Investigating the Readiness Factors for Industry 4.0 Implementation for Manufacturing Industry in Egypt

Abstract

1. Introduction

2. Literature Review

3. Research Problem

4. Research Method

- H1: Readiness factors of I4.0 implementation change from males to females.

- H2: As age groups change, readiness factors of I4.0 implementation change.

- H3: Readiness factors of I4.0 implementation change among different sectors.

- H4: There is a significant difference in readiness factors of I4.0 implementation among different numbers of employees.

5. Results and Findings

5.1. T-Test and ANOVA Test

5.2. Data Testing Using Validity and Reliability for the Research Variables

5.3. Principal Component Analysis

5.4. Readiness Factor Importance According to the Mean Values

5.5. Development of SSIM for I4.0 Techniques

- A forward relationship with the sign V is said to exist if factor i is noticed to lead to factor j.

- Conversely, if j is found to lead to factor i, it is a backward relationship, which takes the symbol A.

- If factors i and j interact, it is referred to as a mutual relationship and is denoted by the letter X.

- No relationship, denoted by the sign O, is the case if factors i and j are unrelated to one another.

5.6. Development of the Initial Reachability Matrix for Assessment of Readiness Factors That Affect I4.0 Implementation

- The (i, j) value in the reachability matrix will be 1 and the (j, i) value will change to 0 if the entry of (i, j) in the SSIM is “V”.

- The binary matrix value of (i, j) becomes 0 and the value of (j, i) becomes 1 if the entry of (i, j) in the SSIM is “A”.

- The values of (i, j) and (j, i) in the reachability matrix will both be 1 if the entry of (i and j) in the SSIM is “X”.

- The binary matrix values for (i, j) and (j, i) become 0 if the entry for (i, j) in the SSIM is “O”.

| LK | SF | DWI | CWET | MSL | AM | FS | Com | SCMC | CFI | Sus | SO | GSP | CT | L | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LK | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| SF | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| DWI | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| CWET | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| MSL | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| AM | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| FS | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Com | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| SCMC | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 |

| CFI | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Sus | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

| SO | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 |

| GSP | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 |

| CT | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 |

| L | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 |

5.7. Development of the Final Reachability Matrix for Assessment of Readiness Factors That Affect I4.0 Implementation

5.8. Level Partition for Assessment of Readiness Factors That Affect I4.0 Implementation

5.9. Development of the Digraph and ISM for Assessment of Readiness Factors That Affect I4.0 Implementation

5.10. AHP Analysis per Sector

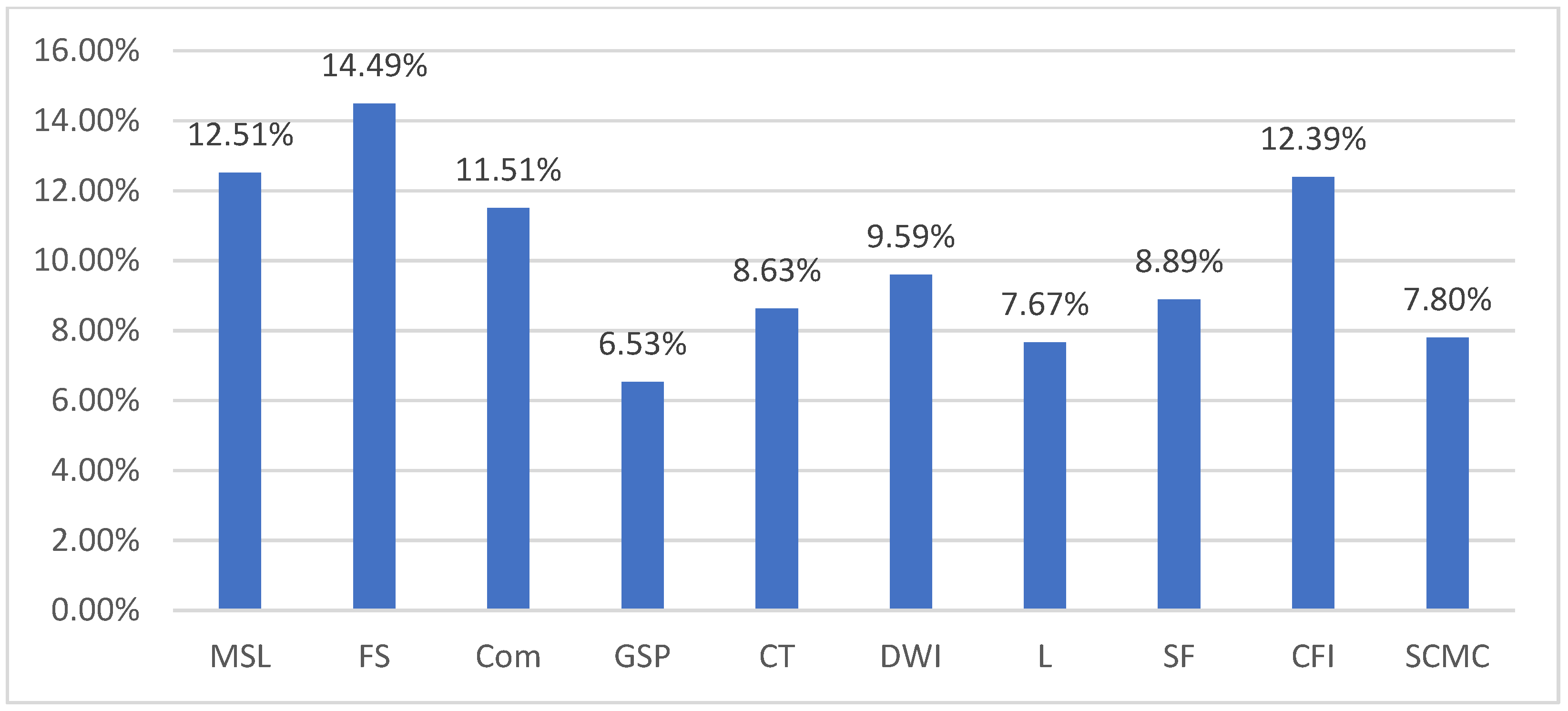

5.10.1. Food Sector

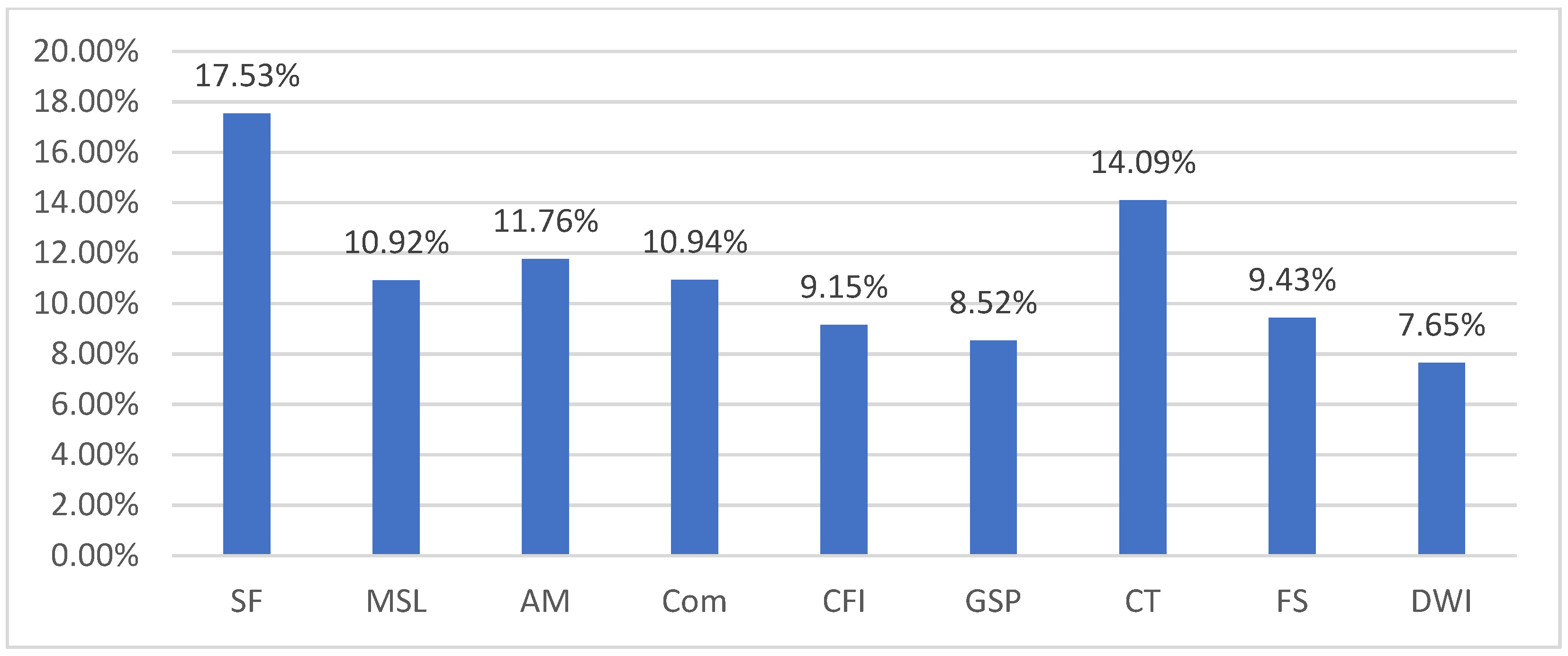

5.10.2. Automotive and Spare Parts Sector

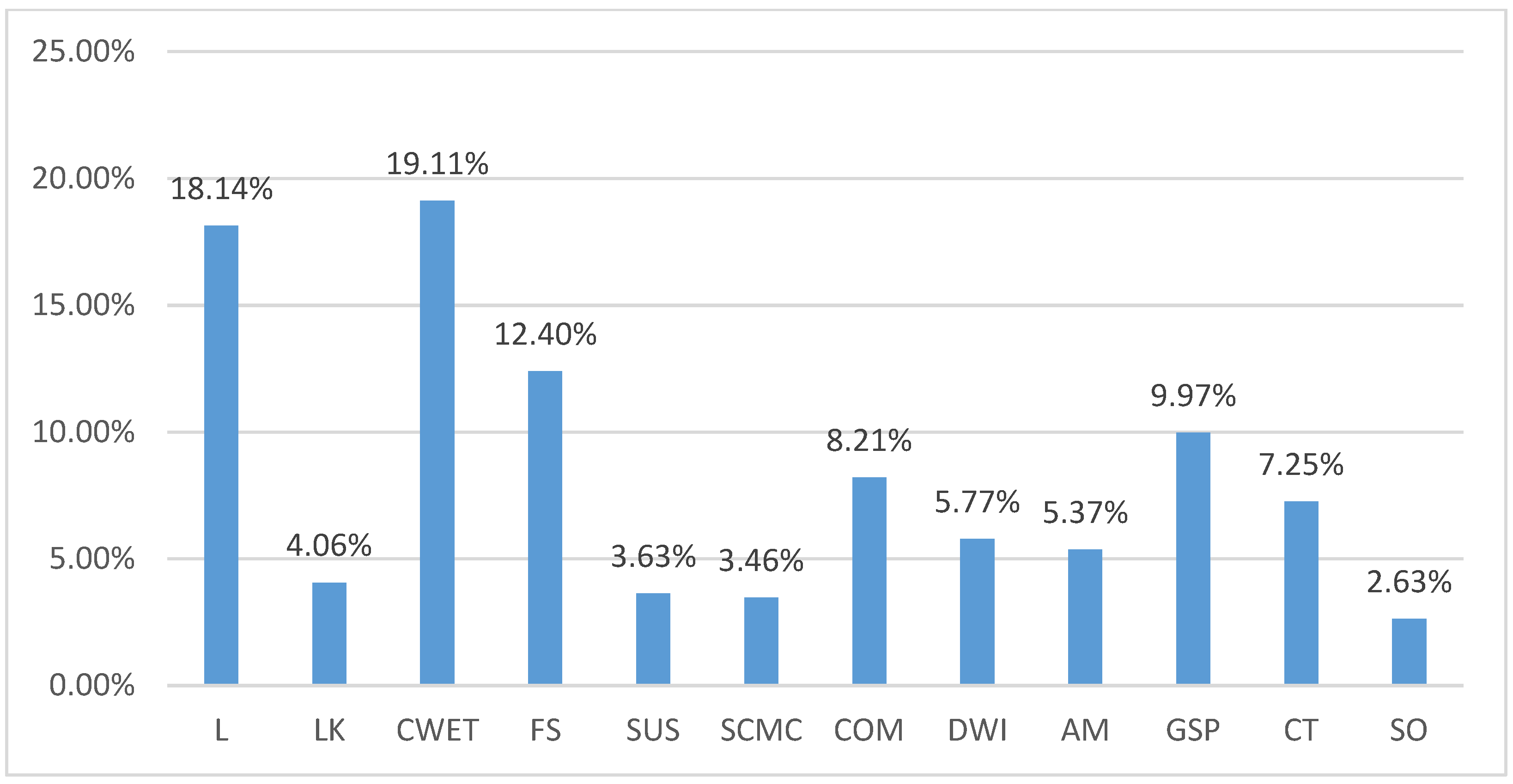

5.10.3. Iron and Steel Sector

5.10.4. Pharma Sector

5.10.5. Oil/Gas Sector

5.10.6. Chemical Sector

5.10.7. Electronics and Electrics Sector

6. Conclusions

7. Theoretical and Practical Contribution

8. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tortorella, G.L.; Giglio, R.; van Dun, D.H. Industry 4.0 implementation as a moderator of the impact of lean production practices on operational performance improvement. Int. J. Oper. Prod. Manag. 2019, 39, 860–886. [Google Scholar] [CrossRef]

- Kannan, K.S.P.N.; Garad, A. Competencies of quality professionals in the era of industry 4.0: A case study of electronics manufacturer from Malaysia. Int. J. Qual. Reliab. Manag. 2021, 38, 839–887. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2019, 58, 7543. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0–a glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Tang, Y.; Huang, J.; Pedrycz, W.; Li, B.; Ren, F. A Fuzzy Clustering Validity Index Induced by Triple Center Relation. IEEE Trans. Cybern. 2023, 1–13. [Google Scholar] [CrossRef]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T.S. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Varela, L.; Araujo, A.; Avila, P.; Castro, H.; Putnik, G. Evaluation of the relation between lean manufacturing, industry 4.0, and sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P. and Da Silva, E.H.D.R. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Acioli, C.; Da Cunha Reis, A.; Scavarda, A. Applying Industry 4.0 technologies in the COVID–19 sustainable chains. Int. J. Product. Perform. Manag. 2021, 70, 988–1016. [Google Scholar] [CrossRef]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 technologies on Lean principles. Int. J. Prod. Res. 2020, 58, 1644–1661. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fettermann, D. Implementation of Industry 4.0 and lean production in Brazilian manufacturing companies. Int. J. Prod. Res. 2018, 56, 2975–2987. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.S.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Change 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Sanders, A.; Elangeswaran, C.; Wulfsberg, J. Industry 4.0 implies lean manufacturing: Research activities in industry 4.0 function as enablers for lean manufacturing. J. Ind. Eng. Manag. 2016, 9, 811–833. [Google Scholar] [CrossRef]

- Sanders, A.; Subramanian, K.; Redlich, T.; Wulfsberg, J. Industry 4.0 and lean management: Synergy or contradiction? In Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing, Proceedings of IFIP International Conference on Advances in Production Management Systems, Hamburg, Germany, 3–7 September 2017; Springer: Cham, Switzerland, 2017; pp. 341–349. [Google Scholar]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Fatorachian, H.; Kazemi, H. A Critical Investigation of Industry 4.0 in Manufacturing: Theoretical Operationalisation Framework. Prod. Plan. Control 2018, 29, 633–644. [Google Scholar] [CrossRef]

- Fettermann, D.C.; Cavalcante, C.; Almeida, T.; Tortorella, G.L. How Does Industry 4.0 Contribute to Operations Management? J. Ind. Prod. Eng. 2018, 35, 255–268. [Google Scholar] [CrossRef]

- Santos, P.H.A.; Martins, R.A. Continuous Improvement Programs and Industry 4.0: Descriptive Bibliometric Analysis. In Proceedings of the 4th ICQEM Conference, Braga, Portugal, 21–22 September 2020. [Google Scholar]

- Frederico, G.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, Maturity and Research Agenda. Supply Chain Manag. Int. J. 2020, 25, 262–282. [Google Scholar] [CrossRef]

- Frederico, G.; Garza-Reyes, J.; Kumar, A.; Kumar, V. Performance measurement for supply chains in the industry 4.0 era: A balanced scorecard approach. Int. J. Product. Perform. Manag. 2021, 70, 789–807. [Google Scholar] [CrossRef]

- Grufman, N.; Lyons, S.; Sneiders, E. Exploring Readiness of SMEs for Industry 4.0. Complex Syst. Inform. Model. Q. 2021, 146, 54–86. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying the Current Trends and Future Perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; de Sousa Jabbour, A.B.L.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Sony, M. Pros and cons of implementing Industry 4.0 for the organizations: A review and synthesis of evidence. Prod. Manuf. Res. 2020, 8, 244–272. [Google Scholar] [CrossRef]

- Luthra, S.; Kumar, A.; Zavadskas, E.; Mangla, S.; Garza-Reyes, J. Industry 4.0 as an enabler of sustainability diffusion in supply chain: An analysis of influential strength of drivers in an emerging economy. Int. J. Prod. Res. 2020, 58, 1505–1521. [Google Scholar] [CrossRef]

- Ministry of Communications and Information Technology—(MCIT, 8 June 2021). Available online: https://mcit.gov.eg/en/Media_Center/Latest_News/News/63419 (accessed on 5 May 2022).

- Itida.gov. 1 April 2021. Available online: https://itida.gov.eg/English/PressReleases/Pages/MoU-to-Establish-the-1st-Industry-4.0-Innovation-Center-in-Egypt.asp1 (accessed on 5 May 2022).

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing industry 4.0 readiness in manufacturing: Evidence for the European union. Comput. Ind. 2019, 107, 22–32. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M. Corporate survival in Industry 4.0 era: The enabling role of lean-digitized manufacturing. J. Manuf. Technol. Manag. 2020, 31, 1–30. [Google Scholar] [CrossRef]

- Genesta, M.; Gamache, S. Prerequisites for the Implementation of Industry 4.0 in Manufacturing SMEs Marie Charbonneau. In Proceedings of the 30th International Conference on Flexible Automation and Intelligent Manufacturing (FAIM2021), Athens, Greece, 15–18 June 2021. [Google Scholar]

- Sriram, R.M.; Vinodh, S. Analysis of readiness factors for Industry 4.0 implementation in SMEs using COPRAS. Int. J. Qual. Reliab. Manag. 2021, 38, 1178–1192. [Google Scholar] [CrossRef]

- Peng, G.; Chen, S.; Chen, X.; Liu, C. An Investigation to the Industry 4.0 Readiness of Manufacturing Enterprises: The Ongoing Problems of Information Systems Strategic Misalignment. J. Glob. Inf. Manag. 2021, 29, 1–20. [Google Scholar] [CrossRef]

- Antony, J.; Sony, M.; McDermott, O. Conceptualizing Industry 4.0 readiness model dimensions: An exploratory sequential mixed-method study. TQM J. 2021, 35, 1754–2731. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Critical factors for the successful implementation of Industry 4.0: A review and future research direction. Prod. Plan. Control 2020, 31, 799–815. [Google Scholar] [CrossRef]

- Antony, J.; Sony, M.; McDermott, O.; Furterer, S.; Pepper, M. How does performance vary between early and late adopters of Industry 4.0? A qualitative viewpoint. Int. J. Qual. Reliab. Manag. 2023, 40, 1–24. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fogliatto, F.S.; Anzanello, M.J.; Vergara, A.M.C.; Vassolo, R.; Garza-Reyes, J.A. Modeling the impact of industry 4.0 base technologies on the development of organizational learning capabilities. Oper. Manag. Res. 2022. [Google Scholar] [CrossRef]

- Nimawat, D.; Gidwani, B.D. Causal interactions among essential factors of Industry 4.0 innovation using DEMATEL technique in manufacturing industries. Int. J. Innov. Sci. 2022, 14, 351–375. [Google Scholar] [CrossRef]

- Aggarwal, S.C.; Goldar, B. Structure and growth of employment: Evidence from India KLEMS data. Indian Growth Dev. Rev. 2019, 12, 202–228. [Google Scholar] [CrossRef]

- Zhou, Y.; Lu, L.; Shaikh, G.M. Evaluating and prioritizing the green supply chain management practices in Pakistan: Based on Delphi and fuzzy AHP approach. Symmetry 2019, 11, 1346. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between Industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020. ahead-of-print. [Google Scholar] [CrossRef]

- Savastano, M.; Amendola, C.; Bellini, F.; D’Ascenzo, F. Contextual impacts on industrial processes brought by the digital transformation of manufacturing: A systematic review. Sustainability 2019, 11, 891. [Google Scholar] [CrossRef]

- Zhang, L. A fine-grained task scheduling mechanism for digital economy services based on intelligent edge and cloud computing. J. Cloud. Comp. 2023, 12, 30. [Google Scholar] [CrossRef]

- Wan, J.; Yi, M.; Li, D.; Zhang, C.; Wang, S. Mobile Services for Customization Manufacturing Systems: An Example of Industry 4.0. IEEE Access 2016, 4, 8977–8986. [Google Scholar] [CrossRef]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and Managerial Challenges in the Path towards Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]

- Teh, S.S.; Kee, D.M.H. The readiness of small and medium enterprises for the industrial revolution 4.0. Glob. J. Bus. Soc. Sci. Rev. 2019, 7, 217–223. [Google Scholar] [CrossRef] [PubMed]

- Jabbour, A.B.L.S.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Trstenjak, M.; Lisjak, D.; Opetuk, T.; Pavkovic, D. Application of multi criteria decision making methods for readiness factor calculation. In Proceedings of the IEEE EUROCON 2019-18th International Conference on Smart Technologies, Novi Sad, Serbia, 1–4 July 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Safar, L.; Sopko, J.; Bednar, S.; Poklemba, R. Concept of SME business model for industry 4.0 environment. TEM J. 2018, 7, 626. [Google Scholar]

- Widayani, A.; Astuti, E.S.; Saifi, M. Competence and readiness of small and medium industries against of industrial revolution 4.0. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 485, No. 1; p. 012114. [Google Scholar]

- Truvé, T.; Wallin, M.; Ryfors, D. Swedish Manufacturing SMEs Readiness for Industry 4.0: What Factors Influence an Implementation of Artificial Intelligence and How Ready Are Manufacturing SMEs in Sweden? Bachelor Thesis, Jonoping University, Jönköping, Sweden, 2019. Available online: https://www.diva-portal.org/smash/get/diva2:1321698/FULLTEXT01.pdf (accessed on 1 October 2022).

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and Supply Chain Sustainability: Framework and Future Research Directions. Benchmarking Int. J. 2018, 28, 1410–1450. [Google Scholar] [CrossRef]

- Stentoft, J.; Jensen, K.W.; Philipsen, K.; Haug, A. Drivers and barriers for industry 4.0 readiness and practice: A SME perspective with empirical evidence. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Maui, HI, USA, 8–11 January 2019. [Google Scholar]

- Nair, J.; Chellasamy, A.; Singh, B.N.B. Readiness factors for information technology adoption in SMEs: Testing an exploratory model in an Indian context. J. Asia Bus. Stud. 2019, 13, 694–718. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing and Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Bär, K.; Herbert-Hansen, Z.N.L.; Khalid, W. Considering Industry 4.0 aspects in the supply chain for an SME. Prod. Eng. 2018, 12, 747–758. [Google Scholar] [CrossRef]

- Zaidi, M.F.A.; Belal, H.M. A preliminary study to understand the SMEs’ readiness on IoT in Malaysia. Int. J. Account. Financ. Bus. IJAFB 2019, 4, 1–12. [Google Scholar]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune Favors the Prepared: How SMEs Approach Business Model Innovations in Industry 4.0. Technol. Forecast. Soc. Change 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Bonilla, S.; Silva, H.; Silva, M.; Gonçalves, R.; Sacomano, J. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Palminder, S. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Yin, R. Qualitative Research from Start to Finish; Guilford Publications: New York, NY, USA, 2015. [Google Scholar]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 7th ed.; Financial Times, Prentice Hall: Harlow, UK, 2016. [Google Scholar]

- Sekaran, U.; Bougie, R. Research Methods for Business a Skill-Building Approach, 6th ed.; Wiley: New York, NY, USA, 2013. [Google Scholar]

- Jolliffe, I.T.; Cadima, J. Principal Component Analysis: A review and recent developments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef]

- Rajbhandari, S.; Devkota, N.; Khanal, G.; Mahato, S.; Raj Paudel, U. Assessing the industrial readiness for adoption of industry 4.0 in Nepal: A structural equation model analysis. Heliyon 2022, 8, e08919. [Google Scholar] [CrossRef]

- Nick, G.; Kovács, T.; Kő, A.; Kádár, B. Industry 4.0 readiness in manufacturing: Company Compass 2.0, a renewed framework and solution for Industry 4.0 maturity assessment. Procedia Manuf. 2021, 54, 39–44. [Google Scholar] [CrossRef]

- Kamigaki, T. Object-Oriented RFID with IoT: A Design Concept of Information Systems in Manufacturing. Electronics 2017, 6, 14. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Fogliatto, F.S.; Cauchick-Miguel, P.A.; Kurnia, S.; Jurburg, D. Integration of Industry 4.0 technologies into Total Productive Maintenance practices. Int. J. Prod. Econ. 2021, 240, 108224. [Google Scholar] [CrossRef]

- Babiceanu, R.F.; Seker, R. Big Data and virtualization for manufacturing cyber-physical systems: A survey of the current status and future outlook. Comput. Ind. 2016, 81, 128–137. [Google Scholar] [CrossRef]

- Alaba, F.A.; Othman, M.; Hashem, I.A.T.; Alotaibi, F. Internet of things security: A survey. J. Netw. Comput. Appl. 2017, 88, 10–28. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Comput. Ind. 2018, 101, 107–119. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Piyathanavong, V.; Huynh, V.N.; Karnjana, J.; Olapiriyakul, S. Role of project management on Sustainable Supply Chain development through Industry 4.0 technologies and Circular Economy during the COVID-19 pandemic: A multiple case study of Thai metals industry. Oper. Manag. Res. 2022. [Google Scholar] [CrossRef]

- Bonczek, R.H.; Holsapple, C.W.; Whinston, A.B. Foundations of Decision Support Systems; Academic Press: New York, NY, USA, 2014. [Google Scholar]

- Kolberg, D.; Knobloch, J.; Zühlke, D. Towards a lean automation interface for workstations. Int. J. Prod. Res. 2017, 55, 2845–2856. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Strange, R.; Zucchella, A. Industry 4.0, global value chains and international business. Multinatl. Bus. Rev. 2017, 25, 174–184. [Google Scholar] [CrossRef]

- Reischauer, G. Industry 4.0 as policy-driven discourse to institutionalize innovation systems in manufacturing. Technol. Forecast. Soc. Change 2018, 132, 26–33. [Google Scholar] [CrossRef]

- Schiele, H.; Bos-Nehles, A.; Delke, V.; Stegmaier, P.; Torn, R.J. Interpreting the industry 4.0 future: Technology, business, society and people. J. Bus. Strategy 2022, 43, 157–167. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Aslam, F.; Aimin, W.; Li, M.; Ur Rehman, K. Innovation in the era of IoT and industry 5.0: Absolute innovation management (AIM) framework. Information 2020, 11, 124. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Zizic, M.C.; Mladineo, M.; Gjeldum, N.; Celent, L. From Industry 4.0 towards Industry 5.0: A Review and Analysis of Paradigm Shift for the People, Organization and Technology. Energies 2022, 15, 5221. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Industry 5.0 and its expected applications in medical field. J. Curr. Med. Res. Pract. 2019, 9, 167–169. [Google Scholar] [CrossRef]

- Sherburne, C. Textile industry 5.0? Fiber computing coming soon to a fabric near you. AATCC Rev. 2020, 20, 25–30. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Haq, M.I.U.; Raina, A.; Suman, R. Industry 5.0: Potential applications in COVID-19. J. Ind. Integr. Manag. 2020, 5, 507–530. [Google Scholar] [CrossRef]

| Readiness Factor | Description | Reference |

|---|---|---|

| 1. Level of knowledge “Comfortability of technology use” |

| [21,25,30,43,44,45,46] |

| 2. Smart factory “Development of infrastructure and IT-based facilities” |

| [21,25,47,48] |

| 3. Hardware and software connection | Because most industries, particularly those in developing nations, lack advanced technology, it is important to have a communication infrastructure that can handle high data traffic. | [25,30,43,45,49] |

| 4. Dealing with insecurity |

| [21,50] |

| 5. Compatibility with existing technology | Technology from the past and present must be able to coexist without any issues. | [28,51] |

| 6. Management support and leadership “Business strategies” | The organization’s top management is expected to offer a strategy to make sure that the goals of the company are compatible with the implementation of new technologies. | [25,30,47,52,53,54] |

| 7. Agility in manufacturing | Flexibility in output quantity and product variety. | [30,48,49] |

| 8. Financial support |

| [21,30,50,54] |

| 9. Competitiveness | Companies may decide to move forward with the implementation of breakthrough technologies under the influence of competition or pressure from business partners. | [25,51] |

| 10. Global engagement | Global connections can aid with a better understanding of the challenges faced by enterprises on their digital journey. | [48,55] |

| 11. Supply-chain management and collaboration | Excellent cooperation and connectedness throughout the entire flow. | [56] |

| Understanding of the advantages of technology is shared by both SC partners and employees. | [9,40] | |

| Senior management involvement in decision-making for sustainable SC management techniques using I4.0. | [9,39] | |

| Considering both economic and environmental considerations when implementing industrial strategy. | [9,41] | |

| Concern over the decline of employment possibilities and the workforce. | [9,38] | |

| 12. Customer-focused innovativeness | Focusing on cutting-edge products and solutions based on client needs without sacrificing efficiency to uphold positive customer relationships | [51,55,57] |

| 13. Sustainability | To ensure a sustainable structure of production and consumption. | [58] |

| 14. Strategy and organization |

| [21] |

| [21] | |

| 15. Data-driven services |

| [21] |

| [21,30] | |

| 16. Government supportive policies |

| [25,52,59] |

| 17. Collaboration and transparency | Businesses need to foster excellent member coordination and collaboration. | [25,58] |

| 18. Lean | One of the initial actions that should be conducted in a firm before I4 should be continuous improvement. | [30,44] |

| Steps | Literature Review | Pilot Study | Questionnaire | Experts Session |

|---|---|---|---|---|

| Purpose | To investigate what makes the Egyptian industrial sector ready for the introduction of I4.0. | To test the reliability and validity of questionnaire. | To gather data regarding employees’ perception about each of the readiness factor within their factories for I4.0 implementation and to recognize the obstacles from participants’ point of view. | To rank the importance of each of the readiness factors obtained and determine their influential effect on each other. |

| Data source | Literature review on relevant literature to I4.0 in various industries especially manufacturing industry. | The data collected from 120 employees (by asking 2 or 3 employees at one company). | The data collected from 632 employees at Egyptian manufacturing organizations. | Thirty experts were considered in a session to fill in the matrix for SSIM modelling. |

| Outcome | 18 factors for implementation of I4.0. | Finding that the questionnaire is reliable and valid so distributed to the rest of companies. | Finding that the most crucial preparation elements for the implementation of I4.0 in Egypt are level of knowledge, financial support, and management support. | Readiness factors were ranked according to their importance and their influential effect considering their driving and independence powers. |

| Item | Frequency | Percentage | Total |

|---|---|---|---|

| Gender | |||

| Male | 519 | 82.1% | 632 |

| Female | 113 | 17.9% | |

| Age group | |||

| Less than 40 years | 395 | 62.5% | 632 |

| 40–less than 50 years | 157 | 24.8% | |

| 50–less than 60 years | 30 | 4.7% | |

| 60 years or more | 50 | 7.9% | |

| Sector | |||

| Food | 76 | 12.0% | 632 |

| Automotive and spare parts | 77 | 12.2% | |

| Iron and steel | 75 | 11.9% | |

| Pharma | 78 | 12.3% | |

| Oil/gas | 82 | 13.0% | |

| Chemical | 72 | 11.4% | |

| Electronics and electrics | 84 | 13.3% | |

| Other industries | 88 | 13.9% | |

| Number of employees | |||

| Between 0 and 9 employees | 178 | 28.2% | 632 |

| Between 10 and 49 employees | 345 | 54.6% | |

| Between 50 and 249 employees | 97 | 15.3% | |

| >250 employees | 12 | 1.9% | |

| Have you heard of the Industry 4.0 concept? | |||

| Yes | 484 | 76.6% | 632 |

| No | 148 | 23.4% | |

| 1. “Comfortability of technology use” |

| The IT team was ready for the new cloud computing technology |

| Hiring sufficient competent employees |

| Have development programs for the workforce |

| 2. Smart factory |

| Systems and machines can be virtually entirely controlled by IT and are totally integrated |

| Possess the ability and connectivity for high-speed internet |

| IT systems are integrated and assist all business processes |

| 3. Hardware and software connection |

| A communication network that can handle heavy data traffic |

| 4. Dealing with insecurity |

| Have a firewall for data security |

| Have a culture that prioritizes externalizing data privacy |

| For all pertinent sectors, IT security solutions have been put in place |

| Autonomous process is used in selected areas or even cross enterprise |

| 5. Compatibility with existing technology |

| The ability of new and old technology to merge |

| 6. Management support and leadership |

| The organization’s goals are ensured by top management’s plan |

| 7. Agility in manufacturing |

| Flexibility in terms of output volume and product diversity |

| 8. Financial support |

| Have multiple financial aids |

| Have financial capacity for cloud investments |

| Have well established strategy towards investing in I4.0 |

| 9. Competitiveness |

| Influence of rivalry and pressure from business partners on brand image |

| 10. Global engagement |

| Have connections across the globe |

| 11. Supply-chain management and collaboration |

| Have effective collaboration and connectivity throughout the process flow |

| Make sure that everyone in the SC, including the staff, is aware of the advantages of technology |

| Senior management uses I4.0 to engage in decision-making processes for sustainable SC management strategies |

| Include consideration of economic and environmental factors when implementing your industrial strategy |

| Being concerned about the decline in employment possibilities and labour force |

| 12. Customer-focused innovativeness |

| Concentrating on cutting-edge products and solutions based on client needs |

| 13. Sustainability |

| Organization is sustainable with existing operations |

| 14. Strategy and organization |

| An I4.0 strategy has been implemented |

| Innovation management has been established |

| 15. Data-driven services |

| The business model fully incorporates data-driven services. |

| More than 50% of collected data is used |

| 16. Government supportive policies |

| Have strong government support and policies |

| 17. Collaboration and transparency |

| Have strong coordination and collaboration among members |

| 18. Lean |

| Lean 4.0 elements support improvement in I4.0 theme |

| 19. Other obstacles that could hinder the I4.0 implementation |

| Gender | N | Mean | Std. Deviation | Std. Error Mean | Sig. | |

|---|---|---|---|---|---|---|

| LK | Male | 519 | 4.6763 | 0.63309 | 0.02779 | 0.412 |

| Female | 113 | 4.6991 | 0.59589 | 0.05606 | ||

| SF | Male | 519 | 3.7033 | 0.45725 | 0.02007 | 0.377 |

| Female | 113 | 3.6814 | 0.46800 | 0.04403 | ||

| HSC | Male | 519 | 2.0983 | 0.71388 | 0.03134 | 0.852 |

| Female | 113 | 2.0885 | 0.72651 | 0.06834 | ||

| DWI | Male | 519 | 4.5260 | 0.55472 | 0.02435 | 0.014 |

| Female | 113 | 4.6283 | 0.52090 | 0.04900 | ||

| CWET | Male | 519 | 3.7823 | 0.41310 | 0.01813 | 0.038 |

| Female | 113 | 3.7345 | 0.44356 | 0.04173 | ||

| MSL | Male | 519 | 4.4123 | 0.61788 | 0.02712 | 0.320 |

| Female | 113 | 4.5221 | 0.58397 | 0.05494 | ||

| AM | Male | 519 | 3.9017 | 0.29796 | 0.01308 | 0.953 |

| Female | 113 | 3.9027 | 0.29775 | 0.02801 | ||

| FS | Male | 519 | 4.6859 | 0.61167 | 0.02685 | 0.661 |

| Female | 113 | 4.6991 | 0.59589 | 0.05606 | ||

| COM | Male | 519 | 4.3738 | 0.60800 | 0.02669 | 0.030 |

| Female | 113 | 4.3717 | 0.68393 | 0.06434 | ||

| GL | Male | 519 | 2.1888 | 0.62678 | 0.02751 | 0.512 |

| Female | 113 | 2.1504 | 0.67110 | 0.06313 | ||

| SCMC | Male | 519 | 4.0366 | 0.65510 | 0.02876 | 0.561 |

| Female | 113 | 4.0354 | 0.68046 | 0.06401 | ||

| CFI | Male | 519 | 4.3738 | 0.71320 | 0.03131 | 0.619 |

| Female | 113 | 4.3097 | 0.70811 | 0.06661 | ||

| SUS | Male | 519 | 4.1503 | 0.35770 | 0.01570 | 0.000 |

| Female | 113 | 4.0796 | 0.27195 | 0.02558 | ||

| SO | Male | 519 | 4.1387 | 0.34600 | 0.01519 | 0.399 |

| Female | 113 | 4.1239 | 0.33093 | 0.03113 | ||

| DDS | Male | 519 | 2.0019 | 0.52541 | 0.02306 | 0.373 |

| Female | 113 | 2.0000 | 0.56695 | 0.05333 | ||

| GSP | Male | 519 | 4.3333 | 0.52234 | 0.02293 | 0.293 |

| Female | 113 | 4.3717 | 0.53776 | 0.05059 | ||

| CT | Male | 519 | 4.0443 | 0.63669 | 0.02795 | 0.358 |

| Female | 113 | 3.9912 | 0.61956 | 0.05828 | ||

| L | Male | 519 | 4.2254 | 0.47449 | 0.02083 | 0.009 |

| Female | 113 | 4.1593 | 0.43438 | 0.04086 |

| N | Mean | Std. Dev. | Std. Error | Significance | ||

|---|---|---|---|---|---|---|

| LK | Less than 40 years | 395 | 4.6684 | 0.63637 | 0.03202 | 0.537 |

| 40–less than 50 years | 157 | 4.6624 | 0.62588 | 0.04995 | ||

| 50–less than 60 years | 30 | 4.8000 | 0.55086 | 0.10057 | ||

| 60 years or more | 50 | 4.7600 | 0.59109 | 0.08359 | ||

| Total | 632 | 4.6804 | 0.62621 | 0.02491 | ||

| SF | Less than 40 years | 395 | 3.7063 | 0.45602 | 0.02294 | 0.178 |

| 40–less than 50 years | 157 | 3.7325 | 0.44408 | 0.03544 | ||

| 50–less than 60 years | 30 | 3.6333 | 0.49013 | 0.08949 | ||

| 60 years or more | 50 | 3.5800 | 0.49857 | 0.07051 | ||

| Total | 632 | 3.6994 | 0.45890 | 0.01825 | ||

| HSC | Less than 40 years | 395 | 2.0911 | 0.71375 | 0.03591 | 0.847 |

| 40–less than 50 years | 157 | 2.1338 | 0.72586 | 0.05793 | ||

| 50–less than 60 years | 30 | 2.0333 | 0.71840 | 0.13116 | ||

| 60 years or more | 50 | 2.0600 | 0.71171 | 0.10065 | ||

| Total | 632 | 2.0965 | 0.71559 | 0.02846 | ||

| DWI | Less than 40 years | 395 | 4.5494 | 0.54677 | 0.02751 | 0.759 |

| 40–less than 50 years | 157 | 4.5096 | 0.57309 | 0.04574 | ||

| 50–less than 60 years | 30 | 4.6000 | 0.56324 | 0.10283 | ||

| 60 years or more | 50 | 4.5800 | 0.49857 | 0.07051 | ||

| Total | 632 | 4.5443 | 0.54983 | 0.02187 | ||

| CWET | Less than 40 years | 395 | 3.7747 | 0.41832 | 0.02105 | 0.310 |

| 40–less than 50 years | 157 | 3.8089 | 0.39441 | 0.03148 | ||

| 50–less than 60 years | 30 | 3.7000 | 0.46609 | 0.08510 | ||

| 60 years or more | 50 | 3.7000 | 0.46291 | 0.06547 | ||

| Total | 632 | 3.7737 | 0.41874 | 0.01666 | ||

| MSL | Less than 40 years | 395 | 4.4329 | 0.60239 | 0.03031 | 0.637 |

| 40–less than 50 years | 157 | 4.3949 | 0.63809 | 0.05092 | ||

| 50–less than 60 years | 30 | 4.5333 | 0.62881 | 0.11480 | ||

| 60 years or more | 50 | 4.4800 | 0.61412 | 0.08685 | ||

| Total | 632 | 4.4320 | 0.61295 | 0.02438 | ||

| AM | Less than 40 years | 395 | 3.9013 | 0.29868 | 0.01503 | 0.524 |

| 40–less than 50 years | 157 | 3.9236 | 0.26654 | 0.02127 | ||

| 50–less than 60 years | 30 | 3.8667 | 0.34575 | 0.06312 | ||

| 60 years or more | 50 | 3.8600 | 0.35051 | 0.04957 | ||

| Total | 632 | 3.9019 | 0.29769 | 0.01184 | ||

| FS | Less than 40 years | 395 | 4.6785 | 0.61324 | 0.03086 | 0.580 |

| 40–less than 50 years | 157 | 4.6688 | 0.62418 | 0.04981 | ||

| 50–less than 60 years | 30 | 4.8000 | 0.55086 | 0.10057 | ||

| 60 years or more | 50 | 4.7600 | 0.55549 | 0.07856 | ||

| Total | 632 | 4.6883 | 0.60844 | 0.02420 | ||

| COM | Less than 40 years | 395 | 4.3772 | 0.61039 | 0.03071 | 0.522 |

| 40–less than 50 years | 157 | 4.3439 | 0.62750 | 0.05008 | ||

| 50–less than 60 years | 30 | 4.3000 | 0.65126 | 0.11890 | ||

| 60 years or more | 50 | 4.4800 | 0.67733 | 0.09579 | ||

| Total | 632 | 4.3734 | 0.62168 | 0.02473 | ||

| GL | Less than 40 years | 395 | 2.1848 | 0.62419 | 0.03141 | 0.731 |

| 40–less than 50 years | 157 | 2.2102 | 0.65076 | 0.05194 | ||

| 50–less than 60 years | 30 | 2.1000 | 0.66176 | 0.12082 | ||

| 60 years or more | 50 | 2.1200 | 0.65900 | 0.09320 | ||

| Total | 632 | 2.1820 | 0.63455 | 0.02524 | ||

| SCMC | Less than 40 years | 395 | 4.0532 | 0.64494 | 0.03245 | 0.737 |

| 40–less than 50 years | 157 | 4.0318 | 0.68332 | 0.05453 | ||

| 50–less than 60 years | 30 | 3.9667 | 0.66868 | 0.12208 | ||

| 60 years or more | 50 | 3.9600 | 0.69869 | 0.09881 | ||

| Total | 632 | 4.0364 | 0.65916 | 0.02622 | ||

| CFI | Less than 40 years | 395 | 4.3722 | 0.70942 | 0.03570 | 0.926 |

| 40–less than 50 years | 157 | 4.3567 | 0.71623 | 0.05716 | ||

| 50–less than 60 years | 30 | 4.3667 | 0.76489 | 0.13965 | ||

| 60 years or more | 50 | 4.3000 | 0.70711 | 0.10000 | ||

| Total | 632 | 4.3623 | 0.71216 | 0.02833 | ||

| SUS | Less than 40 years | 395 | 4.1570 | 0.36423 | 0.01833 | 0.214 |

| 40–less than 50 years | 157 | 4.1146 | 0.31962 | 0.02551 | ||

| 50–less than 60 years | 30 | 4.1333 | 0.34575 | 0.06312 | ||

| 60 years or more | 50 | 4.0600 | 0.23990 | 0.03393 | ||

| Total | 632 | 4.1377 | 0.34481 | 0.01372 | ||

| SO | Less than 40 years | 395 | 4.1367 | 0.34398 | 0.01731 | 0.420 |

| 40–less than 50 years | 157 | 4.1210 | 0.32719 | 0.02611 | ||

| 50–less than 60 years | 30 | 4.2333 | 0.43018 | 0.07854 | ||

| 60 years or more | 50 | 4.1200 | 0.32826 | 0.04642 | ||

| Total | 632 | 4.1361 | 0.34314 | 0.01365 | ||

| DDS | Less than 40 years | 395 | 1.9873 | 0.53539 | 0.02694 | 0.846 |

| 40–less than 50 years | 157 | 2.0191 | 0.52467 | 0.04187 | ||

| 50–less than 60 years | 30 | 2.0333 | 0.55605 | 0.10152 | ||

| 60 years or more | 50 | 2.0400 | 0.53299 | 0.07538 | ||

| Total | 632 | 2.0016 | 0.53261 | 0.02119 | ||

| GSP | Less than 40 years | 395 | 4.3722 | 0.51449 | 0.02589 | 0.093 |

| 40–less than 50 years | 157 | 4.2484 | 0.53895 | 0.04301 | ||

| 50–less than 60 years | 30 | 4.3667 | 0.55605 | 0.10152 | ||

| 60 years or more | 50 | 4.3600 | 0.52528 | 0.07429 | ||

| Total | 632 | 4.3402 | 0.52491 | 0.02088 | ||

| CT | Less than 40 years | 395 | 4.0177 | 0.62290 | 0.03134 | 0.657 |

| 40–less than 50 years | 157 | 4.0828 | 0.66950 | 0.05343 | ||

| 50–less than 60 years | 30 | 3.9667 | 0.61495 | 0.11227 | ||

| 60 years or more | 50 | 4.0600 | 0.61974 | 0.08764 | ||

| Total | 632 | 4.0348 | 0.63350 | 0.02520 | ||

| L | Less than 40 years | 395 | 4.2177 | 0.44856 | 0.02257 | 0.944 |

| 40–less than 50 years | 157 | 4.2166 | 0.52279 | 0.04172 | ||

| 50–less than 60 years | 30 | 4.1667 | 0.46113 | 0.08419 | ||

| 60 years or more | 50 | 4.2000 | 0.45175 | 0.06389 | ||

| Total | 632 | 4.2136 | 0.46793 | 0.01861 | ||

| N | Mean | Std. Dev. | Std. Error | p-Value | ||

|---|---|---|---|---|---|---|

| LK | Food | 76 | 4.6842 | 0.59353 | 0.06808 | 0.756 |

| Automotive and spare parts | 77 | 4.5974 | 0.69320 | 0.07900 | ||

| Iron and steel | 75 | 4.7600 | 0.56569 | 0.06532 | ||

| Pharma | 78 | 4.6795 | 0.61356 | 0.06947 | ||

| Oil/gas | 82 | 4.7073 | 0.61840 | 0.06829 | ||

| Chemical | 72 | 4.5972 | 0.70531 | 0.08312 | ||

| Electronics and electrics | 84 | 4.7024 | 0.63587 | 0.06938 | ||

| Other industries | 88 | 4.7045 | 0.59033 | 0.06293 | ||

| Total | 632 | 4.6804 | 0.62621 | 0.02491 | ||

| SF | Food | 76 | 3.7368 | 0.44327 | 0.05085 | 0.667 |

| Automotive and spare parts | 77 | 3.6883 | 0.46622 | 0.05313 | ||

| Iron and steel | 75 | 3.6667 | 0.47458 | 0.05480 | ||

| Pharma | 78 | 3.7051 | 0.45894 | 0.05196 | ||

| Oil/gas | 82 | 3.7073 | 0.45779 | 0.05055 | ||

| Chemical | 72 | 3.6806 | 0.46953 | 0.05534 | ||

| Electronics and electrics | 84 | 3.7738 | 0.42088 | 0.04592 | ||

| Other industries | 88 | 3.6364 | 0.48380 | 0.05157 | ||

| Total | 632 | 3.6994 | 0.45890 | 0.01825 | ||

| HSC | Food | 76 | 2.1184 | 0.76537 | 0.08779 | 0.830 |

| Automotive and spare parts | 77 | 2.1688 | 0.71456 | 0.08143 | ||

| Iron and steel | 75 | 2.1067 | 0.68917 | 0.07958 | ||

| Pharma | 78 | 2.1410 | 0.63908 | 0.07236 | ||

| Oil/gas | 82 | 1.9756 | 0.70230 | 0.07756 | ||

| Chemical | 72 | 2.0972 | 0.71522 | 0.08429 | ||

| Electronics and electrics | 84 | 2.0952 | 0.73827 | 0.08055 | ||

| Other industries | 88 | 2.0795 | 0.76145 | 0.08117 | ||

| Total | 632 | 2.0965 | 0.71559 | 0.02846 | ||

| DWI | Food | 76 | 4.5658 | 0.52499 | 0.06022 | 0.611 |

| Automotive and spare parts | 77 | 4.5974 | 0.51961 | 0.05921 | ||

| Iron and steel | 75 | 4.5333 | 0.57735 | 0.06667 | ||

| Pharma | 78 | 4.6410 | 0.53390 | 0.06045 | ||

| Oil/gas | 82 | 4.4756 | 0.59266 | 0.06545 | ||

| Chemical | 72 | 4.5417 | 0.57989 | 0.06834 | ||

| Electronics and electrics | 84 | 4.5000 | 0.50300 | 0.05488 | ||

| Other industries | 88 | 4.5114 | 0.56719 | 0.06046 | ||

| Total | 632 | 4.5443 | 0.54983 | 0.02187 | ||

| CWET | Food | 76 | 3.8158 | 0.39023 | 0.04476 | 0.297 |

| Automotive and spare parts | 77 | 3.7532 | 0.43395 | 0.04945 | ||

| Iron and steel | 75 | 3.7333 | 0.44519 | 0.05141 | ||

| Pharma | 78 | 3.7692 | 0.42405 | 0.04801 | ||

| Oil/gas | 82 | 3.7927 | 0.40788 | 0.04504 | ||

| Chemical | 72 | 3.7778 | 0.41866 | 0.04934 | ||

| Electronics and electrics | 84 | 3.8571 | 0.35203 | 0.03841 | ||

| Other industries | 88 | 3.6932 | 0.46382 | 0.04944 | ||

| Total | 632 | 3.7737 | 0.41874 | 0.01666 | ||

| MSL | Food | 76 | 4.4868 | 0.62168 | 0.07131 | 0.641 |

| Automotive and spare parts | 77 | 4.4675 | 0.64040 | 0.07298 | ||

| Iron and steel | 75 | 4.4133 | 0.61717 | 0.07126 | ||

| Pharma | 78 | 4.5385 | 0.59636 | 0.06752 | ||

| Oil/gas | 82 | 4.3902 | 0.64322 | 0.07103 | ||

| Chemical | 72 | 4.3889 | 0.57053 | 0.06724 | ||

| Electronics and electrics | 84 | 4.4167 | 0.60536 | 0.06605 | ||

| Other industries | 88 | 4.3636 | 0.60991 | 0.06502 | ||

| Total | 632 | 4.4320 | 0.61295 | 0.02438 | ||

| AM | Food | 76 | 3.9079 | 0.29110 | 0.03339 | 0.563 |

| Automotive and spare parts | 77 | 3.9351 | 0.24803 | 0.02827 | ||

| Iron and steel | 75 | 3.9067 | 0.29286 | 0.03382 | ||

| Pharma | 78 | 3.8846 | 0.32155 | 0.03641 | ||

| Oil/gas | 82 | 3.9024 | 0.29855 | 0.03297 | ||

| Chemical | 72 | 3.9167 | 0.27832 | 0.03280 | ||

| Electronics and electrics | 84 | 3.9286 | 0.25909 | 0.02827 | ||

| Other industries | 88 | 3.8409 | 0.36786 | 0.03921 | ||

| Total | 632 | 3.9019 | 0.29769 | 0.01184 | ||

| FS | Food | 76 | 4.6974 | 0.56615 | 0.06494 | 0.796 |

| Automotive and spare parts | 77 | 4.6234 | 0.62910 | 0.07169 | ||

| Iron and steel | 75 | 4.7600 | 0.54127 | 0.06250 | ||

| Pharma | 78 | 4.6923 | 0.60961 | 0.06903 | ||

| Oil/gas | 82 | 4.7195 | 0.61412 | 0.06782 | ||

| Chemical | 72 | 4.5972 | 0.70531 | 0.08312 | ||

| Electronics and electrics | 84 | 4.7024 | 0.61663 | 0.06728 | ||

| Other industries | 88 | 4.7045 | 0.59033 | 0.06293 | ||

| Total | 632 | 4.6883 | 0.60844 | 0.02420 | ||

| COM | Food | 76 | 4.4079 | 0.63619 | 0.07298 | 0.996 |

| Automotive and spare parts | 77 | 4.3636 | 0.62637 | 0.07138 | ||

| Iron and steel | 75 | 4.3733 | 0.63189 | 0.07296 | ||

| Pharma | 78 | 4.3205 | 0.61356 | 0.06947 | ||

| Oil/gas | 82 | 4.3902 | 0.62373 | 0.06888 | ||

| Chemical | 72 | 4.3611 | 0.61221 | 0.07215 | ||

| Electronics and electrics | 84 | 4.3810 | 0.63823 | 0.06964 | ||

| Other industries | 88 | 4.3864 | 0.61461 | 0.06552 | ||

| Total | 632 | 4.3734 | 0.62168 | 0.02473 | ||

| GL | Food | 76 | 2.2105 | 0.67953 | 0.07795 | 0.884 |

| Automotive and spare parts | 77 | 2.1948 | 0.68899 | 0.07852 | ||

| Iron and steel | 75 | 2.1600 | 0.63756 | 0.07362 | ||

| Pharma | 78 | 2.1667 | 0.61193 | 0.06929 | ||

| Oil/gas | 82 | 2.0854 | 0.61265 | 0.06766 | ||

| Chemical | 72 | 2.2083 | 0.60369 | 0.07115 | ||

| Electronics and electrics | 84 | 2.2381 | 0.59352 | 0.06476 | ||

| Other industries | 88 | 2.1932 | 0.65842 | 0.07019 | ||

| Total | 632 | 2.1820 | 0.63455 | 0.02524 | ||

| SCMC | Food | 76 | 4.0395 | 0.64168 | 0.07361 | 0.721 |

| Automotive and spare parts | 77 | 4.0260 | 0.66834 | 0.07616 | ||

| Iron and steel | 75 | 4.0000 | 0.69749 | 0.08054 | ||

| Pharma | 78 | 3.9744 | 0.68328 | 0.07737 | ||

| Oil/gas | 82 | 3.9878 | 0.63817 | 0.07047 | ||

| Chemical | 72 | 4.0000 | 0.69201 | 0.08155 | ||

| Electronics and electrics | 84 | 4.1190 | 0.60926 | 0.06648 | ||

| Other industries | 88 | 4.1250 | 0.65763 | 0.07010 | ||

| Total | 632 | 4.0364 | 0.65916 | 0.02622 | ||

| CFI | Food | 76 | 4.2895 | 0.79692 | 0.09141 | 0.281 |

| Automotive and spare parts | 77 | 4.4545 | 0.65985 | 0.07520 | ||

| Iron and steel | 75 | 4.3333 | 0.64375 | 0.07433 | ||

| Pharma | 78 | 4.4231 | 0.73005 | 0.08266 | ||

| Oil/gas | 82 | 4.3780 | 0.69638 | 0.07690 | ||

| Chemical | 72 | 4.5000 | 0.69201 | 0.08155 | ||

| Electronics and electrics | 84 | 4.3095 | 0.76009 | 0.08293 | ||

| Other industries | 88 | 4.2386 | 0.69471 | 0.07406 | ||

| Total | 632 | 4.3623 | 0.71216 | 0.02833 | ||

| SUS | Food | 76 | 4.1579 | 0.36707 | 0.04211 | 0.937 |

| Automotive and spare parts | 77 | 4.1429 | 0.35222 | 0.04014 | ||

| Iron and steel | 75 | 4.1333 | 0.34222 | 0.03952 | ||

| Pharma | 78 | 4.1026 | 0.30535 | 0.03457 | ||

| Oil/gas | 82 | 4.1098 | 0.31451 | 0.03473 | ||

| Chemical | 72 | 4.1528 | 0.36230 | 0.04270 | ||

| Electronics and electrics | 84 | 4.1667 | 0.37492 | 0.04091 | ||

| Other industries | 88 | 4.1364 | 0.34514 | 0.03679 | ||

| Total | 632 | 4.1377 | 0.34481 | 0.01372 | ||

| SO | Food | 76 | 4.0921 | 0.29110 | 0.03339 | 0.691 |

| Automotive and spare parts | 77 | 4.1948 | 0.39865 | 0.04543 | ||

| Iron and steel | 75 | 4.1200 | 0.32715 | 0.03778 | ||

| Pharma | 78 | 4.1282 | 0.33648 | 0.03810 | ||

| Oil/gas | 82 | 4.1341 | 0.34291 | 0.03787 | ||

| Chemical | 72 | 4.1111 | 0.31648 | 0.03730 | ||

| Electronics and electrics | 84 | 4.1667 | 0.37492 | 0.04091 | ||

| Other industries | 88 | 4.1364 | 0.34514 | 0.03679 | ||

| Total | 632 | 4.1361 | 0.34314 | 0.01365 | ||

| DDS | Food | 76 | 2.1184 | 0.54079 | 0.06203 | 0.338 |

| Automotive and spare parts | 77 | 1.9091 | 0.54246 | 0.06182 | ||

| Iron and steel | 75 | 2.0000 | 0.43496 | 0.05022 | ||

| Pharma | 78 | 2.0256 | 0.48280 | 0.05467 | ||

| Oil/gas | 82 | 1.9878 | 0.55542 | 0.06134 | ||

| Chemical | 72 | 1.9861 | 0.48912 | 0.05764 | ||

| Electronics and electrics | 84 | 2.0476 | 0.57884 | 0.06316 | ||

| Other industries | 88 | 1.9432 | 0.59419 | 0.06334 | ||

| Total | 632 | 2.0016 | 0.53261 | 0.02119 | ||

| GSP | Food | 76 | 4.3158 | 0.52181 | 0.05986 | 0.886 |

| Automotive and spare parts | 77 | 4.3896 | 0.51697 | 0.05891 | ||

| Iron and steel | 75 | 4.3467 | 0.53254 | 0.06149 | ||

| Pharma | 78 | 4.3590 | 0.48280 | 0.05467 | ||

| Oil/gas | 82 | 4.2805 | 0.47854 | 0.05285 | ||

| Chemical | 72 | 4.3889 | 0.57053 | 0.06724 | ||

| Electronics and electrics | 84 | 4.3452 | 0.52627 | 0.05742 | ||

| Other industries | 88 | 4.3068 | 0.57452 | 0.06124 | ||

| Total | 632 | 4.3402 | 0.52491 | 0.02088 | ||

| CT | Food | 76 | 3.9605 | 0.68197 | 0.07823 | 0.941 |

| Automotive and spare parts | 77 | 4.0390 | 0.67749 | 0.07721 | ||

| Iron and steel | 75 | 4.0800 | 0.60983 | 0.07042 | ||

| Pharma | 78 | 4.0256 | 0.62365 | 0.07061 | ||

| Oil/gas | 82 | 4.0122 | 0.55542 | 0.06134 | ||

| Chemical | 72 | 4.0278 | 0.60450 | 0.07124 | ||

| Electronics and electrics | 84 | 4.0952 | 0.68757 | 0.07502 | ||

| Other industries | 88 | 4.0341 | 0.63334 | 0.06751 | ||

| Total | 632 | 4.0348 | 0.63350 | 0.02520 | ||

| L | Food | 76 | 4.2105 | 0.47091 | 0.05402 | 0.920 |

| Automotive and spare parts | 77 | 4.2727 | 0.47673 | 0.05433 | ||

| Iron and steel | 75 | 4.1867 | 0.45599 | 0.05265 | ||

| Pharma | 78 | 4.2179 | 0.41552 | 0.04705 | ||

| Oil/gas | 82 | 4.2195 | 0.44512 | 0.04916 | ||

| Chemical | 72 | 4.1944 | 0.49330 | 0.05814 | ||

| Electronics and electrics | 84 | 4.2381 | 0.48144 | 0.05253 | ||

| Other industries | 88 | 4.1705 | 0.50791 | 0.05414 | ||

| Total | 632 | 4.2136 | 0.46793 | 0.01861 | ||

| N | Mean | Std. Dev. | Std. Error | Sig. | ||

|---|---|---|---|---|---|---|

| LK | 1.00 | 178 | 4.6124 | 0.68169 | 0.05110 | 0.062 |

| 2.00 | 345 | 4.6725 | 0.62874 | 0.03385 | ||

| 3.00 | 97 | 4.8144 | 0.48584 | 0.04933 | ||

| 4.00 | 12 | 4.8333 | 0.57735 | 0.16667 | ||

| Total | 632 | 4.6804 | 0.62621 | 0.02491 | ||

| SF | 1.00 | 178 | 3.7191 | 0.45071 | 0.03378 | 0.332 |

| 2.00 | 345 | 3.7072 | 0.45569 | 0.02453 | ||

| 3.00 | 97 | 3.6598 | 0.47624 | 0.04835 | ||

| 4.00 | 12 | 3.5000 | 0.52223 | 0.15076 | ||

| Total | 632 | 3.6994 | 0.45890 | 0.01825 | ||

| HSC | 1.00 | 178 | 2.0674 | 0.74101 | 0.05554 | 0.353 |

| 2.00 | 345 | 2.1130 | 0.70832 | 0.03813 | ||

| 3.00 | 97 | 2.0515 | 0.68269 | 0.06932 | ||

| 4.00 | 12 | 2.4167 | 0.79296 | 0.22891 | ||

| Total | 632 | 2.0965 | 0.71559 | 0.02846 | ||

| DWI | 1.00 | 178 | 4.5337 | 0.55387 | 0.04151 | 0.220 |

| 2.00 | 345 | 4.5188 | 0.56065 | 0.03018 | ||

| 3.00 | 97 | 4.6495 | 0.50086 | 0.05085 | ||

| 4.00 | 12 | 4.5833 | 0.51493 | 0.14865 | ||

| Total | 632 | 4.5443 | 0.54983 | 0.02187 | ||

| CWET | 1.00 | 178 | 3.8315 | 0.37540 | 0.02814 | 0.136 |

| 2.00 | 345 | 3.7594 | 0.42806 | 0.02305 | ||

| 3.00 | 97 | 3.7320 | 0.44524 | 0.04521 | ||

| 4.00 | 12 | 3.6667 | 0.49237 | 0.14213 | ||

| Total | 632 | 3.7737 | 0.41874 | 0.01666 | ||

| MSL | 1.00 | 178 | 4.3652 | 0.63452 | 0.04756 | 0.050 |

| 2.00 | 345 | 4.4232 | 0.61051 | 0.03287 | ||

| 3.00 | 97 | 4.5773 | 0.57437 | 0.05832 | ||

| 4.00 | 12 | 4.5000 | 0.52223 | 0.15076 | ||

| Total | 632 | 4.4320 | 0.61295 | 0.02438 | ||

| AM | 1.00 | 178 | 3.8989 | 0.30234 | 0.02266 | 0.585 |

| 2.00 | 345 | 3.9130 | 0.28218 | 0.01519 | ||

| 3.00 | 97 | 3.8660 | 0.34244 | 0.03477 | ||

| 4.00 | 12 | 3.9167 | 0.28868 | 0.08333 | ||

| Total | 632 | 3.9019 | 0.29769 | 0.01184 | ||

| FS | 1.00 | 178 | 4.6404 | 0.64216 | 0.04813 | 0.063 |

| 2.00 | 345 | 4.6696 | 0.62490 | 0.03364 | ||

| 3.00 | 97 | 4.8144 | 0.48584 | 0.04933 | ||

| 4.00 | 12 | 4.9167 | 0.28868 | 0.08333 | ||

| Total | 632 | 4.6883 | 0.60844 | 0.02420 | ||

| COM | 1.00 | 178 | 4.4213 | 0.59849 | 0.04486 | 0.112 |

| 2.00 | 345 | 4.3275 | 0.61942 | 0.03335 | ||

| 3.00 | 97 | 4.4124 | 0.67319 | 0.06835 | ||

| 4.00 | 12 | 4.6667 | 0.49237 | 0.14213 | ||

| Total | 632 | 4.3734 | 0.62168 | 0.02473 | ||

| GL | 1.00 | 178 | 2.2079 | 0.60744 | 0.04553 | 0.381 |

| 2.00 | 345 | 2.1797 | 0.64443 | 0.03469 | ||

| 3.00 | 97 | 2.1134 | 0.62710 | 0.06367 | ||

| 4.00 | 12 | 2.4167 | 0.79296 | 0.22891 | ||

| Total | 632 | 2.1820 | 0.63455 | 0.02524 | ||

| SCMC | 1.00 | 178 | 4.1292 | 0.61077 | 0.04578 | 0.159 |

| 2.00 | 345 | 4.0087 | 0.65808 | 0.03543 | ||

| 3.00 | 97 | 3.9691 | 0.71376 | 0.07247 | ||

| 4.00 | 12 | 4.0000 | 0.85280 | 0.24618 | ||

| Total | 632 | 4.0364 | 0.65916 | 0.02622 | ||

| CFI | 1.00 | 178 | 4.4607 | 0.68982 | 0.05170 | 0.127 |

| 2.00 | 345 | 4.3391 | 0.71390 | 0.03844 | ||

| 3.00 | 97 | 4.2887 | 0.72109 | 0.07322 | ||

| 4.00 | 12 | 4.1667 | 0.83485 | 0.24100 | ||

| Total | 632 | 4.3623 | 0.71216 | 0.02833 | ||

| SUS | 1.00 | 178 | 4.1742 | 0.38031 | 0.02851 | 0.007 |

| 2.00 | 345 | 4.1507 | 0.35830 | 0.01929 | ||

| 3.00 | 97 | 4.0412 | 0.19987 | 0.02029 | ||

| 4.00 | 12 | 4.0000 | 0.00000 | 0.00000 | ||

| Total | 632 | 4.1377 | 0.34481 | 0.01372 | ||

| SO | 1.00 | 178 | 4.1629 | 0.37034 | 0.02776 | 0.551 |

| 2.00 | 345 | 4.1188 | 0.32407 | 0.01745 | ||

| 3.00 | 97 | 4.1443 | 0.35325 | 0.03587 | ||

| 4.00 | 12 | 4.1667 | 0.38925 | 0.11237 | ||

| Total | 632 | 4.1361 | 0.34314 | 0.01365 | ||

| DDS | 1.00 | 178 | 1.9663 | 0.49744 | 0.03728 | 0.362 |

| 2.00 | 345 | 1.9971 | 0.55247 | 0.02974 | ||

| 3.00 | 97 | 2.0619 | 0.51669 | 0.05246 | ||

| 4.00 | 12 | 2.1667 | 0.57735 | 0.16667 | ||

| Total | 632 | 2.0016 | 0.53261 | 0.02119 | ||

| GSP | 1.00 | 178 | 4.3708 | 0.53955 | 0.04044 | 0.411 |

| 2.00 | 345 | 4.3449 | 0.53362 | 0.02873 | ||

| 3.00 | 97 | 4.2887 | 0.47782 | 0.04851 | ||

| 4.00 | 12 | 4.1667 | 0.38925 | 0.11237 | ||

| Total | 632 | 4.3402 | 0.52491 | 0.02088 | ||

| CT | 1.00 | 178 | 4.0562 | 0.60804 | 0.04557 | 0.518 |

| 2.00 | 345 | 4.0029 | 0.63107 | 0.03398 | ||

| 3.00 | 97 | 4.1031 | 0.66903 | 0.06793 | ||

| 4.00 | 12 | 4.0833 | 0.79296 | 0.22891 | ||

| Total | 632 | 4.0348 | 0.63350 | 0.02520 | ||

| L | 1.00 | 178 | 4.2191 | 0.47808 | 0.03583 | 0.764 |

| 2.00 | 345 | 4.2145 | 0.47657 | 0.02566 | ||

| 3.00 | 97 | 4.1856 | 0.41658 | 0.04230 | ||

| 4.00 | 12 | 4.3333 | 0.49237 | 0.14213 | ||

| Total | 632 | 4.2136 | 0.46793 | 0.01861 | ||

| Variable | Statement | Factor Loading | AVE | Cronbach’s Alpha |

|---|---|---|---|---|

| Level of Knowledge | LK1 | 0.991 | 98.239% | 0.991 |

| LK2 | 0.979 | |||

| LK3 | 0.977 | |||

| Smart Factory | SF1 | 0.787 | 83.670% | 0.901 |

| SF2 | 0.810 | |||

| SF3 | 0.913 | |||

| Dealing with Insecurity | DWI1 | 0.753 | 68.566% | 0.847 |

| DWI2 | 0.746 | |||

| DWI3 | 0.551 | |||

| DWI4 | 0.693 | |||

| Financial Support | FS1 | 0.938 | 92.570% | 0.960 |

| FS2 | 0.922 | |||

| FS3 | 0.917 | |||

| Supply Chain Management and Collaboration | SCMC1 | 0.871 | 89.171% | 0.970 |

| SCMC2 | 0.919 | |||

| SCMC3 | 0.906 | |||

| SCMC4 | 0.886 | |||

| SCMC5 | 0.877 | |||

| Strategy and Organization | SO1 | 0.860 | 85.964% | 0.827 |

| SO2 | 0.860 | |||

| Data-Driven Services | DDS1 | 0.950 | 94.956% | 0.947 |

| DDS2 | 0.950 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LK1 | 0.985 | ||||||||||||||

| LK2 | 0.975 | ||||||||||||||

| LK3 | 0.972 | ||||||||||||||

| SF1 | 0.879 | ||||||||||||||

| SF2 | 0.851 | ||||||||||||||

| SF3 | 0.953 | ||||||||||||||

| HSC | 0.929 | ||||||||||||||

| DWI1 | 0.419 | 0.822 | |||||||||||||

| DWI2 | 0.923 | ||||||||||||||

| DWI3 | 0.932 | ||||||||||||||

| DWI4 | 0.927 | ||||||||||||||

| CWET | 0.893 | ||||||||||||||

| MSL | 0.928 | ||||||||||||||

| AM | 0.936 | ||||||||||||||

| FS1 | 0.934 | ||||||||||||||

| FS2 | 0.985 | ||||||||||||||

| FS3 | 0.913 | ||||||||||||||

| COM | 0.961 | ||||||||||||||

| GL | 0.938 | ||||||||||||||

| SCMC1 | 0.925 | ||||||||||||||

| SCMC2 | 0.958 | ||||||||||||||

| SCMC3 | 0.912 | ||||||||||||||

| SCMC4 | 0.939 | ||||||||||||||

| SCMC5 | 0.899 | ||||||||||||||

| CFI | 0.844 | ||||||||||||||

| SUS | 0.976 | ||||||||||||||

| SO1 | 0.873 | ||||||||||||||

| SO2 | 0.865 | ||||||||||||||

| DDS1 | 0.906 | ||||||||||||||

| DDS2 | 0.909 | ||||||||||||||

| GSP | 0.436 | 0.802 | |||||||||||||

| CT | 0.916 | ||||||||||||||

| L | 0.948 |

| Factor | Mean | Std. Deviation |

|---|---|---|

| Level of Knowledge | 4.6804 | 0.62621 |

| Smart Factory | 3.6994 | 0.45890 |

| Hardware and Software Connection | 2.0965 | 0.71559 |

| Dealing With Insecurity | 4.5443 | 0.54983 |

| Compatibility with Existing Technology | 3.7737 | 0.41874 |

| Management Support and Leadership | 4.4320 | 0.61295 |

| Agility in Manufacturing | 3.9019 | 0.29769 |

| Financial Support | 4.6883 | 0.60884 |

| Competitiveness | 4.3734 | 0.62168 |

| Global Engagement | 2.1820 | 0.63455 |

| Supply Chain Management and Collaboration | 4.0364 | 0.65916 |

| Customer-Focused Innovativeness | 4.3623 | 0.71216 |

| Sustainability | 4.1962 | 0.39744 |

| Strategy and Organization | 4.1361 | 0.34314 |

| Data-Driven Services | 2.0016 | 0.53261 |

| Government Supportive Policies | 4.3402 | 0.52491 |

| Collaboration and Transparency | 4.0348 | 0.63350 |

| Lean | 4.2136 | 0.46793 |

| LK | SF | DWI | CWET | MSL | AM | FS | Com | SCMC | CFI | Sus | SO | GSP | CT | L | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LK | X | V | V | V | X | V | X | V | V | V | V | V | V | V | V |

| SF | A | X | A | X | A | X | A | A | A | A | A | A | A | A | A |

| DWI | A | V | X | V | A | V | A | V | V | V | V | V | V | V | V |

| CWET | A | X | A | X | A | X | A | A | A | A | A | A | A | A | A |

| MSL | X | V | V | V | X | V | X | V | V | V | V | V | V | V | V |

| AM | A | X | A | X | A | X | A | A | A | A | A | A | A | A | A |

| FS | X | V | V | V | X | V | X | V | V | V | V | V | V | V | V |

| Com | A | V | A | V | A | V | A | X | V | V | V | V | V | V | V |

| SCMC | A | V | A | V | A | V | A | A | X | A | A | A | A | A | A |

| CFI | A | V | A | V | A | V | A | A | V | X | V | V | V | V | V |

| Sus | A | V | A | V | A | V | A | A | V | A | X | V | A | V | X |

| SO | A | V | A | V | A | V | A | A | V | A | A | X | A | X | A |

| GSP | A | V | A | V | A | V | A | A | V | A | V | V | X | V | V |

| CT | A | V | A | V | A | V | A | A | V | A | A | X | A | X | A |

| L | A | V | A | V | A | V | A | A | V | A | X | V | A | V | X |

| LK | SF | DWI | CWET | MSL | AM | FS | Com | SCMC | CFI | Sus | SO | GSP | CT | L | Driving Power | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LK | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 15 |

| SF | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 |

| DWI | 0 | 1 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 12 |

| CWET | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 |

| MSL | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 15 |

| AM | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 3 |

| FS | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 15 |

| Com | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 11 |

| SCMC | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 4 |

| CFI | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 10 |

| Sus | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 8 |

| SO | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 6 |

| GSP | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 9 |

| CT | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 6 |

| L | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 8 |

| Dependence Power | 3 | 15 | 4 | 15 | 3 | 15 | 3 | 5 | 12 | 6 | 9 | 11 | 7 | 11 | 9 |

| Item | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| LK | LK, SF, DWI, CWET, MSL, AM, FS, Com, SCMC, CFI, Sus, SO, GSP, CT, L | LK, MSL, FS | LK, MSL, FS | 9 |

| SF | SF, CWET, AM | LK, SF, DWI, CWET, MSL, AM, FS, Com, SCMC, CFI, Sus, SO, GSP, CT, L | SF, CWET, AM | 1 |

| DWI | SF, DWI, CWET, AM, Com, SCMC, CFI, Sus, SO, GSP, CT, L | LK, DWI, MSL, FS | DWI | 8 |

| CWET | SF, CWET, AM | LK, SF, DWI, CWET, MSL, AM, FS, Com, SCMC, CFI, Sus, SO, GSP, CT, L | SF, CWET, AM | 1 |

| MSL | LK, SF, DWI, CWET, MSL, AM, FS, Com, SCMC, CFI, Sus, SO, GSP, CT, L | LK, MSL, FS | LK, MSL, FS | 9 |

| AM | SF, CWET, AM | LK, SF, DWI, CWET, MSL, AM, FS, Com, SCMC, CFI, Sus, SO, GSP, CT, L | SF, CWET, AM | 1 |

| FS | LK, SF, DWI, CWET, MSL, AM, FS, Com, SCMC, CFI, Sus, SO, GSP, CT, L | LK, MSL, FS | LK, MSL, FS | 9 |

| Com | SF, CWET, AM, Com, SCMC, CFI, Sus, SO, GSP, CT, L | LK, DWI, MSL, FS, Com | Com | 7 |

| SCMC | SF, CWET, AM, SCMC | LK, DWI, MSL, FS, Com, SCMC, CFI, Sus, SO, GSP, L | SCMC | 2 |

| CFI | SF, CWET, AM, SCMC, CFI, Sus, SO, GSP, CT, L | LK, DWI, MSL, FS, Com, CFI | CFI | 6 |

| Sus | SF, CWET, AM, SCMC, Sus, SO, CT, L | LK, DWI, MSL, FS, Com, CFI, Sus, GSP, L | Sus, L | 4 |

| SO | SF, CWET, AM, SCMC, SO, CT | LK, DWI, MSL, FS, Com, CFI, Sus, SO, GSP, CT, L | SO, CT | 3 |

| GSP | SF, CWET, AM, SCMC, Sus, SO, GSP, CT, L | LK, DWI, MSL, FS, Com, CFI, GSP | GSP | 5 |

| CT | SF, CWET, AM, SCMC, SO, CT | LK, DWI, MSL, FS, Com, CFI, Sus, SO, GSP, CT, L | SO, CT | 3 |

| L | SF, CWET, AM, SCMC, Sus, SO, CT, L | LK, DWI, MSL, FS, Com, CFI, Sus, GSP, L | Sus, L | 4 |

| Factors | CW | Rank |

|---|---|---|

| CWET | 3.32 | 2 |

| DWI | 0.68 | 10 |

| LK | 3.46 | 1 |

| MSL | 2.44 | 3 |

| AM | 0.69 | 9 |

| FS | 0.58 | 11 |

| COM | 1.57 | 5 |

| SCMC | 1.21 | 7 |

| CFI | 0.98 | 8 |

| SUS | 1.68 | 4 |

| SO | 1.31 | 6 |

| L | 0.47 | 12 |

| Factors | CW | Rank |

|---|---|---|

| MSL | 1.36 | 2 |

| FS | 1.55 | 1 |

| Com | 1.23 | 4 |

| GSP | 0.70 | 10 |

| CT | 0.93 | 7 |

| DWI | 1.02 | 5 |

| L | 0.82 | 9 |

| SF | 0.95 | 6 |

| CFI | 1.32 | 3 |

| SCMC | 0.84 | 8 |

| Factors | CW | Rank |

|---|---|---|

| SF | 1.68 | 1 |

| MSL | 1.05 | 5 |

| AM | 1.13 | 3 |

| Com | 1.04 | 4 |

| CFI | 0.88 | 7 |

| GSP | 0.82 | 8 |

| CT | 1.35 | 2 |

| FS | 0.90 | 6 |

| DWI | 0.73 | 9 |

| Factors | CW | Rank |

|---|---|---|

| LK | 1.19 | 4 |

| AM | 1.16 | 5 |

| SF | 1.20 | 3 |

| CT | 1.31 | 1 |

| GSP | 0.61 | 8 |

| FS | 0.98 | 5 |

| L | 1.25 | 2 |

| SUS | 0.96 | 6 |

| CFI | 0.87 | 7 |

| Factors | CW | Rank |

|---|---|---|

| L | 3.18 | 2 |

| LK | 0.70 | 9 |

| CWET | 3.31 | 1 |

| FS | 2.18 | 3 |

| SUS | 0.62 | 10 |

| SCMC | 0.60 | 11 |

| COM | 1.44 | 5 |

| DWI | 1.04 | 7 |

| AM | 0.95 | 8 |

| GSP | 1.74 | 4 |

| CT | 1.27 | 6 |

| SO | 0.47 | 12 |

| Factors | CW | Rank |

|---|---|---|

| AM | 1.54 | 1 |

| SF | 1.30 | 2 |

| FS | 1.20 | 3 |

| CT | 0.86 | 7 |

| MSL | 0.80 | 8 |

| LK | 0.79 | 9 |

| SUS | 1.04 | 4 |

| SO | 0.97 | 5 |

| CWET | 0.95 | 6 |

| Factors | CW | Rank |

|---|---|---|

| CT | 1.38 | 3 |

| L | 1.83 | 1 |

| DWI | 1.34 | 4 |

| SCMC | 0.65 | 10 |

| MSL | 0.73 | 9 |

| COM | 0.92 | 7 |

| LK | 0.86 | 8 |

| SF | 0.94 | 6 |

| CFI | 1.38 | 2 |

| GSP | 1.02 | 5 |

| Barrier | Industry Implementation |

|---|---|

| LK: Level of Knowledge. | 1 |

| SF: Smart Factory. | 9 |

| DWI: Dealing with Insecurity. | 2 |

| CWET: Compatibility with Existing Technology. | 9 |

| MSL: Management Support and Leadership. | 1 |

| AM: Agility in Manufacturing. | 9 |

| FS: Financial Support. | 1 |

| Com: Competitiveness. | 3 |

| SCMC: Supply Chain Management and Collaboration. | 8 |

| CFI: Customer-Focused Innovativeness. | 4 |

| Sus: Sustainability. | 6 |

| SO: Strategy and Organization. | 7 |

| GSP: Government Supportive Policies. | 5 |

| CT: Collaboration and Transparency. | 7 |

| L: Lean. | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khourshed, N.F.; Elbarky, S.S.; Elgamal, S. Investigating the Readiness Factors for Industry 4.0 Implementation for Manufacturing Industry in Egypt. Sustainability 2023, 15, 9641. https://doi.org/10.3390/su15129641

Khourshed NF, Elbarky SS, Elgamal S. Investigating the Readiness Factors for Industry 4.0 Implementation for Manufacturing Industry in Egypt. Sustainability. 2023; 15(12):9641. https://doi.org/10.3390/su15129641

Chicago/Turabian StyleKhourshed, Nevien Farouk, Sahar Sobhy Elbarky, and Sarah Elgamal. 2023. "Investigating the Readiness Factors for Industry 4.0 Implementation for Manufacturing Industry in Egypt" Sustainability 15, no. 12: 9641. https://doi.org/10.3390/su15129641

APA StyleKhourshed, N. F., Elbarky, S. S., & Elgamal, S. (2023). Investigating the Readiness Factors for Industry 4.0 Implementation for Manufacturing Industry in Egypt. Sustainability, 15(12), 9641. https://doi.org/10.3390/su15129641