Development and Characterization of Polymeric Composites Reinforced with Lignocellulosic Wastes for Packaging Applications

Abstract

:1. Introduction

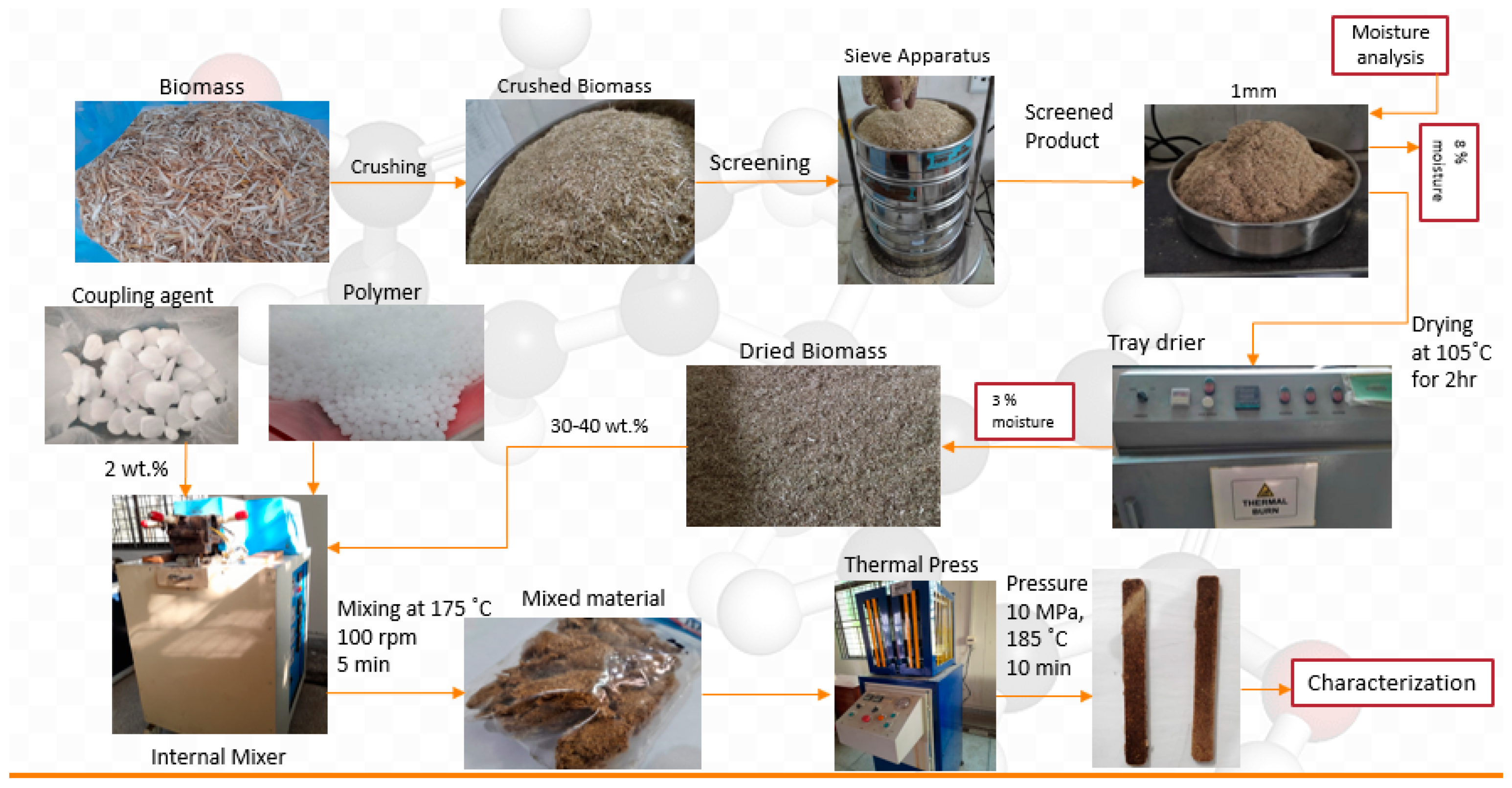

2. Methodology

2.1. Materials and Chemicals

2.2. Preparation of Agricultural Waste Samples

2.3. Mixing of Biomass with Polymer

2.4. Fabrication of Biocomposite Sheets

2.5. Characterizations

3. Results and Discussion

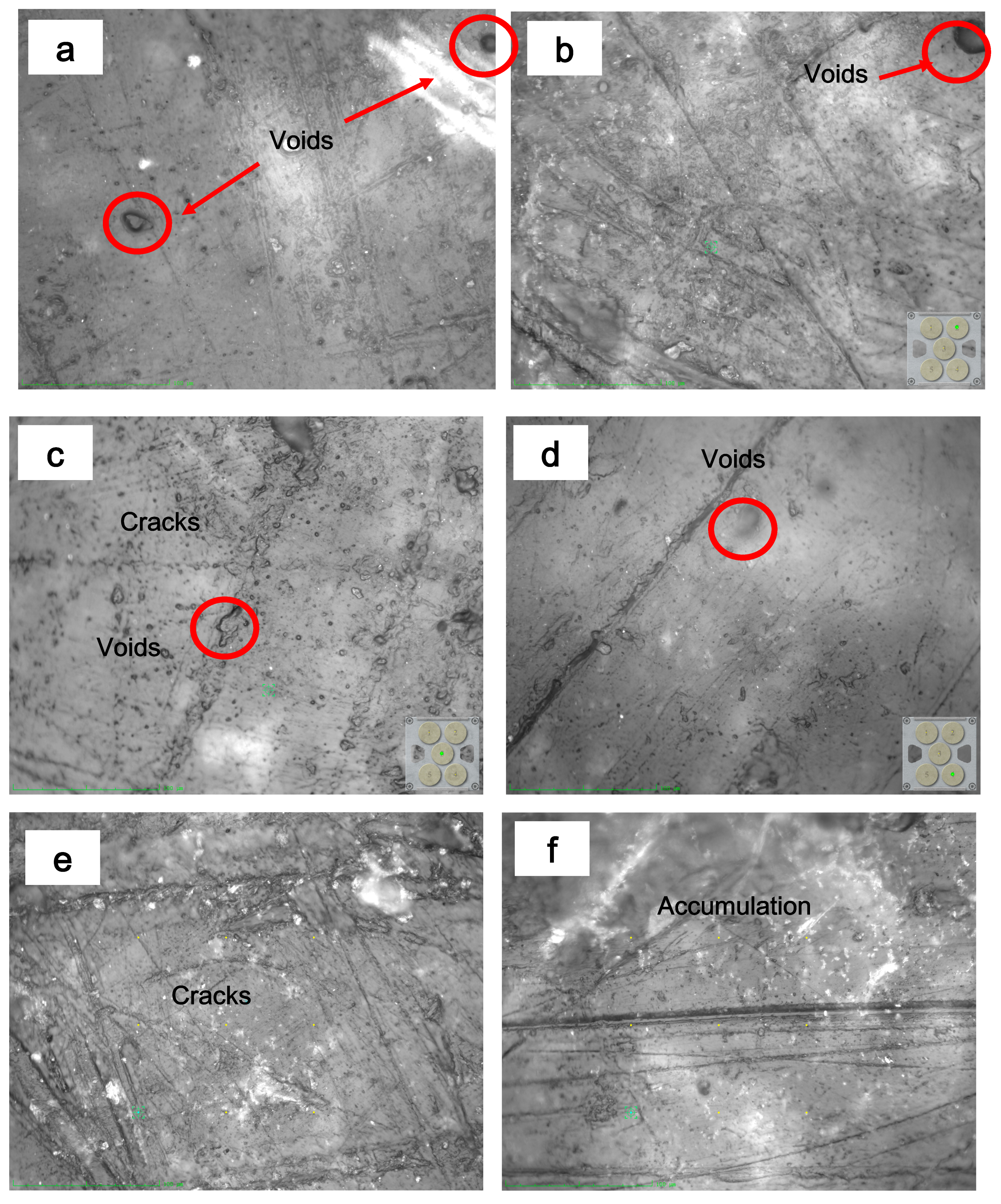

3.1. Surface Morphological Analysis

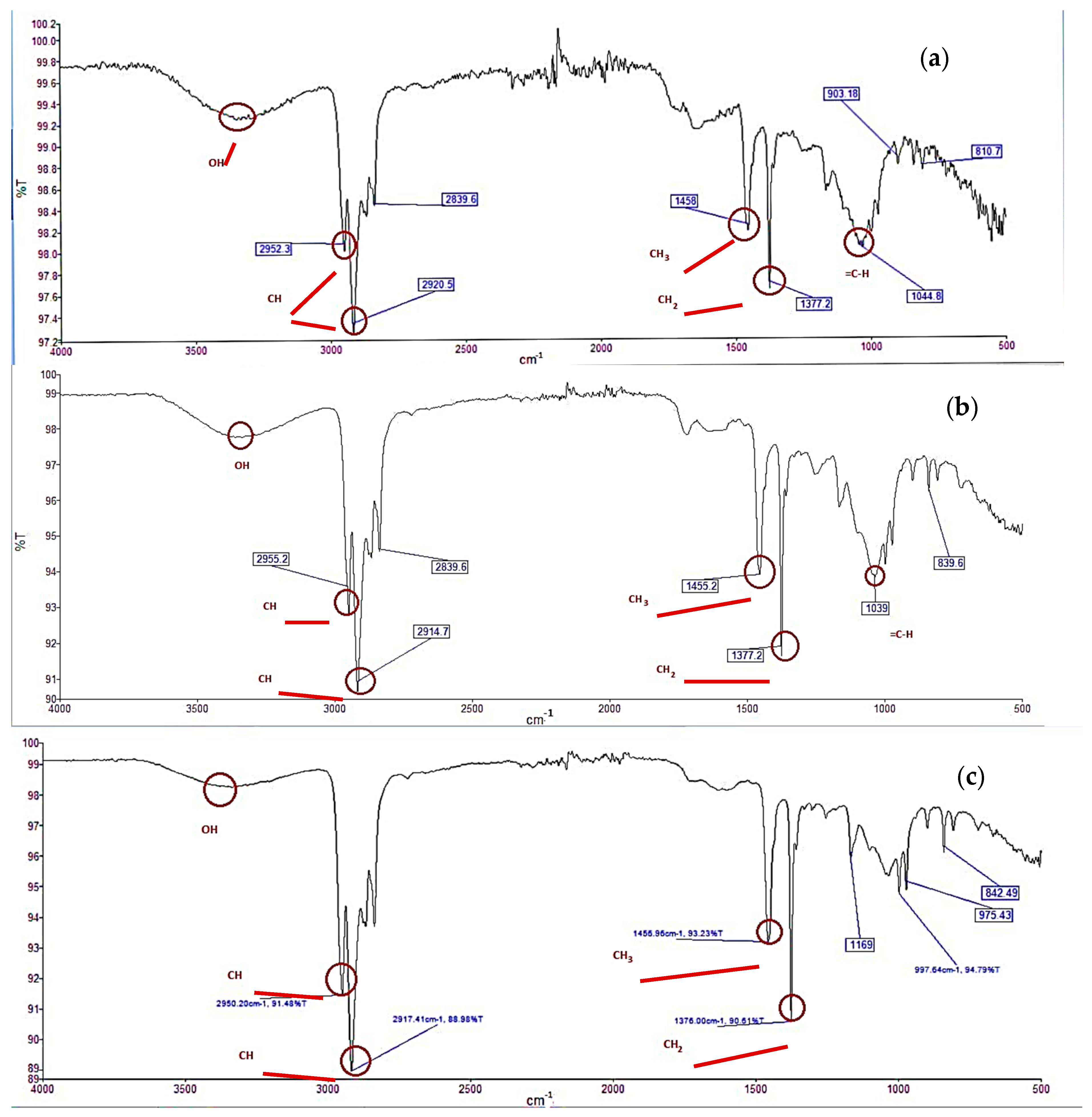

3.2. Functional Group Analysis

3.2.1. Water Absorption and Thickness Swelling Behavior of Biocomposites

3.2.2. Impact Strength Analysis

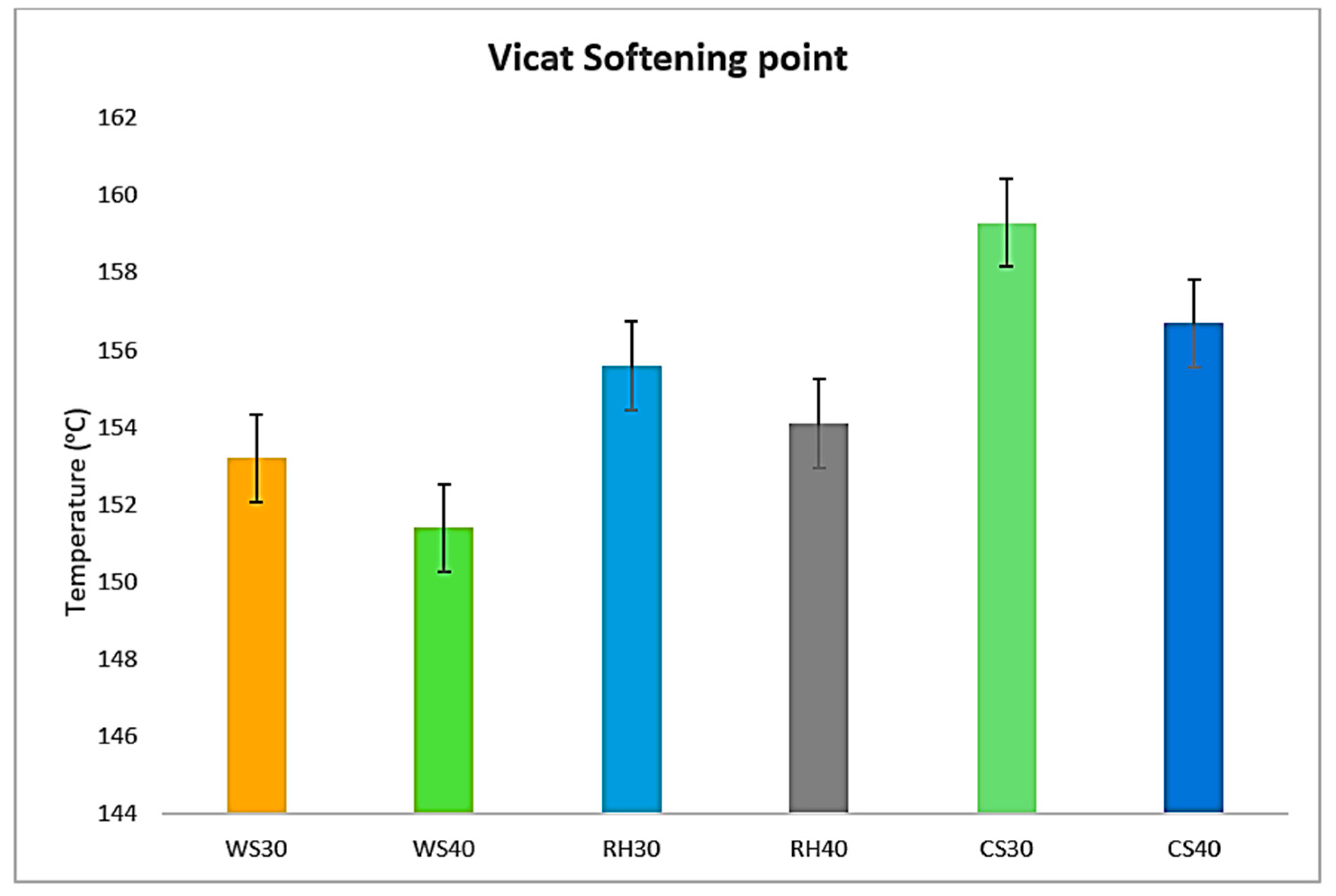

3.2.3. VICAT Softening Point Analysis

3.2.4. Hardness Elastic Modulus Analysis

3.2.5. Creep Analysis

4. Conclusions and Future Perspectives

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RH | rice husk |

| WS | wheat straw |

| CS | corn stalk |

| PPCO | polypropylene copolymer |

| FTIR | fourier transform infrared spectroscopy |

| OM | optical microscopy |

| WA | water absorption |

| TS | thickness swelling |

| QCSM | quasi continueous stiffness mode |

References

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Khalina, A.; Nurazzi, N.M.; Lee, S.H.; Lee, C.H. A Comprehensive Review on Advanced Sustainable Woven Natural Fibre Polymer Composites. Polymers 2021, 13, 471. [Google Scholar]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer Composite Materials: A Comprehensive Review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Rayung, M.; Abu, F.; Ahmad, S.; Fadil, F.; Karim, A.A.; Norizan, M.N.; Sarifuddin, N.; Mat Desa, M.S.; Mohd Basri, M.S.; et al. A Review on Antimicrobial Packaging from Biodegradable Polymer Composites. Polymers 2022, 14, 174. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Biesold, G.M.; Choi, W.; Yu, J.; Deng, Y.; Silvestre, C.; Lin, Z. Recent Advances in Polymers and Polymer Composites for Food Packaging. Mater. Today 2022, 53, 134–161. [Google Scholar] [CrossRef]

- Caiw, L. A review on the selection of raw Materials and reactors for biomass fast pyrolysis in China. Fuel Process. Technol. 2021, 221, 106919. [Google Scholar]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of Lignocellulosic Biomass: A Review on Recent Advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Yan, H.; Zuo, J.; Tian, Y.; Zillante, G. A Critical Review of Factors Affecting the Wind Power Generation Industry in China. Renew. Sustain. Energy Rev. 2013, 19, 499–508. [Google Scholar]

- Dey, N.; Vickram, S.; Thanigaivel, S.; Subbaiya, R.; Kim, W.; Karmegam, N.; Govarthanan, M. Nanomaterials for Transforming Barrier Properties of Lignocellulosic Biomass towards Potential Applications—A Review. Fuel 2022, 316, 123444. [Google Scholar] [CrossRef]

- Salins, S.S.; Reddy, S.V.K.; Kumar, S. Assessment of Process Parameters in a Dehumidification Process Using Biomass-Based Wood Shaving as a Packing Material. Indoor Built Environ. 2022, 31, 496–509. [Google Scholar]

- Trifol, J.; Marin Quintero, D.C.; Moriana, R. Pine Cone Biorefinery: Integral Valorization of Residual Biomass into Lignocellulose Nanofibrils (LCNF)-Reinforced Composites for Packaging. ACS Sustain. Chem. Eng. 2021, 9, 2180–2190. [Google Scholar] [CrossRef]

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-Sourced Polymers as Alternatives to Conventional Food Packaging Materials: A Review. Trends Food Sci. Technol. 2021, 115, 87–104. [Google Scholar] [CrossRef]

- Jeyasri, R.; Muthuramalingam, P.; Satish, L.; Pandian, S.K.; Chen, J.-T.; Ahmar, S.; Wang, X.; Mora-Poblete, F.; Ramesh, M. An Overview of Abiotic Stress in Cereal Crops: Negative Impacts, Regulation, Biotechnology and Integrated Omics. Plants 2021, 10, 1472. [Google Scholar] [CrossRef]

- Sulaiman, M.; Rabbani, F.A.; Iqbal, T.; Kazmi, M.A.; Yasin, S.; Mujtaba, M.; Kalam, M.; Almomani, F. Impact of eco-friendly chemical pretreatment on physicochemical and surface mechanical properties of sustainable lignocellulosic agricultural waste. Algal Res. 2023, 71, 103051. [Google Scholar] [CrossRef]

- Rabbani, F.A.; Yasin, S.; Iqbal, T.; Farooq, U. Experimental Study of Mechanical Properties of Polypropylene Random Copolymer and Rice-Husk-Based Biocomposite by Using Nanoindentation. Materials 2022, 15, 1956. [Google Scholar] [PubMed]

- Jawaid, M.; Alothman, O.Y.; Salit, M.S. Green Biocomposites: Design and Applications; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Radzi, A.M.; Sapuan, S.M.; Jawaid, M.; Mansor, M.R. Water Absorption, Thickness Swelling and Thermal Properties of Roselle/Sugar Palm Fibre Reinforced Thermoplastic Polyurethane Hybrid Composites. J. Mater. Res. Technol. 2019, 8, 3988–3994. [Google Scholar] [CrossRef]

- Xie, Q.; Li, F.; Li, J.; Wang, L.; Li, Y.; Zhang, C.; Xu, J.; Chen, S. A New Biodegradable Sisal Fiber–Starch Packing Composite with Nest Structure. Carbohydr. Polym. 2018, 189, 56–64. [Google Scholar] [PubMed]

- Sukudom, N.; Jariyasakoolroj, P.; Jarupan, L.; Tansin, K. Mechanical, Thermal, and Biodegradation Behaviors of Poly(Vinyl Alcohol) Biocomposite with Reinforcement of Oil Palm Frond Fiber. J. Mater. Cycles Waste Manag. 2019, 21, 125–133. [Google Scholar] [CrossRef]

- Asadollahzadeh, M.; Mahboubi, A.; Taherzadeh, M.J.; Åkesson, D.; Lennartsson, P.R. Application of Fungal Biomass for the Development of New Polylactic Acid-Based Biocomposites. Polymers 2022, 14, 1738. [Google Scholar]

- Bax, B.; Müssig, J. Impact and Tensile Properties of PLA/Cordenka and PLA/Flax Composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar]

- Iqbal, T.; Yasin, S.; Zafar, M.; Zahid, S.; Ishteyaque, S.; Briscoe, B.J. Nanoindentation response of scratched Polymeric Surfaces. Tribol. Trans. 2015, 58, 801–806. [Google Scholar] [CrossRef]

- Tian, S.; Li, B.; He, H.; Liu, X.; Wen, X.; Zhang, Z. Fabrication and Mechanical Properties of High-Durability Polypropylene Composites via Reutilization of SiO2 In-Situ-Synthesized Waste Printed Circuit Board Powder. Polymers 2022, 14, 1045. [Google Scholar] [CrossRef] [PubMed]

- Girones, J.; Lopez, J.P.; Vilaseca, F.; Bayer, J.; Franco, R.P.J.; Mutje, P. Biocomposite from musa textilis and propylene: Evaluation of flexural properties and impact strength. Compos. Sci. Technol. 2010, 71, 122–128. [Google Scholar] [CrossRef]

- Sulaiman, M.; Iqbal, T.; Yasin, S.; Mahmood, H.; Shakeel, A. Study of Nano-Mechanical Performance of Pretreated Natural Fiber in Ldpe Composite for Packaging Applications. Materials 2020, 13, 4977. [Google Scholar] [CrossRef]

- Sulaiman, M.; Iqbal, T.; Yasin, S.; Mahmood, H.; Shakeel, A. Fabrication and Nanomechanical Characterization of Thermoplastic Biocomposites Based on Chemically Treated Lignocellulosic Biomass for Surface Engineering Applications. Front. Mater. 2021, 8, 733109. [Google Scholar] [CrossRef]

- Wang, J.; Euring, M.; Ostendorf, K.; Zhang, K. Biobased materials for food packaging. J. Bioresour. Bioprod. 2022, 7, 1–13. [Google Scholar] [CrossRef]

- Zhang, Y.; Wen, B.; Cao, L.; Li, X.; Zhang, J. Preparation and properties of unmodified ramie fiber reinforced polypropylene composite. J. Wuhan Univ. Technol. 2015, 30, 198–202. [Google Scholar] [CrossRef]

| Sample Name | Impact Strength (kJ/m2) (30 wt% Loading) | Impact Strength (kJ/m2) (40 wt% Loading) |

|---|---|---|

| RH biocomposite | 5.8215 | 7.5565 |

| CS biocomposite | 7.3317 | 3.5313 |

| WS biocomposite | 3.5296 | 3.6318 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sulaiman, M.; Rabbani, F.A.; Iqbal, T.; Riaz, F.; Raashid, M.; Ullah, N.; Yasin, S.; Fouad, Y.; Abbas, M.M.; Kalam, M.A. Development and Characterization of Polymeric Composites Reinforced with Lignocellulosic Wastes for Packaging Applications. Sustainability 2023, 15, 10161. https://doi.org/10.3390/su151310161

Sulaiman M, Rabbani FA, Iqbal T, Riaz F, Raashid M, Ullah N, Yasin S, Fouad Y, Abbas MM, Kalam MA. Development and Characterization of Polymeric Composites Reinforced with Lignocellulosic Wastes for Packaging Applications. Sustainability. 2023; 15(13):10161. https://doi.org/10.3390/su151310161

Chicago/Turabian StyleSulaiman, Muhammad, Fahad Ali Rabbani, Tanveer Iqbal, Fahid Riaz, Muhammad Raashid, Nehar Ullah, Saima Yasin, Yasser Fouad, Muhammad Mujtaba Abbas, and M. A. Kalam. 2023. "Development and Characterization of Polymeric Composites Reinforced with Lignocellulosic Wastes for Packaging Applications" Sustainability 15, no. 13: 10161. https://doi.org/10.3390/su151310161

APA StyleSulaiman, M., Rabbani, F. A., Iqbal, T., Riaz, F., Raashid, M., Ullah, N., Yasin, S., Fouad, Y., Abbas, M. M., & Kalam, M. A. (2023). Development and Characterization of Polymeric Composites Reinforced with Lignocellulosic Wastes for Packaging Applications. Sustainability, 15(13), 10161. https://doi.org/10.3390/su151310161