Quick Electrical Drive Selection Method for Bus Retrofitting

Abstract

:1. Introduction

- (1)

- suburban and regional transport operators do not have sufficient funds to purchase new electric buses;

- (2)

- the retrofit process uses commercially available electric motors and transmissions whose technical characteristics are provided by the manufacturers and used for modelling purposes;

- (3)

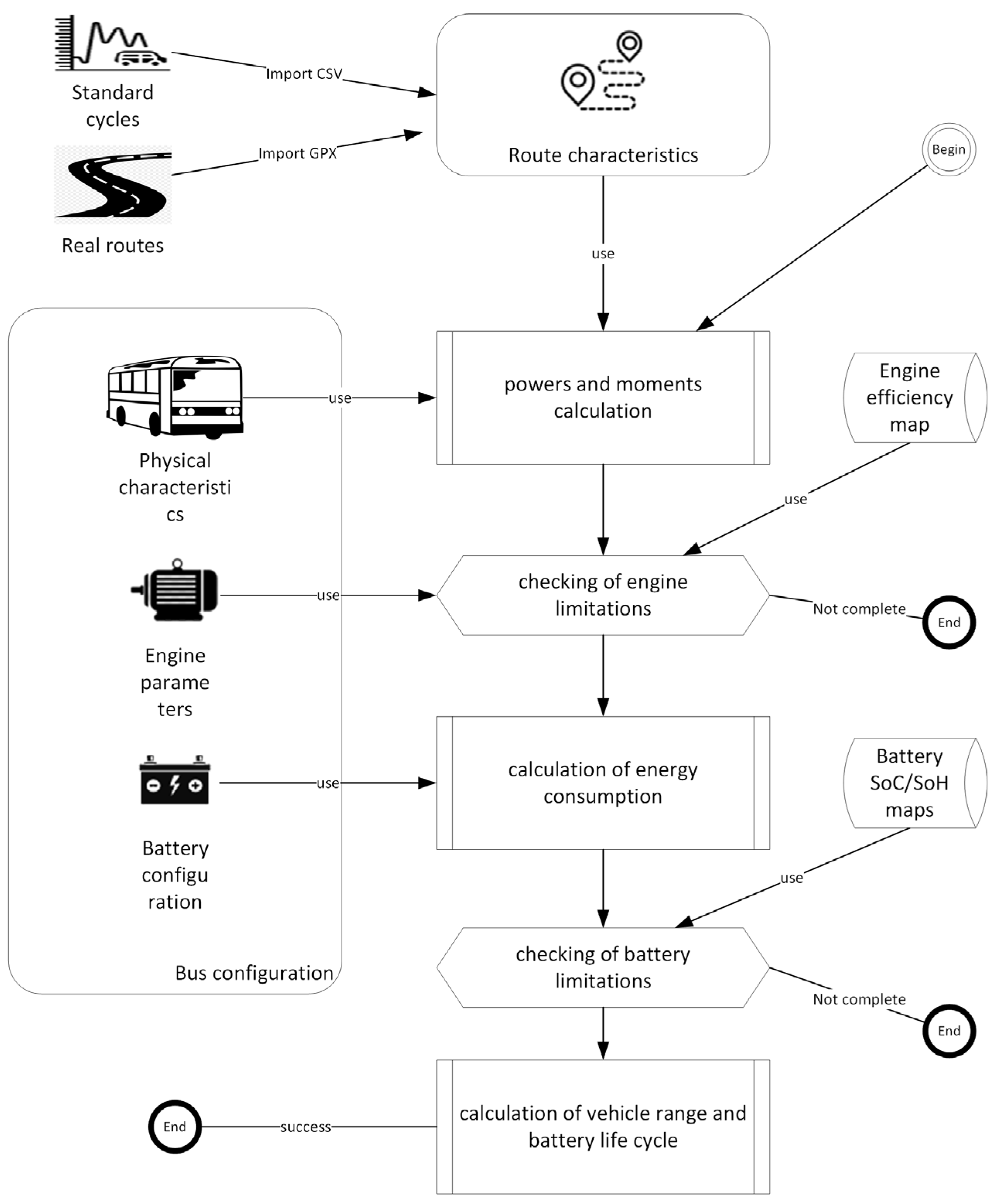

- the motor is selected based on an analysis of the route to be covered by the bus;

- (4)

- the battery pack is placed in a drawer so that it can be quickly replaced at bus stops, which solves the problem of providing electrical connections in remote areas so that the battery pack can be quickly recharged on the bus when stationary;

- (5)

- mathematical models of the bus, the traction system, and the battery allow simulation calculations to be performed to check whether the bus—after modification—will meet the operator’s requirements, what its maximum range will be, and how quickly the battery will age;

- (6)

- a component database allows rapid prototyping of the vehicle and storage of the configuration of already retrofitted buses to track their further operation and facilitate the repeatability of subsequent conversions.

2. Materials and Methods

- ECECOL–UN/ECE Elementary Urban Cycle (Part One of the Type 1 Test);

- EUDCCOL–UN/ECE Reg 83 Extra-Urban Driving Cycle for Low-Powered Vehicles (Part 2 of the Type 1 Test);

- EUDCLCOL–HDUDDS Urban Dynamometer Driving Schedule for Heavy Duty Vehicles.

- NYCCCOL–New York City Cycle;

- UDDSCOL–US06 Supplemental FTP Driving Schedule;

- US06COL–aggressive urban test.

3. Results

3.1. Mathematical Model of Electric Motor

3.2. Battery Pack Model

3.3. Bus Model

- Based on a defined drive cycle and a system of bus motion equations, the authors determined the required central unit torque waveforms (in addition, taking into account the values of bus road wheel diameters, kinematic ratios and rear drive axle power losses). The calculation results for standard drive cycles are shown in Figure 7.

- Based on the calculation results, the authors concluded that the proposed drive system, which consists of a motor and a rear axle, can correctly operate under the UDDSCOL implementation conditions. Next, the authors determined the required traction battery load. The obtained waveform is shown in Figure 11—graph in blue (UDDSCOL cycle).

4. Discussion

- it has been developed using simulation analyses of drive systems intended for a 12 m long bus;

- it describes stationary operating conditions using energy demand (machine and inverter), state of charge (), state of health (), capacity loss (), and energy throughput maps;

- it employs maps of operating conditions described with polynomial approximations obtained through the regression method for simulation analyses results;

- it can be used for fast setup of electro-traction drive devices based on the required motion conditions (drive cycles) at the vehicle prototyping stage.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wach-Kloskowska, M.; Rzeźny-Cieplińska, J. Smart and Sustainable Transport Development as an Element of the Implementation of the Smart City Concept—Polish and European Examples. Urban Stud. 2018, 30, 99–108. [Google Scholar]

- Ogryzek, M.; Wolny-Kucińska, A. Sustainable Development of Transport as a Regional Policy Target for Sustainable Development—A Case Study of Poland. ISPRS Int. J. Geo-Inf. 2021, 10, 132. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Maricq, M.; Ntziachristos, L.; Dardiotis, C.; Wang, X.; Axmann, H.; Bergmann, A.; Schindler, W. Review of Motor Vehicle Particulate Emissions Sampling and Measurement: From Smoke and Filter Mass to Particle Number. J. Aerosol Sci. 2014, 67, 48–86. [Google Scholar] [CrossRef]

- Liu, Z.; Shah, A.N.; Ge, Y.; Ding, Y.; Tan, J.; Jiang, L.; Yu, L.; Zhao, W.; Wang, C.; Zeng, T. Effects of Continuously Regenerating Diesel Particulate Filters on Regulated Emissions and Number-Size Distribution of Particles Emitted from a Diesel Engine. J. Environ. Sci. 2011, 23, 798–807. [Google Scholar] [CrossRef] [PubMed]

- Fleischman, R.; Amiel, R.; Czerwinski, J.; Mayer, A.; Tartakovsky, L. Buses Retrofitting with Diesel Particle Filters: Real-World Fuel Economy and Roadworthiness Test Considerations. J. Environ. Sci. 2018, 67, 273–286. [Google Scholar] [CrossRef] [PubMed]

- Judah, A. Electric Bus Analysis for New York City Transit; Columbia University: New York, NY, USA, 2016. [Google Scholar]

- Topal, O.; Nakir, İ. Total Cost of Ownership Based Economic Analysis of Diesel, CNG and Electric Bus Concepts for the Public Transport in Istanbul City. Energies 2018, 11, 2369. [Google Scholar] [CrossRef] [Green Version]

- Retrofit All-Electric Bus for Reduced Operator Operating Costs in Urban Transport (REBOOT). 2018. Available online: https://cordis.europa.eu/project/id/651630 (accessed on 3 June 2023).

- EU-Elabus4.0 (Reduce–Recycle–Reuse EMobility–Retrofitting-Kits for Busses); 2015. Available online: https://cordis.europa.eu/project/id/673330 (accessed on 3 June 2023).

- Statistics Poland, Road Transport in Poland in the Years 2018 and 2019. Available online: https://stat.gov.pl/files/gfx/portalinformacyjny/pl/defaultaktualnosci/5511/6/6/1/td_w_pl_2018_2019.pdf (accessed on 23 March 2023).

- Statistics Poland, Road Transport in Poland in the Years 2010, 2011. Available online: https://stat.gov.pl/cps/rde/xbcr/gus/TL_transport_drogowy_2010-2011.pdf (accessed on 24 March 2023).

- Transportation—Results of Operations in 2021. Available online: https://stat.gov.pl/obszary-tematyczne/transport-i-lacznosc/transport/transport-wyniki-dzialalnosci-w-2021-roku,9,21.html (accessed on 23 March 2023).

- Statistics Poland, Financial Economy of Local Government Units 2020. Available online: https://stat.gov.pl/download/gfx/portalinformacyjny/pl/defaultaktualnosci/5483/5/17/1/gospod_finansowa_jst_2020.pdf (accessed on 24 March 2023).

- PSE, Highest Voltage Transmission Network Plan. Available online: https://www.pse.pl/obszary-dzialalnosci/krajowy-system-elektroenergetyczny/plan-sieci-elektroenergetycznej-najwyzszych-napiec (accessed on 24 March 2023).

- PSE, Information Regarding the Duration of Interruptions in the Supply of Electricity to Customers Connected to the Transmission Network. Available online: https://www.pse.pl/obszary-dzialalnosci/krajowy-system-elektroenergetyczny/wskazniki-ciaglosci-dostaw-energii-elektrycznej (accessed on 24 March 2023).

- Berzi, L.; Baldanzini, N.; Barbani, D.; Barbieri, R.; Locorotondo, E.; Pierini, M.; Pugi, L.; Alessandrini, A.; Cignini, F.; Ortenzi, F.; et al. Structural and Energy Storage Retrofit of an Electric Bus for High-Power Flash Recharge. Procedia Struct. Integr. 2019, 24, 408–422. [Google Scholar] [CrossRef]

- Warburton, S. Horiba Mira Urges Bus Owners to Retrofit with Electric. Available online: https://www.horiba-mira.com/media-centre/news/2019/10/21/horiba-mira-urges-bus-owners-and-operators-to-consider-retrofitting-amid-50m-e-bus-pledge/ (accessed on 24 March 2023).

- Alessandrini, A.; Cignini, F.; Ortenzi, F.; Pede, G.; Stam, D. Advantages of Retrofitting Old Electric Buses and Minibuses. Energy Procedia 2017, 126, 995–1002. [Google Scholar] [CrossRef]

- Standardized Battery Systems for Commercial Vehicles. Available online: https://www.webasto-electrified.com/int/products/cv-standard-battery-system/ (accessed on 24 March 2023).

- Webasto Battery Systems—Product Showcase CV NextGen Battery @ the Battery Show 2021. 2021. Available online: https://www.youtube.com/watch?v=rUlxq_dGphc (accessed on 3 June 2023).

- Kozłowski, M.; Tomczuk, K.; Szczypior, J. Methodology of Determining Basic Technical Parameters of Electric-Drive Car. Electr. Rev. 2011, 87, 299–304. [Google Scholar]

- Rakov, V.; Ivanov, V.N.; Karpov, Y.G.; Melehin, V.F.; Izmailov, R.A.; Yun, V.K.; Zaripova, D.A. Method for Determining the Basic Energy Characteristics of Elements of a Hybrid Car Engine. IOP Conf. Ser. Earth Environ. Sci. 2019, 337, 012066. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Ye, P.; Zhang, Y.; Ni, H.; Deng, Y.; Lv, S.; Yuan, Y.; Zhu, Y. Parameter Optimization Method for Power System of Medium-Sized Bus Based on Orthogonal Test. Energies 2022, 15, 7243. [Google Scholar] [CrossRef]

- Bekheira, T.; Sofiane, D.; Abdelaziz, K.; Mohamed, B. A Power Presizing Methodology for Electric Vehicle Traction Motors. Int. Rev. Model. Simul. 2013, 6, 29–32. [Google Scholar]

- Husain, I.; Ozpineci, B.; Islam, M.S.; Gurpinar, E.; Su, G.-J.; Yu, W.; Chowdhury, S.; Xue, L.; Rahman, D.; Sahu, R. Electric Drive Technology Trends, Challenges, and Opportunities for Future Electric Vehicles. Proc. IEEE 2021, 109, 1039–1059. [Google Scholar] [CrossRef]

- Efficiency and Loss Mapping of AC Motors. Available online: https://www.hbm.com/en/6207/white-paper-efficiency-and-loss-mapping-of-ac-motors/ (accessed on 26 March 2023).

- Gang, L.; Zhi, Y. Energy Saving Control Based on Motor Efficiency Map for Electric Vehicles with Four-Wheel Independently Driven in-Wheel Motors. Adv. Mech. Eng. 2018, 10, 168781401879306. [Google Scholar] [CrossRef] [Green Version]

- Schwager, L.; Tuysuz, A.; Zwyssig, C.; Kolar, J.W. Modeling and Comparison of Machine and Converter Losses for PWM and PAM in High-Speed Drives. IEEE Trans. Ind. Appl. 2014, 50, 995–1006. [Google Scholar] [CrossRef]

- Increasing the Range of EV with the Same Battery Size—Part I—The Efficiency. Available online: https://www.silicon-mobility.com/increasing-the-range-of-ev-with-the-same-battery-part-i-the-efficiency/ (accessed on 26 March 2023).

- Sato, D.; Itoh, J. Total Loss Comparison of Inverter Circuit Topologies with Interior Permanent Magnet Synchronous Motor Drive System. In Proceedings of the 2013 IEEE ECCE Asia Downunder, Melbourne, VIC, Australia, 3–6 June 2013; pp. 537–543. [Google Scholar]

- Stark, A. EV Design—Electric Motors. Available online: https://x-engineer.org/automotive-engineering/vehicle/electric-vehicles/ev-design-electric-motors/ (accessed on 26 March 2023).

- Liu, H.; Huang, X.; Lin, F.; Yang, Z. Loss Model and Efficiency Analysis of Tram Auxiliary Converter Based on a SiC Device. Energies 2017, 10, 2018. [Google Scholar] [CrossRef] [Green Version]

- Stabile, A.; Estima, J.O.; Boccaletti, C.; Marques Cardoso, A.J. Converter Power Loss Analysis in a Fault-Tolerant Permanent-Magnet Synchronous Motor Drive. IEEE Trans. Ind. Electron. 2015, 62, 1984–1996. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Soong, W.L.; Pellegrino, G.; Armando, E. Efficiency Maps of Electrical Machines. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2015; pp. 2791–2799. [Google Scholar]

- Ng, A.; Ma, T. CS229 Lecture Notes. Available online: https://cs229.stanford.edu/notes2022fall/main_notes.pdf (accessed on 26 March 2023).

- Plett, G.L. Battery Modeling. In Battery Management Systems; University of Colorado: Colorado Springs, CO, USA, 2015; Volume I. [Google Scholar]

- How Simcenter Amesim Can Help You in the Battery Pack Design for Electrical Vehicles. Available online: https://community.sw.siemens.com/s/article/how-simcenter-amesim-can-help-you-in-the-battery-pack-design-for-electrical-vehicles (accessed on 26 March 2023).

- Kozłowski, M. Simulation Method for Determining Traction Power of ATN–PRT Vehicle. Transport 2016, 33, 335–343. [Google Scholar] [CrossRef] [Green Version]

- Vehicle and Fuel Emissions Testing. Dynamometer Drive Schedules. Available online: https://www.epa.gov/vehicle-and-fuel-emissions-testing/dynamometer-drive-schedules (accessed on 26 March 2023).

- Emission Test Cycles. Available online: https://dieselnet.com/standards/cycles/index.php (accessed on 26 March 2023).

- Barlow, T.J.; Latham, S.; Mccrae, I.S.; Boulter, P.G. A Reference Book of Driving Cycles for Use in the Measurement of Road Vehicle Emissions; Transport Research Laboratory: Crowthorne, UK, 2009. [Google Scholar]

| 0.1580 | −0.2733 | −0.2278 | 0.7812 | 1.4745 | 1.1305 | −0.2249 | −1.9670 |

| −1.0319 | −0.3290 | 0.0198 | 0.4836 | 0.8965 | −0.0003 | 0.1103 |

| −0.0519 | 43.8916 | 0.0695 | −8.1747 | −1.4921 |

| 14,662 | 18,541 | −57,168 | −2626 | 44,938 |

| Parameter | Value |

|---|---|

| , [%] | 95 |

| Full discharge (cycles) | 7 |

| Distance travelled, [km] | 84 |

| Average , [kWh]/100 km | 118 |

| Energy Throughput, [kWh]/100 km | 139 |

| Battery life cycles used per trip | 33 × 4/ET = ~1 |

| Expected daily mileage, [km] | 100 |

| Assumed battery cycles | 3000 |

| Estimated battery life [years] | 5 |

| Benefits | Issues |

|---|---|

| Electric buses converted through the retrofitting process do not emit pollutants, contributing to improved air quality and reducing the local environmental impact. | Retrofitting does not result in a new bus, so design deficiencies and problems with other bus components may emerge during operation. |

| Electric motors have higher efficiency than combustion engines, resulting in lower bus operating costs. | Accommodating the battery pack may require structural modifications; an alternative solution could involve placing the batteries in the luggage compartment. |

| The ability to recuperate electric energy reduces overall energy consumption. | Existing systems, such as cooling or air conditioning, need to be adapted to meet the requirements of an electric bus. |

| Electric traction systems have simpler designs and fewer components, reducing maintenance and repair costs. | The service center responsible for repairs and maintenance of retrofitted buses should be adequately equipped, and its staff should be trained in handling electric buses. |

| Electric motors operate with lower noise levels, creating a more pleasant environment for residents living near roads. | Retrofitted electric buses generally have a lower range compared to their combustion counterparts. |

| The investment costs for bus modernization are significantly lower than purchasing new electric buses. | The operational lifespan of retrofitted buses will be shorter than new buses. |

| When retrofitting a combustion bus, a considerable portion of its components can still be utilized, eliminating the need for their scrapping. | When using a solution with a removable battery placed in a tray, the issue of high currents at the battery contacts during connection should be taken into account, as well as the fire safety aspects of the battery pack. |

| Advantages | Disadvantages |

|---|---|

| The method allows the estimation of the range and operational period of a 12-m bus based on a small number of control variables, such as the continuous rated power of the motor and battery capacity. | The method is specifically designed for 12-m buses. This limitation arises because the authors for propulsion systems suitable for this type of bus investigated the weighting coefficients determining the map parameters. |

| Due to its simplicity, the method requires minimal computational resources and can be employed by investors without specialized design offices for rapid bus pre-prototyping. | Extending this method to other vehicles, such as passenger or heavy-duty vehicles, would require new fitting calculations. |

| The method can be used to assess the range (for determining charging points) or the remaining operational time for buses already in operation. | Building efficiency maps may require specialized engineering software (e.g., Matlab R2022a, Simulink R2022a, Amesim 2022.1—depending on the used model). |

| The method allows a quick check of whether the bus configuration allows for traveling along a selected route. It enables rapid verification of operating condition constraints for given movement patterns (scheduled speed plan + road profiles). It is sufficient to import the route profile, for example, from Google Maps into the program to accomplish this. | Adding new components to the library requires constructing efficiency maps and parameters describing the battery. For this method to be reliable, it is necessary to have accurate loss maps and battery models provided by the manufacturer. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozłowski, M.; Czerepicki, A. Quick Electrical Drive Selection Method for Bus Retrofitting. Sustainability 2023, 15, 10484. https://doi.org/10.3390/su151310484

Kozłowski M, Czerepicki A. Quick Electrical Drive Selection Method for Bus Retrofitting. Sustainability. 2023; 15(13):10484. https://doi.org/10.3390/su151310484

Chicago/Turabian StyleKozłowski, Maciej, and Andrzej Czerepicki. 2023. "Quick Electrical Drive Selection Method for Bus Retrofitting" Sustainability 15, no. 13: 10484. https://doi.org/10.3390/su151310484

APA StyleKozłowski, M., & Czerepicki, A. (2023). Quick Electrical Drive Selection Method for Bus Retrofitting. Sustainability, 15(13), 10484. https://doi.org/10.3390/su151310484