide to analyze and improve the results of the previous shift. It fully grasps the current progress and potential risks and determines the tasks and targets of the current shift, balancing quantity and efficiency. Short interval schedule planning is a dynamic process that needs to be adjusted and optimized on a rolling basis with the reporting of feedback information to minimize operational deviations.

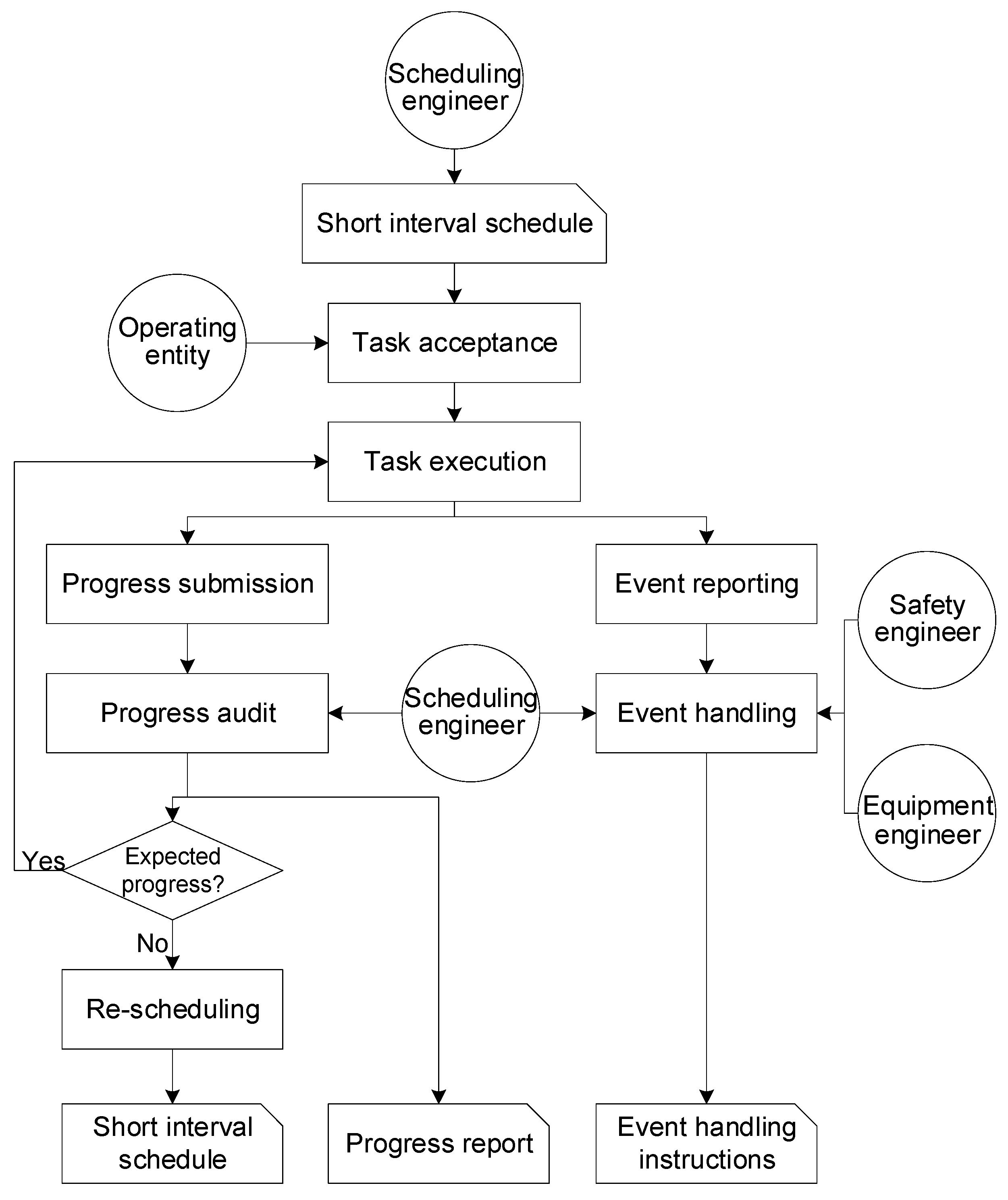

3.2.3. Short Interval Inspection and Feedback

Short interval inspection and feedback is crucial for short interval control. Its objective is to minimize inspection intervals and provide regular feedback on task progress and status, allowing for the prompt rectification of production deviations and the avoidance of task delays due to unexpected events, operational errors, and other issues. The process is shown in

Figure 5, where the on-site production management entity reports task completion information, events, and risks through mobile terminals in real-time. Then, the scheduling management entity completes the progress, events, and risks summary of each task by checking progress at a short interval control node. By adjusting and rescheduling the lagging tasks, the redeployment of the task list is completed, and on-site production in the next interval is guided.

3.2.4. Short Interval Analysis and Improvement

Short interval analysis and improvement aim to evaluate the progress, quantity, and quality of the current shift at its end, providing optimization and decision support for future planning and instruction issuance. The specific process is shown in

Figure 6. After the shift ends, the current progress, scheduling plan, and other relevant data are analyzed. By comparing the planned and actual progress, production efficiency and decision rationality are evaluated, and the decision support basis is provided for the scheduling of the next shift and future operation planning. This process enables a rapid response to changes in production conditions through short interval analysis and improvement.

3.3. Hardware Architecture

Short interval control is a management method that relies on short time cycles and high frequencies, and as such, it requires the implementation of digital mining and intelligent hardware. The hardware architecture mainly comprises a basic communication network, management terminals, mobile terminals, web terminals, and an industrial big data platform, as shown in

Figure 7.

- ①

Basic Communication Network: Network coverage is the foundation for ensuring the effective implementation of the short interval control system. This includes the use of high-speed industrial ring networks, high-coverage wireless AP networks, network bridges, and network firewalls.

- ②

Management Terminal: To ensure effective coordination and decision-making, underground scheduling instructions must be formulated and issued by the ground control center. Management terminals play a critical role in serving the control center and completing various scheduling tasks, such as data collection, summarization, instruction formulation, issuance, analysis, production optimization, and more. The essential hardware includes large screens, scheduling computers, and other related devices.

- ③

Mobile Terminal: Mobile terminals are responsible for receiving scheduling instructions and reporting progress and events, playing a vital role in extending scheduling instructions to the on-site production team. The essential hardware includes vehicle mobile terminals and personal mobile terminals.

- ④

Web Terminal: Web terminals provide multiple query functions for authorized users to access relevant data through the internet, ensuring timely and independent access within the scope of authorization. To ensure data and system security, a complete user authorization and network firewall are required.

- ⑤

Industrial Big Data Platform: The implementation of short interval control heavily relies on digital mining and intelligent hardware. An industrial big data platform is essential for constructing short interval control computing and storage services, taking advantage of their high-performance computing and storage capabilities. This platform completes the core processing of short interval control, including algorithm library, computing nodes, and memory nodes. It realizes various functions, such as instruction sending and receiving, storage, data statistics and aggregation, and self-learning of optimization models.

3.4. Decision Support Algorithm Library

The scheduling decision-making process in underground mines is complex and involves multiple tasks, including development, mining, haulage, ventilation, drainage, and labor scheduling. Traditional methods of decision-making, which rely on manual scheduling of tasks or limited computer-aided techniques, were difficult to obtain optimal solutions for for complex constraints. Therefore, the scheduling decision support algorithm library was developed to improve the scientificity and feasibility of decision-making in underground mines. This library provided interactive decision-making tools for scheduling management entities using machine learning and big data analysis, based on operational progress and monitored big data collected by short interval control.

The scheduling decision support algorithm library is dynamic and continuously improved and expanded.

Figure 8 shows the existing algorithm library, which includes the following algorithms:

- ①

Task Assignment Algorithm for Trackless Equipment [

23,

24,

25,

26]: Underground mining is a location-discrete, multi-process, and multi-equipment collaborative production process. This algorithm was used to configure equipment and assign tasks under complex underground mining constraints to rationalize the sequence of operations and maximize efficiency and mining succession. The algorithm could be customized to achieve different objectives, such as the shortest working interval, the maximum productivity, the overall working time, and the maximum equipment utilization rate, according to the preferences of the scheduling management entities.

Figure 9 showed a typical output of this algorithm.

- ②

Truck-loader Matching Algorithm [

27]: Some mines use trucks for ore transportation. The truck-loader matching algorithm was designed to optimize the number of loaders and trucks to achieve the best vehicle utilization and transportation capacity under the constraints of production capacity, transportation routes and capacity, and vehicle capacity. This algorithm built a transportation route model and divided the ore haulage of trucks into three parts, including ore loading, truck transportation, and ore unloading.

- ③

Path Planning Algorithm for Trackless Equipment [

28]: Path planning is one of the key technologies for unmanned driving of underground intelligent vehicles. The path planning algorithm was used to solve the problem of path planning for trackless equipment in underground mines based on the articulated structure and drift environment conditions.

Figure 10 showed a typical output of this algorithm, which made a shorter, smoother, and more feasible driving path for trucks and other trackless equipment.

- ④

Man–machine Efficacy Algorithm [

29]: The man–machine efficacy in underground mines is difficult to evaluate due to the effects of multiple factors on the working efficiency of equipment operation by personnel. The man–machine efficacy algorithm was used to quantify the impact of personnel, equipment, and the environment on man–machine efficacy to ensure operational safety. If the evaluation result indicates inadequate operational safety, the scheduling management entities should be informed and reminded to stop relevant operations.

- ⑤

Hazardous Risks Prediction Algorithm [

30]: Hazardous risks in underground mines can affect production and even disrupt progress. The hazardous risks prediction algorithm was used to analyze and predict potential risks in underground mines. The algorithm predicted hazardous risks by using association rules and classifies them according to the dimensions of time, place, cause, responsible personnel, potential consequences, etc., based on text mining.

The scheduling decision support algorithm library provides a suite of decision-making tools that improve the scientificity and feasibility of scheduling management in underground mines. These algorithms provide efficient, accurate, and fast decision-making recommendations for scheduling entities, helping to maximize efficiency and safety in underground mining operations.

4. Case Study

4.1. Platform

A scheduling platform was developed, based on the lean scheduling management framework of underground mines. The platform was designed to incorporate intelligent perception, analysis, prediction, and decision-making to support the scheduling process. The platform utilized the latest technologies, such as the IoT, big data, and cloud computing, to integrate computing, communication, and control through sensing, analysis, data mining, evaluation, prediction, optimization, collaboration, and other functions. The platform achieved a high degree of restoration from the physical space to the virtual space and efficient control from the virtual space to the physical space. The scheduling platform made short interval decisions for mining activities and collaboratively dispatched related equipment for efficient task execution to maximize mining production.

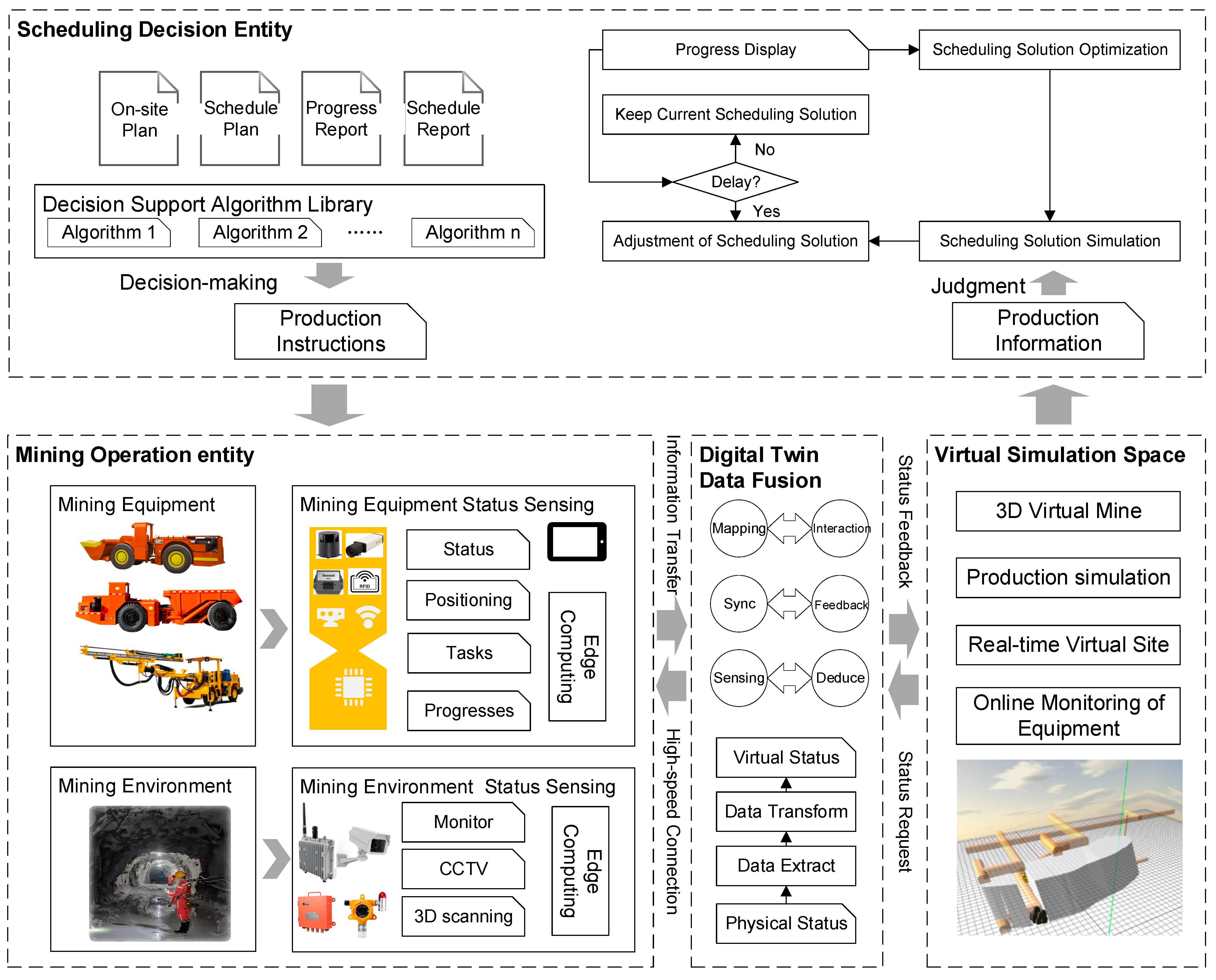

The Mine Cloud 2.0 (TM) by China Coal Technology and Engineering Group (R) was used as the basis for developing the platform. Digital twin technology was utilized to achieve simultaneous evolution of physical devices and the virtual world by mapping and interacting physical entities with virtual information. The platform’s framework consisted of four main components, including the mining operation entity, virtual simulation space, digital twin data fusion, and scheduling decision entity. The platform utilized IoT sensors and mobile terminals for state sensing of mining operation entities, and digital twin data fusion was used to map state information to the virtual simulation space to provide highly transparent and reproducible operation information. On this basis, the algorithms and tools of scheduling decisions were used to formulate and issue instructions and complete the control of mining operation entities.

Figure 11 illustrates the framework of the scheduling platform, highlighting the components and their interactions. The platform’s development achieved a high degree of integration and collaboration of different technologies, leading to an efficient and effective scheduling process for underground mines.

4.2. Application

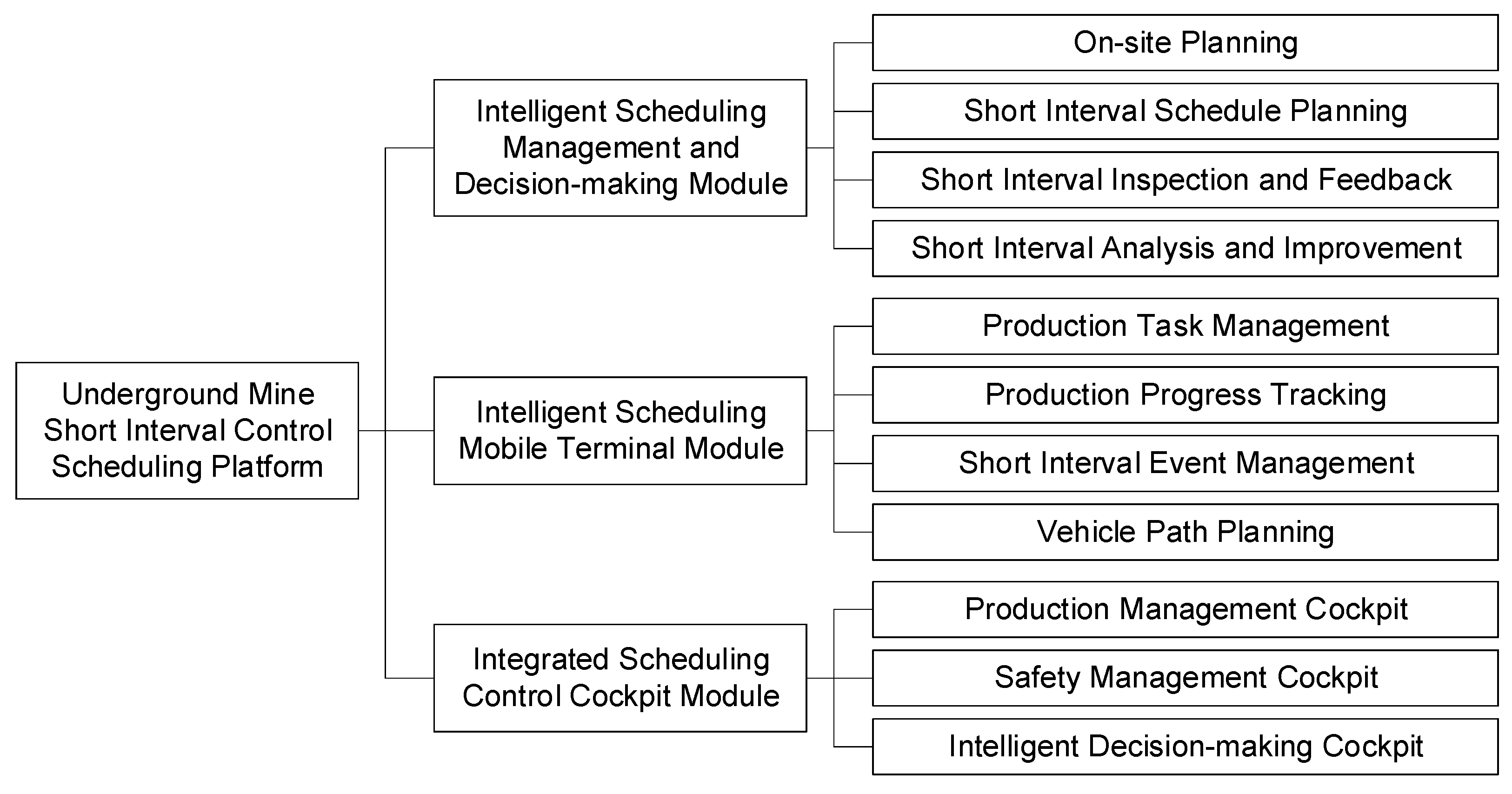

The functional system of the underground mine short interval control scheduling platform included intelligent scheduling management and decision-making module, intelligent scheduling mobile terminal module, and integrated scheduling control cockpit module, as shown in

Figure 11. The intelligent scheduling management and decision-making module served the control center personnel and was used to realize scheduling instructions and decisions, mainly including data collection, scheduling optimization, decision-making, instruction issuance, etc. The intelligent scheduling mobile terminal module served front-line operators and equipment and was used to realize instruction reception and progress reporting for mining operation entities. The integrated scheduling control cockpit module served the large screen in the control center, conference room, and other scenes, and it was used to realize virtual simulation space visualization.

The functional system of the underground mine short interval control scheduling platform included an intelligent scheduling management and decision-making module, an intelligent scheduling mobile terminal module, and an integrated scheduling control cockpit module, as shown in

Figure 12. The intelligent scheduling management and decision-making module served the control center personnel and was used to realize scheduling instructions and decisions, mainly completing data collection, scheduling optimization, decision-making, and instruction issuance. The intelligent scheduling mobile terminal module served front-line operators and equipment and was used to realize instruction reception and progress reporting for mining operation entities. The integrated scheduling control cockpit module served the large screen in the control center, conference room, and other scenes and was used to realize virtual simulation space visualization.

- ①

Intelligent Scheduling Management and Decision-making Module: This module provided intelligent processing of scheduling business. It achieved distributed collection of operation information, automatic unsupervised processing, and formatted chart generation, while also performing big data analysis, decision support algorithm library invocation, and scheduling instruction formulation and issuance. Part of the interfaces is shown in

Figure 13. Based on Information Resource Planning (IRP) and information integration, with the help of cloud computing, data warehouse, and Online Analytical Processing (OLAP) tools, it ensured intelligence and reliability and assists scheduling personnel in playing central roles in mining scheduling.

- ②

Intelligent Scheduling Mobile Terminal Module: The mobile terminal technology was used to realize scheduling instructions directly to the operation execution unit with a quick response, collect and organize relevant feedback information, and send it back to the control center, thus improving the response speed of the mining scheduling process. Part of the interfaces is shown in

Figure 14. This improves work efficiency while changing the way of scheduling information interaction, allowing for targeted and agile processing of tasks.

- ③

Integrated Scheduling Control Cockpit Module: The digital twin was used to realize the information processing of virtual mining operation space and the multi-dimensional display of data through Business Intelligence (BI) to achieve real-time three-dimensional visualization of the mining processes in the control center. Part of the interface is shown in

Figure 15. The distributed data collection and processing logic of level-by-level integration were constructed through data flow planning to complete multi-topic, multi-dimensional, and multi-level analysis of mining data. Finally, it formed a complete multi-dimensional information display solution, thereby effectively improving the comprehensive analysis and decision-making capability.

4.3. Discussion

The physical space, consisting of equipment and operators, represented the production capacity of a mine. In contrast, the virtual space, created through environment perception and data modeling, represented the capacity for lean management, data analysis, and knowledge discovery. The underground mine short interval control scheduling platform discussed in this paper integrated physical entities and virtual space, allowing for improved closed-loop iterative management of “operation-analysis-improvement” in the production process, and it thereby fully reflected the value of information and management.

The platform demonstrated several benefits in improving the mining production process. In terms of information transparency, the platform was able to quickly and visually identify production bottlenecks, improving the response speed to events and reducing the negative impact of unplanned events during operations. Additionally, the platform was effective in flexible scheduling, shortening the scheduling cycle, adjusting the operation sequence, and redeploying tasks to ensure production order and rapid response in the underground. The platform also aided scientific decision-making by using optimization algorithms to allocate underground resources more effectively, reducing idleness and conflicts, strengthening the relevance of production organization, and enhancing the science, accuracy, and operability of the mining processes, resulting in a more balanced, orderly, and sustainable mining operation. Finally, the platform facilitated lean production by optimizing the mine production scheduling processes and realizing intelligent scheduling control. By doing so, the platform freed scheduling engineers from complicated, repetitive, and low-level work, thereby improving the efficiency and quality of work and helping engineers to convert to decision-optimized management. These benefits had a positive impact on efficiency and economic production.

Despite its benefits, the study had specific flaws. First, the decision support algorithm library was limited, and the current algorithms were far from meeting the requirement of intelligent decision-making. The platform needed more supplements in image recognition, intelligent warning, linkage control, and safety management. Second, the implementation of short interval control required the adjustment of the existing scheduling mode and had high resistance to reform, while the method for switching mode had not been proposed in this paper. Finally, the platform was applied for a relatively short period in the mine site, making it challenging to conduct a quantitative analysis of its impact on technical and economic indicators. However, such analysis will be performed in the future after a more extended period of application.

For future verification of the advantages of the framework proposed in this paper, the application survey should be conducted in aspects of efficiency, economy, and hominization. The specific calculation method is shown in

Table 1.

5. Conclusions

Production scheduling management significantly impacts mine productivity. With the increasing trend of intelligent mines, it is crucial to develop a lean scheduling management approach that aligns with intelligent conditions. The lean scheduling framework, based on short interval control, is an effective tool for adapting intelligent scheduling in underground mines. By shortening the production monitoring and adjustment cycle from the traditional post-shift feedback to a “near real-time” approach, and closing the feedback loop on production progress, corrective measures can be taken promptly to minimize schedule deviations and enhance overall production efficiency. Building upon this foundation, the implementation of the platform has achieved intelligent perception, analysis, prediction, and decision-making in scheduling. The digital twin platform framework comprises the intelligent scheduling management and decision-making module, intelligent scheduling mobile terminal module, and integrated scheduling control cockpit module. The results indicate that the platform is effective in promoting mine intelligence by enhancing information transparency, flexible scheduling, lean production, and scientific decision-making in underground mine scheduling.

However, the method in this paper still has limitations, and future research will focus on the following aspects. (1) Continuously expanding the library of decision support algorithms to cover more businesses to enable more scientific and intelligent scheduling decisions is needed. (2) Exploring transition methods that can smoothly implement short interval control scheduling reform by practicing in more mines to reduce resistance to implementation is needed. (3) Finally, quantitatively analyzing the revenue value of production scheduling in short interval control for mines through longer-term follow-up practice is needed.