Abstract

The current study aims to evaluate the viscosity and rheological properties of PG 64-22 modified with Styrene–Isoprene–Styrene (SIS) and Processed Oil (PO) to enhance asphalt binder properties. Performance properties were measured at high, intermediate, and low temperatures. PG 64-22 was blended with SIS and Processed Oil at three levels (5%, 10%, and 15% by weight of binder) and two concentrations (6% and 12% by weight of binder), respectively. Modified binders underwent two short and long artificial aging processes, through the spinning of the thin film in an RTFO oven and a pressure aging vessel (PAV). The Superpave binder evaluations were carried out using a rotational viscometer (RV), dynamic shear rheometer (DSR), and bending beam rheometer (BBR). According to the findings of the research, the addition of SIS caused higher values of viscosity, but when co-modified with processed oil, there was a substantial decrease in viscosity values. As a result, workability was improved. (1) It was observed that a greater reduction in viscosity was achieved when the processed oil was present at a higher concentration at 135 °C compared to a lower concentration. (2) The study showed that the incorporation of processed oil led to a reduction in rutting performance of the asphalt binder. However, the addition of SIS resulted in a notable enhancement of rutting resistance. (3) The role of processed oil as co-modifier at concentrations of 6% and 12% caused significant decreases in G*sin δ, based on the susceptibility of asphalt molecules to accept oil molecules in their network links. (4) The extracted measurements from the BBR tests indicated that modification with SIS and PO improved the low-temperature cracking resistance significantly. Comparison of asphalt binders modified with 6% and 12% PO and the same SIS content showed significant changes in modification with 12% PO rather than 6%.

1. Introduction

Asphalt binders are the most commonly used material for road construction. Currently, due to the increasing population and number of vehicles, more dynamic loads are applied on asphalt pavements, resulting in severe defects and problems. Derived from petroleum refineries, asphalt binder is a complex chain of molecules that exhibits moderate polarity, molecular weight, and functionality [1]. Due to excessive dynamic loads and harsh weather conditions, the top layers of asphalt pavements are more susceptible to damage than the other structural layers [2]. Due to the reduction in the viscosity of asphalt binders at excessive high temperatures, surface rutting occurs, which may create many severe problems on roads and highways. Thermal cracking is a common issue that arises at low temperatures and is caused by the loss of viscoelastic properties in the molecular configuration of the binder [3]. Due to the conversion of aromatics to asphaltene during the aging of binders, greater viscosity has been observed in older asphalt binders than in virgin asphalt binders [4].

Modification of asphalt binders has been considered and studied for decades as an available solution to optimize the quality of asphalt binders. Enhancing the viscosity of asphalt binders helps to increase the resistance against dynamic loads and harsh situations at ambient temperatures [5]. The selection and mixing design of modifiers is very important; however, the laboratory performance may be different from that in situ [6]. On the construction site, workability and handling of modified asphalt should be considered due to its higher viscosity and high melting temperature [7]. The asphalt industry commonly employs several modifiers, including Styrene–Butadiene–Styrene (SBS), Styrene–Butadiene–Rubber (SBR), Crumbed Rubber Modifier (CRM), Polyethylene (PE), and Styrene–Isoprene–Styrene (SIS) [8]. The presence of these modifiers enriches the viscosity; this means an improvement will be achieved in rutting resistance, but it causes difficulties in workability and pumping during the construction of asphalt pavements [9].

As a modifier, SIS increases the viscosity and improves the rutting resistance of asphalt binder [10,11]. Due to the increase in viscosity, the stiffness of SIS-modified asphalt binders consequently increases, which may cause thermal and fatigue cracking [12]. Co-modifiers such as oil compounds help to improve the ability of asphalt binder to handle obstacles, since they are susceptible to alternate properties of asphalt binders [13,14]. Due to the high solubility rate of oil in asphalt, studies have shown its inclusion leads to asphalt rejuvenation and dynamic viscosity reduction in addition to the reduction in stiffness [15,16,17,18]. As a co-modifier of asphalt binder, processed oil is known to reduce viscosity and enhance its resistance to stiffness at low temperatures, thereby preventing thermal cracking defects [19]. However, there is not a lot of research on the impact of oil compounds as co-modifiers with primary modifiers at various temperature ranges in asphalt binders. The study of road performance of modified asphalt mixtures is a crucial area of research in civil engineering and materials science. It involves investigating the effects of modifying asphalt, the binder used in asphalt concrete, with various additives or modifiers to enhance its performance. This research aims to improve the overall performance of asphalt concrete, which is used in road construction. Evaluating the road performance of modified asphalt mixtures helps engineers to understand how the modified asphalt behaves under different conditions and to assess its ability to withstand heavy loads, resist deformation, and maintain its integrity over time. By studying road performance, researchers can determine the optimal dosage and combination of modifiers, develop guidelines for their use, and ensure the durability and longevity of asphalt pavements.

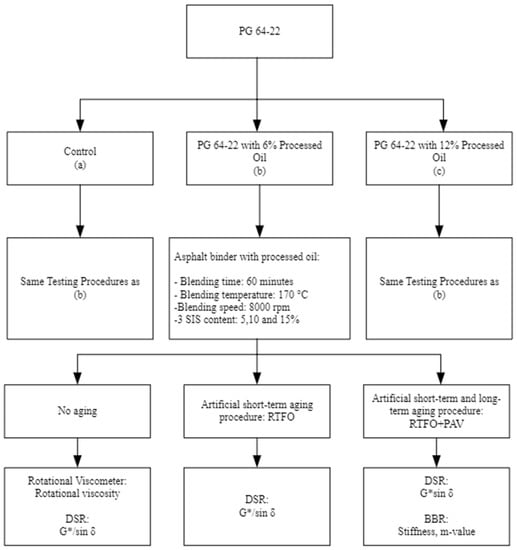

The present investigation was conducted to explore the impacts of incorporating processed oil and SIS on the characteristics of asphalt binders. The research was designed to determine the effects of different levels of processed oil and SIS on the viscosity and stiffness of the asphalt binder, as well as its resistance to rutting, thermal cracking, and fatigue cracking. This research focused on the rheological and cracking characteristics of asphalt binders that had been modified with SIS and processed oil. This study utilized the RTFO and PAV to evaluate the impact of short-term and long-term aging on the asphalt binder. To assess the high-temperature viscosity of modified asphalt binders, measurements were carried out with a rotational viscometer (RV) at temperatures between 135 °C and 180 °C at 15 °C intervals. The outcomes were studied as a function of SIS and PO contents. The dynamic shear rheometer (DSR) was employed to analyze the rutting resistance of asphalt binders in their original state, short-term-aged state after RTFO, and long-term-aged state after RTFO + PAV. Finally, the bending beam rheometer (BBR) was utilized to determine the low-temperature cracking resistance of long-term-aged binders after RTFO+PAV at −12 °C and −24 °C. The study design is illustrated in Figure 1.

Figure 1.

Experimental design flow chart. (a) Control binder preparation process, containing processed oil. (b) Samples preparation process, containing 6% processed oil and SIS. (c) Samples preparation process, containing 12% processed oil and SIS.

2. Research Methodology

2.1. Components

A base asphalt binder with a performance grade of 64-22 (PG64-22) was employed as the raw material both for the control and to be modified using processed oil and SIS. The properties of the base binder, according to AASHTO PP6 standards, are presented in Table 1. SIS, which has a linear molecular structure and consists of 15 wt%, was selected as the primary modifier. The characteristics of SIS can be found in Table 2. To enhance workability and improve low-temperature performance, processed oil was added as a co-modifier. PO is a blackish byproduct of petroleum refining that is typically used for slicking industrial equipment to decrease friction. The characteristics of the PO are presented in Table 3 based on different ASTM standards.

Table 1.

Asphalt binder PG64-22 properties.

Table 2.

Properties of SIS.

Table 3.

Properties of processed oil.

2.2. Preparation Process

At a designated temperature of 170.0 ± 5 °C, processed oil was added into the base binder while mixing was on-going. SIS was added at various concentrations after reaching the target temperature, and the duration of mixing was set at 10 min using 8000 rpm. To maintain the original characteristics of the binder, the mixing temperature was manually monitored and controlled not to exceed its boiling point.

Two distinct concentrations of processed oil were utilized as modifiers in this study, comprising 6% and 12% of the sample’s weight of the unmodified binder. Once the ten-minute mixing process was complete, SIS was introduced directly to the agitation vessel in three separate concentrations of 5%, 10%, and 15% as a fraction of sample weight. To keep the coherence throughout the whole tests, the modifiers were sourced from the same product package.

Two long-term and short-term aging processes were performed to age the samples. The short-term aging process proceeded artificially at 163 °C for 85 min. This was followed by a long-term aging treatment, which was performed under 2 bars of pressure at 100 °C for 20 h in the PAV. Once the aging treatments were completed, the tests mentioned in the study design flowchart were conducted to investigate the impact of modification via SIS–PO. The appearance of the PO is depicted in Figure 2.

Figure 2.

Processed oil (PO).

2.2.1. Fundamental Attribute Assessments

To assess the asphalt mixture regarding its workability and handling, a rotational viscosity (RV) test was conducted over a temperature range of 135–180 °C at 15 °C intervals, using a constant velocity of 20 rpm. The test was performed on 10.5 g samples via cylindrical spindle number 27, and the timespan of the RV test was fixed at 20 min per sample for data collection. The determination of the asphalt binder’s viscoelastic properties and resistance to rutting involved the measurement of complex shear modulus (G*) and the sine of the phase angle (δ) at 82 °C, enabling the calculation of G*/sin δ. To assess the fatigue cracking resistance of the modified asphalt binder, G* and sin δ factors were measured at 25 °C. The modified asphalt binder’s stiffness values were investigated at two temperatures of −12 °C and −24 °C using BBR (Canon, Huntington, NY, USA) equipment based on the standards of AASHTO T 313. To measure the creep stiffness of the samples, which had dimensions of 125 × 6.35 × 12.7 mm3, they were molded and placed in a bath.

2.2.2. Data Analysis

The investigation applied a statistical analysis technique known as Analysis of Variance (ANOVA) using the Social Sciences Statistical Program (SSSP 28) with Fisher’s Minimum Significant Difference (MSD) contrast and a significance level of α = 0.05. The primary parameters examined in this study were the PO concentrations of 0%, 6%, and 12%, and SIS concentrations of 0%, 5%, 10%, and 15%. ANOVA was executed to identify significant dissimilarities among sample averages. To assess the differentiation between two populations, the Mean Square Deviation (MSD) was calculated based on the deviation between sample means, with a comparison made for each pair of means. If the difference between two sample means equaled or exceeded the MSD value, it indicated a statistically significant distinction between the population means. The study utilized a confidence level of 95%, ensuring a 95% probability of accuracy for each finding.

3. Results and Discussion

3.1. Viscosity

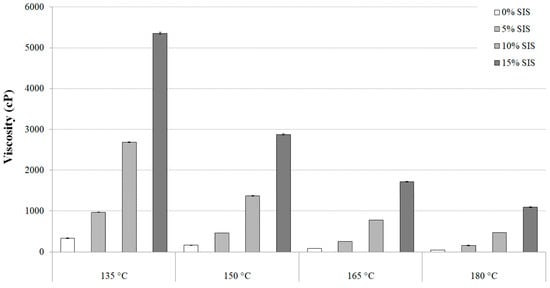

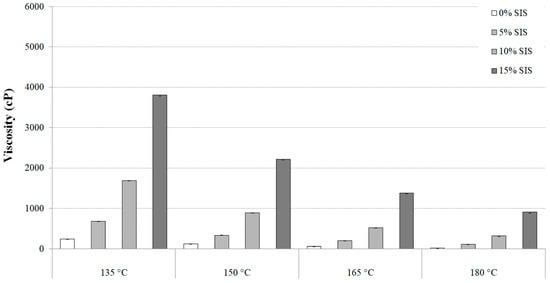

The flowability of asphalt binder within an asphalt plant, its ability to fully coat the aggregate in a HMA mixture, and its capacity to create a new pavement surface upon placement and compaction are influenced by its high-temperature viscosity. This viscosity is a crucial factor in determining the optimal working temperature (Asphalt Institute, 2003) [20]. Figure 3 and Figure 4 present the results obtained from the standard RV test of PG 64-22 asphalt binder modified with PO and SIS across a temperature range of 135 °C to 180 °C. Figure 3 illustrates that the viscosity of the modified asphalt binder with 6% PO increases as the amount of added SIS (0%, 5%, 10%, and 15%) increases at each temperature level. The viscosity values of the 6%-processed-oil-modified binder containing 0%, 5%, 10%, and 15% SIS at 135 °C were observed to be 331, 966, 2681, and 5356 cP, respectively. Figure 4 illustrates that the measured viscosity values for the binder modified with 12% processed oil with the previous SIS contents at 135 ℃ were 234, 681, 1687, and 3812 cP, respectively. It shows that an increase in processed oil content caused viscosity reduction for each SIS content (0, 5, 10, and 15%) of 26, 29, 37, and 28%, respectively. With an increase in temperature to 150 °C, the viscosity values for asphalt binder modified with 6% processed oil and 0, 5, 10, and 15% SIS were 162, 462, 1368, and 2874 cP, respectively. For asphalt binder modified with 12% processed oil and 0, 5, 10, and 15% SIS, the viscosity values were measured 118, 337, 887, and 2218, respectively. At 150 °C, there was a reduction in viscosity of 27, 27, 35, and 22% at 0, 5, 10, and 15% SIS content, respectively, due to the increase in processed oil concentration from 6% to 12%. Subsequently, the same pattern of reduction was observed at 165 °C. At 180 °C, with SIS contents of 0, 5, 10, and 15% for both modified binders, reductions of 50, 28, 31, and 17% were observed, respectively, with 12% processed oil.

Figure 3.

Effect of SIS content on the viscosity of PG 64-22 binder modified with 6% processed oil.

Figure 4.

Effect of SIS content on the PG 64-22 binder’s viscosity modified with 12% processed oil.

While an increase in SIS significantly raised the value of G*/sin δ, the introduction of processed oil as a co-modifier led to a reduction in viscosity due to the high rate of diffusion in asphalt molecules and the restructuring of the chains of asphaltene molecules; this results in an improvement in workability. A higher concentration of processed oil (12% compared to 6%) in the modified asphalt binders led to a greater reduction in viscosity and good workability. These results show how processed oil can be effective at improving handling, pumping, coating, and compaction on the construction site, by joining with SIS to improve viscosity and workability simultaneously. Figure 3 and Figure 4 show a reduction in viscosity which satisfies Superpave’s specifications [20]; except for the ones containing 15% SIS at 135 ℃, the binders all had a viscosity lower than 3000 cP. Due to the properties of processed oil, it seems that this effectiveness can be maintained by conjugating other common modifiers, such as Styrene–Butadiene–Styrene, Styrene–Butadiene–Rubber, Crumbed Rubber Modifier, etc.

Table 4 and Table 5 display the statistical significance of changes in viscosity values caused by variations in processed oil content, SIS content, and temperature. The findings indicate that altering the temperature in accordance with changes in processed oil and SIS content can significantly affect the viscosity values of binders.

Table 4.

Viscosity data analysis of modified PG 64-22 with 6% processed oil as a function of SIS content (α = 0.05).

Table 5.

Data analysis of viscosity values of modified PG 64-22 with 12% processed oil as a function of SIS content (α = 0.05).

3.2. Rutting Properties

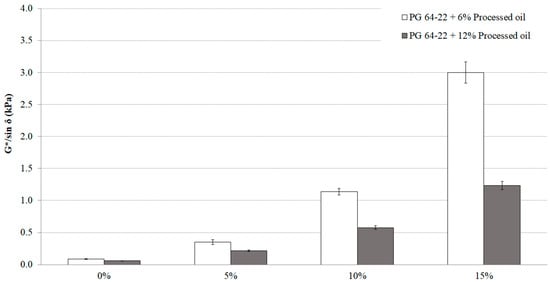

According to the specifications of Superpave [20], a greater G*/sin δ in dynamic shear rheometer (DSR) tests means more resistance and effectiveness against the high temperature rutting defect. The G*/sin δ values were examined at different states of aging, including original and short-term RTFO, at the temperature of 82 °C. Figure 5 shows the values of G*/sin δ at their original state. Due to the application of processed oil as a co-modifier, a decrease in rutting resistance values was expected; however, the G*/sin δ values show an increase for asphalt binders modified with both 6 and 12% processed oil, because of the addition of SIS. Therefore, the inclusion of SIS has enhanced the resistance of asphalt binders against rutting, while the processed oil contents have altered the workability of the binder. As presented in Figure 5, the G*/sin δ values for the asphalt binder modified with 6% processed oil demonstrated significant increases of 410%, 297%, and 260% upon the addition of 5%, 10%, and 15% SIS, respectively. Conversely, for the modified asphalt binders containing 12% processed oil, a rise in the values of G*/sin δ was observed by 358%, 267%, and 214% due to the incorporation of 5%, 10%, and 15% SIS, respectively. As a result of the higher proportion of processed oil, the rate of growth in values of G*/sin δ was moderate in comparison to the binder that was modified with 6% processed oil.

Figure 5.

Influence of SIS concentration on G*/sin δ values for PG 64-22 binders modified with 6% and 12% processed oil at 82 °C.

Table 6 presents the statistical analysis and significance of variations in G*/sin δ values for the initial state of modified asphalt binders. The binders contained 6% and 12% processed oil, with SIS contents ranging from 5% to 15%. Notably, significant alterations were observed in the asphalt binder modified with 6% processed oil when 15% SIS was added. Conversely, for the asphalt binder modified with 12% processed oil, significant changes were noted with the addition of both 10% and 15% SIS.

Table 6.

Analysis of G*/sin δ values for PG 64-22 at original state, and modified with processed oil and SIS (α = 0.05).

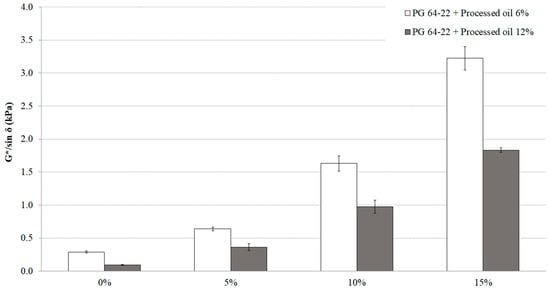

Figure 6 illustrates the G*/sin δ of asphalt binders modified with 6% and 12% processed oil at a short-term-aged state, after the addition of 5%, 10%, and 15% SIS. The findings indicate that, in the case of the asphalt binder modified with 6% processed oil, the G*/sin δ values exhibited increases of 220%, 255%, and 197%, respectively. Conversely, for the asphalt binder modified with 12% processed oil, the G*/sin δ values experienced increases of 383%, 267%, and 187%, respectively. These results provide further affirmation of the notable influence of processed oil on G*/sin δ values, an effect primarily attributed to its impact on the viscosity of asphalt binders.

Figure 6.

Effect of SIS concentration on G*/sin δ values of RTFO-aged PG 64-22 binder modified with 6% and 12% processed oil at 82 °C.

Table 7 presents the noteworthy variations in G*/sin δ observed under short-term-aged conditions, resulting from adjustments in the content of SIS and processed oil. The results demonstrate that the inclusion of SIS in both modified binders containing 6% and 12% processed oil yielded significant changes. These findings underscore the influence of SIS on the viscoelastic properties of asphalt binders, as well as its capacity to improve resistance against rutting at elevated temperatures.

Table 7.

G*/sin δ values data analysis of short-term-aged PG 64-22, modified with processed oil and SIS (α = 0.05).

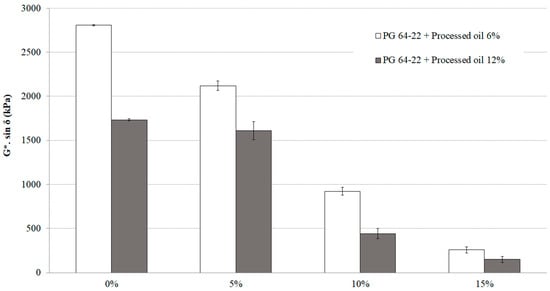

3.3. Fatigue Cracking

Figure 7 depicts the test results and values of G*sin δ for asphalt binders modified with 6% and 12% processed oil after long-term aging (RTFO+PAV), as observed from the DSR test. G* represents stiffness, while δ indicates the viscoelasticity of the binder. All binders containing 0%, 5%, 10%, and 15% SIS were tested at 25 ℃ to investigate the fatigue cracking resistance. For the asphalt binder modified with 6% concentration of processed oil and 5%, 10%, and 15% concentrations of SIS, a decrease was observed in the values of G* sin δ of 25%, 56%, and 72%, respectively. On the other hand, the asphalt binder modified with 12% processed oil and the same contents of SIS showed a more severe reduction in values of G* sin δ. These reductions were 7%, 72%, and 66%, for 5%, 10% and 15% of SIS, respectively. These results demonstrate the impact of processed oil as a co-modifier alongside SIS; it reduces G* sin δ values and improves fatigue cracking resistance.

Figure 7.

G*sin δ values of PG 64-22 binder modified with processed oil as a function of SIS content at 25 °C and long-term aging with RTFO + PAV.

The data analysis of changes in fatigue cracking resistance of modified asphalt binders containing 6% processed oil and 12% processed oil and 0%, 5%, 10%, and 15% SIS is presented in Table 8. The obtained values show that the application of SIS as modifier in conjunction with processed oil as co-modifier enhanced the fatigue cracking resistance of both modified asphalt binders significantly, regardless of the percentage of content.

Table 8.

Analysis of G*sin δ values for PG 64-22 modified with processed oil and SIS after long-term aging with RTFO+PAV (α = 0.05).

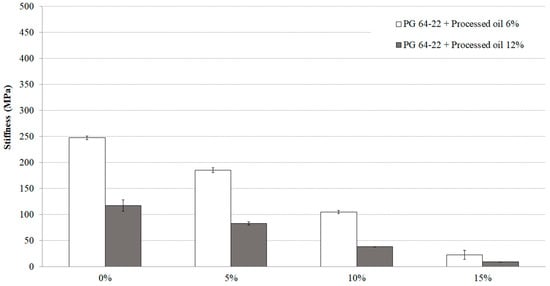

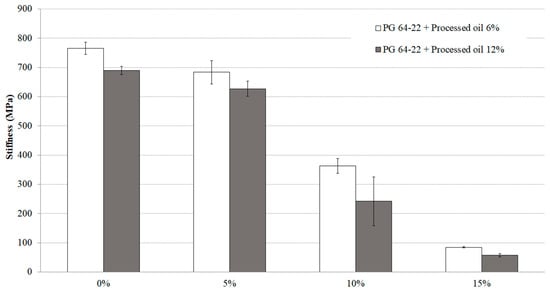

3.4. Thermal Cracking Resistance and Characteristics

To comply with the specifications of Superpave asphalt binders, the maximum permitted value of creep stiffness for asphalt binders is 300 MPa. Lower stiffness values are desirable to reduce tensile stress in the asphalt binder. The BBR tests were performed at temperatures of −12 °C and −24 °C on modified asphalt binders. These binders consisted of 6% processed oil and 12% processed oil, incorporating SIS contents of 0%, 5%, 10%, and 15%. Figure 8 and Figure 9 illustrate the stiffness values of the asphalt binders at −12 °C and −24 °C. The stiffness values obtained from the BBR test for the asphalt binder modified with 6% processed oil, with varying SIS contents (0%, 5%, 10%, and 15%), were 247 MPa, 185 MPa, 105 MPa, and 22 MPa, respectively. Similarly, for the asphalt binders modified with 12% processed oil, at the same temperature and SIS contents, the stiffness values were recorded as 117 MPa, 83 MPa, 38 MPa, and 9.8 MPa, respectively.

Figure 8.

Effect of SIS content on stiffness of RTFO+PAV-aged PG 64-22 binders containing 6% and 12% processed oil at −12 °C.

Figure 9.

Effect of SIS content on stiffness of RTFO+PAV-aged PG 64-22 binders containing 6% and 12% processed oil at −24 °C.

The influence of SIS and processed oil content on the stiffness values of modified asphalt binders containing 6% and 12% processed oil was examined at −24 °C. The results of the study demonstrate the notable impact of incorporating SIS and processed oil on the stiffness values. Specifically, for the asphalt binder modified with 6% processed oil, the stiffness values at 0%, 5%, 10%, and 15% SIS content were 765 MPa, 683 MPa, 363 MPa, and 84 MPa, respectively. Similarly, the stiffness values for the asphalt binder modified with 12% processed oil, with the same SIS contents, were determined to be 690 MPa, 627 MPa, 242 MPa, and 57 MPa, respectively. These findings indicate that the inclusion of SIS and processed oil in modified asphalt binders enhances their resistance to low-temperature cracking.

Table 9 and Table 10 display the data analysis and significance and non-significance of changes in matter for binders modified with 6% and 12% processed oil, with varying concentrations of SIS (0%, 5%, 10%, and 15%). It is notable that the inclusion of SIS in the modified binders that contain processed oil results in a significant effect at both −12 °C and −24 °C. The only instance where a change was found to be non-significant was in the modified binder that contained 12% processed oil and 5% SIS, as compared to 0%, at −24 °C.

Table 9.

Statistical analysis of the effect of SIS content on stiffness of PG 64-22 modified with 6% and 12% processed oil after long-term aging at −12 °C (α = 0.05).

Table 10.

Statistical analysis of the effect of SIS content on stiffness of modified PG 64-22 with 6% and 12% processed oil after long-term aging, at −24 °C (α = 0.05).

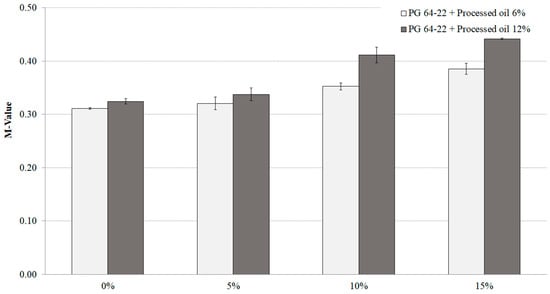

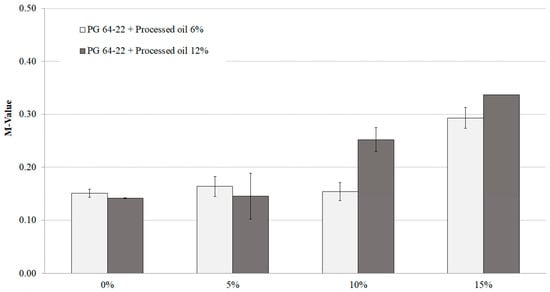

Figure 10 and Figure 11 depict the m-values for asphalt binders modified with 6% processed oil and 12% processed oil at −12 °C and −24 °C. The processed oil contained SIS in varying percentages of 0, 5, 10, and 15%. The addition of SIS did not cause a significant increase in the m-values of either of the modified asphalt binders. For the asphalt binder modified with 6% processed oil, the m-values at −12 °C were 0.311, 0.32, 0.352, and 0.385 at SIS concentrations of 0, 5, 10, and 15%, respectively. The asphalt binder modified with 12% processed oil showed increases in m-values of 0.325, 0.337, 0.411, and 0.442 at SIS concentrations 0, 5, 10, and 15%, respectively. At −24 °C, the m-values for the asphalt binder modified with a processed oil content of 6% and SIS concentrations of 0, 5, 10, and 15% were 0.15, 0.163, 0.154, and 0.293, respectively. The asphalt binder modified with 12% processed oil had m-values of 0.141, 0.145, 0.252, and 0.337, respectively, at the same temperature.

Figure 10.

Impact of SIS content on m-values of long-term-aged PG 64-22 binders, modified with 6% processed oil and 12% processed oil, at the temperature of −12 °C.

Figure 11.

Effect of SIS content on m-values of long-term-aged PG 64-22 binders, modified with 6% processed oil and 12% processed oil, at the temperature of −24 °C.

The inclusion of processed oil in combination with SIS has a direct impact on the effectiveness of modified asphalt binders. The high penetration rate of processed oil and the resulting improvements in viscosity and viscoelasticity are the main factors contributing to the observed trends in the m-values of both modified asphalt binders.

Table 11 and Table 12 depict the m-values of asphalt binders modified with varying levels of SIS at −12 °C and −24 °C. The introduction of 10% and 15% SIS as a modifier resulted in noticeable changes at −12 °C for asphalt binders modified with both 6% processed oil and 12% processed oil. At −24 °C, significant changes were observed in the modified asphalt binders with added SIS, except for the binder containing 5% SIS.

Table 11.

Data analysis results of the impact of SIS content on m-values of PG 64-22 modified with 6% processed oil and 12% processed oil after long-term aging, at −12 °C (α = 0.05).

Table 12.

Data analysis results of the impact of SIS content on m-values of PG 64-22 modified with 6% and 12% processed oil at long-term aging with RTFO+PAV, at −24 °C (α = 0.05).

4. Conclusions

To study the impact of processed oil and SIS on the characteristics of modified asphalt binder at three states of aging, including original, short-term, and long-term, mechanical tests and other rheology experiments were performed. Various tests, such as rotational viscosity, DSR, and BBR, were performed to assess the characteristics of modified asphalt binders in their different aging states. The outcomes of the research shed light on the combination of processed oil and SIS, resulting in the following deductions:

- Although the addition of SIS increases viscosity, the presence of processed oil as a co-modifier leads to a substantial improvement in viscosity values. The modified asphalt binders containing 12% processed oil exhibit a more considerable reduction in viscosity for all SIS contents (5%, 10%, and 15%) when contrasted with the 6% processed oil modification.

- DSR testing revealed that the inclusion of processed oil mitigates the negative impact of SIS and enhances both viscosity and rutting performance at high temperatures. A decrease in G*/sin δ values was observed in modified asphalt binders at original and short-term (RTFO) aging states, which provides evidence of the positive effects of co-modification using processed oil and SIS.

- Values extracted from DSR, and evaluation of fatigue cracking tests showed a significant decrease due to addition of processed oil and SIS. The addition of processed oil had a positive effect on the viscosity and viscoelasticity of long-term-aged asphalt and its rejuvenating. Therefore, the application of processed oil along with SIS showed effectiveness in improving the resistance against fatigue cracking.

- The results of the BBR test indicated that the incorporation of processed oil and SIS caused a significant reduction in stiffness of asphalt binder modified with different contents of processed oil and SIS, while the same positive effect of this conjugation was observed in m-values. These results show the important role of processed oil in viscoelasticity of asphalt binders.

- Simultaneous application of processed oil and SIS had a positive effect on the resistance of asphalt binders at high and low temperatures, which shows how processed oil can be effective as a co-modifier in mixture design. It is desirable to study the impact of processed oil in conjunction with other modifiers such as SBS, CRM, SBR, and other common ones.

Author Contributions

Conceptualization, S.-J.L.; Validation, S.-J.L.; Resources, M.-S.L.; Writing—original draft, N.H. and J.Y.; Writing—review & editing, M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by a grant from a government funding project (2023 National Highway Pavement Management System).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are included within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kriz, P.; Stastna, J.; Zanzotto, L. Glass transition and phase stability in asphalt binders. Road Mater. Pavement Des. 2008, 9 (Suppl. S1), 37–65. [Google Scholar] [CrossRef]

- Wang, J.; Sun, J.; Luo, S.; Li, Q. Laboratory and Field Performance Evaluation of High-Workability Ultra-Thin Asphalt Overlays. Materials 2022, 15, 2123. [Google Scholar] [CrossRef] [PubMed]

- Tabatabaee, H.A.; Velasquez, R.; Bahia, H.U. Predicting low temperature physical hardening in asphalt binders. Constr. Build. Mater. 2012, 34, 162–169. [Google Scholar] [CrossRef]

- Corbett, L.W.; Schweyer, H.E. Composition and Rheology Considerations in Age Hardening of Bitumen. Available online: https://trid.trb.org/view/725873 (accessed on 13 March 2023).

- Ou, L.; Zhu, H.; Xu, Y.; Chen, R.; Yang, X. Gray correlation entropy analysis of zero shear viscosity and high-temperature rheological parameters of phosphogypsum-modified asphalt. Case Stud. Constr. Mater. 2022, 17, e01448. [Google Scholar] [CrossRef]

- Hemmati, N.; Vigneswaran, S.; Mazumder, M.; Lee, M.S.; Lee, S.J. Laboratory Assessment of Modified Asphalt Binders Using Crumb Rubber Modifier (CRM) and Processed Oil. Constr. Mater. 2023, 3, 93–109. [Google Scholar] [CrossRef]

- Diab, A.; You, L.; Saboo, N.; Li, X. Appraising bitumen coverage, workability, and production temperatures of warm asphalt-aggregate blends. Road Mater. Pavement Des. 2022, 24, 1793–1819. [Google Scholar] [CrossRef]

- Hemmati, N.; Vigneswaran, S.; Kim, H.H.; Lee, M.S.; Lee, S.J. Laboratory Evaluation of Asphalt Binders Containing Styrene-Butadiene-Styrene (SBS) and Processed Oil. Materials 2023, 16, 1235. [Google Scholar] [CrossRef] [PubMed]

- Ameri, M.; Abdipour, S.V.; Yengejeh, A.R.; Shahsavari, M.; Yousefi, A.A. Evaluation of rubberised asphalt mixture including natural Zeolite as a warm mix asphalt (WMA) additive. Int. J. Pavement Eng. 2022, 1–12. [Google Scholar] [CrossRef]

- Ji, B.; Lee, S.J.; Mazumder, M.; Lee, M.S.; Kim, H.H. Deep regression prediction of rheological properties of SIS-modified asphalt binders. Materials 2020, 13, 5738. [Google Scholar] [CrossRef] [PubMed]

- Mazumder, M.; Siddique, A.; Ahmed, R.; Lee, S.J.; Lee, M.S. Rheological and Morphological Characterization of Styrene-Isoprene-Styrene (SIS) Modified Asphalt Binder. Adv. Civ. Eng. 2020, 2020, 8877371. [Google Scholar] [CrossRef]

- Zhao, R.; Jing, F.; Li, C.; Wang, R.; Xi, Z.; Cai, J.; Wang, Q.; Xie, H. Viscosity-curing time behavior, viscoelastic properties, and phase separation of graphene oxide/epoxy asphalt composites. Polym. Compos. 2022, 43, 5454–5464. [Google Scholar] [CrossRef]

- Halle, M.; Rukavina, T.; Domitrovic, J. Influence of temperature on asphalt stiffness modulus. In Proceedings of the 5th Eurasphalt Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012; pp. 13–15. [Google Scholar]

- Yan, S.; Dong, Q.; Chen, X.; Zhou, C.; Dong, S.; Gu, X. Application of waste oil in asphalt rejuvenation and modification: A comprehensive review. Constr. Build. Mater. 2022, 340, 127784. [Google Scholar] [CrossRef]

- Borhan, M.N.; Suja, F.; Ismail, A.; Rahmat RA, O.K. The effects of used cylinder oil on asphalt mixes. Eur. J. Sci. Res. 2009, 28, 398–411. Available online: http://www.eurojournals.com/ejsr.htm (accessed on 1 January 2009).

- Woszuk, A.; Wróbel, M.; Franus, W. Influence of waste engine oil addition on the properties of zeolite-foamed asphalt. Materials 2019, 12, 2265. [Google Scholar] [CrossRef] [PubMed]

- Sonibare, K.; Rucker, G.; Zhang, L. Molecular dynamics simulation on vegetable oil modified model asphalt. Constr. Build. Mater. 2021, 270, 121687. [Google Scholar] [CrossRef]

- Shoukat, T.; Yoo, P.J. Rheology of asphalt binder modified with 5W30 viscosity grade waste engine oil. Appl. Sci. 2018, 8, 1194. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, K. Review on performance of asphalt and asphalt mixture with waste cooking oil. Materials 2023, 16, 1341. [Google Scholar] [CrossRef] [PubMed]

- Asphalt Institute. Individual Asphalt Binder Tests; Asphalt Institute: Lexington, KY, USA, 2003; Available online: https://interstatetesting.com/binder-lab/ (accessed on 19 November 2021).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).