Manufacturing in the Age of Human-Centric and Sustainable Industry 5.0: Application to Holonic, Flexible, Reconfigurable and Smart Manufacturing Systems

Abstract

:1. Introduction

2. Methodology

3. The Rise of Industry 4.0

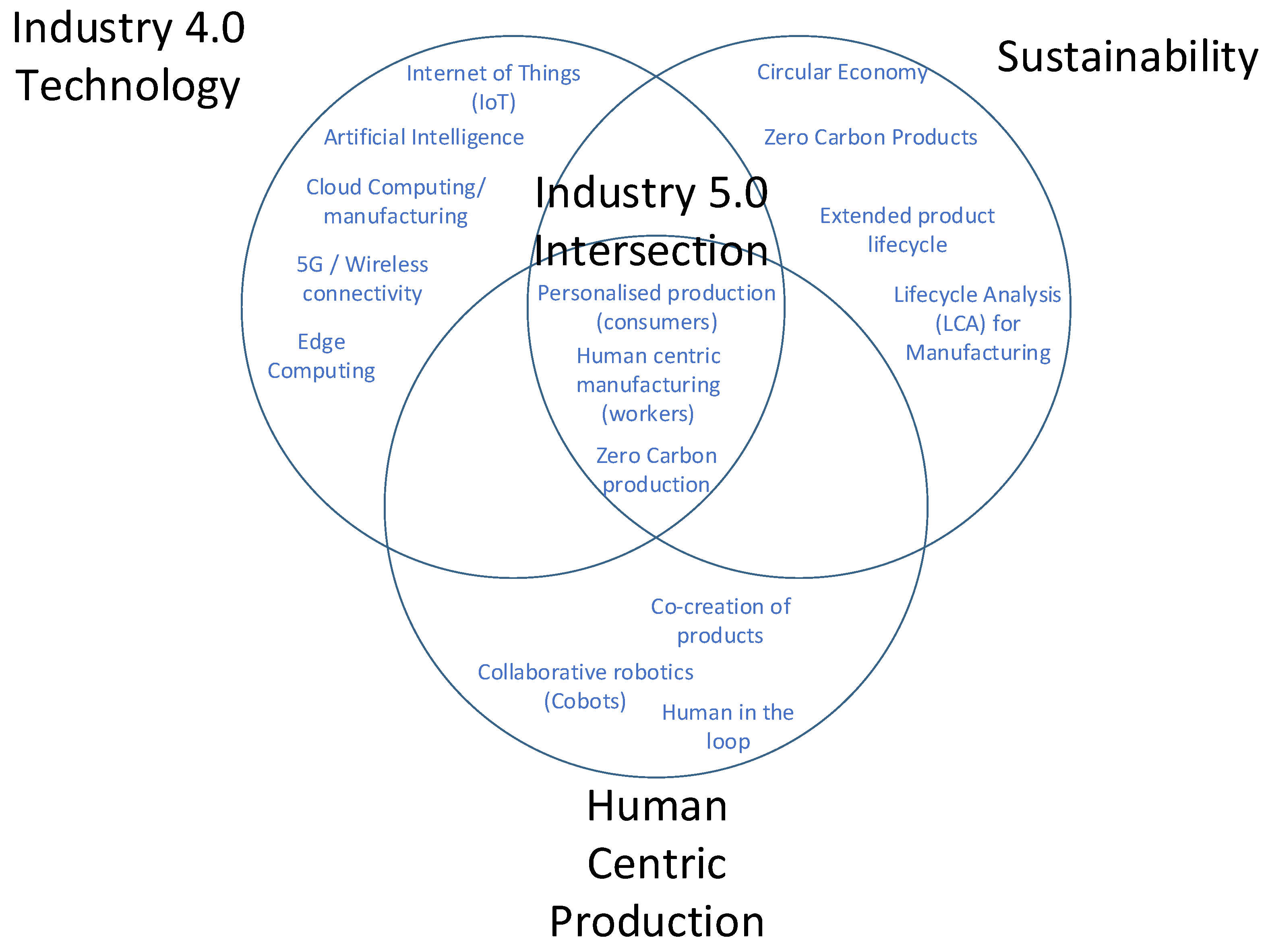

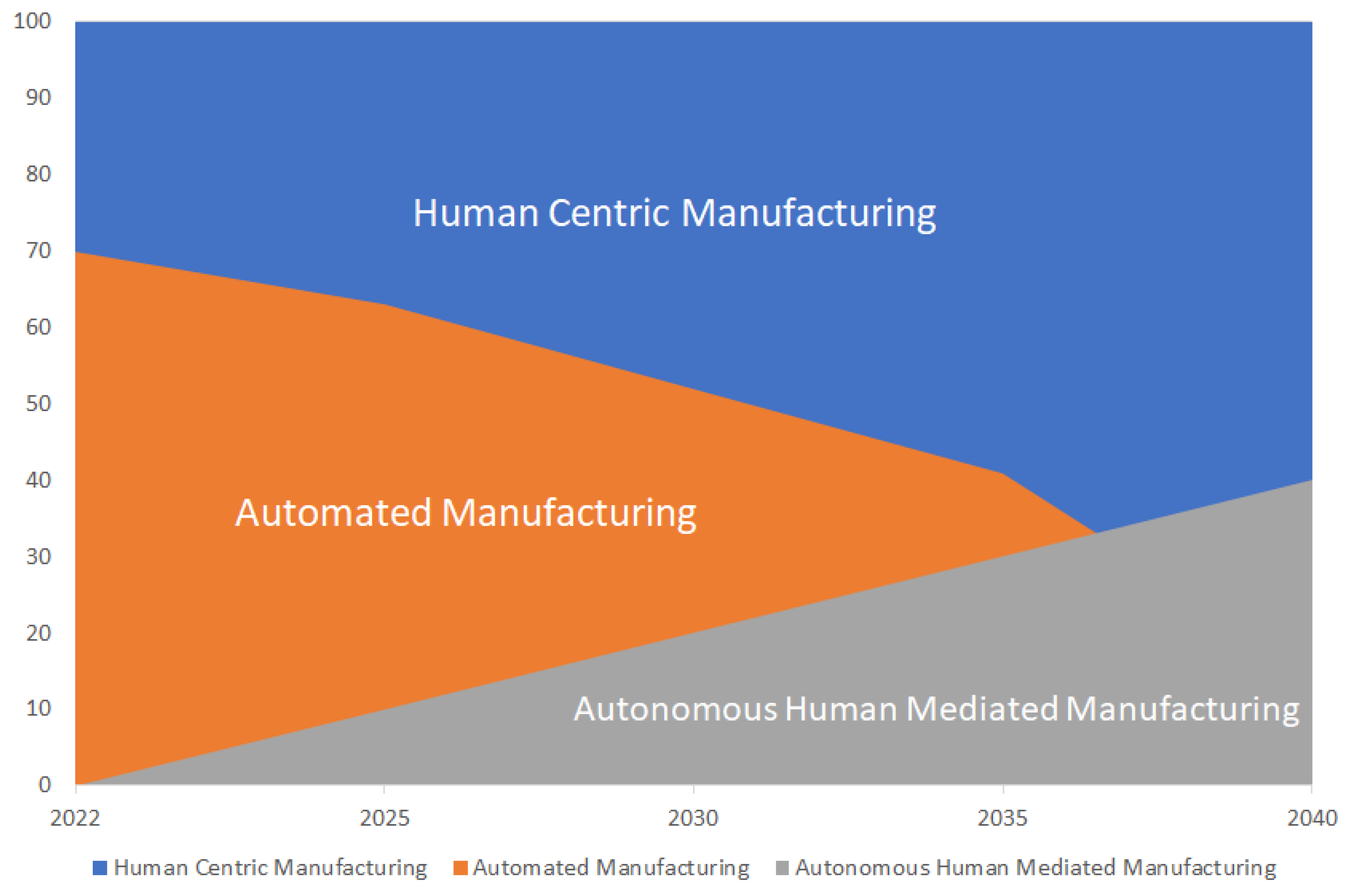

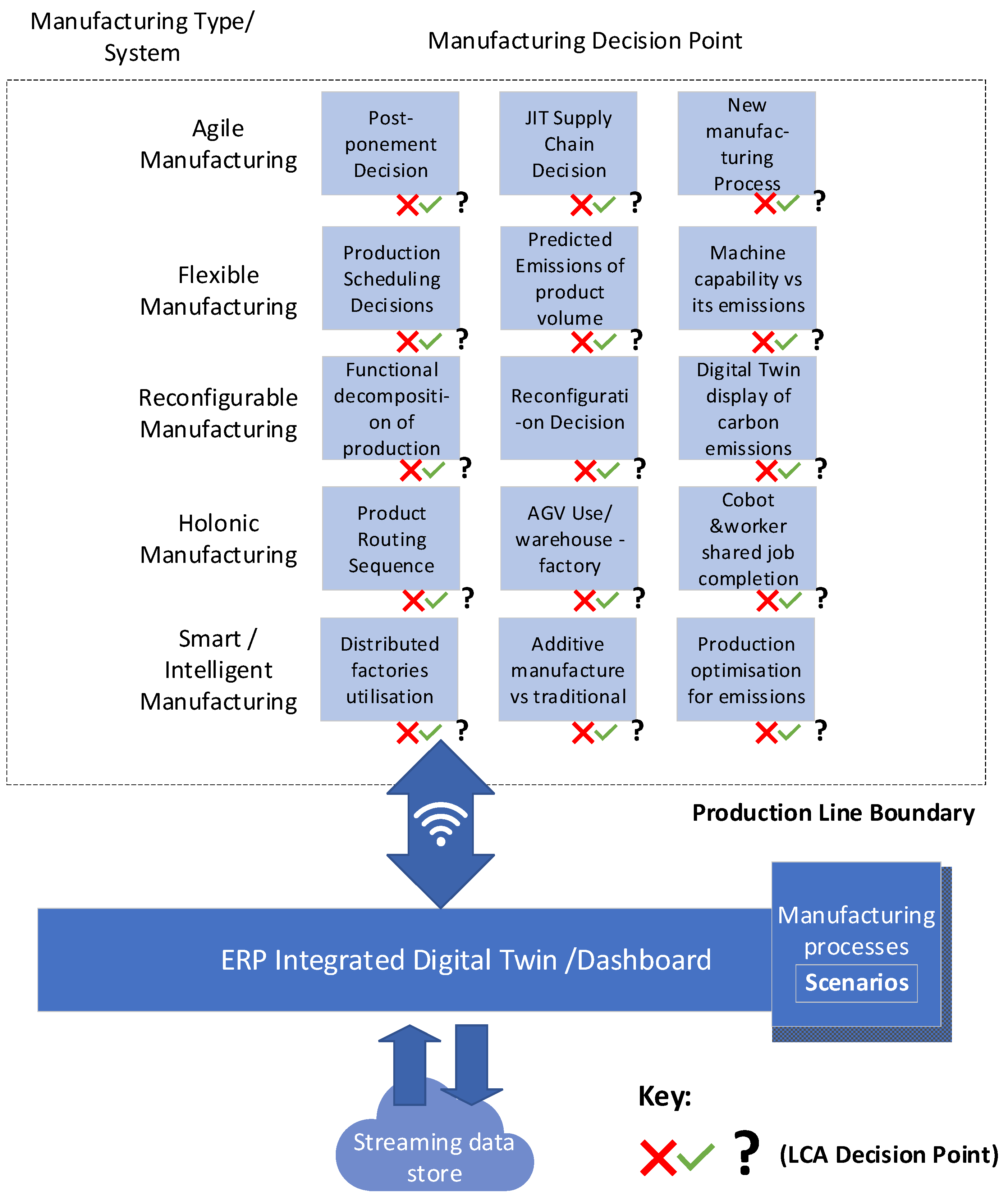

4. Industry 5.0: Human-Centric and Sustainability Pillars

4.1. Human-Centric Manufacturing

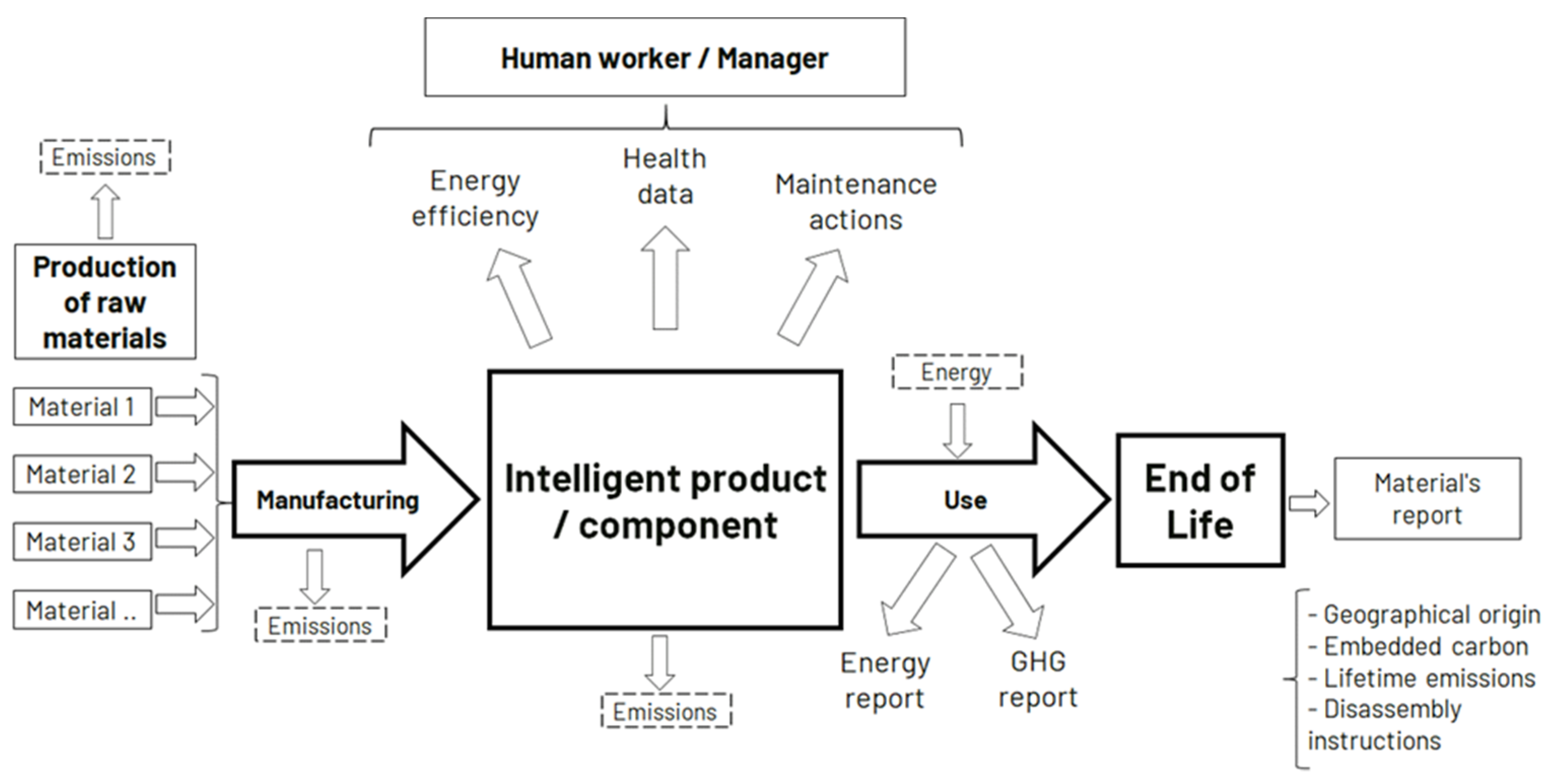

4.2. Sustainability in Industry 5.0 and LCA

4.3. LCA Use in the Circular Economy

- Reducing production losses;

- Changing material composition;

- Using more of technical lifetime (incl. reuse);

- Remanufacturing;

- Material recycling;

- Energy recovery;

- Increasing technical lifetime by design;

- Material extraction;

- Material production;

- Component and product manufacturing;

- Use;

- End of life.

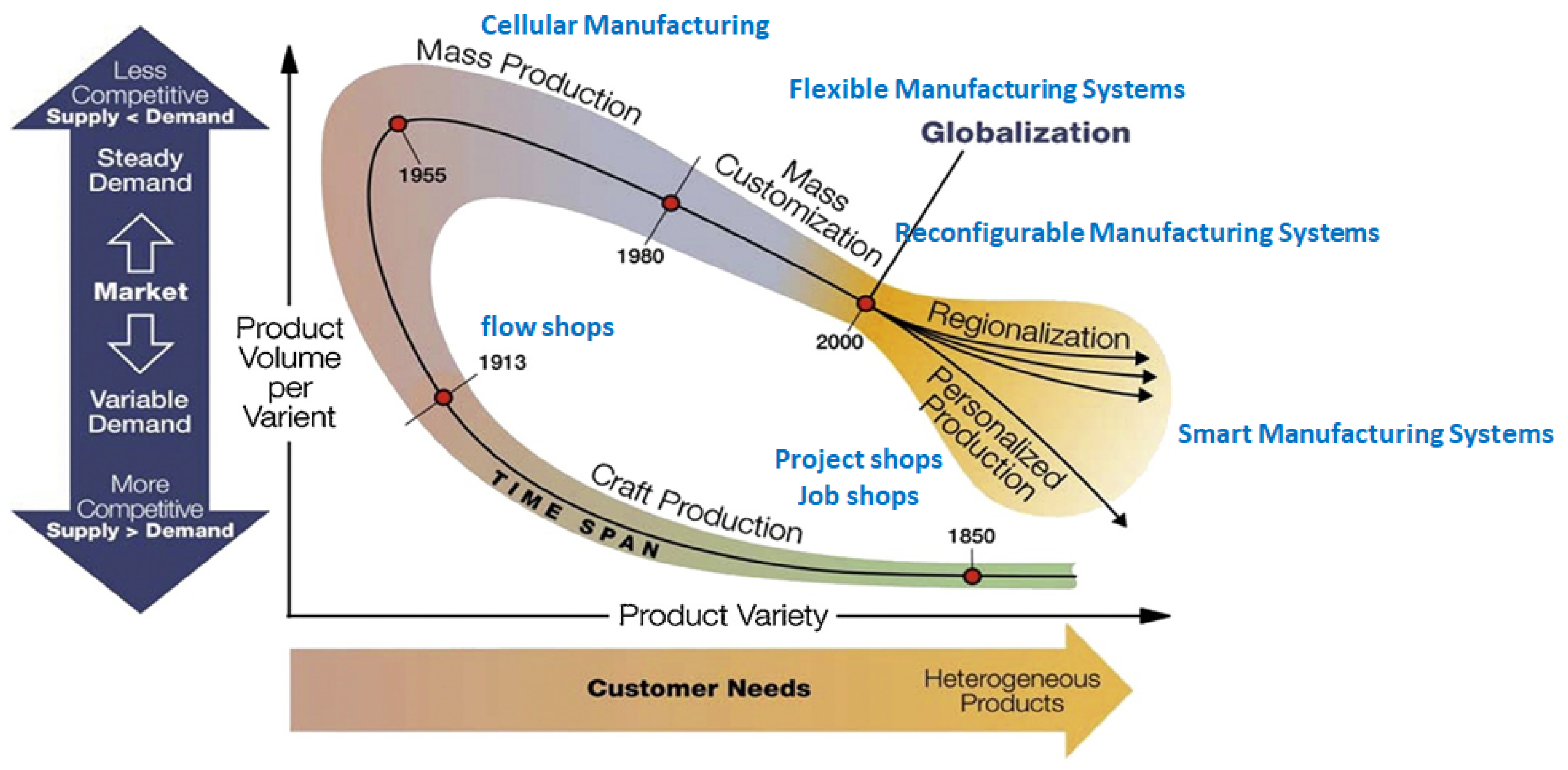

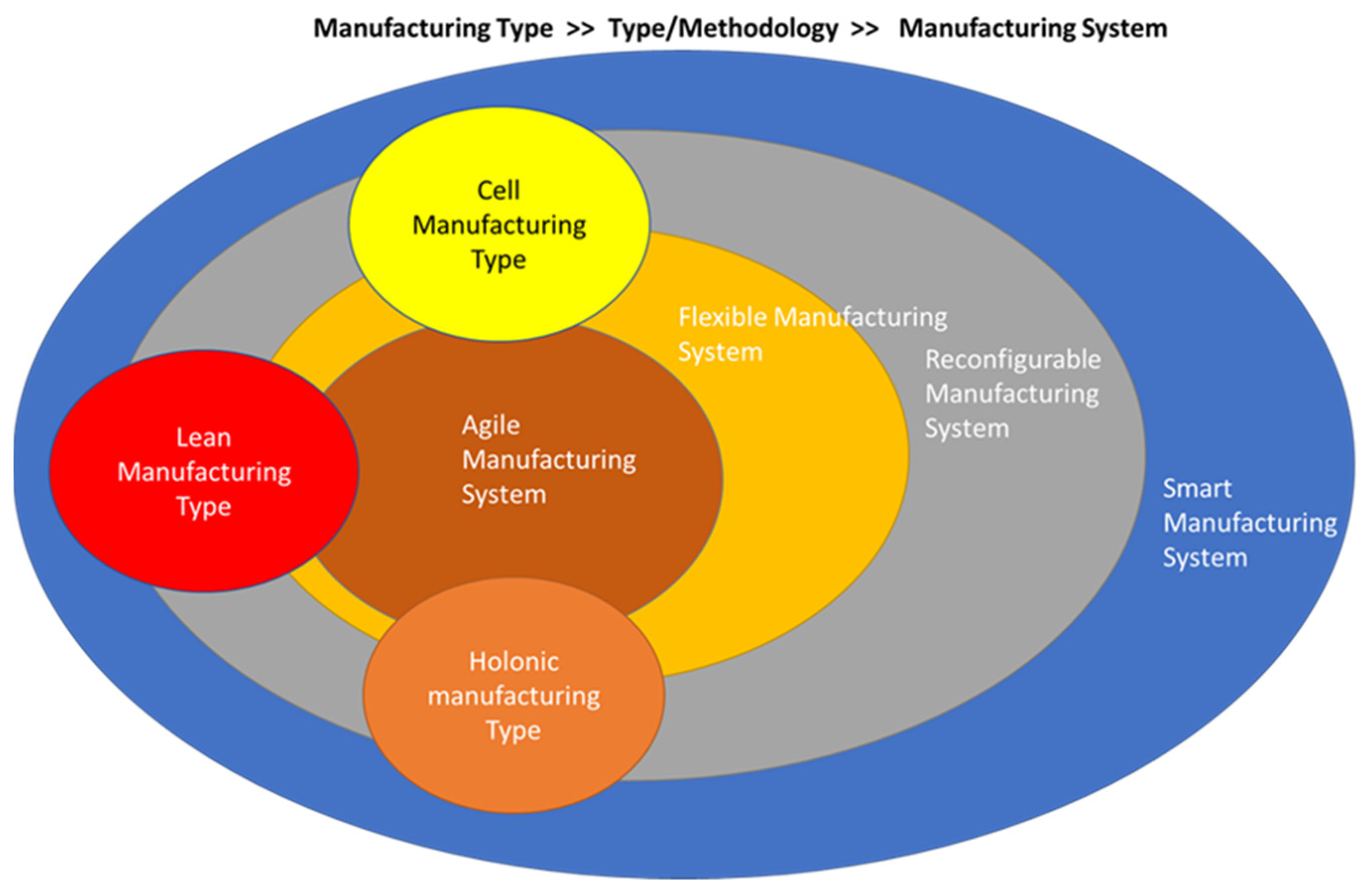

5. Review of the Classic Factory Types

Research Gaps

| Manufacturing Type or System | Agile Type | Flexible System | Holonic Type | Reconfigurable System | Smart/Intelligent System | Cell Type |

|---|---|---|---|---|---|---|

| Digital Technology or Approach | ||||||

| IoT | Beldiceanu et al., 2021 [122] Yli-Ojanpera et al., 2019 [81] Cheng et al., 2018 [80] Houyou et al., 2012 [79] Atmojo et al., 2019 [123] Yang et al., 2017 [124] | Radziwon et al., 2014 [67] Yao et al., 2018 [69] | Raileanu et al., 2018 [98] Fernandes et al., 2023 [125] | Kombaya Touckia et al., 2022 [126] Arnarson et al., 2022 [127] | Li et al., 2023 [128] Radziwon et al., 2014 [67] Cunha et al., 2021 [129] Zhou et al., 2020 [130] Turner et al., 2022 [131] Fraga-Lamas et al., 2022 [132] Noor-A-Rahim et al., 2022 [133] | Arnarson et al., 2022 [127] Cunha et al., 2021 [129] Zhou et al., 2020 [130] |

| Semantic/ontology | Spoladore and Pessot, 2022 [134] Nagy et al., 2022 [135] Ameri et al., 2022 [136] | Cheng et al., 2017 [68] Nagy et al., 2022 [135] Profanter et al., 2021 [137] | Ávila-Gutiérrez et al., 2020 [110] | Markusheska et al., 2022 [138] Profanter et al., 2021 [137] Capra, 2021 [139] Lu et al., 2020 [5] Pfrommer et al., 2015 [92] | Wong and Chui, 2022 [140] Tang et al., 2017 [103] | Sosa-Ceron and Gonzalez-Hernandez, 2022 [141] Trautner et al., 2021 [142] |

| Simulation | Khorasani et al., 2022 [143] | Filz et al., 2020 [72] El-Tamimi et al., 2012 [144] Yao et al., 2018 [69] Yadav and Jayswal, 2018 [71] Liu et al., 2022 [145] Ye et al., 2022 [146] | Fernandes et al., 2023 [126] Cristescu et al., 2021 [147] | Kombaya Touckia et al., 2022 [126] Mo et al., 2023 [148] | Turner and Garn, 2022 [149] Boccella et al., 2020 [150] Cristescu et al., 2021 [147] | Ye et al., 2022 [146] |

| Cobot/robot and automation | Atmojo et al., 2019 [123] Sadik et al., 2018 [151] Sadik et al., 2017 [152] | Mourtzis et al., 2020 [111] Eder et al., 2014 [153] Popper and Ruskowski, 2022 [154] Sadik et al., 2017 [152] Profanter et al., 2021 [137] | Yoshitake et al., 2019 Sadik and Urban, 2019 [155] Sadik et al., 2018 [152] Sadik et al., 2017 [109] Sadik et al., 2017 [152] | Wang and Koren, 2012 [87] Arnarson et al., 2022 [127] Markusheska et al., 2022 [138] Profanter et al., 2021 [137] | Mazumder et al., 2023 [156] Li et al., 2023 [128] Macherki et al., 2020 [157] Li et al., 2023 [158] Di Marino et al., 2022 [159] Brusaferri et al., 2014 [22] Yang et al., 2022 [160] Ren, and Li, 2022 [161] Fraga-Lamas et al., 2022 [132] Noor-A-Rahim et al., 2022 [133] Fan et al., 2022 [162] Turner et al., 2021 [3] | Umbrico et al., 2022 [163] Sosa-Ceron and Gonzalez-Hernandez, 2022 [141] Mourtzis et al., 2020 [111] Arnarson et al., 2022 [127] |

| Digital Twin | Fan et al., 2022b [164] Kombaya Touckia et al., 2022 [126] Kalaboukas et al., 2021 [165] Julien and Martin, 2021 [166] | Minca et al., 2022 [167] Fan et al., 2022 [164] Kombaya Touckia et al., 2022 [126] | Derigent et al., 2021 [97] Cristescu et al., 2021 [147] | Zhang et al., 2019 [91] Kombaya Touckia et al., 2022 [126] Arnarson et al., 2022 [127] Mo et al., 2023 [148] | Mazumder et al., 2023 [156] Yin et al., 2023 [168] Cristescu et al., 2021 [147] Zhou et al., 2020 [130] Fan et al., 2022a [162] Julien and Martin, 2021 [166] Xia et al., 2021 [169] Tao et al., 2018 [24] | Minca et al., 2022 [167] Arnarson et al., 2022 [127] Xia et al., 2021 [169] Zhou et al., 2020 [130] |

| Deep learning | Liu et al., 2022 [142] Minguillon, and Lanza, 2019 [170] | Song et al., 2023 [171] Wang et al., 2022 [172] Yan et al., 2022 [110] Chang et al., 2022 [173] Popper and Ruskowski, 2022 [154] Liu et al., 2022 [145] | Oborski and Wysockim, 2022 [174] | Tang et al., 2022 [175] | Li et al., 2023 [158] Zhang et al., 2022 [176] Yang et al., 2022 [160] Chang et al., 2022 [173] Yan et al., 2022 [114] Fan et al., 2022 [162] Xia et al., 2021 [169] | Rosioru et al., 2022 [177] Banjanovic-Mehmedovic et al., 2021 [178] Xia et al., 2021 [169] |

| Other machine learning | Beldiceanu et al., 2021 [122] | Priore et al., 2006 [70] Priore et al., 2018 [179] Yadav and Jayswal, 2018 [71] | van Brussel and Valckenaers, 2017 [96] Derigent et al., 2021 [97] Kruger and Basson, 2017 [112] Cardin et al., 2018 [180] Naticchia et al., 2019 [107] | Capra, 2021 [136] Kruger and Basson, 2017 [112] Khezri et al., 2021 [181] Wang and Koren, 2012 [87] Koren et al., 2018 [93] Maganha et al., 2019 [90] Montalto et al., 2020 [94] Yelles-Chaouche et al., 2020 [88] Bortolini et al., 2018 [95] Azab and Naderi, 2015 [89] Mo et al., 2023 [148] | Ren, and Li, 2022 [161] Turner and Garn, 2022 [149] Turner et al., 2021 [3] Sgarbossa et al., 2020 [182] Tang et al., 2017 [103] | Minca et al., 2022 [167] |

| Human-in-the loop/human-centric approaches | Sadik et al., 2018 [151] Yang et al., 2017 [124] Sadik et al., 2017 [152] | Profanter et al., 2021 [137] Eder et al., 2014 [153] Sadik et al., 2017 [152] | Sparrow et al., 2022 [183] Valette et al., 2021 [184] Macherki et al., 2020 [157] Sadik and Urban, 2019 [155] Leuvennink et al., 2019 [106] Sadik et al., 2017 [152] Sadik et al., 2018 [151] | Macherki et al., 2020 [157] Capra, 2021 [139] Profanter et al., 2021 [137] Lu et al., 2020 [5] | Yin et al., 2023 [168] Li et al., 2023 [128] Turner and Oyekan, 2023 [185] Mazumder et al., 2023 [156] Bhattacharya et al., 2023 [186] Di Marino et al., 2023 [159] Ren, and Li, 2022 [161] Simonetto et al., 2022 [187] Turner and Garn, 2022 [149] Turner et al., 2022 [131] Turner et al., 2021 [3] Fraga-Lamas et al., 2022 [132] Fan et al., 2022 [162] Wang et al., 2022 [11] | Umbrico et al., 2022 [163] Sosa-Ceron, et al., 2022 [141] |

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y. Integrated and intelligent manufacturing: Perspectives and enablers. Engineering 2017, 3, 588–595. [Google Scholar] [CrossRef]

- Van Brussel, H.; Wyns, J.; Valckenaers, P.; Bongaerts, L.; Peeters, P. Reference architecture for holonic manufacturing systems: PROSA. Comput. Ind. 1998, 37, 255–274. [Google Scholar] [CrossRef]

- Turner, C.; Ma, R.; Chen, J.; Oyekan, J. Human in the Loop: Industry 4.0 technologies and scenarios for worker mediation of automated manufacturing. IEEE Access 2021, 9, 103950–103966. [Google Scholar] [CrossRef]

- Koren, Y. The Global Manufacturing Revolution: Product-Process-Business Integration and Reconfigurable Systems; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 80. [Google Scholar]

- Lu, Y.; Xu, X.; Wang, L. Smart manufacturing process and system automation—A critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar] [CrossRef]

- German Federal Government. Industrie 4.0. 2021. Available online: https://www.bmwi.de/Navigation/EN/Topic/topic.html?cl2Categories_LeadKeyword=industrie-40 (accessed on 9 May 2023).

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0. Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, P.; Yin, Y.; Shih, A.; Wang, L. Toward human-centric smart manufacturing: A human-cyber-physical systems (HCPS) perspective. J. Manuf. Syst. 2022, 63, 471–490. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.A.; Yang, S. Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp 2014, 16, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Weyer, S.; Schmitt, M.; Ohmer, M.; Gorecky, D. Towards Industry 4.0-Standardization as the crucial challenge for highly modular, multi-vendor production systems. IFAC-Pap. 2015, 48, 579–584. [Google Scholar] [CrossRef]

- Pinzone, M.; Albè, F.; Orlandelli, D.; Barletta, I.; Berlin, C.; Johansson, B.; Taisch, M. A framework for operative and social sustainability functionalities in Human-Centric Cyber-Physical Production Systems. Comput. Ind. Eng. 2020, 139, 105132. [Google Scholar] [CrossRef]

- Barbosa, J.; Leitão, P.; Trentesaux, D.; Colombo, A.W.; Karnouskos, S. Cross benefits from cyber-physical systems and intelligent products for future smart industries. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN), Potiers, France, 19–21 July 2016; pp. 504–509. [Google Scholar]

- Leitao, P.; Karnouskos, S.; Ribeiro, L.; Lee, J.; Strasser, T.; Colombo, A.W. Smart agents in industrial cyber–physical systems. Proc. IEEE 2016, 104, 1086–1101. [Google Scholar] [CrossRef] [Green Version]

- Trappey, A.J.; Trappey, C.V.; Govindarajan, U.H.; Sun, J.J.; Chuang, A.C. A review of technology standards and patent portfolios for enabling cyber-physical systems in advanced manufacturing. IEEE Access 2016, 4, 7356–7382. [Google Scholar] [CrossRef]

- Nunes, D.S.; Zhang, P.; Silva, J.S. A survey on human-in-the-loop applications towards an internet of all. IEEE Commun. Surv. Tutor. 2015, 17, 944–965. [Google Scholar] [CrossRef]

- Cimini, C.; Pirola, F.; Pinto, R.; Cavalieri, S. A Human-in-the-Loop Manufacturing Control Architecture for the Next Generation of Production Systems. J. Manuf. Syst. 2020, 54, 258–271. [Google Scholar] [CrossRef]

- Brusaferri, A.; Ballarino, A.; Cavadini, F.A.; Manzocchi, D.; Mazzolini, M. CPS-based hierarchical and self-similar automation architecture for the control and verification of reconfigurable manufacturing systems. In Proceedings of the 2014 IEEE Emerging Technology and Factory Automation (ETFA), Barcelona, Spain, 16–19 September 2014. [Google Scholar] [CrossRef]

- Perera, C.; Zaslavsky, A.; Christen, P.; Georgakopoulos, D. Context aware computing for the internet of things: A survey. IEEE Commun. Surv. Tutor. 2013, 16, 414–454. [Google Scholar] [CrossRef] [Green Version]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, J.; Kiritsis, D. The emergence of cognitive digital twin: Vision, challenges and opportunities. Int. J. Prod. Res. 2022, 60, 7610–7632. [Google Scholar] [CrossRef]

- Eyre, J.; Hyde, S.; Walker, D.; Ojo, S.; Hayes, O.; Hartley, R.; Scott, R.; Bray, J. Untangling the Requirements of a Digital Twin. Advanced Manufacturing Research Centre. Technical Report. 2020. Available online: https://www.amrc.co.uk/files/document/406/1605271035_1604658922_AMRC_Digital_Twin_AW.pdf (accessed on 9 May 2023).

- Emmanouilidis, C.; Pistofidis, P.; Bertoncelj, L.; Katsouros, V.; Fournaris, A.; Koulamas, C.; Ruiz-Carcel, C. Enabling the human in the loop: Linked data and knowledge in industrial cyber-physical systems. Annu. Rev. Control 2019, 47, 249–265. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Garn, W.; Duggan, C.; Abdou, K. Industry 5.0 and the Circular Economy: Utilizing LCA with Intelligent Products. Sustainability 2022, 14, 14847. [Google Scholar] [CrossRef]

- Rojas, C.N.; Peñafiel, G.A.A.; Buitrago, D.F.L. Society 5.0: A Japanese Concept for a Superintelligent Society. Sustainability 2021, 13, 6567. [Google Scholar] [CrossRef]

- Marcon, É.; Soliman, M.; Gerstlberger, W.; Frank, A.G. Sociotechnical factors and Industry 4.0: An integrative perspective for the adoption of smart manufacturing technologies. J. Manuf. Technol. Manag. 2022, 33, 259–286. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Welfare, K.S.; Hallowell, M.R.; Shah, J.A.; Riek, L.D. Consider the human work experience when integrating robotics in the workplace. In Proceedings of the 2019 14th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Daegu, Republic of Korea, 11–14 March 2019; pp. 75–84. [Google Scholar]

- Romero, D.; Stahre, J.; Wuest, T.; Noran, O.; Bernus, P.; Fast-Berglund, Å.; Gorecky, D. Towards an operator 4.0 typology: A human-centric perspective on the fourth industrial revolution technologies. In Proceedings of the International Conference on Computers and Industrial Engineering, CIE46, Tianjin, China, 29–31 October 2016; pp. 29–31. [Google Scholar]

- Romero, D.; Stahre, J.; Taisch, M. The Operator 4.0: Towards socially sustainable factories of the future. Comput. Ind. Eng. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Romero, D.; Stahre, J. Towards the Resilient Operator 5.0: The Future of Work in Smart Resilient Manufacturing Systems. Procedia CIRP 2021, 104, 1089–1094. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef] [Green Version]

- Doyle-Kent, M. Collaborative Robotics in Industry 5.0. Ph.D. Dissertation, Technische Universität Wien, Wien, Austria, 2021. [Google Scholar]

- Dudek, M.; Bashynska, I.; Filyppova, S.; Yermak, S.; Cichoń, D. Methodology for assessment of inclusive social responsibility of the energy industry enterprises. J. Clean. Prod. 2023, 394, 136317. [Google Scholar] [CrossRef]

- Kumar, A. From mass customization to mass personalization: A strategic transformation. Int. J. Flex. Manuf. Syst. 2007, 19, 533–547. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving paradigms of manufacturing: From mass production to mass customization and personalization. Procedia Cirp 2013, 7, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.; Ji, Y.; Jiao, R.J. Affective and cognitive design for mass personalization: Status and prospect. J. Intell. Manuf. 2013, 24, 1047–1069. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M. Design and planning of manufacturing networks for mass customisation and personalisation: Challenges and outlook. Procedia CIRP 2014, 19, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Aheleroff, S.; Philip, R.; Zhong, R.Y.; Xu, X. The degree of mass personalisation under industry 4.0. Procedia CIRP 2019, 81, 1394–1399. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Koren, Y.; Shpitalni, M.; Gu, P.; Hu, S.J. Product design for mass-individualization. Procedia CIRP 2015, 36, 64–71. [Google Scholar] [CrossRef] [Green Version]

- MacArthur, E. Towards a Circular Economy: Business Rationale for an Accelerated Transition, The Ellen MacArthur Foundation. 2015. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/publications/TCE_Ellen-MacArthur-Foundation_26-Nov-2015.pdf (accessed on 9 May 2023).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Guinée, J.B.; Lindeijer, E. (Eds.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2002; Volume 7. [Google Scholar]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- Ketkale, H.; Simske, S. A LifeCycle Analysis and Economic Cost Analysis of Corrugated Cardboard Box Reuse and Recycling in the United States. Resources 2023, 12, 22. [Google Scholar] [CrossRef]

- Roy, P.; Nei, D.; Orikasa, T.; Xu, Q.; Okadome, H.; Nakamura, N.; Shiina, T. A review of life cycle assessment (LCA) on some food products. J. Food Eng. 2009, 90, 1–10. [Google Scholar] [CrossRef]

- Feng, H.; Zhao, J.; Hollberg, A.; Habert, G. Where to focus? Developing a LCA impact category selection tool for manufacturers of building materials. J. Clean. Prod. 2023, 1, 136936. [Google Scholar] [CrossRef]

- Rivera, X.S.; Balcombe, P.; Niero, M. Life Cycle Assessment as a Metric for Circular Economy. In Life Cycle Assessment; Borrion, A., Black, M.J., Mwabonje, O., Eds.; The Royal Society of Chemistry: London, UK, 2021; pp. 54–80. [Google Scholar] [CrossRef]

- Morlet, A.; Blériot, J.; Opsomer, R.; Linder, M.; Henggeler, A.; Bluhm, A.; Carrera, A. Intelligent Assets: Unlocking the Circular Economy Potential. Ellen MacArthur Found. 2016, pp. 1–25. Available online: https://ellenmacarthurfoundation.org/intelligent-assets-unlocking-the-circular-economy-potential (accessed on 9 May 2023).

- Tóth Szita, K. The application of life cycle assessment in circular economy. Hung. Agric. Eng. 2017, 31, 5–9. [Google Scholar] [CrossRef]

- Hegab, H.; Shaban, I.; Jamil, M.; Khanna, N. Toward sustainable future: Strategies, indicators, and challenges for implementing sustainable production systems. Sustain. Mater. Technol. 2023, 36, e00617. [Google Scholar] [CrossRef]

- Jerome, A.; Helander, H.; Ljunggren, M.; Janssen, M. Mapping and testing circular economy product-level indicators: A critical review. Resour. Conserv. Recycl. 2022, 178, 106080. [Google Scholar] [CrossRef]

- Beemsterboer, S.; Baumann, H.; Wallbaum, H. Ways to get work done: A review and systematisation of simplification practices in the LCA literature. Int. J. Life Cycle Assess. 2020, 25, 2154–2168. [Google Scholar] [CrossRef]

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. J. Intell. Manuf. 2000, 11, 403–419. [Google Scholar] [CrossRef]

- Prendeville, S.; Hartung, G.; Purvis, E.; Brass, C.; Hall, A. Makespaces: From Redistributed Manufacturing to a Circular Economy. In SDM 2016: Sustainable Design and Manufacturing 2016; Smart Innovation, Systems and Technologies, Volume 52; Setchi, R., Howlett, R., Liu, Y., Theobald, P., Eds.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef] [Green Version]

- Pathak, S.; Arunkumar, O.N.; Kurian, J.; Garn, W.; Turner, C. Optimisation of Reverse Logistics for e-waste Management. In Proceedings of the 2nd Pritam Singh Memorial (PRISM) Conference, Nagpur, India, 17–19 November 2022. [Google Scholar]

- Jackson, M.; Zaman, A. Factory-in-a-box–mobile production capacity on demand. Int. J. Mod. Eng. 2007, 8, 12–26. [Google Scholar]

- El Maraghy, H.A. Flexible and reconfigurable manufacturing systems paradigms. Flex. Serv. Manuf. J. 2006, 17, 261–276. [Google Scholar] [CrossRef]

- Browne, J.; Dubois, D.; Rathmill, K.; Sethi, S.P.; Stecke, K.E. Classification of Flexible Manufacturing Systems. FMS Mag. 1984, 2, 114–117. Available online: http://www.researchgate.net/publication/242625866_Classification_of_Flexible_Manufacturing_Systems (accessed on 9 May 2023).

- Radziwon, A.; Bilberg, A.; Bogers, M.; Madsen, E.S. The smart factory: Exploring adaptive and flexible manufacturing solutions. Procedia Eng. 2014, 69, 1184–1190. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Xue, L.; Wang, P.; Zeng, P.; Yu, H. Ontology-based web service integration for flexible manufacturing systems. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 351–356. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, J.; Li, Y.; Zhang, C. Towards flexible rfid event-driven integrated manufacturing for make-to-order production. Int. J. Comput. Integr. Manuf. 2018, 31, 228–242. [Google Scholar] [CrossRef]

- Priore, P.; De La Fuente, D.; Puente, J.; Parreño, J. A comparison of machine-learning algorithms for dynamic scheduling of flexible manufacturing systems. Eng. Appl. Artif. Intell. 2006, 19, 247–255. [Google Scholar] [CrossRef]

- Yadav, A.; Jayswal, S.C. Modelling of flexible manufacturing system: A review. Int. J. Prod. Res. 2018, 56, 2464–2487. [Google Scholar] [CrossRef]

- Filz, M.-A.; Herrmann, C.; Thiede, S. Simulation-based Data Analysis to Support the Planning of Flexible Manufacturing Systems. SNE Simul. Notes Eur. 2020, 30, 131–137. [Google Scholar] [CrossRef]

- Gunasekaran, A. Agile manufacturing: A framework for research and development. Int. J. Prod. Econ. 1999, 62, 87–105. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Yusuf, Y.Y. Agile manufacturing: A taxonomy of strategic and technological imperatives. Int. J. Prod. Res. 2002, 40, 1357–1385. [Google Scholar] [CrossRef]

- Sharifi, H.; Zhang, Z. Agile manufacturing in practice Application of a methodology. Int. J. Oper. Prod. Manag. 2001, 21, 772–779. [Google Scholar] [CrossRef]

- Sanchez, L.M.; Nagi, R. A review of agile manufacturing systems. Int. J. Prod. Res. 2001, 39, 3561–3600. [Google Scholar] [CrossRef]

- Yusuf, Y.Y.; Sarhadi, M.; Gunasekaran, A. Agile manufacturing: The drivers, concepts and attributes. Int. J. Prod. Econ. 1999, 62, 33–43. [Google Scholar] [CrossRef]

- Zhang, Z.D.; Sharifi, H. Towards theory building in agile manufacturing strategy—A taxonomical approach. IEEE Trans. Eng. Manag. 2007, 54, 351–370. [Google Scholar] [CrossRef]

- 'Houyou, A.M.; Huth, H.-P.; Kloukinas, C.; Trsek, H.; Rotondi, D. Agile manuacturing: General challenges and an IoT@Work perspective. In Proceedings of the 2012 IEEE 17th International Conference on Emerging Technologies & Factory Automation (ETFA 2012), Krakow, Poland, 17–21 September 2012; pp. 1–7. [Google Scholar] [CrossRef]

- Cheng, Y.; Tao, F.; Xu, L.; Zhao, D. Advanced manufacturing systems: Supply–demand matching of manufacturing resource based on complex networks and Internet of Things. Enterp. Inf. Syst. 2018, 12, 780–797. [Google Scholar] [CrossRef]

- Yli-Ojanperä, M.; Sierla, S.; Papakonstantinou, N.; Vyatkin, V. Adapting an agile manufacturing concept to the reference architecture model industry 4.0: A survey and case study. J. Ind. Inf. Integr. 2018, 15, 147–160. [Google Scholar] [CrossRef]

- Rauch, E.; Dallasega, P.; Matt, D.T. Distributed manufacturing network models of smart and agile mini-factories. Int. J. Agil. Syst. Manag. 2017, 10, 185–205. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, Y.; Zhang, L.; Nee, A.Y.C. Advanced manufacturing systems: Socialization characteristics and trends. J. Intell. Manuf. 2017, 28, 1079–1094. [Google Scholar] [CrossRef]

- Potdar, P.K.; Routroy, S.; Behera, A. Agile manufacturing: A systematic review of literature and implications for future research. Benchmarking 2017, 24, 2022–2048. [Google Scholar] [CrossRef]

- Koren, Y.; Heisel, U.; Jovane, U.; Moriwaki, T.; Ulsoy, G. Reconfigurable manufacturing systems. CIRP Ann. Manuf. Technol. 1999, 48, 527–540. [Google Scholar] [CrossRef]

- Koren, Y.; Shpitalni, M. Design of reconfigurable manufacturing systems. J. Manuf. Syst. 2010, 29, 130–141. [Google Scholar] [CrossRef]

- Wang, W.; Koren, Y. Scalability planning for reconfigurable manufacturing systems. J. Manuf. Syst. 2012, 31, 83–91. [Google Scholar] [CrossRef]

- Yelles-Chaouche, A.R.; Gurevsky, E.; Brahimi, N.; Dolgui, A. Reconfigurable manufacturing systems from an optimisation perspective: A focused review of literature. Int. J. Prod. Res. 2020, 1, 13913. [Google Scholar] [CrossRef]

- Azab, A.; Naderi, B. Modelling the problem of production scheduling for reconfigurable manufacturing systems. Procedia CIRP 2015, 33, 76–80. [Google Scholar] [CrossRef] [Green Version]

- Maganha, I.; Silva, C.; Ferreira, L.M.D.F. The layout design in reconfigurable manufacturing systems: A literature review. Int. J. Adv. Manuf. Technol. 2019, 105, 683–700. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D.T. A reconfigurable modeling approach for digital twin-based manufacturing system. Procedia CIRP 2019, 83, 118–125. [Google Scholar] [CrossRef]

- Pfrommer, J.; Stogl, D.; Aleksandrov, K.; Navarro, S.E.; Hein, B.; Beyerer, J. Plug & produce by modelling skills and service-oriented orchestration of reconfigurable manufacturing systems. At. Autom. 2015, 63, 790–800. [Google Scholar] [CrossRef]

- Koren, Y.; Gu, X.; Guo, W. Reconfigurable manufacturing systems: Principles, design, and future trends. Front. Mech. Eng. 2018, 13, 121–136. [Google Scholar] [CrossRef] [Green Version]

- Montalto, A.; Graziosi, S.; Bordegoni, M.; Di Landro, L.; van Tooren, M.J.L. An approach to design reconfigurable manufacturing tools to manage product variability: The mass customisation of eyewear. J. Intell. Manuf. 2020, 31, 87–102. [Google Scholar] [CrossRef] [Green Version]

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems: Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- Van Brussel, H.; Valckenaers, P. Design of holonic manufacturing systems. J. Mach. Eng. 2017, 17, 5–23. [Google Scholar]

- Derigent, W.; Cardin, O.; Trentesaux, D. Industry 4.0: Contributions of holonic manufacturing control architectures and future challenges. J. Intell. Manuf. 2021, 32, 1797–1818. [Google Scholar] [CrossRef] [Green Version]

- Raileanu, S.; Borangiu, T.; Morariu, O.; Iacob, I. Edge computing in industrial iot framework for cloud-based manufacturing control. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; pp. 261–266. [Google Scholar] [CrossRef]

- McFarlane, D.; Sarma, S.; Chirn, J.L.; Wong, C.Y.; Ashton, K. The intelligent product in manufacturing control and management. IFAC Proc. Vol. 2002, 35, 49–54. [Google Scholar] [CrossRef] [Green Version]

- McFarlane, D.; Giannikas, V.; Wong, A.C.; Harrison, M. Intelligent products in the supply chain-10 years on. IFAC Proc. Vol. 2012, 45, 655–660. [Google Scholar] [CrossRef]

- Valckenaers, P.; Van Brussel, H. Holonic manufacturing execution systems. CIRP Ann. Manuf. Technol. 2005, 54, 427–432. [Google Scholar] [CrossRef]

- Leitão, P.; Restivo, F.J. Implementation of a holonic control system in a flexible manufacturing system. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2008, 38, 699–709. [Google Scholar] [CrossRef]

- Tang, H.; Li, D.; Wang, S.; Dong, Z. CASOA: An architecture for agent-based manufacturing system in the context of industry 4.0. IEEE Access 2017, 6, 12746–12754. [Google Scholar] [CrossRef]

- Cao, H.; Yang, X.; Deng, R. Ontology-Based Holonic Event-Driven Architecture for Autonomous Networked Manufacturing Systems. IEEE Trans. Autom. Sci. Eng. 2020, 18, 205–215. [Google Scholar] [CrossRef]

- Valckenaers, P. Perspective on holonic manufacturing systems: PROSA becomes ARTI. Comput. Ind. 2020, 120, 103226. [Google Scholar] [CrossRef]

- Leuvennink, J.; Kruger, K.; Basson, A. Architectures for human worker integration in holonic manufacturing systems. Stud. Comput. Intell. 2019, 803, 133–144. [Google Scholar] [CrossRef]

- Naticchia, B.; Carbonari, A.; Vaccarini, M.; Giorgi, R. Holonic execution system for real-time construction management. Autom. Constr. 2019, 104, 179–196. [Google Scholar] [CrossRef]

- Yoshitake, H.; Kamoshida, R.; Nagashima, Y. New Automated Guided Vehicle System Using Real-Time Holonic Scheduling for Warehouse Picking. IEEE Robot. Autom. Lett. 2019, 4, 1045–1052. [Google Scholar] [CrossRef]

- Sadik, A.R.; Urban, B. An ontology-based approach to enable knowledge representation and reasoning in Worker-Cobot agile manufacturing. Future Internet 2017, 9, 90. [Google Scholar] [CrossRef] [Green Version]

- Ávila-Gutiérrez, M.J.; Martín-Gómez, A.; Aguayo-González, F.; Lama-Ruiz, J.R. Eco-Holonic 4.0 Circular Business Model to Conceptualize Sustainable Value Chain towards Digital Transition. Sustainability 2020, 12, 1889. [Google Scholar] [CrossRef] [Green Version]

- Mourtzis, D.; Angelopoulos, J.; Dimitrakopoulos, G. Design and development of a flexible manufacturing cell in the concept of learning factory paradigm for the education of generation 4.0 engineers. Procedia Manuf. 2020, 45, 361–366. [Google Scholar] [CrossRef]

- Kruger, K.; Basson, A. Erlang-based control implementation for a holonic manufacturing cell. Int. J. Comput. Integr. Manuf. 2017, 30, 641–652. [Google Scholar] [CrossRef]

- Coalition, S.M.L. Implementing 21st Century Smart Manufacturing. Workshop Summary Report. 2011. Available online: https://www.controlglobal.com/assets/11WPpdf/110621_SMLC-smart-manufacturing.pdf (accessed on 9 May 2023).

- Yan, Q.; Wu, W.; Wang, H. Deep reinforcement learning for distributed flow shop scheduling with flexible maintenance. Machines 2022, 10, 210. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Li, H.X.; Si, H. Control for intelligent manufacturing: A multiscale challenge. Engineering 2017, 3, 608–615. [Google Scholar] [CrossRef]

- Marques, M.; Agostinho, C.; Zacharewicz, G.; Jardim-Gonçalves, R. Decentralized decision support for intelligent manufacturing in Industry 4.0. J. Ambient. Intell. Smart Environ. 2017, 9, 299–313. [Google Scholar] [CrossRef] [Green Version]

- Yao, X.; Zhou, J.; Zhang, J.; Boër, C.R. From intelligent manufacturing to smart manufacturing for industry 4.0 driven by next generation artificial intelligence and further on. In Proceedings of the 2017 5th International Conference on Enterprise Systems (ES), Tokyo, Japan, 4–6 September 2017; pp. 311–318. [Google Scholar]

- Kumar, N.; Lee, S.C. Human-machine interface in smart factory: A systematic literature review. Technol. Forecast. Soc. Change 2022, 174, 121284. [Google Scholar] [CrossRef]

- Liu, C.; Jiang, P. A cyber-physical system architecture in shop floor for intelligent manufacturing. Procedia CIRP 2016, 56, 372–377. [Google Scholar] [CrossRef] [Green Version]

- McFarlane, D.; Ratchev, S.; Thorne, A.; Parlikad, A.K.; De Silva, L.; Schönfuß, B.; Hawkridge, G.; Terrazas, G.; Tlegenov, Y. Digital manufacturing on a shoestring: Low cost digital solutions for SMEs. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future: Proceedings of SOHOMA 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 40–51. [Google Scholar]

- Beldiceanu, N.; Dolgui, A.; Gonnermann, C.; Gonzalez-Castañé, G.; Kousi, N.; Meyers, B.; Prud’Homme, J.; Thevenin, S.; Vyhmeister, E.; Östberg, P.O. Assistant: Learning and robust decision support system for agile manufacturing environments. IFAC Pap. 2021, 54, 641–646. [Google Scholar] [CrossRef]

- Atmojo, U.D.; Blech, J.O.; Sierla, S.; Vyatkin, V. Service-based architecture with product-centric control in a production island-based agile factory. In Proceedings of the 2019 IEEE International Conference on Industrial Internet (ICII), Sydney, Australia, 3–7 November 2019; pp. 305–306. [Google Scholar]

- Yang, L.; Li, W.; Luo, Y.; Duan, Y.; Fortino, G. A social-d2d architecture for people-centric industrial internet of things. In Proceedings of the 2017 IEEE 14th International Conference on Networking, Sensing and Control (ICNSC), London, UK, 4–7 May 2017; pp. 744–749. [Google Scholar]

- Fernandes, N.; Barros, J.P.; Campos-Rebelo, R. Graphic Model for Shop Floor Simulation and Control in the Context of Industry 5.0. Appl. Sci. 2023, 13, 930. [Google Scholar] [CrossRef]

- Kombaya Touckia, J.; Hamani, N.; Kermad, L. Digital twin framework for reconfigurable manufacturing systems (RMSs): Design and simulation. Int. J. Adv. Manuf. Technol. 2022, 120, 5431–5450. [Google Scholar] [CrossRef]

- Arnarson, H.; Mahdi, H.; Solvang, B.; Bremdal, B.A. Towards automatic configuration and programming of a manufacturing cell. J. Manuf. Syst. 2022, 64, 225–235. [Google Scholar] [CrossRef]

- Li, S.; Zheng, P.; Liu, S.; Wang, Z.; Wang, X.V.; Zheng, L.; Wang, L. Proactive human–robot collaboration: Mutual-cognitive, predictable, and self-organising perspectives. Robot. Comput. Integr. Manuf. 2023, 81, 102510. [Google Scholar] [CrossRef]

- Cunha, J.; Batista, N.; Cardeira, C.; Melicio, R. Upgrading a legacy manufacturing cell to IoT. J. Sens. Actuator Netw. 2021, 10, 65. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, C.; Li, Z.; Ding, K.; Wang, C. Knowledge-driven digital twin manufacturing cell towards intelligent manufacturing. Int. J. Prod. Res. 2020, 58, 1034–1051. [Google Scholar] [CrossRef]

- Turner, C.; Okorie, O.; Emmanouilidis, C.; Oyekan, J. XAI Sustainable Human in the Loop Maintenance. In Proceedings of the 2022 Advanced Maintenance Engineering, Services and Technology (AMEST) Conference, Bogota, Columbia, 26–29 July 2022. [Google Scholar]

- Fraga-Lamas, P.; Barros, D.; Lopes, S.I.; Fernández-Caramés, T.M. Mist and Edge Computing Cyber-Physical Human-Centered Systems for Industry 5.0: A Cost-Effective IoT Thermal Imaging Safety System. Sensors 2022, 22, 8500. [Google Scholar] [CrossRef]

- Noor-A-Rahim, M.; Firyaguna, F.; John, J.; Khyam, M.O.; Pesch, D.; Armstrong, E.; Claussen, H.; Poor, H.V. Toward Industry 5.0: Intelligent Reflecting Surface in Smart Manufacturing. IEEE Commun. Mag. 2022, 60, 72–78. [Google Scholar] [CrossRef]

- Spoladore, D.; Pessot, E. An evaluation of agile ontology engineering methodologies for the digital transformation of companies. Comput. Ind. 2022, 140, 103690. [Google Scholar] [CrossRef]

- Nagy, L.; Ruppert, T.; Abonyi, J. Human-centered knowledge graph-based design concept for collaborative manufacturing. In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA) 2022, Beijing, China, 7–11 August 2022; pp. 1–8. [Google Scholar]

- Ameri, F.; Sormaz, D.; Psarommatis, F.; Kiritsis, D. Industrial ontologies for interoperability in agile and resilient manufacturing. Int. J. Prod. Res. 2022, 60, 420–441. [Google Scholar] [CrossRef]

- Profanter, S.; Perzylo, A.; Rickert, M.; Knoll, A. A generic plug & produce system composed of semantic opc ua skills. IEEE Open J. Ind. Electron. Soc. 2021, 2, 128–141. [Google Scholar]

- Markusheska, N.; Srinivasan, V.; Walther, J.N.; Gindorf, A.; Biedermann, J.; Meller, F.; Nagel, B. Implementing a system architecture model for automated aircraft cabin assembly processes. CEAS Aeronaut. J. 2022, 13, 689–703. [Google Scholar] [CrossRef]

- Capra, L. A maude implementation of rewritable petri nets: A feasible model for dynamically reconfigurable systems. Electron. Proc. Theor. Comput. Sci. 2021, 349, 31–49. [Google Scholar] [CrossRef]

- Wong, P.M.; Chui, C.K. Cognitive engine for augmented human decision-making in manufacturing process control. J. Manuf. Syst. 2022, 65, 115–129. [Google Scholar] [CrossRef]

- Sosa-Ceron, A.D.; Gonzalez-Hernandez, H.G.; Reyes-Avendaño, J.A. Learning from Demonstrations in Human-Robot Collaborative Scenarios: A Survey. Robotics 2022, 11, 126. [Google Scholar] [CrossRef]

- Trautner, T.; Ayatollahi, I.; Strutzenberger, D.; Frühwirth, T.; Pauker, F.; Kittl, B. Behavioral modeling of manufacturing skills in OPC UA for automated execution by an independent cell controller. Procedia CIRP 2021, 99, 633–638. [Google Scholar] [CrossRef]

- Khorasani, M.; Loy, J.; Ghasemi, A.H.; Sharabian, E.; Leary, M.; Mirafzal, H.; Cochrane, P.; Rolfe, B.; Gibson, I. A review of Industry 4.0 and additive manufacturing synergy. Rapid Prototyp. J. 2022, 28, 1462–1475. [Google Scholar] [CrossRef]

- El-Tamimi, A.M.; Abidi, M.H.; Mian, S.H.; Aalam, J. Analysis of performance measures of flexible manufacturing system. J. King Saud Univ.-Eng. Sci. 2012, 24, 115–129. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Piplani, R.; Toro, C. Deep reinforcement learning for dynamic scheduling of a flexible job shop. Int. J. Prod. Res. 2022, 60, 4049–4069. [Google Scholar] [CrossRef]

- Ye, Z.; Cai, Z.; Si, S.; Zhou, F. Operational reliability and quality loss of diversely configurated manufacturing cells with heterogeneous feedstocks. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2022, 236, 955–967. [Google Scholar] [CrossRef]

- Cristescu, G.; Chenaru, O.; Dobrescu, R. A holonic approach of manufacturing systems modeling and simulation. In Proceedings of the 2021 23rd International Conference on Control Systems and Computer Science (CSCS), Paris, France, 14–18 December 2021; pp. 238–242. [Google Scholar]

- Mo, F.; Rehman, H.U.; Monetti, F.M.; Chaplin, J.C.; Sanderson, D.; Popov, A.; Maffei, A.; Ratchev, S. A framework for manufacturing system reconfiguration and optimisation utilising digital twins and modular artificial intelligence. Robot. Comput. Integr. Manuf. 2023, 82, 102524. [Google Scholar] [CrossRef]

- Turner, C.; Garn, W. Next Generation DES Simulation: A Research Agenda for Human Centric Manufacturing Systems. J. Ind. Inf. Integr. 2022, 28, 100354. [Google Scholar] [CrossRef]

- Boccella, A.R.; Centobelli, P.; Cerchione, R.; Murino, T.; Riedel, R. Evaluating centralized and heterarchical control of smart manufacturing systems in the era of Industry 4.0. Appl. Sci. 2020, 10, 755. [Google Scholar] [CrossRef] [Green Version]

- Sadik, A.R.; Urban, B. CPROSA-holarchy: An enhanced PROSA model to enable worker—Cobot agile manufacturing. Int. J. Mech. Eng. Robot. Res. 2018, 7, 296–304. [Google Scholar] [CrossRef]

- Sadik, A.R.; Urban, B.; Adel, O. Using hand gestures to interact with an industrial robot in a cooperative flexible manufacturing scenario. In Proceedings of the 3rd International Conference on Mechatronics and Robotics Engineering, London, UK, 10–15 August 2017; pp. 11–16. [Google Scholar]

- Eder, K.; Harper, C.; Leonards, U. Towards the safety of human-in-the-loop robotics: Challenges and opportunities for safety assurance of robotic co-workers’. In Proceedings of the 23rd IEEE International Symposium on Robot and Human Interactive Communication, Vienna, Austria, 17–19 June 2014; pp. 660–665. [Google Scholar]

- Popper, J.; Ruskowski, M. Using Multi-Agent Deep Reinforcement Learning for Flexible Job Shop Scheduling Problems. Procedia CIRP 2022, 112, 63–67. [Google Scholar] [CrossRef]

- Sadik, A.R.; Urban, B. Ontology in Holonic Cooperative Manufacturing: A Solution to Share and Exchange the Knowledge. In Knowledge Discovery, Knowledge Engineering and Knowledge Management, Proceedings of the 9th International Joint Conference, IC3K 2017, Funchal, Madeira, Portugal, 1–3 November 2017; Revised Selected Papers 9; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 203–223. [Google Scholar]

- Mazumder, A.; Sahed, M.F.; Tasneem, Z.; Das, P.; Badal, F.R.; Ali, M.F.; Ahamed, M.H.; Abhi, S.H.; Sarker, S.K.; Das, S.K.; et al. Towards Next Generation Digital Twin in Robotics: Trends, Scopes, Challenges, and Future; Heliyon: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Macherki, D.; Diallo, T.M.; Choley, J.Y.; Guizani, A.; Barkallah, M.; Haddar, M. The Q-Holon: A quadridimensional holon to design and operate an adaptive and scalable architecture for CPPS. In Proceedings of the 2020 21st International Conference on Research and Education in Mechatronics (REM), Beijing, China, 19–22 October 2020; pp. 1–6. [Google Scholar]

- Li, C.; Zheng, P.; Yin, Y.; Pang, Y.M.; Huo, S. An AR-assisted Deep Reinforcement Learning-based approach towards mutual-cognitive safe human-robot interaction. Robot. Comput. Integr. Manuf. 2023, 80, 102471. [Google Scholar] [CrossRef]

- Di Marino, C.; Rega, A.; Vitolo, F.; Patalano, S. Enhancing Human-Robot Collaboration in the Industry 5.0 Context: Workplace Layout Prototyping. In Advances on Mechanics, Design Engineering and Manufacturing IV, Proceedings of the International Joint Conference on Mechanics, Design Engineering & Advanced Manufacturing, JCM 2022, Ischia, Italy, 1–3 June 2022; Springer International Publishing: Cham, Switzerland, 2022; pp. 454–465. [Google Scholar]

- Yang, C.; Wang, Y.; Lan, S.; Wang, L.; Shen, W.; Huang, G.Q. Cloud-edge-device collaboration mechanisms of deep learning models for smart robots in mass personalization. Robot. Comput. Integr. Manuf. 2020, 77, 102351. [Google Scholar] [CrossRef]

- Ren, Y.; Li, G.P. An Interactive and Adaptive Learning Cyber Physical Human System for Manufacturing with a Case Study in Worker Machine Interactions. IEEE Trans. Ind. Inform. 2022, 18, 6723–6732. [Google Scholar] [CrossRef]

- Fan, J.; Zheng, P.; Li, S. Vision-based holistic scene understanding towards proactive human–robot collaboration. Robot. Comput. Integr. Manuf. 2022, 75, 102304. [Google Scholar] [CrossRef]

- Umbrico, A.; Orlandini, A.; Cesta, A.; Faroni, M.; Beschi, M.; Pedrocchi, N.; Scala, A.; Tavormina, P.; Koukas, S.; Zalonis, A.; et al. Design of advanced human–robot collaborative cells for personalized human-robot collaborations. Appl. Sci. 2022, 12, 6839. [Google Scholar] [CrossRef]

- Fan, Y.; Dai, C.; Huang, S.; Hu, P.; Wang, X.; Yan, M. A life-cycle digital-twin collaboration framework based on the industrial internet identification and resolution. Int. J. Adv. Manuf. Technol. 2022, 123, 2883–2911. [Google Scholar] [CrossRef]

- Kalaboukas, K.; Rožanec, J.; Košmerlj, A.; Kiritsis, D.; Arampatzis, G. Implementation of cognitive digital twins in connected and agile supply networks—An operational model. Appl. Sci. 2021, 11, 4103. [Google Scholar] [CrossRef]

- Julien, N.; Martin, E. How to characterize a digital twin: A usage-driven classification. IFAC Pap. 2021, 54, 894–899. [Google Scholar] [CrossRef]

- Mincă, E.; Filipescu, A.; Cernega, D.; Șolea, R.; Filipescu, A.; Ionescu, D.; Simion, G. Digital Twin for a Multifunctional Technology of Flexible Assembly on a Mechatronics Line with Integrated Robotic Systems and Mobile Visual Sensor—Challenges towards Industry 5.0. Sensors 2022, 22, 8153. [Google Scholar] [CrossRef]

- Yin, Y.; Zheng, P.; Li, C.; Wang, L. A state-of-the-art survey on Augmented Reality-assisted Digital Twin for futuristic human-centric industry transformation. Robot. Comput. Integr. Manuf. 2023, 81, 102515. [Google Scholar] [CrossRef]

- Xia, K.; Sacco, C.; Kirkpatrick, M.; Saidy, C.; Nguyen, L.; Kircaliali, A.; Harik, R. A digital twin to train deep reinforcement learning agent for smart manufacturing plants: Environment, interfaces and intelligence. J. Manuf. Syst. 2021, 58, 210–230. [Google Scholar] [CrossRef]

- Minguillon, F.E.; Lanza, G. Coupling of centralized and decentralized scheduling for robust production in agile production systems. Procedia CIRP 2019, 79, 385–390. [Google Scholar] [CrossRef]

- Song, W.; Chen, X.; Li, Q.; Cao, Z. Flexible Job-Shop Scheduling via Graph Neural Network and Deep Reinforcement Learning. IEEE Trans. Ind. Inform. 2022, 19, 1600–1610. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, J.; Liu, C.; Zhang, Y.; Hu, S.; Chen, L. Multi-objective reinforcement learning framework for dynamic flexible job shop scheduling problem with uncertain events. Appl. Soft Comput. 2022, 131, 109717. [Google Scholar] [CrossRef]

- Chang, J.; Yu, D.; Hu, Y.; He, W.; Yu, H. Deep reinforcement learning for dynamic flexible job shop scheduling with random job arrival. Processes 2022, 10, 760. [Google Scholar] [CrossRef]

- Oborski, P.; Wysocki, P. Intelligent Visual Quality Control System Based on Convolutional Neural Networks for Holonic Shop Floor Control of Industry 4.0 Manufacturing Systems. Advances in Science and Technology. Res. J. 2022, 16, 89–98. [Google Scholar] [CrossRef]

- Tang, J.; Haddad, Y.; Salonitis, K. Reconfigurable manufacturing system scheduling: A deep reinforcement learning approach. Procedia CIRP 2022, 107, 1198–1203. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, H.; Tang, D.; Zhou, T.; Gui, Y. Dynamic job shop scheduling based on deep reinforcement learning for multi-agent manufacturing systems. Robot. Comput. Integr. Manuf. 2022, 78, 102412. [Google Scholar] [CrossRef]

- Rosioru, S.; Stamatescu, G.; Stamatescu, I.; Fagarasan, I.; Popescu, D. Deep Learning based Parts Classification in a Cognitive Robotic Cell System. In Proceedings of the 2022 26th International Conference on System Theory, Control and Computing (ICSTCC), Berlin, Germany, 4–7 April 2022; pp. 403–408. [Google Scholar]

- Banjanovic-Mehmedovic, L.; Gurdić, A. Object Classification in an Intelligent Robotic Cell Using Deep Learning. In New Technologies, Development and Application IV; Springer International Publishing: Cham, Switzerland, 2021; pp. 101–112. [Google Scholar]

- Priore, P.; Ponte, B.; Puente, J.; Gómez, A. Learning-based scheduling of flexible manufacturing systems using ensemble methods. Comput. Ind. Eng. 2018, 126, 282–291. [Google Scholar] [CrossRef] [Green Version]

- Cardin, O.; Derigent, W.; Trentesaux, D. Evolution of holonic control architectures towards Industry 4.0: A short overview. IFAC-PapersOnLine 2018, 51, 1243–1248. [Google Scholar] [CrossRef]

- Khezri, A.; Benderbal, H.H.; Benyoucef, L. Towards a sustainable reconfigurable manufacturing system (SRMS): Multi-objective based approaches for process plan generation problem. Int. J. Prod. Res. 2021, 59, 4533–4558. [Google Scholar] [CrossRef]

- Sgarbossa, F.; Peron, M.; Fragapane, G. Cloud Material Handling Systems: Conceptual Model and Cloud-Based Scheduling of Handling Activities. In Scheduling in Industry 4.0 and Cloud Manufacturing; Springer: Berlin/Heidelberg, Germany, 2020; pp. 87–101. [Google Scholar]

- Sparrow, D.E.; Kruger, K.; Basson, A.H. An architecture to facilitate the integration of human workers in Industry 4.0 environments. Int. J. Prod. Res. 2022, 60, 4778–4796. [Google Scholar] [CrossRef]

- Valette, E.; Demesure, G.; El-Haouzi, H.B.; Pannequin, R. Formal and modelling frameworks for social holonic control architectures. Comput. Ind. 2021, 132, 103521. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J. Personalised Production in the Age of Circular Additive Manufacturing. Appl. Sci. 2023, 13, 4912. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Penica, M.; O’Connell, E.; Southern, M.; Hayes, M. Human-in-Loop: A Review of Smart Manufacturing Deployments. Systems 2023, 11, 35. [Google Scholar] [CrossRef]

- Simonetto, M.; Arena, S.; Peron, M. A methodological framework to integrate motion capture system and virtual reality for assembly system 4.0 workplace design. Saf. Sci. 2022, 146, 105561. [Google Scholar] [CrossRef]

- Elkins, D.A.; Huang, N.; Alden, J.M. Agile manufacturing systems in the automotive industry. Int. J. Prod. Econ. 2004, 91, 201–214. [Google Scholar] [CrossRef]

- Oyekan, J.O.; Hutabarat, W.; Tiwari, A.; Grech, R.; Aung, M.H.; Mariani, M.P.; López-Dávalos, L.; Ricaud, T.; Singh, S.; Dupuis, C. The effectiveness of virtual environments in developing collaborative strategies between industrial robots and humans. Robot. Comput. -Integr. Manuf. 2019, 55, 41–54. [Google Scholar] [CrossRef]

- Huang, K.; Chen, J.; Oyekan, J. Decentralised aerial swarm for adaptive and energy efficient transport of unknown loads. Swarm Evol. Comput. 2019, 67, 100957. [Google Scholar] [CrossRef]

| Search Term | Peak Year | Published in 2022–2023 | Total |

|---|---|---|---|

| “Agile Manufacturing and Human Centric” OR “Human in the Loop” | 2022 | 4 | 9 |

| “Flexible Manufacturing and Human Centric” OR “Human in the Loop” | 2022 | 23 | 77 |

| “Holonic Manufacturing and Human” | 2005 | 3 | 32 |

| “Reconfigurable Manufacturing and Human Centric” OR “Human in the Loop” | 2022 | 4 | 9 |

| “Smart Manufacturing and Human Centric” OR “Human in the Loop” | 2022 | 50 | 112 |

| “Intelligent Manufacturing and Human Centric” OR “Human in the Loop” | 2022 | 25 | 90 |

| “Cell Manufacturing and Human Centric” OR “Human in the Loop” | 2022 | 5 | 9 |

| Agile Type | Flexible System | Holonic Type | Reconfigurable | Smart/Intelligent | Cell | |

|---|---|---|---|---|---|---|

| Simulation | ||||||

| Digital Twin | ||||||

| IoT | ||||||

| Edge computing | ||||||

| Semantic/ontology | ||||||

| Robot automation | ||||||

| Cobot automation | ||||||

| Deep learning | ||||||

| Other Machine Learning | ||||||

| Human in the loop/human centric | ||||||

| Key | Limited/no research | Research in progress | Advanced/mature research area |

| Materials Input | Manufacturing | Supply Chain | |

|---|---|---|---|

| Supply-chain manager/worker need | View of embodied carbon for raw materials and components to be transported; predicted emissions of required logistics | View of embodied carbon for completed products; predicted emissions of required logistics | Holistic view of emissions logistics and prediction of future logistics emissions |

| Raw-materials/component manufacturer | Carbon content of raw materials and their extraction/processing or embedded carbon and manufacturing process emissions of components to be supplied | Carbon emissions prediction of component manufacture/raw materials processing | View of emissions of inbound logistics and prediction of outbound logistics emissions |

| Manufacturing-manager/supervisor need | View of emissions for raw materials and components before further manufacture | Holistic view of emissions of entire manufacturing operation and predicted emissions of future production scenarios | View of emissions of inbound logistics and prediction of outbound logistics emissions |

| Production-line-worker need | Holistic dashboard access to emissions for raw materials and components | Emissions of manufacturing process and predicted emissions of production choices in the remit of line operatives | Holistic dashboard access to emissions for inbound logistics |

| NPD/product-designer need | Carbon content and emissions of components to be used or materials required | Predicted carbon emissions for manufacturing process required | Logistics emissions view for components and raw materials transport and outbound logistics completed product carbon emissions forecast |

| Consumer need | Holistic view of embodied carbon, carbon emissions in terms of materials extraction/processing and components production | Holistic view of embodied carbon; carbon emissions for production | Holistic view of embodied carbon; carbon emissions from logistics |

| Repair/recycling/remanufacturing-agentneed | Materials inventory of end-of-life products or recycling, product maintenance history carbon emissions for remanufacturing and repair (influencing repair/remanufacture/recycle/ decision) | Emissions at manufacturing stage and remanufacturing and repair emissions | Logistics carbon emissions for returned products at the end of life |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turner, C.; Oyekan, J. Manufacturing in the Age of Human-Centric and Sustainable Industry 5.0: Application to Holonic, Flexible, Reconfigurable and Smart Manufacturing Systems. Sustainability 2023, 15, 10169. https://doi.org/10.3390/su151310169

Turner C, Oyekan J. Manufacturing in the Age of Human-Centric and Sustainable Industry 5.0: Application to Holonic, Flexible, Reconfigurable and Smart Manufacturing Systems. Sustainability. 2023; 15(13):10169. https://doi.org/10.3390/su151310169

Chicago/Turabian StyleTurner, Chris, and John Oyekan. 2023. "Manufacturing in the Age of Human-Centric and Sustainable Industry 5.0: Application to Holonic, Flexible, Reconfigurable and Smart Manufacturing Systems" Sustainability 15, no. 13: 10169. https://doi.org/10.3390/su151310169

APA StyleTurner, C., & Oyekan, J. (2023). Manufacturing in the Age of Human-Centric and Sustainable Industry 5.0: Application to Holonic, Flexible, Reconfigurable and Smart Manufacturing Systems. Sustainability, 15(13), 10169. https://doi.org/10.3390/su151310169