Evaluation of Anti-Aging Effect in Biochar-Modified Bitumen

Abstract

:1. Introduction

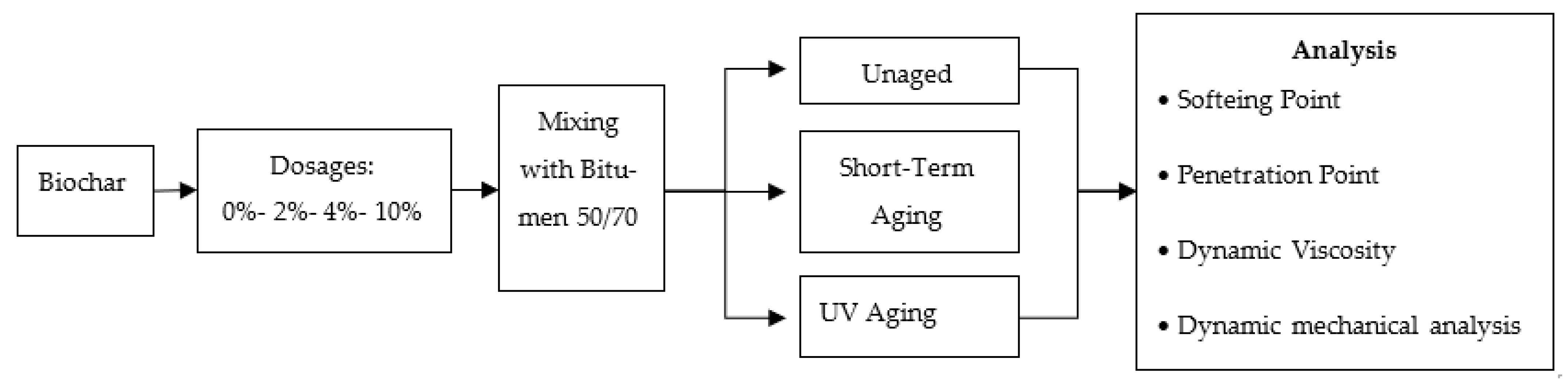

2. Materials and Methods

2.1. Materials

Biochar-Modified Bitumen

2.2. Methods

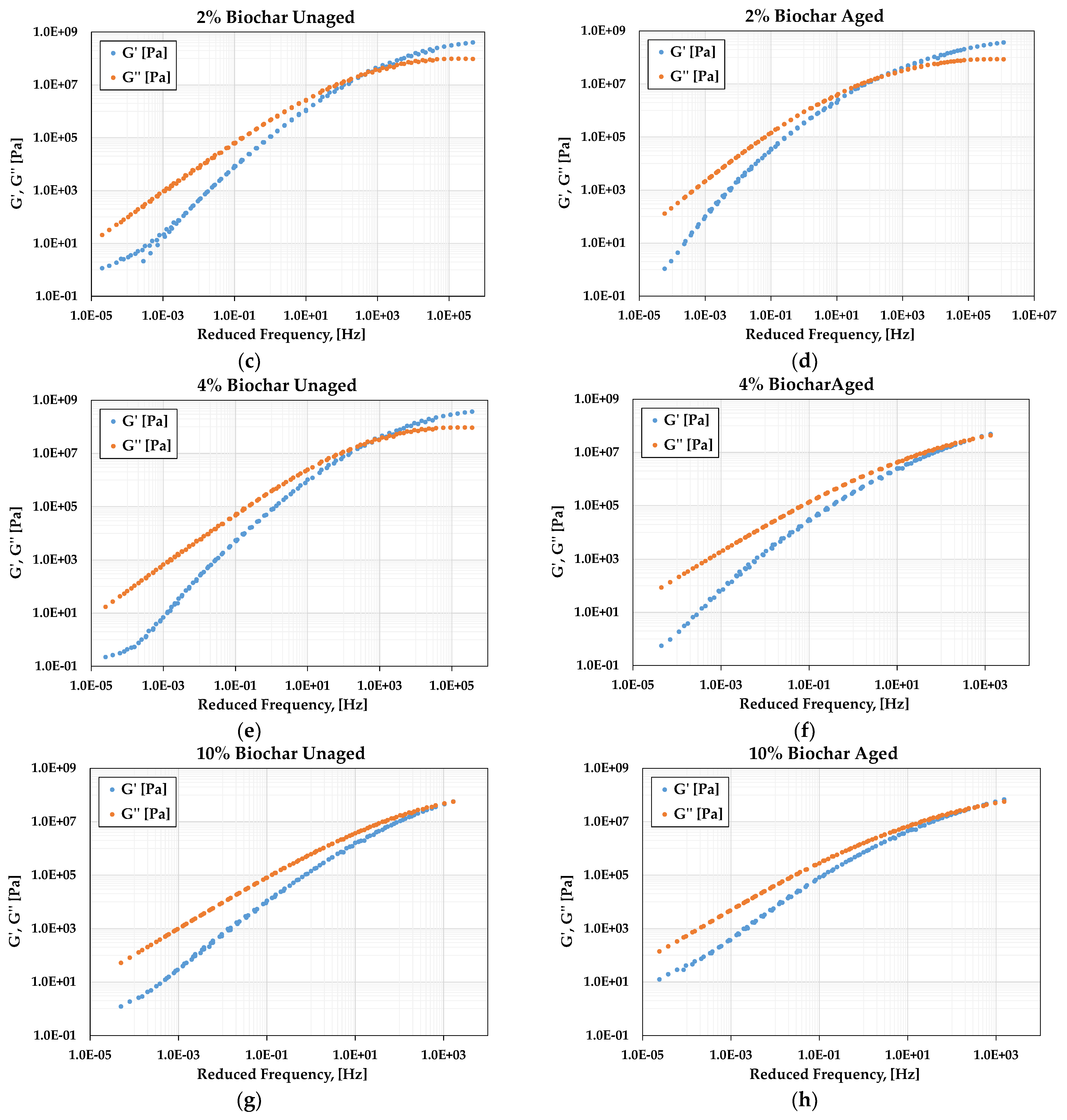

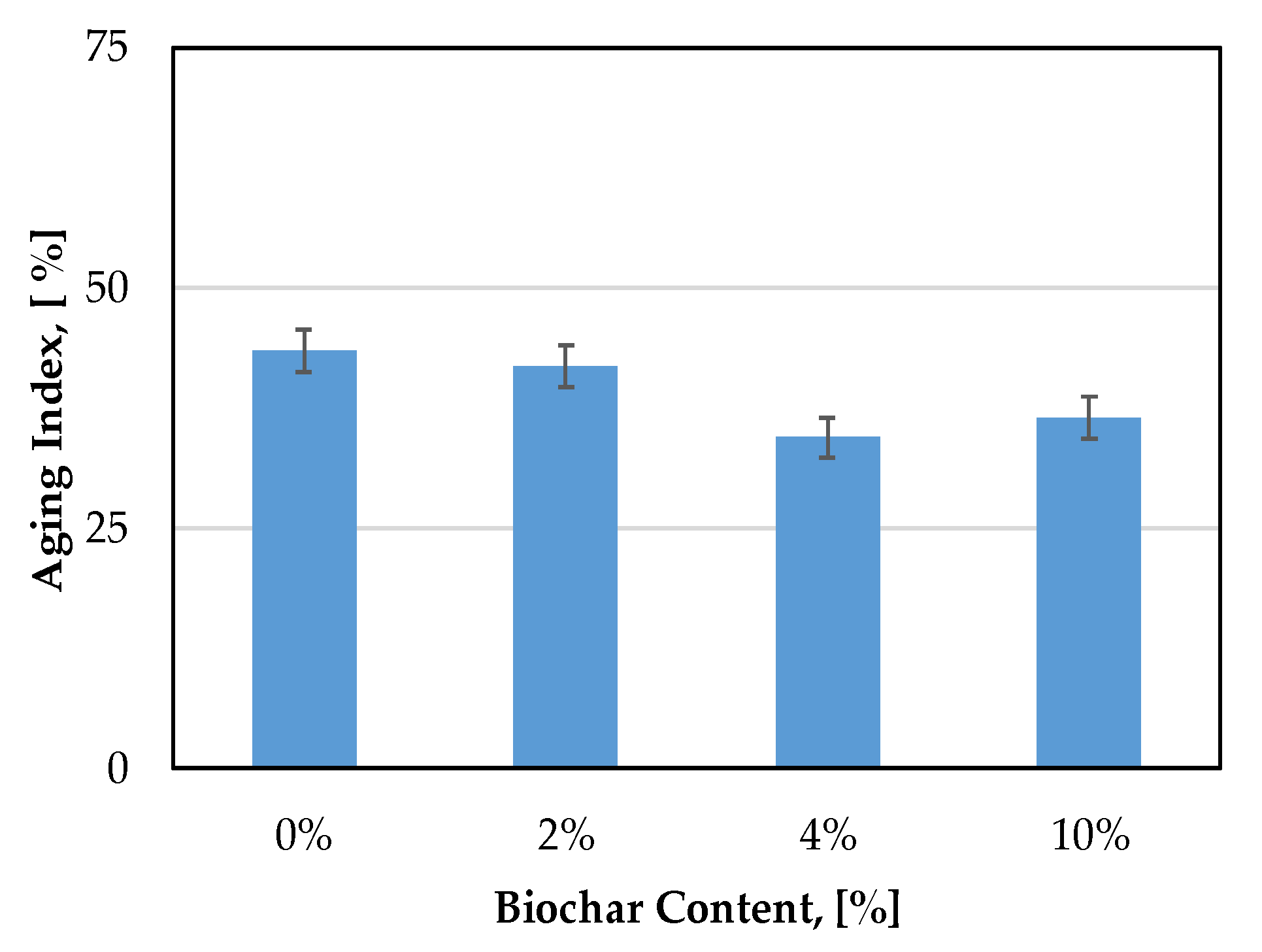

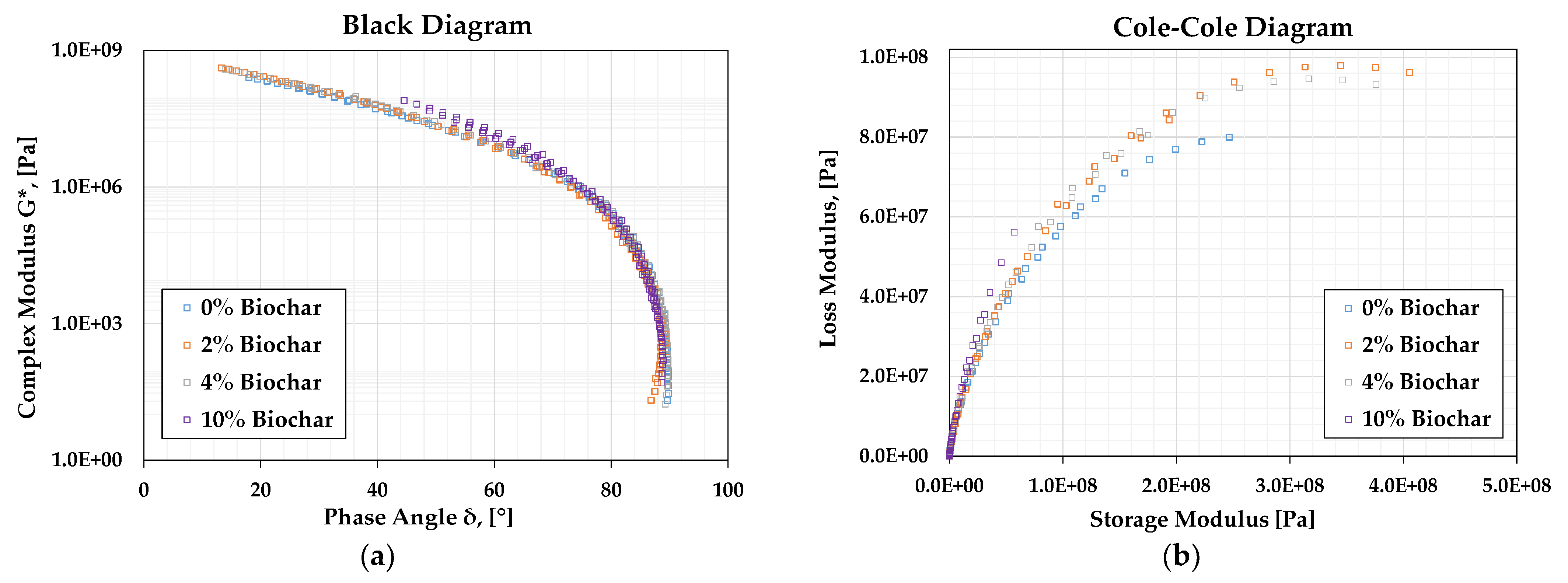

3. Results and Discussion

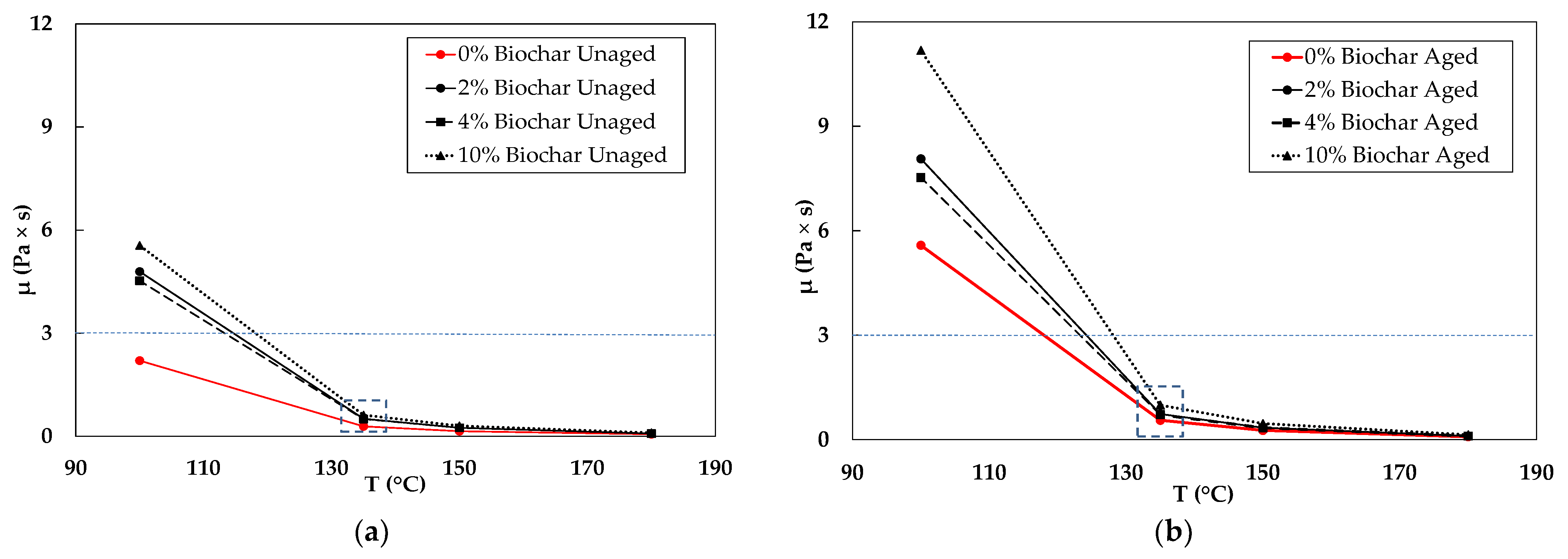

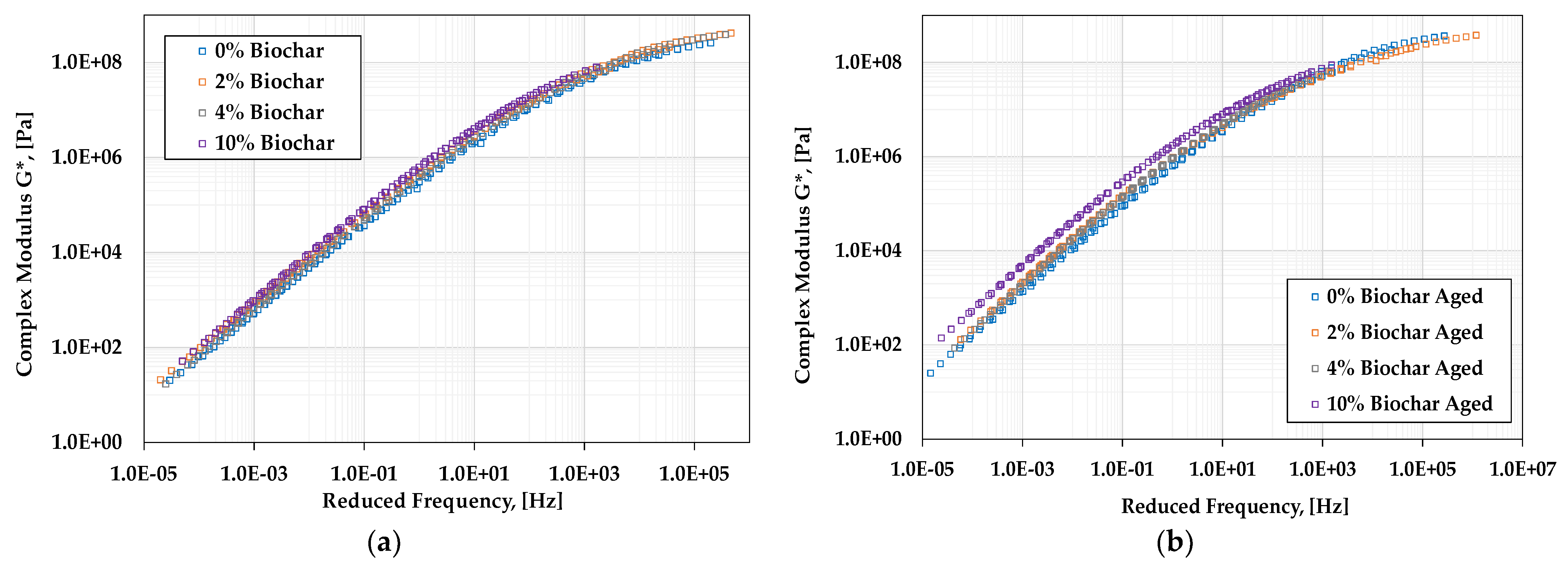

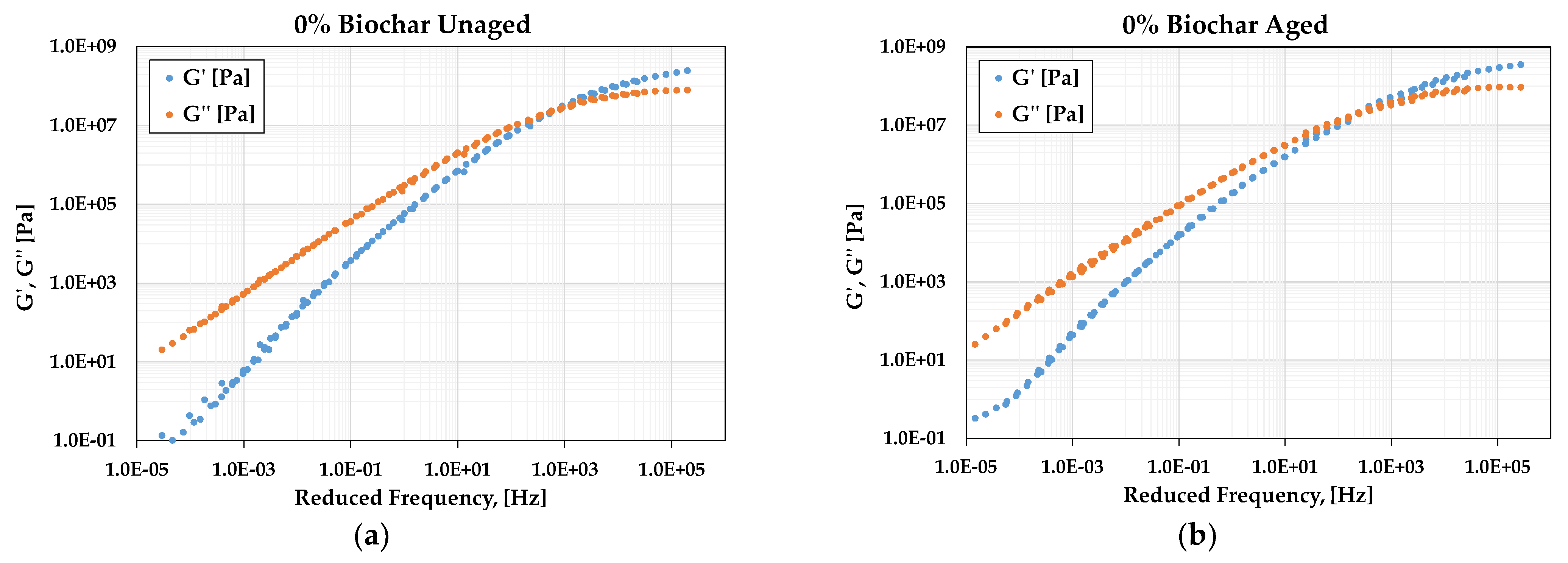

3.1. Bitumen and Modified Binders’ Characterization

3.2. Storage Stability Tests

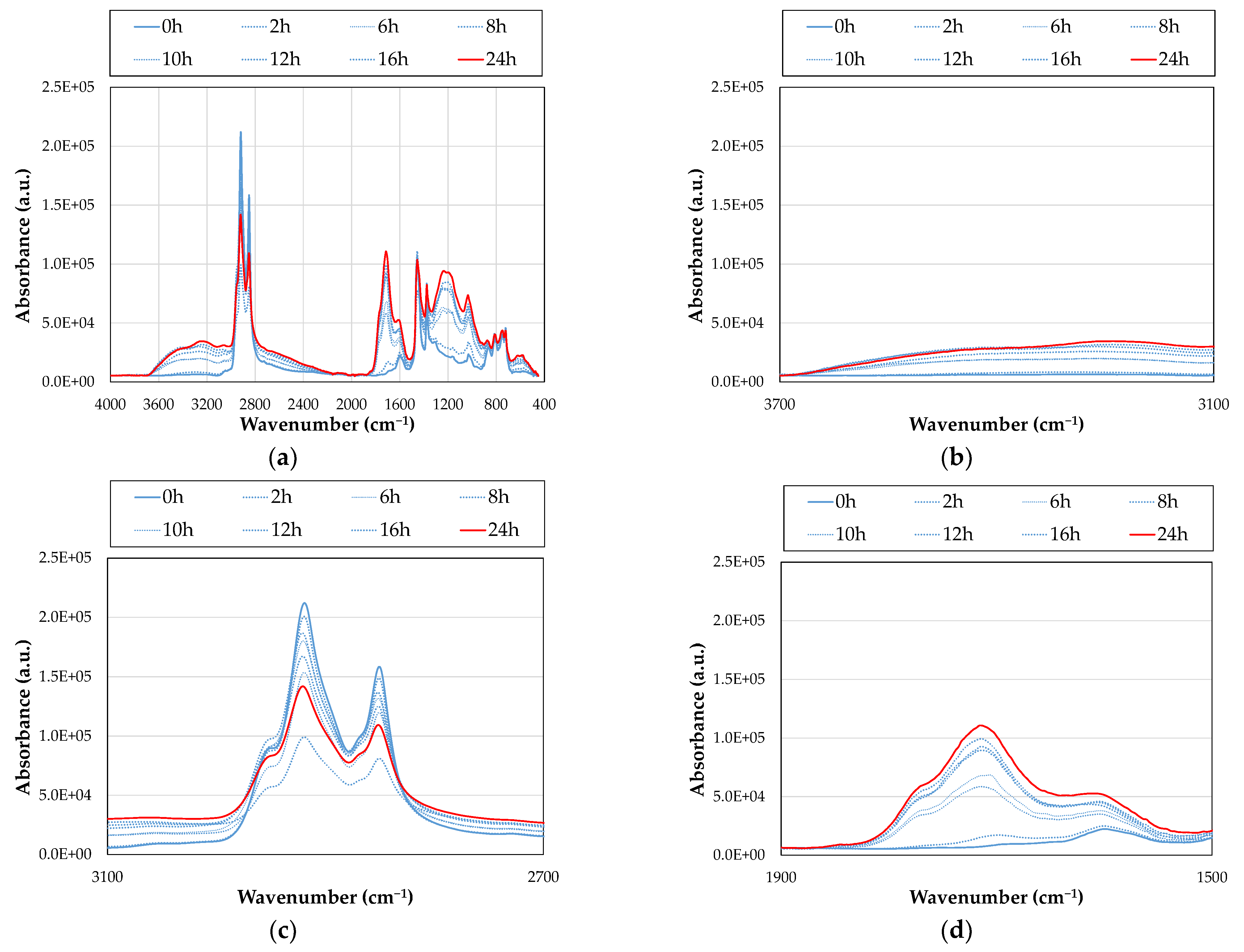

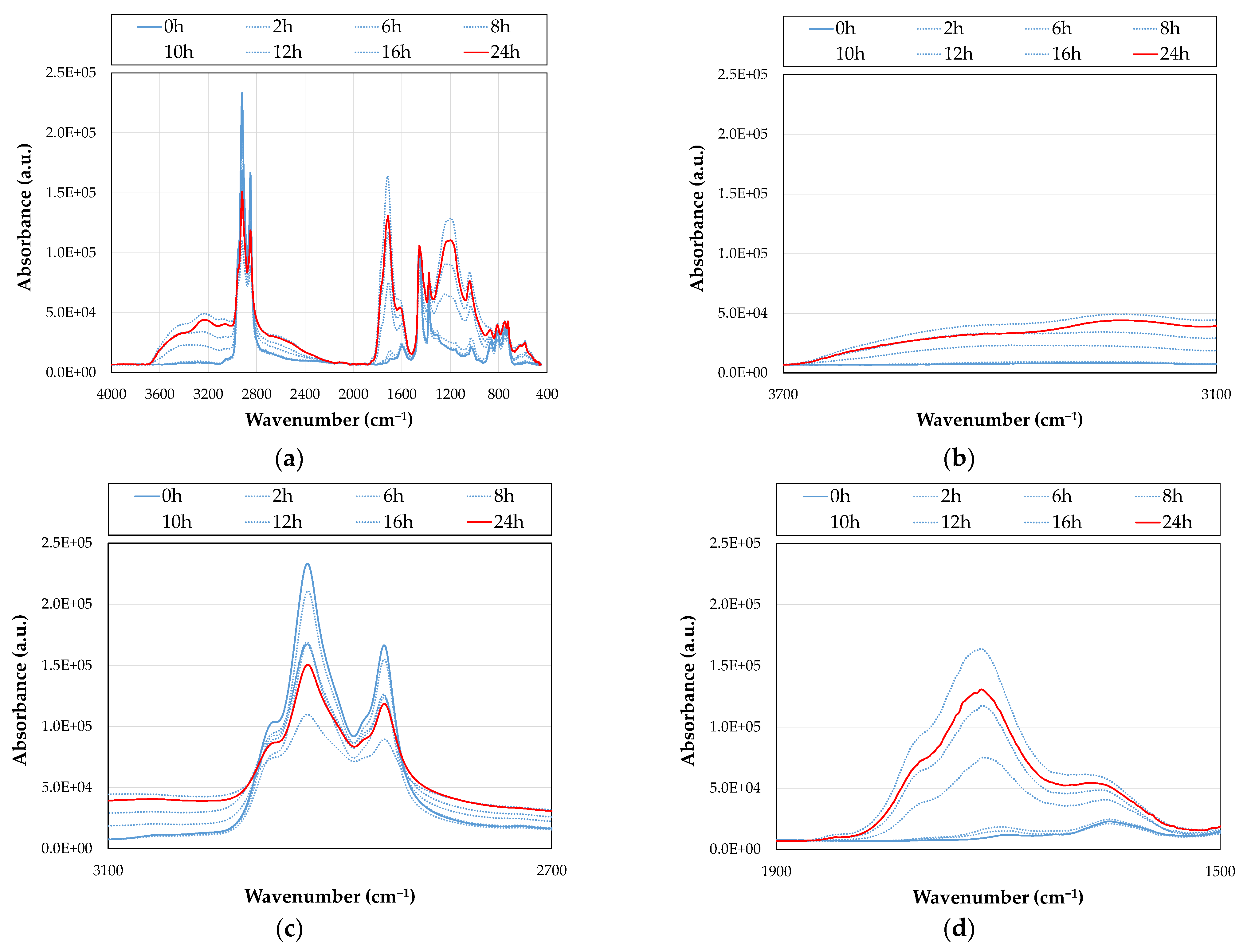

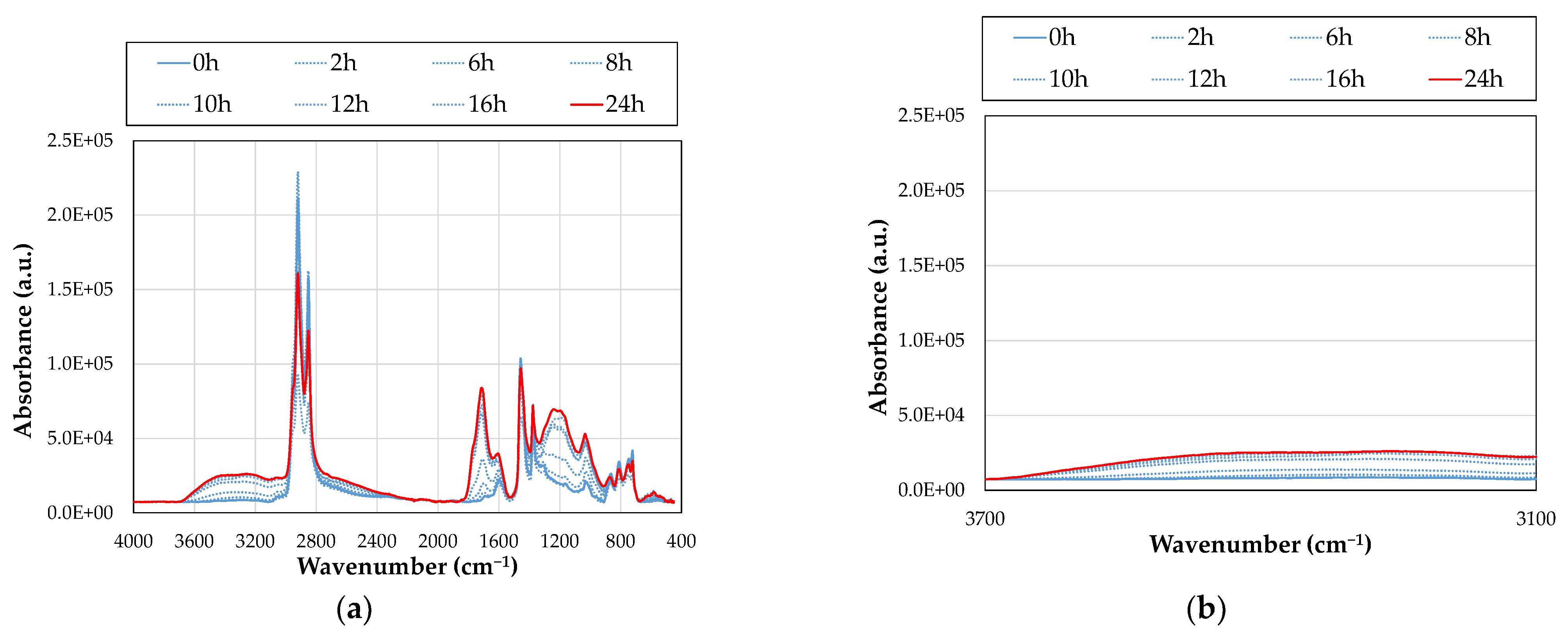

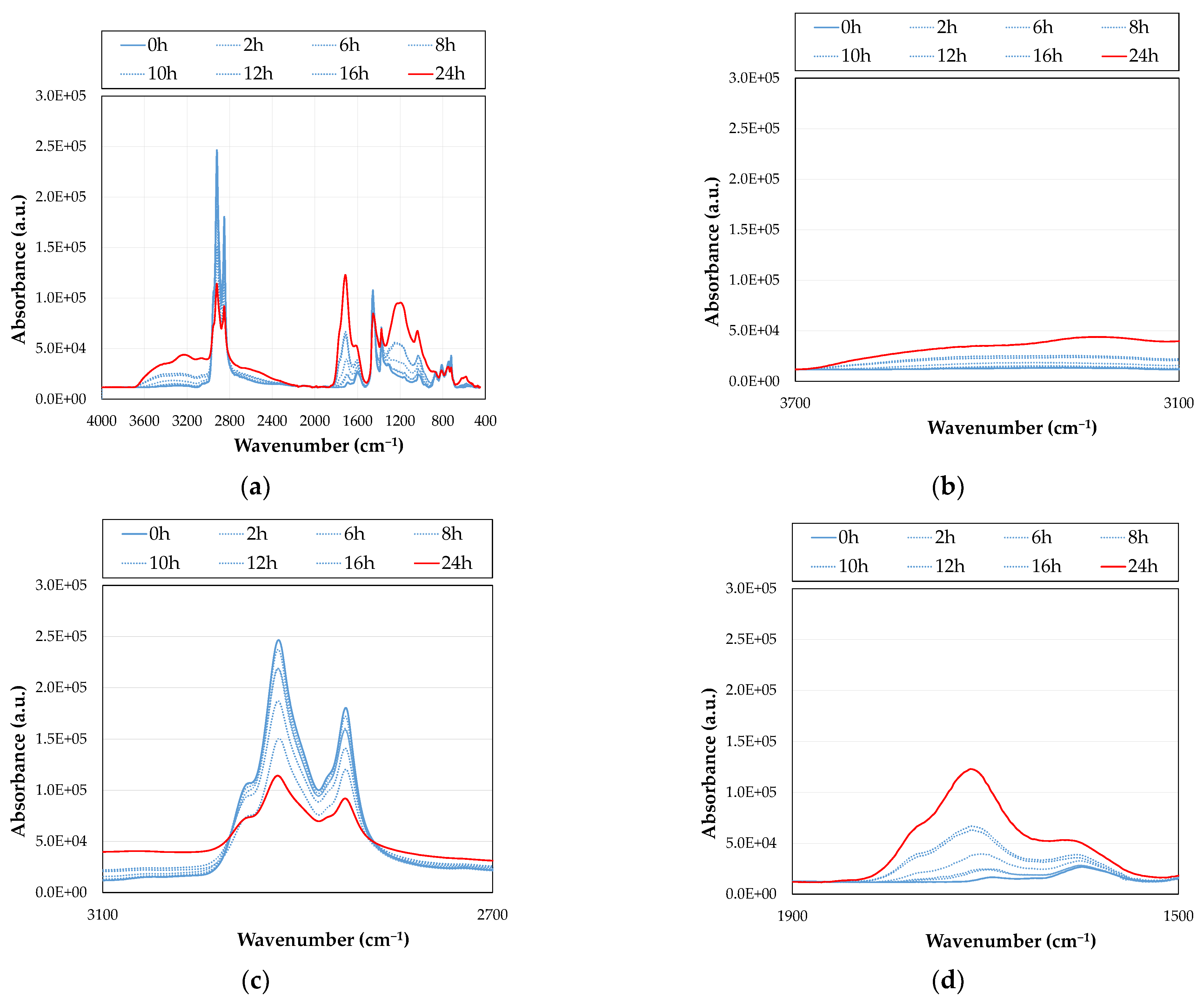

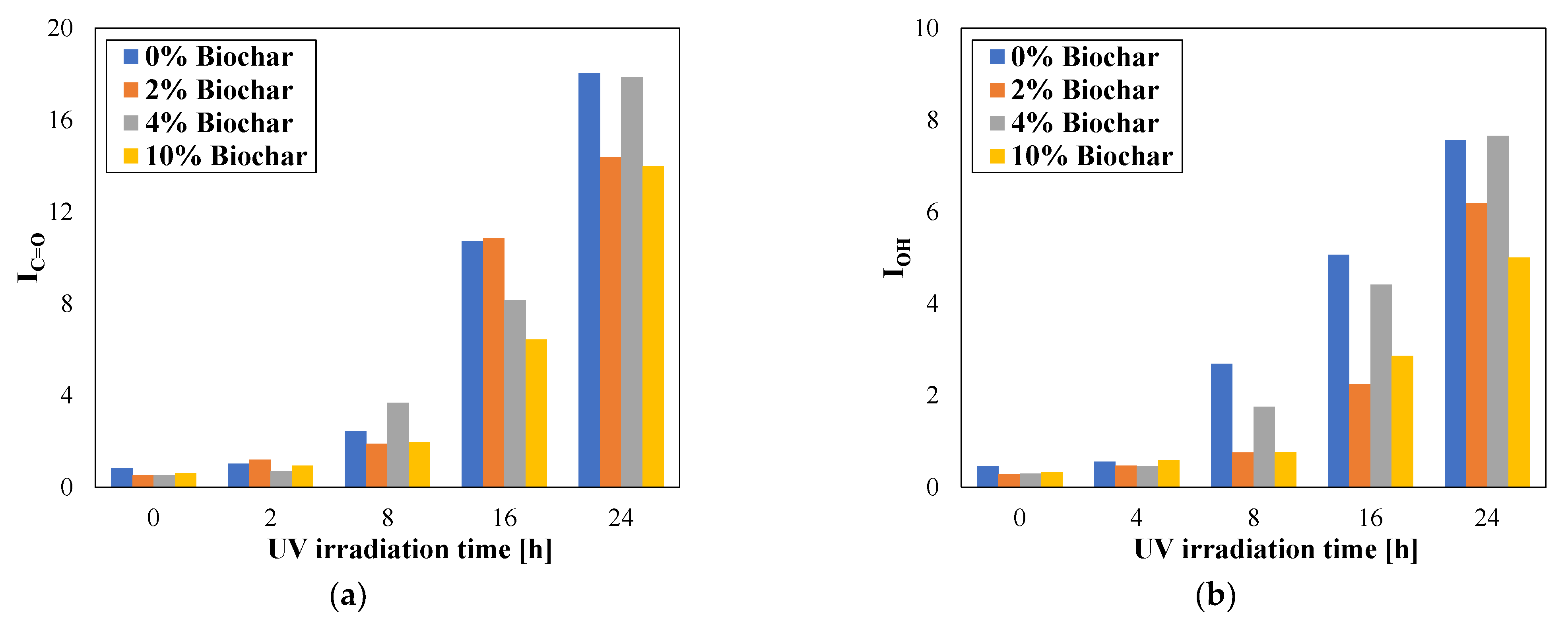

3.3. UV Irradiation Aging

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mensah, R.A.; Shanmugam, V.; Narayanan, S.; Razavi, S.M.J.; Ulfberg, A.; Blanksvärd, T.; Sayahi, F.; Simonsson, P.; Reinke, B.; Försth, M.; et al. Biochar-Added Cementitious Materials—A Review on Mechanical, Thermal, and Environmental Properties. Sustainability 2021, 13, 9336. [Google Scholar] [CrossRef]

- Legan, M.; Gotvajn, A.Ž.; Zupan, K. Potential of Biochar Use in Building Materials. J. Environ. Manag. 2022, 309, 114704. [Google Scholar] [CrossRef] [PubMed]

- Vincevica-gaile, Z.; Teppand, T.; Kriipsalu, M.; Krievans, M.; Jani, Y.; Klavins, M.; Hendroko Setyobudi, R.; Grinfelde, I.; Rudovica, V.; Tamm, T.; et al. Towards Sustainable Soil Stabilization in Peatlands: Secondary Raw Materials as an Alternative. Sustainability 2021, 13, 6726. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of Biochar as Carbon Sequestering Additive in Cement Mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- Rondón-Quintana, H.A.; Reyes-Lizcano, F.A.; Chaves-Pabón, S.B.; Bastidas-Martínez, J.G.; Zafra-Mejía, C.A. Use of Biochar in Asphalts: Review. Sustainability 2022, 14, 4745. [Google Scholar] [CrossRef]

- Let, A.; Song, K. Rubberized Biochar Used as Bitumen Additive. In Proceedings of the 18th AAPA International Flexible Pavements Conference, Sydney, Australia, 18–21 August 2019. [Google Scholar]

- Zhao, S.; Huang, B.; Shu, X.; Ye, P. Laboratory Investigation of Biochar-Modified Asphalt Mixture. Transp Res Rec 2014, 2445, 56–63. [Google Scholar] [CrossRef]

- Botta, L.; Teresi, R.; Titone, V.; Salvaggio, G.; La Mantia, F.P.; Lopresti, F. Use of Biochar as Filler for Biocomposite Blown Films: Structure-Processing-Properties Relationships. Polymers 2021, 13, 3953. [Google Scholar] [CrossRef]

- Bartoli, M.; Arrigo, R.; Malucelli, G.; Tagliaferro, A.; Duraccio, D. Recent Advances in Biochar Polymer Composites. Polymers 2022, 14, 2506. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Steele, P.H. Pyrolysis of Wood/Biomass for Bio-Oil: A Critical Review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Demiral, I.; Ayan, E.A. Pyrolysis of Grape Bagasse: Effect of Pyrolysis Conditions on the Product Yields and Characterization of the Liquid Product. Bioresour. Technol. 2011, 102, 3946–3951. [Google Scholar] [CrossRef]

- Liu, Y.; Lonappan, L.; Brar, S.K.; Yang, S. Impact of Biochar Amendment in Agricultural Soils on the Sorption, Desorption, and Degradation of Pesticides: A Review. Sci. Total Environ. 2018, 645, 60–70. [Google Scholar] [CrossRef] [PubMed]

- Garcia, B.; Alves, O.; Rijo, B.; Lourinho, G.; Nobre, C. Biochar: Production, Applications, and Market Prospects in Portugal. Environments 2022, 9, 95. [Google Scholar] [CrossRef]

- Dong, W.; Ma, F.; Li, C.; Fu, Z.; Huang, Y.; Liu, J. Evaluation of Anti-Aging Performance of Biochar Modified Asphalt Binder. Coatings 2020, 10, 1037. [Google Scholar] [CrossRef]

- Zhou, X.; Moghaddam, T.B.; Chen, M.; Wu, S.; Adhikari, S. Biochar Removes Volatile Organic Compounds Generated from Asphalt. Sci. Total Environ. 2020, 745, 141096. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Harvey, J.; Zhang, H.; Tian, Y. Application of Biochar on the Runoff Purification Performance of Porous Asphalt Pavement. Transp. Saf. Environ. 2021, 3, tdab026. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Yang, B.; Xie, N.; Ning, Y. Laboratory Investigation on Pollutant Removal Effect of Purification Materials for Porous Asphalt Pavement. Transp. Res. Rec. J. Transp. Res. Board 2022, 2676, 421–435. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, L.; Mei, Y.; Li, F.; Cao, X. Release of Nutrients and Heavy Metals from Biochar-Amended Soil under Environmentally Relevant Conditions. Environ. Sci. Pollut. Res. 2018, 25, 2517–2527. [Google Scholar] [CrossRef]

- Celauro, C.; Teresi, R.; Dintcheva, N.T. Effect of Short-Term and UV Irradiation Aging on the Behaviour of SBS-Modified Bitumen. Sustainability 2022, 14, 6915. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Duan, H.; Wu, C.; Zhang, S. Long-Term Photo Oxidation Aging Investigation of Temperature-Regulating Bitumen Based on Thermochromic Principle. Fuel 2021, 286, 119403. [Google Scholar] [CrossRef]

- EN 1426; Bitumen and Bituminous Binders. Determination of Needle Penetration. European Committee for Standardization: Bruxelles, Belgium, 2015.

- EN 1427; Bitumen and Bituminous Binders. Determination of the Softening Point. Ring and Ball method. European Committee for Standardization: Bruxelles, Belgium, 2015.

- EN 13302; Bitumen and Bituminous Binders. Determination of Dynamic Viscosity of Bituminous Binder Using a Rotating Spindle Apparatus. European Committee for Standardization: Bruxelles, Belgium, 2018.

- EN 147770; Bitumen and Bituminous Binders—Determination of Complex Shear Modulus and Phase Angle—Dynamic Shear Rheometer (DSR). European Committee for Standardization: Bruxelles, Belgium, 2012.

- Williams, M.L.; Landel, R.F.; Ferry, J.D. The Temperature Dependence of Relaxation Mechanisms in Amorphous Polymers and Other Glass-Forming Liquids. J. Am. Chem. Soc. 1955, 77, 3701–3707. [Google Scholar] [CrossRef]

- EN 12607-1; Bitumen and Bituminous Binders. Determination of the Resistance to Hardening under Influence of Heat and Air RTFOT Method. European Committee for Standardization: Bruxelles, Belgium, 2015.

- EN 13399; Bitumen and Bituminous Binders. Determination of Storage Stability of Modified Bitumen. European Committee for Standardization: Bruxelles, Belgium, 2017.

- Yu, H.; Bai, X.; Qian, G.; Wei, H.; Gong, X.; Jin, J.; Li, Z. Impact of Ultraviolet Radiation on the Aging Properties of SBS-Modified Asphalt Binders. Polymers 2019, 11, 1111. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hunter, R.N.; Self, A.; Read, J. The Shell Bitumen Handbook; ICE Publishing: London, UK, 2015. [Google Scholar]

- Harrigan, E.T.; Leahy, R.B.; Youtcheff, J.S. The Superpave Mix Design System Manual of Specifications, Test Methods, and Practices; Highway Administration: Washington, DC, USA, 1994. [Google Scholar]

- Rajib, A.; Saadeh, S.; Katawal, P.; Mobasher, B.; Fini, E.H. Enhancing Biomass Value Chain by Utilizing Biochar as A Free Radical Scavenger to Delay Ultraviolet Aging of Bituminous Composites Used in Outdoor Construction. Resour. Conserv. Recycl. 2021, 168, 105302. [Google Scholar] [CrossRef]

- Loebera, L.; Muller, G.; Morel, J.; Sutton, O. Bitumen in Colloid Science: A Chemical, Structural and Rheological Approach. Fuel 1998, 77, 1443–1450. [Google Scholar] [CrossRef]

- Jing, R.; Varveri, A.; Liu, X.; Scarpas, A.; Erkens, S. Rheological, Fatigue and Relaxation Properties of Aged Bitumen. Int. J. Pavement Eng. 2020, 21, 1024–1033. [Google Scholar] [CrossRef] [Green Version]

- Porot, L. Rheology and Bituminous Binder, a Review of Different Analyses. In RILEM Bookseries; Springer: Cham, Sweitzerland, 2019; Volume 20, pp. 50–55. [Google Scholar]

- Dintcheva, N.T.; Arrigo, R.; Catalanotto, F.; Morici, E. Improvement of the Photo-Stability of Polystyrene-Block-Polybutadiene-Block-Polystyrene through Carbon Nanotubes. Polym. Degrad. Stab. 2015, 118, 24–32. [Google Scholar] [CrossRef]

- Lu, L.; Yu, H.; Wang, S.; Zhang, Y. Thermal degradation behavior of styrene-butadiene-styrene tri-block copolymer/multiwalled carbon nanotubes composites. J. Appl. Polym. Sci. 2009, 112, 524–531. [Google Scholar] [CrossRef]

| Characteristics | Standard | Unit | 50/70 |

|---|---|---|---|

| Penetration at 25 °C, pen | [21] | 0.1*mm | 52.25 |

| Ring and ball softening point, TR&B | [22] | °C | 52.6 |

| Penetration at 25 °C, pen (After short-term aging, according to EN 12607-1) | [21] | 0.1*mm | 39.3 |

| Ring and ball softening point, TR & B (After RTOFT according to EN12607-1) | [22] | °C | 56 |

| Viscosity at 100 °C | [23] | Pa*s | 2.20 |

| Viscosity at 135 °C | [23] | Pa*s | 0.29 |

| Viscosity at 150 °C | [23] | Pa*s | 0.15 |

| Viscosity at 180 °C | [23] | Pa*s | 0.1 |

| Chemical-Physical Characteristics | |

|---|---|

| Parameter | Tolerance |

| Humidity | 12.0% max |

| Ashes | 4.0% max |

| Benzopyrene | 10 μg/kg max |

| Arsenic | 3 mg/kg max |

| Cadmium | 1 mg/kg max |

| Mercury | 1 mg/kg max |

| Crossover Frequency [Hz] Unaged | Crossover Modulus [Pa] Unaged | Crossover Frequency [Hz] Aged | Crossover Modulus [Pa] Aged | |

|---|---|---|---|---|

| 0%Biochar | 566 | 2.32 × 107 | 246 | 1.97 × 107 |

| 2% Biochar | 348 | 2.30 × 107 | 146 | 1.53 × 107 |

| 4% Biochar | 1525 | 2.64 × 107 | 525 | 2.28 × 107 |

| 10% Biochar | 1044 | 4.57 × 107 | 380 | 3.75 × 107 |

| Requirements | Storage Stability | |||

|---|---|---|---|---|

| Characteristic Standard | Pen, 25°C [21] | Δ Pen EN [27] | TR&B EN [22] | ∆TR&B [27] |

| Unit | 0.1 dmm | 0.1 dmm | °C | °C |

| 2% Biochar TOP | 36 | 2 | 53 | 0.5 |

| 2% Biochar BOTTOM | 38 | 52.5 | ||

| 4% Biochar TOP | not applicable | not applicable | not applicable | not applicable |

| 4% Biochar BOTTOM | not applicable | not applicable | ||

| 10% Biochar TOP | not applicable | not applicable | not applicable | not applicable |

| 10% Biochar BOTTOM | not applicable | not applicable | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celauro, C.; Teresi, R.; Dintcheva, N.T. Evaluation of Anti-Aging Effect in Biochar-Modified Bitumen. Sustainability 2023, 15, 10583. https://doi.org/10.3390/su151310583

Celauro C, Teresi R, Dintcheva NT. Evaluation of Anti-Aging Effect in Biochar-Modified Bitumen. Sustainability. 2023; 15(13):10583. https://doi.org/10.3390/su151310583

Chicago/Turabian StyleCelauro, Clara, Rosalia Teresi, and Nadka Tz. Dintcheva. 2023. "Evaluation of Anti-Aging Effect in Biochar-Modified Bitumen" Sustainability 15, no. 13: 10583. https://doi.org/10.3390/su151310583